Flowing Liquid-Based Triboelectric Nanogenerator Performance Enhancement with Functionalized Polyvinylidene Fluoride Membrane for Self-Powered Pulsating Flow Sensing Application

Abstract

1. Introduction

2. Experimental Section

2.1. Functionalized PVDF Membrane and FL-TENG Device Fabrication

2.2. Characterization and Measurements

3. Results and Discussions

3.1. Working Mechanisms

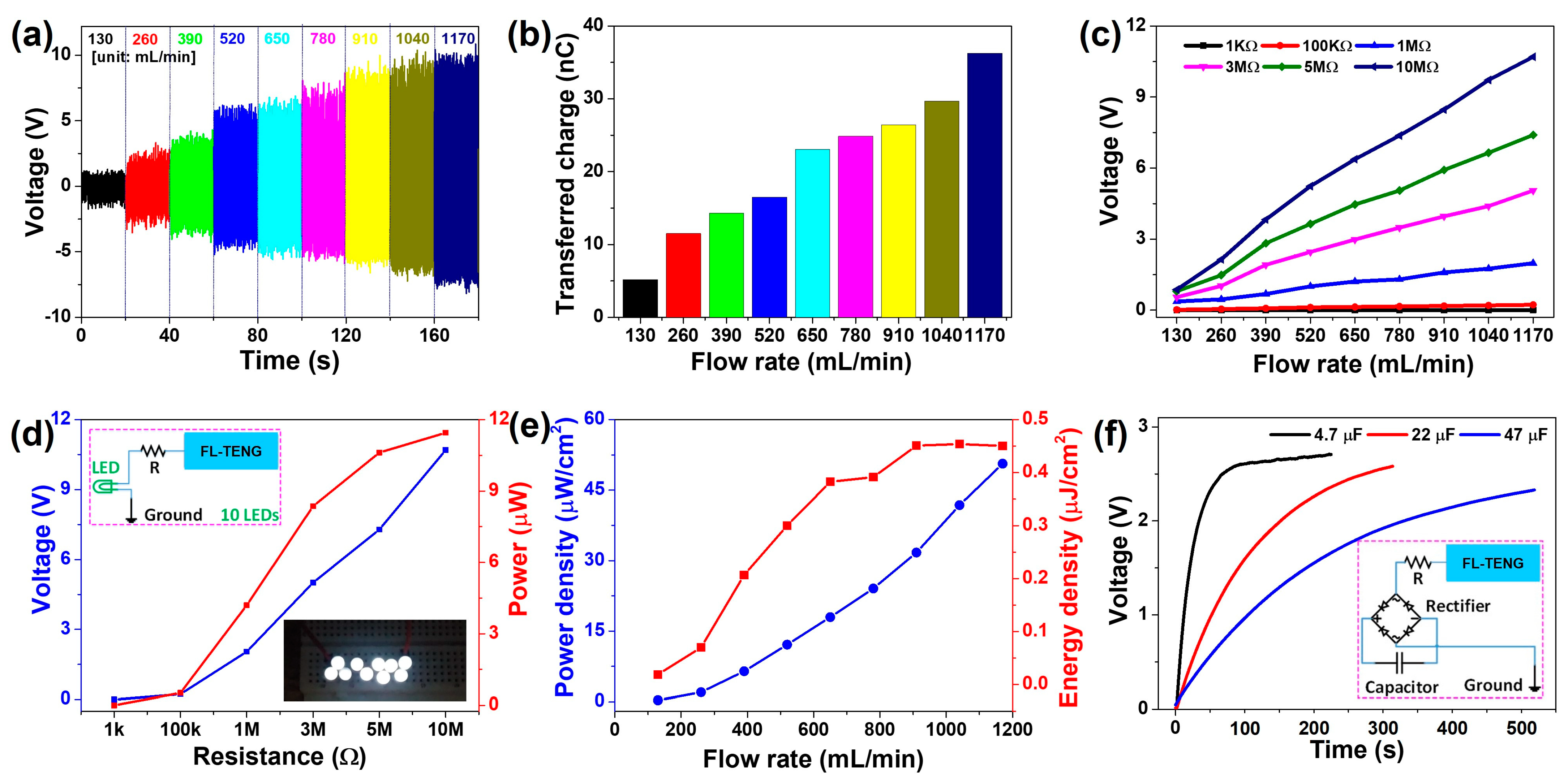

3.2. Electrical Output Characteristics

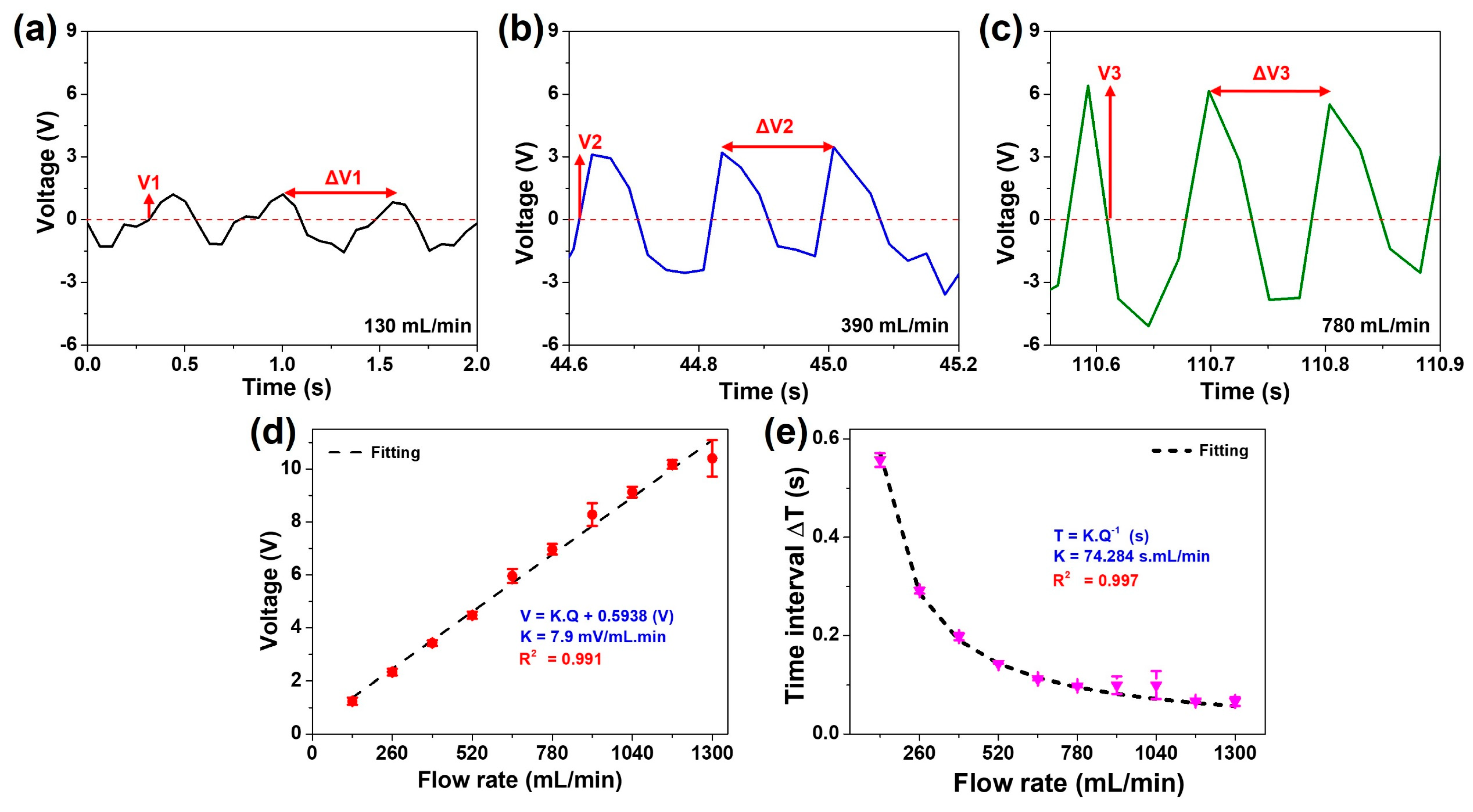

3.3. Application in Self-Powered Flow Sensor

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Sharma, P.; Motte, J.F.; Fournel, F.; Cross, B.; Charlaix, E.; Picard, C. A Direct Sensor to Measure Minute Liquid Flow Rates. Nano Lett. 2018, 18, 5726–5730. [Google Scholar] [CrossRef] [PubMed]

- Ejeian, F.; Azadi, S.; Razmjou, A.; Orooji, Y.; Kottapalli, A.; Ebrahimi Warkiani, M.; Asadnia, M. Design and Applications of MEMS Flow Sensors: A Review. Sens. Actuators A Phys. 2019, 295, 483–502. [Google Scholar] [CrossRef]

- Yick, J.; Mukherjee, B.; Ghosal, D. Wireless Sensor Network Survey. Comput. Netw. 2008, 52, 2292–2330. [Google Scholar] [CrossRef]

- Hanani, Z.; Izanzar, I.; Amjoud, M.; Mezzane, D.; Lahcini, M.; Uršič, H.; Prah, U.; Saadoune, I.; El Marssi, M.; Luk’yanchuk, I.A.; et al. Lead-Free Nanocomposite Piezoelectric Nanogenerator Film for Biomechanical Energy Harvesting. Nano Energy 2021, 81, 105661. [Google Scholar] [CrossRef]

- Lee, P.C.; Hsiao, Y.L.; Dutta, J.; Wang, R.C.; Tseng, S.W.; Liu, C.P. Development of Porous ZnO Thin Films for Enhancing Piezoelectric Nanogenerators and Force Sensors. Nano Energy 2021, 82, 105702. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Y.; Wang, Z.L.; Yang, Y. Standard and Figure-of-Merit for Quantifying the Performance of Pyroelectric Nanogenerators. Nano Energy 2019, 55, 534–540. [Google Scholar] [CrossRef]

- Wang, N.; Feng, Y.; Zheng, Y.; Zhang, L.; Feng, M.; Li, X.; Zhou, F.; Wang, D. New Hydrogen Bonding Enhanced Polyvinyl Alcohol Based Self-Charged Medical Mask with Superior Charge Retention and Moisture Resistance Performances. Adv. Funct. Mater. 2021, 31, 2009172. [Google Scholar] [CrossRef]

- Vu, D.L.; Ahn, K.K. Triboelectric Enhancement of Polyvinylidene Fluoride Membrane Using Magnetic Nanoparticle for Water-Based Energy Harvesting. Polymers 2022, 14, 1547. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.L. Recent Progress of Triboelectric Nanogenerators: From Fundamental Theory to Practical Applications. EcoMat 2020, 2, e12059. [Google Scholar] [CrossRef]

- Kim, W.G.; Kim, D.W.; Tcho, I.W.; Kim, J.K.; Kim, M.S.; Choi, Y.K. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Lin, Z.H.; Jing, Q.; Chen, J.; Zhang, G.; Ma, J.; Wang, Z.L. Integrated Multilayered Triboelectric Nanogenerator for Harvesting Biomechanical Energy from Human Motions. ACS Nano 2013, 7, 3713–3719. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Wang, P.; Wang, L.; Yang, S.; Wu, D. Ecent Advances in Ocean Wave Energy Harvesting by Triboelectric Nanogenerator: An Overview. Nanotechnol. Rev. 2020, 9, 716–735. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, A.C. On the Origin of Contact-Electrification. Mater. Today 2019, 30, 34–51. [Google Scholar] [CrossRef]

- Chen, H.; Xing, C.; Li, Y.; Wang, J.; Xu, Y. Triboelectric Nanogenerators for a Macro-Scale Blue Energy Harvesting and Self-Powered Marine Environmental Monitoring System. Sustain. Energy Fuels 2020, 4, 1063–1077. [Google Scholar] [CrossRef]

- Le, C.D.; Nguyen, T.H.; Vu, D.L.; Vo, C.P.; Ahn, K.K. A Rotational Switched-Mode Water-Based Triboelectric Nanogenerator for Mechanical Energy Harvesting and Vehicle Monitoring. Mater. Today Sustain. 2022, 19, 100158. [Google Scholar] [CrossRef]

- Lai, Y.C.; Wu, H.M.; Lin, H.C.; Chang, C.L.; Chou, H.H.; Hsiao, Y.C.; Wu, Y.C. Entirely, Intrinsically, and Autonomously Self-Healable, Highly Transparent, and Superstretchable Triboelectric Nanogenerator for Personal Power Sources and Self-Powered Electronic Skins. Adv. Funct. Mater. 2019, 29, 1904626. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Vu, D.L.; Le, C.D.; Ahn, K.K. Enhancing the Performance of Triboelectric Generator: A Novel Approach Using Solid–Liquid Interface-Treated Foam and Metal Contacts. Polymers 2023, 15, 2392. [Google Scholar] [CrossRef]

- Ye, C.; Liu, D.; Chen, P.; Cao, L.N.Y.; Li, X.; Jiang, T.; Wang, Z.L. An Integrated Solar Panel with a Triboelectric Nanogenerator Array for Synergistic Harvesting of Raindrop and Solar Energy. Adv. Mater. 2023, 35, e2209713. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, S.M.; Kim, T.Y.; Khan, U.; Kim, S.W. Water Droplet-Driven Triboelectric Nanogenerator with Superhydrophobic Surfaces. Nano Energy 2019, 58, 579–584. [Google Scholar] [CrossRef]

- Kwak, S.S.; Lin, S.; Lee, J.H.; Ryu, H.; Kim, T.Y.; Zhong, H.; Chen, H.; Kim, S.W. Triboelectrification-Induced Large Electric Power Generation from a Single Moving Droplet on Graphene/Polytetrafluoroethylene. ACS Nano 2016, 10, 7297–7302. [Google Scholar] [CrossRef]

- Ding, X.; Cao, H.; Zhang, X.; Li, M.; Liu, Y. Large Scale Triboelectric Nanogenerator and Self-Powered Flexible Sensor for Human Sleep Monitoring. Sensors 2018, 18, 1713. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Vu, D.L.; Le, C.D.; Ahn, K.K. Recent Progress in Self-Powered Sensors Based on Liquid-Solid Triboelectric Nanogenerators. Sensors 2023, 23, 5888. [Google Scholar] [CrossRef] [PubMed]

- Munirathinam, K.; Kim, D.S.; Shanmugasundaram, A.; Park, J.; Jeong, Y.J.; Lee, D.W. Flowing Water-Based Tubular Triboelectric Nanogenerators for Sustainable Green Energy Harvesting. Nano Energy 2022, 102, 107675. [Google Scholar] [CrossRef]

- Rehman, H.M.M.U.; Prasanna, A.P.S.; Rehman, M.M.; Khan, M.; Kim, S.J.; Kim, W.Y. Edible Rice Paper-Based Multifunctional Humidity Sensor Powered by Triboelectricity. Sustain. Mater. Technol. 2023, 36, e00596. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, S.; Zhang, L.; Wang, L.; Xue, H.; Wang, Z.L. Non-Contact and Liquid–Liquid Interfacing Triboelectric Nanogenerator for Self-Powered Water/Liquid Level Sensing. Nano Energy 2020, 72, 104703. [Google Scholar] [CrossRef]

- Nabavi, M.; Siddiqui, K. A Critical Review on Advanced Velocity Measurement Techniques in Pulsating Flows. Meas. Sci. Technol. 2010, 21, 042002. [Google Scholar] [CrossRef]

- Dincau, B.; Dressaire, E.; Sauret, A. Pulsatile Flow in Microfluidic Systems. Small 2020, 16, 1904032. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Zhang, X.; Zhang, H.; Ren, Y. Turbulent Transport Dissimilarities of Particles, Momentum, and Heat. Environ. Res. 2022, 211, 113111. [Google Scholar] [CrossRef] [PubMed]

- Jin, D.X.; Lee, Y.P.; Lee, D.Y. Effects of the Pulsating Flow Agitation on the Heat Transfer in a Triangular Grooved Channel. Int. J. Heat Mass Transf. 2007, 50, 3062–3071. [Google Scholar] [CrossRef]

- Hassani, A.; Scaria, J.; Ghanbari, F.; Nidheesh, P.V. Sulfate Radicals-Based Advanced Oxidation Processes for the Degradation of Pharmaceuticals and Personal Care Products: A Review on Relevant Activation Mechanisms, Performance, and Perspectives. Environ. Res. 2023, 217, 114789. [Google Scholar] [CrossRef]

- Brahma, I. Measurement and Prediction of Discharge Coefficients in Highly Compressible Pulsating Flows to Improve EGR Flow Estimation and Modeling of Engine Flows. Front. Mech. Eng. 2019, 5, 25. [Google Scholar] [CrossRef]

- Matsusaka, S.; Fukuda, H.; Sakura, Y.; Masuda, H.; Ghadiri, M. Analysis of Pulsating Electric Signals Generated in Gas-Solids Pipe Flow. Chem. Eng. Sci. 2008, 63, 1353–1360. [Google Scholar] [CrossRef][Green Version]

- Walker, E.S.; Fedak, K.M.; Good, N.; Balmes, J.; Brook, R.D.; Clark, M.L.; Cole-Hunter, T.; Dinenno, F.; Devlin, R.B.; L’Orange, C.; et al. Acute Differences in Pulse Wave Velocity, Augmentation Index, and Central Pulse Pressure Following Controlled Exposures to Cookstove Air Pollution in the Subclinical Tests of Volunteers Exposed to Smoke (SToVES) Study. Environ. Res. 2020, 180, 108831. [Google Scholar] [CrossRef] [PubMed]

- Tezuka, K.; Mori, M.; Suzuki, T.; Kanamine, T. Ultrasonic Pulse-Doppler Flow Meter Application for Hydraulic Power Plants. Flow Meas. Instrum. 2008, 19, 155–162. [Google Scholar] [CrossRef]

- Tonon, D.; Willems, J.F.H.; Hirschberg, A. Self-Sustained Oscillations in Pipe Systems with Multiple Deep Side Branches: Prediction and Reduction by Detuning. J. Sound Vib. 2011, 330, 5894–5912. [Google Scholar] [CrossRef]

- Huang, H.; Zeng, S.; Luo, C.; Long, T. Separate Effect of Turbulent Pulsation on Internal Mass Transfer in Porous Biofilms. Environ. Res. 2023, 217, 114972. [Google Scholar] [CrossRef] [PubMed]

- Abiev, R.S.; Vasilev, M.P. Pulsating Flow Type Apparatus: Energy Dissipation Rate and Droplets Dispersion. Chem. Eng. Res. Des. 2016, 108, 101–108. [Google Scholar] [CrossRef]

- Olczyk, A. Investigation of the Specific Mass Flow Rate Distribution in Pipes Supplied with a Pulsating Flow. Int. J. Heat Fluid Flow 2009, 30, 637–646. [Google Scholar] [CrossRef]

- Nag, A.; Hvizdos, P.; Dixit, A.R.; Petrů, J.; Hloch, S. Influence of the Frequency and Flow Rate of a Pulsating Water Jet on the Wear Damage of Tantalum. Wear 2021, 477, 203893. [Google Scholar] [CrossRef]

- Ghorbani, H.; Wood, D.A.; Choubineh, A.; Tatar, A.; Abarghoyi, P.G.; Madani, M.; Mohamadian, N. Prediction of Oil Flow Rate through an Orifice Flow Meter: Artificial Intelligence Alternatives Compared. Petroleum 2020, 6, 404–414. [Google Scholar] [CrossRef]

- Watral, Z.; Jakubowski, J.; Michalski, A. Electromagnetic Flow Meters for Open Channels: Current State and Development Prospects. Flow Meas. Instrum. 2015, 42, 16–25. [Google Scholar] [CrossRef]

- Rothfuss, M.A.; Unadkat, J.V.; Gimbel, M.L.; Mickle, M.H.; Sejdić, E. Totally Implantable Wireless Ultrasonic Doppler Blood Flowmeters: Toward Accurate Miniaturized Chronic Monitors. Ultrasound Med. Biol. 2017, 43, 561–578. [Google Scholar] [CrossRef] [PubMed]

- Vu, D.L.; Le, C.D.; Vo, C.P.; Ahn, K.K. Surface Polarity Tuning through Epitaxial Growth on Polyvinylidene Fluoride Membranes for Enhanced Performance of Liquid-Solid Triboelectric Nanogenerator. Compos. Part B Eng. 2021, 223, 109135. [Google Scholar] [CrossRef]

- Lee, J.W.; Jung, S.; Lee, T.W.; Jo, J.; Chae, H.Y.; Choi, K.; Kim, J.J.; Lee, J.H.; Yang, C.; Baik, J.M. High-Output Triboelectric Nanogenerator Based on Dual Inductive and Resonance Effects-Controlled Highly Transparent Polyimide for Self-Powered Sensor Network Systems. Adv. Energy Mater. 2019, 9, 1901987. [Google Scholar] [CrossRef]

- Vu, D.L.; Le, C.D.; Ahn, K.K. Functionalized Graphene Oxide/Polyvinylidene Fluoride Composite Membrane Acting as a Triboelectric Layer for Hydropower Energy Harvesting. Int. J. Energy Res. 2022, 46, 9549–9559. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Wang, A.C.; Wang, Z.L. Quantifying Electron-Transfer in Liquid-Solid Contact Electrification and the Formation of Electric Double-Layer. Nat. Commun. 2020, 11, 399. [Google Scholar] [CrossRef]

- Dong, Z.Q.; Ma, X.H.; Xu, Z.L.; Gu, Z.Y. Superhydrophobic Modification of PVDF-SiO2 Electrospun Nanofiber Membranes for Vacuum Membrane Distillation. RSC Adv. 2015, 5, 67962–67970. [Google Scholar] [CrossRef]

- Kozbial, A.; Li, Z.; Conaway, C.; McGinley, R.; Dhingra, S.; Vahdat, V.; Zhou, F.; Durso, B.; Liu, H.; Li, L. Study on the Surface Energy of Graphene by Contact Angle Measurements. Langmuir 2014, 30, 8598–8606. [Google Scholar] [CrossRef]

- Alparone, A. Dipole (Hyper)Polarizabilities of Fluorinated Benzenes: An Ab Initio Investigation. J. Fluor. Chem. 2012, 144, 94–101. [Google Scholar] [CrossRef]

- Cappelletti, G.; Ardizzone, S.; Meroni, D.; Soliveri, G.; Ceotto, M.; Biaggi, C.; Benaglia, M.; Raimondi, L. Wettability of Bare and Fluorinated Silanes: A Combined Approach Based on Surface Free Energy Evaluations and Dipole Moment Calculations. J. Colloid Interface Sci. 2013, 389, 284–291. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vu, D.L.; Nguyen, Q.T.; Chung, P.S.; Ahn, K.K. Flowing Liquid-Based Triboelectric Nanogenerator Performance Enhancement with Functionalized Polyvinylidene Fluoride Membrane for Self-Powered Pulsating Flow Sensing Application. Polymers 2024, 16, 536. https://doi.org/10.3390/polym16040536

Vu DL, Nguyen QT, Chung PS, Ahn KK. Flowing Liquid-Based Triboelectric Nanogenerator Performance Enhancement with Functionalized Polyvinylidene Fluoride Membrane for Self-Powered Pulsating Flow Sensing Application. Polymers. 2024; 16(4):536. https://doi.org/10.3390/polym16040536

Chicago/Turabian StyleVu, Duy Linh, Quang Tan Nguyen, Pil Seung Chung, and Kyoung Kwan Ahn. 2024. "Flowing Liquid-Based Triboelectric Nanogenerator Performance Enhancement with Functionalized Polyvinylidene Fluoride Membrane for Self-Powered Pulsating Flow Sensing Application" Polymers 16, no. 4: 536. https://doi.org/10.3390/polym16040536

APA StyleVu, D. L., Nguyen, Q. T., Chung, P. S., & Ahn, K. K. (2024). Flowing Liquid-Based Triboelectric Nanogenerator Performance Enhancement with Functionalized Polyvinylidene Fluoride Membrane for Self-Powered Pulsating Flow Sensing Application. Polymers, 16(4), 536. https://doi.org/10.3390/polym16040536