Using Natural Dye Additives to Enhance the Energy Conversion Performance of a Cellulose Paper-Based Triboelectric Nanogenerator

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Preparing Cellulose Fibers

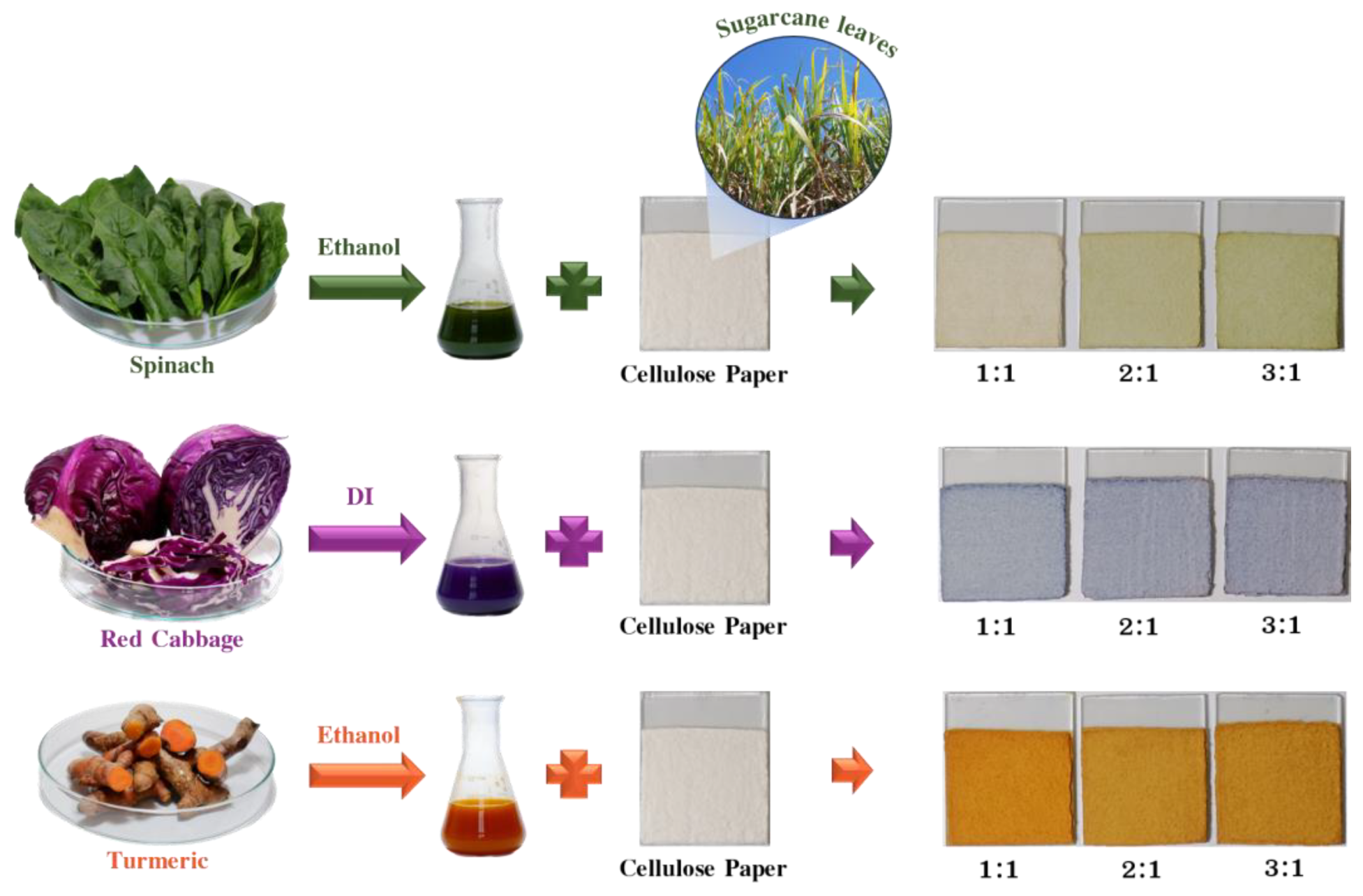

2.3. Natural Dye Extraction

2.4. Preparation of Cellulose Papers with the Incorporation of Natural Dyes

2.5. Characterizations

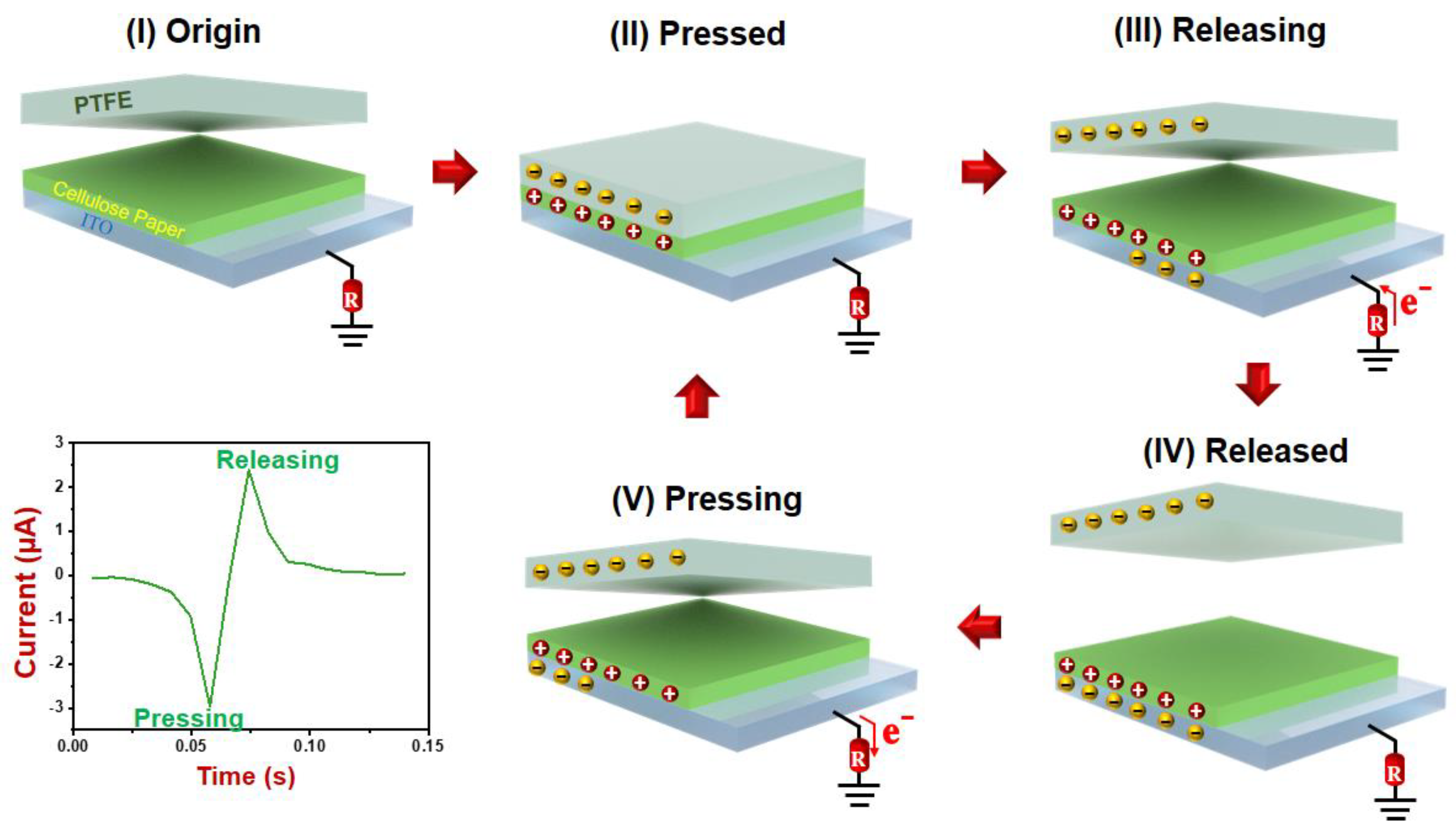

2.6. TENG Output Measurement

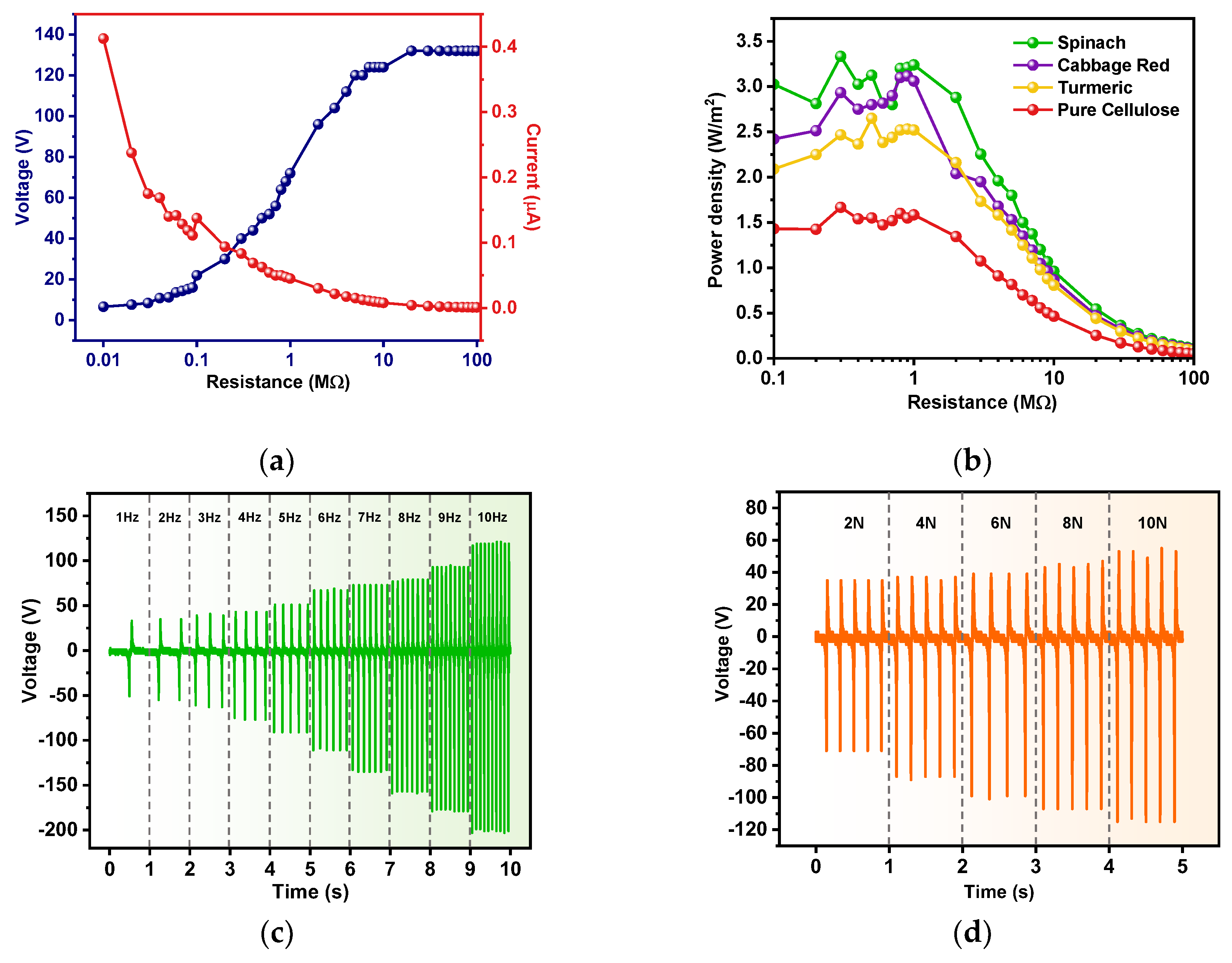

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Seddiqi, H.; Oliaei, E.; Honarkar, H.; Jin, J.; Geonzon, L.C.; Bacabac, R.G.; Klein-Nulend, J. Cellulose and its derivatives: Towards biomedical applications. Cellulose 2021, 28, 1893–1931. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhong, J.; Hu, B.; Hu, Q.; Zhou, J.; Wang, Z.L. A paper-based nanogenerator as a power source and active sensor. Energy Environ. Sci. 2013, 6, 1779–1784. [Google Scholar] [CrossRef]

- Guo, H.; Yeh, M.-H.; Zi, Y.; Wen, Z.; Chen, J.; Liu, G.; Hu, C.; Wang, Z.L. Ultralight Cut-Paper-Based Self-Charging Power Unit for Self-Powered Portable Electronic and Medical Systems. ACS Nano 2017, 11, 4475–4482. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Zhang, N.; Tang, Y.; Wang, M.; Chao, M.; Liang, E. A paper triboelectric nanogenerator for self-powered electronic systems. Nanoscale 2017, 9, 14499–14505. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Hernandez, A.; Yu, Y.; Cai, Z.; Wang, X. Triboelectric nanogenerators and power-boards from cellulose nanofibrils and recycled materials. Nano Energy 2016, 30, 103–108. [Google Scholar] [CrossRef]

- Xia, K.; Zhang, H.; Zhu, Z.; Xu, Z. Folding triboelectric nanogenerator on paper based on conductive ink and teflon tape. Sens. Actuators A Phys. 2018, 272, 28–32. [Google Scholar] [CrossRef]

- Yamklang, W.; Prada, T.; Bunriw, W.; Kaeochana, W.; Harnchana, V. Fe3O4-Filled Cellulose Paper for Triboelectric Nanogenerator Application. Polymers 2023, 15, 94. [Google Scholar] [CrossRef]

- Niu, Z.; Cheng, W.; Cao, M.; Wang, D.; Wang, Q.; Han, J.; Long, Y.; Han, G. Recent advances in cellulose-based flexible triboelectric nanogenerators. Nano Energy 2021, 87, 106175. [Google Scholar] [CrossRef]

- Zhang, R.; Dahlström, C.; Zou, H.; Jonzon, J.; Hummelgård, M.; Örtegren, J.; Blomquist, N.; Yang, Y.; Andersson, H.; Olsen, M.; et al. Cellulose-Based Fully Green Triboelectric Nanogenerators with Output Power Density of 300 W m−2. Adv. Mater. 2020, 32, 2002824. [Google Scholar] [CrossRef] [PubMed]

- Zi, Y.; Niu, S.; Wang, J.; Wen, Z.; Tang, W.; Wang, Z.L. Standards and figure-of-merits for quantifying the performance of triboelectric nanogenerators. Nat. Commun. 2015, 6, 8376. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.; Na, J.; Zhou, W.; Hur, S.; Chien, P.M.; Wang, C.; Wang, L.; Yamauchi, Y.; Yuan, Z. Enhancing energy harvesting performance and sustainability of cellulose-based triboelectric nanogenerators: Strategies for performance enhancement. Nano Energy 2023, 116, 108769. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, H.; Du, C.; Zhang, D.; Lin, H.; Chen, Y.; Xiong, J. Cellulose for Sustainable Triboelectric Nanogenerators. Adv. Energy Sustain. Res. 2022, 3, 2100161. [Google Scholar] [CrossRef]

- He, X.; Zou, H.; Geng, Z.; Wang, X.; Ding, W.; Hu, F.; Zi, Y.; Xu, C.; Zhang, S.L.; Yu, H.; et al. A Hierarchically Nanostructured Cellulose Fiber-Based Triboelectric Nanogenerator for Self-Powered Healthcare Products. Adv. Funct. Mater. 2018, 28, 1805540. [Google Scholar] [CrossRef]

- Shi, K.; Huang, X.; Sun, B.; Wu, Z.; He, J.; Jiang, P. Cellulose/BaTiO3 aerogel paper based flexible piezoelectric nanogenerators and the electric coupling with triboelectricity. Nano Energy 2019, 57, 450–458. [Google Scholar] [CrossRef]

- Roy, S.; Ko, H.-U.; Maji, P.K.; Van Hai, L.; Kim, J. Large amplification of triboelectric property by allicin to develop high performance cellulosic triboelectric nanogenerator. Chem. Eng. J. 2020, 385, 123723. [Google Scholar] [CrossRef]

- Bai, Z.; Xu, Y.; Zhang, Z.; Zhu, J.; Gao, C.; Zhang, Y.; Jia, H.; Guo, J. Highly flexible, porous electroactive biocomposite as attractive tribopositive material for advancing high-performance triboelectric nanogenerator. Nano Energy 2020, 75, 104884. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Liu, Y.; Lin, Z.-H.; Lee, S.; Lin, Z.; Wong, C.P.; Wang, Z.L. Silicon-Based Hybrid Energy Cell for Self-Powered Electrodegradation and Personal Electronics. ACS Nano 2013, 7, 2808–2813. [Google Scholar] [CrossRef]

- Guo, H.; He, X.; Zhong, J.; Zhong, Q.; Leng, Q.; Hu, C.; Chen, J.; Tian, L.; Xi, Y.; Zhou, J. A nanogenerator for harvesting airflow energy and light energy. J. Mater. Chem. A 2014, 2, 2079–2087. [Google Scholar] [CrossRef]

- Pang, Y.; Xue, F.; Wang, L.; Chen, J.; Luo, J.; Jiang, T.; Zhang, C.; Wang, Z.L. Tribotronic Enhanced Photoresponsivity of a MoS2 Phototransistor. Adv. Sci. 2016, 3, 1500419. [Google Scholar] [CrossRef]

- Su, L.; Zhao, Z.; Li, H.; Wang, Y.; Kuang, S.; Cao, G.; Wang, Z.; Zhu, G. Photoinduced enhancement of a triboelectric nanogenerator based on an organolead halide perovskite. J. Mater. Chem. C 2016, 4, 10395–10399. [Google Scholar] [CrossRef][Green Version]

- Fang, H.; Li, Q.; Ding, J.; Li, N.; Tian, H.; Zhang, L.; Ren, T.; Dai, J.; Wang, L.; Yan, Q. A self-powered organolead halide perovskite single crystal photodetector driven by a DVD-based triboelectric nanogenerator. J. Mater. Chem. C 2016, 4, 630–636. [Google Scholar] [CrossRef]

- Hao, S.; Wu, J.; Huang, Y.; Lin, J. Natural dyes as photosensitizers for dye-sensitized solar cell. Sol. Energy 2006, 80, 209–214. [Google Scholar] [CrossRef]

- Hosseinnezhad, M.; Gharanjig, K.; Yazdi, M.K.; Zarrintaj, P.; Moradian, S.; Saeb, M.R.; Stadler, F.J. Dye-sensitized solar cells based on natural photosensitizers: A green view from Iran. J. Alloys Compd. 2020, 828, 154329. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, L.; Gao, Y.; Ma, T. Dye-sensitized solar cells using 20 natural dyes as sensitizers. J. Photochem. Photobiol. A Chem. 2011, 219, 188–194. [Google Scholar] [CrossRef]

- Richhariya, G.; Kumar, A.; Tekasakul, P.; Gupta, B. Natural dyes for dye sensitized solar cell: A review. Renew. Sustain. Energy Rev. 2017, 69, 705–718. [Google Scholar] [CrossRef]

- Syafinar, R.; Gomesh, N.; Irwanto, M.; Fareq, M.; Irwan, Y.M. Chlorophyll Pigments as Nature Based Dye for Dye-Sensitized Solar Cell (DSSC). Energy Procedia 2015, 79, 896–902. [Google Scholar] [CrossRef]

- Amogne, N.Y.; Ayele, D.W.; Tsigie, Y.A. Recent advances in anthocyanin dyes extracted from plants for dye sensitized solar cell. Mater. Renew. Sustain. Energy 2020, 9, 23. [Google Scholar] [CrossRef]

- Hug, H.; Bader, M.; Mair, P.; Glatzel, T. Biophotovoltaics: Natural pigments in dye-sensitized solar cells. Appl. Energy 2014, 115, 216–225. [Google Scholar] [CrossRef]

- Kim, H.-J.; Kim, D.-J.; Karthick, S.N.; Hemalatha, K.V.; Raj, C.J.; Ok, S.; Choe, Y. Curcumin Dye Extracted from Curcuma longa L. Used as Sensitizers for Efficient Dye-Sensitized Solar Cells. Int. J. Electrochem. Sci. 2013, 8, 8320–8328. [Google Scholar] [CrossRef]

- Balakrishnan, M.; Batra, V.S. Valorization of solid waste in sugar factories with possible applications in India: A review. J. Environ. Manag. 2011, 92, 2886–2891. [Google Scholar] [CrossRef] [PubMed]

- Ungureanu, N.; Vlăduț, V.; Biriș, S.-Ș. Sustainable Valorization of Waste and By-Products from Sugarcane Processing. Sustainability 2022, 14, 11089. [Google Scholar] [CrossRef]

- Lichtenthaler, H.K.; Buschmann, C. Chlorophylls and Carotenoids: Measurement and Characterization by UV-VIS Spectroscopy. Curr. Protoc. Food Anal. Chem. 2001, 1, F4.3.1–F4.3.8. [Google Scholar] [CrossRef]

- Van Nong, H.; Hung, L.X.; Thang, P.N.; Chinh, V.D.; Vu, L.V.; Dung, P.T.; Van Trung, T.; Nga, P.T. Fabrication and vibration characterization of curcumin extracted from turmeric (Curcuma longa) rhizomes of the northern Vietnam. SpringerPlus 2016, 5, 1147. [Google Scholar] [CrossRef] [PubMed]

- Pratiwi, D.D.; Nurosyid, F.; Supriyanto, A.; Suryana, R. Optical properties of natural dyes on the dye-sensitized solar cells (DSSC) performance. J. Phys. Conf. Ser. 2016, 776, 012007. [Google Scholar] [CrossRef]

- Mandal, R.; Dutta, G. From photosynthesis to biosensing: Chlorophyll proves to be a versatile molecule. Sens. Int. 2020, 1, 100058. [Google Scholar] [CrossRef]

- Ammar, A.M.; Mohamed, H.S.H.; Yousef, M.M.K.; Abdel-Hafez, G.M.; Hassanien, A.S.; Khalil, A.S.G. Dye-Sensitized Solar Cells (DSSCs) Based on Extracted Natural Dyes. J. Nanomater. 2019, 2019, 1867271. [Google Scholar] [CrossRef]

- Chigurupati, N.; Saiki, L.; Gayser, C.; Dash, A. Evaluation of red cabbage dye as a potential natural color for pharmaceutical use. Int. J. Pharm. 2002, 241, 293–299. [Google Scholar] [CrossRef]

- Cocean, A.; Cocean, I.; Cimpoesu, N.; Cocean, G.; Cimpoesu, R.; Postolachi, C.; Popescu, V.; Gurlui, S. Laser Induced Method to Produce Curcuminoid-Silanol Thin Films for Transdermal Patches Using Irradiation of Turmeric Target. Appl. Sci. 2021, 11, 4030. [Google Scholar] [CrossRef]

- Chumroenphat, T.; Somboonwatthanakul, I.; Saensouk, S.; Siriamornpun, S. Changes in curcuminoids and chemical components of turmeric (Curcuma longa L.) under freeze-drying and low-temperature drying methods. Food Chem. 2021, 339, 128121. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Salleh, W.N.W.; Jaafar, J.; Asri, S.E.A.M.; Ismail, A.F. Physicochemical properties of “green” nanocrystalline cellulose isolated from recycled newspaper. RSC Adv. 2015, 5, 29842–29849. [Google Scholar] [CrossRef]

- Koifman, O.I.; Stuzhin, P.A.; Travkin, V.V.; Pakhomov, G.L. Chlorophylls in thin-film photovoltaic cells, a critical review. RSC Adv. 2021, 11, 15131–15152. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Appamato, I.; Bunriw, W.; Harnchana, V.; Siriwong, C.; Mongkolthanaruk, W.; Thongbai, P.; Chanthad, C.; Chompoosor, A.; Ruangchai, S.; Prada, T.; et al. Engineering Triboelectric Charge in Natural Rubber–Ag Nanocomposite for Enhancing Electrical Output of a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2023, 15, 973–983. [Google Scholar] [CrossRef] [PubMed]

| Natural Dyes | Chemical Structures | Wavenumber (cm−1) | Functional Group |

|---|---|---|---|

| Chlorophyll |  | 3318 | O-H stretching |

| 2915 | C-H stretching | ||

| 2848 | C-H stretching | ||

| 1637 | C=O stretching | ||

| 1312 | C-N-C bending | ||

| 1022 | C-O-C stretching | ||

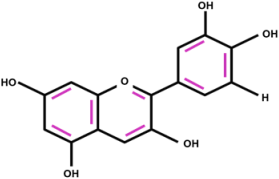

| Anthocyanin |  | 3318 | O-H stretching |

| 2917 | C–H stretching | ||

| 1637 | C=O stretching | ||

| 1022 | C-O-C stretching | ||

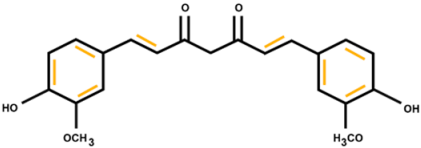

| Curcumin |  | 3318 | O-H stretching |

| 2915 | C-H stretching | ||

| 1589 | C=C stretching | ||

| 1508 | C-O-C stretching | ||

| 1029 | C-O-C stretching |

| TENGs | S:L | Vpp (V) | Ipp (µA) |

|---|---|---|---|

| CP | - | 57 | 5.7 |

| CP@Turmeric | 1:1 | 100 | 8.8 |

| 2:1 | 114 | 9.6 | |

| 3:1 | 102 | 9.2 | |

| CP@Red cabbage | 1:1 | 100 | 8.9 |

| 2:1 | 114 | 10.2 | |

| 3:1 | 108 | 9.4 | |

| CP@Spinach | 1:1 | 88 | 8.0 |

| 2:1 | 108 | 10.5 | |

| 3:1 | 126 | 11.4 |

| TENGs | Power Density (W/m2) | Matched Load (MΩ) |

|---|---|---|

| CP | 1.9 | 0.01 |

| CP@Turmeric | 2.6 | 0.5 |

| CP@Red cabbage | 3.1 | 0.9 |

| CP@Spinach | 3.3 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piwbang, S.; Kaeochana, W.; Luechar, P.; Bunriw, W.; Chimsida, P.; Yamklang, W.; Sintusiri, J.; Harnchana, V. Using Natural Dye Additives to Enhance the Energy Conversion Performance of a Cellulose Paper-Based Triboelectric Nanogenerator. Polymers 2024, 16, 476. https://doi.org/10.3390/polym16040476

Piwbang S, Kaeochana W, Luechar P, Bunriw W, Chimsida P, Yamklang W, Sintusiri J, Harnchana V. Using Natural Dye Additives to Enhance the Energy Conversion Performance of a Cellulose Paper-Based Triboelectric Nanogenerator. Polymers. 2024; 16(4):476. https://doi.org/10.3390/polym16040476

Chicago/Turabian StylePiwbang, Supisara, Walailak Kaeochana, Pawonpart Luechar, Weeraya Bunriw, Praphadsorn Chimsida, Wimonsiri Yamklang, Jirapan Sintusiri, and Viyada Harnchana. 2024. "Using Natural Dye Additives to Enhance the Energy Conversion Performance of a Cellulose Paper-Based Triboelectric Nanogenerator" Polymers 16, no. 4: 476. https://doi.org/10.3390/polym16040476

APA StylePiwbang, S., Kaeochana, W., Luechar, P., Bunriw, W., Chimsida, P., Yamklang, W., Sintusiri, J., & Harnchana, V. (2024). Using Natural Dye Additives to Enhance the Energy Conversion Performance of a Cellulose Paper-Based Triboelectric Nanogenerator. Polymers, 16(4), 476. https://doi.org/10.3390/polym16040476