Abstract

A thin, lightweight and flexible electromagnetic interference (EMI) shielding paper composite is an urgent need for modern military confrontations. Herein, a sandwich-structured EMI shielding paper composite with an easy pavement consisting of a filter paper layer, middle AgNWs/MXene layer, and polyvinyl butyral (PVB) layer was constructed by vacuum-assisted filtration, spraying and air-drying. The middle AgNWs/MXene compound endowed the filter paper with excellent electrical conductivity (166 S cm−1) and the fabricated filter paper–AgNWs/MXene–PVB composite exhibits superior EMI shielding (30 dB) with a 141 μm thickness. Remarkably, the specific EMI shielding effectiveness (SSE/t) of the filter paper–AgNWs/MXene–PVB composite reached 13,000 dB cm2 g−1 within the X-band frequency range. This value represents one of the highest reported for cellulose-based EMI shielding materials. Therefore, our sandwich-structured filter paper composite with superior EMI shielding performance can be used in the medical and military fields.

1. Introduction

With the advancement of contemporary society, daily life is increasingly dominated by a plethora of electronic devices, which, while facilitating routine activities, also contribute to a significant amount of electromagnetic pollution. Many studies have indicated that long-time exposure to electromagnetic waves may adversely affect human health. Therefore, investigations of electromagnetic interference (EMI) shielding materials have emerged as a prominent area of research in recent years [1,2,3,4,5,6].

Recently, biomass materials have been used to fabricate EMI shielding materials using a top-down method or bottom-up strategy [7]. Wood, characterized as a sustainable biomass resource, stands out as an excellent prospect for electromagnetic interference (EMI) shielding materials due to its cost-effectiveness, lightweight nature, and inherently porous and stratified structural properties [8,9,10,11]. A diverse array of carbon composites derived from wood have been engineered to yield high-performance EMI shielding materials, demonstrating considerable shielding effectiveness [12,13]. However, the above-fabricated materials are bulky and hard to use in practical applications. A bottom-up strategy can transform wood-derived biomass materials (mainly cellulose and lignin) into flexible and mechanically strong films/papers with superior EMI shielding properties [14]. However, this fabrication process is time-consuming, toxic, expensive, and hard to adapt to large-scale production. Another example is cellulose-based carbon aerogel [15,16,17]. Although these aerogels are lightweight, insulating and have good EMI shielding properties, their construction also comes with the aforementioned drawbacks. Moreover, these aerogels are commonly brittle and demonstrate poor physical and mechanical performance.

The paper making industry has a well-established history of using cellulose materials, including wood and recycled paper, to fabricate new paper via a sequence of processing and manufacturing steps. With the arrival of the Industrial Revolution, the paper industry grew to a larger scale and implemented greater efficiency. Traditional papermaking methods were gradually replaced by mechanization and automation, resulting in significantly increased production capacity. Currently, a multitude of paper products find utility across diverse sectors, encompassing decoration, automotives, and aerospace, among others. Therefore, the direct employment of paper substrates for producing EMI shielding materials will be practical and favorable. More recently, MXene and silver nanowires (AgNWs) have proved particularly suitable for EMI shielding applications, owing to their remarkable electrical conductivity and solution compatibility [16,18,19,20]. They can be coated on the surface of the matrix to fabricate superior EMI shielding materials. Unfortunately, the coating can easily be destroyed by physical friction, causing a low EMI SE. Polyvinyl butyral (PVB) is a prevalent thermoplastic resin frequently used to improve mechanical properties, thermal stability, and water- and oil-proofing performance [21].

In this study, we present an innovative and promising technique for fabricating large-format electromagnetic interference (EMI) shielding paper composites utilizing a vacuum impregnation, spray deposition, and evaporation drying strategy. Readily available filter paper serves as the substrate, with MXene/AgNWs acting as the intermediate functional layer, and an external layer of polyvinyl butyral (PVB) providing protection. This layered configuration bestows the filter paper–AgNWs/MXene–PVB composite with superior EMI shielding effectiveness (SE) along with robust physical and mechanical characteristics.

2. Materials and Methods

2.1. Materials and Chemicals

The filter paper (diameter: 60 mm; pore size: 20~25 μm) and hydrophilic PTFE microporous membrane were purchased from Cytiva (Shanghai, China). Sulfuric acid (H2SO4, 72%), ethanol (99.7%), acetone (99.5%), iron chloride (FeCl3, 99.9%), silver nitrate (AgNO3), ethylene glycol (EG), polyvinyl pyrrolidone (PVP), and polyvinyl butyral (PVB) were purchased from Aladdin (Shanghai, China). A delaminated solution of titanium carbide (Ti3C2 MXene solution, 5 mg/mL) was purchased from Jilin 11 Technology Co., Ltd. (Changchun, China).

2.2. Synthesis of Silver Nanowires (AgNWs)

AgNWs were prepared using a modified polyol method based on previous reports [12]. Specifically, 0.2 g PVP was absolutely dissolved in 25 mL EG under magnetic stirring at room temperature. Then, 0.25 g AgNO3 was added into the PVP/EG solution and stirred to form a transparent, uniform solution. Afterward, 3.5 g 0.6 mmol/L FeCl3 salt solution was dripped into the above mixture with stirring for 10 min to produce a uniform solution. Finally, the mixed solution was transferred into oil bath reactor (180 °C) for 45 min to grow AgNWs at a slow stirring speed. After the end of reaction, generated AgNWs were purified five times using a solvent exchange method with acetone and ethanol with the aid of centrifugation (5000 rpm, 5 min for each time and type of instrument). Finally, the AgNW precipitate was redispersed in ethanol with a concentration of 2.35 mg/mL for use. The microstructure of the AgNWs resembles long rods (Figure S1).

2.3. Preparation of Sandwich-Structured Filter Paper–AgNWs/MXene–PVB Composite

MXene solution was homogeneously dispersed in deionized water (5 mg/mL) and AgNWs was dispersed in ethanol (2.35 mg/mL) for after use. The filter paper was placed on the PTFE microporous membrane (0.22 μm pore size), and then 1.82 mL MXene solution and 0.39 mL AgNWs solution were applied and filtered through vacuum-assisted filtration, resulting in the formation of an MXene/AgNWs composite film. After that, the filter paper–MXene/AgNWs was peeled off from the filter, followed by air-drying. In the final stage, the air-dried filter paper–MXene/AgNWs composite film underwent a spraying process with 2 mL of a 2 wt% PVB solution, culminating in the creation of a functional filter paper–MXene/AgNWs–PVB (FMAP) composite for EMI shielding applications. The density of the fabricated FMAP is 0.73 g cm−3.

2.4. Characterizations

The lignin contents (Klason lignin) of the filter paper were determined by following a standard TAPPI T 222 om−2 method [22]. The Fourier transform infrared (FTIR) spectra of filter paper, filter paper–MXene/AgNWs, and filter paper–MXene/AgNWs–PVB were obtained using a Fourier transform infrared spectrometer (VERTEX 80 V, Bruker, Bremen, Germany) from 4000 to 400 cm−1 at a spectral resolution of 6 cm−1 and a total of 32 scans. The morphologies and microstructures of AgNWs, filter paper, filter paper–MXene/AgNWs and filter paper–MXene/AgNWs–PVB were observed by Phenom scanning electron microscopy (SEM) (Phenom XL G2, Phenom-World BV, Eindhoven, The Netherlands). A Four-Point-Probe instrument (Guangzhou Four-Point-Probe Technology, SDY-4, Guangzhou, China) was used to test the conductivity of samples. At least four parts were tested for all samples, and the average and standard deviation were reported. A Vector Network Analyzer (Agilent Technologies N5063A, Palo Alto, CA, USA) was used to measure the EMI shielding effectiveness in the frequency range of 8.2–12.4 GHz (X-band) (Figure S2), according to our previous study [23].

2.5. EMI Shielding Parameters

According to Schelkunoff theory, the total EMI shielding effectiveness (SET) consists of absorption (SEA), reflection (SER), and multi-reflection (SEM), where SEM is often ignored when the SET is over 15 dB. The S-parameter is derived from the wave quantities a and b of the incident and reflected waves in the vector analysis tester.

The reflection coefficient R, the absorption coefficient A, and the transmission coefficient T are calculated from the S-parameters S11 and S21.

Reflection is the main mechanism of shielding, which occurs at the interface of two different media with different refractive index or impedance characteristics. The reflection loss is given by the Frensel equation, as shown in the following equation:

Absorption attenuation is given by the following equation:

3. Results

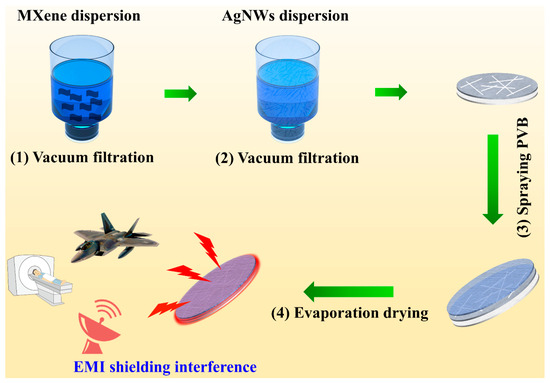

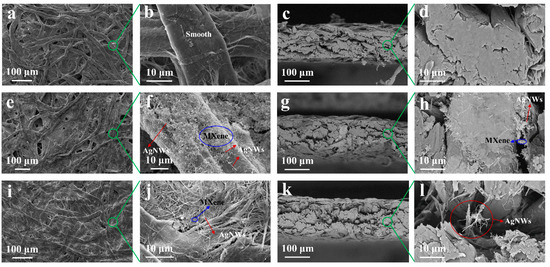

The schematic for fabrication of the sandwich structural filter paper–AgNWs/MXene–PVB composite for electromagnetic shielding is depicted in Figure 1. Specifically, the filter paper was positioned beneath the Buchner flask, and then MXene solution and AgNWs solution were vacuum-filtered to fabricate the filter paper–MXene/AgNWs composite (FMA). Next, the FMA was peeled off from the filter flask followed by spraying with PVB and evaporation–drying to obtain the filter paper–MXene/AgNWs–PVB composite (FMAP). In this work, SEM was applied to investigate the surfaces of materials [24,25,26,27,28,29]. Figure 2 shows the morphologies of the filter paper, FMA, and FMAP. Figure 2a–d shows the microstructure of the pure filter paper. The filter paper was fabricated using smooth fibers through the papermaking process. After vacuum filtration of the MXene/AgNWs solution, the top surface of the filter paper was covered by the MXene layer and AgNWs rods. More importantly, the MXene and AgNWs were inserted into the inner of the filter paper through the cutting surface morphologies of FMA (Figure 2e–h). After PVB coating, the filter paper became denser, and we also observed that the PVB formed a membrane-like layer on the top surface of FMA. Meanwhile, the MXene and AgNWs were not influenced by the PVB membrane, having a good intrinsic morphology, which plays an important role in EMI SE.

Figure 1.

Schematic illustration for fabrication of the sandwich-structured filter paper–AgNWs/MXene–PVB composite.

Figure 2.

(a) Surface microstructure of filter paper and (b) its magnified SEM image. (c) Cutting surface morphologies of filter paper and (d) corresponding magnified SEM image. (e) Surface microstructure of filter paper–MXene/AgNWs sample and (f) its magnified SEM image. (g) Cutting surface morphologies of filter paper–MXene/AgNWs sample and (h) corresponding magnified SEM image. (i) Surface microstructure of filter paper–MXene/AgNWs–PVB sample and (j) its magnified SEM image. (k) Cutting surface morphologies of filter paper–MXene/AgNWs–PVB sample and (l) corresponding magnified SEM image.

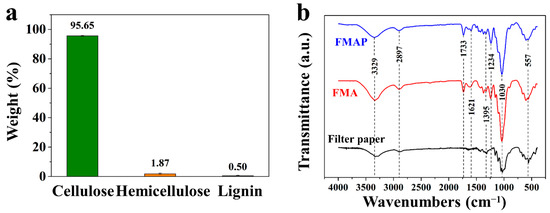

The chemical composition of the filter paper was analyzed using the standard Technical Association of the Pulp and Paper Industry (TAPPI)T 222 om−2 method. The result showed the filter paper is composed of 95.65% cellulose, 1.87% hemicellulose, and 0.50% lignin (Figure 3a), suggesting that the cellulose is the most dominated by matrix, which facilitates its mechanical flexibility. FTIR was used to obtain an infrared spectrum of the absorption or emission of the solid, liquid, or gas, which is helpful in determining the chemical structures of materials [30,31,32,33,34,35,36]. The FTIR spectra of the filter paper, FMA sample, and FMAP sample are displayed and compared in Figure 3b. Obvious characteristic peaks appear at 3329 cm−1 (O–H stretching vibration), 2897 cm−1 (C–H stretching vibration), and 1030 cm−1 (C–O stretching vibration) of cellulose, respectively. In addition, there are small peaks at 1733 cm−1, which correspond to the unconjugated carbonyl C=O of hemicellulose. The above analysis shows that the filter paper is mainly composed of cellulose, which is in accordance with the result of composition data. Commonly, silver itself does not contain organic elements, leading to no obvious absorption peak in the FTIR spectra. Yet, the surface of MXene has several characteristic peaks at 1395 cm−1, 557 cm−1, 1621 cm−1, 1234 cm−1, and 1030 cm−1 belonging to the C–F, –OH, C=O of alkone, C=C–O, and C–O–C stretching vibration functional groups. These typical peaks actually appeared in the FTIR spectra of FMA sample and FMAP sample, which indicated that there is a good connection between the filter paper and the AgNWs/MXene composite.

Figure 3.

(a) Chemical composition of filter paper. (b) FTIR spectra of filter paper, FMA, and FMAP samples.

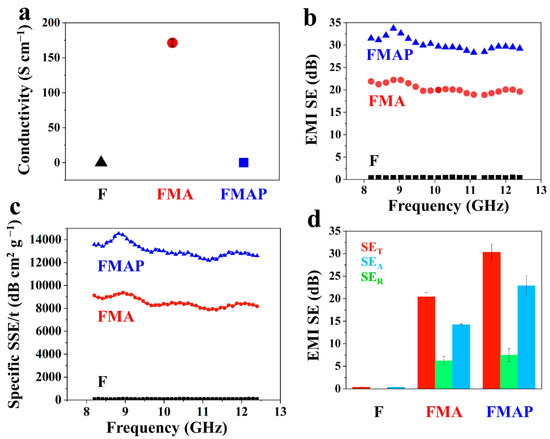

Conductivity is a critical factor influencing the electromagnetic interference (EMI) shielding performance of materials. The unmodified filter paper is dielectric (=0 S cm−1) (Figure 4a), having no EMI shielding effectiveness (~0 dB) (Figure 4b). After depositing conductive MXene and AgNWs on the surface of filter paper, the fabricated FMA sample shows superior conductivity with 166 S cm−1 (Figure 4a), further exhibiting good EMI shielding effectiveness. The total shielding effectiveness (SET) of FMA achieves 21 dB at a thickness of 141 μm in the 8.2–12.4 GHz frequency range (Figure 4b). To provide a more comprehensive assessment of material performance, the specific EMI shielding effectiveness (SSE/t), calculated by dividing SE by density and thickness, is utilized. As depicted in Figure 4c, the EMI SSE/t values of FMA sample are above 8000 dB cm2 g−1. It is well known that the surface coatings of MXene and AgNWs are susceptible to damage, potentially leading to a loss of EMI shielding effectiveness. To address this issue, the FMA sample was coated with a layer of polyvinyl butyral (PVB), known for its high physical and mechanical strength, thus forming the FMAP composite MXene. Then, the conductivity and EMI shielding effectiveness of FMAP were evaluated, and the results showed that the FMA was covered by dielectric PVB (the conductivity of FMAP = 0 S cm−1) (Figure 4a). Surprisingly, the EMI shielding effectiveness did not decrease; conversely, it increased to up to 30 dB (Figure 4b), and the specific EMI SE of FMAP reached a very high value of 13,000 dB cm2 g−1 (Figure 4c). In addition, there was greater absorption efficiency (SEA) than reflection efficiency (SER) in the FMA and FMAP samples, indicating SEA plays a more important role than SER in EMI SE. The result also shows that MXene/AgNWs are more effective in terms of EMI SE through enhanced SEA due to the PVB protection effect (Figure 4d). The reason is that when PVB is sprayed on paper, ethanol will loosen AgNWs and Mxene at the interface, and after drying again, more bonding points will appear at the interface, which is beneficial for improving absorption efficiency (SEA). In order to make a good comparison, we also tested the EMI SE of the carbon pencil and explained our reasoning (Figure S3).

Figure 4.

(a) Electrical conductivities of the F (filter paper), FMA, and FMAP samples. (b) EMI SET and (c) the corresponding specific SST/t of the F, FMA and FMAP samples. (d) Comparison of the SET, SEA, and SER of the aforementioned specimens.

4. Conclusions

In summary, this work showcases the fabrication of a sandwich-structured filter paper–MXene/AgNWs–PVB composite for high-performance electromagnetic interference shielding. This was achieved through a two-step vacuum-assisted filtration process, followed by a methodical spraying and evaporation drying technique. An exhaustive examination of the filter paper–MXene/AgNWs–PVB composite’s chemical structure, microstructure, electrical conductivity, and EMI shielding effectiveness was undertaken. The middle MXene/AgNWs layer showed a high electrical conductivity of 166 S cm−1, achieving good EMI SE (30 dB) and a high SSE/t value (13,000 dB cm2 g−1) in the filter paper–MXene/AgNWs–PVB composite. The composite’s comprehensive properties make it an ideal candidate for future applications in smart homes and the aerospace, military, and artificial intelligence domains.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/polym16060760/s1, Figure S1: (1) SEM image of AgNWs; (2) TEM micrograph of MXene nanosheets. Figure S2: Vector Network Analyzer (Agilent Technologies N5063A, Palo Alto, State of California, USA) was used to measure the EMI shielding effectiveness in the frequency range of 8.2−12.4 GHz (X-band). The cross-section size is 22.86 mm × 10.16 mm. Figure S3: Comparison of SET, SEA, and SER of the F, FMA, FMAP and FC samples.

Author Contributions

X.H.: investigation, conceptualization, methodology, writing—original draft preparation; H.F.: data curation; W.T.: resources and investigation; K.Z.: methodology, validation; L.Z.: conceptualization, reviewing, and editing; J.W.: reviewing and supervision; S.J.: writing—reviewing, editing, and supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Foundation (GZKF202129) of State Key Laboratory of Biobased Material and Green Papermaking, Qilu University of Technology, Shandong Academy of Sciences; The National Natural Science Foundation of China (32301518); The Natural Science Foundation of the Jiangsu Higher Education Institutions of China (23KJB220003); the Chunhui Research Grant (HZKY20220168, 202201269), Department of International Cooperation and Exchanges, Ministry of Education of the People’s Republic of China.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Mao, F.Z.; Fan, X.K.; Long, L.; Li, Y.; Chen, H.; Zhou, W. Constructing 3D hierarchical CNTs/VO2 composite micro-spheres with superior electromagnetic absorption performance. Ceram. Int. 2023, 49 Pt A, 16924–16931. [Google Scholar] [CrossRef]

- Zhu, H.H.; Qin, G.; Zhou, W.; Li, Y.; Zhou, X.B. Constructing flake-like ternary rare earth Pr3Si2C2 ceramic on SiC whiskers to enhance electromagnetic wave absorption properties. Ceram. Int. 2024, 50 Pt A, 134–142. [Google Scholar] [CrossRef]

- Mao, F.Z.; Long, L.; Pi, W.Q.; Li, Y.; Zhou, W. X-band electromagnetic absorption and mechanical properties of mul-lite/Ti3AlC2 composites. Mater. Chem. Phys. 2022, 292, 126819. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.D.; Wu, N.; Han, M.R.; Liu, W.; Liu, J.R.; Zeng, Z.H. Diverse Structural Design Strategies of MXene-Based Macrostructure for High-Performance Electromagnetic Interference Shielding. Nano-Micro Lett. 2023, 15, 240. [Google Scholar] [CrossRef]

- Li, X.L.; Li, M.H.; Li, X.; Fan, X.M.; Zhi, C.Y. Low Infrared Emissivity and Strong Stealth of Ti-Based MXenes. Research 2022, 2022, 9892628. [Google Scholar] [CrossRef]

- Verma, R.; Thakur, P.; Chauhan, A.; Jasrotia, R.; Thakur, A. A review on MXene and its? composites for electromagnetic interference (EMI) shielding applications. Carbon 2023, 208, 170–190. [Google Scholar] [CrossRef]

- Mao, F.Z.; Long, L.; Zeng, G.L.; Chen, H.; Li, Y.; Zhou, W. Achieving excellent electromagnetic wave absorption property by constructing VO2 coated biomass carbon heterostructures. Diam. Relat. Mater. 2022, 130, 109422. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Zhang, Q.T.; Chi, M.C.; Guo, C.Y.; Wang, S.F.; Min, D.Y. Preparation and performance of different carbon-ized wood electrodes. J. For. Eng. 2022, 7, 127–135. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Xiao, H.N.; Xiong, R.H.; Huang, C.B. Xylan-based ratiometric fluorescence carbon dots composite with delignified wood for highly efficient water purification and photothermal conversion. Sep. Purif. Technol. 2023, 324, 124513. [Google Scholar] [CrossRef]

- Gan, W.T.; Wang, Y.X.; Xiao, K.; Zhai, M.K.; Wang, H.G.; Xie, Y.J. Research review of energy storage and conversion materials based on wood cell wall functional modification. J. For. Eng. 2022, 7, 1–12. [Google Scholar] [CrossRef]

- Lu, Y.; Liang, Z.X.; Fu, Z.Y.; Zhang, S.F. Research advances and prospect of wood cell wall nanotechnology. J. For. Eng. 2022, 7, 1–11. [Google Scholar] [CrossRef]

- Chen, Y.M.; Pang, L.; Li, Y.; Luo, H.; Duan, G.G.; Mei, C.T.; Xu, W.H.; Zhou, W.; Liu, K.M.; Jiang, S.H. Ultra-thin and highly flexible cellulose nanofiber/silver nanowire conductive paper for effective electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105960. [Google Scholar] [CrossRef]

- Ma, X.F.; Guo, H.T.; Zhang, C.M.; Chen, D.H.; Tian, Z.W.; Wang, Y.F.; Chen, Y.M.; Wang, S.W.; Han, J.Q.; Lou, Z.C.; et al. ZIF-67/wood derived self-supported carbon composites for electromagnetic interference shielding and sound and heat insulation. Inorg. Chem. Front. 2022, 9, 6305–6316. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Q.T.; Xu, P.H.; Feng, Y.Z.; Ma, J.M.; Liu, C.T.; Shen, C.Y. An asymmetric sandwich structural cellulose-based film with self-supported MXene and AgNW layers for flexible electromagnetic interference shielding and thermal management. Nanoscale 2021, 13, 2378–2388. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.R.; Jiang, Y.; Ma, Z.W.; Shi, Y.Q.; Zhu, Y.J.; Huang, R.Z.; Feng, Y.Z.; Wang, Z.B.; Hong, M.; Gao, J.F.; et al. Hyperelastic, Robust, Fire-Safe Multifunctional MXene Aerogels with Unprecedented Electromagnetic Interference Shielding Efficiency. Adv. Funct. Mater. 2023, 33, 2306884. [Google Scholar] [CrossRef]

- Chen, Y.M.; Luo, H.; Guo, H.T.; Liu, K.M.; Mei, C.T.; Li, Y.; Duan, G.G.; He, S.J.; Han, J.Q.; Zheng, J.J.; et al. Anisotropic cellulose nanofibril composite sponges for electromagnetic interference shielding with low reflection loss. Carbohydr. Polym. 2022, 276, 118799. [Google Scholar] [CrossRef] [PubMed]

- Xin, W.; Ma, M.G.; Chen, F. Silicone-Coated MXene/Cellulose Nanofiber Aerogel Films with Photothermal and Joule Heating Performances for Electromagnetic Interference Shielding. Acs Appl. Nano Mater. 2021, 4, 7234–7243. [Google Scholar] [CrossRef]

- Weng, C.X.; Xing, T.L.; Jin, H.; Wang, G.R.; Dai, Z.H.; Pei, Y.M.; Liu, L.Q.; Zhang, Z. Mechanically robust ANF/MXene composite films with tunable electromagnetic interference shielding performance. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105927. [Google Scholar] [CrossRef]

- Liu, L.; Chen, W.; Zhang, H.; Wang, Q.; Guan, F.; Yu, Z. Flexible and multifunctional silk textiles with biomimetic leaf-like MXene/silver nanowire nanostructures for electromagnetic interference shielding, humidity monitoring, and self-derived hydrophobicity. Adv. Funct. Mater. 2019, 29, 1905197. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, J.; Ji, H.; Wang, N.; Feng, S.; Xiao, H. Electromagnetic interference shielding with absorption-dominant performance of Ti3C2TX MXene/non-woven laminated fabrics. Text. Res. J. 2021, 91, 2448–2458. [Google Scholar] [CrossRef]

- Harandi, D.; Moradienayat, M. Multifunctional PVB nanocomposite wood coating by cellulose nanocrystal/ZnO nanofiller: Hydrophobic, water uptake, and UV-resistance properties. Prog. Org. Coat. 2023, 179, 107546. [Google Scholar] [CrossRef]

- Han, X.S.; Ye, Y.H.; Lam, F.; Pu, J.W.; Jiang, F. Hydrogen-bonding-induced assembly of aligned cellulose nanofibers into ultrastrong and tough bulk materials. J. Mater. Chem. A 2019, 7, 27023–27031. [Google Scholar] [CrossRef]

- Ma, X.F.; Liu, S.Y.; Luo, H.; Guo, H.T.; Jiang, S.H.; Duan, G.G.; Zhang, G.Y.; Han, J.Q.; He, S.J.; Lu, W.; et al. MOF@wood Derived Ultrathin Carbon Composite Film for Electromagnetic Interference Shielding with Effective Absorption and Electrothermal Management. Adv. Funct. Mater. 2023, 34, 202310126. [Google Scholar] [CrossRef]

- Zhu, L.Y.; Li, Y.C.; Zhao, J.Y.; Liu, J.; Lei, J.D.; Wang, L.Y.; Huang, C.B. A novel green lignosulfonic acid/Nafion composite membrane with reduced cost and enhanced thermal stability. Chem. Commun. 2021, 57, 9288–9291. [Google Scholar] [CrossRef]

- Deng, W.N.; Xu, Y.X.; Zhang, X.C.; Li, C.Y.; Liu, Y.X.; Xiang, K.X.; Chen, H. (NH4)2Co2V10O28·16H2O/(NH4)2V10O25·8H2O heterostructure as cathode for high-performance aqueous Zn-ion batteries. J. Alloys Compd. 2022, 903, 163824. [Google Scholar] [CrossRef]

- Qu, Q.L.; Zhang, X.L.; Yang, A.Q.; Wang, J.; Cheng, W.X.; Zhou, A.Y.; Deng, Y.K.; Xiong, R.H.; Huang, C.B. Spatial confinement of multi-enzyme for cascade catalysis in cell-inspired all-aqueous multicompartmental microcapsules. J. Colloid Interface Sci. 2022, 626, 768–774. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.N.; Li, Y.H.; Xu, D.F.; Zhou, W.; Xiang, K.X.; Chen, H. Three-dimensional hierarchically porous nitro-gen-doped carbon from water hyacinth as selenium host for high-performance lithium–selenium batteries. Rare Met. 2022, 41, 3432–3445. [Google Scholar] [CrossRef]

- Zhou, W.; Niu, Z.B.; Chen, X.; Xiao, P.; Li, Y. Synergistic effect of water vapour on the thermal corrosion of CFAS melt to Yb2Si2O7 environmental barrier coating material. Corros. Sci. 2023, 225, 111625. [Google Scholar] [CrossRef]

- Wen, X.Y.; Luo, J.H.; Xiang, K.X.; Zhou, W.; Zhang, C.F.; Chen, H. High-performance monoclinic WO3 nanospheres with the novel NH4+ diffusion behaviors for aqueous ammonium-ion batteries. Chem. Eng. J. 2023, 458, 141381. [Google Scholar] [CrossRef]

- Deng, W.N.; Liu, W.M.; Zhu, H.; Chen, L.; Liao, H.Y.; Chen, H. Click-chemistry and ionic cross-linking induced double cross-linking ionogel electrolyte for flexible lithium-ion batteries. J. Energy Storage 2023, 72, 108509. [Google Scholar] [CrossRef]

- Wu, D.D.; Wang, D.M.; Ye, X.M.; Yuan, K.R.; Xie, Y.L.; Li, B.H.; Huang, C.B.; Kuang, T.R.; Yu, Z.Q.; Chen, Z. Fluo-rescence detection of Escherichia coli on mannose modified ZnTe quantum dots. Chin. Chem. Lett. 2020, 31, 1504–1507. [Google Scholar] [CrossRef]

- Cui, J.X.; Lu, T.; Li, F.H.; Wang, Y.L.; Lei, J.D.; Ma, W.J.; Zou, Y.; Huang, C.B. Flexible and transparent composite nanofibre membrane that was fabricated via a “green” electrospinning method for efficient particulate matter 2.5 capture. J. Colloid Interface Sci. 2021, 582, 506–514. [Google Scholar] [CrossRef] [PubMed]

- Zeng, G.L.; Wang, Y.Q.; Lou, X.M.; Chen, H.; Jiang, S.H.; Zhou, W. Vanadium oxide/carbonized chestnut needle com-posites as cathode materials for advanced aqueous zinc-ion batteries. J. Energy Storage 2024, 77, 109859. [Google Scholar] [CrossRef]

- Ma, W.J.; Ding, Y.C.; Li, Y.S.; Gao, S.T.; Jiang, Z.C.; Cui, J.X.; Huang, C.B.; Fu, G.D. Durable, self-healing superhy-drophobic nanofibrous membrane with self-cleaning ability for highly-efficient oily wastewater purification. J. Membr. Sci. 2021, 634, 119402. [Google Scholar] [CrossRef]

- Deng, Y.K.; Lu, T.; Zhang, X.L.; Zeng, Z.Y.; Tao, R.P.; Qu, Q.L.; Zhang, Y.Y.; Zhu, M.M.; Xiong, R.H.; Huang, C.B. Multi-hierarchical nanofiber membrane with typical curved-ribbon structure fabricated by green electrospinning for effi-cient, breathable and sustainable air filtration. J. Membr. Sci. 2022, 660, 120857. [Google Scholar] [CrossRef]

- Lu, T.; Liang, H.B.; Cao, W.X.; Deng, Y.K.; Qu, Q.L.; Ma, W.J.; Xiong, R.H.; Huang, C.B. Blow-spun nanofibrous composite Self-cleaning membrane for enhanced purification of oily wastewater. J. Colloid Interface Sci. 2022, 608, 2860–2869. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).