Improvement in an Analytical Approach for Modeling the Melting Process in Single-Screw Extruders

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

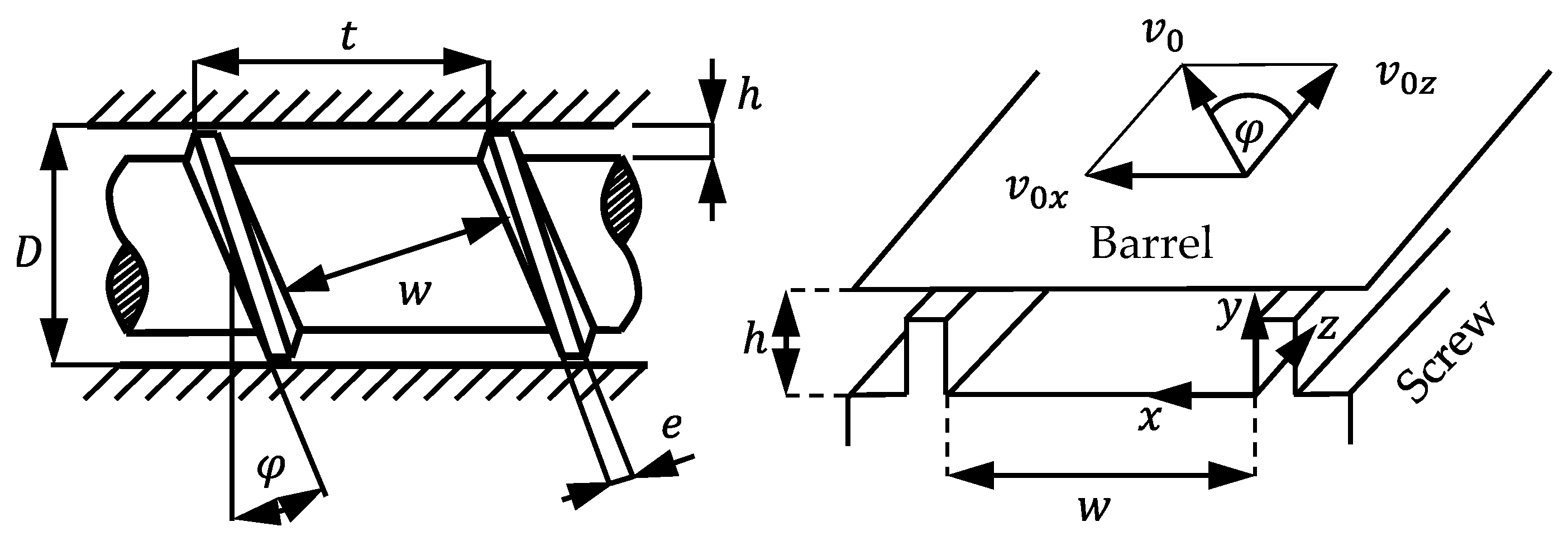

2.2. Extruders and Screws

2.3. Investigation Method

2.3.1. Determination of the Delay Zone Length

2.3.2. Determination of the Melting Profile

2.4. Experimental Design

2.4.1. Investigation of the Delay Zone Length

2.4.2. Investigation of Solid Bed Dynamics

2.5. Modeling

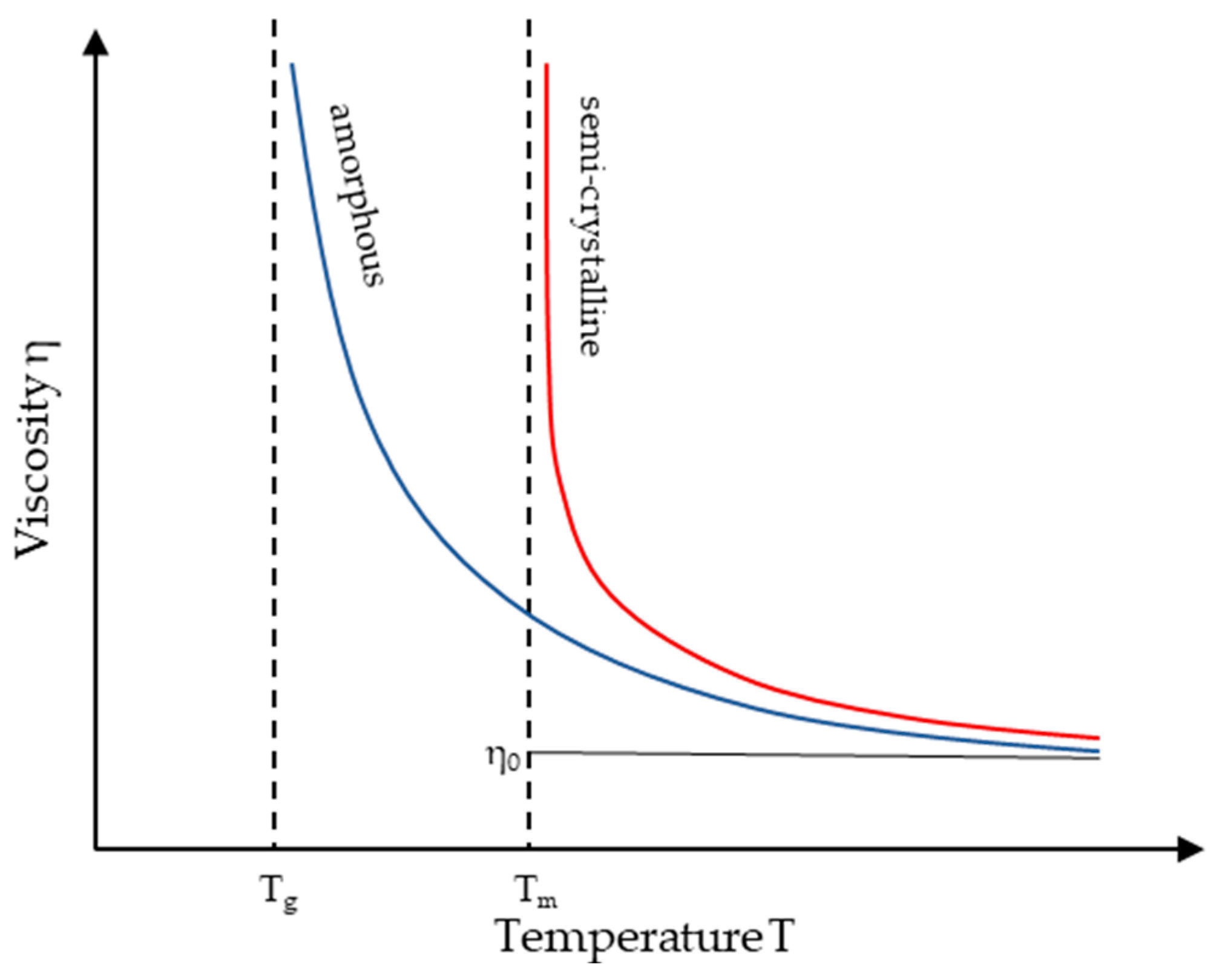

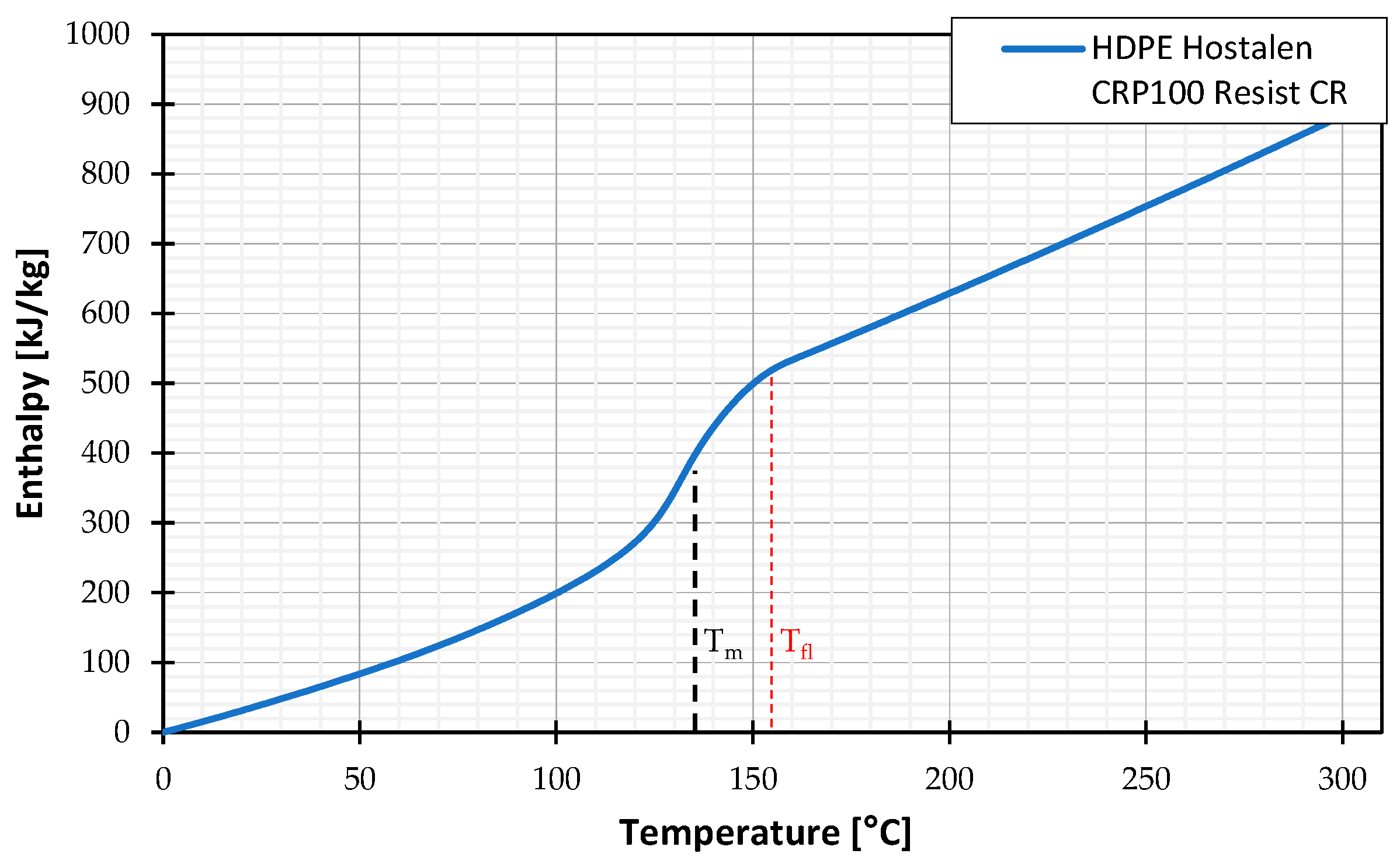

2.5.1. Definition of the Flow Temperature

2.5.2. Modeling of the Delay Zone Length

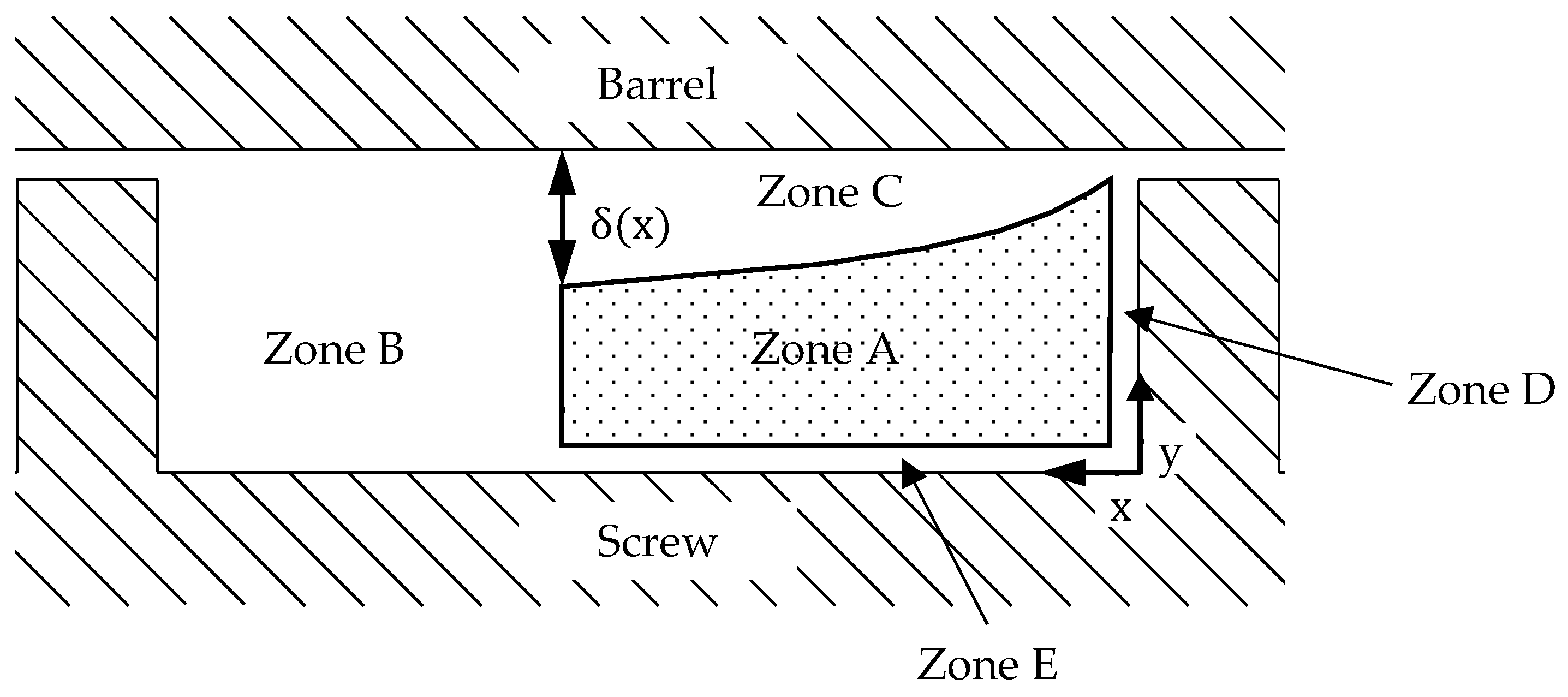

2.5.3. Modeling of Solid Bed Dynamics

3. Results

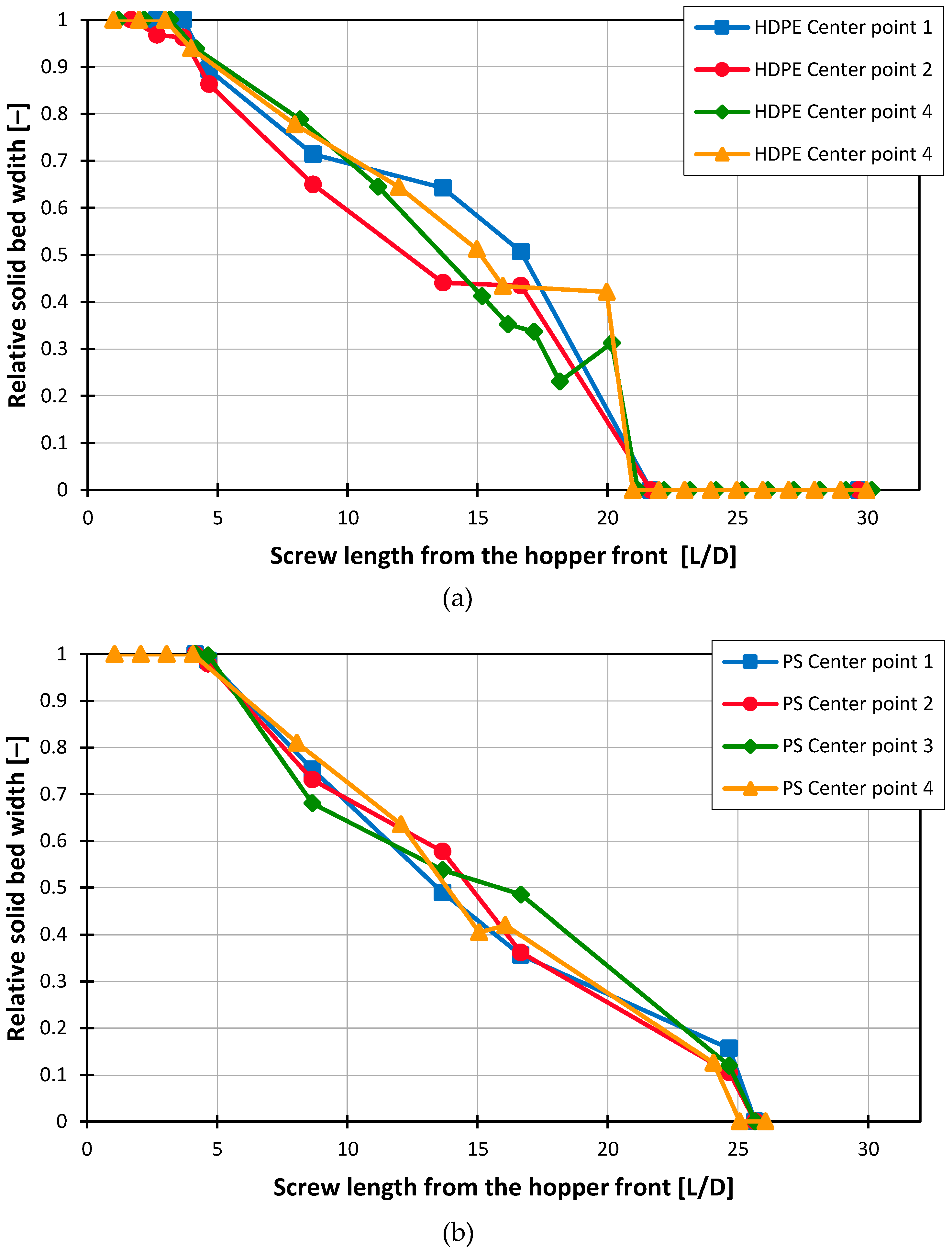

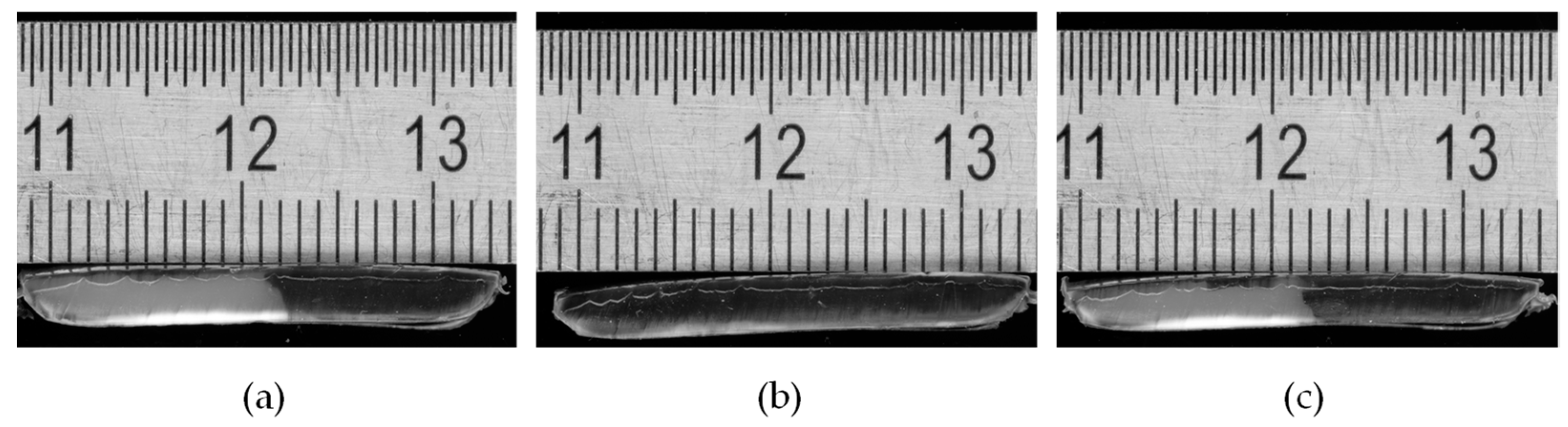

3.1. Reproducibility of the Results

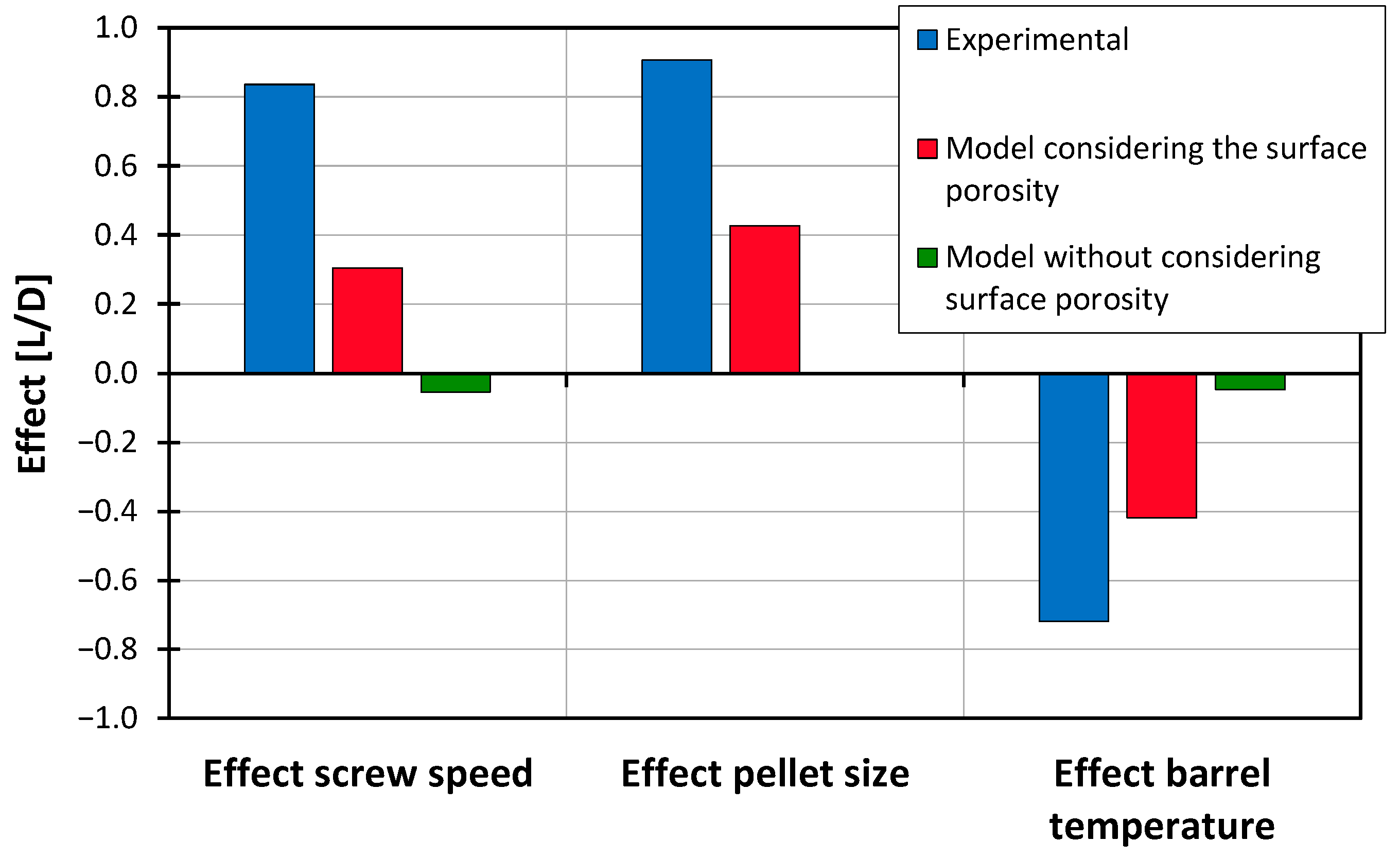

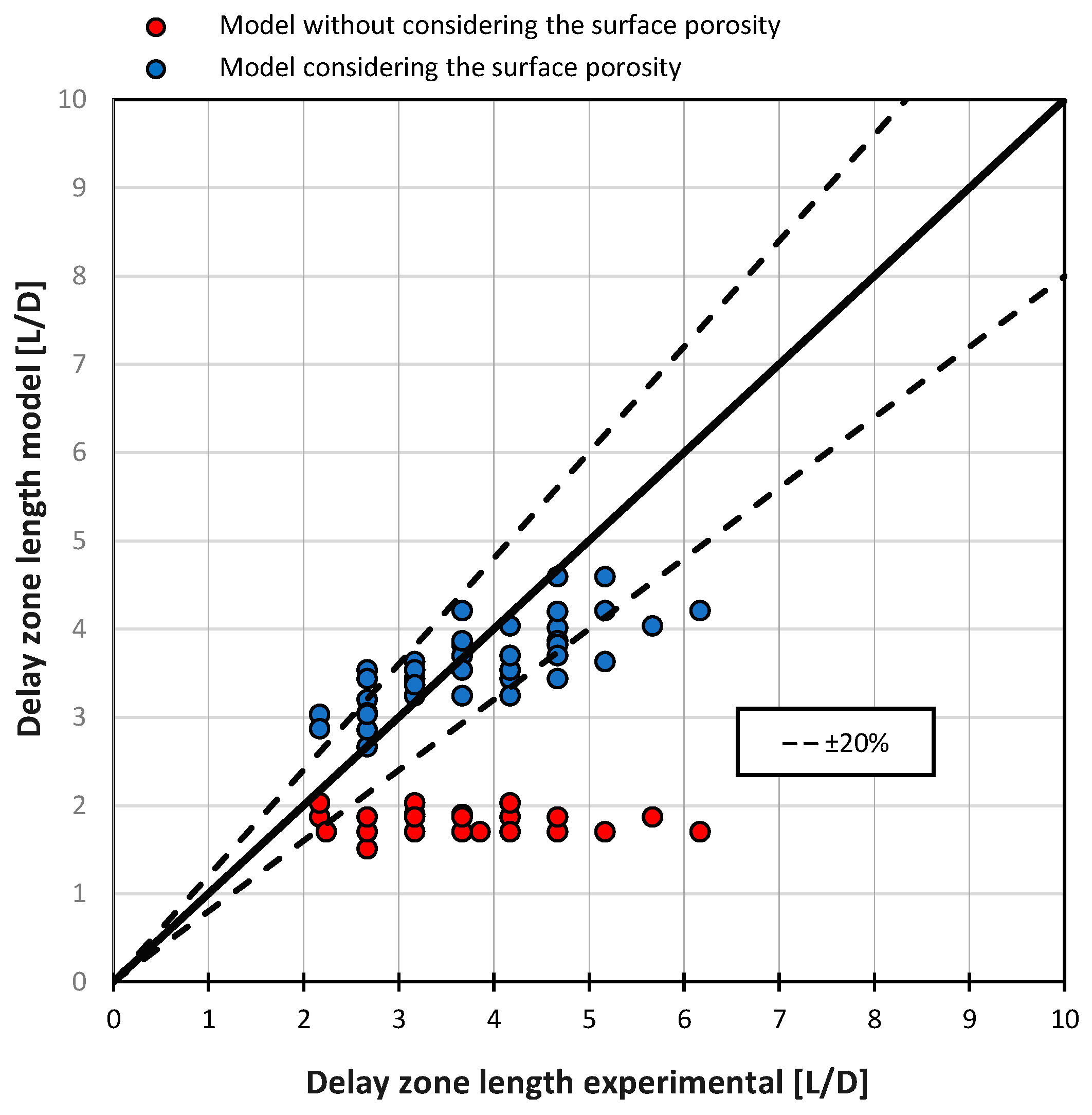

3.2. Model Validation Regarding the Delay Zone Length

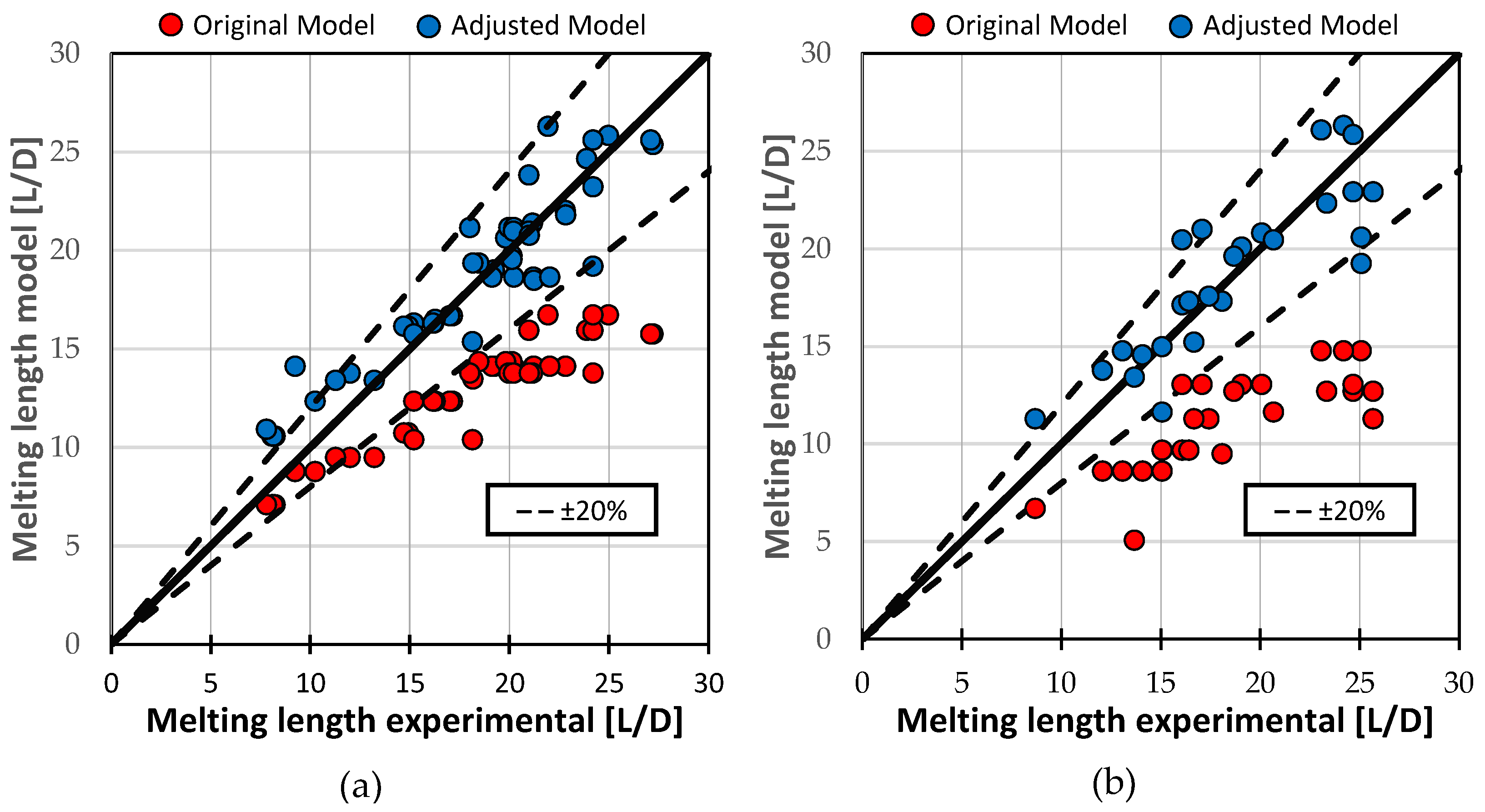

3.3. Model Validation Regarding the Solid Bed Dynamics

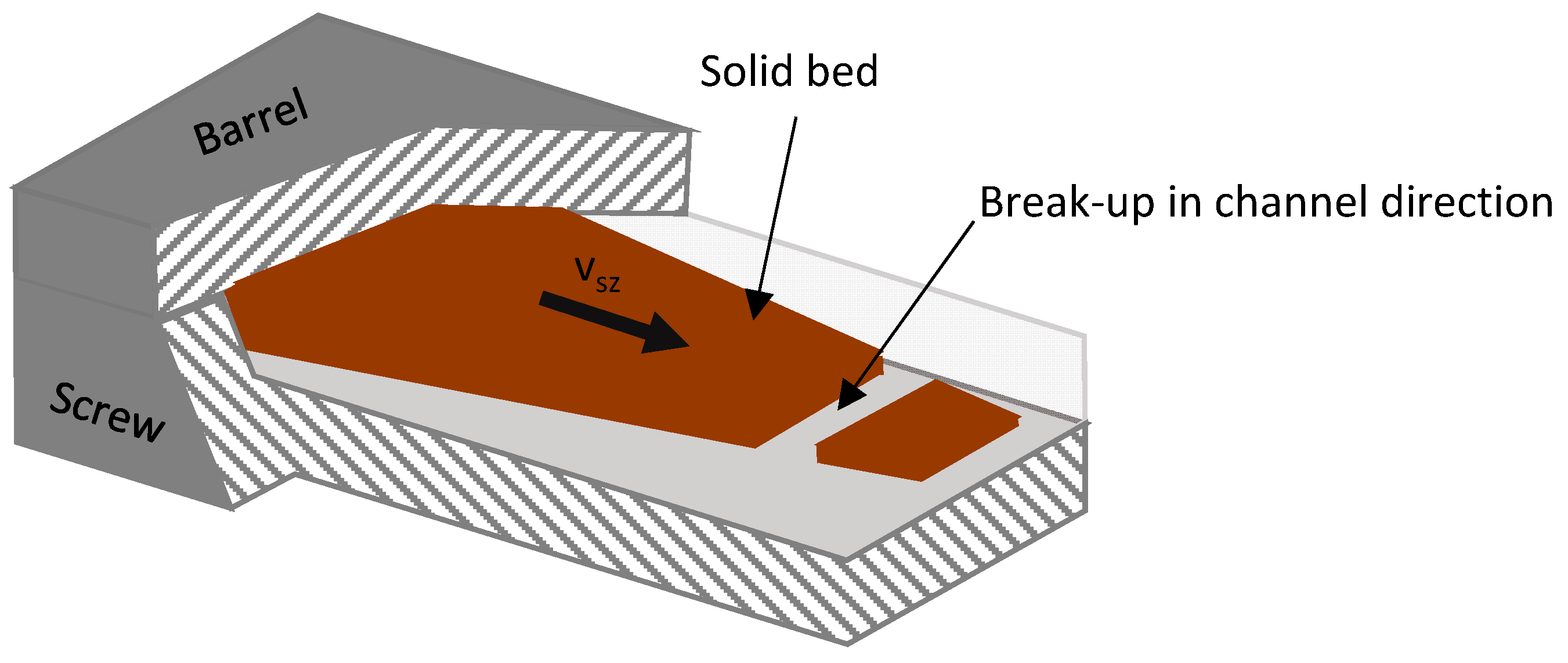

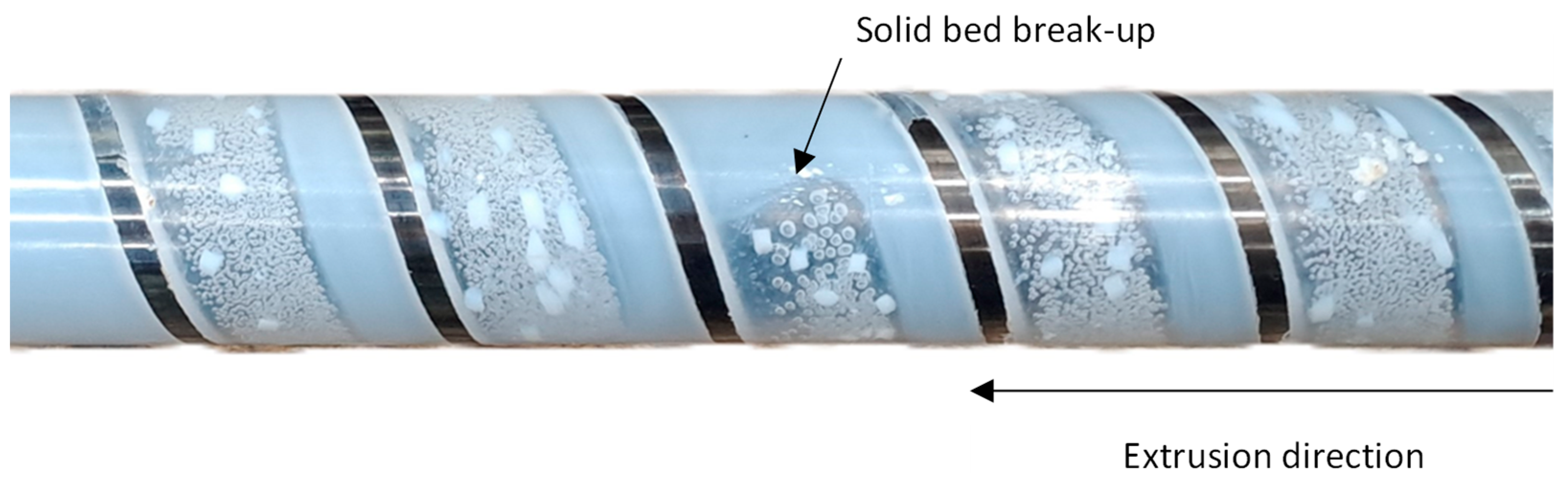

Occurrence of Solid Bed Break-Ups

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| Character | Meaning |

| CFD | Computational Fluid Dynamics |

| DEM | Discrete Element Method |

| DSC | Differential Scanning Calorimetry |

| FEM | Finite Element Method |

| FVM | Finite Volume Method |

| HDPE | High Density Polyethylen |

| KTP | Kunststofftechnik Paderborn |

| MAE | Mean Absolute Error |

| MaxAE | Maximum Absolute Error |

| MSE | Mean Squared Error |

| PS | Polystyrene |

| Roman characters | |

| Character | Meaning |

| a | Exponent for consideration of the solid bed dynamics |

| aS | Thermal diffusivity of the solid |

| c | Contour exponent of the melt film |

| c′ | Contour exponent of the melt film taking into account the leakage flow |

| D | Barrel diameter |

| dp | Pellet diameter |

| E | Empirically determined exponent |

| Er | Relaxation modulus |

| h | Screw channel height |

| hsb | Solid bed height |

| k1 | Parameter to take into account the temperature dependence of viscosity |

| L | Length |

| Heat flux into the solid bed | |

| Tfl | Flow temperature |

| Tg | Glass transition temperature |

| Tm | Crystallite melting temperature |

| Ts | Temperature of the solid |

| u | Normalized height of the solid bed |

| v0 | Cylinder circumferential speed |

| v0x | Cylinder circumferential speed in x-direction |

| v0z | Cylinder circumferential speed in z-direction |

| vsz | Velocity of the solid bed in z-direction |

| w | Channel width |

| Y | Normalized solid bed width |

| Z | Length of the channel interval |

| Greek characters | |

| Character | Meaning |

| α | Axial point factor |

| β | Slope parameter |

| δ | Melt film thickness |

| δ0 | Melt film thickness at the active flight |

| Average melt film thickness of the melting zone | |

| Δhm | Melting enthalpy |

| Δhs | Solid enthalpy |

| ε | Surface porosity |

| εs | Proportion of contact surface between granulate and cylinder |

| η | Shear viscosity |

| λs | Thermal conductivity of the melt |

| π | Normalized melting rate |

| ρb,0 | Density of the bulk material |

| ρb,channel | Density of the bulk material in the screw channel |

| ρm | Density of the melt |

| ρs | Density of the solid |

| φ | Helix angle |

| Ψ | Normalized melt film thickness |

| ΨS | Normalized melt film thickness over the flights |

References

- Chung, C.I. Extrusion of Polymers: Theory and Practice, 3rd ed.; Hanser: Munich, Germany, 2019. [Google Scholar]

- Viriyayuthakorn, M.; Kassahun, B. A three dimensional model for plasticating extrusion screw design. SPE-Antec Tech. Pap. 1985, 30, 81–84. [Google Scholar]

- Syrjäla, S. A New Approach for the Simulation of Melting in Extruders. Int. Commun. Heat Mass Transf. 2000, 27, 623–634. [Google Scholar] [CrossRef]

- Altınkaynak, A.; Gupta, M.; Spalding, M.A.; Crabtree, S.L. Melting in a Single Screw Extruder: Experiments and 3D Finite Element Simulations. Int. Polym. Process. 2011, 26, 182–196. [Google Scholar] [CrossRef]

- Karrenberg, G.; Wortberg, J. 3D-CFD-simulation of melting processes in a high-speed-extruder with solid-melt-separation. AIP Conf. Proc. 2014, 1593, 623–627. [Google Scholar]

- Karrenberg, G.; Neubrech, B.; Wortberg, J. CFD-Simulation der Kunststoffplastifizierung in einem Extruder mit durchgehend genutetem Zylinder und Barriereschnecke. J. Plast. Technol. 2016, 12, 205–227. [Google Scholar] [CrossRef]

- Karrenberg, G. Einsatz innovativer Simulationstechniken zur Entwicklung Eines High-Speed-Extrusionskonzeptes auf Basis von Feststoff-Schmelze-Trennung. Ph.D. Thesis, Universität of Duisburg-Essen, Duisburg, Germany, 2016. [Google Scholar]

- Lewandowski, A.; Wilczynski, K. General model of polymer melting in extrusion process. Polimery 2018, 63, 444–452. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef]

- Dörner, M. Wave-Schnecken in der Einschneckenextrusion. Ph.D. Thesis, University of Paderborn, Paderborn, Germany, 2022. [Google Scholar]

- Schall, C. Materialschonende Bearbeitung von Thermoplasten auf Wave-Schnecken. Ph.D. Thesis, University of Paderborn, Paderborn, Germany, 2023. [Google Scholar]

- Celik, A. Vorhersage des Aufschmelzvorgangs von Kunststoffen in Partikelbeladenen Strömungen Mittels CFD-DEM. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2023. [Google Scholar]

- Maddock, B. A visual analysis of flow and mixing in extruder screw. SPE J. 1959, 15, 383–389. [Google Scholar]

- Street, L.F. Plastifying Extrusion. Intern. Plast. Eng. 1961, 1, 289–296. [Google Scholar]

- Tadmor, Z. Fundamentals of plasticating extrusion. I. A theoretical model for melting. Polym. Eng. Sci. 1966, 6, 185–190. [Google Scholar] [CrossRef]

- Tadmor, Z.; Duvdevani, I.; Klein, I. Melting in plasticating extuders theory and experiments. Polym. Eng. Sci. 1967, 7, 198–217. [Google Scholar] [CrossRef]

- Tadmor, Z.; Klein, I. The effect of design and operating conditions on melting in plasticating extruders. Polym. Eng. Sci. 1969, 9, 1–10. [Google Scholar] [CrossRef]

- Hinrichs, D.R.; Lilleleht, L.U. A modified melting model for plastifying extruders. Polym. Eng. Sci. 1970, 10, 268–278. [Google Scholar] [CrossRef]

- Kacir, L.; Tadmor, Z. Solids conveying in screw extruders part III: The delay zone. Polym. Eng. Sci. 1972, 12, 387–395. [Google Scholar] [CrossRef]

- Naranjo, A.; Noriega, M.; Osswald, T. Comparison of the Melting Behavior of HDPE and PP in Single Screw Extruders. In Proceedings of the 69th Annual Technical Conference of the Society of Plastics Engineers (Antec), Boston, MA, USA, 1–5 May 2011. [Google Scholar]

- Chung, C.I. Plasticating single-screw extrusion theory. Polym. Eng. Sci. 1971, 11, 93–98. [Google Scholar] [CrossRef]

- Donovan, R.C. A theoretical melting model for plasticating extruders. Polym. Eng. Sci. 1971, 11, 247–257. [Google Scholar] [CrossRef]

- Vermeulen, J.R.; Gerson, P.M.; Beek, W.J. The melting of a bed of polymer granules on a hot moving surface. Chem. Eng. Sci. 1971, 26, 1445–1455. [Google Scholar] [CrossRef]

- Edmondson, I.R.; Fenner, R.T. Melting of thermoplastics in single screw extruders. Polymer 1974, 16, 49–56. [Google Scholar] [CrossRef]

- Cox, A.P.D.; Fenner, R.T. Melting performance in the single screw extrusion of thermoplastics. Polym. Eng. Sci. 1980, 20, 562–571. [Google Scholar] [CrossRef]

- Pearson, J. On the melting of solids near a hot moving interface, with particular refference to beds of granular. Int. J. Heat Mass Transf. 1976, 19, 405–411. [Google Scholar] [CrossRef]

- Shapiro, J.; Halmos, A.L.; Pearson, J. Melting in single screw extruders. Polymer 1976, 17, 905–918. [Google Scholar] [CrossRef]

- Mount, E.M.; Watson, J.G.; Chung, C.I. Analytical melting model for extrusion: Melting rate of fully compacted solid polymers. Polym. Eng. Sci. 1982, 22, 729–737. [Google Scholar] [CrossRef]

- McClelland, D.E.; Chung, C.I. Shear Stress at Polymer/Metal Interface During Melting in Extrusion. Polym. Eng. Sci. 1983, 23, 101–104. [Google Scholar] [CrossRef]

- Fukase, H.; Takeshi, K. A plasticating model for single-screw extruders. Polym. Eng. Sci. 1982, 22, 578–586. [Google Scholar] [CrossRef]

- Rauwendaal, C. An improved analytical melting theory. Adv. Polym. Technol. 1989, 9, 331–336. [Google Scholar] [CrossRef]

- Rauwendaal, C. Melting theory for temperature-dependent fluids, exact analytical solution for power-law fluids. Adv. Polym. Technol. 1991, 11, 19–25. [Google Scholar] [CrossRef]

- Potente, H.; Schöppner, V. Rechnergestützte Extruderauslegung (REX). Lecture Script. University of Paderborn: Paderborn, Germany, 1992. [Google Scholar]

- Altmann, D.; Praher, B.; Steinbichler, G. Simulation of the melting behavior in an injection molding plasticizing unit as measured by pressure and ultrasound measurement technology. AIP Conf. Proc. 2019, 2055, 40003. [Google Scholar]

- Anger, K.; Potente, H.; Schöppner, V. Dynamic Temperature and Pressure Measurement in Polymer Processing. J. Plast. Technol. 2009, 5, 31–47. [Google Scholar]

- Zhu, F.; Chen, L. Studies on the theory of single screw plasticating extrusion. Part I: A new experimental method for extrusion. Polym. Eng. Sci. 1991, 31, 1113–1116. [Google Scholar] [CrossRef]

- Schröder, T. Rheologie der Kunststoffe—Theorie und Praxis; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2018. [Google Scholar]

- Dahlmann, R.; Haberstroh, E.; Menges, G. Menges Werkstoffkunde Kunststoffe, 7th ed.; Hanser: München, Germany, 2021. [Google Scholar]

- Han, C.D.; Lee, K.Y.; Wheeler, N.C. Plasticating single-screw extrusion of amorphous polymers: Development of a mathematical model and comparison with experiment. Polym. Eng. Sci. 1996, 36, 1360–1376. [Google Scholar] [CrossRef]

- Cowie, J.M.G.; Arrighi, V. Polymers: Chemistry and Physics of Modern Materials, 3rd ed.; CRC Press Taylor & Francis Group: Boca Raton, USA, 2007. [Google Scholar]

- Baur, E.; Drummer, D.; Osswald, T.A.; Rudolph, N. Saechtling Kunststoff-Handbuch, 32nd ed.; Hanser: Munich, Germany, 2022. [Google Scholar]

- DIN EN ISO 11357-3:2018; Kunststoffe—Dynamische Differenz-Thermoanalyse (DSC)—Teil 3: Bestimmung der Schmelz- und Kristallisationstemperatur und der Schmelz- und Kristallisationsenthalpie. Beuth Verlag: Berlin, Germany, 2018.

- Schöppner, V. Verfahrenstechnische Auslegung von Extrusionsanlagen. Habilitation Thesis. University of Paderborn: Paderborn, Germany, 2001. [Google Scholar]

- Schulze, D. Pulver und Schüttgüter; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Brüning, F.; Schöppner, V. Numerical Simulation of Solids Conveying in Grooved Feed Sections of Single Screw Extruders. Polymers 2022, 14, 256. [Google Scholar] [CrossRef] [PubMed]

- ISO 60:1977; Plastics—Determination of Apparent Density of Material That Can Be Poured from a Specified Funnel. International Organization for Standardization (ISO): Geneva, Switzerland, 1977.

- Kleppmann, W. Versuchsplanung: Produkte und Prozesse Optimieren, 3rd ed.; Hanser: München, Germany, 2018. [Google Scholar]

- Campbell, G.; Spalding, M.A. A Mechanism for Solid Bed Breakup in Single-Screw Extruders. In Proceedings of the 72nd Annual Technical Conference of the Society of Plastics Engineers (Antec), Las Vegas, NV, USA, 28–30 April 2014. [Google Scholar]

- Tadmor, Z.; Gogos, C. Principles of Polymer Processing, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

| Geometric Aspect | Screw 1 | Screw 2 | Screw 3 |

|---|---|---|---|

| Diameter [mm] | 45 | 30 | 30 |

| Length [L/D] | 32.9 | 35.4 | 35.4 |

| Pitch [L/D] | 1 | 1 | 1 |

| Flight width [mm] | 5 | 3 | 3 |

| Feed Section | |||

| Length [L/D] | 13.9 | 12.7 | 12.7 |

| Channel depth [mm] | 9 | 5.4 | 5.4 |

| Compression section | |||

| Length [L/D] | 11 | 16 | 7 |

| Metering section | |||

| Length [L/D] | 8 | 6.7 | 15.7 |

| Channel depth [mm] | 3.5 | 2.1 | 2.1 |

| Factor | Unit | −α | −1 | 0 | +1 | +α |

|---|---|---|---|---|---|---|

| Barrel temperature | °C | 170 | 180 | 200 | 220 | 230 |

| Screw speed | rpm | 30 | 60 | 120 | 180 | 210 |

| Pellet diameter | mm | - | 1 | 2 | 3 | - |

| Factor | Unit | −α | −1 | 0 | +1 | +α |

|---|---|---|---|---|---|---|

| Rotational Speed | rpm | 30 | 60 | 120 | 180 | 210 |

| Pellet diameter | mm | - | 1 | 2 | 3 | - |

| Back pressure | - | Low | Medium | High |

| Experimental Point | Throughput [kg/h] | Delay Zone Length [L/D] | Melting Length [L/D] |

|---|---|---|---|

| HDPE | |||

| Average | 15.54 | 3.88 | 21.5 |

| Standard deviation | 0.12 | 0.25 | 0.58 |

| PS | |||

| Average | 20.16 | 4.38 | 25.75 |

| Standard deviation | 0.17 | 0.25 | 0.5 |

| Variations | MAE [L/D] | MSE [L²/D²] | MaxAE [L/D] |

|---|---|---|---|

| HDPE | |||

| a = −1 | 2.40 | 7.80 | 7.56 |

| a = −0.5 | 1.71 | 4.16 | 4.90 |

| a = 0 | 1.52 | 3.85 | 5.00 |

| a = 0.5 | 1.61 | 4.36 | 6.08 |

| a = 1 | 1.94 | 5.82 | 6.80 |

| PS | |||

| a = −1 | 1.78 | 8.35 | 6.61 |

| a = −0.5 | 1.62 | 5.97 | 6.01 |

| a = 0 | 1.44 | 4.98 | 5.83 |

| a = 0.5 | 1.37 | 5.16 | 6.79 |

| a = 1 | 1.66 | 7.54 | 7.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knaup, F.; Brüning, F.; Schöppner, V. Improvement in an Analytical Approach for Modeling the Melting Process in Single-Screw Extruders. Polymers 2024, 16, 3130. https://doi.org/10.3390/polym16223130

Knaup F, Brüning F, Schöppner V. Improvement in an Analytical Approach for Modeling the Melting Process in Single-Screw Extruders. Polymers. 2024; 16(22):3130. https://doi.org/10.3390/polym16223130

Chicago/Turabian StyleKnaup, Felix, Florian Brüning, and Volker Schöppner. 2024. "Improvement in an Analytical Approach for Modeling the Melting Process in Single-Screw Extruders" Polymers 16, no. 22: 3130. https://doi.org/10.3390/polym16223130

APA StyleKnaup, F., Brüning, F., & Schöppner, V. (2024). Improvement in an Analytical Approach for Modeling the Melting Process in Single-Screw Extruders. Polymers, 16(22), 3130. https://doi.org/10.3390/polym16223130