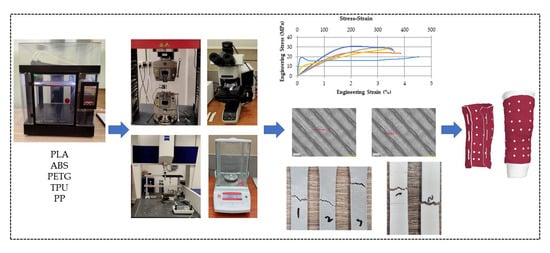

An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study

Abstract

1. Introduction

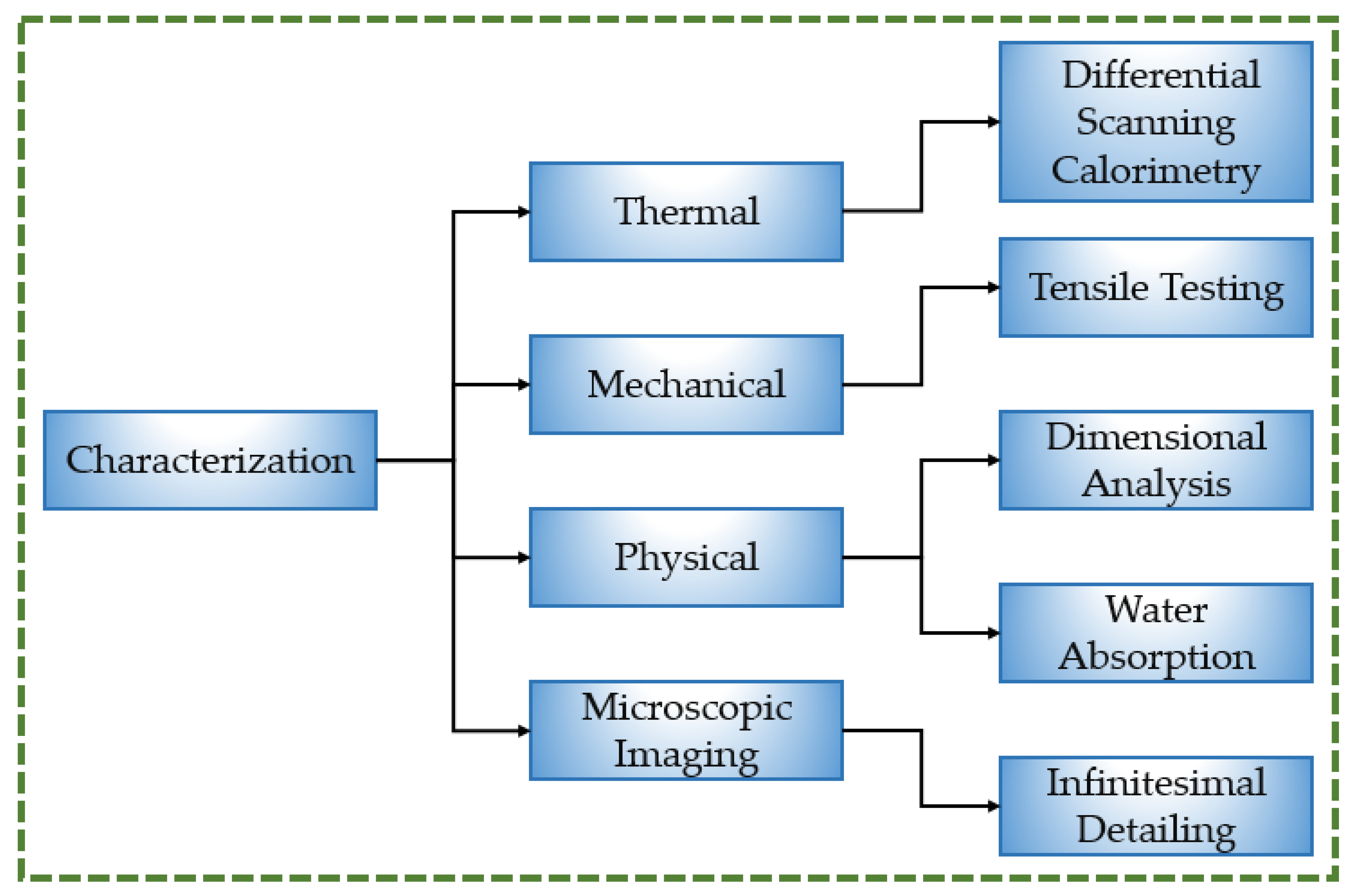

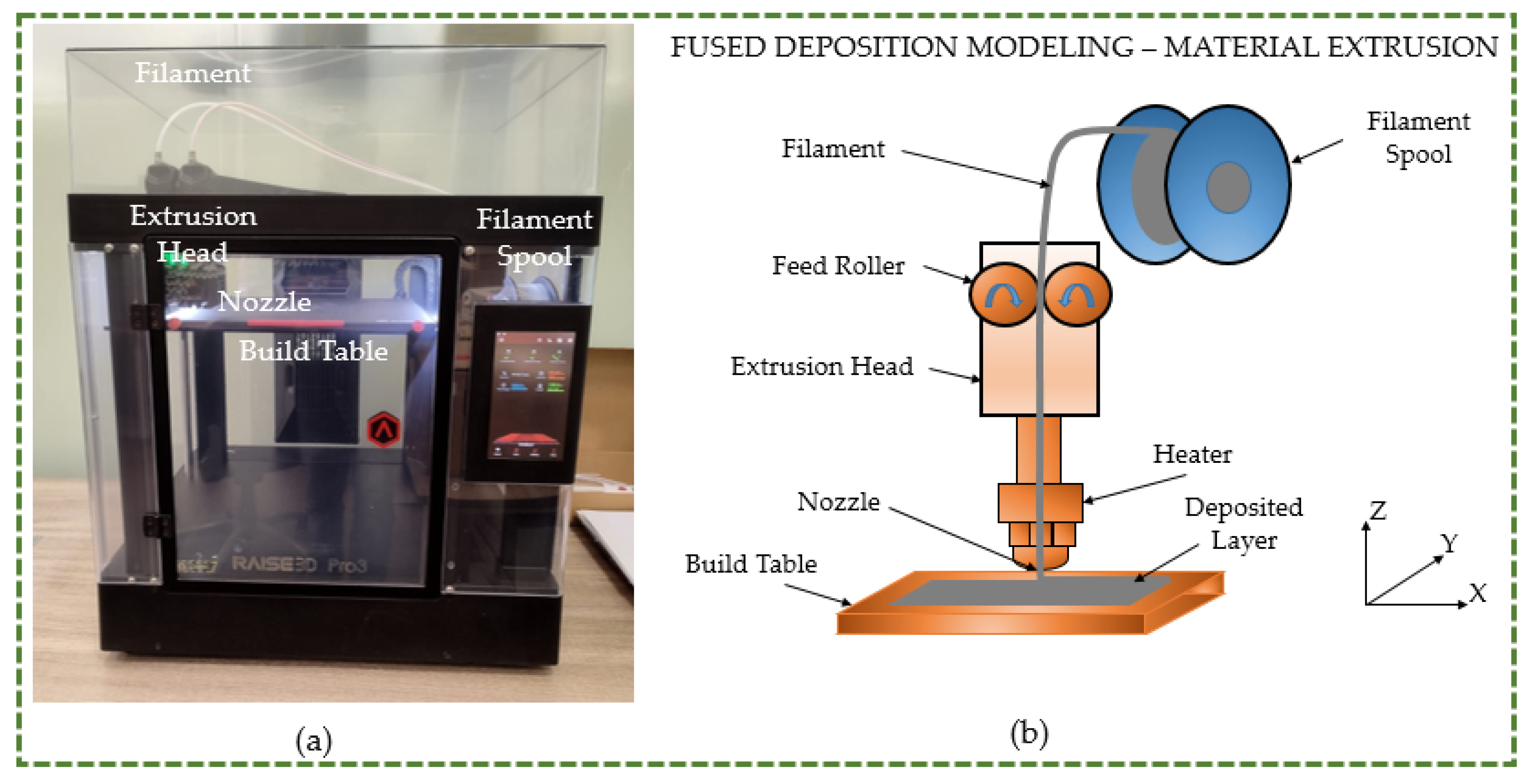

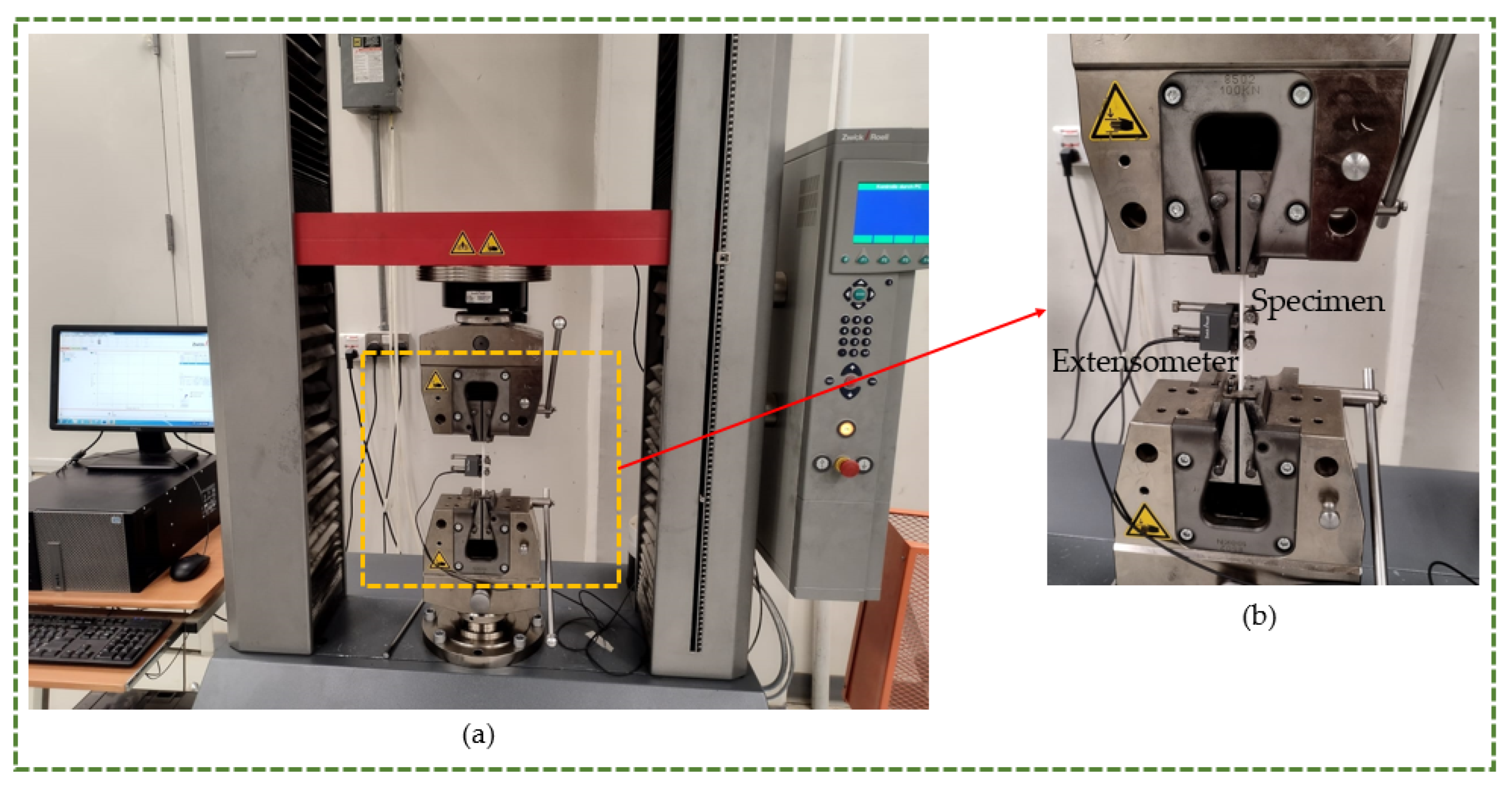

2. Materials and Methods

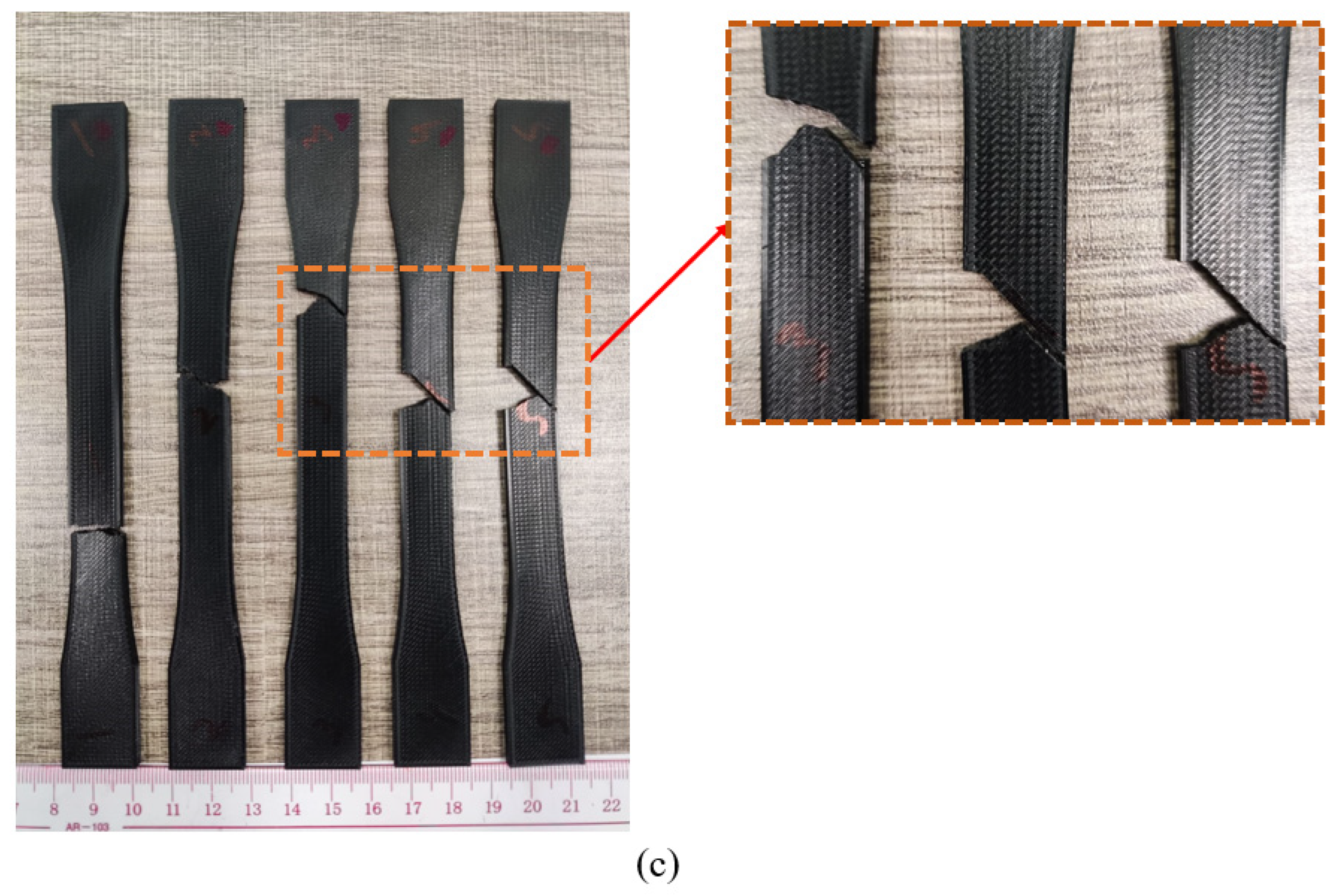

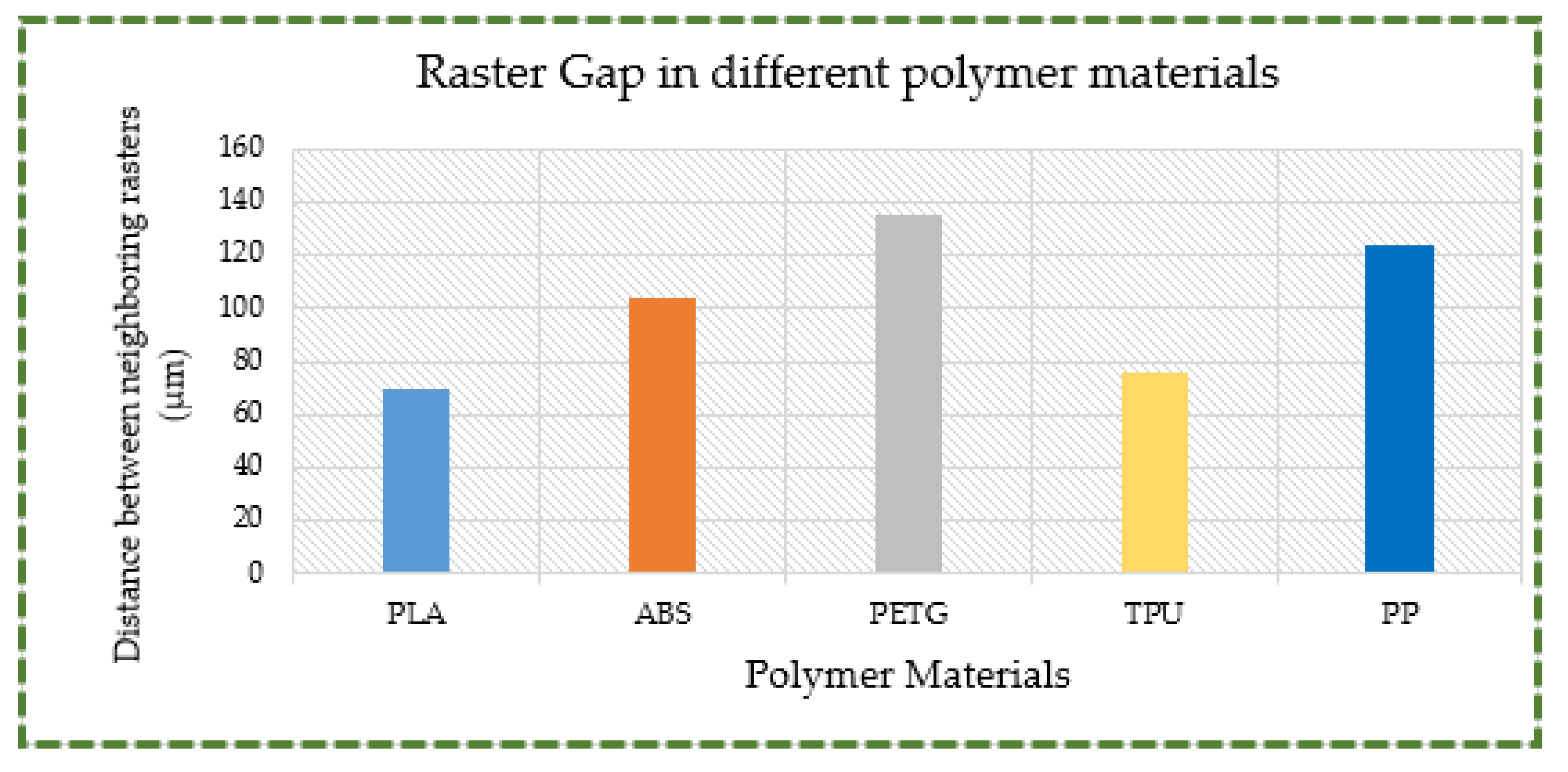

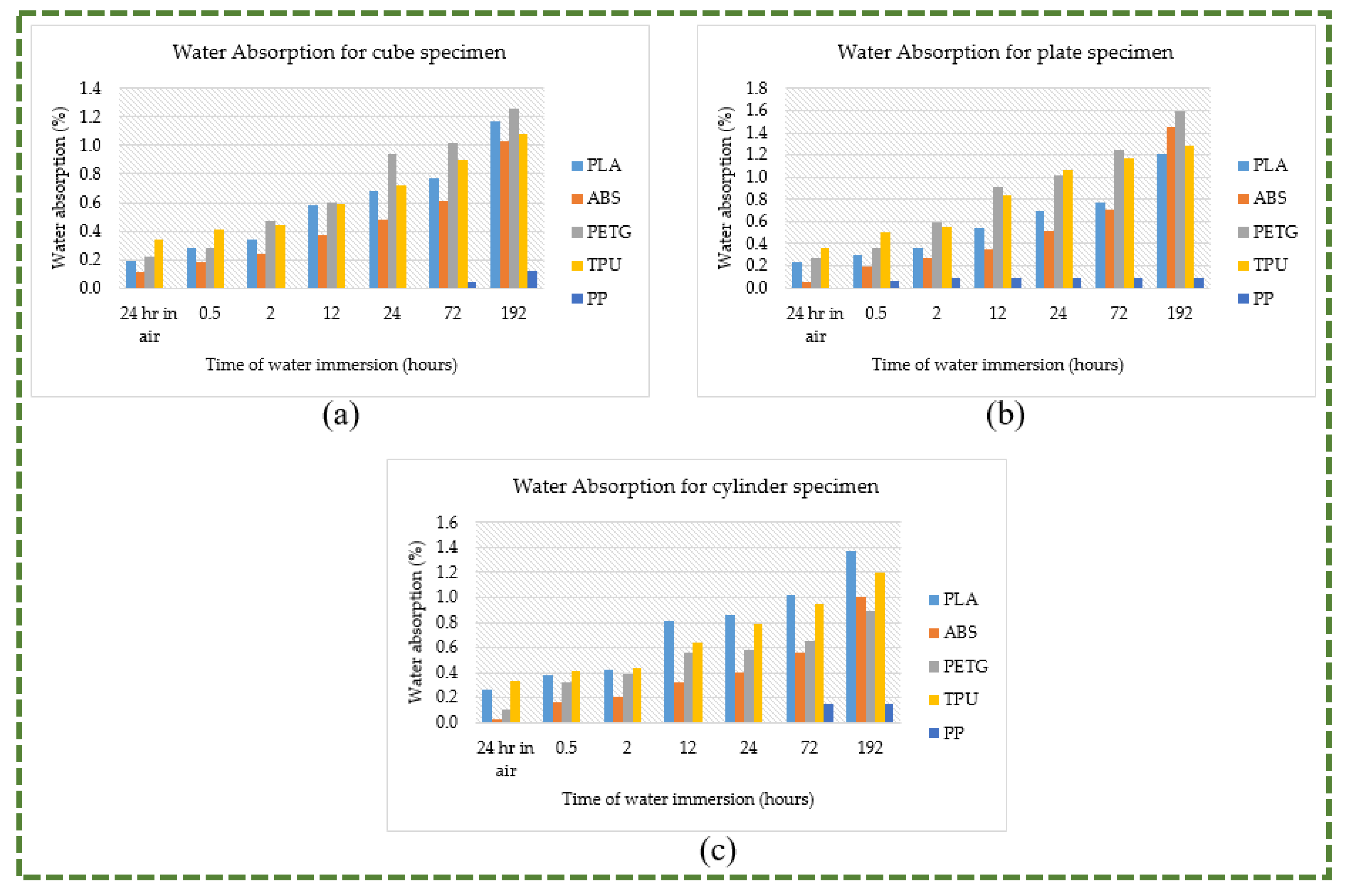

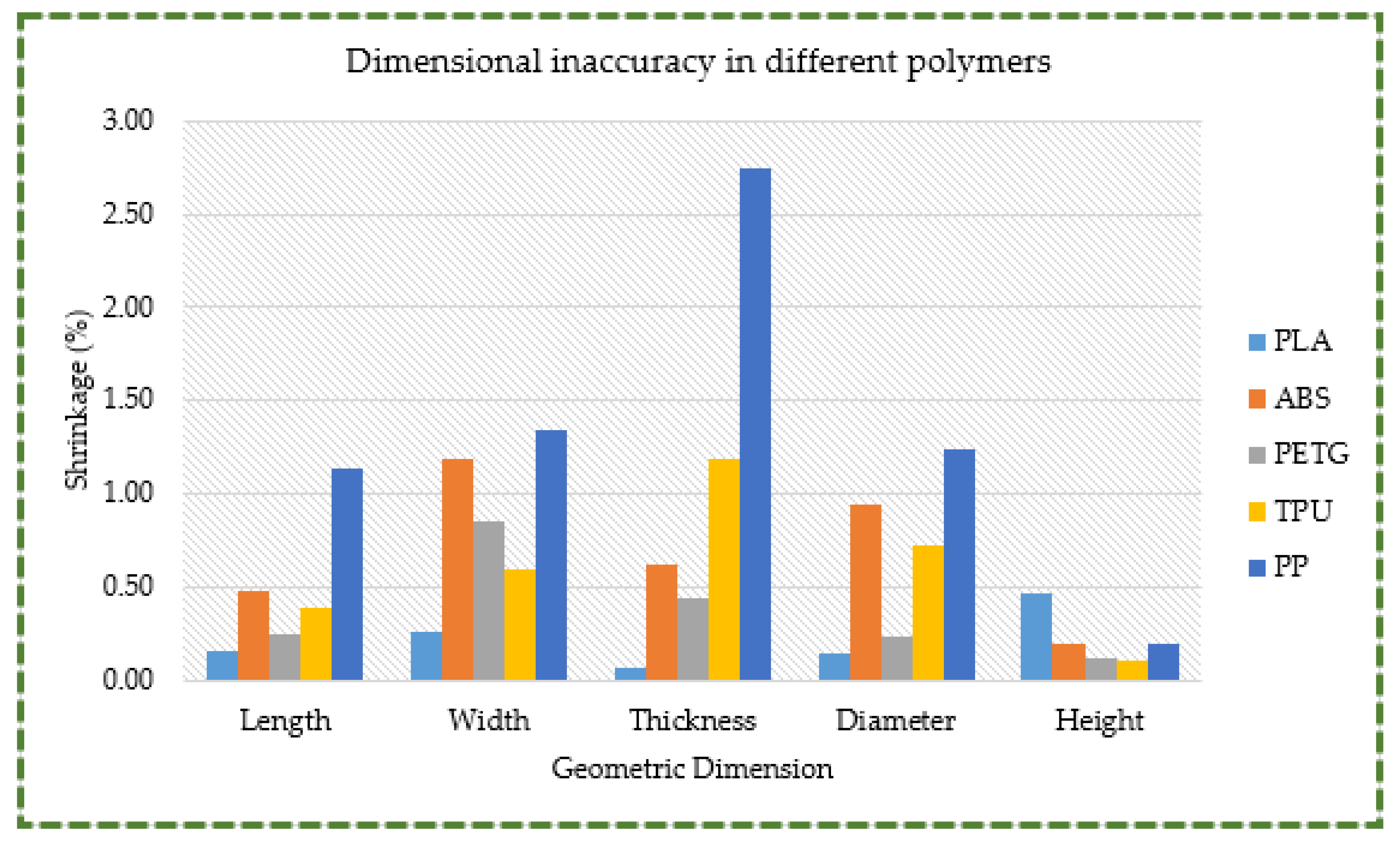

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grimmer, M.; Riener, R.; Walsh, C.J.; Seyfarth, A. Mobility Related Physical and Functional Losses Due to Aging and Disease—A Motivation for Lower Limb Exoskeletons. J. NeuroEng. Rehabil. 2019, 16, 2. [Google Scholar] [CrossRef]

- Ontario Health. Stance-Control Knee–Ankle–Foot Orthoses for People with Knee Instability: A Health Technology Assessment. Ont. Health Technol. Assess. Ser. 2021, 21, 1–96. [Google Scholar]

- Fesharaki, S.A.; Farahmand, F.; Saeedi, H.; Raeissadat, S.A.; Abdollahy, E.; Ahmadi, A.; Maroufi, N. The Effects of Knee Orthosis with Two Degrees of Freedom Joint Design on Gait and Sit-to-Stand Task in Patients with Medial Knee Osteoarthritis. Sultan Qaboos Univ. Med. J. 2020, 20, e324–e331. [Google Scholar] [CrossRef]

- Farhan, M.; Wang, J.Z.; Bray, P.; Burns, J.; Cheng, T.L. Comparison of 3D Scanning versus Traditional Methods of Capturing Foot and Ankle Morphology for the Fabrication of Orthoses: A Systematic Review. J. Foot Ankle Res. 2021, 14, 2. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Kim, S.J.; Cha, Y.H.; Lee, K.H.; Kwon, J.-Y. Effect of Personalized Wrist Orthosis for Wrist Pain with Three-Dimensional Scanning and Printing Technique: A Preliminary, Randomized, Controlled, Open-Label Study. Prosthet. Orthot. Int. 2018, 42, 636–643. [Google Scholar] [CrossRef]

- Wojciechowski, E.; Chang, A.Y.; Balassone, D.; Ford, J.; Cheng, T.L.; Little, D.; Menezes, M.P.; Hogan, S.; Burns, J. Feasibility of Designing, Manufacturing and Delivering 3D Printed Ankle-Foot Orthoses: A Systematic Review. J. Foot Ankle Res. 2019, 12, 11. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.; Soares, B.; Leite, M.; Jacinto, J. Design and Development of a Customised Knee Positioning Orthosis Using Low Cost 3D Printers. Virtual Phys. Prototyp. 2017, 12, 322–332. [Google Scholar] [CrossRef]

- Savini, A.; Savini, G.G. A Short History of 3D Printing, a Technological Revolution Just Started. In Proceedings of the 2015 ICOHTEC/IEEE International History of High-Technologies and Their Socio-Cultural Contexts Conference (HISTELCON), Tel-Aviv, Israel, 18–19 August 2015; p. 8. [Google Scholar]

- Lakkala, P.; Munnangi, S.R.; Bandari, S.; Repka, M. Additive Manufacturing Technologies with Emphasis on Stereolithography 3D Printing in Pharmaceutical and Medical Applications: A Review. Int. J. Pharm. X 2023, 5, 100159. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Noor, S.; Khan, K.M. Comparative Study of I-Optimal Design and Definitive Screening Design for Developing Prediction Models and Optimization of Average Surface Roughness of PLA Printed Parts Using Fused Deposition Modeling. Int. J. Adv. Manuf. Technol. 2023, 125, 689–700. [Google Scholar] [CrossRef]

- Klein, G.T.; Lu, Y.; Wang, M.Y. 3D Printing and Neurosurgery—Ready for Prime Time? World Neurosurg. 2013, 80, 233–235. [Google Scholar] [CrossRef]

- 2024 “3D Printing Healthcare Market”: Overview & Predictions for 2031|Industry Research Biz. Available online: https://www.linkedin.com/pulse/2024-3d-printing-healthcare-market-overview-aeqbf (accessed on 7 November 2023).

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Salgado, D.R. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials 2020, 13, 295. [Google Scholar] [CrossRef]

- Regulation (EU) 2017/745 of the European Parliament and of the Council of 5 April 2017 on medical devices, amending Directive 2001/83/EC, Regulation (EC) No 178/2002 and Regulation (EC) No 1223/2009 and repealing Council Directives 90/385/EEC and 93/42/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32017R0745 (accessed on 2 December 2023).

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Cunha, A.; Yi, X.; Bernardo, C.A. Key Properties to Understand the Performance of Polycarbonate Reprocessed by Injection Molding. J. Appl. Polym. Sci. 2000, 77, 1393–1400. [Google Scholar] [CrossRef]

- He, T.; Wang, G.; Wang, Y.; Liu, Y.; Lai, W.; Wang, X.; Feng, Y.; Liu, X. Simultaneously Enhancing of Wear-Resistant and Mechanical Properties of Polyurethane Composite Based on the Selective Interaction of Fluorinated Graphene Derivatives. Compos. Part B Eng. 2019, 169, 200–208. [Google Scholar] [CrossRef]

- Farcas, M.T.; Stefaniak, A.B.; Knepp, A.K.; Bowers, L.; Mandler, W.K.; Kashon, M.; Jackson, S.R.; Stueckle, T.A.; Sisler, J.D.; Friend, S.A.; et al. Acrylonitrile Butadiene Styrene (ABS) and Polycarbonate (PC) Filaments Three-Dimensional (3-D) Printer Emissions-Induced Cell Toxicity. Toxicol. Lett. 2019, 317, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Ronca, A.; Abbate, V.; Redaelli, D.F.; Storm, F.A.; Cesaro, G.; De Capitani, C.; Sorrentino, A.; Colombo, G.; Fraschini, P.; Ambrosio, L. A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace. Materials 2022, 15, 5724. [Google Scholar] [CrossRef]

- Geueke, B.; Phelps, D.W.; Parkinson, L.V.; Muncke, J. Hazardous Chemicals in Recycled and Reusable Plastic Food Packaging. Camb. Prism. Plast. 2023, 1, e7. [Google Scholar] [CrossRef]

- Paton, J.; Jones, R.B.; Stenhouse, E.; Bruce, G. The Physical Characteristics of Materials Used in the Manufacture of Orthoses for Patients with Diabetes. Foot Ankle Int. 2007, 28, 1057–1063. [Google Scholar] [CrossRef] [PubMed]

- Filip, N.; Radu, I.; Veliceasa, B.; Filip, C.; Pertea, M.; Clim, A.; Pinzariu, A.C.; Drochioi, I.C.; Hilitanu, R.L.; Serban, I.L. Biomaterials in Orthopedic Devices: Current Issues and Future Perspectives. Coatings 2022, 12, 1544. [Google Scholar] [CrossRef]

- Bai, H.; Deng, S.; Bai, D.; Zhang, Q.; Fu, Q. Recent Advances in Processing of Stereocomplex-Type Polylactide. Macromol. Rapid Commun. 2017, 38, 1700454. [Google Scholar] [CrossRef]

- Memarian, F.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Effect of Acrylonitrile Butadiene Styrene on the Shape Memory, Mechanical, and Thermal Properties of Thermoplastic Polyurethane. J. Vinyl. Addit. Technol. 2018, 24, E96–E104. [Google Scholar] [CrossRef]

- Sorimpuk, N.P.; Choong, W.H.; Chua, B.-L. Thermoforming Characteristics of PLA/TPU Multi-Material Specimens Fabricated with Fused Deposition Modelling under Different Temperatures. Polymers 2022, 14, 4304. [Google Scholar] [CrossRef] [PubMed]

- Gavrila, D.E.; Stoian, V.; Caramitu, A.; Mitrea, S.; Gavrila, D.E.; Stoian, V.; Caramitu, A.; Mitrea, S. Advanced Polypropylene and Composites with Polypropylene with Applications in Modern Medicine. In Composite Materials; IntechOpen: London, UK, 2020; ISBN 978-1-83962-740-8. [Google Scholar]

- Popescu, D.; Baciu, F.; Vlăsceanu, D.; Marinescu, R.; Lăptoiu, D. Investigations on the Fatigue Behavior of 3D-Printed and Thermoformed Polylactic Acid Wrist–Hand Orthoses. Polymers 2023, 15, 2737. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.K.; Mohanty, A.K.; Misra, M. Additive Manufacturing Technology of Polymeric Materials for Customized Products: Recent Developments and Future Prospective. RSC Adv. 2021, 11, 36398–36438. [Google Scholar] [CrossRef] [PubMed]

- Umer, U.; Mian, S.H.; Moiduddin, K.; Alkhalefah, H. Exploring Orthosis Designs for 3D Printing Applying the Finite Element Approach: Study of Different Materials and Loading Conditions. J. Disabil. Res. 2023, 2, 85–97. [Google Scholar] [CrossRef]

- ASTM D3418-21; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM: West Conshohocken, PA, USA, 2021.

- Mulligan, D.; Gnaniah, S.; Sims, G. Measurement Good Practice Guide No. 62—Thermal Analysis Techniques for Composites and Adhesives; NPL Materials Centre—National Physical Laboratory: Middlesex, UK, 2003. [Google Scholar]

- Billah, K.M.M.; Lorenzana, F.A.R.; Martinez, N.L.; Chacon, S.; Wicker, R.B.; Espalin, D. Thermal Analysis of Thermoplastic Materials Filled with Chopped Fiber for Large Area 3D Printing. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019. [Google Scholar]

- Rajan, K.; Samykano, M.; Kadirgama, K.; Harun, W.S.W.; Rahman, M.M. Fused Deposition Modeling: Process, Materials, Parameters, Properties, and Applications. Int. J. Adv. Manuf. Technol. 2022, 120, 1531–1570. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D412-16(2021); Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM: West Conshohocken, PA, USA, 2021.

- Egan, B.C.; Brownell, C.J.; Murray, M.M. Experimental Assessment of Performance Characteristics for Pitching Flexible Propulsors. J. Fluids Struct. 2016, 67, 22–33. [Google Scholar] [CrossRef]

- Dobos, J.; Hanon, M.M.; Oldal, I. Effect of Infill Density and Pattern on the Specific Load Capacity of FDM 3D-Printed PLA Multi-Layer Sandwich. J. Polym. Eng. 2022, 42, 118–128. [Google Scholar] [CrossRef]

- Zhang, G.; Luo, J.; Zheng, G.; Bai, Z.; Cao, L.; Mao, H. Is the 0.2%-Strain-Offset Approach Appropriate for Calculating the Yield Stress of Cortical Bone? Ann. Biomed. Eng. 2021, 49, 1747–1760. [Google Scholar] [CrossRef] [PubMed]

- Selvamani, S.K.; Rajan, K.; Samykano, M.; Kumar, R.R.; Kadirgama, K.; Mohan, R.V. Investigation of Tensile Properties of PLA–Brass Composite Using FDM. Prog. Addit. Manuf. 2022, 7, 839–851. [Google Scholar] [CrossRef]

- Shimadzu Co. Tensile Properties of Rigid and Semi-Rigid Plastics (ASTM D638 and ISO 527); Material Testing System; Shimadzu: Kyoto, Japan, 2017. [Google Scholar]

- Intertek. Tensile Properties ASTM D638 vs. ASTM D3039. Available online: https://pdfcoffee.com/astm-d638-vsd3039-pdf-free.html (accessed on 2 December 2023).

- The Definitive Guide to ASTM D412 Tensile Testing of Elastomers. Available online: https://www.instron.com/en/testing-solutions/astm-standards/astm-d412 (accessed on 6 November 2023).

- ASTM D412 Tensile Test Rubber & Elastomers. Available online: https://www.zwickroell.com/industries/plastics/plastics-testing-standards/astm-d412-tensile-test-elastomers/ (accessed on 6 November 2023).

- Mian, S.H.; Moiduddin, K.; Abdo, B.M.A.; Sayeed, A.; Alkhalefah, H. Modelling and Evaluation of Meshed Implant for Cranial Reconstruction. Int. J. Adv. Manuf. Technol. 2022, 118, 1967–1985. [Google Scholar] [CrossRef]

- Booth, M.A.; Pope, L.; Sherrell, P.C.; Stacey, A.; Tran, P.A.; Fox, K.E. Polycrystalline Diamond Coating on 3D Printed Titanium Scaffolds: Surface Characterisation and Foreign Body Response. Mater. Sci. Eng. C 2021, 130, 112467. [Google Scholar] [CrossRef] [PubMed]

- Cooperstein, I.; Indukuri, S.R.K.C.; Bouketov, A.; Levy, U.; Magdassi, S. 3D Printing of Micrometer-Sized Transparent Ceramics with On-Demand Optical-Gain Properties. Adv. Mater. 2020, 32, 2001675. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Crater, C.; Ordonez, A.; Ward, C.; Waller, M.; Ginn, C. Material Properties and Shrinkage of 3D Printing Parts Using Ultrafuse Stainless Steel 316LX Filament. MATEC Web. Conf. 2018, 249, 01001. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. Irianto Mechanical, Thermal and Physical Characteristics of Oil Palm (Elaeis Guineensis) Fiber Reinforced Thermoplastic Composites for FDM—Type 3D Printer. Polym. Test. 2023, 120, 107972. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. A New Approach to Use Arenga Pinnata as Sustainable Biopolymer: Effects of Plasticizers on Physical Properties. Procedia Chem. 2012, 4, 254–259. [Google Scholar] [CrossRef]

- Raise 3D. Raise3D Premium PLA Technical Data Sheet; Raise 3D: Irvine, CA, USA, 2019. [Google Scholar]

- Raise 3D. Raise3D Premium ABS Technical Data Sheet; Raise 3D: Irvine, CA, USA, 2023. [Google Scholar]

- Raise 3D. Raise3D Premium PETG Technical Data Sheet; Raise 3D: Irvine, CA, USA, 2017. [Google Scholar]

- Biosurfaces: A Materials Science and Engineering Perspective|Wiley. Available online: https://www.wiley.com/en-us/Biosurfaces%3A+A+Materials+Science+and+Engineering+Perspective-p-9781118299975 (accessed on 31 December 2023).

- Drzeżdżon, J.; Jacewicz, D.; Sielicka, A.; Chmurzyński, L. Characterization of Polymers Based on Differential Scanning Calorimetry Based Techniques. TrAC Trends Anal. Chem. 2019, 110, 51–56. [Google Scholar] [CrossRef]

- Raise 3D. Technical Data Sheet: P-Filament; Raise 3D: Irvine, CA, USA, 2019. [Google Scholar]

- Podsiadły, B.; Skalski, A.; Rozpiórski, W.; Słoma, M. Are We Able to Print Components as Strong as Injection Molded?—Comparing the Properties of 3D Printed and Injection Molded Components Made from ABS Thermoplastic. Appl. Sci. 2021, 11, 6946. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic Material Properties of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K. Comparison of Physical and Mechanical Properties of PLA, ABS and Nylon 6 Fabricated Using Fused Deposition Modeling and Injection Molding. Compos. Part B Eng. 2019, 176, 107341. [Google Scholar] [CrossRef]

- Lin, X.; Gao, J.; Wang, J.; Wang, R.; Gong, M.; Zhang, L.; Lu, Y.; Wang, D.; Zhang, L. Desktop Printing of 3D Thermoplastic Polyurethane Parts with Enhanced Mechanical Performance Using Filaments with Varying Stiffness. Addit. Manuf. 2021, 47, 102267. [Google Scholar] [CrossRef]

- Reiter, M.; Miron, V.M.; Lämmermann, S.; Freudenthaler, P.J.; Jerabek, M.; Major, Z. Comparing the Mechanical Properties of Additively Manufactured Post-Consumer Polypropylene to Injection Molded Specimens. Mater. Today Proc. 2022, 70, 55–60. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Sorrentino, A.; Titomanlio, G. Mechanical Properties Distribution within Polypropylene Injection Molded Samples: Effect of Mold Temperature under Uneven Thermal Conditions. Polymers 2017, 9, 585. [Google Scholar] [CrossRef] [PubMed]

- Leite, M.; Fernandes, J.; Deus, A.M.; Reis, L.; Vaz, M.F. Study of the influence of 3D printing parameters on the mechanical properties of PLA. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Nanyang Technological University, Singapore, 14–18 May 2018. [Google Scholar]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3D-Printed PLA and PETG, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef] [PubMed]

- Adanur, S.; Jayswal, A. Additive Manufacturing of Interlaced Fibrous Structures. Rapid Prototyp. J. 2021, 27, 671–681. [Google Scholar] [CrossRef]

- Hohimer, C.; Christ, J.; Aliheidari, N.; Mo, C.; Ameli, A. 3D Printed Thermoplastic Polyurethane with Isotropic Material Properties. In Proceedings of the Behavior and Mechanics of Multifunctional Materials and Composites 2017, Portland, OR, USA, 26–28 March 2017; SPIE: Bellingham, WA, USA, 2017; Volume 10165, pp. 213–221. [Google Scholar]

- Raise 3D. Raise3D Premium TPU-95A Technical Data Sheet; Raise 3D: Irvine, CA, USA, 2021. [Google Scholar]

- Petersmann, S.; Spoerk, M.; Van De Steene, W.; Üçal, M.; Wiener, J.; Pinter, G.; Arbeiter, F. Mechanical Properties of Polymeric Implant Materials Produced by Extrusion-Based Additive Manufacturing. J. Mech. Behav. Biomed. Mater. 2020, 104, 103611. [Google Scholar] [CrossRef] [PubMed]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D Printing of PLA-TPU with Different Component Ratios: Fracture Toughness, Mechanical Properties, and Morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Kopar, M.; Yildiz, A.R. Experimental Investigation of Mechanical Properties of PLA, ABS, and PETG 3-d Printing Materials Using Fused Deposition Modeling Technique. Mater. Test. 2023, 65, 1795–1804. [Google Scholar] [CrossRef]

- Çelik, S.; Tünçay, M.M.; Yumuşak, G. Comparative Strength Analysis of PLA, ABS, PETG, TPU, and ASA Filaments: Influence of Nozzle Size and Filling Parameters. In Properties of Materials; BIDGE Publications: Ankara, Turkey, 2023; ISBN 978-625-6707-34-4. [Google Scholar]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- Priya, M.S.; Naresh, K.; Jayaganthan, R.; Velmurugan, R. A Comparative Study between In-House 3D Printed and Injection Molded ABS and PLA Polymers for Low-Frequency Applications. Mater. Res. Express 2019, 6, 085345. [Google Scholar] [CrossRef]

- Pernica, J.; Sustr, M.; Dostal, P.; Brabec, M.; Dobrocky, D. Tensile Testing of 3D Printed Materials Made by Different Temperature. Manuf. Technol. 2021, 21, 398–404. [Google Scholar] [CrossRef]

- Musil, J.; Zeman, P.; Baroch, P. 4.13—Hard Nanocomposite Coatings. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas, B., Eds.; Elsevier: Oxford, UK, 2014; pp. 325–353. ISBN 978-0-08-096533-8. [Google Scholar]

- Abramowitch, S.; Easley, D. Chapter Four—Introduction to Classical Mechanics. In Biomechanics of the Female Pelvic Floor; Hoyte, L., Damaser, M., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 89–107. ISBN 978-0-12-803228-2. [Google Scholar]

- Khosravani, M.R.; Berto, F.; Ayatollahi, M.R.; Reinicke, T. Characterization of 3D-Printed PLA Parts with Different Raster Orientations and Printing Speeds. Sci. Rep. 2022, 12, 1016. [Google Scholar] [CrossRef]

- Yao, T.; Ye, J.; Deng, Z.; Zhang, K.; Ma, Y.; Ouyang, H. Tensile Failure Strength and Separation Angle of FDM 3D Printing PLA Material: Experimental and Theoretical Analyses. Compos. Part B Eng. 2020, 188, 107894. [Google Scholar] [CrossRef]

- Uddin, M.S.; Sidek, M.F.R.; Faizal, M.A.; Ghomashchi, R.; Pramanik, A. Evaluating Mechanical Properties and Failure Mechanisms of Fused Deposition Modeling Acrylonitrile Butadiene Styrene Parts. J. Manuf. Sci. Eng. 2017, 139, 081018. [Google Scholar] [CrossRef]

- Khan, W. Comparison on Performance of Injection Moulding and 3D Printed Parts. Bachelor’s Thesis, Mechanical Engineering, Edinburgh Napier University, Edinburgh, Scotland, 2020. [Google Scholar]

- Banjo, A.D.; Agrawal, V.; Auad, M.L.; Celestine, A.-D.N. Moisture-Induced Changes in the Mechanical Behavior of 3D Printed Polymers. Compos. Part C Open Access 2022, 7, 100243. [Google Scholar] [CrossRef]

- Ecker, J.V.; Haider, A.; Burzic, I.; Huber, A.; Eder, G.; Hild, S. Mechanical Properties and Water Absorption Behaviour of PLA and PLA/Wood Composites Prepared by 3D Printing and Injection Moulding. Rapid Prototyp. J. 2019, 25, 672–678. [Google Scholar] [CrossRef]

- Schwarz, D.; Pagáč, M.; Petruš, J.; Polzer, S. Effect of Water-Induced and Physical Aging on Mechanical Properties of 3D Printed Elastomeric Polyurethane. Polymer 2022, 14, 5496. [Google Scholar] [CrossRef]

- Hall, D.C.; Palmer, P.; Ji, H.-F.; Ehrlich, G.D.; Król, J.E. Bacterial Biofilm Growth on 3D-Printed Materials. Front. Microbiol. 2021, 12, 646303. [Google Scholar] [CrossRef] [PubMed]

- Faust, J.L.; Kelly, P.G.; Jones, B.D.; Roy-Mayhew, J.D. Effects of Coefficient of Thermal Expansion and Moisture Absorption on the Dimensional Accuracy of Carbon-Reinforced 3D Printed Parts. Polymer 2021, 13, 3637. [Google Scholar] [CrossRef]

- Zhang, Q.; Yan, D.; Zhang, K.; Hu, G. Pattern Transformation of Heat-Shrinkable Polymer by Three-Dimensional (3D) Printing Technique. Sci. Rep. 2015, 5, 8936. [Google Scholar] [CrossRef] [PubMed]

- Van Der Putten, J.; Snoeck, D.; De Coensel, R.; De Schutter, G.; Van Tittelboom, K. Early Age Shrinkage Phenomena of 3D Printed Cementitious Materials with Superabsorbent Polymers. J. Build. Eng. 2021, 35, 102059. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Mohanty, A.K.; Misra, M. Miscibility and Performance Evaluation of Biocomposites Made from Polypropylene/Poly(Lactic Acid)/Poly(Hydroxybutyrate-Co-Hydroxyvalerate) with a Sustainable Biocarbon Filler. ACS Omega 2017, 2, 6446–6454. [Google Scholar] [CrossRef] [PubMed]

- Ngaowthong, C.; Borůvka, M.; Běhálek, L.; Lenfeld, P.; Švec, M.; Dangtungee, R.; Siengchin, S.; Rangappa, S.M.; Parameswaranpillai, J. Recycling of Sisal Fiber Reinforced Polypropylene and Polylactic Acid Composites: Thermo-Mechanical Properties, Morphology, and Water Absorption Behavior. Waste Manag. 2019, 97, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Butylina, S.; Martikka, O.; Kärki, T. Comparison of Water Absorption and Mechanical Properties of Wood–Plastic Composites Made from Polypropylene and Polylactic Acid. Wood Mater. Sci. Eng. 2010, 5, 220–228. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material Extrusion-Based Additive Manufacturing of Polypropylene: A Review on How to Improve Dimensional Inaccuracy and Warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Milovanović, A.; Sedmak, A.; Grbović, A.; Golubović, Z.; Mladenović, G.; Čolić, K.; Milošević, M. Comparative Analysis of Printing Parameters Effect on Mechanical Properties of Natural PLA and Advanced PLA-X Material. Procedia Struct. Integr. 2020, 28, 1963–1968. [Google Scholar] [CrossRef]

- Ullah, I.; Wasif, M.; Tufail, M. Analysis of Shrinkage and Dimensional Accuracy of Additively Manufactured Tooling for the Composite Manufacturing. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. 3D printing of flexible parts using EVA material. Mater. Phys. Mech. 2018, 62, 124–132. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, L.; Zou, Q.; Xu, S.; Ma, M.; Ye, C. A Comparative Applied Study on Optimizing Printing Parameters for Six Fused Deposition Modeling Materials. J. Mater. Eng. Perform. 2023, 32, 5249–5260. [Google Scholar] [CrossRef]

- Laroche, D.; Morisset, C.; Fortunet, C.; Gremeaux, V.; Maillefert, J.-F.; Ornetti, P. Biomechanical Effectiveness of a Distraction–Rotation Knee Brace in Medial Knee Osteoarthritis: Preliminary Results. Knee 2014, 21, 710–716. [Google Scholar] [CrossRef] [PubMed]

| Material | Parameters | |||||

|---|---|---|---|---|---|---|

| Heated Bed Temperature (°C) | Nozzle Temperature (°C) | Speed (mm/s) | Layer Height (mm) | Infill (%) | Extrusion Width (mm) | |

| PLA | 55 | 205 | 70 | 0.1 | 100 | 0.4 |

| ABS | 100 | 250 | ||||

| PETG | 60 | 245 | ||||

| TPU | 60 | 225 | 50 | |||

| PP | 70 | 220 | 60 | |||

| Material | Yield Strength | Tensile Strength | Elongation at Break | Water Absorption (%) | Shrinkage Percentage (%) | Ease of Printing | Cost (USD)/Kg |

|---|---|---|---|---|---|---|---|

| PLA | 25.98 | 30.89 | 5.96 | 1.37 | 0.46 | Easy | 34.99 |

| ABS | 20.70 | 24.99 | 4.07 | 1.44 | 0.85 | Easy | 34.99 |

| PETG | 19.55 | 29.72 | 3.38 | 1.59 | 1.18 | Easy | 34.99 |

| TPU | 6.75 | 28.07 | 332.10 | 1.29 | 1.19 | Difficult | 79.99 |

| PP | 6.58 | 20.23 | 407.99 | 0.15 | 2.75 | Difficult | 59.99 |

| Study | Objective | Findings |

|---|---|---|

| Petersmann et al. [68] | Six distinct 3D printable polymers—PEEK, PLA, PMMA, PETG, PVDF, and PP—that could be useful in medical applications were examined for their tensile properties. | Results showed that PLA had the maximum tensile strength when compared to PETG and PP. |

| Rahmatabadi et al. [69] | Three PLA-TPU composites were compared for their mechanical properties. | Strength and printability of the PLA-TPU combination diminished as the proportion of TPU increased. |

| Kopar and Yildiz [70] | Mechanical characteristics of materials made of PLA, PETG, and ABS were investigated at different raster angles. | Maximum tensile strength was observed in PLA components manufactured at a 45° raster angle. |

| ÇELİK et al. [71] | Evaluated the strength of PLA, ABS, PETG, TPU, and ASA filaments. | PLA had the highest tensile strength of all the materials taken into consideration. |

| Rodríguez-Panes [72] | Explored the mechanical properties of ABS and PLA parts. | PLA test specimens performed better than ABS in terms of stiffness and tensile strength. |

| Pernica [74] | Tensile characteristics of PLA, PETG, and ABS manufactured at ±45° were studied. | PLA showed the greatest strength while PETG had the lowest tensile strength. |

| Ngaowthong et al. [89] | Investigated the recycled PLA’s and PP’s propensity to absorb water. | Water absorption was higher in PLA than in PP. |

| Butylina et al. [90] | Investigated the mechanical characteristics and water absorption of composites composed of softwood sawdust and polymers like PLA and PP. | Compared to PP composites, PLA composites absorbed more water. |

| Spoerk et al. [91] | Evaluated the techniques to reduce shrinkage in PP parts produced via 3D printing. | Established that the primary drawback of PP in 3D printing was its extreme proneness to shrink. Further discovered that PLA was 3D printed easily due to its significantly lower shrinkage tendency. |

| Milovanović et al. [92] | Analyzed the effects of printing factors on PLA’s mechanical characteristics. | Stated that PLA shrunk less than ABS. |

| Irshad Ullah et al. [93] | Studied the shrinkage and dimensional accuracy in ABS, PLA, and PETG. | PLA showed the lowest overall average shrinking percentage. |

| Kumar et al. [94] | Explored the material deposition of ethylene vinyl acetate, a flexible material. | Revealed that it was more difficult to 3D print flexible materials than rigid ones. |

| Zhou et al. [95] | Six materials—ABS, PLA, TPU, PETG, polyvinyl alcohol (PVA), and polycarbonate (PC)—were investigated in 3D printed trimalleolar fracture models to figure out their attributes. | Authors noted that tha PLA and 1:1 scale replica were favored by the patients. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mian, S.H.; Abouel Nasr, E.; Moiduddin, K.; Saleh, M.; Alkhalefah, H. An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study. Polymers 2024, 16, 403. https://doi.org/10.3390/polym16030403

Mian SH, Abouel Nasr E, Moiduddin K, Saleh M, Alkhalefah H. An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study. Polymers. 2024; 16(3):403. https://doi.org/10.3390/polym16030403

Chicago/Turabian StyleMian, Syed Hammad, Emad Abouel Nasr, Khaja Moiduddin, Mustafa Saleh, and Hisham Alkhalefah. 2024. "An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study" Polymers 16, no. 3: 403. https://doi.org/10.3390/polym16030403

APA StyleMian, S. H., Abouel Nasr, E., Moiduddin, K., Saleh, M., & Alkhalefah, H. (2024). An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study. Polymers, 16(3), 403. https://doi.org/10.3390/polym16030403