Influence of Polymer Nature on Electroadhesion

Abstract

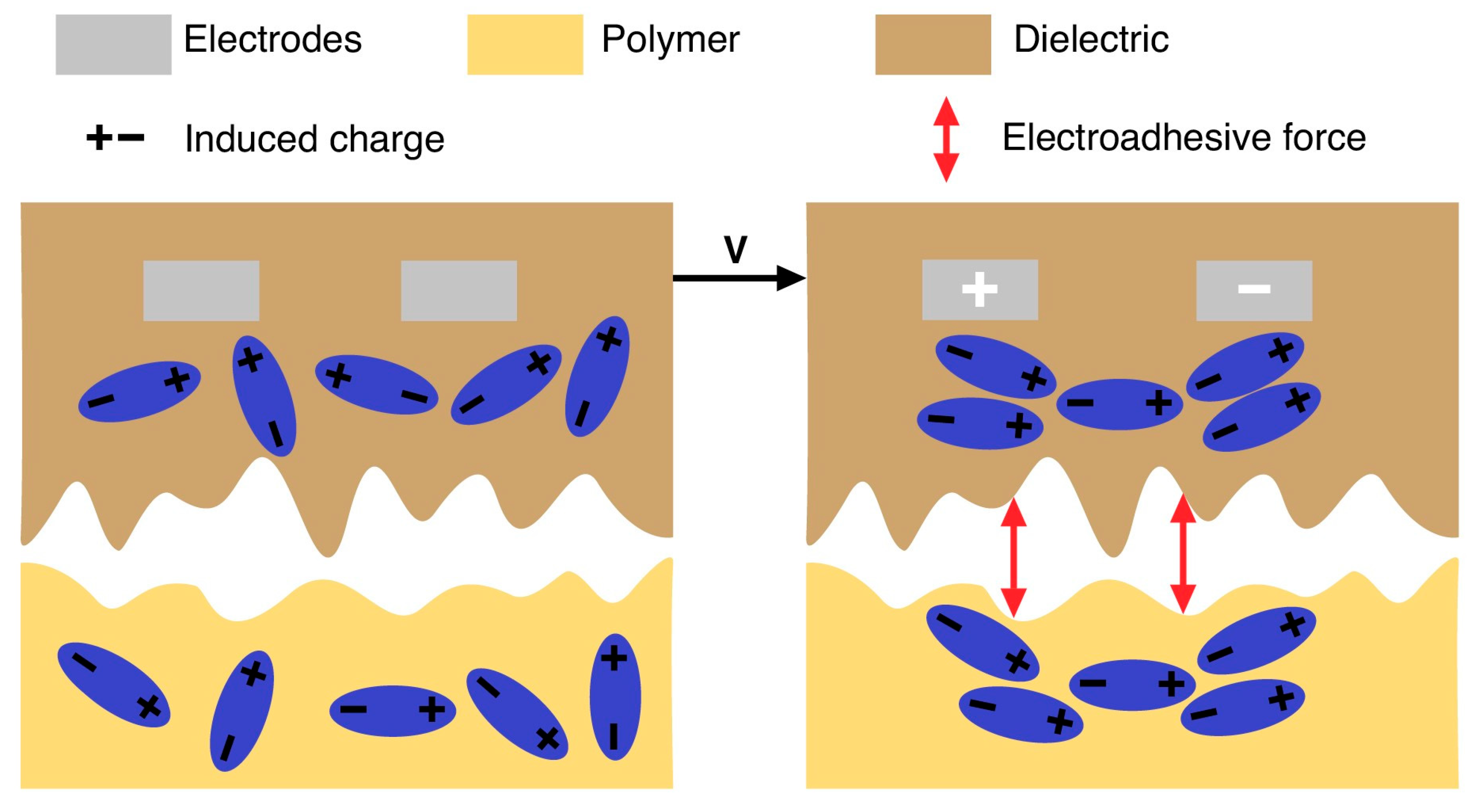

1. Introduction

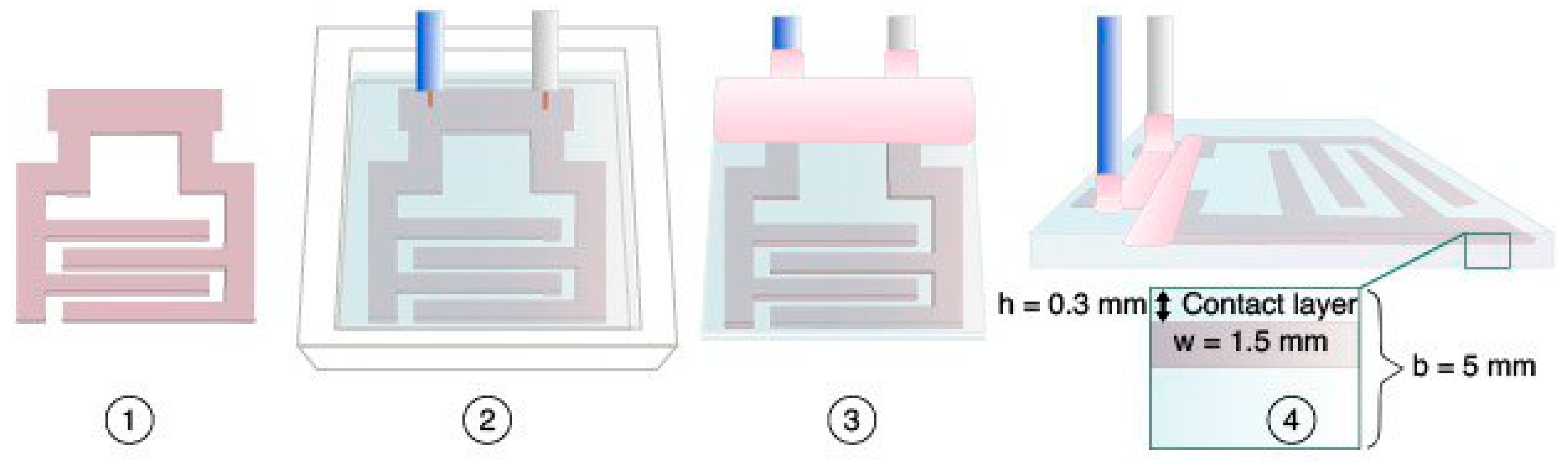

2. Materials and Methods

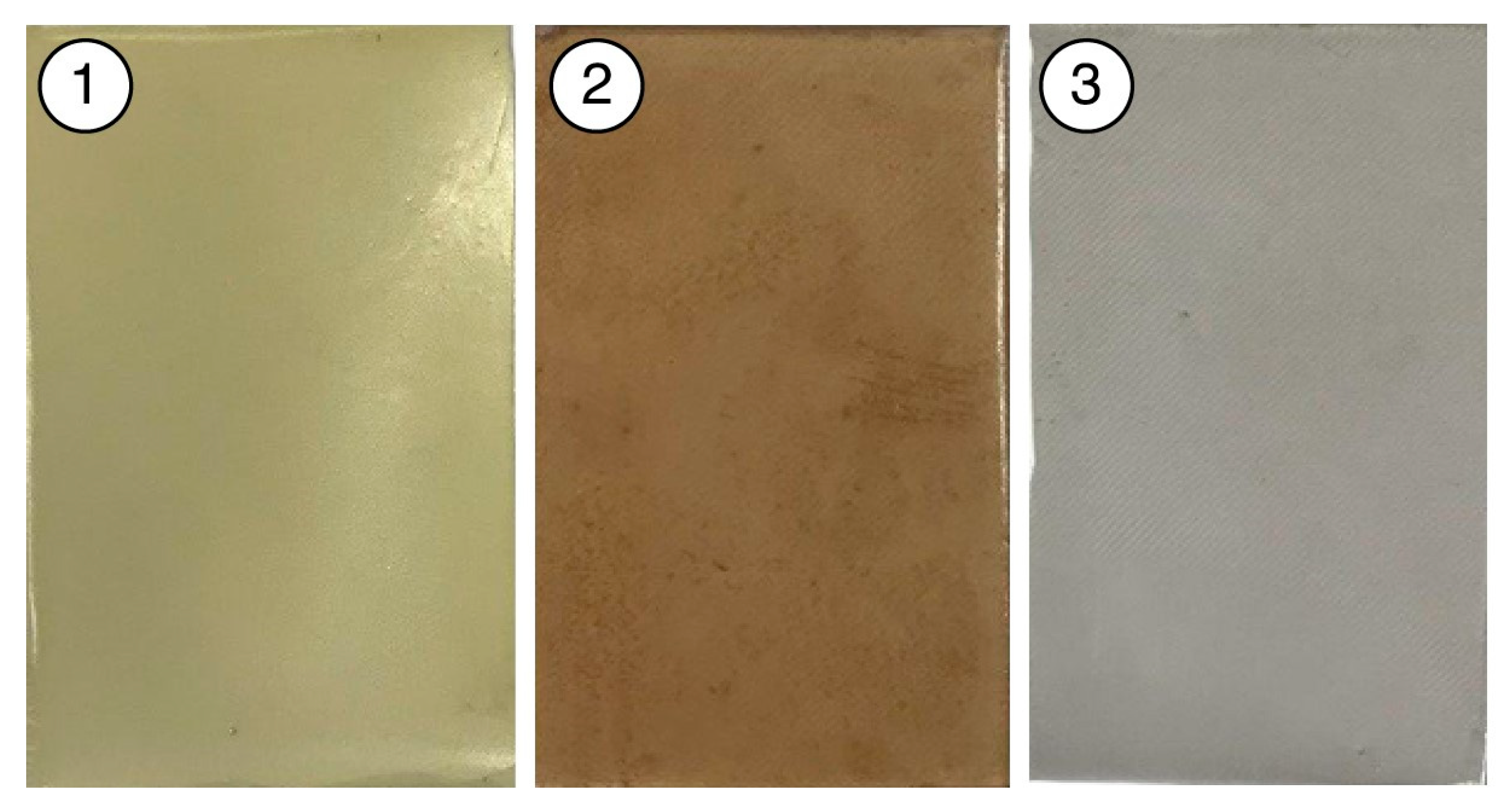

2.1. Materials

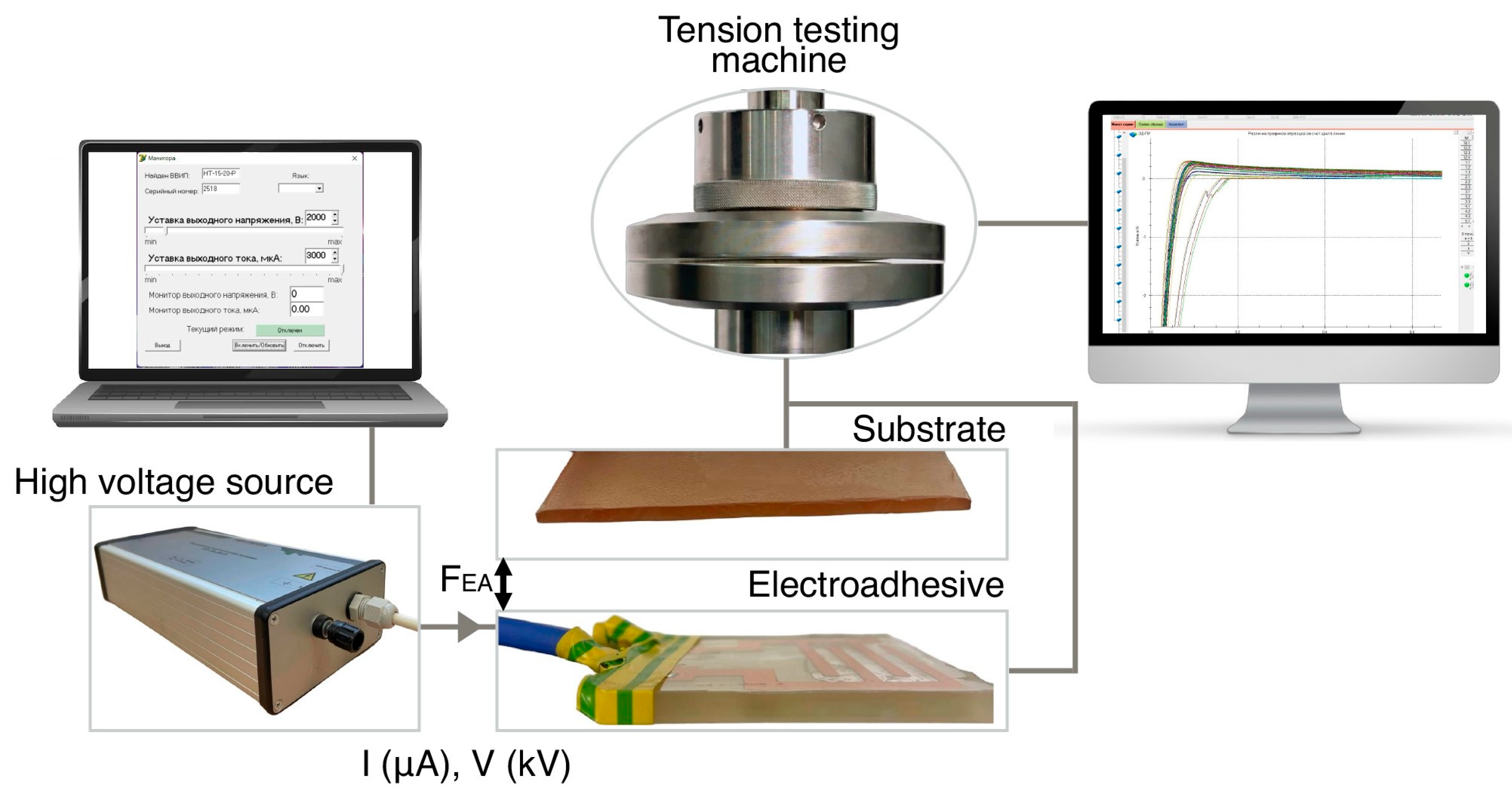

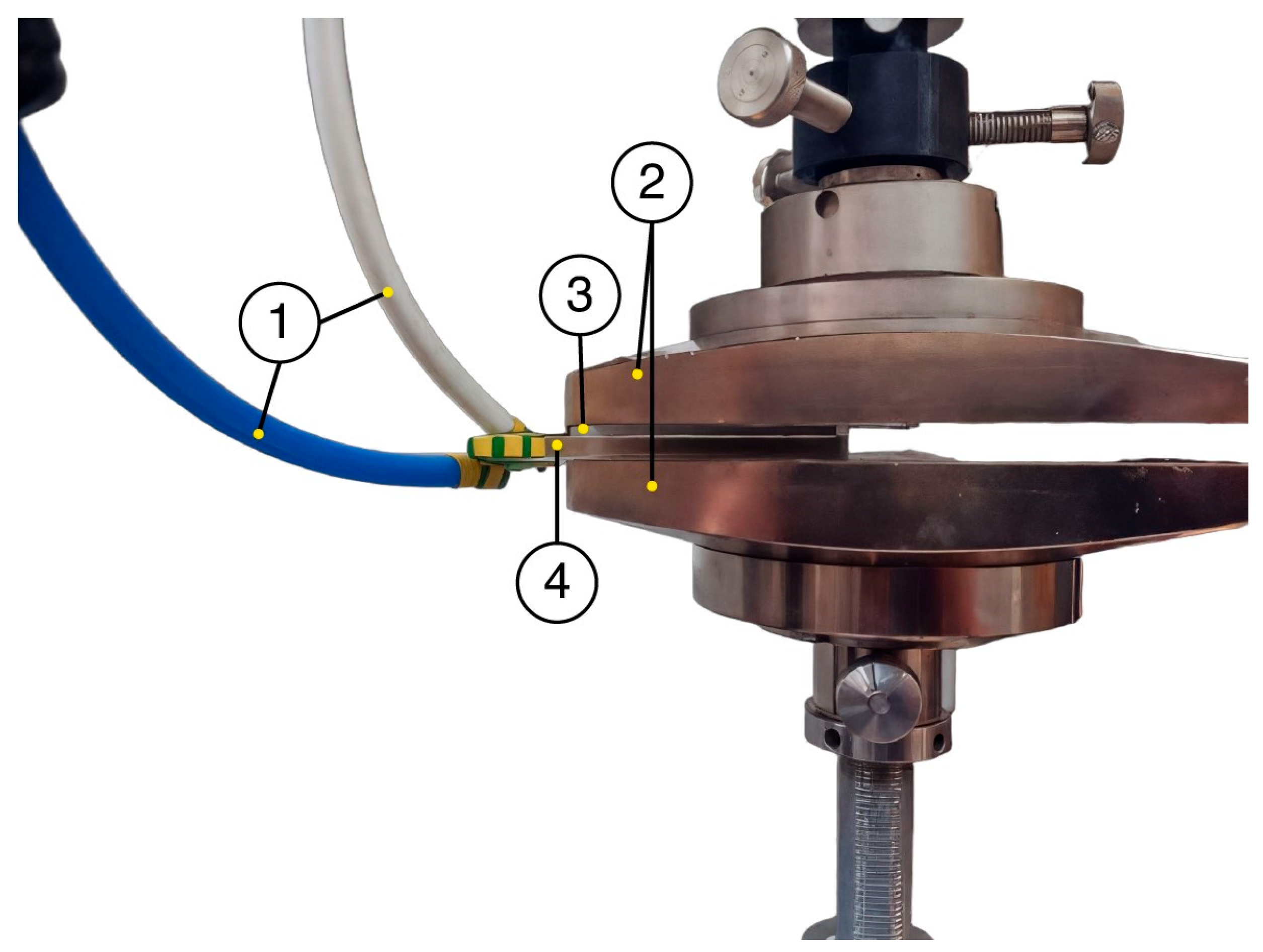

2.2. Methods

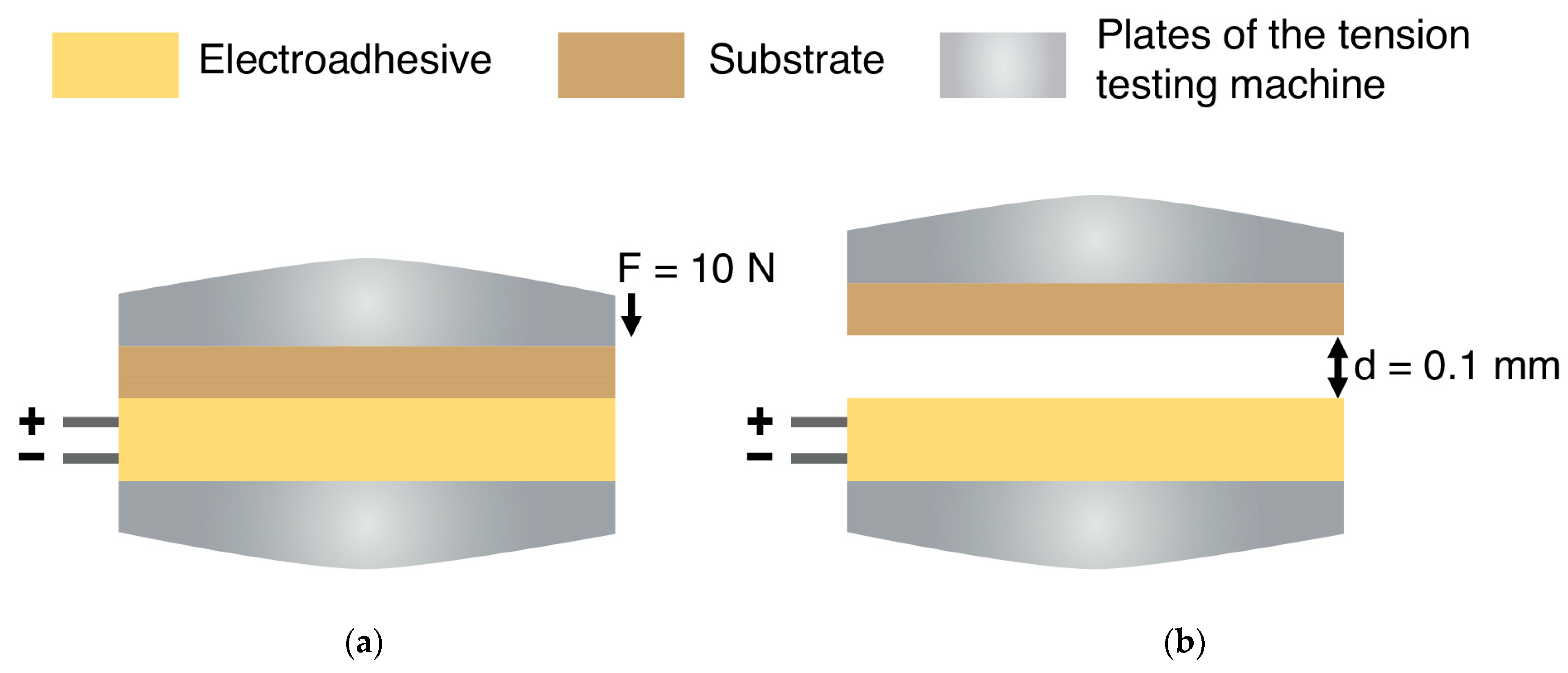

- (1)

- Bring the electroadhesive and substrate into contact with a preload of 10 N.

- (2)

- Apply an electric voltage in the range from 2 to 9 kV.

- (3)

- Charge the electroadhesive and plate for 30 s.

- (4)

- Perform a normal tear-off at a speed of 2 mm/min without removing the electric voltage.

- (5)

- Switch off the current source and discharge the electroadhesive and substrate for 120 s.

- (1)

- Set the gap between the electroadhesive and the substrate to 0.1 mm.

- (2)

- Turn on the movement of the crosshead with a minimum breakaway speed of 0.000001 mm/hour.

- (3)

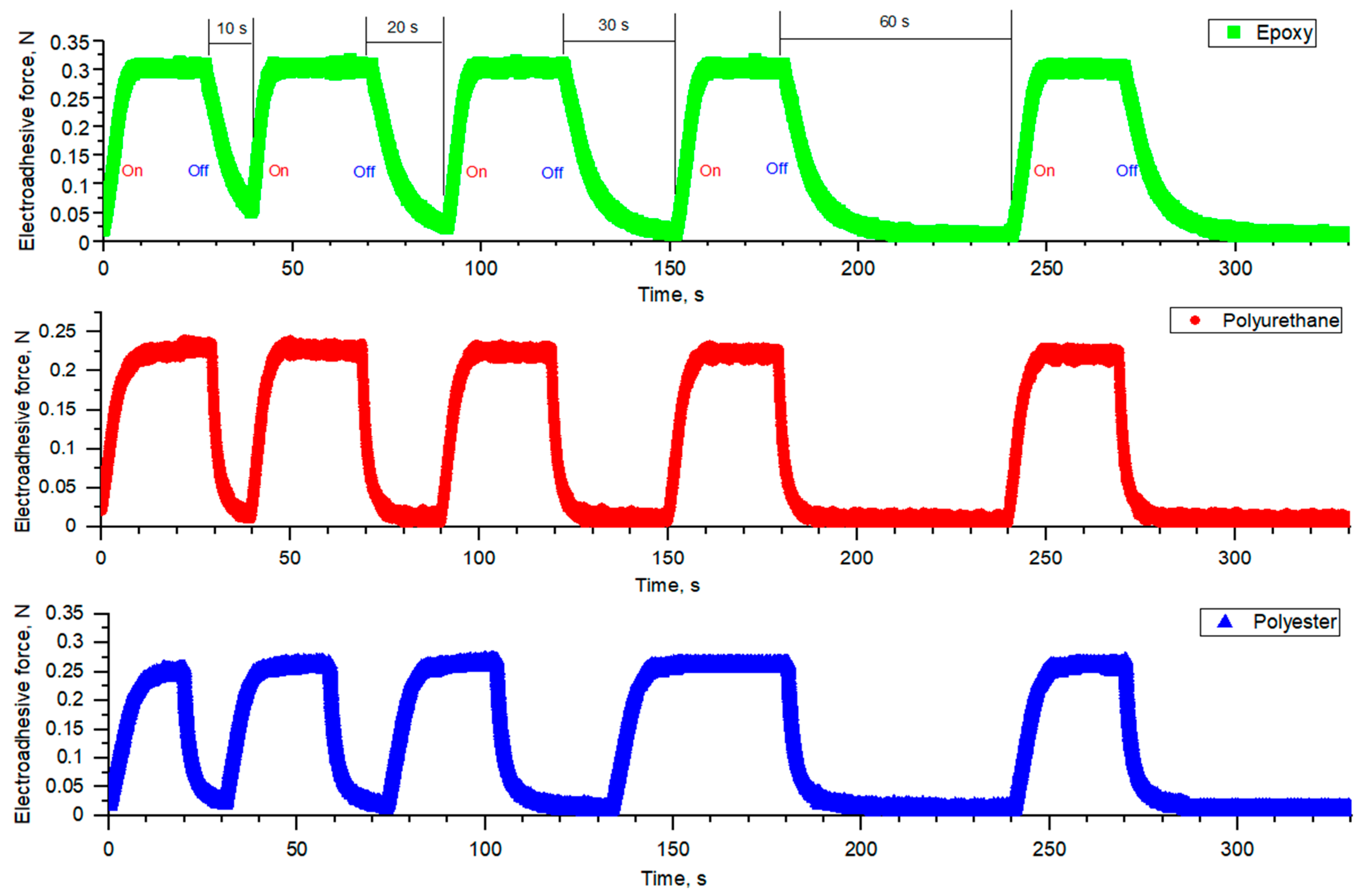

- Alternately apply and remove electrical voltage in the range from 2 to 9 kV with discharge intervals of 10, 20, 30 and 60 s (the charging of the surfaces of the electroadhesive and substrate takes 30 s).

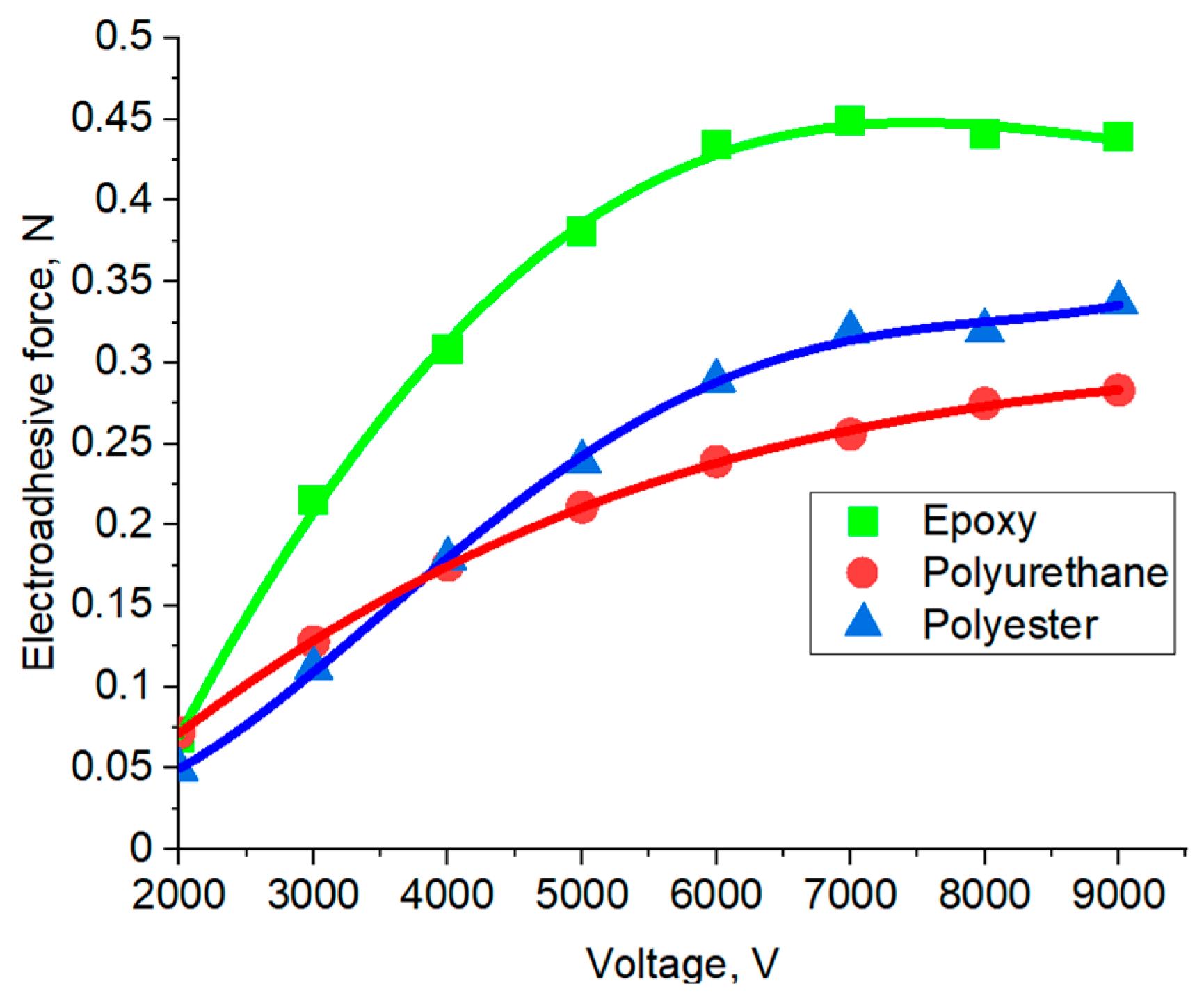

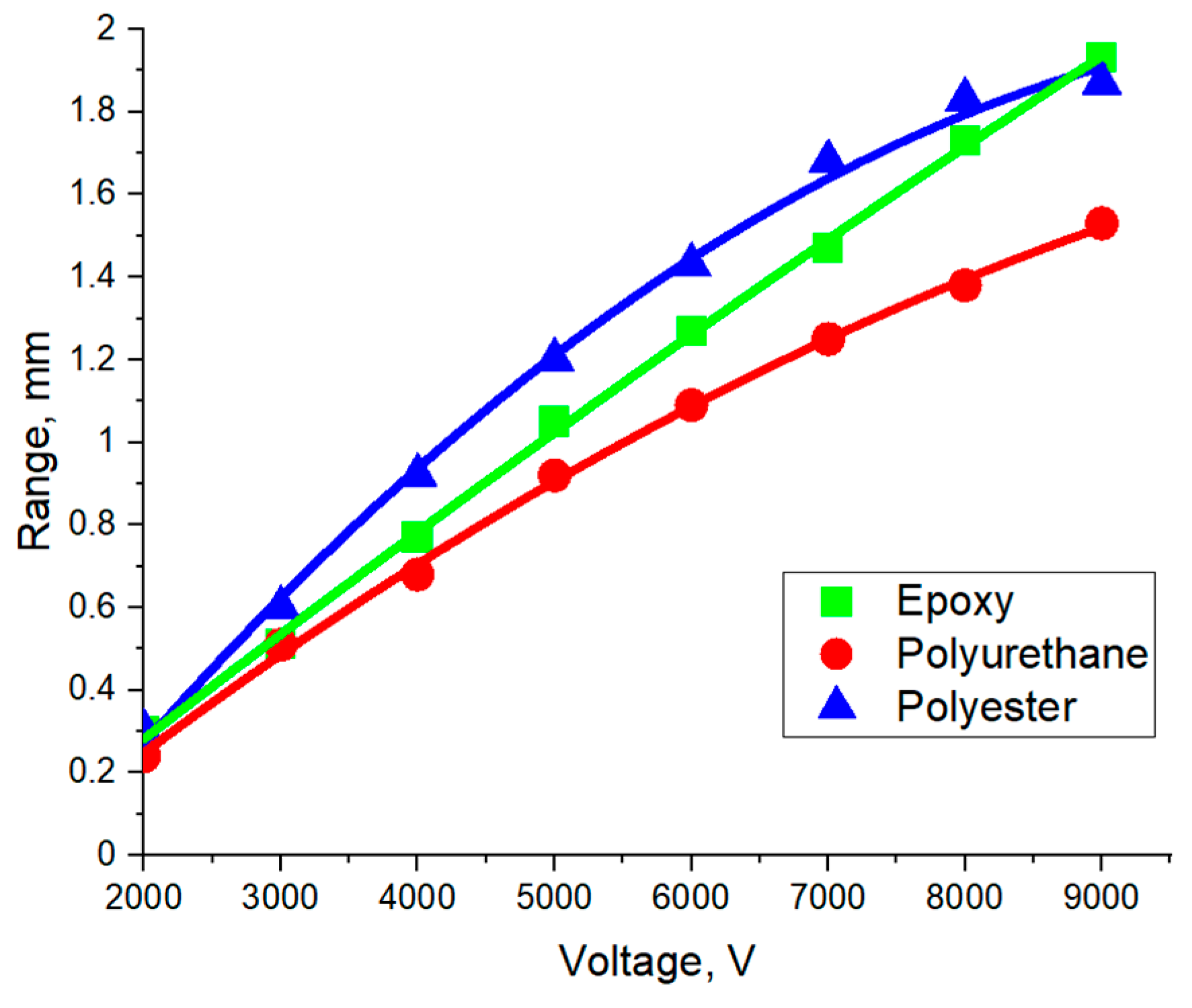

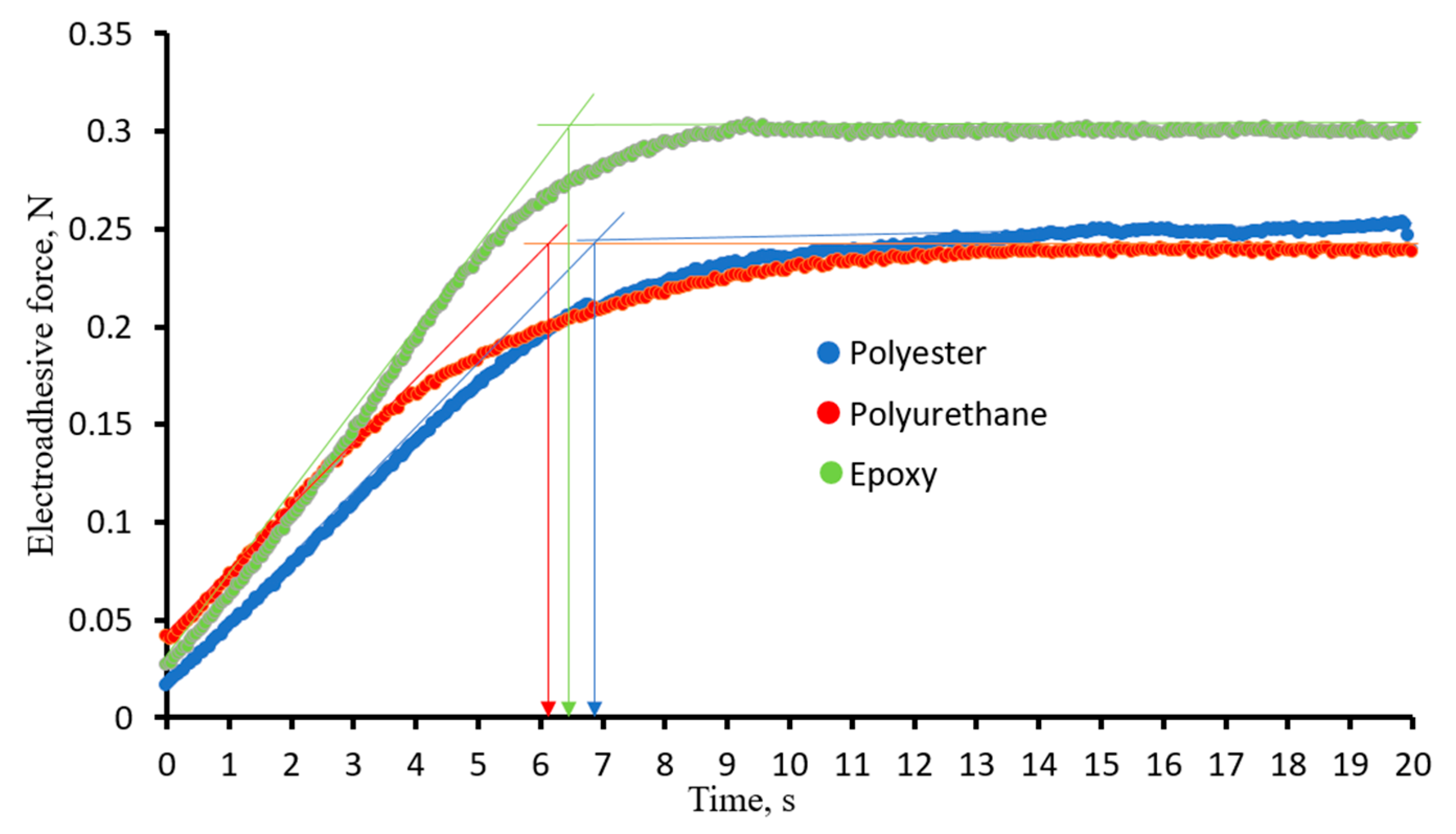

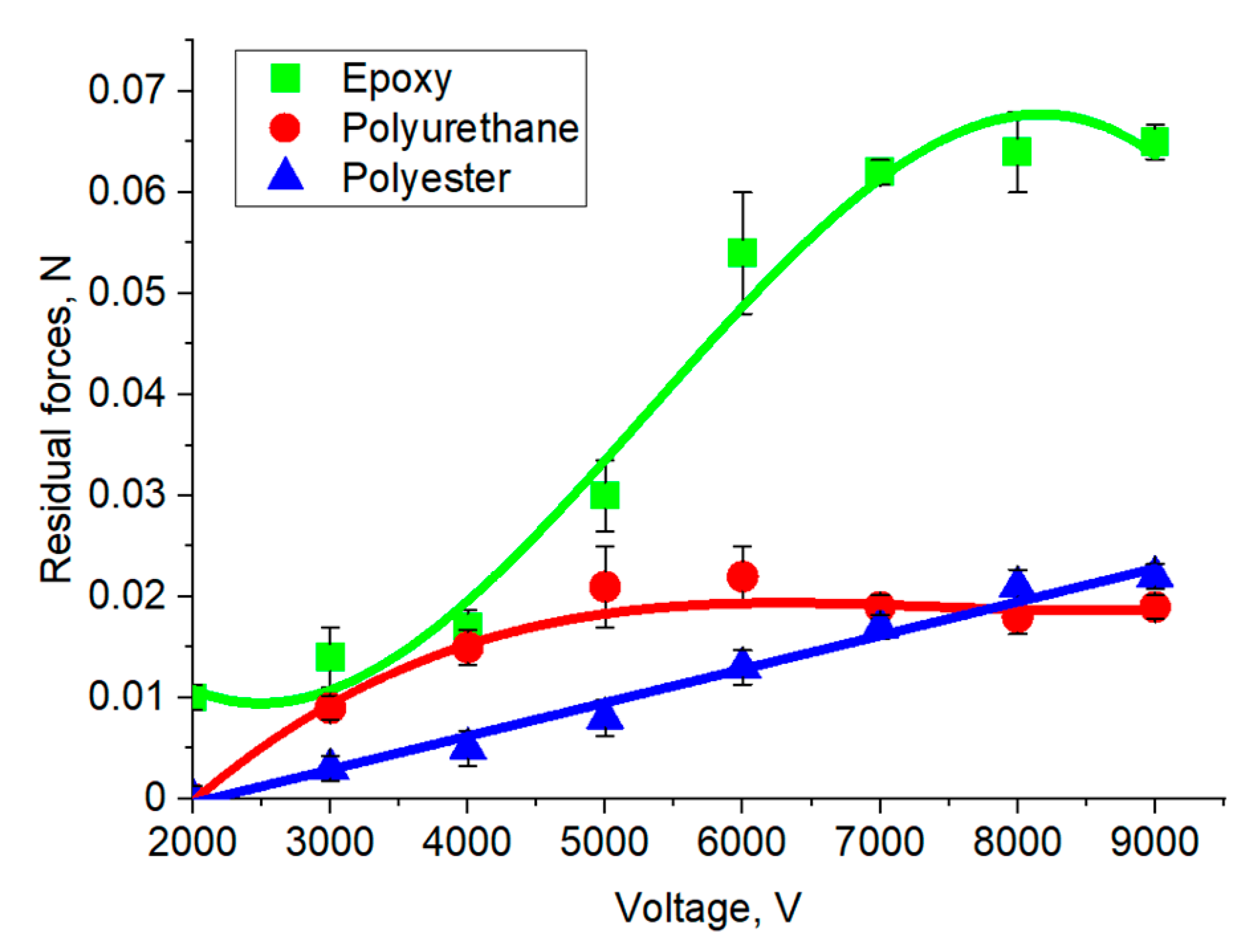

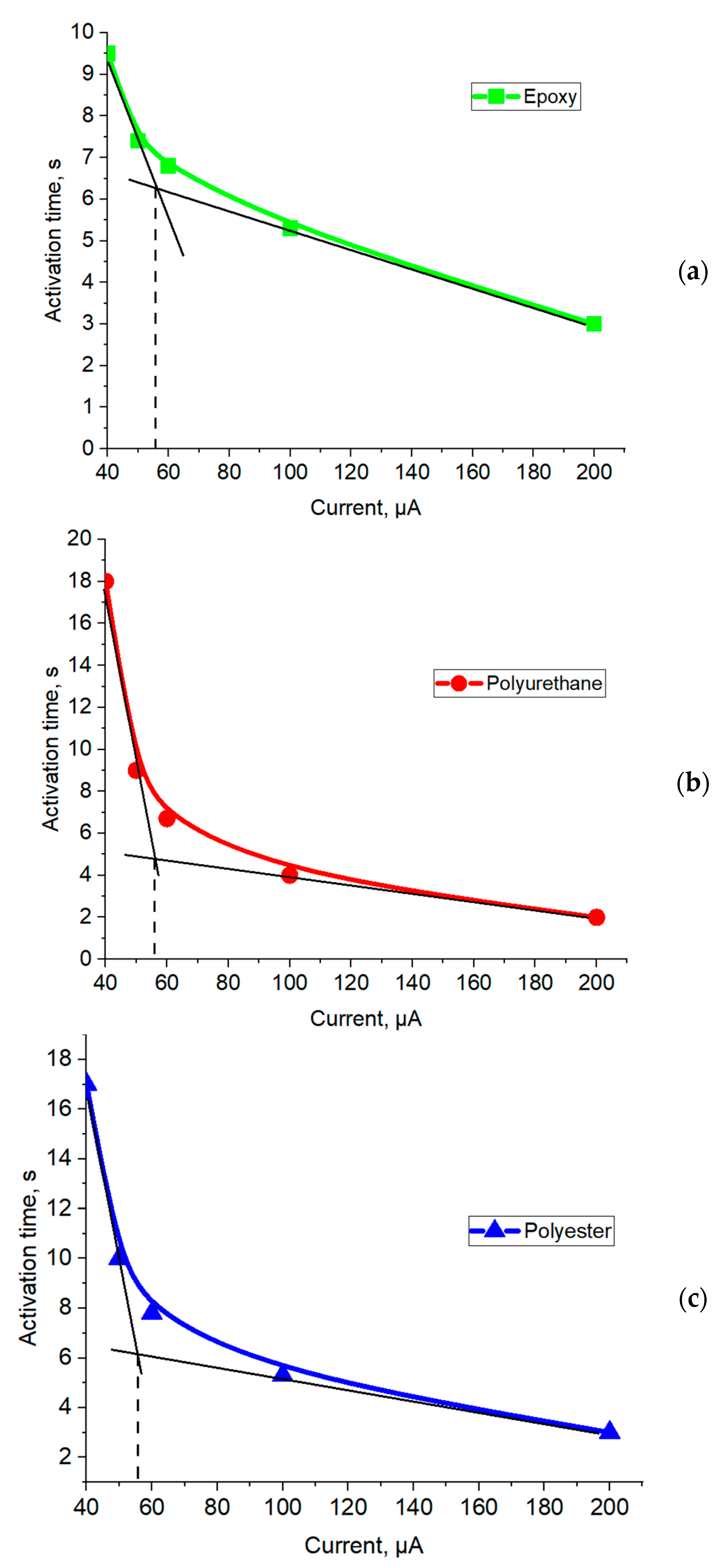

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, J.; Leng, J.; Rossiter, J. Electroadhesion Technologies for Robotics: A Comprehensive Review. IEEE Trans. Robot. 2020, 36, 313–327. [Google Scholar] [CrossRef]

- Guo, J.; Tailor, M.; Bamber, T.; Chamberlain, M.; Justham, L.; Jackson, M. Investigation of Relationship between Interfacial Electroadhesive Force and Surface Texture. J. Phys. D Appl. Phys. 2016, 49, 035303. [Google Scholar] [CrossRef]

- Ruffatto, D.; Shah, J.; Spenko, M. Optimization of Electrostatic Adhesives for Robotic Climbing and Manipulation. In Proceedings of the ASME 2012 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference: 36th Mechanisms and Robotics Conference, Parts A and B, Chicago, IL, USA, 12–15 August 2012; American Society of Mechanical Engineers: Chicago, IL, USA, 2012; Volume 4, pp. 1143–1152. [Google Scholar]

- Guo, J.; Elgeneidy, K.; Xiang, C.; Lohse, N.; Justham, L.; Rossiter, J. Soft Pneumatic Grippers Embedded with Stretchable Electroadhesion. Smart Mater. Struct. 2018, 27, 055006. [Google Scholar] [CrossRef]

- Chen, R.; Liu, F.; Wang, H.; Zhu, X.; Tao, X.; Zhang, S.; Jiang, G. Theoretical and Experimental Analyses of the Dynamic Electroadhesion Force. Extrem. Mech. Lett. 2022, 56, 101892. [Google Scholar] [CrossRef]

- Guo, J.; Bamber, T.; Chamberlain, M.; Justham, L.; Jackson, M. Optimization and Experimental Verification of Coplanar Interdigital Electroadhesives. J. Phys. D Appl. Phys. 2016, 49, 415304. [Google Scholar] [CrossRef]

- Dadkhah, M.; Ruffatto, D.; Zhao, Z.; Spenko, M. Increasing Adhesion via a New Electrode Design and Improved Manufacturing in Electrostatic/Microstructured Adhesives. J. Electrost. 2018, 91, 48–55. [Google Scholar] [CrossRef]

- Fimbel, A.; Abensur, T.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers. Polymers 2021, 14, 24. [Google Scholar] [CrossRef]

- Nakamura, T.; Yamamoto, A. Modeling and Control of Electroadhesion Force in DC Voltage. Robomech. J. 2017, 4, 18. [Google Scholar] [CrossRef]

- Choi, K.; Chan Kim, Y.; Sun, H.; Kim, S.-H.; Yoo, J.W.; Park, I.-K.; Lee, P.-C.; Choi, H.J.; Choi, H.R.; Kim, T.; et al. Quantitative Electrode Design Modeling of an Electroadhesive Lifting Device Based on the Localized Charge Distribution and Interfacial Polarization of Different Objects. ACS Omega 2019, 4, 7994–8000. [Google Scholar] [CrossRef]

- Park, S.; Chang, H.; Kim, J.; Gwak, Y.; Moon, J. Superior Electroadhesion Force with Permittivity-Engineered Bilayer Films Using Electrostatic Simulation and Machine Learning Approaches. Sci. Rep. 2024, 14, 17026. [Google Scholar] [CrossRef]

- Park, S.; Shintake, J.; Piskarev, Y.; Wei, Y.; Joshipura, I.; Frey, E.; Neumann, T.; Floreano, D.; Dickey, M.D. Stretchable and Soft Electroadhesion Using Liquid-Metal Subsurface Microelectrodes. Adv. Mater. Technol. 2021, 6, 2100263. [Google Scholar] [CrossRef]

- Ciavarella, M.; Papangelo, A. A Simplified Theory of Electroadhesion for Rough Interfaces. Front. Mech. Eng. 2020, 6, 27. [Google Scholar] [CrossRef]

- Ruffatto, D.; Parness, A.; Spenko, M. Improving Controllable Adhesion on Both Rough and Smooth Surfaces with a Hybrid Electrostatic/Gecko-like Adhesive. J. R. Soc. Interface 2014, 11, 20131089. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.-J.; Hong, T.-H.; Lee, H.-J.; Kim, K. Optimal Design of the Electroadhesion Pad with a Dual-Insulating Layer for Climbing Robots. Actuators 2022, 11, 36. [Google Scholar] [CrossRef]

- Gao, X.; Cao, C.; Guo, J.; Conn, A. Elastic Electroadhesion with Rapid Release by Integrated Resonant Vibration. Adv. Mater. Technol. 2019, 4, 1800378. [Google Scholar] [CrossRef]

- Xiang, C.; Guan, Y.; Zhu, H.; Lin, S.; Song, Y. All 3D Printed Ready-to-Use Flexible Electroadhesion Pads. Sens. Actuators A Phys. 2022, 344, 113747. [Google Scholar] [CrossRef]

- Shultz, C.D.; Peshkin, M.A.; Colgate, J.E. Surface Haptics via Electroadhesion: Expanding Electrovibration with Johnsen and Rahbek. In Proceedings of the 2015 IEEE World Haptics Conference (WHC), Evanston, IL, USA, 22–26 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 57–62. [Google Scholar]

- Li, Q.; Le Duigou, A.; Guo, J.; Thakur, V.K.; Rossiter, J.; Liu, L.; Leng, J.; Scarpa, F. Biobased and Programmable Electroadhesive Metasurfaces. ACS Appl. Mater. Interfaces 2022, 14, 47198–47208. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Guo, J. Electroadhesion for Soft Adhesive Pads and Robotics: Theory and Numerical Results. Soft Matter 2019, 15, 8032–8039. [Google Scholar] [CrossRef]

- Tang, H.; Beebe, D.J. A Microfabricated Electrostatic Haptic Display for Persons with Visual Impairments. IEEE Trans. Rehabil. Eng. 1998, 6, 241–248. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Guo, J.; Conn, A. De-Electroadhesion of Flexible and Lightweight Materials: An Experimental Study. Appl. Sci. 2019, 9, 2796. [Google Scholar] [CrossRef]

- Rajagopalan, P.; Muthu, M.; Liu, Y.; Luo, J.; Wang, X.; Wan, C. Advancement of Electroadhesion Technology for Intelligent and Self-Reliant Robotic Applications. Adv. Intell. Syst. 2022, 4, 2200064. [Google Scholar] [CrossRef]

- Xie, G.; Wang, W.; Zhao, X.; Wang, H. Low-Voltage Electroadhesive Pad with Thin Insulation Layer Fabricated by Parylene Deposition. In Proceedings of the 2019 IEEE 9th Annual International Conference on CYBER Technology in Automation Control and Intelligent Systems (CYBER), Suzhou, China, 29 July–2 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 197–202. [Google Scholar]

- AliAbbasi, E.; Muzammil, M.; Sirin, O.; Lefévre, P.; Martinsen, Ø.G.; Basdogan, C. Effect of Finger Moisture on Tactile Perception of Electroadhesion. IEEE Trans. Haptics 2024. online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Sun, X.; Wang, D.; Liu, Y.; Zhang, Y. Effect of Electrostatic Tactile Feedback on Accuracy and Efficiency of Pan Gestures on Touch Screens. IEEE Trans. Haptics 2018, 11, 51–60. [Google Scholar] [CrossRef] [PubMed]

- Plyusnina, I.O.; Nikulova, U.V.; Khasbiullin, R.R.; Shapagin, A.V. Regulation of the Phase Structure in the Crystallizing Curing System PCL–DGEBA. Polymers 2024, 16, 2695. [Google Scholar] [CrossRef] [PubMed]

- Ponomarenko, A.D.; Nikulova, U.V.; Shapagin, A.V. Phase Equilibria and Interdiffusion in the Ternary System Epoxy Oligomer–Polysulfone–Alkyl Glycidyl Ether. Polymers 2023, 16, 130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharov, K.I.; Stepanenko, V.Y.; Nikulova, U.V.; Shapagin, A.V. Influence of Polymer Nature on Electroadhesion. Polymers 2024, 16, 3344. https://doi.org/10.3390/polym16233344

Sharov KI, Stepanenko VY, Nikulova UV, Shapagin AV. Influence of Polymer Nature on Electroadhesion. Polymers. 2024; 16(23):3344. https://doi.org/10.3390/polym16233344

Chicago/Turabian StyleSharov, Konstantin I., Valentina Yu. Stepanenko, Uliana V. Nikulova, and Aleksey V. Shapagin. 2024. "Influence of Polymer Nature on Electroadhesion" Polymers 16, no. 23: 3344. https://doi.org/10.3390/polym16233344

APA StyleSharov, K. I., Stepanenko, V. Y., Nikulova, U. V., & Shapagin, A. V. (2024). Influence of Polymer Nature on Electroadhesion. Polymers, 16(23), 3344. https://doi.org/10.3390/polym16233344