Rheological and Flexural Strength Characteristics of Cement Mixtures through the Synergistic Effects of Graphene Oxide and PVA Fibers

Abstract

1. Introduction

2. Experimental Program

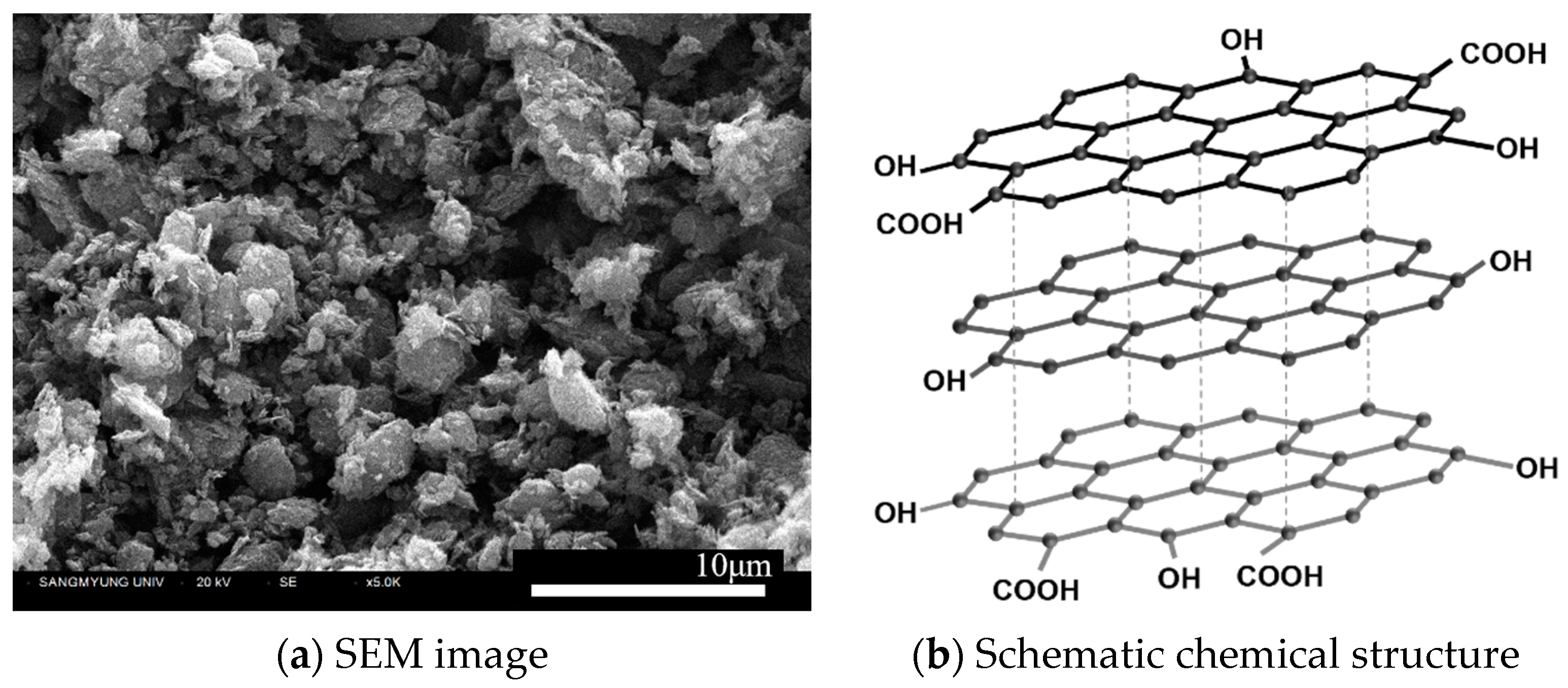

2.1. Materials and Mix Proportion

2.2. Test Procedure

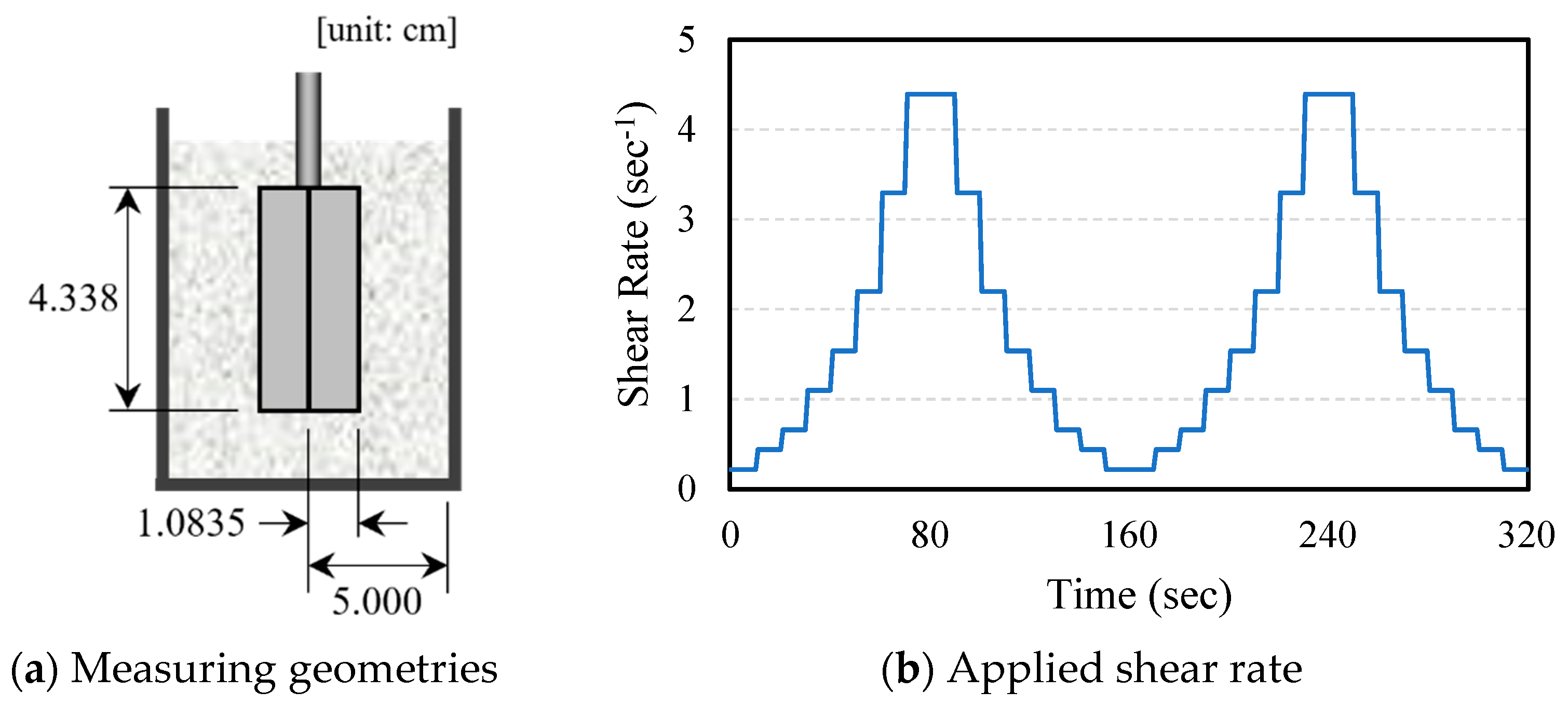

2.2.1. Rheological Test

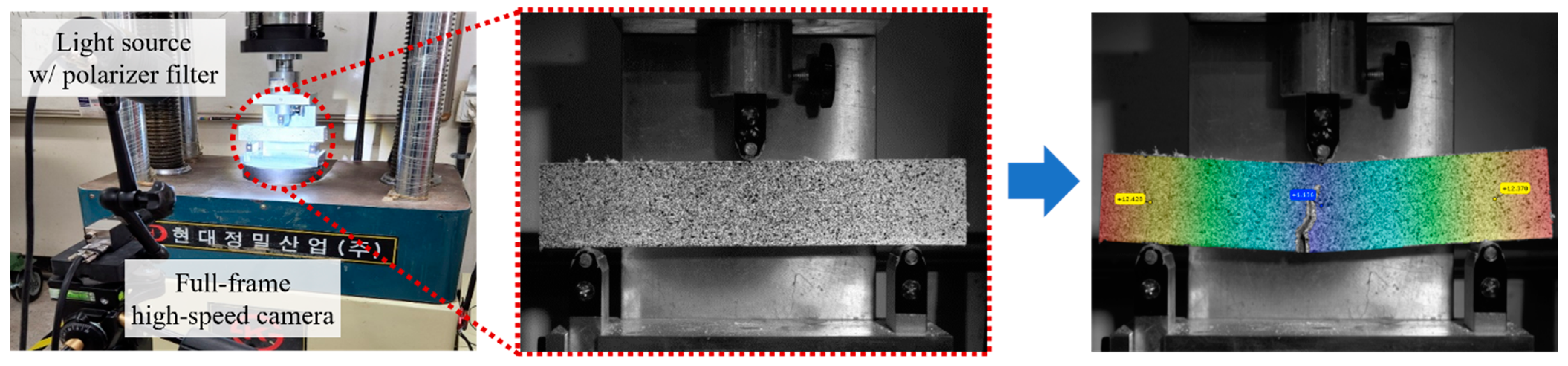

2.2.2. Flexural Strength Test

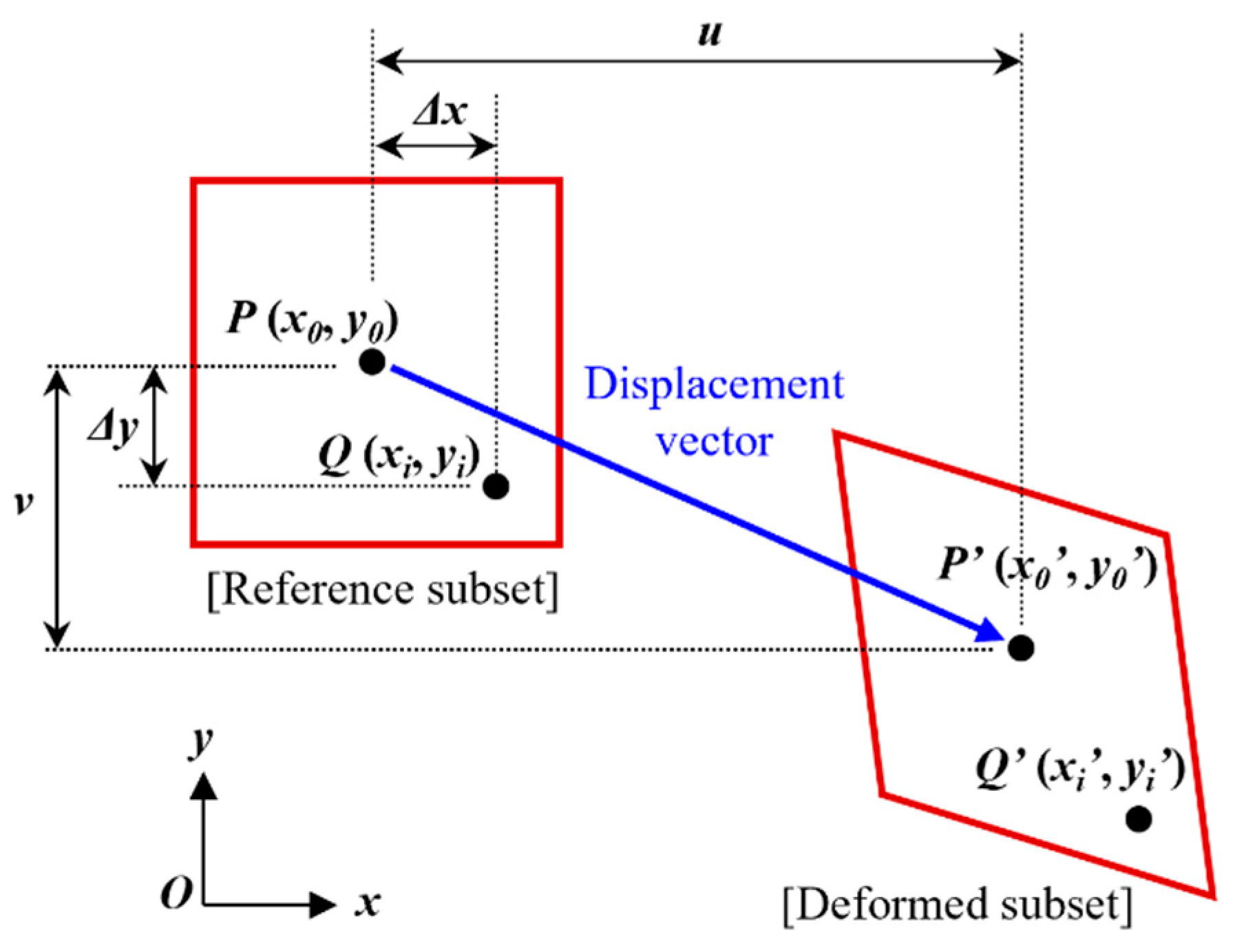

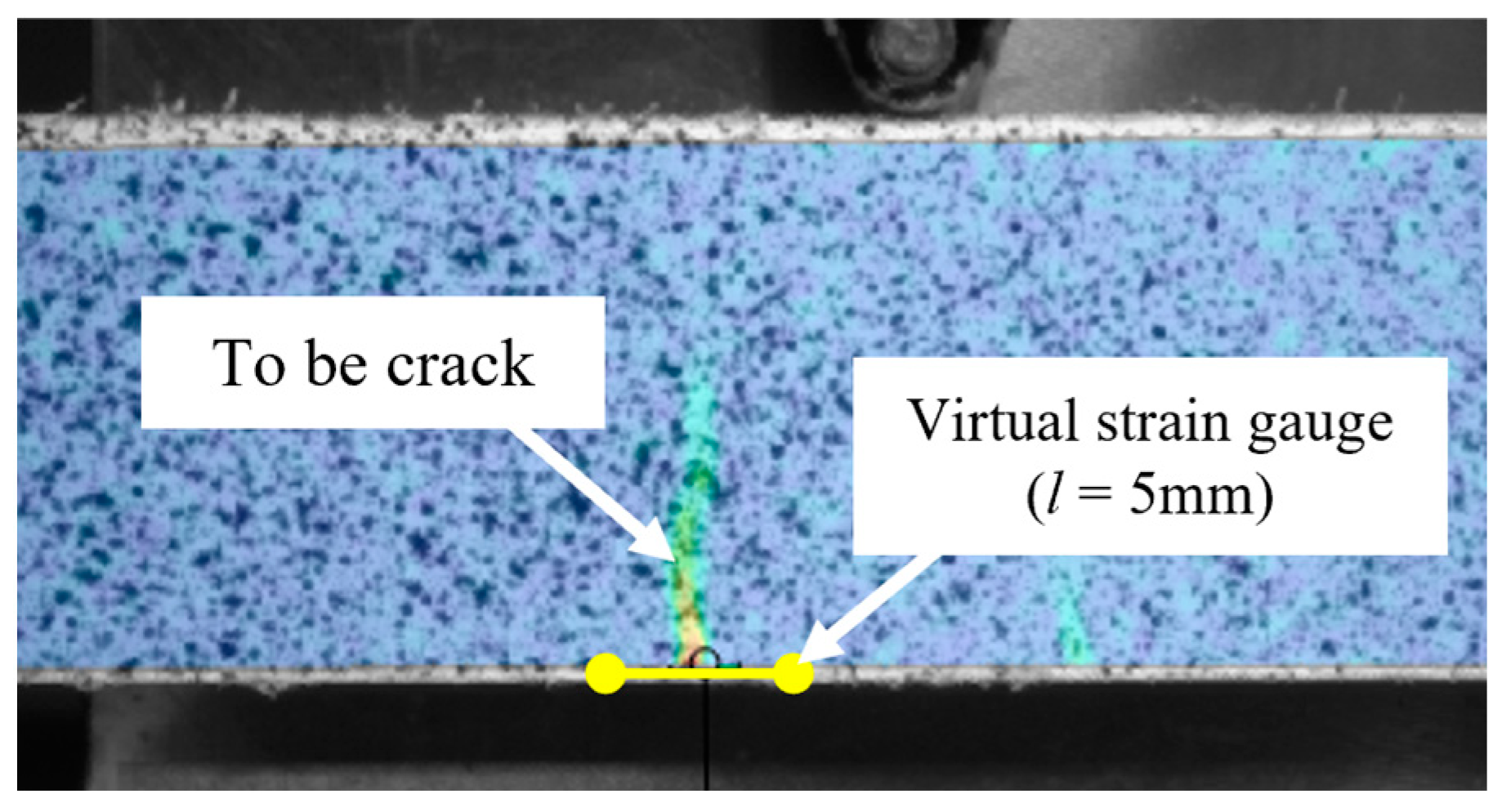

2.2.3. Digital Image Correlation (DIC)

2.2.4. Microscopic Analysis

3. Results and Discussion

3.1. Rheological Characteristics

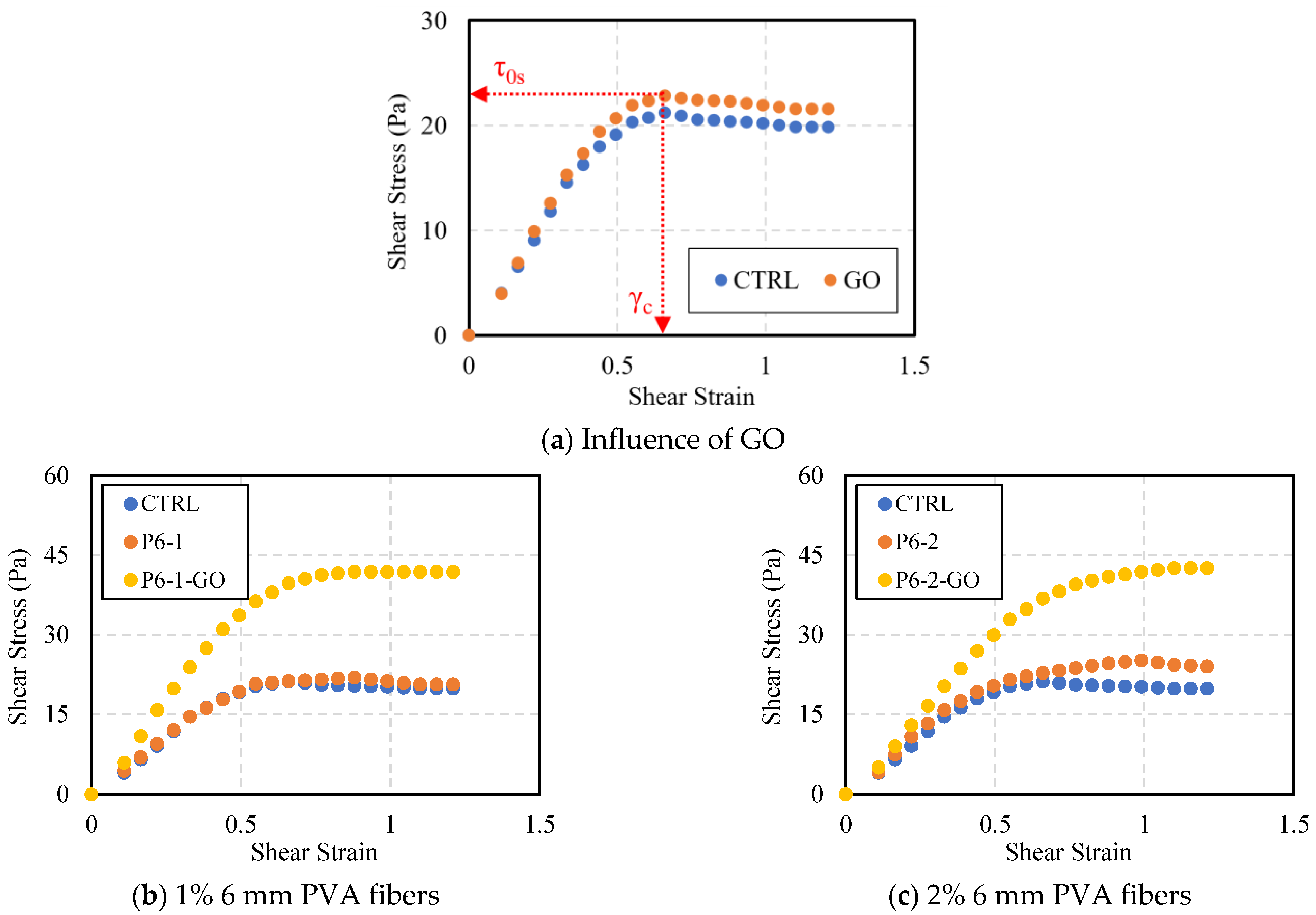

3.1.1. Static Yield Stress—Critical Shear Strain

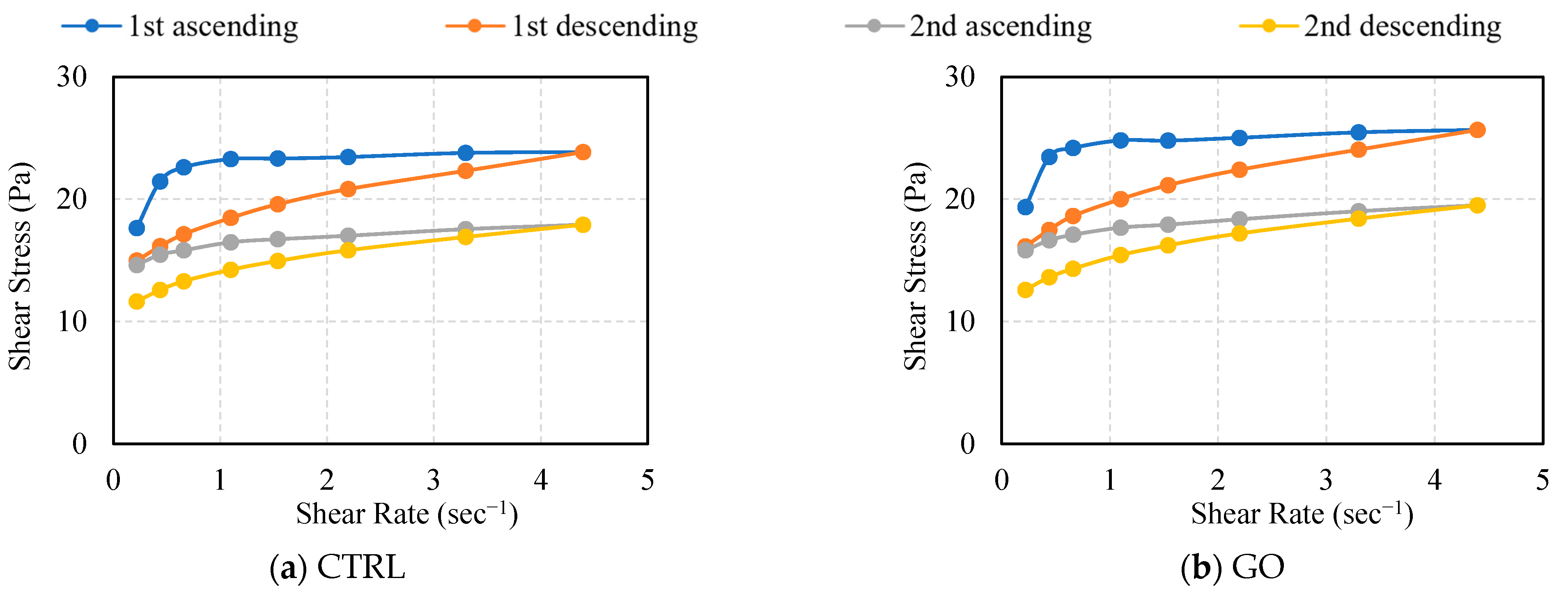

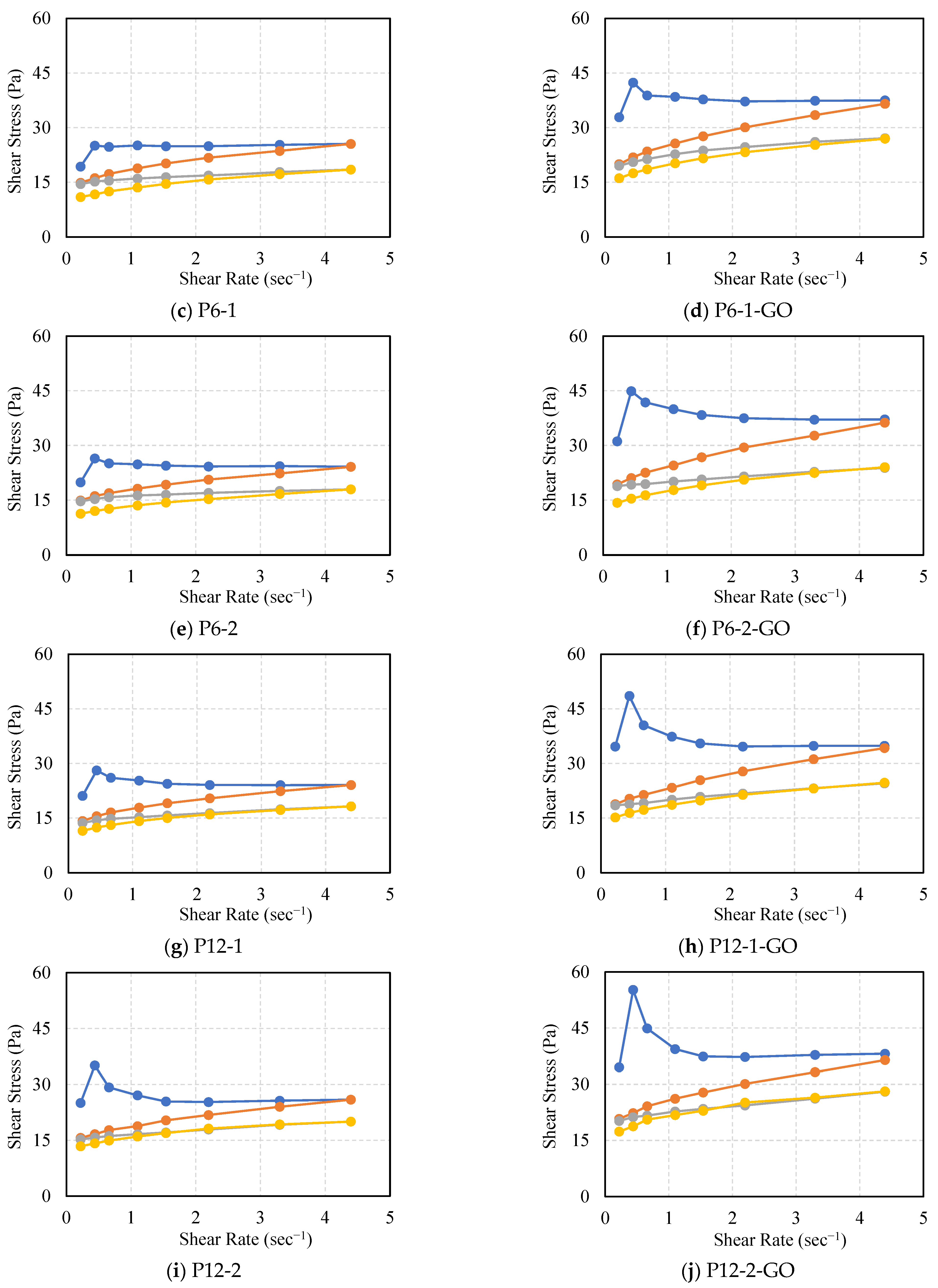

3.1.2. Shear Rate—Shear Stress

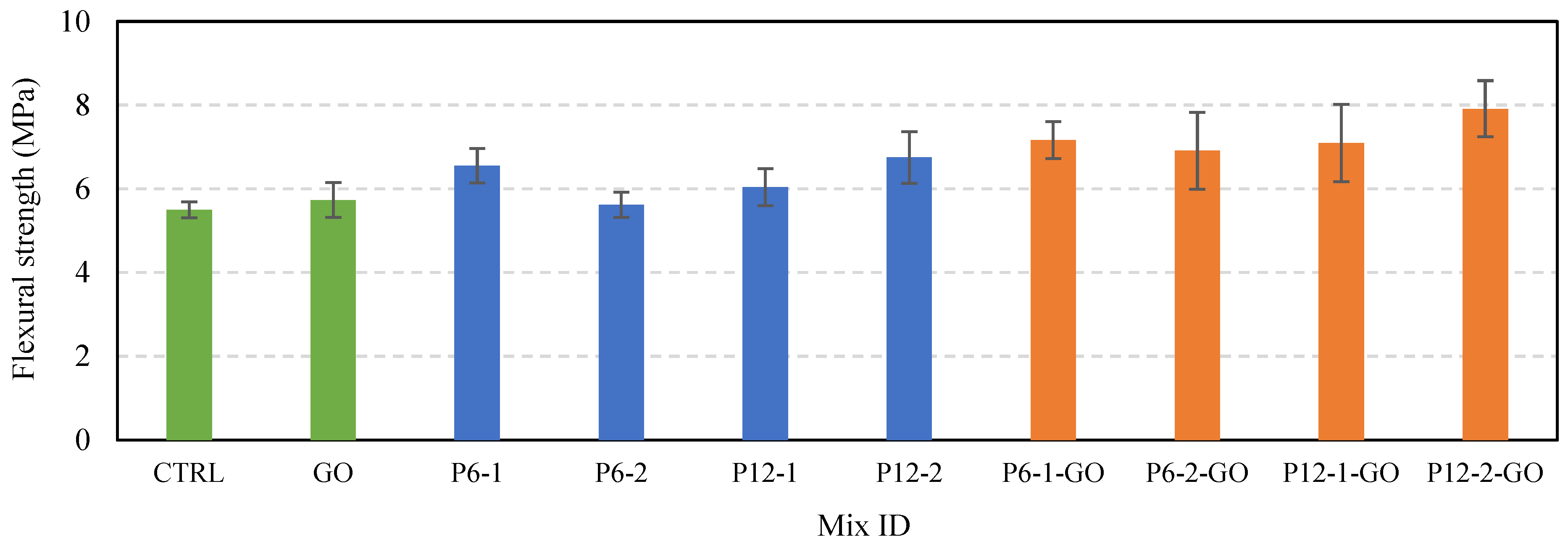

3.2. Flexural Strength Characteristics

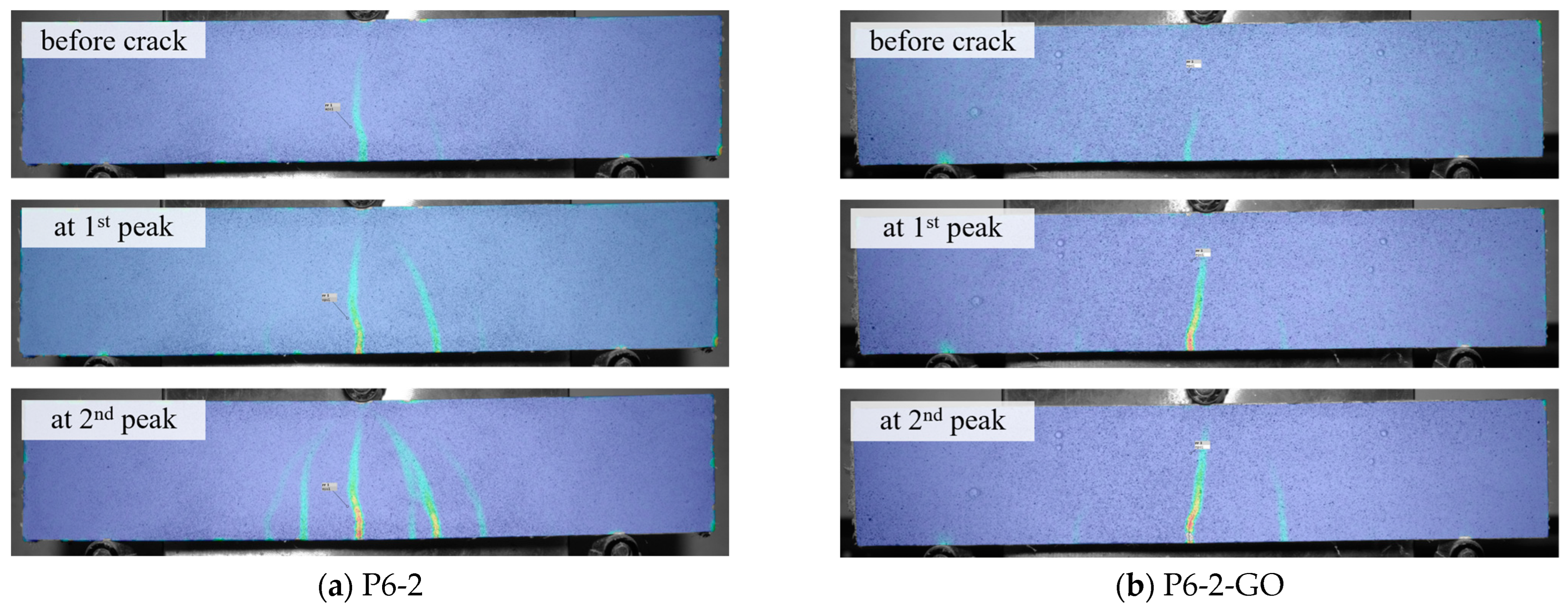

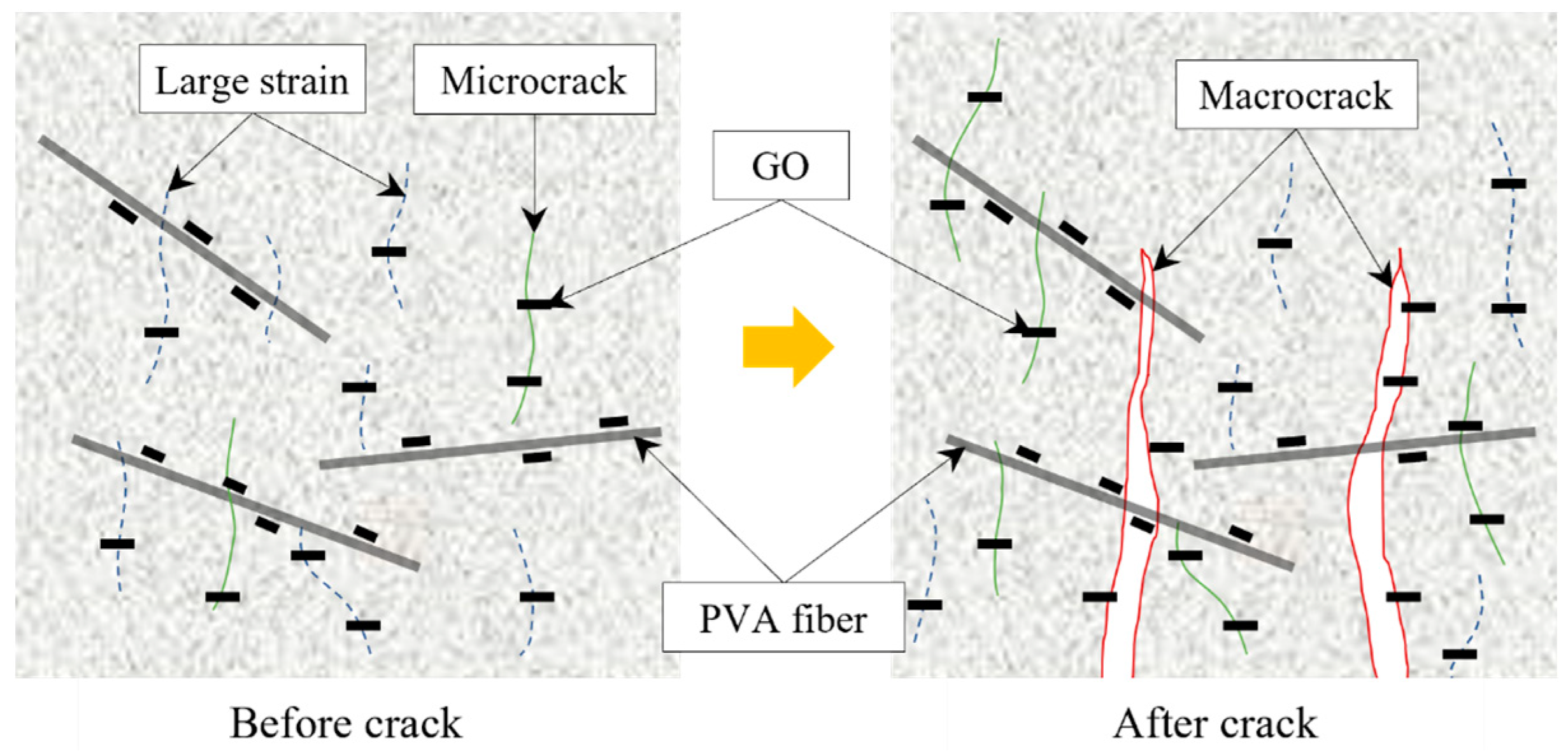

3.3. Virtual Strain Analysis via DIC

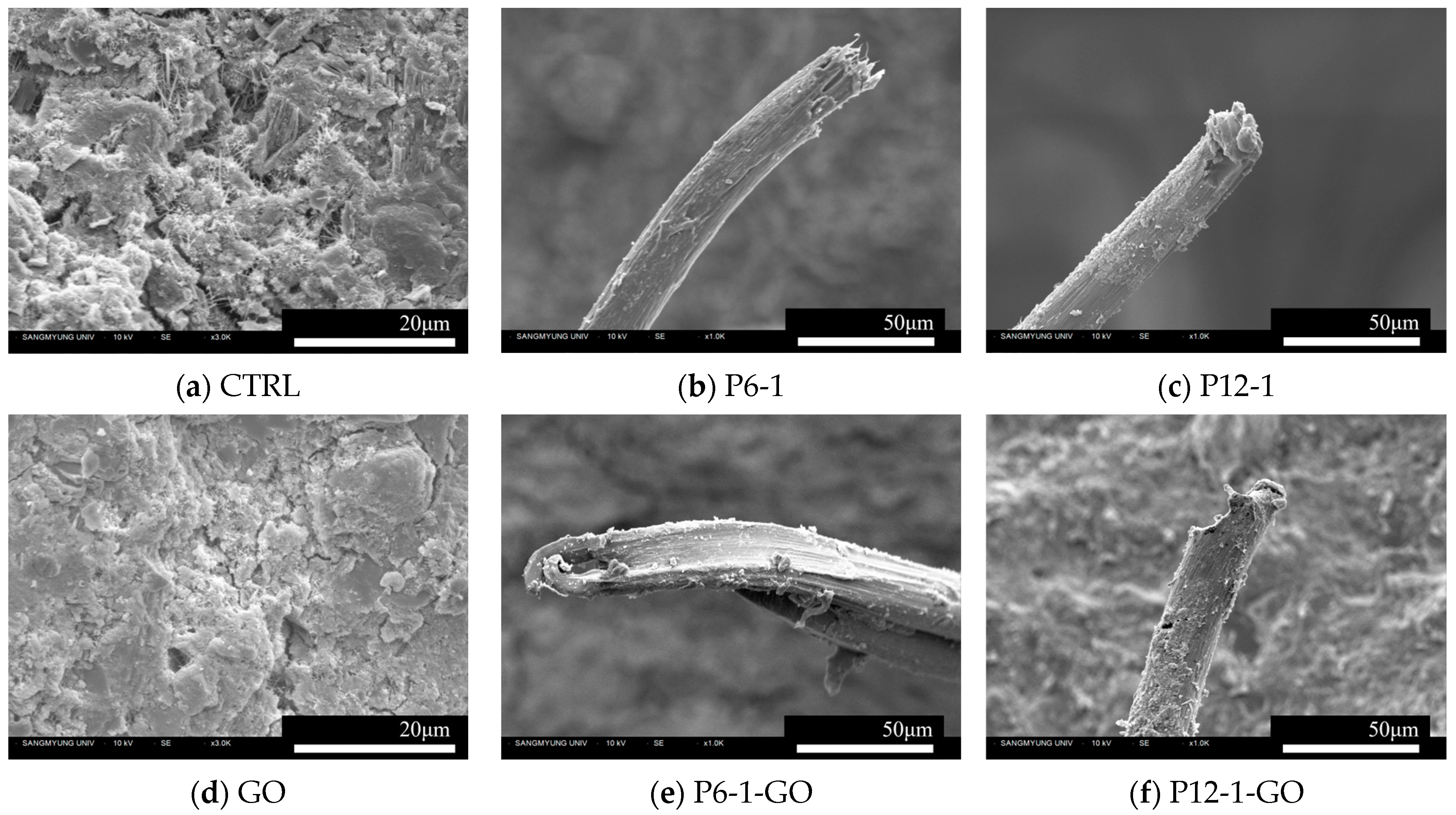

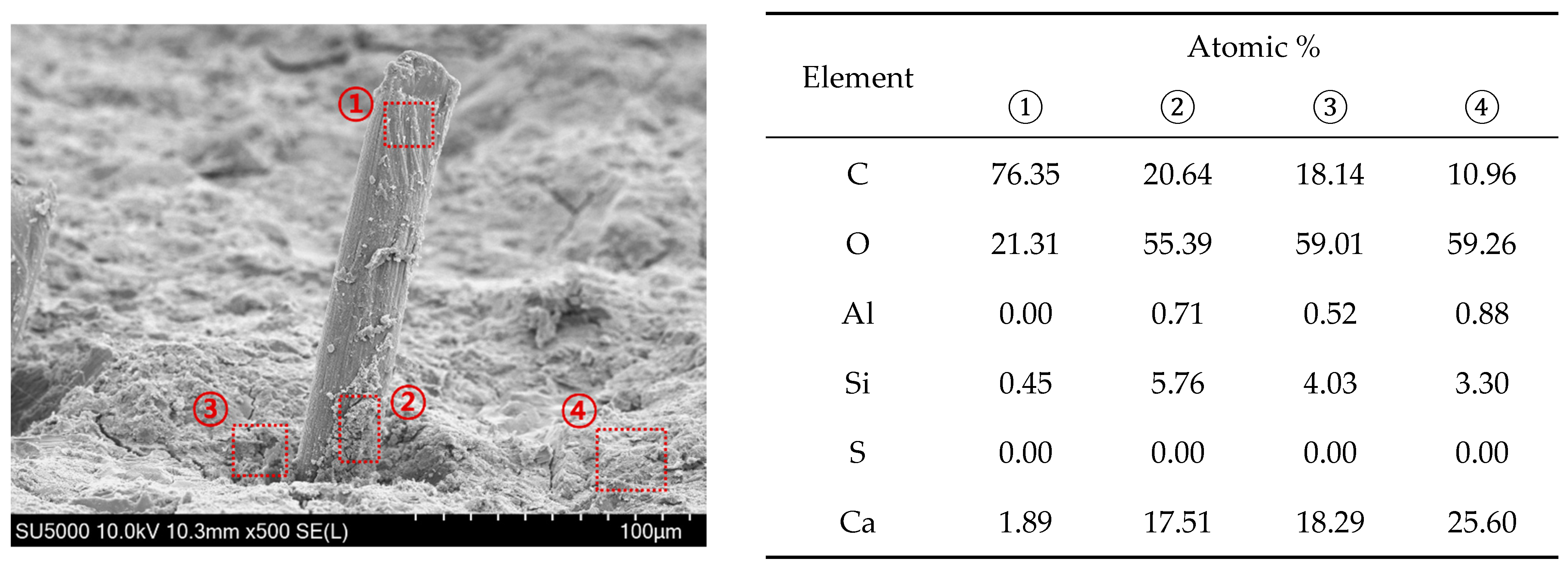

3.4. Microscopic Analysis

4. Conclusions

- The inclusion of GO in cement mixtures increases static yield stress, while adding PVA fibers raises both static yield stress and critical shear strain, particularly with longer or more abundant fibers. Notably, the combined effect of PVA fibers and GO significantly increases yield stress more than either additive alone.

- Adding GO results in higher mixture viscosity, and combining it with PVA fibers leads to pronounced viscosity fluctuations, indicating a more significant effect on the rheological properties. Furthermore, the length of PVA fibers is more influential than the number of strands in determining the rheological characteristics of the mixtures.

- Adding GO to PVA fiber-reinforced cement mixtures reduces the crack propagation rate and delays crack initiation. While smaller amounts of PVA fibers lead to sudden failure after cracking, incorporating GO increases pre-crack strain by 30 to 50% and mitigates further crack propagation.

- SEM analysis shows that GO contributes to a denser microstructure and effectively interacts with PVA fibers, enhancing the adherence of hydration products at their interface. This improves resistance to pull-out and overall mechanical strength.

- EDS analysis reveals a concentrated presence of GO around and on PVA fibers, promoting increased C-S-H gel formation, crucial for the cement’s mechanical properties. This may be attributed to the functionalized oxygen groups in GO, which enhance the hydration process and play a vital role in improving the composite’s flexural strength and altering its behavior.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chua, C.K.; Pumera, M. Chemical reduction of graphene oxide: A synthetic chemistry viewpoint. Chem. Soc. Rev. 2014, 43, 291–312. [Google Scholar] [CrossRef]

- Wang, X.; Shi, G. An introduction to the chemistry of graphene. Phys. Chem. Chem. Phys. 2015, 17, 28484–28504. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Li, X.; Hanif, A.; Chen, B.; Parthasarathy, P.; Yu, J.; Li, Z. Early-age interaction mechanism between the graphene oxide and cement hydrates. Constr. Build. Mater. 2017, 152, 232–239. [Google Scholar] [CrossRef]

- Yang, H.; Monasterio, M.; Cui, H.; Han, N. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite. Compos. Part A Appl. Sci. Manuf. 2017, 102, 263–272. [Google Scholar] [CrossRef]

- Devasena, M.; Karthikeyan, J. Investigation on strength properties of graphene oxide concrete. Int. J. Eng. Sci. Invent. Res. Dev. 2015, 1, 307–310. [Google Scholar]

- Li, X.; Lu, Z.; Chuah, S.; Li, W.; Liu, Y.; Duan, W.H.; Li, Z. Effects of graphene oxide aggregates on hydration degree, sorptivity, and tensile splitting strength of cement paste. Compos. Part A Appl. Sci. Manuf. 2017, 100, 1–8. [Google Scholar] [CrossRef]

- Garmor. Available online: http://garmortech.com/wordpress1/ (accessed on 27 December 2023).

- Khawaji, M.; Cho, B.H.; Nam, B.H.; Alharbi, Y.; An, J. Edge-oxidized graphene oxide as additive in fiber-reinforced concrete: Effects on fresh and hardened properties. J. Mater. Civ. Eng. 2020, 32, 04020028. [Google Scholar] [CrossRef]

- An, J.; Nam, B.H.; Alharbi, Y.; Cho, B.H.; Khawaji, M. Edge-oxidized graphene oxide (eogo) in cement composites: Cement hydration and microstructure. Compos. Part B Eng. 2019, 173, 106795. [Google Scholar] [CrossRef]

- Cho, B.H.; Khawaji, M.; Nam, B.H.; Alharbi, Y.; An, J. Static and cyclic flexural behaviors of edge-oxidized graphene oxide cement composites. J. Mater. Civ. Eng. 2019, 31, 04019273. [Google Scholar] [CrossRef]

- Alharbi, Y.; Cho, B.H.; An, J.; Nam, B.H. Rheological behaviors of edge-oxidized graphene oxide cement composites. J. Mater. Civ. Eng. 2020, 32, 04020134. [Google Scholar] [CrossRef]

- Cho, B.H.; Nam, B.H.; Khawaji, M. Flexural fatigue behaviors and damage evolution analysis of edge-oxidized graphene oxide (eogo) reinforced concrete composites. Cem. Concr. Compos. 2021, 122, 104082. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Mijowska, E.; Kalenczuk, R.J.; Aleksandrzak, M.; Mijowska, S. Nanocomposite of cement/graphene oxide–impact on hydration kinetics and young’s modulus. Constr. Build. Mater. 2015, 78, 234–242. [Google Scholar] [CrossRef]

- Garcia, S.; Naaman, A.E.; Pera, J. Experimental investigation on the potential use of poly (vinyl alcohol) short fibers in fiber-reinforced cement-based composites. Mater. Struct. 1997, 30, 43–52. [Google Scholar] [CrossRef]

- Mobasher, B.; Li, C.Y. Effect of interfacial properties on the crack propagation in cementitious composites. Adv. Cem. Based Mater. 1996, 4, 93–105. [Google Scholar] [CrossRef]

- Thong, C.; Teo, D.; Ng, C. Application of polyvinyl alcohol (pva) in cement-based composite materials: A review of its engineering properties and microstructure behavior. Constr. Build. Mater. 2016, 107, 172–180. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; Lyu, Z.; He, Z.; Nguyen, K.T. Fresh and rheological characteristics of fiber reinforced concrete—A review. Constr. Build. Mater. 2021, 296, 123734. [Google Scholar] [CrossRef]

- Si, W.; Cao, M.; Li, L. Establishment of fiber factor for rheological and mechanical performance of polyvinyl alcohol (pva) fiber reinforced mortar. Constr. Build. Mater. 2020, 265, 120347. [Google Scholar] [CrossRef]

- Cao, M.; Si, W.; Xie, C. Relationship of rheology, fiber dispersion, and strengths of polyvinyl alcohol fiber-reinforced cementitious composites. ACI Mater. J. 2020, 117, 191–204. [Google Scholar]

- Schulte, J.; Kilic, U.; Ma, J.; Ozbulut, O.E. Rheological and buildability characterization of pva fiber-reinforced cementitious composites for additive construction. In Behavior and Mechanics of Multifunctional Materials XV; SPIE: Washington, DC, USA, 2021; pp. 75–87. [Google Scholar]

- ASTM C150/C150M-22; Standard Specification for Portland Cement. ASTM Int.: West Conshohocken, PA, USA, 2022.

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Nováček, M.; Jankovský, O.; Luxa, J.; Sedmidubský, D.; Pumera, M.; Fila, V.; Lhotka, M.; Klímová, K.; Matějková, S.; Sofer, Z. Tuning of graphene oxide composition by multiple oxidations for carbon dioxide storage and capture of toxic metals. J. Mater. Chem. A 2017, 5, 2739–2748. [Google Scholar] [CrossRef]

- Alharbi, Y.; An, J.; Cho, B.H.; Khawaji, M.; Chung, W.; Nam, B.H. Mechanical and sorptivity characteristics of edge-oxidized graphene oxide (eogo)-cement composites: Dry-and wet-mix design methods. Nanomaterials 2018, 8, 718. [Google Scholar] [CrossRef]

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM Int.: West Conshohocken, PA, USA, 2016.

- Yamaguchi, I. Speckle displacement and decorrelation in the diffraction and image fields for small object deformation. Opt. Acta Int. J. Opt. 1981, 28, 1359–1376. [Google Scholar] [CrossRef]

- Peters, W.; Ranson, W. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Sutton, M.; Mingqi, C.; Peters, W.; Chao, Y.; McNeill, S. Application of an optimized digital correlation method to planar deformation analysis. Image Vis. Comput. 1986, 4, 143–150. [Google Scholar] [CrossRef]

- Sutton, M.A.; Yan, J.; Tiwari, V.; Schreier, H.; Orteu, J.-J. The effect of out-of-plane motion on 2d and 3d digital image correlation measurements. Opt. Lasers Eng. 2008, 46, 746–757. [Google Scholar] [CrossRef]

- Sutton, M.; Hild, F. Recent advances and perspectives in digital image correlation. Exp. Mech. 2015, 55, 1–8. [Google Scholar] [CrossRef]

- Sutton, M.A.; Wolters, W.; Peters, W.; Ranson, W.; McNeill, S. Determination of displacements using an improved digital correlation method. Image Vis. Comput. 1983, 1, 133–139. [Google Scholar] [CrossRef]

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | IR a | LOI b |

|---|---|---|---|---|---|---|---|

| Portion (%) | 64.90 | 21.49 | 4.21 | 3.50 | 0.70 | 0.65 | - |

| ASTM C150 [21] | - | Min 20.0 | Max 6.0 | Max 6.0 | Max 3.0 | 0.75 | Max 3.0 |

| Material | Property | Value |

|---|---|---|

| GO | Carbon | 90–95% |

| Oxygen | 5–10% | |

| Surface area | 200–300 m2/g | |

| Mean particle size | 450 nm | |

| Thickness | ~10 nm | |

| Specific gravity | 1.91 | |

| Bulk density | ~1.8 g/cm3 | |

| PVA fiber | Diameter | 26 μm |

| Length | 6.0 mm, 12.0 mm | |

| Tensile strength | 1200 MPa | |

| Specific gravity | 1.3 ± 0.1 | |

| Elastic modulus | 24.5 GPa |

| ID | w/c | GO (wt%) | PVA (vol%) | |

|---|---|---|---|---|

| 6 mm | 12 mm | |||

| CTRL | 0.5 | - | - | - |

| GO | 0.5 | 0.05 | - | - |

| P6-1 | 0.5 | - | 1 | - |

| P6-2 | 0.5 | - | 2 | - |

| P12-1 | 0.5 | - | - | 1 |

| P12-2 | 0.5 | - | - | 2 |

| P6-1-GO | 0.5 | 0.05 | 1 | - |

| P6-2-GO | 0.5 | 0.05 | 2 | - |

| P12-1-GO | 0.5 | 0.05 | - | 1 |

| P12-2-GO | 0.5 | 0.05 | - | 2 |

| ID | 1st Peak | 2nd Peak | E (GPa) | ||

|---|---|---|---|---|---|

| Load (kN) | Deflection (mm) | Load (kN) | Deflection (mm) | ||

| CTRL | 1.563 | 0.028 | - | - | 18.25 |

| GO | 1.631 | 0.028 | - | - | 19.21 |

| P6-1 | 1.965 | 0.033 | 1.331 | 0.253 | 19.49 |

| P6-2 | 1.599 | 0.034 | 1.893 | 0.244 | 15.53 |

| P12-1 | 1.718 | 0.039 | 1.562 | 0.234 | 14.43 |

| P12-2 | 1.895 | 0.037 | 1.982 | 0.214 | 17.01 |

| P6-1-GO | 2.163 | 0.037 | 1.360 | 0.220 | 19.69 |

| P6-2-GO | 1.966 | 0.035 | 2.064 | 0.229 | 18.48 |

| P12-1-GO | 2.019 | 0.031 | 1.657 | 0.228 | 21.80 |

| P12-2-GO | 2.251 | 0.036 | 2.449 | 0.315 | 21.10 |

| ID | εxx at 1st Peak (10−3) | ⓑ/ⓐ (%) | εxx at 2nd Peak (10−3) | ⓑ/ⓐ (%) | ||

|---|---|---|---|---|---|---|

| Without GO (ⓐ) | With GO (ⓑ) | Without GO (ⓐ) | With GO (ⓑ) | |||

| P6-1 | 2.77 | 4.17 | 150.54 | 95.55 | 88.41 | 92.53 |

| P6-2 | 4.09 | 6.14 | 150.12 | 73.64 | 74.18 | 100.73 |

| P12-1 | 4.26 | 5.52 | 129.58 | 80.46 | 82.31 | 102.30 |

| P12-2 | 3.74 | 5.26 | 140.64 | 139.67 | 145.88 | 104.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, B.H.; Choi, D.W.; Park, M.H. Rheological and Flexural Strength Characteristics of Cement Mixtures through the Synergistic Effects of Graphene Oxide and PVA Fibers. Polymers 2024, 16, 482. https://doi.org/10.3390/polym16040482

Cho BH, Choi DW, Park MH. Rheological and Flexural Strength Characteristics of Cement Mixtures through the Synergistic Effects of Graphene Oxide and PVA Fibers. Polymers. 2024; 16(4):482. https://doi.org/10.3390/polym16040482

Chicago/Turabian StyleCho, Byoung Hooi, Dong Wook Choi, and Mi Hwan Park. 2024. "Rheological and Flexural Strength Characteristics of Cement Mixtures through the Synergistic Effects of Graphene Oxide and PVA Fibers" Polymers 16, no. 4: 482. https://doi.org/10.3390/polym16040482

APA StyleCho, B. H., Choi, D. W., & Park, M. H. (2024). Rheological and Flexural Strength Characteristics of Cement Mixtures through the Synergistic Effects of Graphene Oxide and PVA Fibers. Polymers, 16(4), 482. https://doi.org/10.3390/polym16040482