Using Plantain Rachis Fibers and Mopa-Mopa Resin to Develop a Fully Biobased Composite Material

Abstract

1. Introduction

2. Materials

3. Experimental Procedure

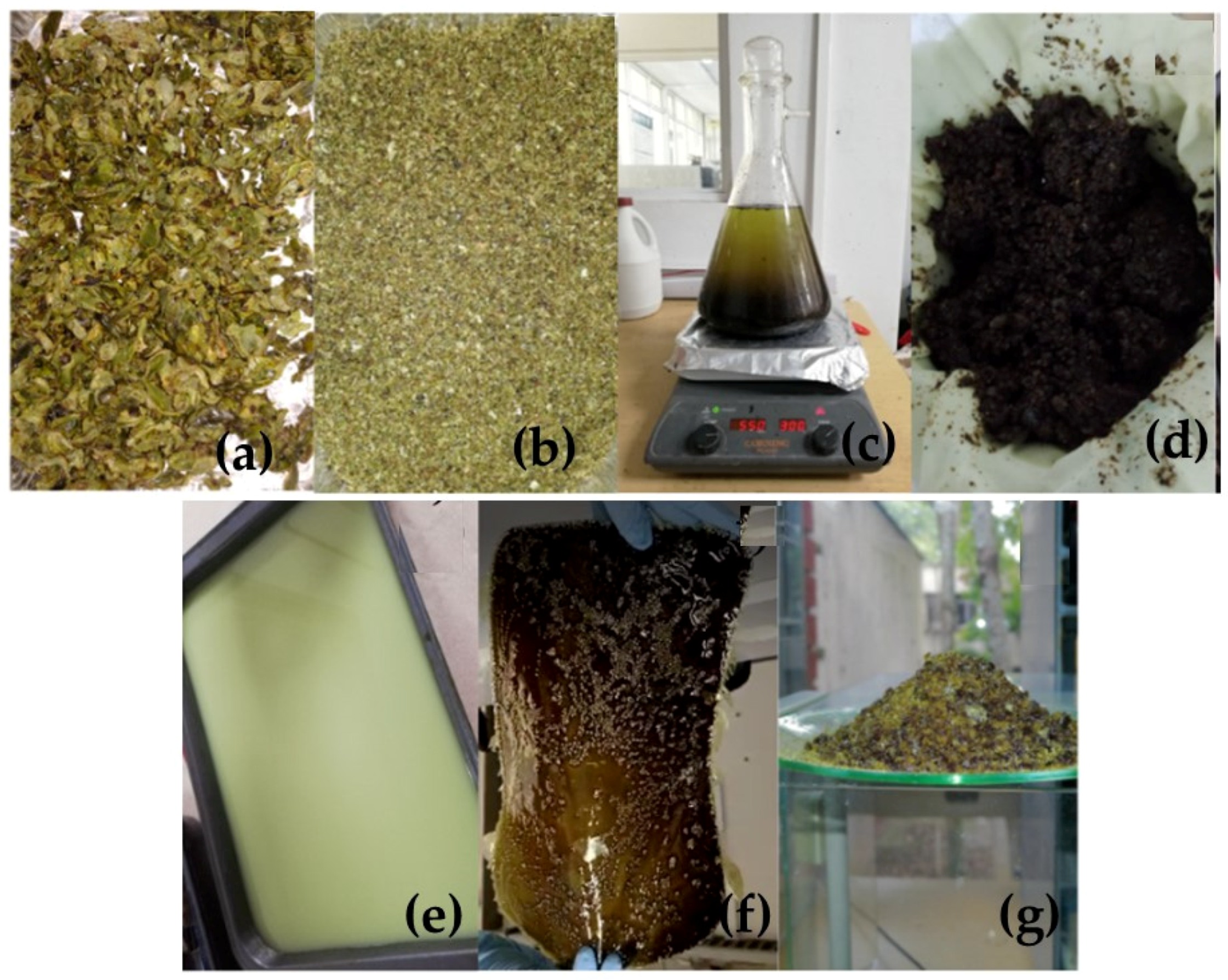

3.1. Obtaining the Mopa-Mopa Resin

3.2. Extraction of Plantain Rachis Fibers

3.3. Alkalinization Process of Plantain Fibers

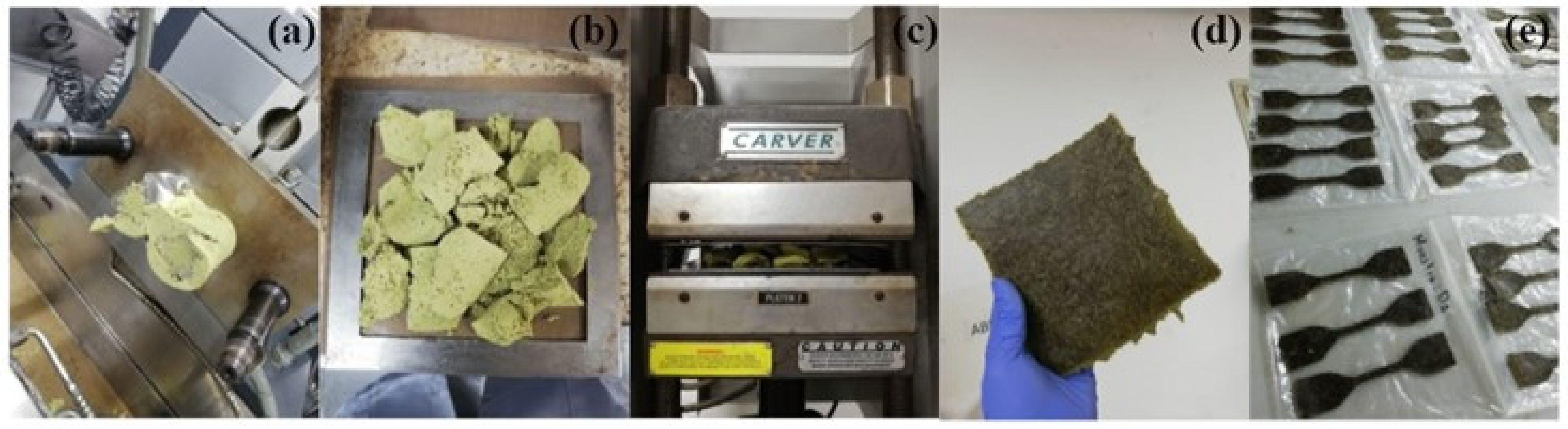

3.4. Preparation of Biobased Composite Material

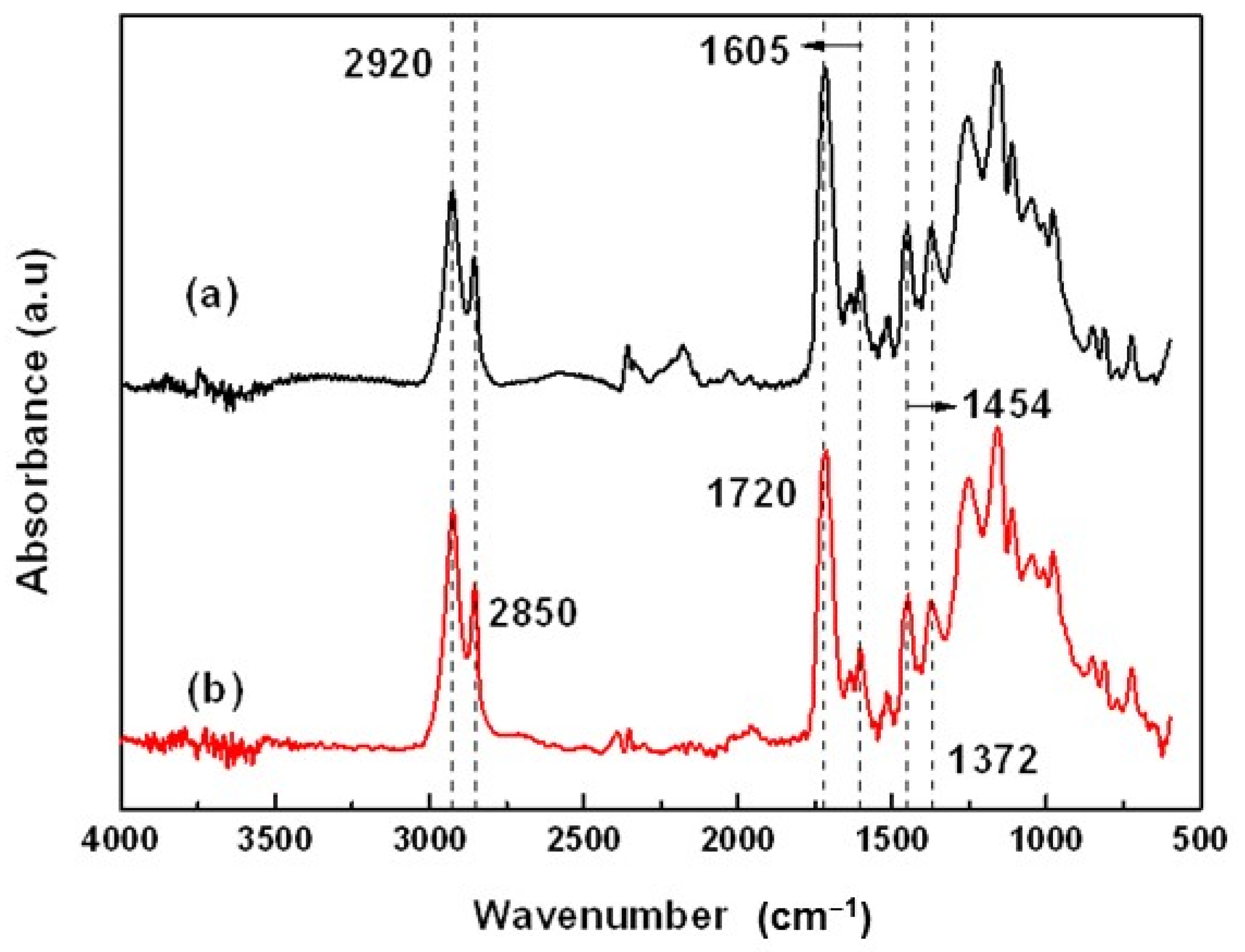

3.5. Fourier Transform Infrared Spectroscopy (FT-IR)

3.6. Moisture Absorption

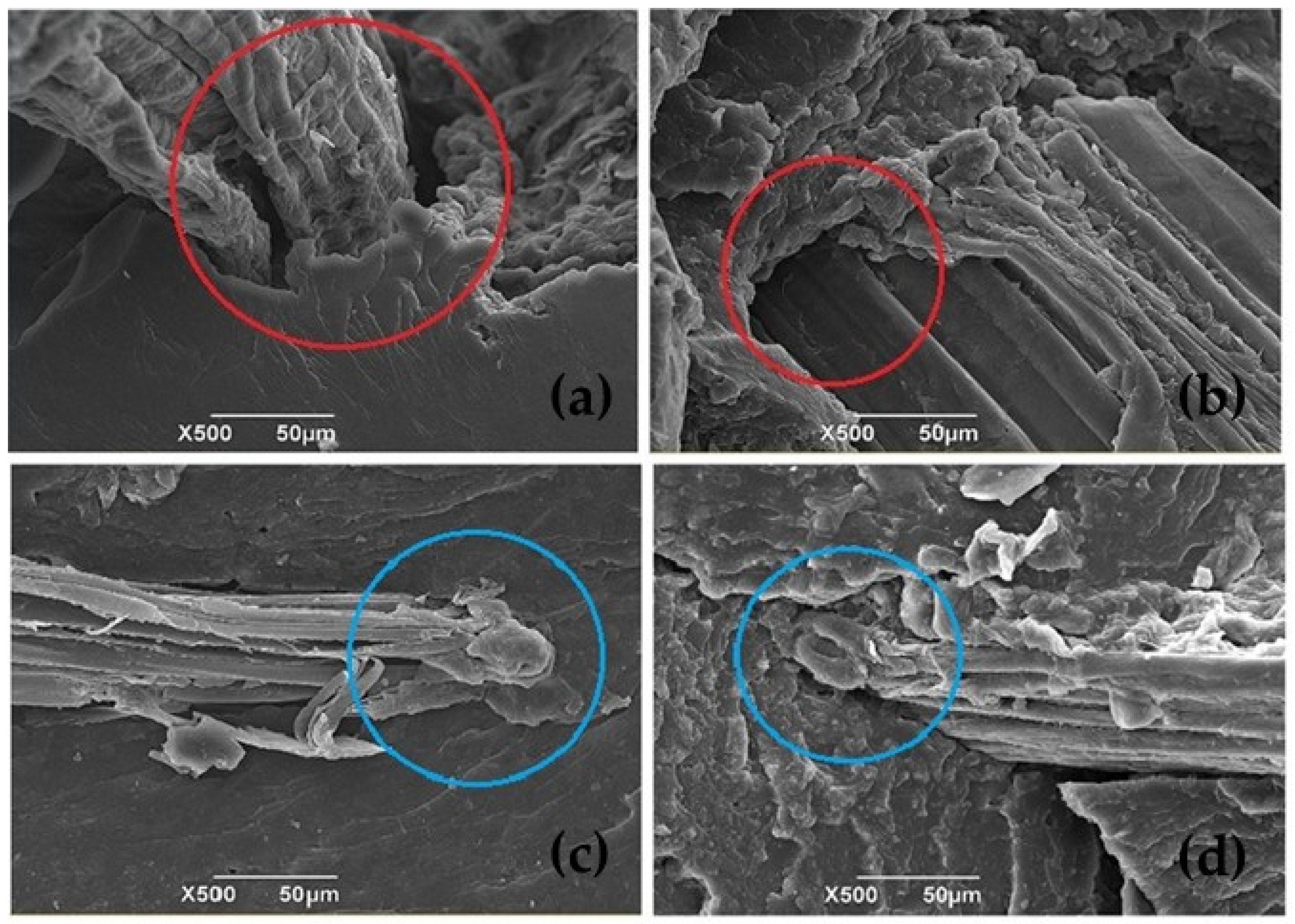

3.7. Scanning Electron Microscopy (SEM)

3.8. Tensile Test

4. Results and Discussion

4.1. Fourier Transform Infrared Spectroscopy (FT-IR)

4.2. Scanning Electron Microscopy (SEM)

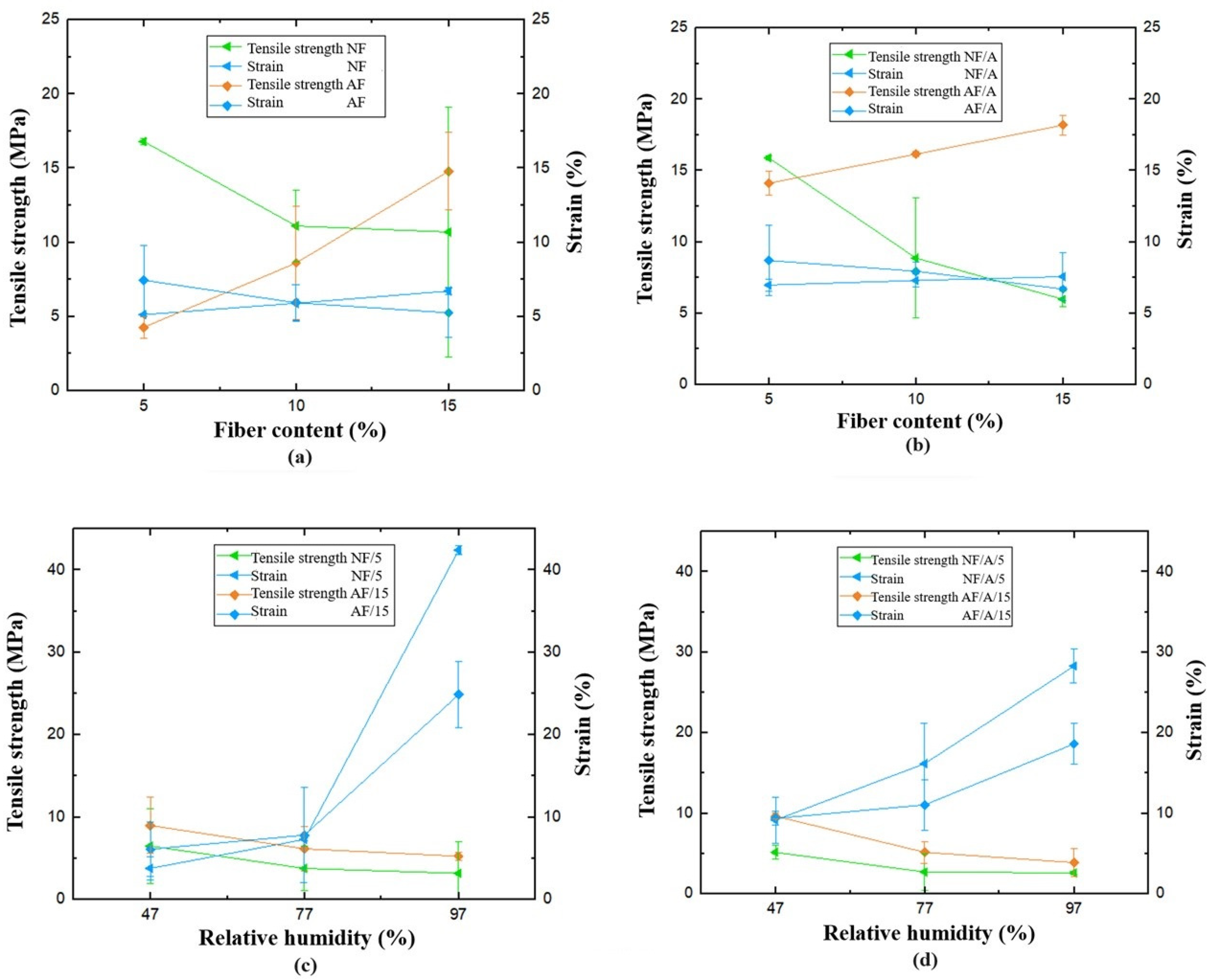

4.3. Tensile Test

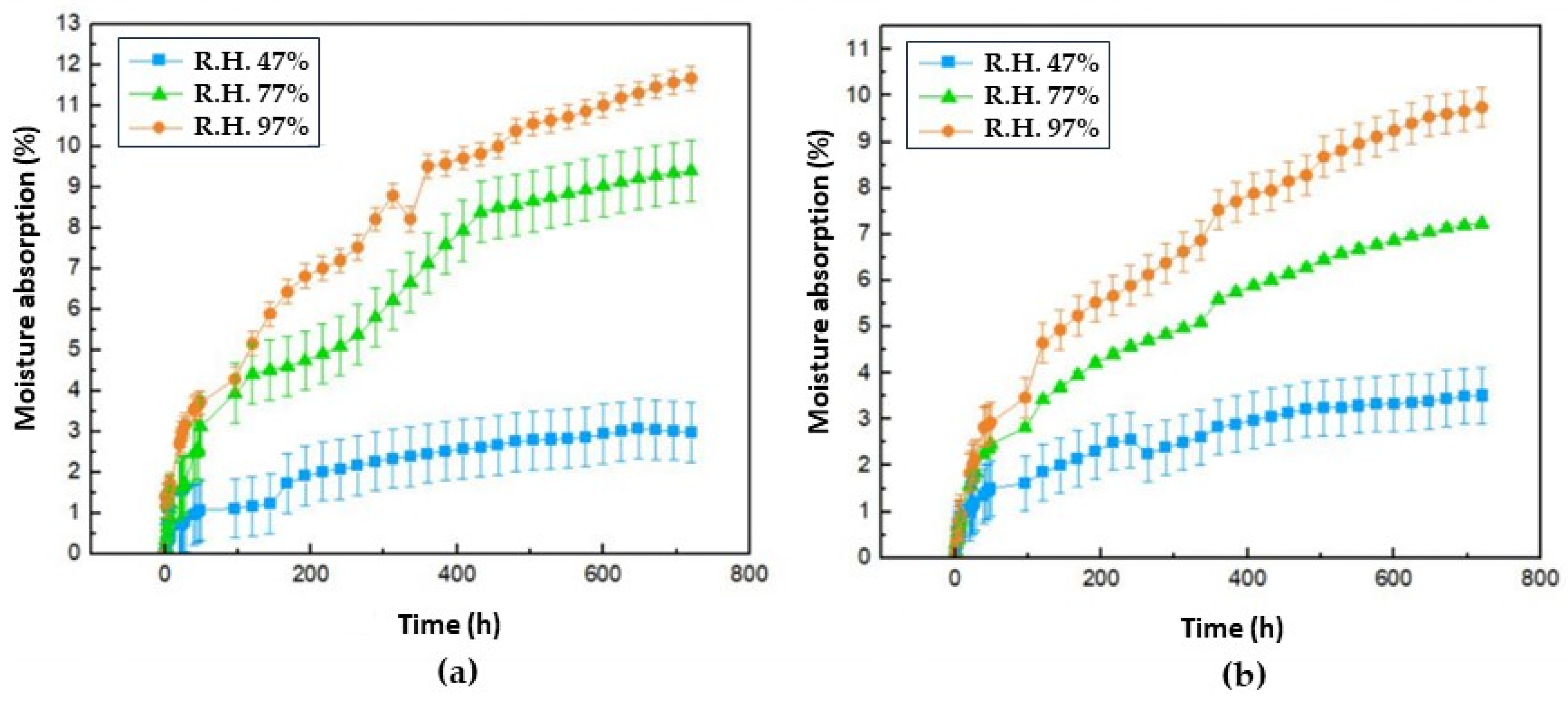

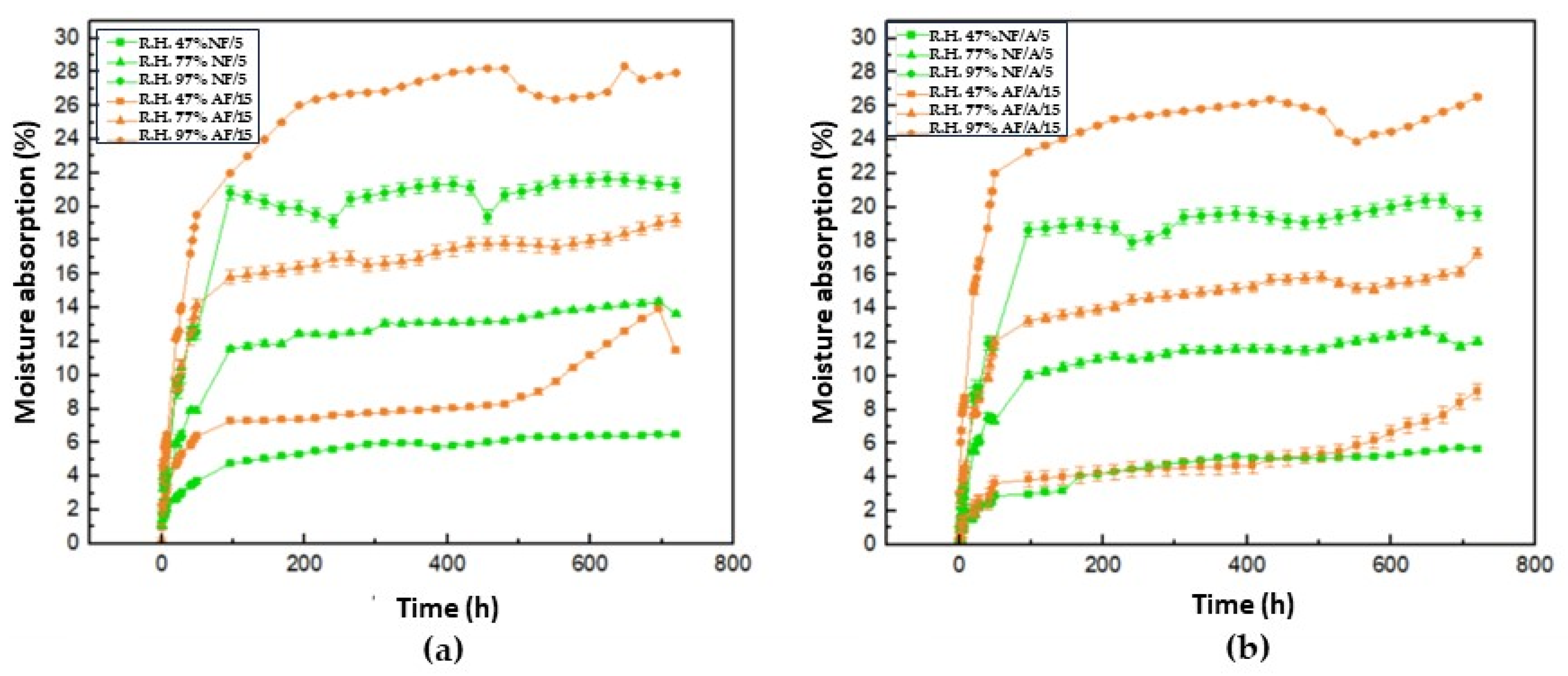

4.4. Moisture Absorption

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ávila, M.P.; Ochoa, I.C.; Rodríguez, C.E. Memoria de Oficio: Mopa Mopa Pasto; Atesanías de Colombia: Bogotá, Colombia, 2016. [Google Scholar]

- Cortés, C. La Lógica de la representación en lo artesanal; un asunto de identidad. Rev. Estud. Latinoam. 2000, 1, 42–62. [Google Scholar]

- Newman, R.; Kaplan, E.; Derrick, M. Mopa mopa: Scientific analysis and history of an unusual south american resin used by the inka and artisans in Pasto, Colombia. J. Am. Inst. Conserv. 2015, 54, 123–148. [Google Scholar] [CrossRef]

- Botina, R.; Mejía, M. Contribución al Conocimiento del Barniz o "Mopa-Mopa”, Elaeagia pastoensis Mora. Acta Agron. 1987, 37, 56–65. [Google Scholar]

- Los Conocimientos y Técnicas Asociados al Barniz de Pasto Mopa-Mopa de Colombia, Son Declarados Patrimonio de la Humanidad. Available online: https://www.mincultura.gov.co/prensa/noticias/Paginas/Los-Conocimientos-y-T%C3%A9cnicas-asociados-al-Barniz-de-Pasto-Mopa-Mopa-de-Colombia,-son-declarados-patrimonio-de-la-humanidad-.aspx (accessed on 13 November 2023).

- Tres Fuentes de la Artesanía Colombiana. Available online: https://redaprende.colombiaaprende.edu.co/recursos/colecciones/34UDQKC25D1/S0PAABXQ3CV/1283 (accessed on 13 November 2023).

- Insuasty, B.; Argoti, J.C.; Altarejos, J.; Cuenca, G.; Chamorro, E. Caracterización fisicoquímica preliminar de la resina del mopa-mopa (Elaeagia pastoensis Mora), Barniz de Pasto. Sci. Et Tech. 2007, 13, 365–368. [Google Scholar]

- Mina, J.; Anderson, S.; Bolaños, C.; Toro, E. Preparación y caracterización físico-química y térmica de mezclas binarias de resina mopa-mopa (elaeagia pastoensis mora) y policaprolactona (PCL). Rev. Latinoam. Metal. Mater. 2012, 32, 176–184. [Google Scholar]

- Toro, E.; Mina, J.; Bolaños, C. Estudio físico-mecánico y térmico de una resina natural Mopa-Mopa acondicionada a diferentes humedades relativas. Biotecnol. Sect. Agropecu. Agroind. 2013, 11, 30–36. [Google Scholar]

- Mina, J.H.; Toro, E.; Caicedo, K.; Meneses, C.A. Effect of Fique Fibers in the Behavior of a New Biobased Composite from Renewable Mopa-Mopa Resin. Polymers 2020, 12, 1573. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.; Haraguchi, S.K.; Muniz, E.C.; Rubira, A.F. Aplicações de fibras lignocelulosicas na quimica de polimeros e em compositos. Quim. Nova 2009, 32, 661–671. [Google Scholar] [CrossRef]

- Los Residuos del Plátano se Pueden Aprovechar Eficientemente. Available online: https://caracol.com.co/radio/2011/03/04/ecologia/1299231060_434552.html (accessed on 5 August 2023).

- CADENA DE PLÁTANO Dirección de Cadenas Agrícolas y Forestales Marzo 2021. Available online: https://sioc.minagricultura.gov.co/Platano/Documentos/2021-03-31%20Cifras%20Sectoriales.pdf (accessed on 11 May 2023).

- Kenned, J.J.; Sankaranarayanasamy, K.; Binoj, J.S.; Suresh Kumar-Chelliah, S. Thermo-mechanical and morphological characterization of needle punched non-woven banana fiber reinforced polymer composites. Compos. Sci. Technol. 2020, 185, 107890. [Google Scholar] [CrossRef]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2019, 38, 50–67. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Lu, Y.; Wang, H. Eco Polymeric Materials and Natural Polymer. Polymers 2023, 15, 4021. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bio-nano composites. Carbohydr. Polym. 2018, 200, 186–202. [Google Scholar] [CrossRef] [PubMed]

- Yatigala, N.S.; Bajwa, D.S.; Bajwa, S.G. Compatibilization improves physico-mechanical properties of biodegradable biobased polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 315–325. [Google Scholar] [CrossRef]

- Maqsood, M.; Seide, G. Development of biobased socks from sustainable polymer and statistical modeling of their thermo-physiological properties. J. Clean. Prod. 2018, 197, 170–177. [Google Scholar] [CrossRef]

- Kong, X.; Omonov, T.S.; Curtis, J.M. The development of canola oil based bio-resins. Lipid Technol. 2012, 24, 7–10. [Google Scholar] [CrossRef]

- Mal Uso de Polímeros Puede Afectar el Medio Ambiente. Available online: https://www.eluniversal.com.co/ambiente/mal-uso-de-polimeros-puede-afectar-el-medio-ambiente-120250-GSEU207809 (accessed on 12 June 2023).

- La Contaminación Por Plásticos Crece sin Cesar, en Tanto Que la Gestión de Residuos y el Reciclaje se Quedan Cortos, Dice la OCDE. Available online: https://www.oecd.org/espanol/noticias/perspectivas-globales-del-plastico.html (accessed on 13 November 2023).

- La Decoración se Apunta al Reciclaje Con Muebles y Textiles Sostenibles. Available online: https://www.levante-emv.com/vida-y-estilo/decoracion/2021/04/30/decoracion-reciclaje-muebles-residuos-49936241.html (accessed on 13 October 2023).

- Valadez, A.; Cervantes, J.M.; Olayo, R.; Herrera, P.J. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos. Part B 1999, 30, 309–320. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM E104-02; Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions. ASTM: West Conshohocken, PA, USA, 2012.

- Newman, R.; Kaplan, E.; Álvarez-White, M.C. The Story of Elaeagia Resin (Mopa-Mopa), So Far. Heritage 2023, 6, 4320–4344. [Google Scholar] [CrossRef]

- Suarez, J.L.; Restrepo, J.W.; Quinchía, A.; Mercado, F.A. Fibras vegetales colombianas como refuerzo en compuestos de matriz polimérica. Rev. Tecnura 2017, 21, 57–66. [Google Scholar] [CrossRef]

- Le-Troedec, M.; Rachini, A.; Peyratout, C.; Rossignol, S.; Max, E.; Kaftan, O.; Smith, A. Influence of chemical treatments on adhesion properties of hemp fibres. J. Colloid Interface Sci. 2011, 356, 303–310. [Google Scholar] [CrossRef]

- Gañán, P.; Mondragón, I. Fique fiber-reinforced polyester composites: Effects of fiber surface treatments on mechanical behavior. J. Mater. Sci. 2004, 39, 321–328. [Google Scholar] [CrossRef]

- Lubis, M.; Harahap, M.B.; Ginting, M.H.S.; Sartika, M.; Azmi, H. Production of bioplastic from avocado seed starch reinforced with microcrystalline cellulose from sugar palm fibers. J. Eng. Sci. Technol. 2018, 16, 381–393. [Google Scholar]

- Golubev, Y.V.; Makarov, I.S.; Vinogradov, M.I.; Golova, L.K.; Smyslov, A.G. Technical fiber based on flax cellulose as tire cord precursor. Fibre Chem. 2023, 55, 223–231. [Google Scholar] [CrossRef]

- Chen, H.; Miao, M.; Ding, X. Influence of moisture absorption on the interfacial strength of bamboo/vinyl ester composites. Compos. Part A 2009, 40, 2013–2019. [Google Scholar] [CrossRef]

- Mohammed, M.; Mohamad-Jawad, A.J.; Mohammed, A.M.; Oleiwi, J.K.; Adam, T.; Osman, A.F.; Dahham, O.S.; Betari, B.O.; Gopinath, S.; Jaafar, M. Challenges and advancement in water absorption of natural fiber-reinforced polymer composites. Polym. Test. 2023, 124, 108083. [Google Scholar] [CrossRef]

- Ramakrishnan, T.; Kumar, S.; Chelladurai, S.; Gnanasekaran, S.; Geetha, N.K.; Arthanari, R.; Debtera, B. Effect of Moisture Content on Mechanical Properties of AAM Natural Fiber-Reinforced Isophthalic Polyester Composites. Adv. Mater. Sci. Eng. 2022, 2022, 3533143. [Google Scholar] [CrossRef]

- Musthaq, M.A.; Dhakal, H.N.; Zhang, Z.; Barouni, A.; Zahari, R. The Effect of Various Environmental Conditions on the Impact Damage Behaviour of Natural-Fibre-Reinforced Composites (NFRCs)—A Critical Review. Polymers 2023, 15, 1229. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, Y.; Chen, G.; Cai, M. Enhanced mechanical and hydrophobic properties of composite cassava starch films with stearic acid modified MCC (microcrystalline cellulose)/ NCC (nanocellulose) as strength agent. Int. J. Biol. Macromol. 2020, 142, 846–854. [Google Scholar] [CrossRef] [PubMed]

- Karnnet, S.; Potiyaraj, P.; Pimpan, V. Preparation and properties of biodegradable stearic acid-modified gelatin films. Polym. Degrad. Stab. 2005, 90, 106–110. [Google Scholar] [CrossRef]

- Satria, M.; Saleh, T.A. Synthesis of Superhydrophobic/Superoleophilic stearic acid and Polymer-modified magnetic polyurethane for Oil-Water Separation: Effect of polymeric nature. J. Colloid Interface Sci. 2023, 629, 522–534. [Google Scholar] [CrossRef] [PubMed]

- Lodha, P.; Netravali, A.N. Characterization of stearic acid modified soy protein isolate resin and ramie fiber reinforced green composites. Compos. Sci. Technol. 2005, 65, 1211–1225. [Google Scholar] [CrossRef]

- Lodha, P.; Netravali, A.N. Thermal and mechanical properties of environment-friendly ‘green’ plastics from stearic acid modified-soy protein isolate. Ind. Crops Prod. 2005, 21, 49–64. [Google Scholar] [CrossRef]

- Mina, J.H.; Valadez, A.; Herrera-Franco, P.J.; Toledano, T. Influencia del tiempo de almacenamiento en las propiedades estructurales de un almidón termoplástico de yuca (TPS). Ing. Compet. 2009, 11, 95–106. [Google Scholar] [CrossRef]

- Da Róz, A.L.; Zambon, M.D.; Curvelo, A.A.; Carvalho, A.J. Thermoplastic starch modified during melt processing with organic acids: The effect of molar mass on thermal and mechanical properties. Ind. Crops Prod. 2011, 33, 152–157. [Google Scholar] [CrossRef]

- Mina, J.H. Effect of the Incorporation of Polycaprolactone (PCL) on the Retrogradation of Binary Blends with Cassava Thermoplastic Starch (TPS). Polymers 2021, 13, 38. [Google Scholar] [CrossRef]

- Aranda-García, F.J.; González-Núñez, R.; Jasso-Gastinel, C.F.; Mendizábal, E. Water Absorption and Thermomechanical Characterization of Extruded Starch/Poly(lactic acid)/Agave Bagasse Fiber Bioplastic Composites. Int. J. Polym. Sci. 2015, 2015, 343294. [Google Scholar] [CrossRef]

| Factors | Level 1 (with Additive) Sublevels | Level 2 (without Additive) Sublevels | |||||

|---|---|---|---|---|---|---|---|

| Block 1 | Fiber content Test specimen * | 5% NF/A/5 | 10% NF/A/10 | 15% NF/A/15 | 5% NF/5 | 10% NF/10 | 15% NF/15 |

| Fiber type | Native | Native | Native | Native | Native | Native | |

| Block 2 | Fiber content Test specimen ** | 5% AF/A/5 | 10% AF/A/10 | 15% AF/A/15 | 5% AF/5 | 10% AF/10 | 15% AF/15 |

| Fiber type | Alkalized | Alkalized | Alkalized | Alkalized | Alkalized | Alkalized | |

| Block | Level | Test Specimen | Additive Content | Fiber Type | Fiber Content (%) | Tensile Strength (MPa) | Strain (%) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | NF/A/5 | with | Native | 5 | 15.9 | 7.0 |

| NF/A/10 | 10 | 8.9 | 7.3 | ||||

| NF/A/15 | 15 | 6.0 | 7.6 | ||||

| 2 | NF/5 | without | Native | 5 | 16.8 | 5.1 | |

| NF/10 | 10 | 11.1 | 5.9 | ||||

| NF/15 | 15 | 10.7 | 6.7 | ||||

| 2 | 1 | AF/A/5 | with | Alkalized | 5 | 14.1 | 8.7 |

| AF/A/10 | 10 | 16.2 | 8.0 | ||||

| AF/A/15 | 15 | 18.2 | 6.7 | ||||

| 2 | AF/5 | without | Alkalized | 5 | 4.3 | 7.5 | |

| AF/10 | 10 | 8.6 | 5.9 | ||||

| AF/15 | 15 | 14.8 | 5.3 |

| Test Specimen | Additive Content | Time (D) | Relativity Humidity (%) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|---|---|

| Mopa-Mopa | with | 0 | - | 11.8 | 7.1 |

| 30 | 47 | 8.9 | 31.4 | ||

| 77 | 8.1 | 79.9 | |||

| 97 | 4.5 | 80.9 | |||

| without | 0 | - | 20.9 | 9.0 | |

| 30 | 47 | 18.1 | 13.0 | ||

| 77 | 12.1 | 25.8 | |||

| 97 | 6.3 | 26.1 | |||

| NF/A/5 | with | 0 | - | 15.9 | 7.0 |

| 30 | 47 | 5.2 | 9.2 | ||

| 77 | 2.7 | 16.2 | |||

| 97 | 2.6 | 28.3 | |||

| NF/5 | without | 0 | - | 16.8 | 5.1 |

| 30 | 47 | 6.5 | 3.8 | ||

| 77 | 3.8 | 7.3 | |||

| 97 | 3.2 | 42.4 | |||

| AF/A/15 | with | 0 | - | 18.2 | 6.7 |

| 30 | 47 | 9.7 | 9.4 | ||

| 77- | 5.2 | 11.1 | |||

| 97 | 3.9 | 18.7 | |||

| AF/15 | without | 0 | - | 14.8 | 5.3 |

| 30 | 47 | 9.0 | 6.1 | ||

| 77 | 6.2 | 7.8 | |||

| 97 | 5.3 | 24.9 |

| Matrix Type | Fiber Type | Fiber Content (%) | Moisture Absorption (%) | Reference | |||

|---|---|---|---|---|---|---|---|

| 47 | 77 | 97 | Other Moisture | ||||

| Mopa-Mopa | N/A | 0 | 0.09 | 0.64 | 1.90 | - | [10] |

| Fique untreated | 10 | 0.54 | 2.20 | 4.96 | - | ||

| 20 | 0.46 | 2.04 | 6.63 | - | |||

| Fique alkalized | 10 | 0.77 | 3.34 | 7.00 | - | ||

| 20 | 0.88 | 3.95 | 12.32 | - | |||

| Mopa-Mopa with additive | N/A | N/A | 2.97 | 9.41 | 11.68 | - | Experimental date |

| Plantain untreated | 5 | 5.61 | 12.07 | 19.65 | - | ||

| Plantain alkalized | 15 | 9.11 | 17.27 | 26.54 | - | ||

| Mopa-Mopa without additive | N/A | 0 | 3.51 | 7.23 | 9.75 | ||

| Plantain untreated | 5 | 6.47 | 13.65 | 21.28 | - | ||

| Plantain alkalized | 15 | 11.46 | 19.22 | 27.96 | |||

| Corn TPS | - | - | - | - | 60.00 | 11.4 (53%) | [44] |

| Cassava TPS | - | - | - | - | - | 7.00 (54%) | [45] |

| 1.00 (29%) | |||||||

| Corn TPS | - | - | - | - | - | 9.30 (53%) | [46] |

| Agave bagasse | 10 | - | - | - | 8.64 (53%) | ||

| 15 | - | - | - | 8.52 (53%) | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez Morales, V.; Martínez Salinas, B.A.; Mina Hernandez, J.H.; Córdoba Urrutia, E.; Fajardo Cabrera de Lima, L.d.P.; Maturana Peña, H.; Valadez González, A.; Ríos-Soberanis, C.R.; Pérez-Pacheco, E. Using Plantain Rachis Fibers and Mopa-Mopa Resin to Develop a Fully Biobased Composite Material. Polymers 2024, 16, 329. https://doi.org/10.3390/polym16030329

Sánchez Morales V, Martínez Salinas BA, Mina Hernandez JH, Córdoba Urrutia E, Fajardo Cabrera de Lima LdP, Maturana Peña H, Valadez González A, Ríos-Soberanis CR, Pérez-Pacheco E. Using Plantain Rachis Fibers and Mopa-Mopa Resin to Develop a Fully Biobased Composite Material. Polymers. 2024; 16(3):329. https://doi.org/10.3390/polym16030329

Chicago/Turabian StyleSánchez Morales, Valeria, Brenda Alejandra Martínez Salinas, Jose Herminsul Mina Hernandez, Estivinson Córdoba Urrutia, Lety del Pilar Fajardo Cabrera de Lima, Harry Maturana Peña, Alex Valadez González, Carlos R. Ríos-Soberanis, and Emilio Pérez-Pacheco. 2024. "Using Plantain Rachis Fibers and Mopa-Mopa Resin to Develop a Fully Biobased Composite Material" Polymers 16, no. 3: 329. https://doi.org/10.3390/polym16030329

APA StyleSánchez Morales, V., Martínez Salinas, B. A., Mina Hernandez, J. H., Córdoba Urrutia, E., Fajardo Cabrera de Lima, L. d. P., Maturana Peña, H., Valadez González, A., Ríos-Soberanis, C. R., & Pérez-Pacheco, E. (2024). Using Plantain Rachis Fibers and Mopa-Mopa Resin to Develop a Fully Biobased Composite Material. Polymers, 16(3), 329. https://doi.org/10.3390/polym16030329