Thermo-Mechanical Characterization of Metal–Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

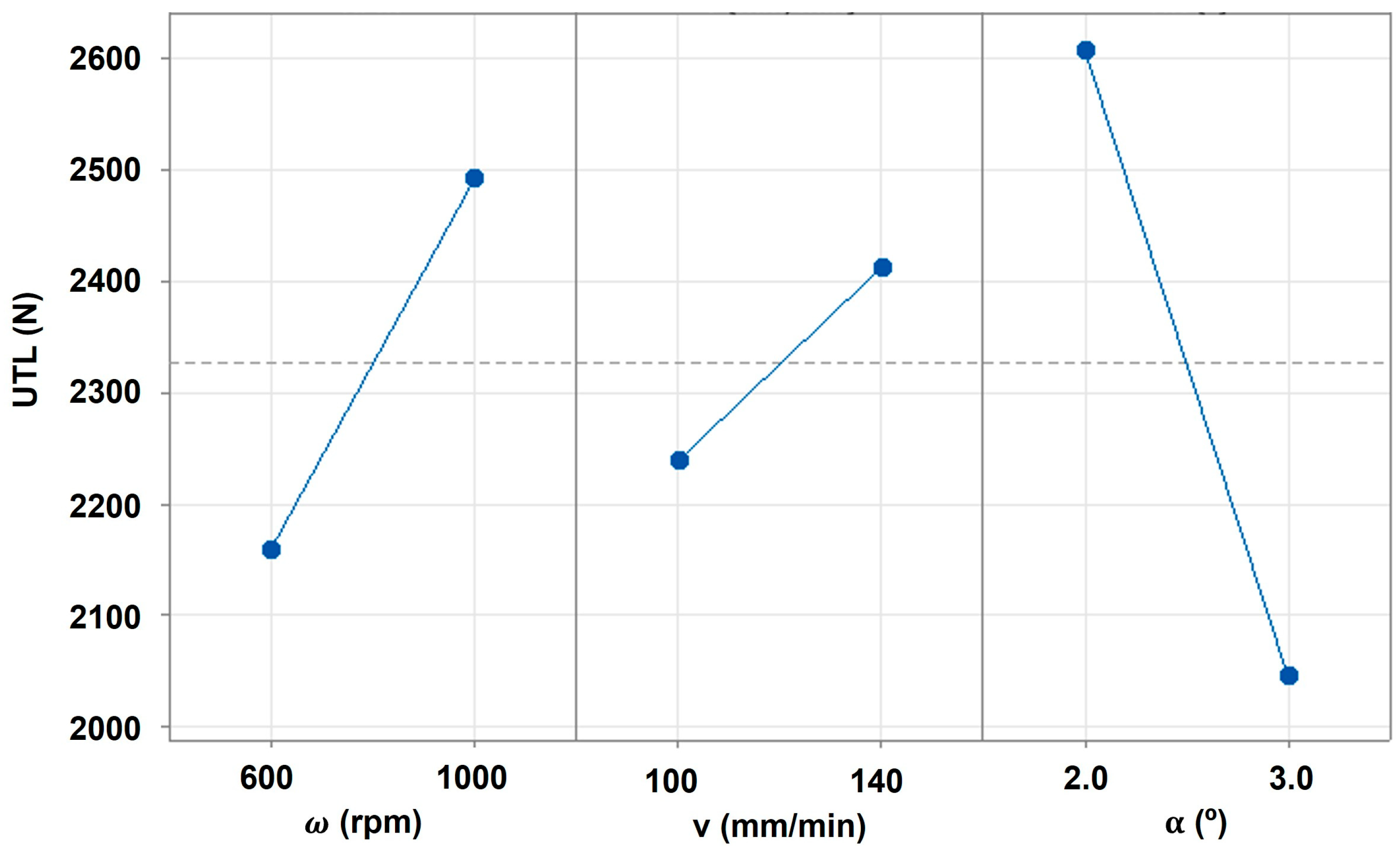

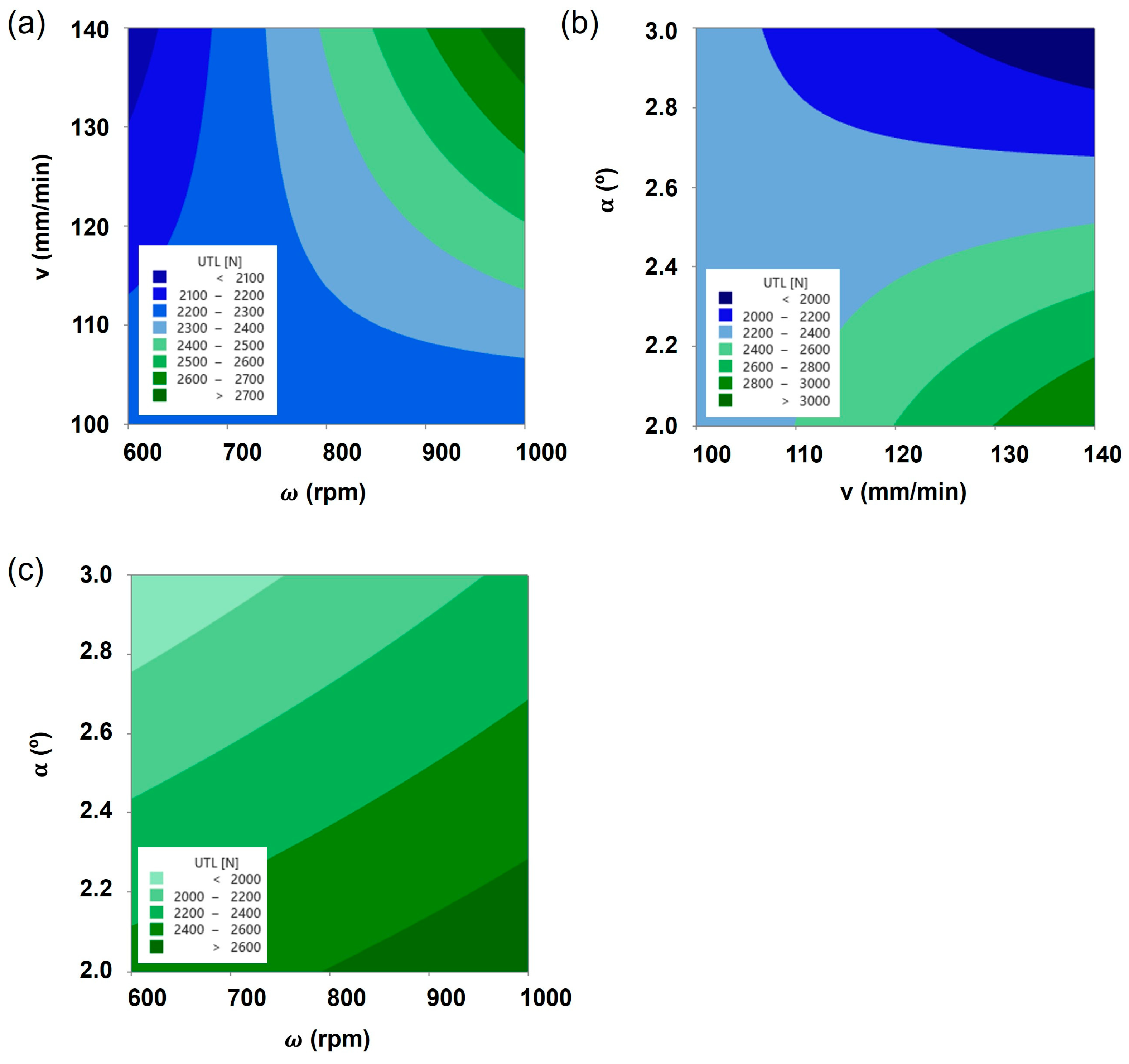

3.1. Mechanical Strength

3.2. Processing Temperature

3.3. Hardness

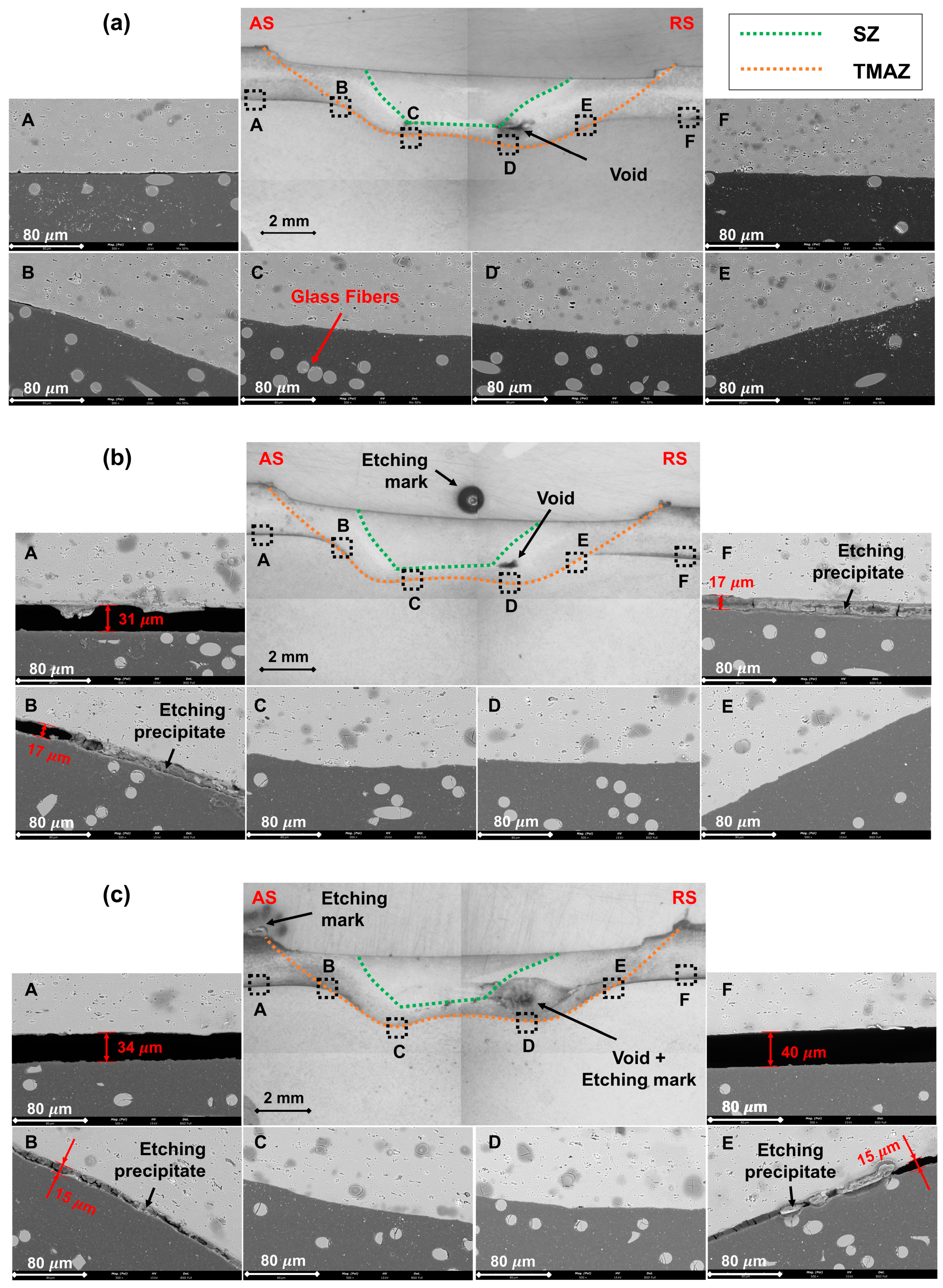

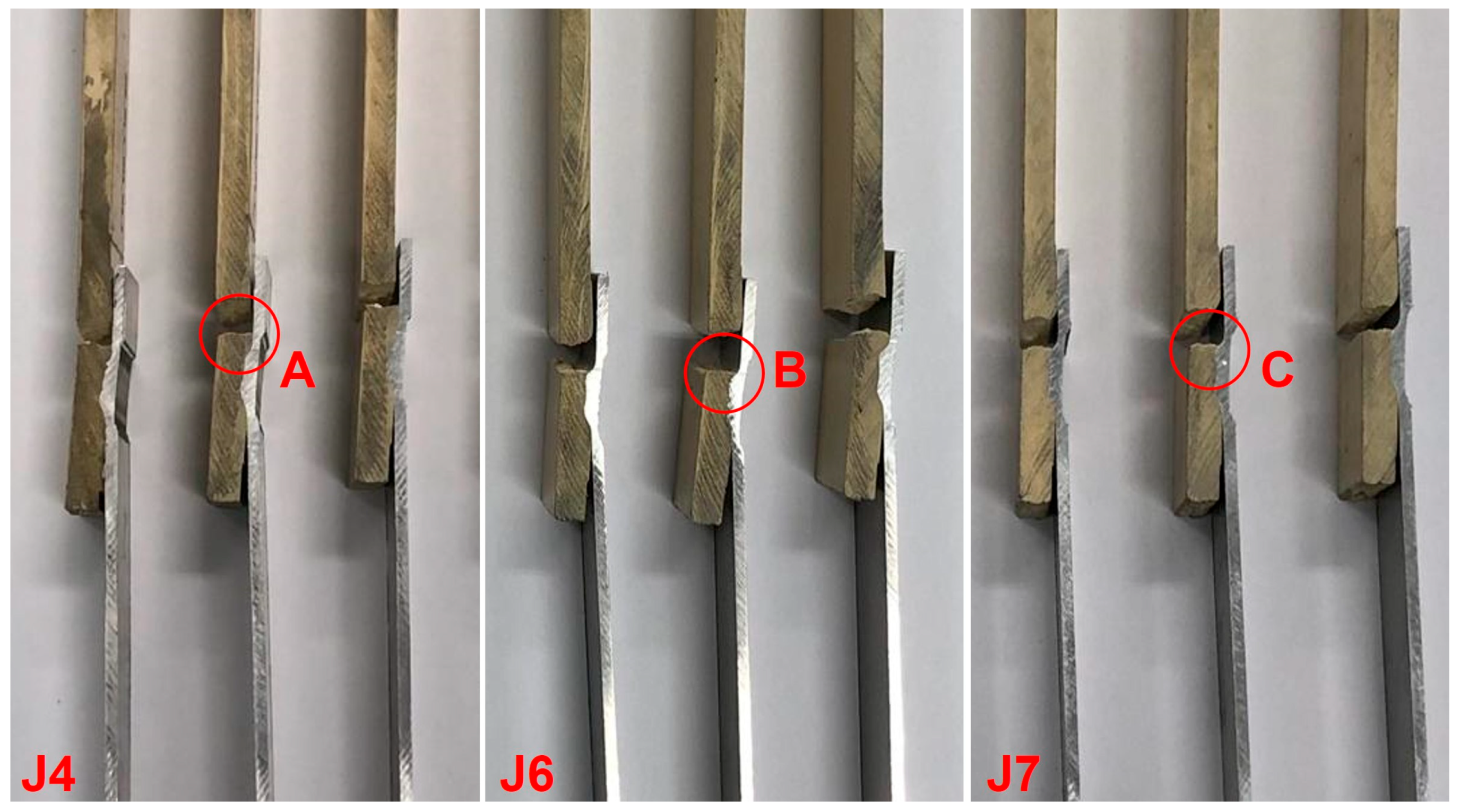

3.4. Macro- and Microstructure

4. Conclusions

- After statistical analysis, it was possible to mathematically describe and predict both the mechanical strength (UTL) and processing temperature (using Tas as proxy) as a function of the processing parameters—rotational speed (ω), travel speed (v), and the tilt angle (). The models were validated after comparing the predicted values, given by the numerical expressions, with the experimental ones. The resulting errors were found to be 0.7% of the UTL prediction and 2.3% of the average Tas prediction.

- From the thermal history of all fabricated joints, it could be concluded that processing temperatures between the softening and melting temperatures of NorylTM enable the development of proper binding mechanisms, resulting in significant joint strength.

- Joint strength was found to be mainly governed by the effective joining area, which might be considerably reduced by micro-gaps between base materials along the composite interface.

- The hardness profiles were found to be similar among the analyzed joints. The measurements taken over the aluminum lines revealed a noticeable decrease in hardness toward the SZ, with the minimum values observed in the TMAZ, forming the characteristic W-shaped profile. The hardness measurements over NorylTM did not evidence a significant change regardless of region and joint under analysis.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- European Environment Agency. Decarbonising Road Transport—The Role of Vehicles, Fuels and Transport Demand; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Nazir, H.; Muthuswamy, N.; Louis, C.; Jose, S.; Prakash, J.; Buan, M.E.M.; Flox, C.; Chavan, S.; Shi, X.; Kauranen, P.; et al. Is the H(2) Economy Realizable in the Foreseeable Future? Part Iii: H(2) Usage Technologies, Applications, and Challenges and Opportunities. Int. J. Hydrogen Energy 2020, 45, 28217–28239. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.; Dash, S.K.; Elavarasan, R.M.; Kaur, A.; Elangovan, D.; Meraj, S.T.; Kasinathan, P.; Said, Z. Hydrogen Energy as Future of Sustainable Mobility. Front. Energy Res. 2022, 10, 893475. [Google Scholar] [CrossRef]

- Sacchi, R.; Bauer, C.; Cox, B.; Mutel, C. When, Where and How Can the Electrification of Passenger Cars Reduce Greenhouse Gas Emissions? Renew. Sustain. Energy Rev. 2022, 162, 112475. [Google Scholar] [CrossRef]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A Review of Battery Electric Vehicle Technology and Readiness Levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Danzi, F.; Salgado, R.M.; Oliveira, J.E.; Arteiro, A.; Camanho, P.P.; Braga, M.H. Structural Batteries: A Review. Molecules 2021, 26, 2203. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Singer, G.; Liang, K.; Yang, Y. Structural Batteries: Advances, Challenges and Perspectives. Mater. Today 2023, 62, 151–167. [Google Scholar] [CrossRef]

- Weragoda, D.M.; Tian, G.; Burkitbayev, A.; Lo, K.-H.; Zhang, T. A Comprehensive Review on Heat Pipe Based Battery Thermal Management Systems. Appl. Therm. Eng. 2023, 224, 120070. [Google Scholar] [CrossRef]

- Rao, Z.; Lyu, P.; Du, P.; He, D.; Huo, Y.; Liu, C. Thermal Safety and Thermal Management of Batteries. Battery Energy 2022, 1, 20210019. [Google Scholar] [CrossRef]

- Massaro, M.C.; Biga, R.; Kolisnichenko, A.; Marocco, P.; Monteverde, A.H.A.; Santarelli, M. Potential and Technical Challenges of on-Board Hydrogen Storage Technologies Coupled with Fuel Cell Systems for Aircraft Electrification. J. Power Sources 2023, 555, 232397. [Google Scholar] [CrossRef]

- Gong, P.; Turk, A.; Nutter, J.; Yu, F.; Wynne, B.; Rivera-Diaz-Del-Castillo, P.; Rainforth, W.M. Hydrogen Embrittlement Mechanisms in Advanced High Strength Steel. Acta Mater. 2022, 223, 117488. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen Embrittlement in Different Materials: A Review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Correia, A.N.; Braga, D.F.; Moreira, P.M.; Infante, V. Review on Dissimilar Structures Joints Failure. Eng. Fail. Anal. 2021, 129, 105652. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Pereira, M.A.R.; Amaro, A.M.; Reis, P.N.B.; Loureiro, A. Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency-a Critical Review. Polymers 2021, 13, 2056. [Google Scholar] [CrossRef] [PubMed]

- Maggiore, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers 2021, 13, 3961. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.M.Z.; Seleman, M.M.E.-S.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef] [PubMed]

- Correia, A.N.; Santos, P.A.M.; Braga, D.F.O.; Baptista, R.; Infante, V. Effects of Friction Stir Welding Process Control and Tool Penetration on Mechanical Strength and Morphology of Dissimilar Aluminum-to-Polymer Joints. J. Manuf. Mater. Process. 2023, 7, 106. [Google Scholar] [CrossRef]

- Patel, V.; De Backer, J.; Hindsefelt, H.; Igestrand, M.; Azimi, S.; Andersson, J.; Säll, J. High Speed Friction Stir Welding of Aa6063-T6 Alloy in Lightweight Battery Trays for Ev Industry: Influence of Tool Rotation Speeds. Mater. Lett. 2022, 318, 132135. [Google Scholar] [CrossRef]

- Kang, S.; Kim, J.; Jang, Y.; Lee, K. Welding Deformation Analysis, Using an Inherent Strain Method for Friction Stir Welded Electric Vehicle Aluminum Battery Housing, Considering Productivity. Appl. Sci. 2019, 9, 3848. [Google Scholar] [CrossRef]

- Gera, D.; Fu, B.; Suhuddin, U.F.; Plaine, A.; Alcantara, N.; dos Santos, J.F.; Klusemann, B. Microstructure, Mechanical and Functional Properties of Refill Friction Stir Spot Welds on Multilayered Aluminum Foils for Battery Application. J. Mater. Res. Technol. 2021, 13, 2272–2286. [Google Scholar] [CrossRef]

- Yahaba, T.; Sayama, M.; Kobayashi, T.; Kato, T. Development of Friction Stir Welding Technology for Subframe for Fuel Cell System. Trans. Soc. Automot. Eng. Jpn. 2009, 47, 19–27. [Google Scholar]

- Khodabakhshi, F.; Haghshenas, M.; Sahraeinejad, S.; Chen, J.; Shalchi, B.; Li, J.; Gerlich, A. Microstructure-Property Characterization of a Friction-Stir Welded Joint between Aa5059 Aluminum Alloy and High Density Polyethylene. Mater. Charact. 2014, 98, 73–82. [Google Scholar] [CrossRef]

- Barakat, A.A.; Darras, B.M.; Nazzal, M.A.; Ahmed, A.A. A Comprehensive Technical Review of the Friction Stir Welding of Metal-to-Polymer Hybrid Structures. Polymers 2022, 15, 220. [Google Scholar] [CrossRef] [PubMed]

- Shahmiri, H.; Movahedi, M.; Kokabi, A.H. Friction Stir Lap Joining of Aluminium Alloy to Polypropylene Sheets. Sci. Technol. Weld. Join. 2016, 22, 120–126. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F.; Simchi, A. Friction-Stir Lap-Joining of Aluminium-Magnesium/Poly-Methyl-Methacrylate Hybrid Structures: Thermo-Mechanical Modelling and Experimental Feasibility Study. Sci. Technol. Weld. Join. 2017, 23, 35–49. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Wang, Y.; Xie, Y.; Zhou, L. Joining of Aluminum Alloy and Polymer Via Friction Stir Lap Welding. J. Mater. Process. Technol. 2018, 257, 148–154. [Google Scholar] [CrossRef]

- Patel, A.R.; Kotadiya, D.J.; Kapopara, J.M.; Dalwadi, C.G.; Patel, N.P.; Rana, H. Investigation of Mechanical Properties for Hybrid Joint of Aluminium to Polymer Using Friction Stir Welding (Fsw). Mater. Today: Proc. 2018, 5, 4242–4249. [Google Scholar] [CrossRef]

- Wang, T.; Li, L.; Pallaka, M.R.; Das, H.; Whalen, S.; Soulami, A.; Upadhyay, P.; Kappagantula, K.S. Mechanical and Microstructural Characterization of Az31 Magnesium-Carbon Fiber Reinforced Polymer Joint Obtained by Friction Stir Interlocking Technique. Mater. Des. 2021, 198, 109305. [Google Scholar] [CrossRef]

- Choi, J.-W.; Morisada, Y.; Liu, H.; Ushioda, K.; Fujii, H.; Nagatsuka, K.; Nakata, K. Dissimilar Friction Stir Welding of Pure Ti and Carbon Fibre Reinforced Plastic. Sci. Technol. Weld. Join. 2020, 25, 600–608. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Haghshenas, M.; Chen, J.; Amirkhiz, B.S.; Li, J.; Gerlich, A. Bonding Mechanism and Interface Characterisation During Dissimilar Friction Stir Welding of an Aluminium/Polymer Bi-Material Joint. Sci. Technol. Weld. Join. 2016, 22, 182–190. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Kashiry Fard, R.; Khodabakhshi, F. Effects of Processing Parameters on the Characteristics of Dissimilar Friction-Stir-Welded Joints between Aa5058 Aluminum Alloy and Pmma Polymer. Weld. World 2017, 62, 117–130. [Google Scholar] [CrossRef]

- Ratanathavorn, W.; Melander, A. Dissimilar Joining between Aluminium Alloy (Aa 6111) and Thermoplastics Using Friction Stir Welding. Sci. Technol. Weld. Join. 2015, 20, 222–228. [Google Scholar] [CrossRef]

- Liu, F.C.; Liao, J.; Gao, Y.; Nakata, K. Effect of Plasma Electrolytic Oxidation Coating on Joining Metal to Plastic. Sci. Technol. Weld. Join. 2015, 20, 291–296. [Google Scholar] [CrossRef]

- Okada, T.; Uchida, S.; Nakata, K. Effect of Anodizing on Direct Joining Properties of Aluminium Alloy and Plastic Sheets by Friction Lap Joining. Weld. Int. 2017, 32, 85–94. [Google Scholar] [CrossRef]

- Alhatti, A.I.; Sheikh-Ahmad, J.; Almaskari, F.; Khan, K.A.; Deveci, S.; Hosny, A.I. A Study of the Friction Stir Lap Welding of Aa5052 and Polypropylene. Polymers 2023, 15, 4481. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Elyasi, M. The Influence of Process Parameters in Friction Stir Welding of Al-Mg Alloy and Polycarbonate. J. Manuf. Process. 2018, 35, 88–98. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 2nd ed.; Wiley: New York, NY, USA, 1984. [Google Scholar]

- Correia, A.N.; Santos, P.A.; Braga, D.F.; Cipriano, G.P.; Moreira, P.M.; Infante, V. Effects of Processing Temperature on Failure Mechanisms of Dissimilar Aluminum-to-Polymer Joints Produced by Friction Stir Welding. Eng. Fail. Anal. 2023, 146, 107155. [Google Scholar] [CrossRef]

- Nandan, R.; Debroy, T.; Bhadeshia, H. Recent Advances in Friction-Stir Welding—Process, Weldment Structure and Properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Cole, E.G.; Fehrenbacher, A.; Duffie, N.A.; Zinn, M.R.; Pfefferkorn, F.E.; Ferrier, N.J. Weld Temperature Effects During Friction Stir Welding of Dissimilar Aluminum Alloys 6061-T6 and 7075-T6. Int. J. Adv. Manuf. Technol. 2013, 71, 643–652. [Google Scholar] [CrossRef]

- Silva, A.C.F.; De Backer, J.; Bolmsjö, G. Temperature Measurements During Friction Stir Welding. Int. J. Adv. Manuf. Technol. 2016, 88, 2899–2908. [Google Scholar] [CrossRef]

- Costa, M.I.; Rodrigues, D.M.; Leitão, C. Analysis of Aa 6082-T6 Welds Strength Mismatch: Stress Versus Hardness Relationships. Int. J. Adv. Manuf. Technol. 2015, 79, 719–727. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; Santos, T.; Tavares, S.M.O.; Richter-Trummer, V.; Vilaça, P.; De Castro, P.M.S.T. Mechanical and Metallurgical Characterization of Friction Stir Welding Joints of Aa6061-T6 with Aa6082-T6. Mater. Des. 2009, 30, 180–187. [Google Scholar] [CrossRef]

- Baratzadeh, F.; Boldsaikhan, E.; Nair, R.; Burford, D.; Lankarani, H. Investigation of Mechanical Properties of Aa6082-T6/Aa6063-T6 Friction Stir Lap Welds. J. Adv. Join. Process. 2020, 1, 100011. [Google Scholar] [CrossRef]

- Kumar, N.; Wei, Y.; Mishra, R.S. Friction Stir Welding of Dissimilar Alloys and Materials; Friction Stir Welding and Processing; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Derazkola, H.A.; Simchi, A. An Investigation on the Dissimilar Friction Stir Welding of T-Joints between Aa5754 Aluminum Alloy and Poly(Methyl Methacrylate). Thin-Walled Struct. 2019, 135, 376–384. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction Stir Welding/Processing of Polymers and Polymer Matrix Composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Li, M.; Xiong, X.; Ji, S.; Hu, W.; Yue, Y. Achieving High-Quality Metal to Polymer-Matrix Composites Joint Via Top-Thermic Solid-State Lap Joining. Compos. Part B Eng. 2021, 219, 108941. [Google Scholar] [CrossRef]

| Base Materials | AA6082 NorylTM | AA6061 PEEK | AA6061 PC | AA5058 PMMA | AA5052 PP | AA5058 PC |

|---|---|---|---|---|---|---|

| Joint efficiency | 47% | 20% | 35% | 60% | 17% | 70% |

| Reference | [19] | [28] | [29] | [33] | [37] | [38] |

| Material | E (GPa) | (g/cm3) | UTS (MPa) | (%) | K (W/(m°C)) | Tmelt (°C) |

|---|---|---|---|---|---|---|

| AA6082-T6 | 70 | 2.70 | * 290 | 10 | 180 | 580 |

| Noryl | 7 | 1.25 | 80 | 2.5 | 0.26 | ** 280 |

| Factor | Symbol | Unit | Level 1 | Level 2 |

|---|---|---|---|---|

| Rotational speed | ω | rpm | 600 | 1000 |

| Travel speed | v | mm/min | 100 | 140 |

| Tilt angle | ◦ | 2 | 3 |

| Joint ID | ω (rpm) | v (mm/min) | (◦) | Avg. UTL (N) | |

|---|---|---|---|---|---|

| FFD joints | J1 | 600 | 100 | 2 | 2294.8 ± 215.2 |

| J2 | 1000 | 100 | 2 | 1749.9 ± 174.7 | |

| J3 | 600 | 140 | 2 | 2168.8 ± 222.4 | |

| J4 | 1000 | 140 | 2 | 3414.2 ± 317.1 | |

| J5 | 600 | 100 | 3 | 1789.6 ± 58.7 | |

| J6 | 1000 | 100 | 3 | 2323.6 ± 244.7 | |

| J7 | 600 | 140 | 3 | 1708.1 ± 45.5 | |

| J8 | 1000 | 140 | 3 | 1845.2 ± 42.4 | |

| Validation joint | J9 | 800 | 120 | 2.5 | 2350.0 ± 192.4 |

| Source | DF | SS | MS | F-Value | p-Value | Contribution |

|---|---|---|---|---|---|---|

| ω | 1 | 666,511 | 666,511 | 14.60 | 0.001 | 7.0% |

| v | 1 | 180,533 | 180,533 | 3.95 | 0.061 | 1.9% |

| 1 | 1,892,478 | 1,892,478 | 41.45 | <0.001 | 20.0% | |

| v | 1 | 996,732 | 996,732 | 21.83 | <0.001 | 10.5% |

| 1 | 23,862 | 23,862 | 0.52 | 0.479 | 0.3% | |

| 1 | 2,399,492 | 2,399,492 | 52.56 | <0.001 | 25.4% | |

| 1 | 2,427,639 | 2,427,639 | 53.17 | <0.001 | 25.7% | |

| Error | 19 | 867,433 | 45,654 | 9.2% | ||

| Total | 26 | 9,454,679 | ||||

| R2 = 90.8%, adjusted R2 = 87.5%, predicted R2 = 80.2% | ||||||

| Joint ID | ω (rpm) | v (mm/min) | (◦) | Avg. Tas * (°C) | Avg. Trs ** (°C) |

|---|---|---|---|---|---|

| J1 | 600 | 100 | 2 | 243.6 ± 7.2 | 240.2 ± 8.4 |

| J2 | 1000 | 100 | 2 | 253.9 ± 11.5 | 236.8 ± 17.2 |

| J3 | 600 | 140 | 2 | 241.5 ± 14.6 | 183.7 ± 15.8 |

| J4 | 1000 | 140 | 2 | 251.5 ± 9.7 | 247.0 ± 27.3 |

| J5 | 600 | 100 | 3 | 203.6 ± 10.7 | 164.5 ± 20.1 |

| J6 | 1000 | 100 | 3 | 228.6 ± 11.8 | 172.8 ± 25.3 |

| J7 | 600 | 140 | 3 | 224.1 ± 12.2 | 193.7 ± 19.2 |

| J8 | 1000 | 140 | 3 | 241.1 ± 14.7 | 186.8 ± 11.1 |

| J9 | 800 | 120 | 2.5 | 232.2 ± 20.9 | 212.1 ± 15.1 |

| Source | DF | SS | MS | F-Value | p-Value | Contribribution |

|---|---|---|---|---|---|---|

| ω | 1 | 485.76 | 485.76 | 15.52 | 0.017 | 24.7% |

| v | 1 | 101.22 | 101.22 | 3.23 | 0.146 | 5.1% |

| 1 | 1083.63 | 1083.63 | 34.63 | 0.004 | 55.0% | |

| 1 | 174.81 | 174.81 | 5.59 | 0.077 | 8.9% | |

| Error | 4 | 125.16 | 31.29 | 6.4% | ||

| Total | 8 | 1970.58 | ||||

| R2 = 93.7%, adjusted R2 = 87.3%, predicted R2 = 70.0% | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Correia, A.N.; Gaspar, B.M.; Cipriano, G.; Braga, D.F.O.; Baptista, R.; Infante, V. Thermo-Mechanical Characterization of Metal–Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments. Polymers 2024, 16, 602. https://doi.org/10.3390/polym16050602

Correia AN, Gaspar BM, Cipriano G, Braga DFO, Baptista R, Infante V. Thermo-Mechanical Characterization of Metal–Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments. Polymers. 2024; 16(5):602. https://doi.org/10.3390/polym16050602

Chicago/Turabian StyleCorreia, Arménio N., Beatriz M. Gaspar, Gonçalo Cipriano, Daniel F. O. Braga, Ricardo Baptista, and Virgínia Infante. 2024. "Thermo-Mechanical Characterization of Metal–Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments" Polymers 16, no. 5: 602. https://doi.org/10.3390/polym16050602

APA StyleCorreia, A. N., Gaspar, B. M., Cipriano, G., Braga, D. F. O., Baptista, R., & Infante, V. (2024). Thermo-Mechanical Characterization of Metal–Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments. Polymers, 16(5), 602. https://doi.org/10.3390/polym16050602