Biochar as Sustainable Filler of Recycled Polylactic Acid (PLA): A New Generation of Processable Biocomposites

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

2.2. Processing

2.3. Characterization Techniques

3. Results and Discussion

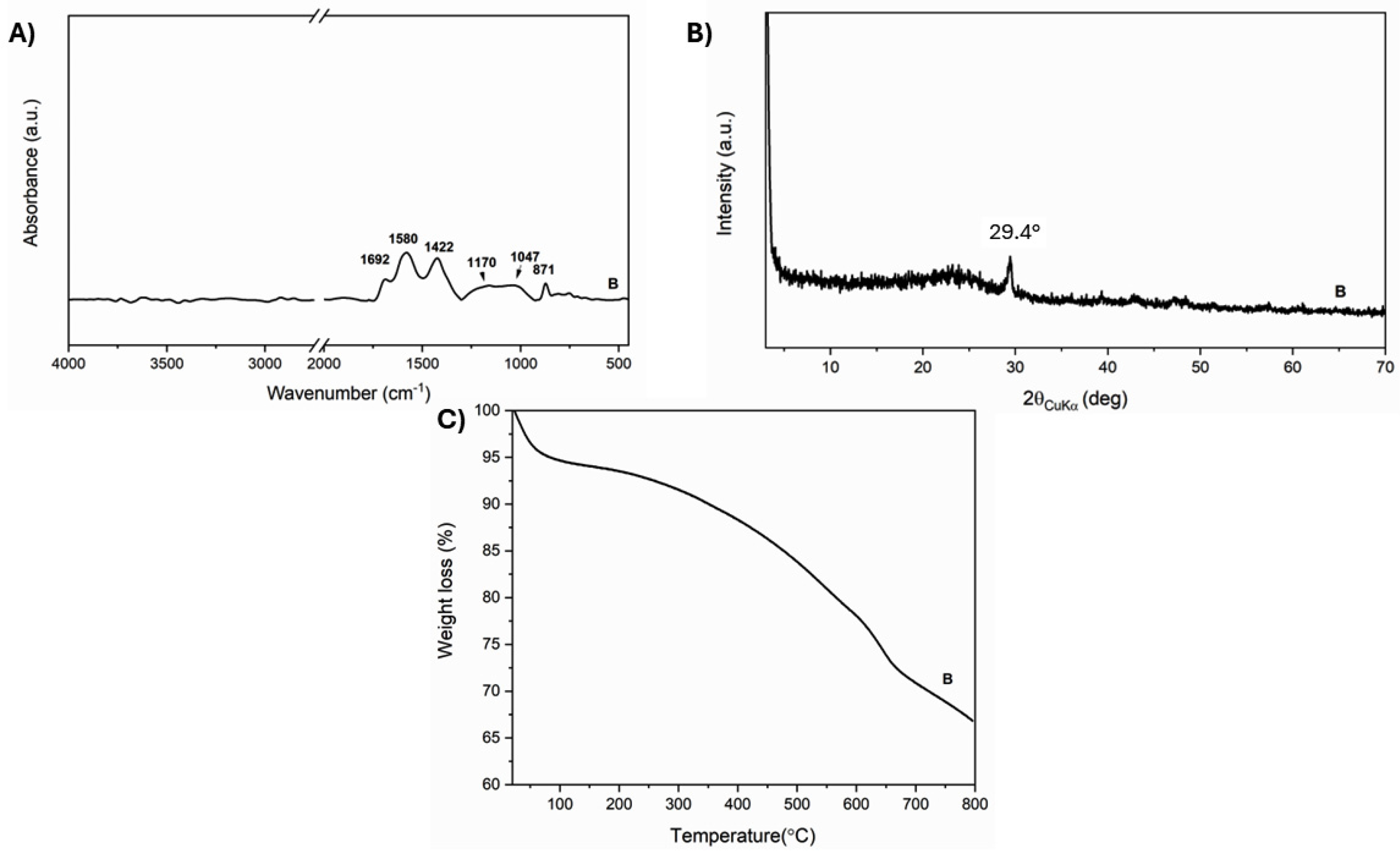

3.1. Characterization of the Carbon Material

3.2. Preparation and Characterization of the PLA-Based Composites

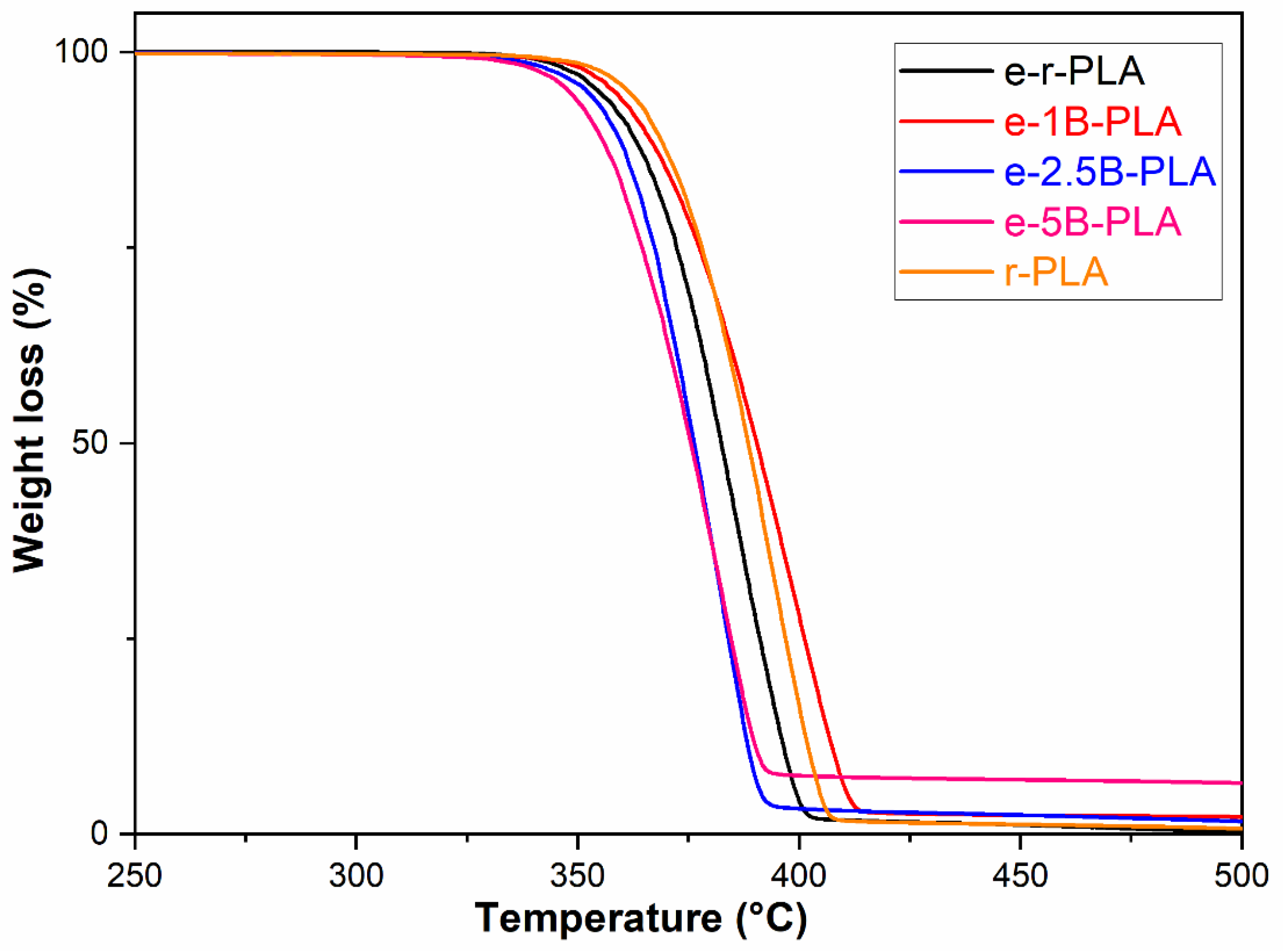

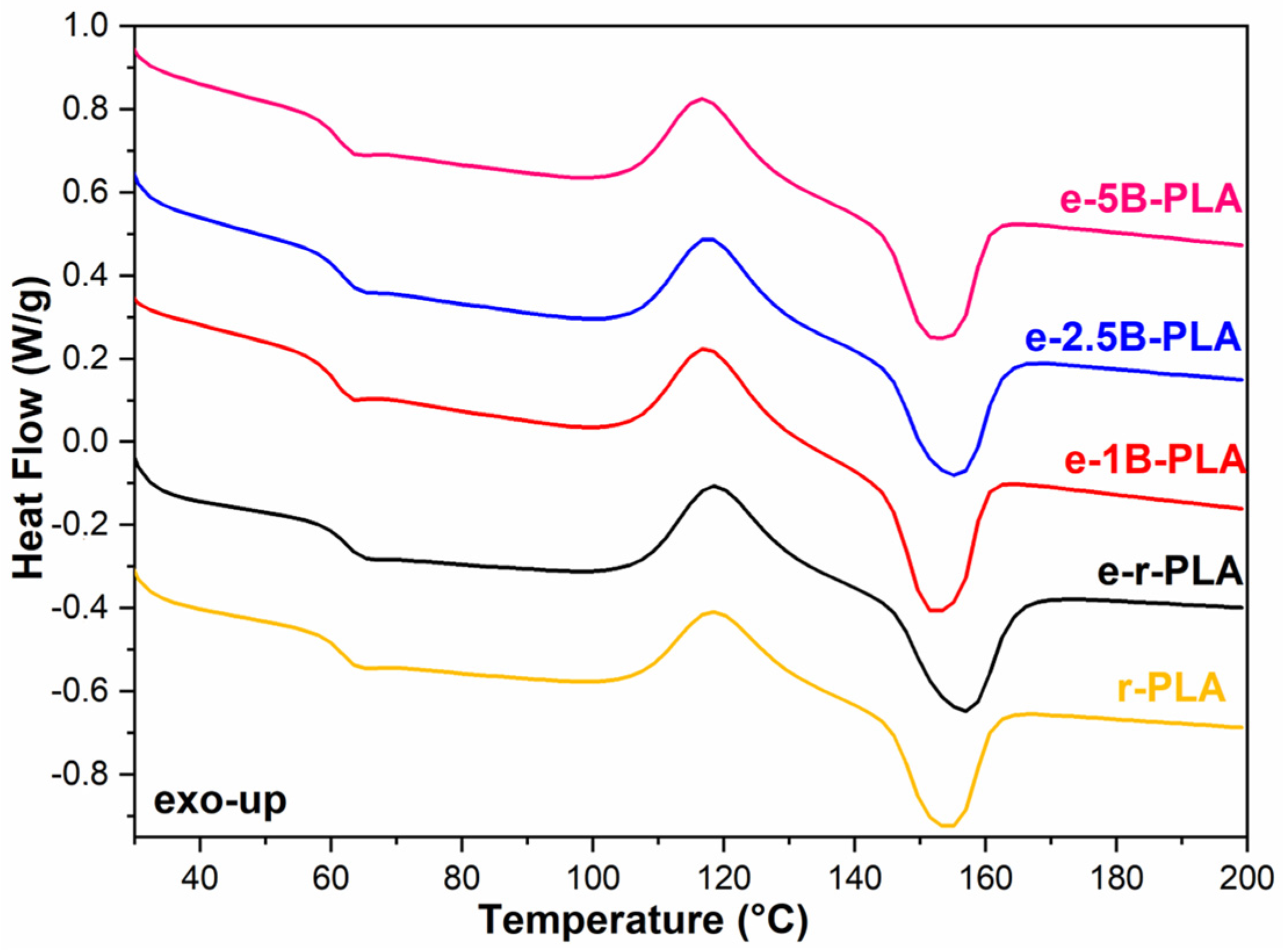

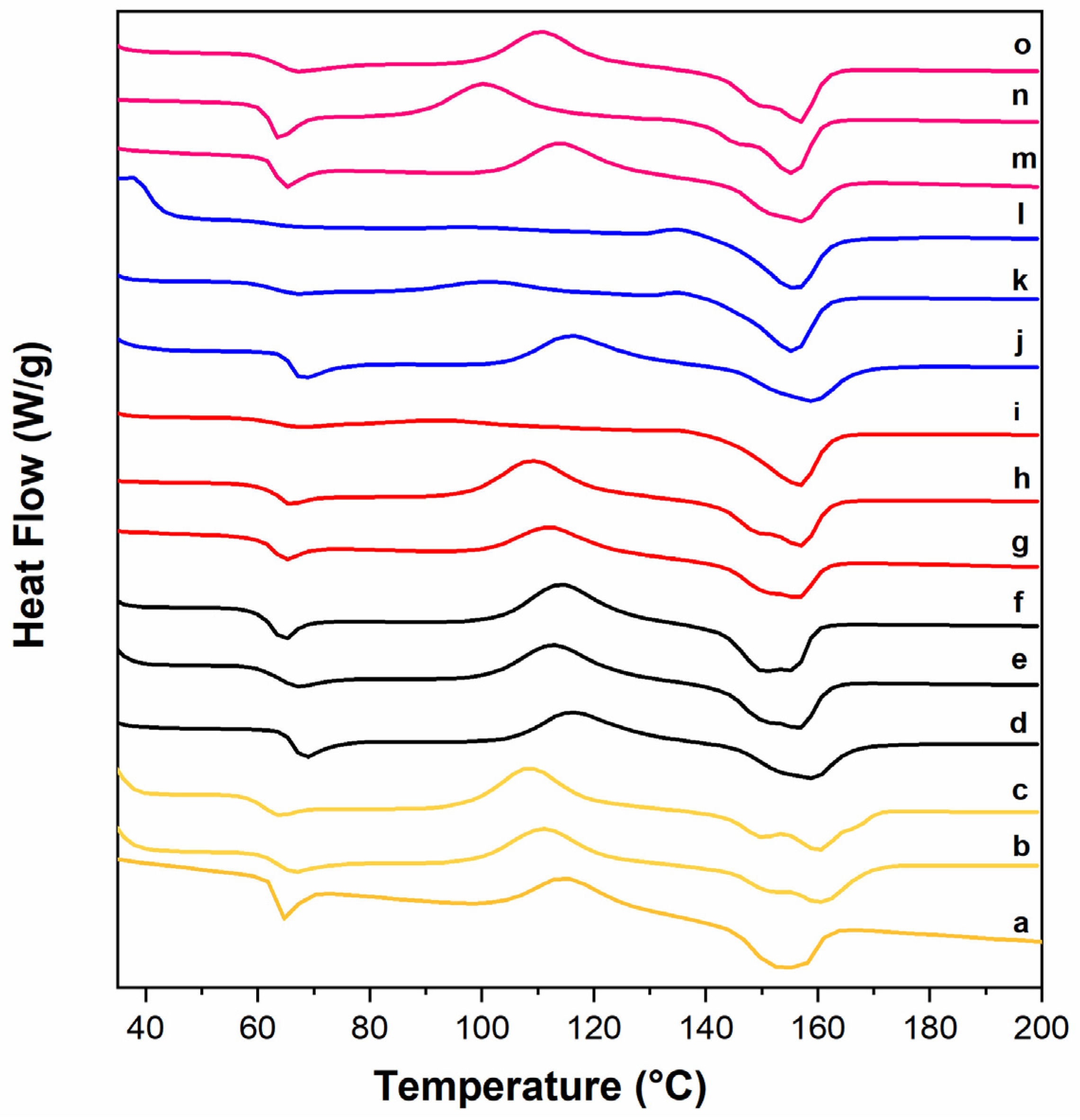

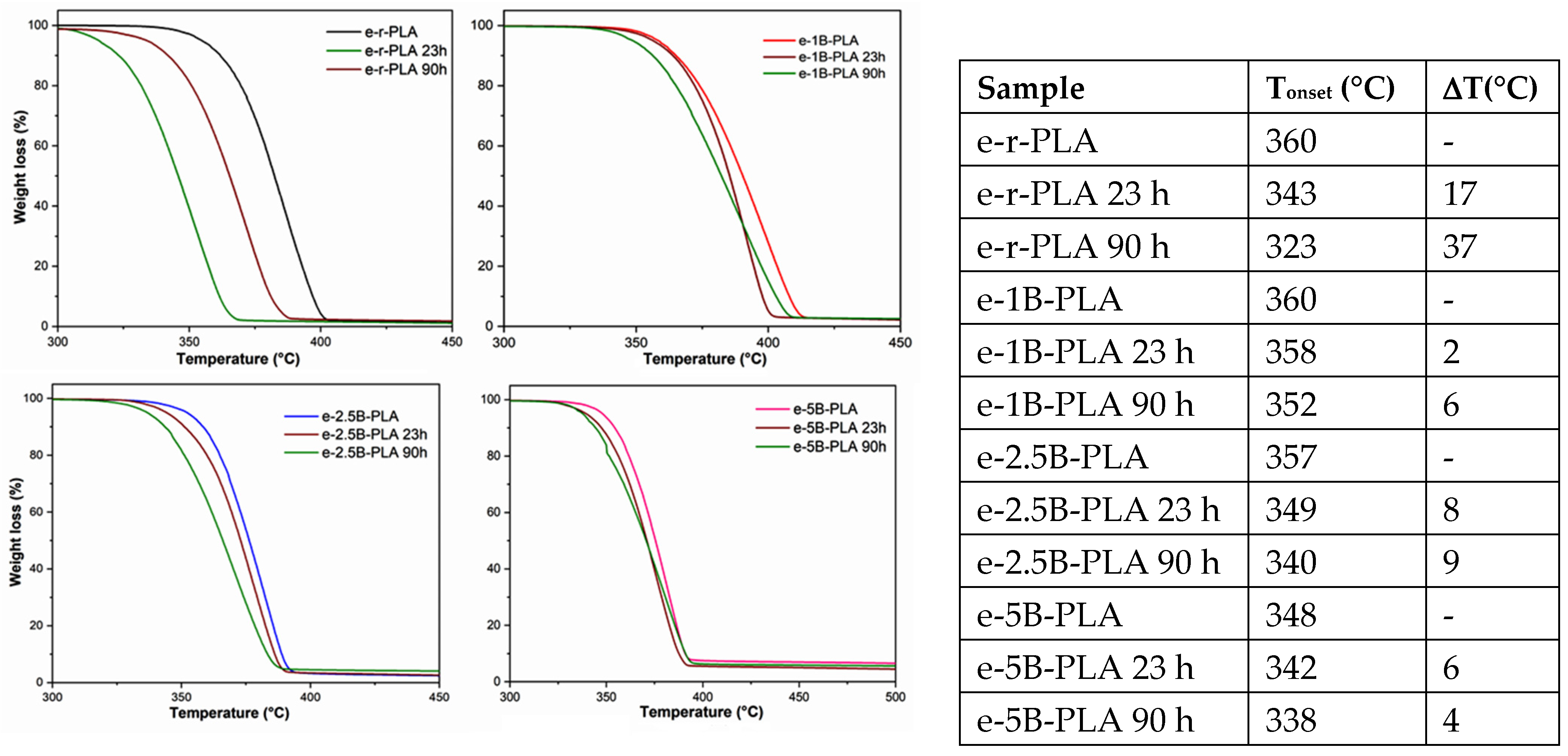

3.3. Thermal Properties

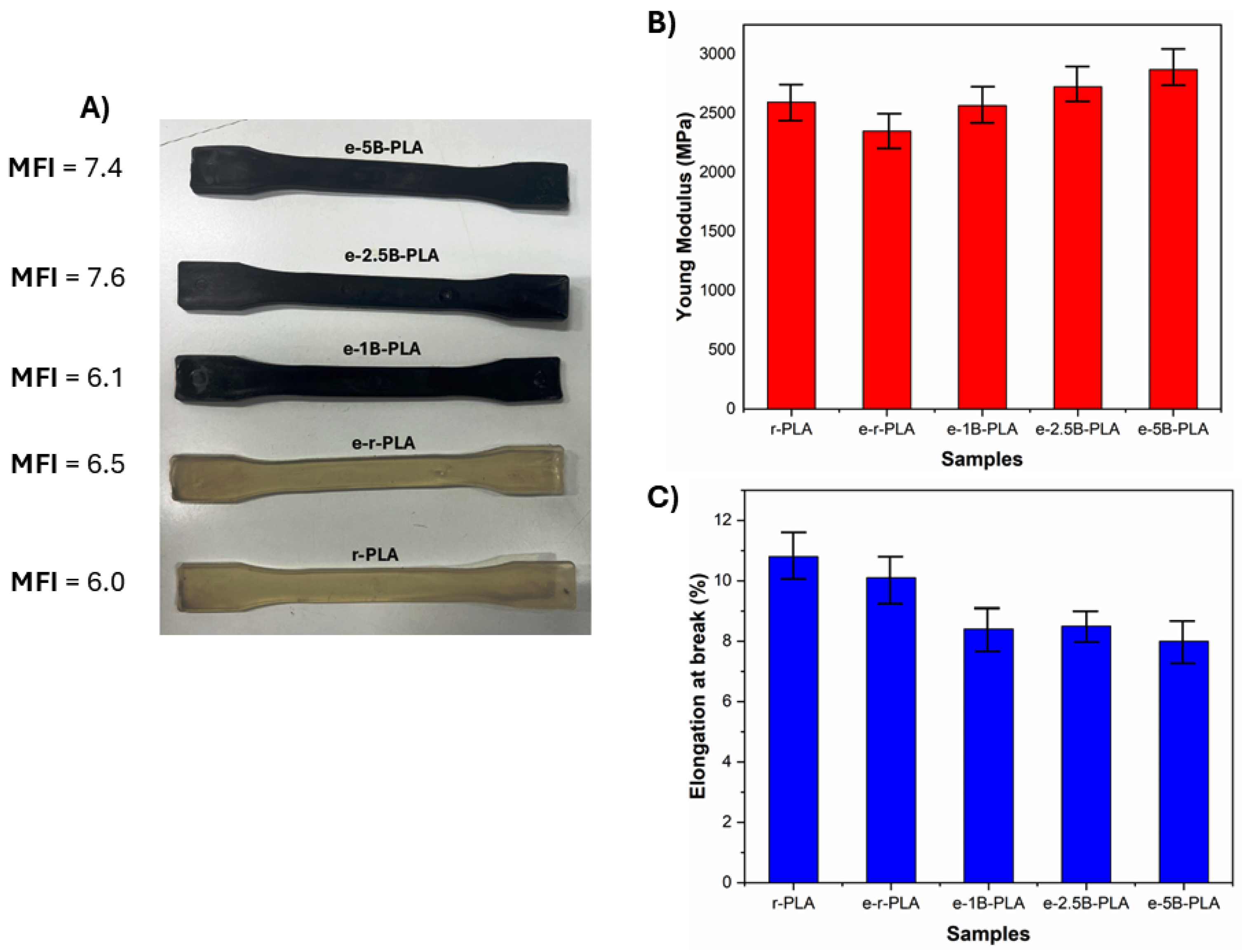

3.4. Processability and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Abd Alsaheb, R.A.; Aladdin, A.; Othman, N.Z.; Abd Malek, R.; Leng, O.M.; Aziz, R.; El Enshasy, H.A. Recent applications of polylactic acid in pharmaceutical and medical industries. J. Chem. Pharm. Res. 2015, 7, 51–63. [Google Scholar]

- Morreale, M.; Liga, A.; Mistretta, M.C.; Ascione, L.; La Mantia, F.P. Mechanical, thermomechanical and reprocessing behavior of green composites from biodegradable polymer and wood flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef] [PubMed]

- Ozyhar, T.; Baradel, F.; Zoppe, J. Effect of functional mineral additive on processability and material properties of wood-fiber reinforced poly(lactic acid) (PLA) composites. Compos. Part. A Appl. Sci. Manuf. 2020, 132, 105827. [Google Scholar] [CrossRef]

- Tongmengyao, J.; Jingyua, D.; Xiaobao, L. A novel lignin/inorganic salt composite filler of alkali lignin/basic magnesium carbonate for enhancing the hydrophobicity of polylactic acid composites. Mater. Lett. 2024, 373, 137156–137158. [Google Scholar]

- Stratiotou Efstratiadis, V.; Argyros, A.; Efthymiopoulos, P.; Maliaris, G.; Nasikas, N.K.; Michailidis, N. Utilization of Silica Filler as Reinforcement Material of Polylactic Acid (PLA) in 3D Printing Applications: Thermal, Rheological, and Mechanical Performance. Polymers 2024, 16, 1326. [Google Scholar] [CrossRef] [PubMed]

- Sit, M.; Dashatan, S.; Zhang, Z.; Dhakal, H.N.; Khalfallah, M.; Gamer, N.; Ling, J. Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation. Polymers 2023, 15, 3221. [Google Scholar] [CrossRef] [PubMed]

- D’Urso, L.; Acocella, M.R.; Guerra, G.; Iozzino, V.; De Santis, F.; Pantani, R. PLA Melt Stabilization by High-Surface-Area Graphite and Carbon Black. Polymers 2018, 10, 139. [Google Scholar] [CrossRef] [PubMed]

- D′Urso, L.; Acocella, M.R.; De Santis, F.; Guerra, G.; Pantani, R. Poly(l-lactic acid) nucleation by alkylated carbon black. Polymer 2022, 256, 125237. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science, Technology, and Implementation; Routledge: New York, NY, USA; Taylor & Francis Group: New York, NY, USA, 2015; pp. 1–39. [Google Scholar]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Giudicianni, P.; Pindozzi, S.; Grottola, C.M.; Stanzione, F.; Faugno, S.; Fagnano, M.; Fiorentino, N.; Ragucci, R. Pyrolysis for exploitation of biomasses selected for soil phytoremediation: Characterization of gaseous and solid products. Waste Manag. 2017, 61, 288–299. [Google Scholar] [CrossRef] [PubMed]

- Volpi, M.P.C.; Silva, J.C.G.; Hornung, A.; Ouadi, M. Review of the Current State of Pyrolysis and Biochar Utilization in Europe: A Scientific Perspective. Clean. Technol. 2024, 6, 152–175. [Google Scholar] [CrossRef]

- Chen, D.; Liu, W.; Wang, Y.; Lu, P. Effect of biochar aging on the adsorption and stabilization of Pb in soil. J. Soils Sediments 2022, 22, 56–66. [Google Scholar] [CrossRef]

- Scotto di Perta, E.; Giudicianni, P.; Mautone, A.; Grottola, C.M.; Cervelli, E.; Ragucci, R.; Pindozzi, S. An Effective biochar application for reducing nitrogen emissions from buffalo digestate storage tank. Appl. Sci. 2024, 14, 6456. [Google Scholar] [CrossRef]

- Senadheera, S.S.; Gupta, S.; Kua, H.W.; Hou, D.; Kim, S.; Tsang, D.C.; Ok, Y.S. Application of biochar in concrete—A review. Cem. Concr. Compos. 2023, 143, 105204–105219. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Jagdale, P.; Rovere, M.; Tagliaferro, A. A Review of Non-Soil Biochar Applications. Materials 2020, 13, 261. [Google Scholar] [CrossRef]

- Bartoli, M.; Troiano, M.; Giudicianni, P.; Amato, D.; Giorcelli, M.; Solimene, R.; Tagliaferro, A. Effect of heating rate and feedstock nature on electrical conductivity of biochar and biochar-based composites. Appl. Energy Combust. Sci. 2022, 12, 100089–100099. [Google Scholar] [CrossRef]

- Oliveira, M.; Santos, E.; Araújo, A.; Fechine, G.J.M.; Machado, A.V.; Botelho, G. The role of shear and stabilizer on PLA degradation. Polym. Test. 2016, 51, 109–116. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.-H.; Kwon, E.E. Biochar as a Catalyst. Renew. Sustain. Energy Rev. 2017, 77, 70–79. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic Acid)–Biochar Biocomposites: Effect of Processing and Filler Content on Rheological, Thermal, and Mechanical Properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef]

- Kamonwan, A.-N.; Mai, N. Effect of carbon-rich biochar on mechanical properties of PLA-biochar composites. Sustain. Chem. Pharm. 2020, 15, 100204–100212. [Google Scholar]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly(lactic acid) biocomposites reinforced with ultrafine bamboo-char: Morphology, mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2016, 133, 43425. [Google Scholar] [CrossRef]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste derived biochar as an alternative filler in—Mechanical, thermal and morphological properties of biochar added biocomposites. J. Clean. Prod. 2021, 278, 123850. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent Advances in Biochar Polymer Composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khana, A.; Pugnob, N.; Rossoe, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Thonemann, N. Life cycle assessment of recycling options for polylactic acid. Resour. Conserv. Recycl. 2019, 149, 86–96. [Google Scholar] [CrossRef]

- Tesfaye, M.; Patwa, R.; Gupta, A.; Kashyap, M.J.; Katiyar, V. Recycling of poly(lactic acid)/silk based bionanocomposites films and its influence on thermal stability, crystallization kinetics, solution and melt rheology. Int. J. Biol. Macromol. 2017, 131, 580–594. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, T.; Saddique, M.T.; Naeem, A.; Westerhoff, P.; Mustafa, S.; Alum, A. Comparison of Different Methods for the Point of Zero Charge Determination of NiO. Ind. Eng. Chem. Res. 2011, 50, 10017–10023. [Google Scholar] [CrossRef]

- Kiani, A.; Lamberti, E.; Viscusi, G.; Giudicianni, P.; Grottola, M.C.; Ragucci, R.; Gorrasi, G.; Acocella, M.R.; Viscusi, G.; Giudicianni, P.; et al. Eco-friendly one-shot approach for producing a functionalized nano-torrefied biomass: A new application of ball milling technology. Mater. Adv. 2024, 5, 695–704. [Google Scholar] [CrossRef]

- Singh, B.; Pal Singh, B.; Cowie, A.L. Characterisation and evaluation of biochars for their application as soil amendment. Aust. J. Soil. Res. 2010, 48, 516–525. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of torrefied coffee grounds as reinforcing agent to produce high-quality biodegradable PBAT composites for food packaging applications. ACS Sustain. Chem. Eng. 2017, 5, 1906–1916. [Google Scholar] [CrossRef]

- Ho, M.; Lau, K.; Hui, D. Improvement of the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part. B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Kiran, M.D.; Govindaraju, H.K.; Jayaraju, T.; Kumar, N. Review-Effect of Fillers on Mechanical Properties of Polymer Matrix Composites. Mater. Today Proc. 2018, 5, 22421–22424. [Google Scholar] [CrossRef]

- Paiva, M.C.; Zhou, B.; Fernando, K.A.S.; Lin, Y.; Kennedy, J.M.; Sun, Y.-P. Mechanical and morphological characterization of polymer–carbon nanocomposites from functionalized carbon nanotubes. Carbon 2004, 42, 2849–2854. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Anwer, M.A.S.; Naguib, H.E.; Celzard, A.; Fierro, V. Comparison of the thermal, dynamic mechanical, and morphological properties of PLA-Lignin & PLA-Tannin particulate green composites. Compos. Part-Eng. 2015, 82, 92–99. [Google Scholar]

- Bednarek, M.; Borska, K.; Kubisa, P. Crosslinking of Polylactide by High Energy Irradiation and Photo-Curing. Molecules 2020, 25, 4919. [Google Scholar] [CrossRef] [PubMed]

| Samples | Yield | C | H | N | O | Fixed Carbon | Volatiles | Ash | pH | pHpzc | BET * |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt% | wt% daf | wt% db | m2/g | ||||||||

| P | - | 48.67 | 5.91 | 0.18 | 45.24 | 16.6 | 79.9 | 3.5 | - | - | - |

| B | 32.2 | 78.29 | 2.85 | 0.61 | 18.25 | 61.52 | 27.51 | 10.96 | 9.8 | 8.2 | 60 |

| P | e% a | B | e% a | ||

|---|---|---|---|---|---|

| Na | mg/Kg | 175 | 7 | 326 | 12 |

| Mg | 670 | 7 | 1627 | 15 | |

| Al | 315 | 0 | 654 | 3 | |

| K | 2511 | 16 | 8397 | 21 | |

| Ca | 11,000 | 8 | 27,330 | 9 | |

| Fe | 790 | 1 | 1785 | 17 |

| Entry | Sample | Mn (kDa) | MW (kDa) | PDI |

|---|---|---|---|---|

| 1 | r-PLA | 59.3 | 113.1 | 1.9 |

| 2 | e-r-PLA | 42.7 | 101.6 | 2.4 |

| 3 | e-1B-PLA | 41.5 | 101.2 | 2.4 |

| 4 | e-2.5B-PLA | 47.3 | 101 | 2.1 |

| 5 | e-5B-PLA | 47.1 | 97.7 | 2.1 |

| Samples | Tg (°C) | Tm (°C) | TCC (°C) | ΔHcc (J/g) | ΔHm (J/g) | χc (%) |

|---|---|---|---|---|---|---|

| r-PLA | 58.6 ± 0.2 | 153.4 ± 0.3 | 118.4 ± 0.2 | 16.2 ± 0.4 | 20.2 ± 0.3 | 4.3 ± 0.1 |

| e-r-PLA | 58.7 ± 0.1 | 155.5 ± 0.4 | 118.2 ± 0.1 | 17.3 ± 0.2 | 23.2 ± 0.2 | 6.3 ± 0.0 |

| e-1B-PLA | 58.3 ± 0.3 | 151.3 ± 0.2 | 117.2 ± 0.3 | 18.6 ± 0.3 | 22.9 ± 0.3 | 4.3 ± 0.2 |

| e-2.5B-PLA | 58.3 ± 0.2 | 154.7 ± 0.4 | 117.4 ± 0.4 | 17.6 ± 0.2 | 22.0 ± 0.2 | 4.8 ± 0.0 |

| e-5B-PLA | 57.9 ± 0.1 | 151.7 ± 0.2 | 116.6 ± 0.5 | 17.2 ± 0.4 | 20.7 ± 0.2 | 3.9 ± 0.2 |

| Samples | Tg (°C) | Tm (°C) | TCC (°C) | ΔHcc (J/g) | ΔHm (J/g) | χc (%) |

|---|---|---|---|---|---|---|

| r-PLA | 61.7 ± 0.3 | 152.4 ± 0.5 | 114.7 ± 0.4 | 25.5 ± 0.5 | 20.8 ± 0.6 | - |

| r-PLA (23 h aged) | 60.9 ± 0.3 | 159.8 ± 0.3 | 111 ± 0.6 | 21.8 ± 0.6 | 26.9 ± 0.4 | 5.4 ± 0.2 |

| r-PLA (90 h aged) | 58.0 ± 0.2 | 159.9 ± 0.4 | 108.5 ± 0.3 | 25.4 ± 0.4 | 27.5 ± 0.5 | 2.2 ± 0.1 |

| e-r-PLA | 64.4 ± 0.1 | 158 ± 0.4 | 116.1 ± 0.2 | 17.9 ± 0.2 | 21.9 ± 0.3 | 4.3 ± 0.1 |

| e-r-PLA (23 h aged) | 60.8 ± 0.2 | 155.8 ± 0.5 | 112.8 ± 0.7 | 22.1 ± 0.5 | 26.1 ± 0.4 | 4.3 ± 0.1 |

| e-r-PLA (90 h aged) | 60.1 ± 0.2 | 154.0 ± 0.5 | 114.1 ± 0.4 | 24.6 ± 0.3 | 25.8 ± 0.2 | - |

| e-1B-PLA | 60.8 ± 0.2 | 155.9 ± 0.4 | 111.8 ± 0.3 | 16.3 ± 0.2 | 20.4 ± 0.4 | 4.4 ± 0.2 |

| e-1B-PLA (23 h aged) | 61.2 ± 0.1 | 156.4 ± 0.3 | 108.8 ± 0.2 | 21.0 ± 0.5 | 25.1 ± 0.5 | 4.4 ± 0.0 |

| e-1B-PLA (90 h aged) | 59.3 ± 0.3 | 156.5 ± 0.6 | / | / | 26.6 ± 0.1 | 29 |

| e-2.5B-PLA | 64.3 ± 0.1 | 157.9 ± 0.1 | 115.7 ± 0.3 | 19.9 ± 0.4 | 19.5 ± 0.2 | - |

| e-2.5B-PLA (23 h aged) | 58.7 ± 0.3 | 154.7 ± 0.2 | 101.3 ± 0.2 | 4.7 ± 0.3 | 27.3 ± 0.2 | 25 |

| e-2.5B-PLA (90 h aged) | 58.6 ± 0.3 | 155.1 ± 0.2 | / | / | 27.4 ± 0.1 | 30 |

| e-5B-PLA | 61.6 ± 0.2 | 157.0 ± 0.3 | 113.7 ± 0.5 | 17.9 ± 0.5 | 24.7 ± 0.3 | 7.6 ± 0.2 |

| e-5B-PLA (23 h aged) | 55.9 ± 0.4 | 156.7 ± 0.4 | 103.5 ± 0.2 | 18.2 ± 0.3 | 24.3 ± 0.4 | 6.9 ± 0.0 |

| e-5B-PLA (90 h aged) | 59.3 ± 0.3 | 155.0 ± 0.2 | 110.4 ± 0.6 | 20.4 ± 0.3 | 27.7 ± 0.4 | 8.2 ± 0.1 |

| Entry | Sample | Mn (kDa) | MW (kDa) | PDI |

|---|---|---|---|---|

| 1 | r-PLA | 59.3 | 113.1 | 1.9 |

| 2 | r-PLA (23 h aged) | 54.9 | 99.5 | 1.8 |

| 3 | r-PLA (90 h aged) | 49.3 | 94.3 | 1.9 |

| 4 | e-r-PLA | 42.7 | 101.6 | 2.4 |

| 5 | e-r-PLA (23 h aged) | 47.3 | 97.9 | 2.1 |

| 6 | e-r-PLA (90 h aged) | 43.2 | 89.8 | 2.1 |

| 7 | e-1B-PLA | 41.5 | 101.2 | 1.8 |

| 8 | e-1B-PLA (23 h aged) | 51.7 | 94.5 | 2.1 |

| 9 | e-1B-PLA (90 h aged) | 50.7 | 89.6 | 1.8 |

| 10 | e-2.5B-PLA | 47.3 | 101 | 2.1 |

| 11 | e-2.5B-PLA (23 h aged) | 41.1 | 85.7 | 2.1 |

| 12 | e-2.5B-PLA (90 h aged) | 48.5 | 85.5 | 1.8 |

| 13 | e-5B-PLA | 47.1 | 97.7 | 2.1 |

| 14 | e-5B-PLA (23 h aged) | 42.0 | 79.0 | 1.9 |

| 15 | e-5B-PLA (90 h aged) | 41.5 | 80.5 | 1.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botta, C.; Grottola, C.M.; Amato, D.; Acocella, M.R. Biochar as Sustainable Filler of Recycled Polylactic Acid (PLA): A New Generation of Processable Biocomposites. Polymers 2024, 16, 3347. https://doi.org/10.3390/polym16233347

Botta C, Grottola CM, Amato D, Acocella MR. Biochar as Sustainable Filler of Recycled Polylactic Acid (PLA): A New Generation of Processable Biocomposites. Polymers. 2024; 16(23):3347. https://doi.org/10.3390/polym16233347

Chicago/Turabian StyleBotta, Chiara, Corinna Maria Grottola, Davide Amato, and Maria Rosaria Acocella. 2024. "Biochar as Sustainable Filler of Recycled Polylactic Acid (PLA): A New Generation of Processable Biocomposites" Polymers 16, no. 23: 3347. https://doi.org/10.3390/polym16233347

APA StyleBotta, C., Grottola, C. M., Amato, D., & Acocella, M. R. (2024). Biochar as Sustainable Filler of Recycled Polylactic Acid (PLA): A New Generation of Processable Biocomposites. Polymers, 16(23), 3347. https://doi.org/10.3390/polym16233347