One-Step Fast Fabrication of Electrospun Fiber Membranes for Efficient Particulate Matter Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of the PSF Fiber Membranes

2.3. Characterization

2.4. Filtration Performance of the PSF Fiber Membranes

2.5. Statistical Analysis

3. Results and Discussion

3.1. Effects of Solution Concentration and Solvent Composition on the Spinnability of the PSF Solutions

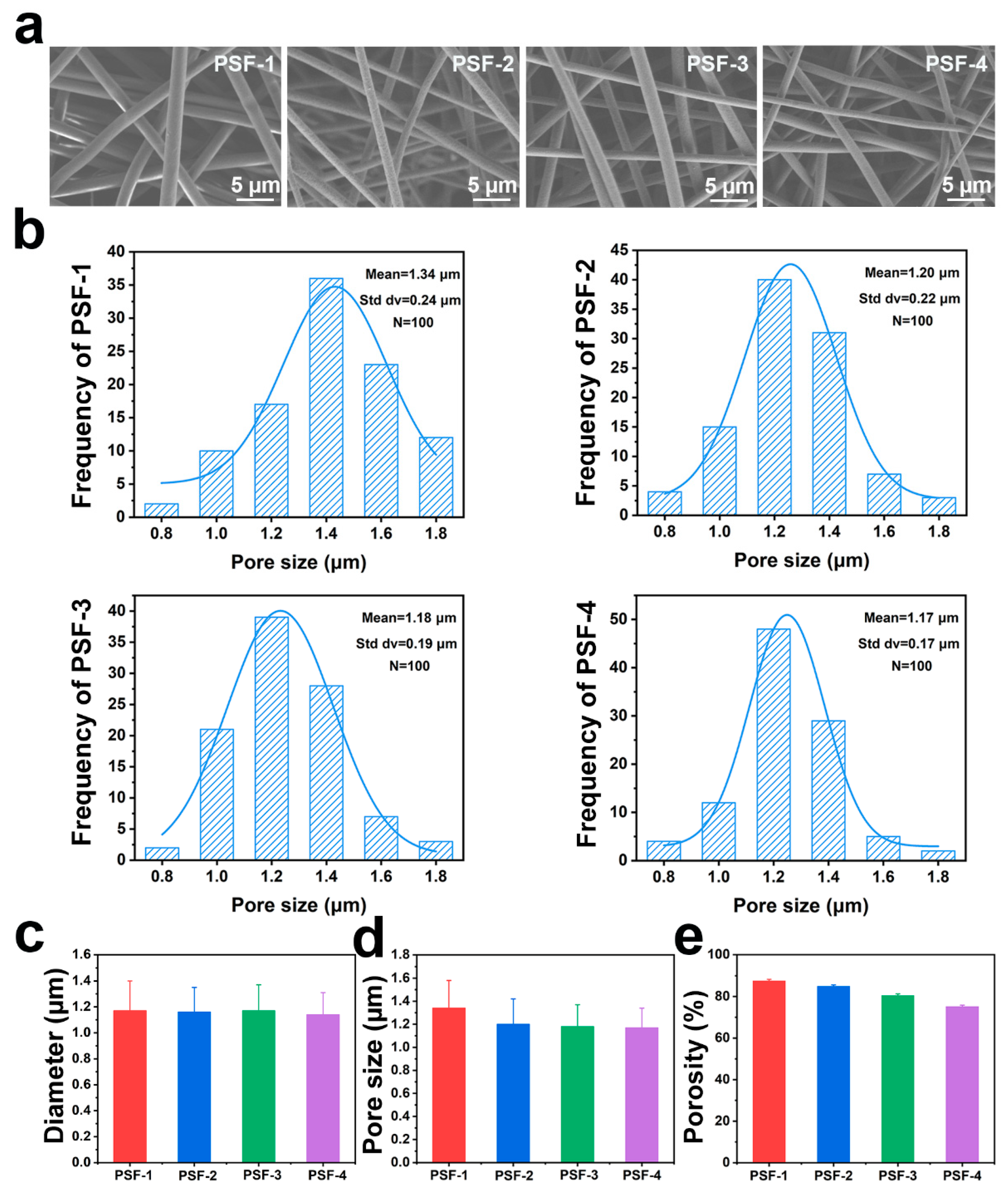

3.2. Morphology of the PSF Fiber Membranes

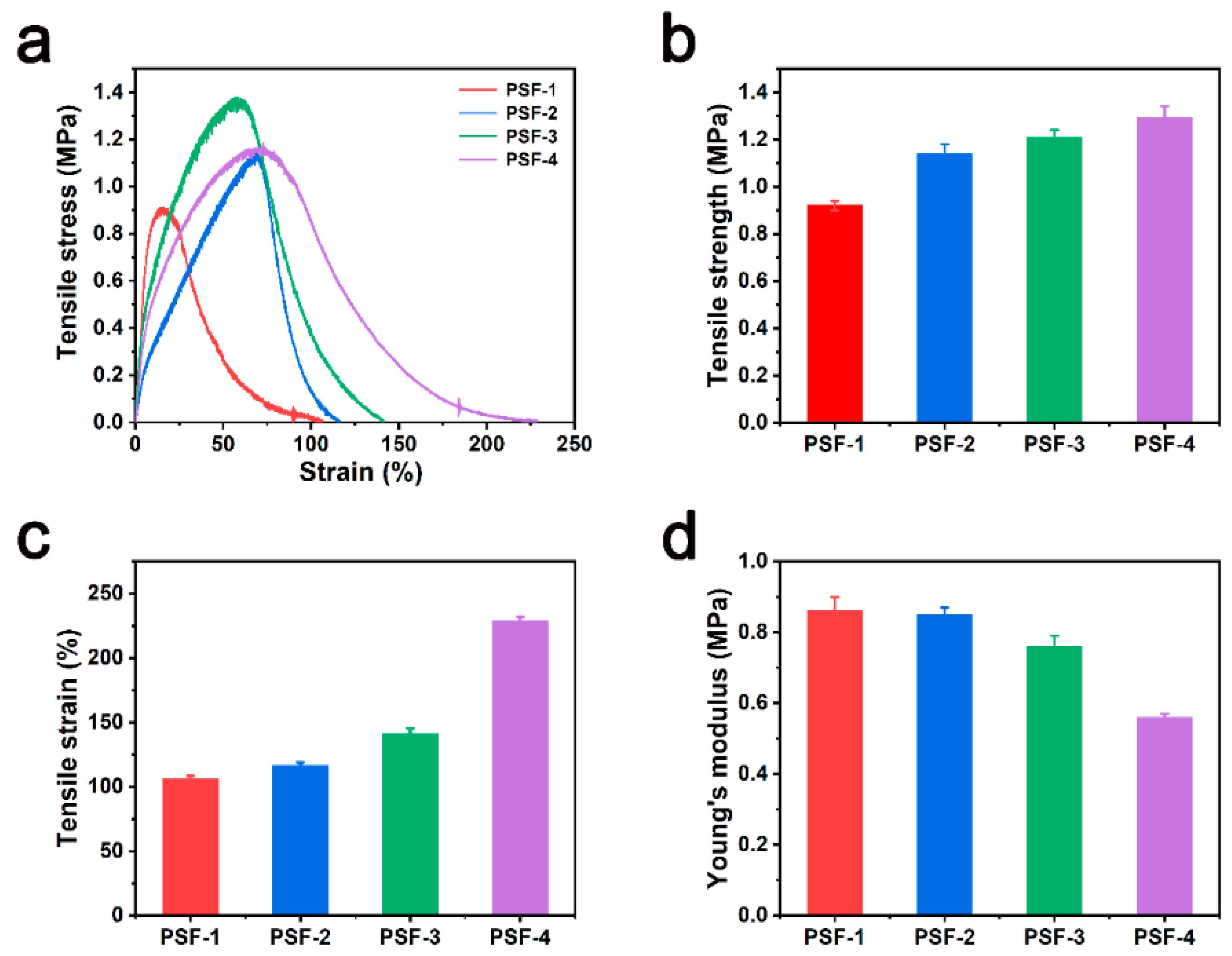

3.3. Mechanical Properties of the PSF Fiber Membranes

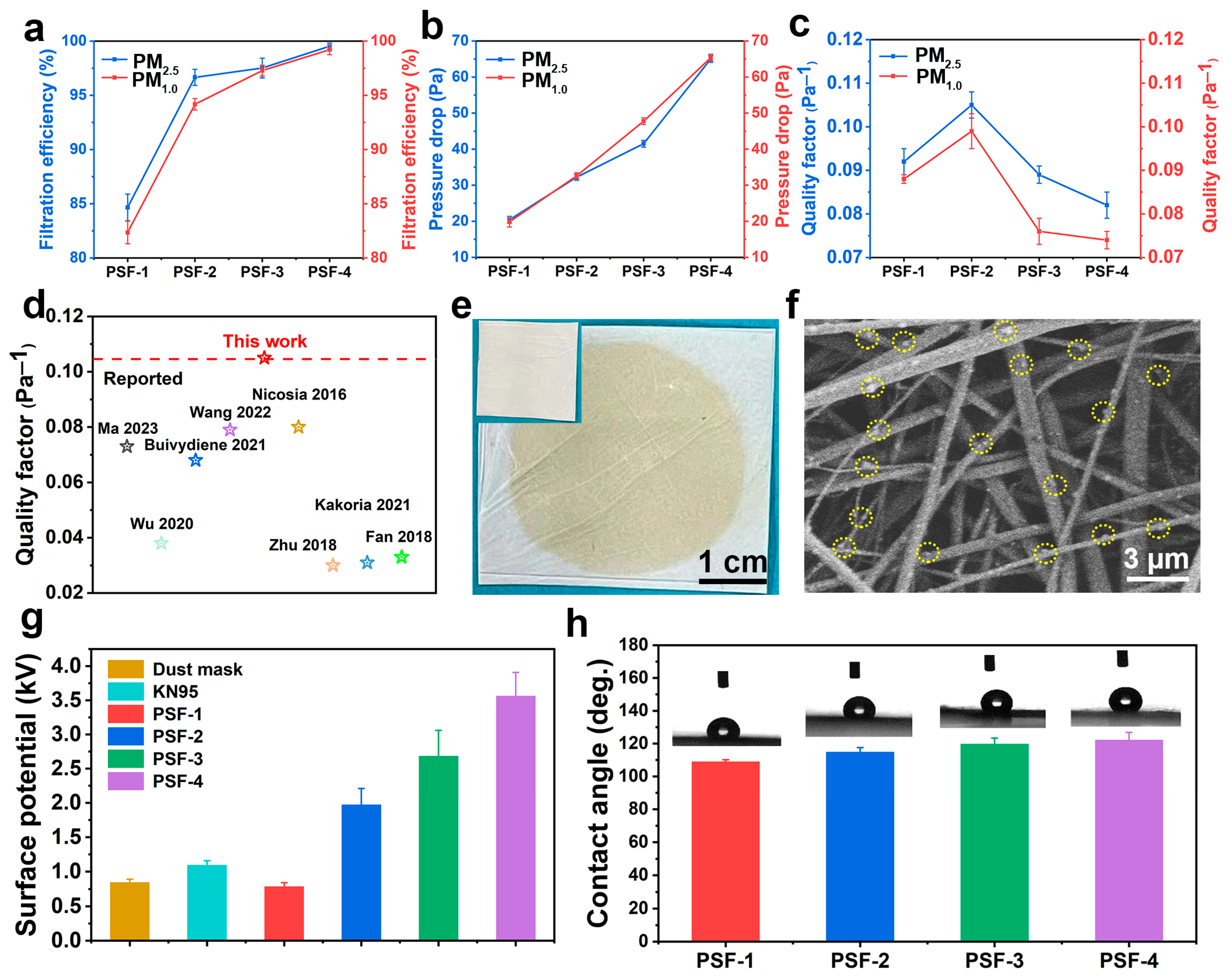

3.4. Filtration Performance of the PSF Fiber Membranes and the Underlying Mechanism

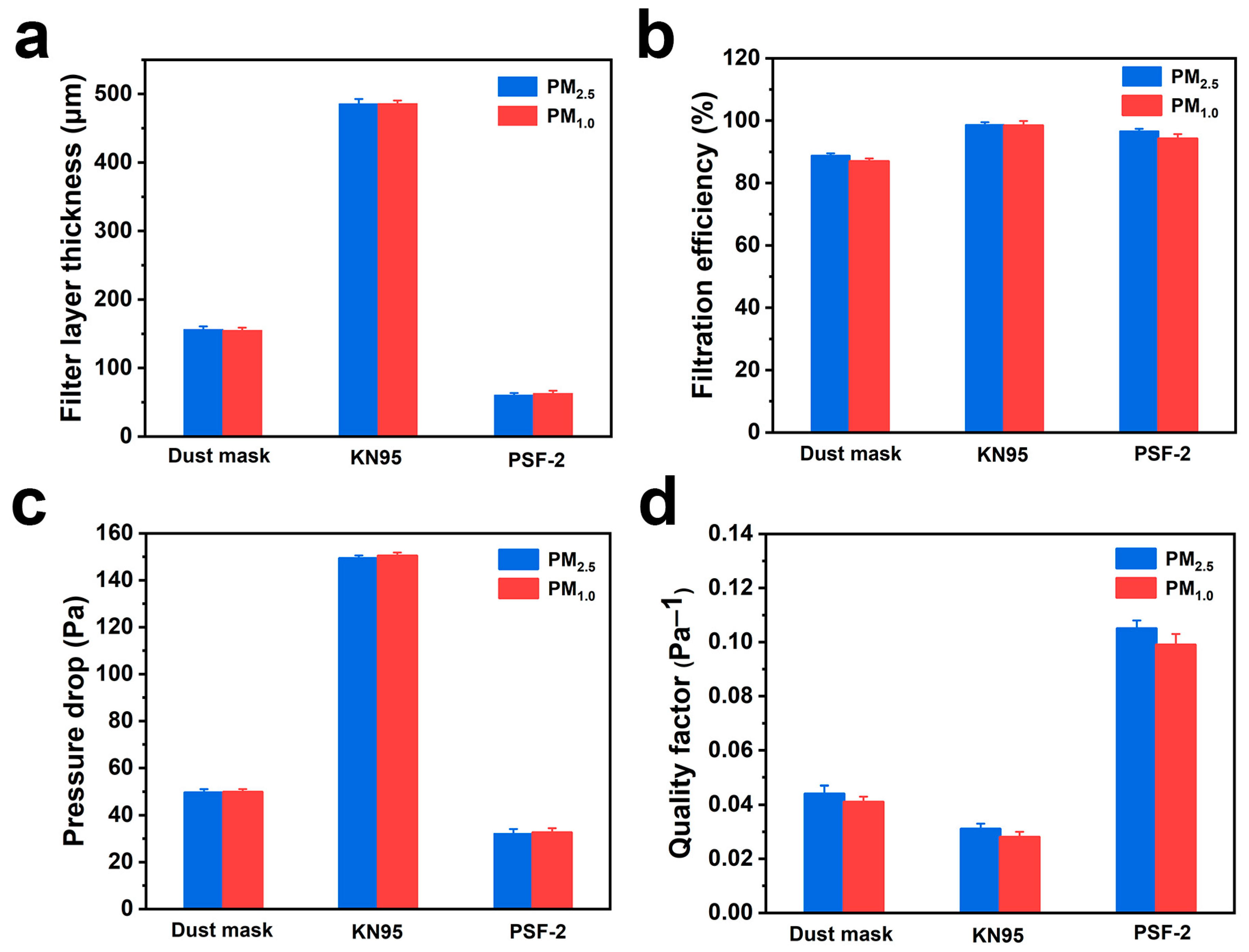

3.5. Comparison of the Filtration Performance of PSF-2 and Commercial Filters

3.6. Filtration Durability of the PSF-2 Fiber Membrane

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Cao, C.; Huang, J.; Chen, Z.; Chen, G.; Lai, Y. Progress on particulate matter filtration technology: Basic concepts, advanced materials, and performances. Nanoscale 2020, 12, 437–453. [Google Scholar] [CrossRef]

- Losacco, C.; Perillo, A. Particulate matter air pollution and respiratory impact on humans and animals. Environ. Sci. Pollut. Res. 2018, 25, 33901–33910. [Google Scholar] [CrossRef]

- Arias-Pérez, R.D.; Taborda, N.A.; Gómez, D.M.; Narvaez, J.F.; Porras, J.; Hernandez, J.C. Inflammatory effects of particulate matter air pollution. Environ. Sci. Pollut. Res. 2020, 27, 42390–42404. [Google Scholar] [CrossRef]

- Ji, X.; Huang, J.; Teng, L.; Li, S.; Li, X.; Cai, W.; Chen, Z.; Lai, Y. Advances in particulate matter filtration: Materials, performance, and application. Green Energy Environ. 2023, 8, 673–697. [Google Scholar] [CrossRef]

- Newman, J.D.; Bhatt, D.L.; Rajagopalan, S.; Balmes, J.R.; Brauer, M.; Breysse, P.N.; Brown, A.G.M.; Carnethon, M.R.; Cascio, W.E.; Collman, G.W.; et al. Cardiopulmonary Impact of Particulate Air Pollution in High-Risk Populations: JACC State-of-the-Art Review. J. Am. Coll. Cardiol. 2020, 76, 2878–2894. [Google Scholar] [CrossRef]

- Combes, A.; Franchineau, G. Fine particle environmental pollution and cardiovascular diseases. Metabolism 2019, 100, 153944. [Google Scholar] [CrossRef]

- Chen, H.-W.; Kuo, Y.-L.; Chen, C.-H.; Chiou, C.-S.; Chen, W.-T.; Lai, Y.-H. Biocompatibile nanofiber based membranes for high-efficiency filtration of nano-aerosols with low air resistance. Process Saf. Environ. Prot. 2022, 167, 695–707. [Google Scholar] [CrossRef]

- Ju, Y.; Han, T.; Yin, J.; Li, Q.; Chen, Z.; Wei, Z.; Zhang, Y.; Dong, L. Bumpy structured nanofibrous membrane as a highly efficient air filter with antibacterial and antiviral property. Sci. Total Environ. 2021, 777, 145768. [Google Scholar] [CrossRef]

- Li, P.; Wang, C.; Zhang, Y.; Wei, F.J.S. Air filtration in the free molecular flow regime: A review of high-efficiency particulate air filters based on carbon nanotubes. Small 2014, 10, 4543–4561. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Zhou, B.; Tseng, C.H.; Hu, S.C.; Shiue, A.; Leggett, G. Evaluation of characterization and filtration performance of air cleaner materials. Int. J. Environ. Sci. Technol. 2021, 18, 2209–2220. [Google Scholar] [CrossRef]

- Patra, S.S.; Nath, J.; Panda, S.; Das, T.; Ramasamy, B. Evaluating the filtration efficiency of commercial facemasks’ materials against respiratory aerosol droplets. J. Air Waste Manag. Assoc. 2022, 72, 3–9. [Google Scholar] [CrossRef]

- Stahl, C.; Frederick, K.; Chaudhary, S.; Morton, C.J.; Loy, D.; Muralidharan, K.; Sorooshian, A.; Parthasarathy, S. Comparison of the Filtration Efficiency of Different Face Masks Against Aerosols. Front. Med. 2021, 8, 23577. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, X.; Gao, X.; Wang, H.; Li, L.; Hussain, N.; Xie, J.; Cheng, Z.; Li, Z.; Yan, J.; et al. Saving 80% Polypropylene in Facemasks by Laser-Assisted Melt-Blown Nanofibers. Nano Lett. 2022, 22, 7212–7219. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, X.; Teng, D.; Zhao, T.; Li, Y.; Zeng, Y. Multi-layered micro/nanofibrous nonwovens for functional face mask filter. Nano Res. 2022, 15, 7549–7558. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, L.; Zhang, Z.; Deng, C.; Li, C.; Du, Y.; Shi, J.; Zhu, M. Highly efficient, low-resistant, well-ordered PAN nanofiber membranes for air filtration. Colloids Surf. A Physicochem. Eng. Asp. 2022, 655, 130302. [Google Scholar] [CrossRef]

- Zhu, M.; Hua, D.; Pan, H.; Wang, F.; Manshian, B.; Soenen, S.J.; Xiong, R.; Huang, C. Green electrospun and crosslinked poly(vinyl alcohol)/poly(acrylic acid) composite membranes for antibacterial effective air filtration. J. Colloid Interface Sci. 2018, 511, 411–423. [Google Scholar] [CrossRef]

- Wang, N.; Raza, A.; Si, Y.; Yu, J.; Sun, G.; Ding, B. Tortuously structured polyvinyl chloride/polyurethane fibrous membranes for high-efficiency fine particulate filtration. J. Colloid Interface Sci. 2013, 398, 240–246. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Yu, L.E.; Lai, J.-Y.; Chung, T.-S. Developing ultra-high gas permeance PVDF hollow fibers for air filtration applications. Sep. Purif. Technol. 2018, 205, 184–195. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Zhang, L.; Wang, S.; Harper, D.P.; Wu, Q.; Young, T.M. Preparation of electrospun nanofibrous poly(vinyl alcohol)/cellulose nanocrystals air filter for efficient particulate matter removal with repetitive usage capability via facile heat treatment. Chem. Eng. J. 2020, 399, 125768. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, L.; Liu, S.; Zhang, J.; Wu, J.; Liang, X. Superhydrophobic and highly moisture-resistant PVA@EC composite membrane for air purification. RSC Adv. 2022, 12, 34921–34930. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Xia, M.; Xiong, Z.; Wu, Y.; Cheng, P.; Cheng, Q.; Xu, J.; Wang, D.; Liu, K. A Hierarchical Structure of Flower-Like Zinc Oxide and Poly(Vinyl Alcohol-co-Ethylene) Nanofiber Hybrid Membranes for High-Performance Air Filters. ACS Omega 2022, 7, 3030–3036. [Google Scholar] [CrossRef]

- Zheng, G.; Shao, Z.; Chen, J.; Jiang, J.; Zhu, P.; Wang, X.; Li, W.; Liu, Y. Self-Supporting Three-Dimensional Electrospun Nanofibrous Membrane for Highly Efficient Air Filtration. Nanomaterials 2021, 11, 2567. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Young, T.M.; Harper, D.P.; Wang, S. A Novel Method for Fabricating an Electrospun Poly(Vinyl Alcohol)/Cellulose Nanocrystals Composite Nanofibrous Filter with Low Air Resistance for High-Efficiency Filtration of Particulate Matter. ACS Sustain. Chem. Eng. 2019, 7, 8706–8714. [Google Scholar] [CrossRef]

- Serbanescu, O.S.; Voicu, S.I.; Thakur, V.K. Polysulfone functionalized membranes: Properties and challenges. Mater. Today Chem. 2020, 17, 100302. [Google Scholar] [CrossRef]

- Kheirieh, S.; Asghari, M.; Afsari, M. Application and modification of polysulfone membranes. Rev. Chem. Eng. 2018, 34, 657–693. [Google Scholar] [CrossRef]

- Li, N.; Wang, W.; Ma, C.; Zhu, L.; Chen, X.; Zhang, B.; Zhong, C. A novel conductive rGO/ZnO/PSF membrane with superior water flux for electrocatalytic degradation of organic pollutants. J. Membr. Sci. 2022, 641, 119901. [Google Scholar] [CrossRef]

- Zhong, D.; Wang, Z.; Zhou, J.; Wang, Y. Additive-free preparation of hemodialysis membranes from block copolymers of polysulfone and polyethylene glycol. J. Membr. Sci. 2021, 618, 118690. [Google Scholar] [CrossRef]

- Mendes, A.C.; Strohmenger, T.; Goycoolea, F.; Chronakis, I.S. Electrostatic self-assembly of polysaccharides into nanofibers. Colloids Surf. A Physicochem. Eng. Asp. 2017, 531, 182–188. [Google Scholar] [CrossRef]

- Gan, Y.; Xu, F.; Luo, J.; Yuan, H.; Jin, C.; Zhang, L.; Fang, C.; Sheng, O.; Huang, H.; Xia, Y.; et al. One-pot Biotemplate Synthesis of FeS2 Decorated Sulfur-doped Carbon Fiber as High Capacity Anode for Lithium-ion Batteries. Electrochim. Acta 2016, 209, 201–209. [Google Scholar] [CrossRef]

- Ghodsi, A.; Fashandi, H.; Zarrebini, M.; Mirzaei, M. Controlling the Morphology of PVDF Hollow Fiber Membranes by Promotion of Liquid–Liquid Phase Separation. Adv. Eng. Mater. 2018, 20, 1701169. [Google Scholar] [CrossRef]

- Russo, F.; Castro-Muñoz, R.; Santoro, S.; Galiano, F.; Figoli, A. A review on electrospun membranes for potential air filtration application. J. Environ. Chem. Eng. 2022, 10, 108452. [Google Scholar] [CrossRef]

- Mirjalili, M.; Zohoori, S. Review for application of electrospinning and electrospun nanofibers technology in textile industry. J. Nanostruct. Chem. 2016, 6, 207–213. [Google Scholar] [CrossRef]

- Shao, Z.; Chen, H.; Wang, Q.; Kang, G.; Wang, X.; Li, W.; Liu, Y.; Zheng, G. High-performance multifunctional electrospun fibrous air filter for personal protection: A review. Sep. Purif. Technol. 2022, 302, 122175. [Google Scholar] [CrossRef]

- Zhang, J.; Gong, S.; Wang, C.; Jeong, D.-Y.; Wang, Z.L.; Ren, K. Biodegradable Electrospun Poly(lactic acid) Nanofibers for Effective PM 2.5 Removal. Macromol. Mater. Eng. 2019, 304, 1900259. [Google Scholar] [CrossRef]

- Al Rai, A.; Stojanovska, E.; Fidan, G.; Yetgin, E.; Polat, Y.; Kilic, A.; Demir, A.; Yilmaz, S. Structure and performance of electroblown PVDF-based nanofibrous electret filters. Polym. Eng. Sci. 2020, 60, 1186–1193. [Google Scholar] [CrossRef]

- Shao, Z.; Chen, Y.; Jiang, J.; Xiao, Y.; Kang, G.; Wang, X.; Li, W.; Zheng, G. Multistage-Split Ultrafine Fluffy Nanofibrous Membrane for High-Efficiency Antibacterial Air Filtration. ACS Appl. Mater. Interfaces 2022, 14, 18989–19001. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Lu, T.; Cui, J.; Keshari Samal, S.; Xiong, R.; Huang, C. Bio-based electrospun nanofiber as building blocks for a novel eco-friendly air filtration membrane: A review. Sep. Purif. Technol. 2021, 277, 119623. [Google Scholar] [CrossRef]

- Nicosia, A.; Keppler, T.; Müller, F.A.; Vazquez, B.; Ravegnani, F.; Monticelli, P.; Belosi, F. Cellulose acetate nanofiber electrospun on nylon substrate as novel composite matrix for efficient, heat-resistant, air filters. Chem. Eng. Sci. 2016, 153, 284–294. [Google Scholar] [CrossRef]

- Zhu, X.; Kim, K. Electrospun polyacrylonitrile fibrous membrane for dust removal. Front. Mater. 2022, 9, 973660. [Google Scholar] [CrossRef]

- Cai, R.-R.; Li, S.-Z.; Zhang, L.-Z.; Lei, Y. Fabrication and performance of a stable micro/nano composite electret filter for effective PM2.5 capture. Sci. Total Environ. 2020, 725, 138297. [Google Scholar] [CrossRef]

- Al-Attabi, R.; She, F.; Zhao, S.; Dumée, L.F.; Schütz, J.A.; Xing, W.; Zhong, Z.; Kong, L. Durable and comfortable electrospun nanofiber membranes for face mask applications. Sep. Purif. Technol. 2023, 322, 124370. [Google Scholar] [CrossRef]

- Zhu, Z.; Yu, M.; Ren, R.; Wang, H.; Kong, B. Thymol incorporation within chitosan/polyethylene oxide nanofibers by concurrent coaxial electrospinning and in-situ crosslinking from core-out for active antibacterial packaging. Carbohydr. Polym. 2024, 323, 121381. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, M.; Zhou, Y.; Yao, A.; Han, Y.; Shi, Y.; Cheng, F.; Zhou, M.; Zhu, P.; Tan, L. Transition sandwich Janus membrane of cellulose acetate and polyurethane nanofibers for oil–water separation. Cellulose 2022, 29, 1841–1853. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, C.; Chen, X.; Jiang, A.; You, Z.; Shah, K.J. Different weathering conditions affect the release of microplastics by masks. Environ. Sci. Pollut. Res. 2023, 30, 66102–66112. [Google Scholar] [CrossRef]

- Mazoochi, T.; Hamadanian, M.; Ahmadi, M.; Jabbari, V. Investigation on the morphological characteristics of nanofiberous membrane as electrospun in the different processing parameters. Int. J. Ind. Chem. 2012, 3, 2. [Google Scholar] [CrossRef]

- Chee, T.Y.; Mohd, Y.A.R.; Abdullah, F.; Wan Mahmood, W.M.A.; Jasni, M.J.F.; Malek, N.A.N.N.; Buang, N.A.; Govarthanan, M. Fabrication, characterization and application of electrospun polysulfone membrane for phosphate ion removal in real samples. Chemosphere 2022, 303, 135228. [Google Scholar] [CrossRef]

- Shao, W.; Niu, J.; Han, R.; Liu, S.; Wang, K.; Cao, Y.; Han, P.; Li, X.; Zhang, H.; Yu, H.; et al. Electrospun Multiscale Poly(lactic acid) Nanofiber Membranes with a Synergistic Antibacterial Effect for Air-Filtration Applications. ACS Appl. Polym. Mater. 2023, 5, 9632–9641. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Kang, W.; Deng, N.; Yan, J.; Ju, J.; Liu, Y.; Cheng, B. Preparation and characterization of tree-like cellulose nanofiber membranes via the electrospinning method. Carbohydr. Polym. 2018, 183, 62–69. [Google Scholar] [CrossRef]

- Peng, Z.; Shi, J.; Xiao, X.; Hong, Y.; Li, X.; Zhang, W.; Cheng, Y.; Wang, Z.; Li, W.J.; Chen, J.; et al. Self-charging electrostatic face masks leveraging triboelectrification for prolonged air filtration. Nat. Commun. 2022, 13, 7835. [Google Scholar] [CrossRef]

- Ma, W.; Qi, H.; Zhang, Y.; Lin, M.; Qiu, Y.; Zhang, C. Fabrication of Laminated Micro/Nano Filter and Its Application for Inhalable PM Removal. Polymers 2023, 15, 1459. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Akampumuza, O.; Liu, P.; Quan, Z.; Zhang, H.; Qin, X.; Wang, R.; Yu, J. 3D structure design and simulation for efficient particles capture: The influence of nanofiber diameter and distribution. Mater. Today Commun. 2020, 23, 100897. [Google Scholar] [CrossRef]

- Buivydiene, D.; Todea, A.M.; Asbach, C.; Krugly, E.; Martuzevicius, D.; Kliucininkas, L. Composite micro/nano fibrous air filter by simultaneous melt and solution electrospinning. J. Aerosol Sci. 2021, 154, 105754. [Google Scholar] [CrossRef]

- Wang, H.; Bao, Y.; Yang, X.; Lan, X.; Guo, J.; Pan, Y.; Huang, W.; Tang, L.; Luo, Z.; Zhou, B.; et al. Study on Filtration Performance of PVDF/PUL Composite Air Filtration Membrane Based on Far-Field Electrospinning. Polymers 2022, 14, 3294. [Google Scholar] [CrossRef] [PubMed]

- Kakoria, A.; Chandel, S.S.; Sinha-Ray, S. Novel supersonically solution blown nanofibers from waste PET bottle for PM0.1-2 filtration: From waste to pollution mitigation. Polymer 2021, 234, 124260. [Google Scholar] [CrossRef]

- Fan, X.; Wang, Y.; Kong, L.; Fu, X.; Zheng, M.; Liu, T.; Zhong, W.-H.; Pan, S. A Nanoprotein-Functionalized Hierarchical Composite Air Filter. ACS Sustain. Chem. Eng. 2018, 6, 11606–11613. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, H.; Wang, M.; Zhang, X.; Gan, Z. Thermoplastic Polyurethane Nanofiber Membrane Based Air Filters for Efficient Removal of Ultrafine Particulate Matter PM0.1. ACS Appl. Nano Mater. 2021, 4, 182–189. [Google Scholar] [CrossRef]

- Kadam, V.; Kyratzis, I.L.; Truong, Y.B.; Schutz, J.; Wang, L.; Padhye, R. Electrospun bilayer nanomembrane with hierarchical placement of bead-on-string and fibers for low resistance respiratory air filtration. Sep. Purif. Technol. 2019, 224, 247–254. [Google Scholar] [CrossRef]

- Segovia, J.M.; Huang, C.-H.; Mamishev, M.; Yuan, N.; He, J.; Novosselov, I. Performance of Textile Mask Materials in Varied Humidity: Filtration Efficiency, Breathability, and Quality Factor. Appl. Sci. 2022, 12, 9360. [Google Scholar] [CrossRef]

- Gao, Y.; Tian, E.; Zhang, Y.; Mo, J. Utilizing electrostatic effect in fibrous filters for efficient airborne particles removal: Principles, fabrication, and material properties. Appl. Mater. Today 2022, 26, 101369. [Google Scholar] [CrossRef]

- Gao, H.; He, W.; Zhao, Y.B.; Opris, D.M.; Xu, G.; Wang, J. Electret mechanisms and kinetics of electrospun nanofiber membranes and lifetime in filtration applications in comparison with corona-charged membranes. J. Membr. Sci. 2020, 600, 117879. [Google Scholar] [CrossRef]

- Liu, C.; Dai, Z.; He, B.; Ke, Q.F. The Effect of Temperature and Humidity on the Filtration Performance of Electret Melt-Blown Nonwovens. Materials 2020, 13, 4774. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Li, S.; Chen, F.; Ma, H.; Gao, C.; Xue, L. Development of coin-shaped ZIF-7 functionalized superhydrophobic polysulfone composite foams for continuous removal of oily contaminants from water. J. Hazard. Mater. 2022, 421, 126788. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Zheng, M.; Zhu, T.; Wang, N.; Wang, L.; Yu, J.; Qin, X. Electrostatic-modulated interfacial crosslinking and waterborne emulsion coating toward waterproof, breathable, and antifouling fibrous membranes. Chem. Eng. J. 2023, 454, 140439. [Google Scholar] [CrossRef]

- Huiming, X.; Gangjin, C.; Xumin, C.; Zhi, C. A Flexible Electret Membrane with Persistent Electrostatic Effect and Resistance to Harsh Environment for Energy Harvesting. Sci. Rep. 2017, 7, 8443. [Google Scholar] [CrossRef]

- GB 2626-2019; Respiratory Protection—Non-Powered Air-Purifying Particle Respirator. China Standard Press: Beijing, China, 2019.

- Fu, Q.; Liu, Y.; Liu, T.; Mo, J.; Zhang, W.; Zhang, S.; Luo, B.; Wang, J.; Qin, Y.; Wang, S.; et al. Air-permeable cellulosic triboelectric materials for self-powered healthcare products. Nano Energy 2022, 102, 107739. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Liu, W.; Jin, X. Needle-punched electret air filters (NEAFs) with high filtration efficiency, low filtration resistance, and superior dust holding capacity. Sep. Purif. Technol. 2022, 282, 120146. [Google Scholar] [CrossRef]

| PSF Solution Concentration (wt%) | Solvent Composition (4 mL) | Spinnability |

|---|---|---|

| 25 wt% | Pure THF | Poor |

| Pure DMF | Poor | |

| DMF:THF = 3:1 | Poor | |

| 30 wt% | Pure THF | Good |

| Pure DMF | Poor | |

| DMF:THF = 3:1 | Excellent | |

| 35 wt% | Pure THF | No |

| Pure DMF | No | |

| DMF:THF = 3:1 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Lai, W.; Shi, Y.; Tian, L.; Li, K.; Bian, L.; Xi, Z.; Lin, B. One-Step Fast Fabrication of Electrospun Fiber Membranes for Efficient Particulate Matter Removal. Polymers 2024, 16, 209. https://doi.org/10.3390/polym16020209

Liu H, Lai W, Shi Y, Tian L, Li K, Bian L, Xi Z, Lin B. One-Step Fast Fabrication of Electrospun Fiber Membranes for Efficient Particulate Matter Removal. Polymers. 2024; 16(2):209. https://doi.org/10.3390/polym16020209

Chicago/Turabian StyleLiu, Huanliang, Wenqing Lai, Yue Shi, Lei Tian, Kang Li, Liping Bian, Zhuge Xi, and Bencheng Lin. 2024. "One-Step Fast Fabrication of Electrospun Fiber Membranes for Efficient Particulate Matter Removal" Polymers 16, no. 2: 209. https://doi.org/10.3390/polym16020209

APA StyleLiu, H., Lai, W., Shi, Y., Tian, L., Li, K., Bian, L., Xi, Z., & Lin, B. (2024). One-Step Fast Fabrication of Electrospun Fiber Membranes for Efficient Particulate Matter Removal. Polymers, 16(2), 209. https://doi.org/10.3390/polym16020209