Optimizing Surface Characteristics of Stainless Steel (SUS) for Enhanced Adhesion in Heterojunction Bilayer SUS/Polyamide 66 Composites

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. SUS Surface Treatment Methods

2.3. Characterization

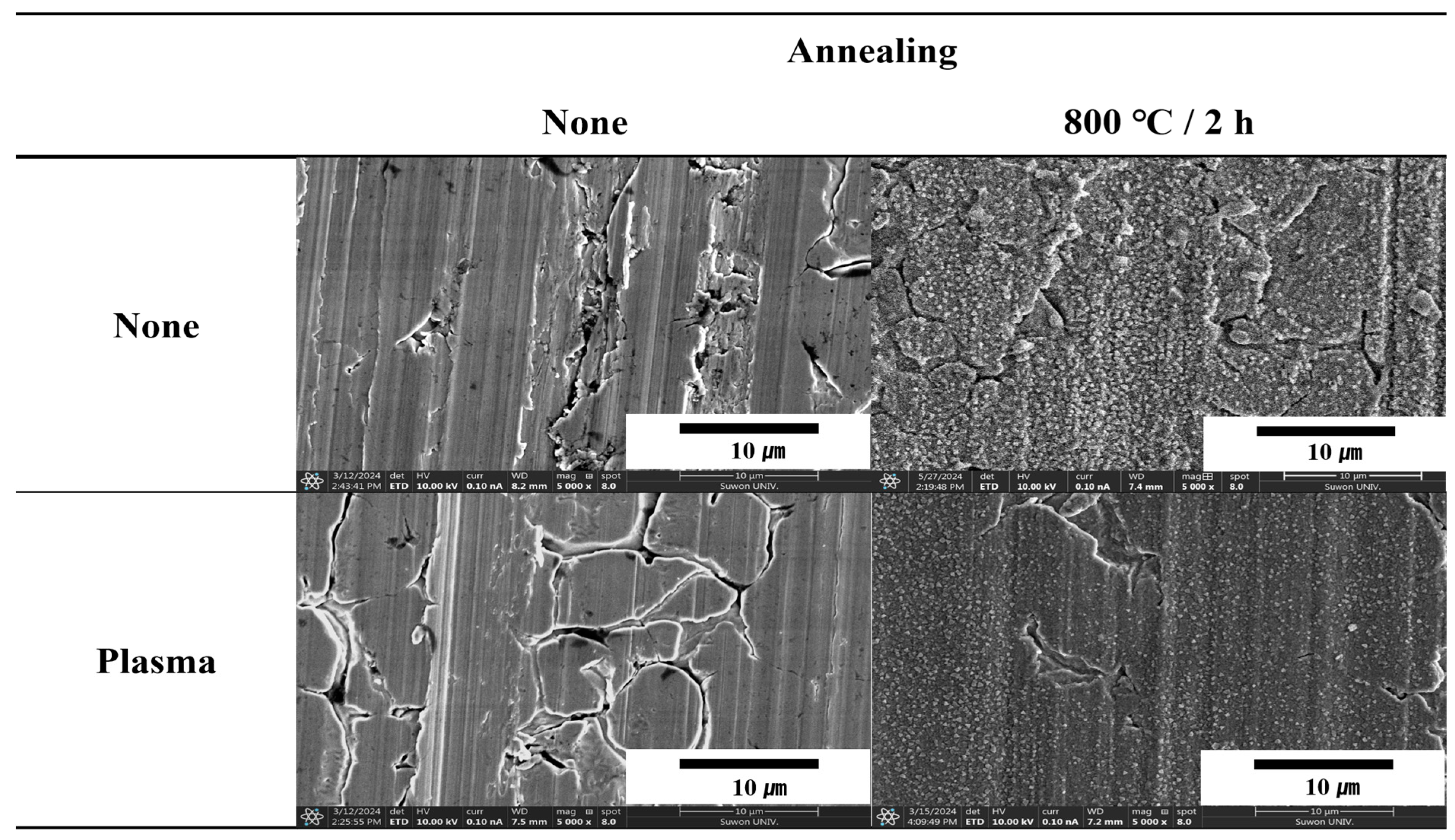

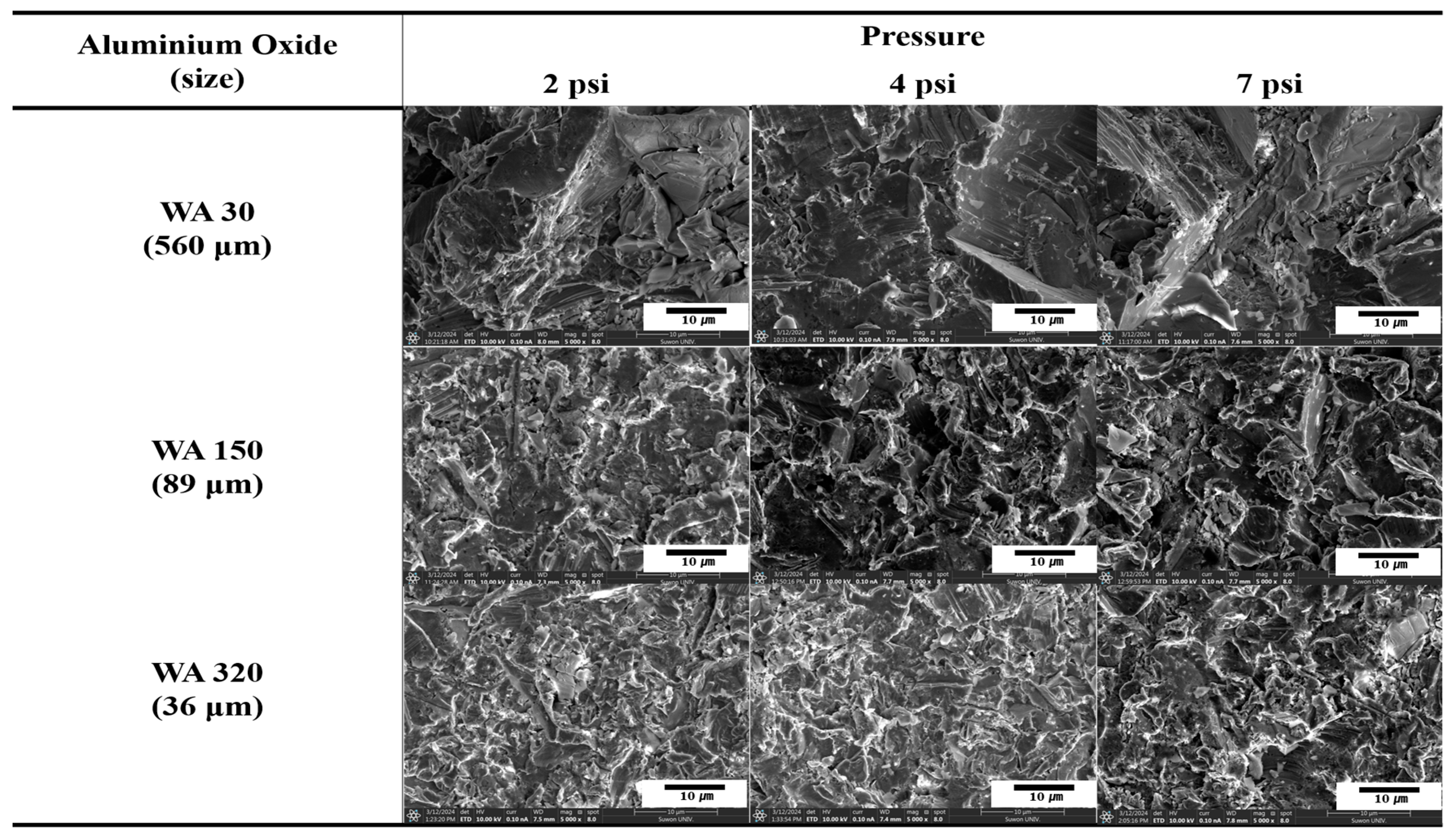

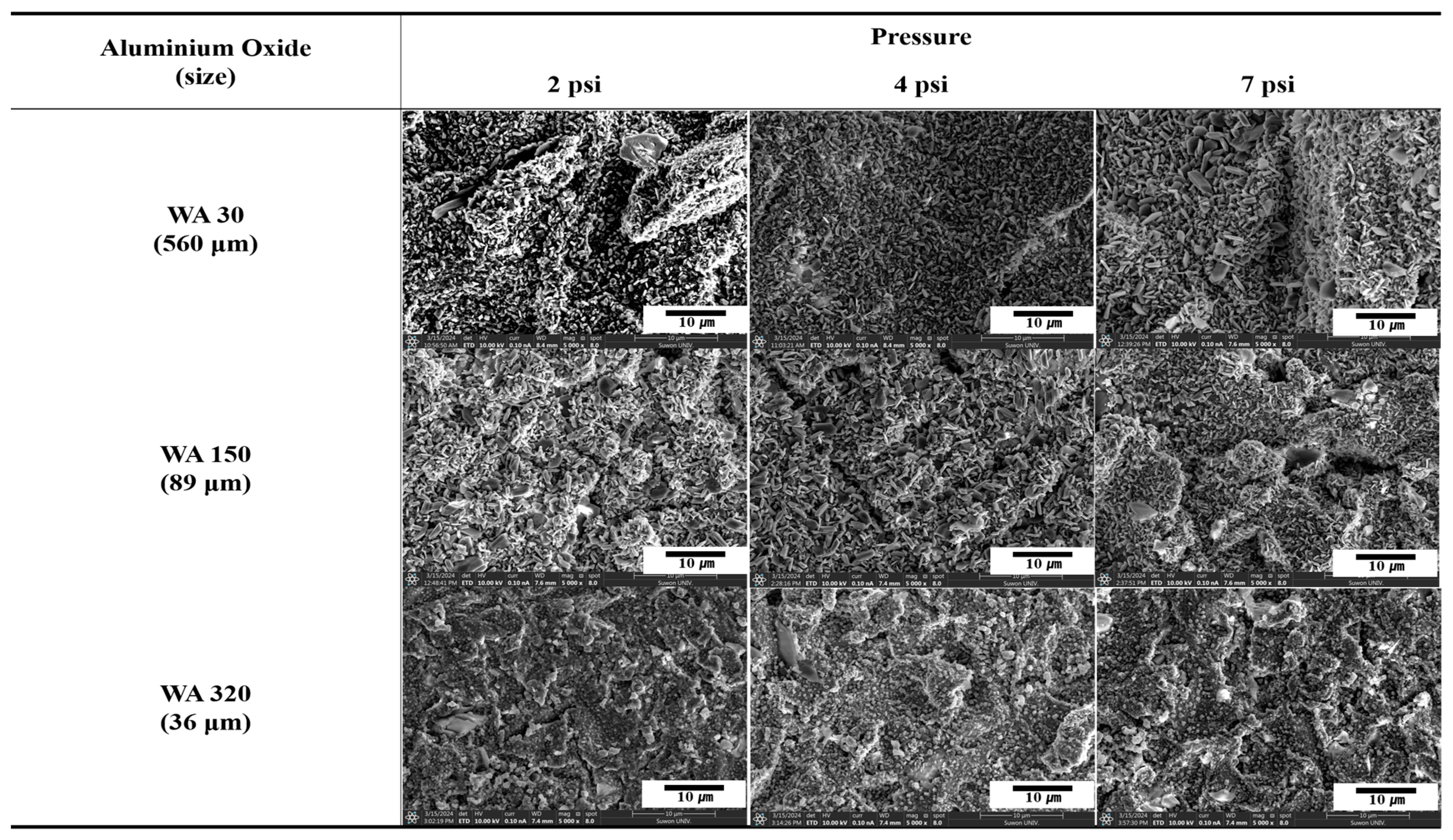

2.3.1. Scanning Electron Microscopy

2.3.2. Single Lap Shear Test

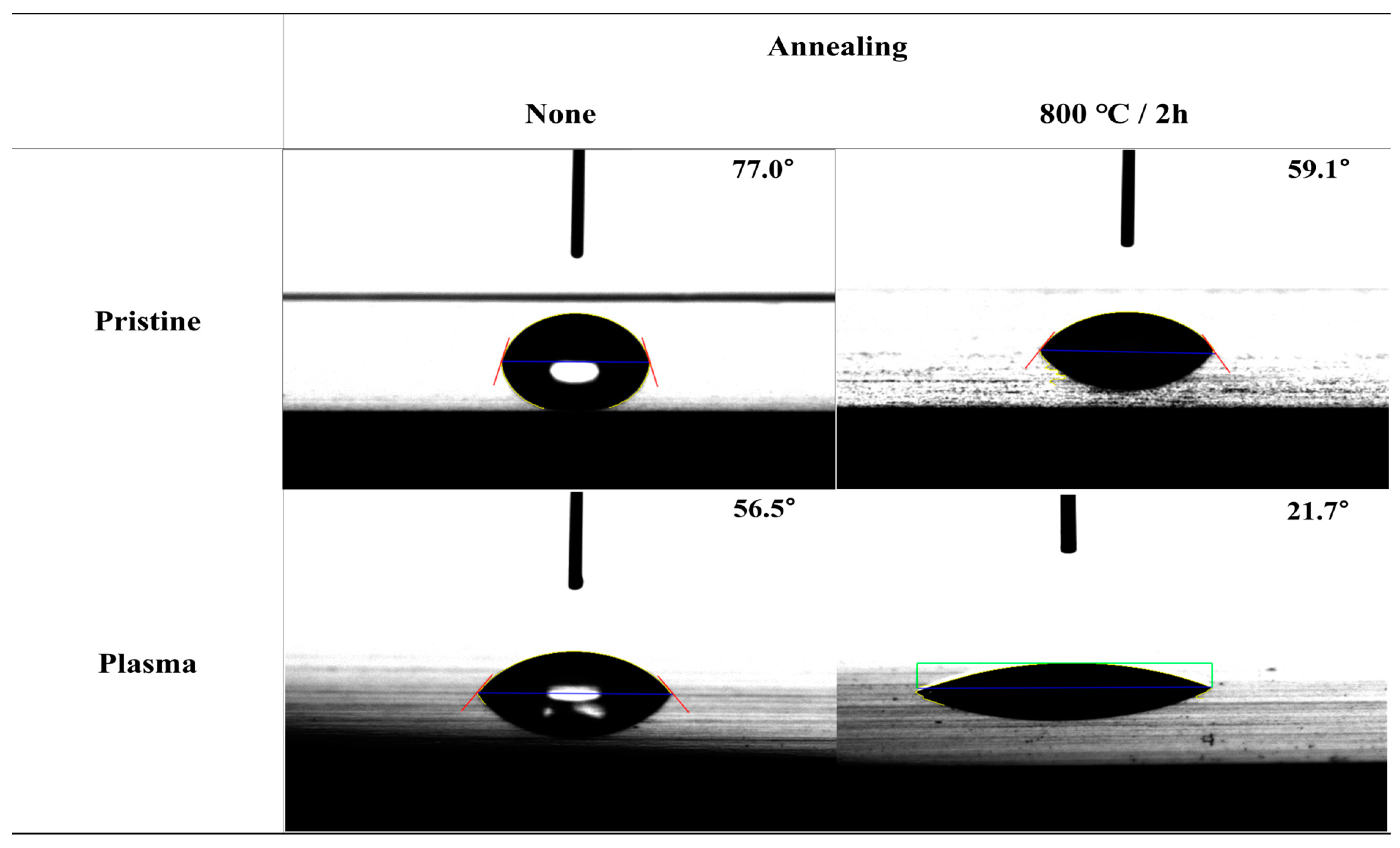

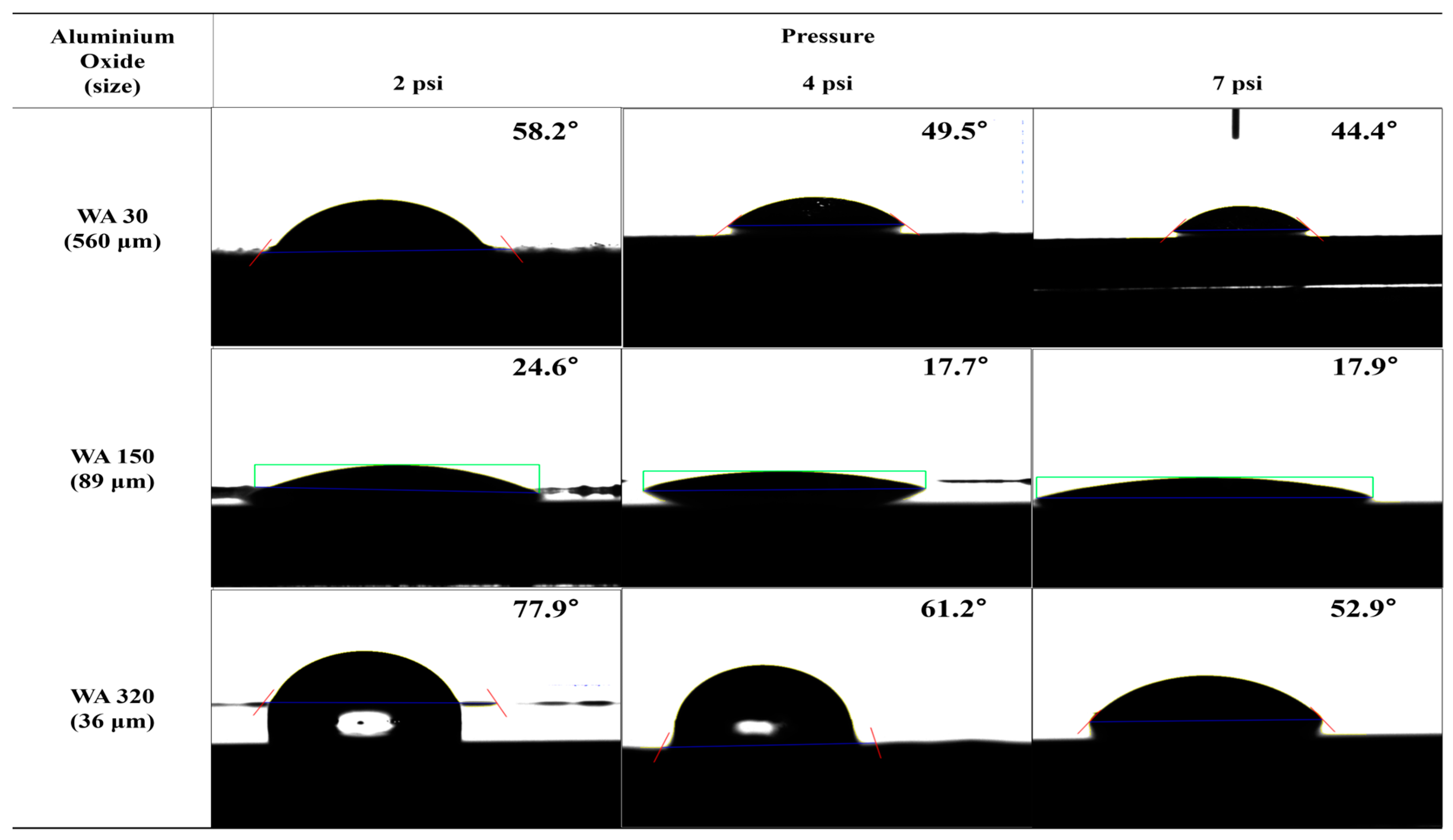

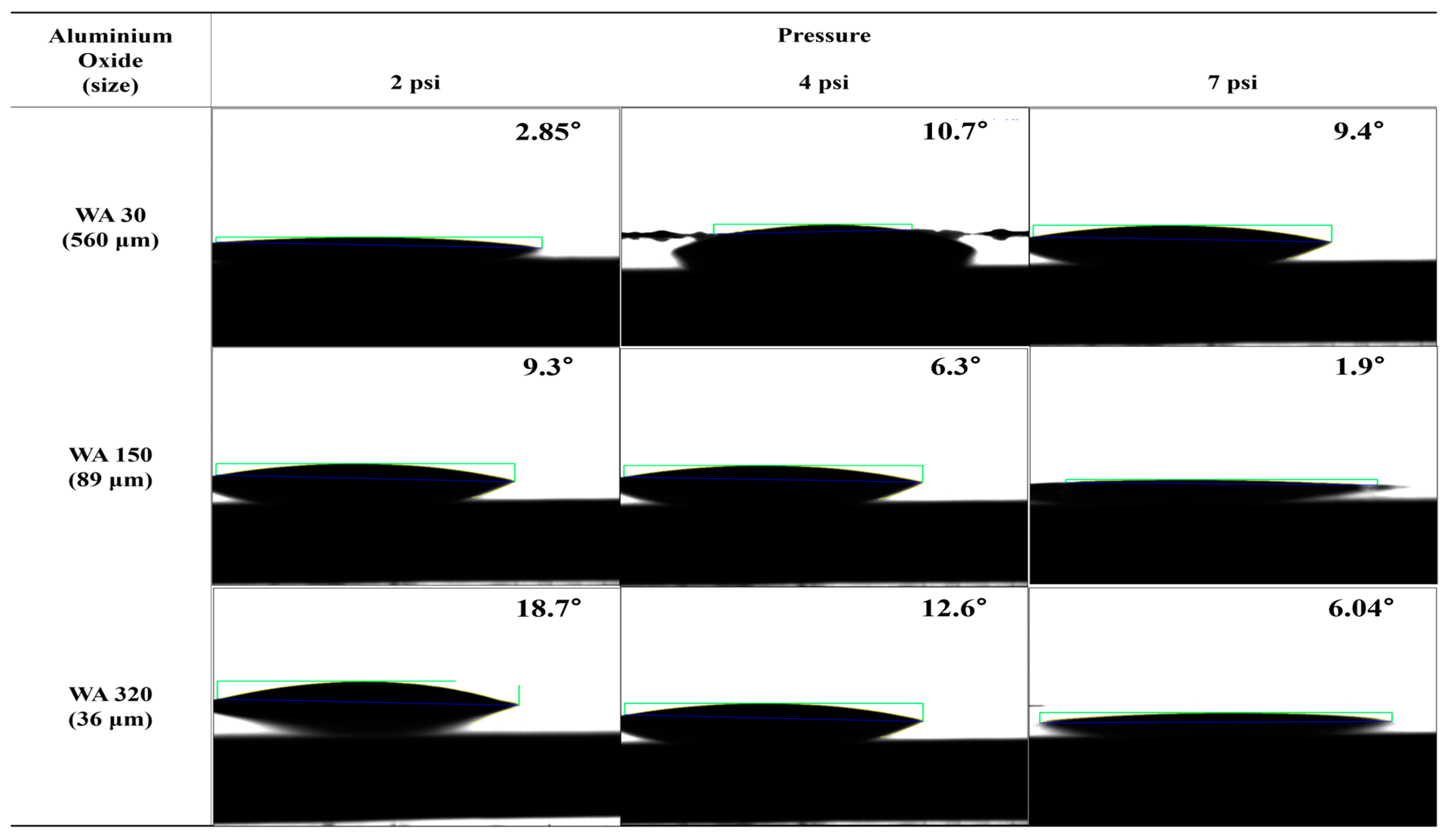

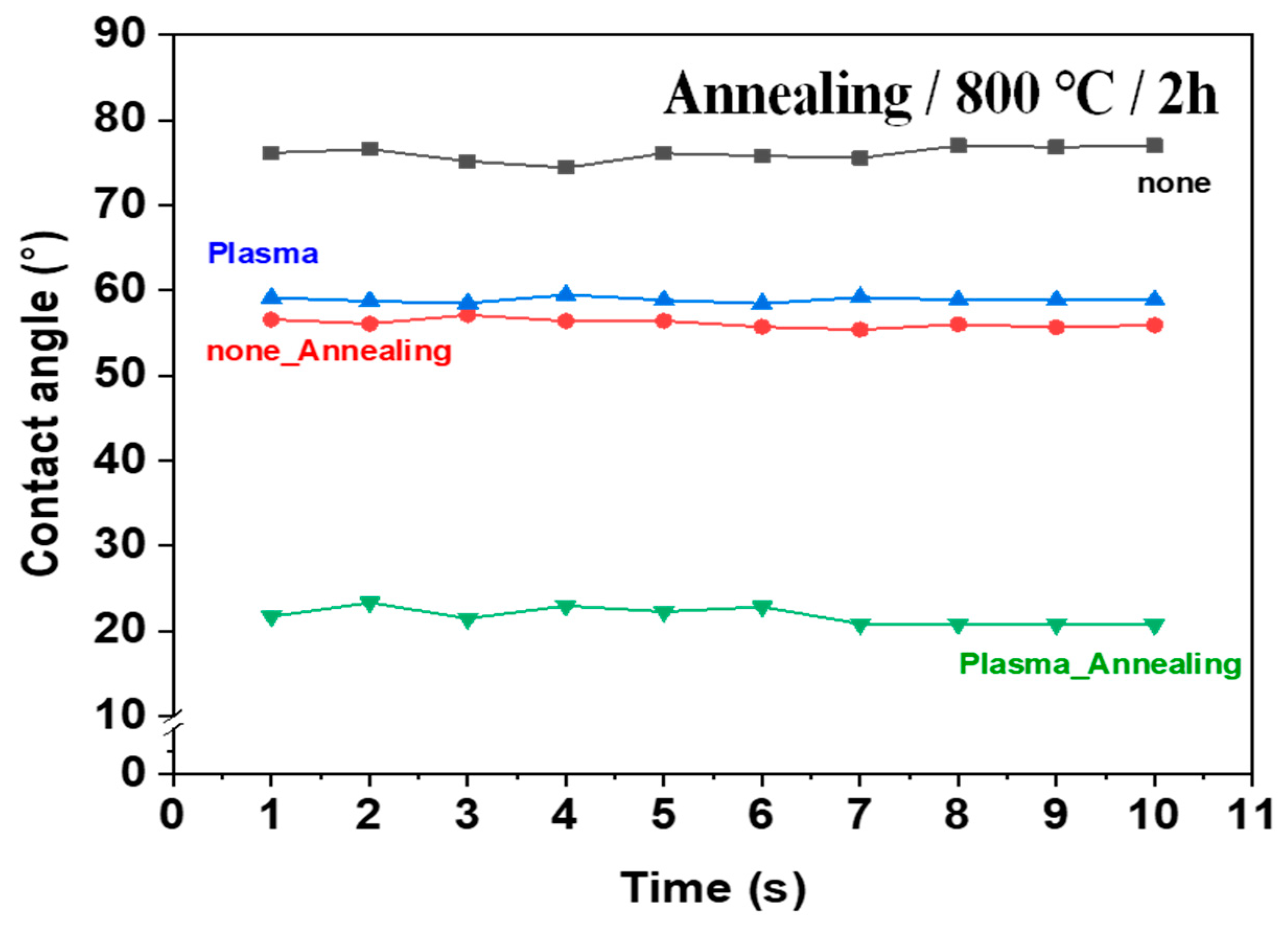

2.3.3. Contact Angle Test

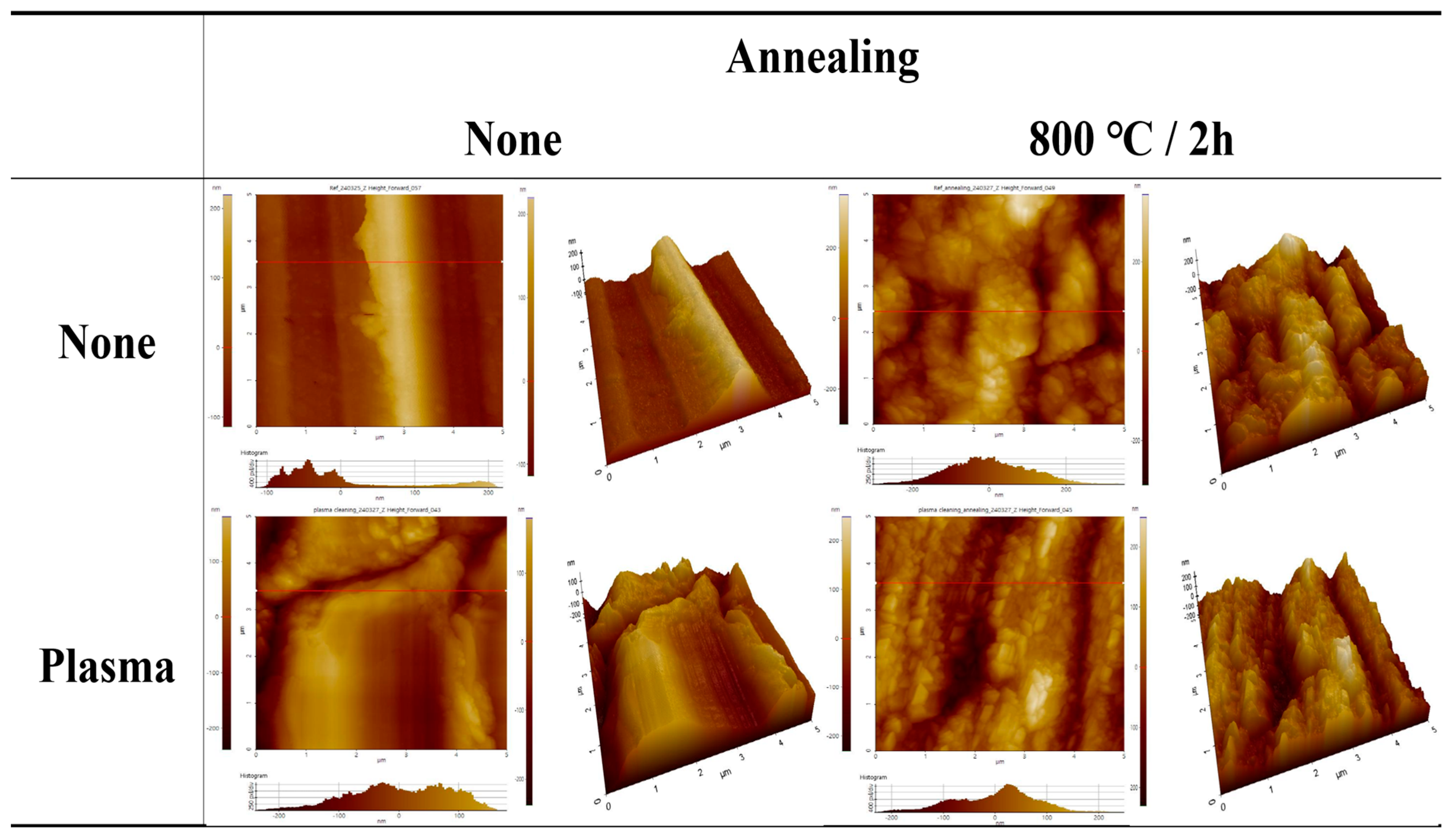

2.3.4. Atomic Force Microscopy

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kawajiri, K.; Kobayashi, M.; Sakamoto, K. Lightweight Materials Equal Lightweight Greenhouse Gas Emissions? A Historical Analysis of Greenhouse Gases of Vehicle Material Substitution. J. Clean. Prod. 2020, 253, 119805. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material Efficiency Strategies to Reducing Greenhouse Gas Emissions Associated with Buildings, Vehicles, and Electronics—A Review. Environ. Res. Lett. 2019, 14, 043004. [Google Scholar] [CrossRef]

- Modaresi, R.; Pauliuk, S.; Løvik, A.N.; Müller, D.B. Global Carbon Benefits of Material Substitution in Passenger Cars until 2050 and the Impact on the Steel and Aluminum Industries. Environ. Sci. Technol. 2014, 48, 10776–10784. [Google Scholar] [CrossRef] [PubMed]

- Kelly, J.C.; Sullivan, J.L.; Burnham, A.; Elgowainy, A. Impacts of Vehicle Weight Reduction via Material Substitution on Life-Cycle Greenhouse Gas Emissions. Environ. Sci. Technol. 2015, 49, 12535–12542. [Google Scholar] [CrossRef]

- Quader, M.A.; Ahmed, S.; Ghazilla, R.A.R.; Ahmed, S.; Dahari, M. A Comprehensive Review on Energy Efficient CO2 Breakthrough Technologies for Sustainable Green Iron and Steel Manufacturing. Renew. Sustain. Energy Rev. 2015, 50, 594–614. [Google Scholar] [CrossRef]

- Pervaiz, M.; Panthapulakkal, S.; Kc, B.; Sain, M.; Tjong, J. Emerging Trends in Automotive Lightweighting through Novel Composite Materials. Mater. Sci. Appl. 2016, 7, 26–38. [Google Scholar] [CrossRef]

- Fayyazbakhsh, A.; Pirouzfar, V. Comprehensive Overview on Diesel Additives to Reduce Emissions, Enhance Fuel Properties and Improve Engine Performance. Renew. Sustain. Energy Rev. 2017, 74, 891–901. [Google Scholar] [CrossRef]

- Khorramshokouh, S.; Pirouzfar, V.; Kazerouni, Y.; Fayyazbakhsh, A.; Abedini, R. Improving the Properties and Engine Performance of Diesel–Methanol–Nanoparticle Blend Fuels via Optimization of the Emissions and Engine Performance. Energy Fuels 2016, 30, 8200–8208. [Google Scholar] [CrossRef]

- Gürü, M.; Karakaya, U.; Altıparmak, D.; Alıcılar, A. Improvement of Diesel Fuel Properties by Using Additives. Energy Convers. Manag. 2002, 43, 1021–1025. [Google Scholar] [CrossRef]

- Askerdal, M.; Fredriksson, J.; Laine, L.; Bruzelius, F. Motion Resistance Modelling and Validation in Winter Conditions with Varying Air Drag. Veh. Syst. Dyn. 2024, 1–20. [Google Scholar] [CrossRef]

- Askerdal, M.; Fredriksson, J.; Laine, L. Development of Simplified Air Drag Models Including Crosswinds for Commercial Heavy Vehicle Combinations. Veh. Syst. Dyn. 2024, 62, 1085–1102. [Google Scholar] [CrossRef]

- Quazi, A.; Crouch, T.; Bell, J.; McGreevy, T.; Thompson, M.C.; Burton, D. A Field Study on the Aerodynamics of Freight Trains. J. Wind. Eng. Ind. Aerodyn. 2021, 209, 104463. [Google Scholar] [CrossRef]

- Pramuanjaroenkij, A.; Kakaç, S. The Fuel Cell Electric Vehicles: The Highlight Review. Int. J. Hydrogen Energy 2023, 48, 9401–9425. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, X.; Sun, C. The Alternative Path for Fossil Oil: Electric Vehicles or Hydrogen Fuel Cell Vehicles? J. Environ. Manag. 2023, 341, 118019. [Google Scholar] [CrossRef]

- Du, B.; Li, Q.; Zheng, C.; Wang, S.; Gao, C.; Chen, L. Application of Lightweight Structure in Automobile Bumper Beam: A Review. Materials 2023, 16, 967. [Google Scholar] [CrossRef]

- Hagnell, M.K.; Kumaraswamy, S.; Nyman, T.; Åkermo, M. From Aviation to Automotive—A Study on Material Selection and Its Implication on Cost and Weight Efficient Structural Composite and Sandwich Designs. Heliyon 2020, 6, e03716. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced Lightweight Materials for Automobiles: A Review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Reddy, V.J.; Hariram, N.P.; Maity, R.; Ghazali, M.F.; Kumarasamy, S. Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles. World Electr. Veh. J. 2024, 15, 93. [Google Scholar] [CrossRef]

- Singh, H.; Singh Brar, G.; Kumar, H.; Aggarwal, V. A Review on Metal Matrix Composite for Automobile Applications. Mater. Today Proc. 2021, 43, 320–325. [Google Scholar] [CrossRef]

- Mouleeswaran, S.; Vijayarangan, S. Analytical and Experimental Studies on Fatigue Life Prediction of Steel and Composite Leaf Spring for Light Passenger Vehicles Using Life Data Analysis. Mater. Sci. 2007, 13, 141–146. [Google Scholar]

- Gupta, P.; Toksha, B.; Patel, B.; Rushiya, Y.; Das, P.; Rahaman, M. Recent Developments and Research Avenues for Polymers in Electric Vehicles. Chem. Rec. 2022, 22, e202200186. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Njuguna, J. An Introduction to Lightweight Composite Materials and Their Use in Transport Structures. In Lightweight Composite Structures in Transport; Elsevier: Amsterdam, The Netherlands, 2016; pp. 3–34. ISBN 978-1-78242-325-6. [Google Scholar]

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of Composite Materials in Automobile Applications—A Review. J. Eng. Res. 2024, in press. [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for Electric Vehicles and Automotive Sector: A Review. Green Energy Intell. Transp. 2023, 2, 100043. [Google Scholar] [CrossRef]

- Parvez, M.S.; Rahman, M.M.; Samykano, M.; Ali, M.Y. Current Advances in Fabric-Based Airbag Material Selection, Design and Challenges for Adoption in Futuristic Automobile Applications. Mater. Today Proc. 2023, in press. [CrossRef]

- Sourav; Patil, S.; Chandra, N.; Kumar, N.; Kumar, D.; Shetty, R.P. Analysis of Mechanical Properties of Casted Aluminium Alloy for Automotive Safety Application. Eng. Proc. 2024, 59, 157. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, X.; Liu, Z. Advanced Lightweight Structural Materials for Automobiles: Properties, Manipulation, and Perspective. Sci. Adv. Mater. 2024, 16, 563–580. [Google Scholar] [CrossRef]

- Landgrebe, D.; Müller, R.; Haase, R.; Scholz, P.; Riemer, M.; Albert, A.; Grützner, R.; Schieck, F. Efficient Manufacturing Methods for Hybrid Metal-Polymer Components. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–16 November 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 2, p. V002T02A053. [Google Scholar]

- Abedsoltan, H. Applications of Plastics in the Automotive Industry: Current Trends and Future Perspectives. Polym. Eng. Sci. 2024, 64, 929–950. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A Review of Carbon Fiber Materials in Automotive Industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Xiong, F.; Wang, D.; Ma, Z.; Chen, S.; Lv, T.; Lu, F. Structure-Material Integrated Multi-Objective Lightweight Design of the Front End Structure of Automobile Body. Struct. Multidisc Optim. 2018, 57, 829–847. [Google Scholar] [CrossRef]

- Choi, G.S.; Jang, K.-S. Surface Treatment of Stainless Steel (SUS) to Improve Interfacial Adhesion of SUS/Polymer Hybrid Bilayer Composites. Int. J. Adhes. Adhes. 2024, 130, 103629. [Google Scholar] [CrossRef]

- Hovorun, T.P.; Berladir, K.V.; Pererva, V.I.; Rudenko, S.G.; Martynov, A.I. Modern Materials for Automotive Industry. J. Eng. Sci. 2017, 4, f8–f18. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, B.; Wang, X.; Lu, Y.; Li, F.; Li, C. Improved Corrosion Resistance of Carbon Steel in Soft Water with Dendritic-Polymer Corrosion Inhibitors. Chem. Eng. J. 2023, 452, 139043. [Google Scholar] [CrossRef]

- Akshitha Sumahi, V.; Jani, S.P.; Uppalapati, S. Impact Study of a Car Bumper by Using Carbon Fiber Reinforced Polyetherimid and S-Glass/ Epoxy Composite. Mater. Today Proc. 2023, 92, 364–370. [Google Scholar] [CrossRef]

- Sarfraz, M.S.; Hong, H.; Kim, S.S. Recent Developments in the Manufacturing Technologies of Composite Components and Their Cost-Effectiveness in the Automotive Industry: A Review Study. Compos. Struct. 2021, 266, 113864. [Google Scholar] [CrossRef]

- Lee, H.; Song, S.-I.; Jang, K.-S. The Role of Surface Treatment and Coupling Agents for Adhesion between Stainless Steel (SUS) and Polyamide (PA) of Heterojunction Bilayer Composites. Polymers 2024, 16, 896. [Google Scholar] [CrossRef]

- Lee, B.-Y.; Jeong, H.-G.; Kim, S.J.; Kang, B.-G.; Jang, K.-S. Physical and Chemical Compatibilization Treatment with Modified Aminosilanes for Aluminum/Polyamide Adhesion. ACS Omega 2022, 7, 23865–23874. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Chemical Modification of Henequén Fibers with an Organosilane Coupling Agent. Compos. Part. B Eng. 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Peck, J.H.; Hwang, S.-H.; Hong, J.; Hong, S.C.; Huh, W.; Lee, S.-W. Preparation and Mechanical Properties of Poly(Vinyl Chloride)/Bamboo Flour Composites with a Novel Block Copolymer as a Coupling Agent. J. Appl. Polym. Sci. 2008, 108, 2654–2659. [Google Scholar] [CrossRef]

- Chauhan, S.; Aggarwal, P.; Karmarkar, A. The Effectiveness of M-TMI-Grafted-PP as a Coupling Agent for Wood Polymer Composites. J. Compos. Mater. 2016, 50, 3515–3524. [Google Scholar] [CrossRef]

- Pletincx, S.; Fockaert, L.L.I.; Mol, J.M.C.; Hauffman, T.; Terryn, H. Probing the Formation and Degradation of Chemical Interactions from Model Molecule/Metal Oxide to Buried Polymer/Metal Oxide Interfaces. NPJ Mater. Degrad. 2019, 3, 23. [Google Scholar] [CrossRef]

- Jannerfeldt, G.; Boogh, L.; Månson, J.-A.E. Tailored Interfacial Properties for Immiscible Polymers by Hyperbranched Polymers. Polymer 2000, 41, 7627–7634. [Google Scholar] [CrossRef]

- Jones, J.J.; Burford, R.P. Morphology of Block Copolymers and Associated Networks. Polym. Int. 1991, 26, 163–170. [Google Scholar] [CrossRef]

- Possart, W.; Bockenheimer, C.; Valeske, B. The State of Metal Surfaces after Blasting Treatment Part I: Technical Aluminium. Surf. Interface Anal. 2002, 33, 687–696. [Google Scholar] [CrossRef]

- Ghara, T.; Paul, S.; Bandyopadhyay, P.P. Effect of Grit Blasting Parameters on Surface and Near-Surface Properties of Different Metal Alloys. J. Therm. Spray. Technol. 2021, 30, 251–269. [Google Scholar] [CrossRef]

- Aronsson, B.-O.; Lausmaa, J.; Kasemo, B. Glow Discharge Plasma Treatment for Surface Cleaning and Modification of Metallic Biomaterials. J. Biomed. Mater. Res. 1997, 35, 49–73. [Google Scholar] [CrossRef]

- Kim, M.C.; Yang, S.H.; Boo, J.-H.; Han, J.G. Surface Treatment of Metals Using an Atmospheric Pressure Plasma Jet and Their Surface Characteristics. Surf. Coat. Technol. 2003, 174–175, 839–844. [Google Scholar] [CrossRef]

- Taljaard, D.J.; Fourie, J.; Kloppers, C.P. The Effect of Sandblasting and Bead Blasting on the Surface Finish of Dry Electrolyte Polishing of Laser Powder Bed Fusion Parts. J. Mater. Eng. Perform. 2023, 32, 2050–2061. [Google Scholar] [CrossRef]

- Kaseem, M.; Fatimah, S.; Nashrah, N.; Ko, Y.G. Recent Progress in Surface Modification of Metals Coated by Plasma Electrolytic Oxidation: Principle, Structure, and Performance. Prog. Mater. Sci. 2021, 117, 100735. [Google Scholar] [CrossRef]

- Laleh, M.; Sadeghi, E.; Revilla, R.I.; Chao, Q.; Haghdadi, N.; Hughes, A.E.; Xu, W.; De Graeve, I.; Qian, M.; Gibson, I.; et al. Heat Treatment for Metal Additive Manufacturing. Prog. Mater. Sci. 2023, 133, 101051. [Google Scholar] [CrossRef]

- Pavlovich, I.I.; Tomashik, Z.F.; Stratiychuk, I.B.; Tomashik, V.M.; Savchuk, O.A.; Kravtsova, A.S. Chemical-Dynamic Polishing of Semiconductor Materials Based on Bi and Sb Chalcogenides by Using HNO3–HCl Solutions. Semicond. Phys. Quantum Electron. Optoelectron. 2011, 14, 200–202. [Google Scholar] [CrossRef]

- Cheraghali, R.; Dehaghi, S.; Ghoranneviss, M.; Aberoomand Azar, P.; Khorrami, S. Etching of 316L Stainless Steel by Different Chemical Etchant Solutions for the Growth of Carbon Nanotubes by Thermal Chemical Vapour Deposition. Asian J. Chem. 2011, 23, 2833–2836. [Google Scholar]

- Valiente Bermejo, M.A. Reagent Selection in Austenitic Stainless Steel Solidification Modes Characterization. Weld. J. 2012, 91, S133–S139. [Google Scholar]

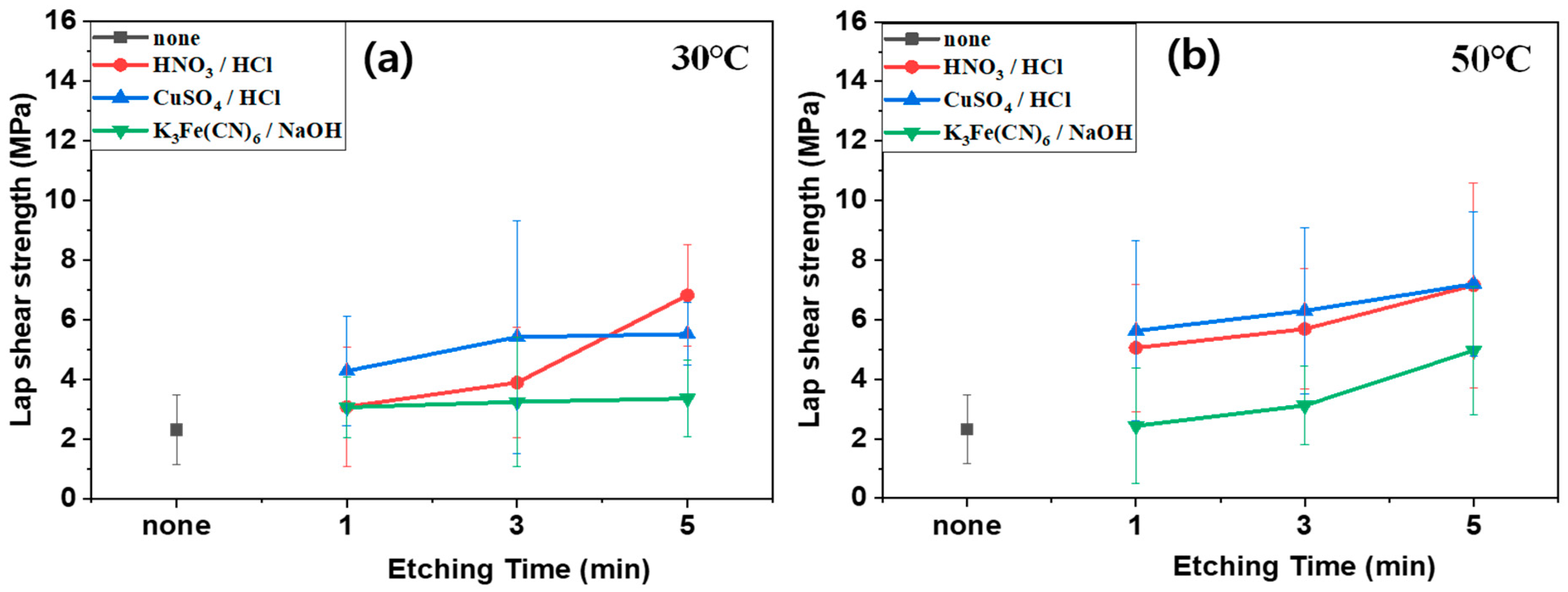

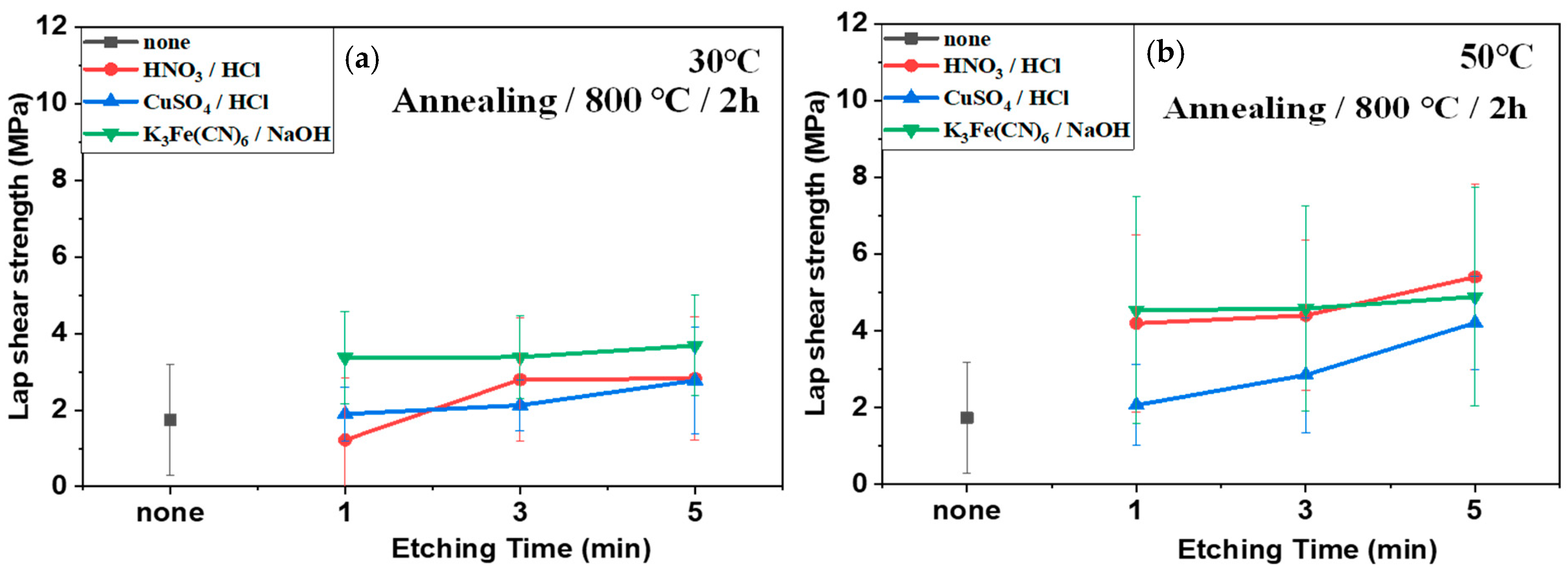

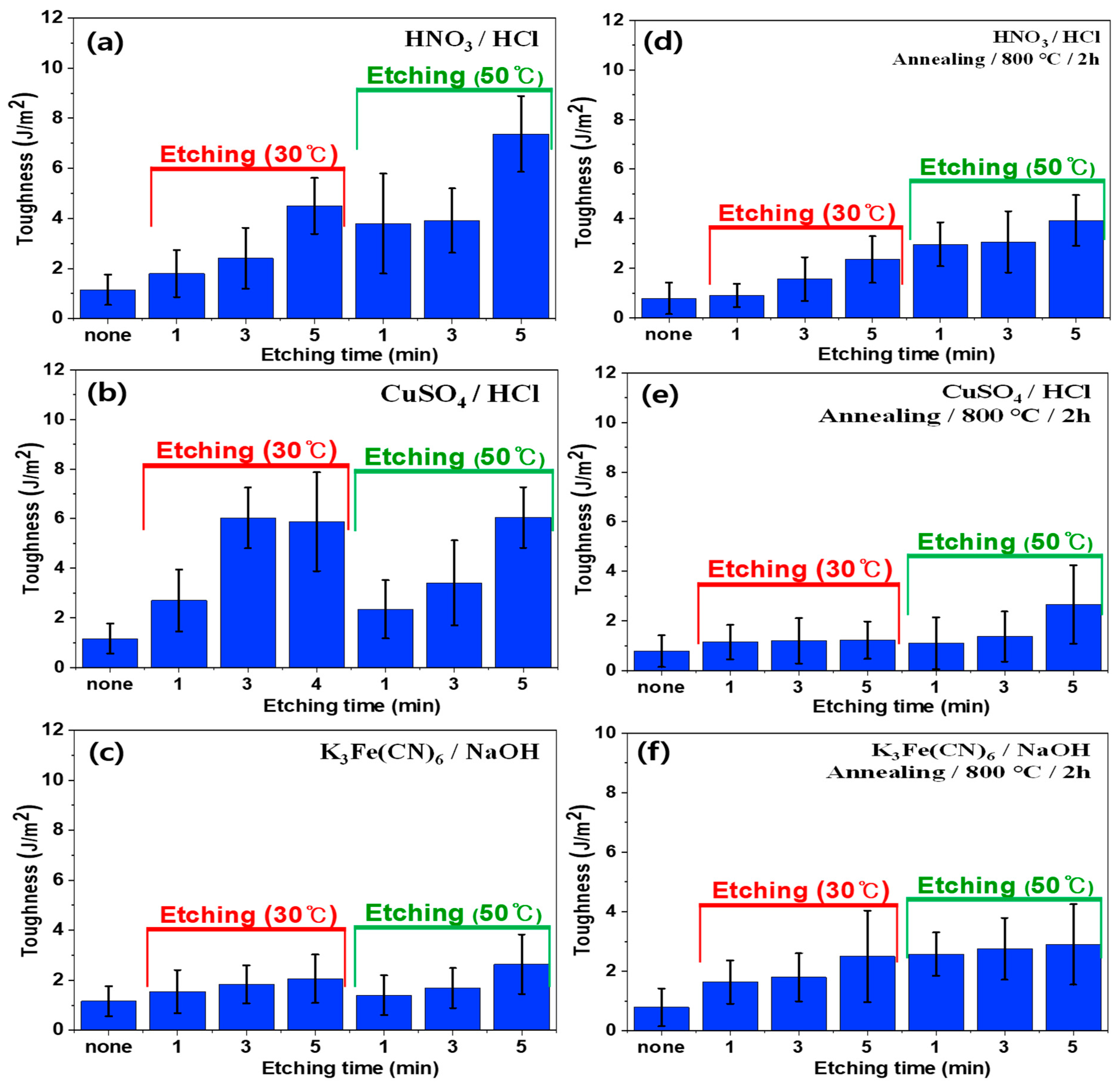

| Etching Solution (100 mL) | Etching Temperature (°C) | Etching Time (min) |

|---|---|---|

| HNO3 20 mL HCl 60 mL DI water 20 mL | 30 | 1 |

| 3 | ||

| 5 | ||

| 50 | 1 | |

| 3 | ||

| 5 | ||

| CuSO4 5H2O 10 g HCl 50 mL DI water 20 mL | 30 | 1 |

| 3 | ||

| 5 | ||

| 50 | 1 | |

| 3 | ||

| 5 | ||

| K3Fe(CN)6 10 g NaOH 10 g DI water 100 mL | 30 | 1 |

| 3 | ||

| 5 | ||

| 50 | 1 | |

| 3 | ||

| 5 |

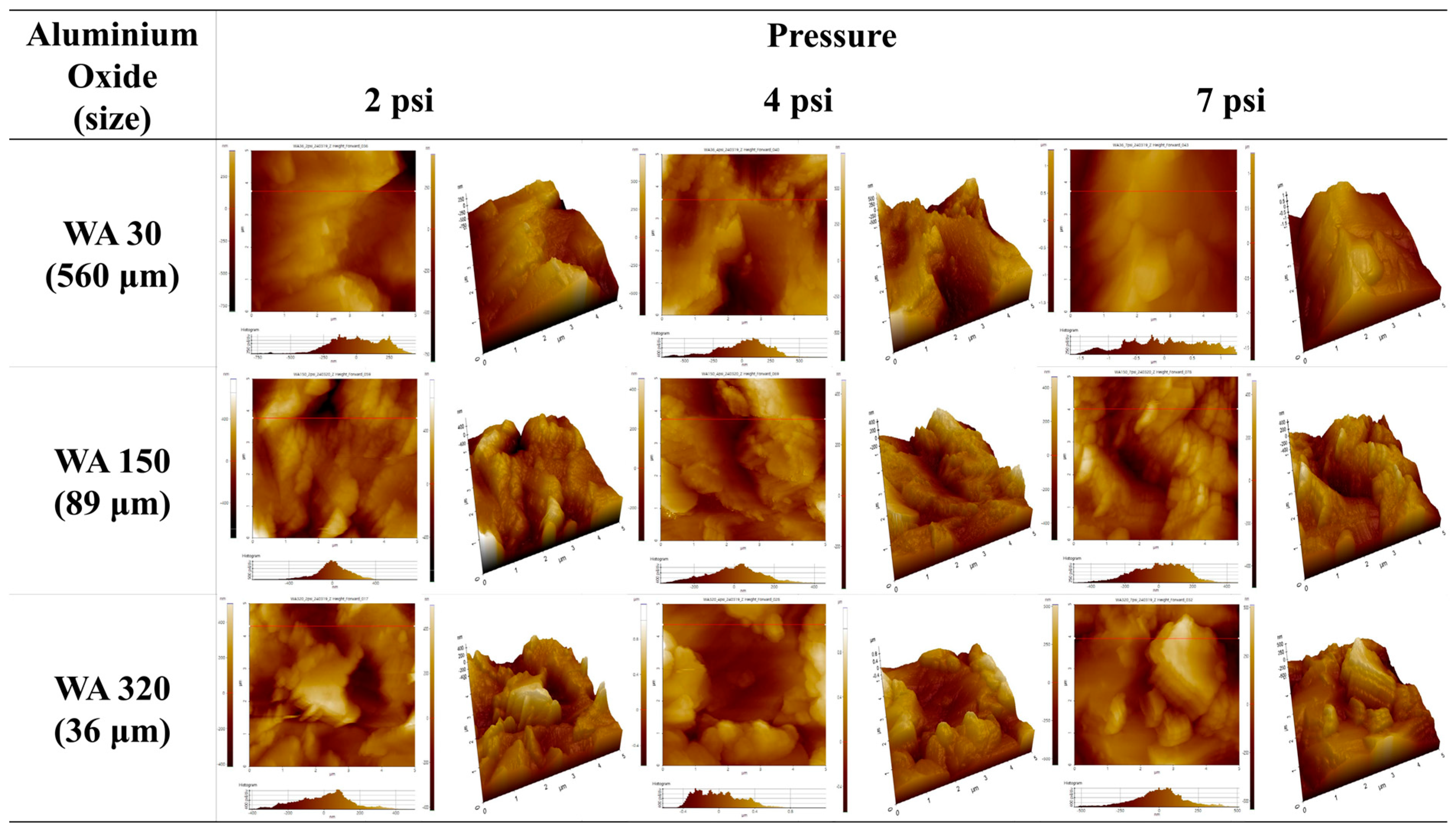

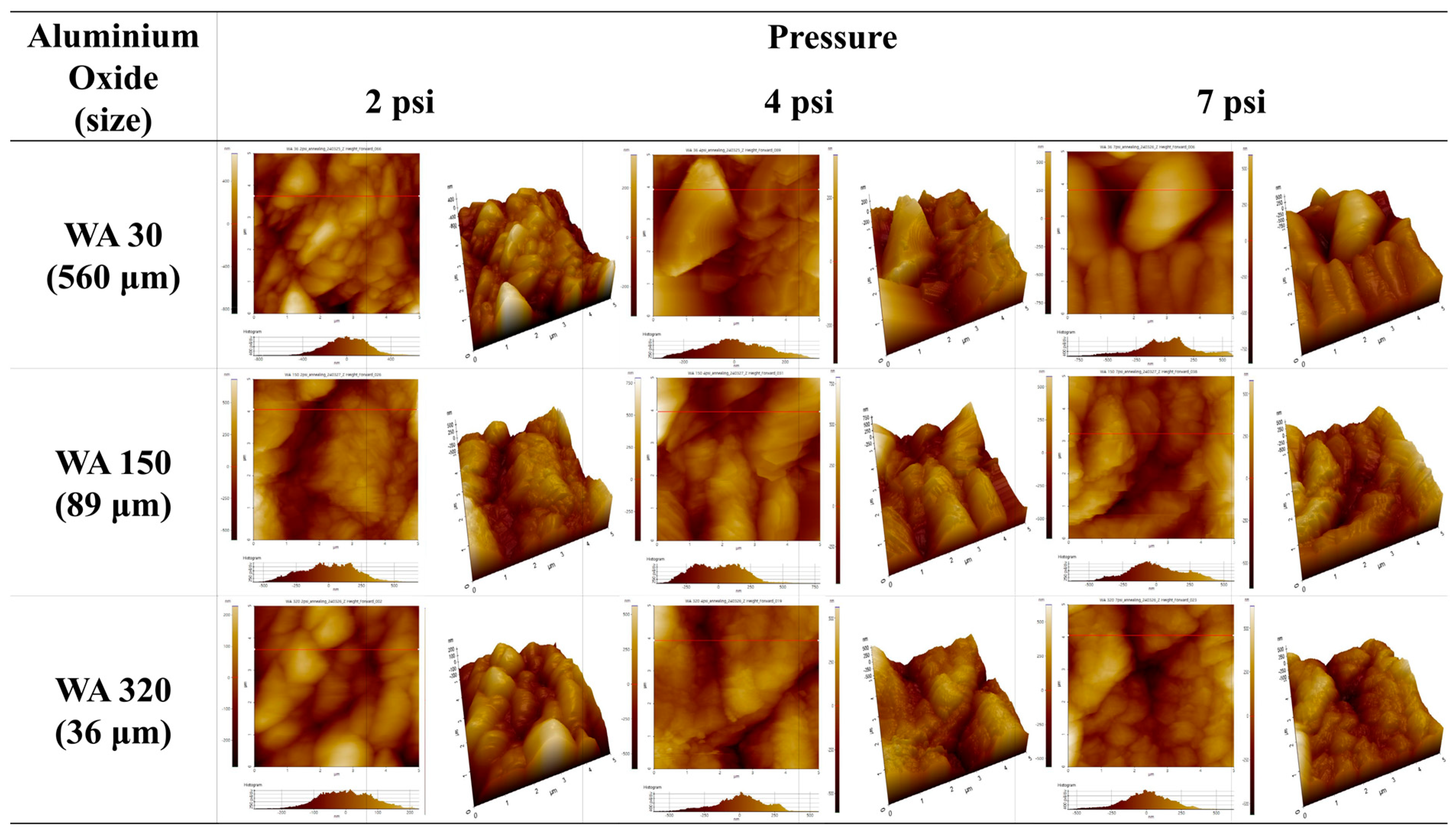

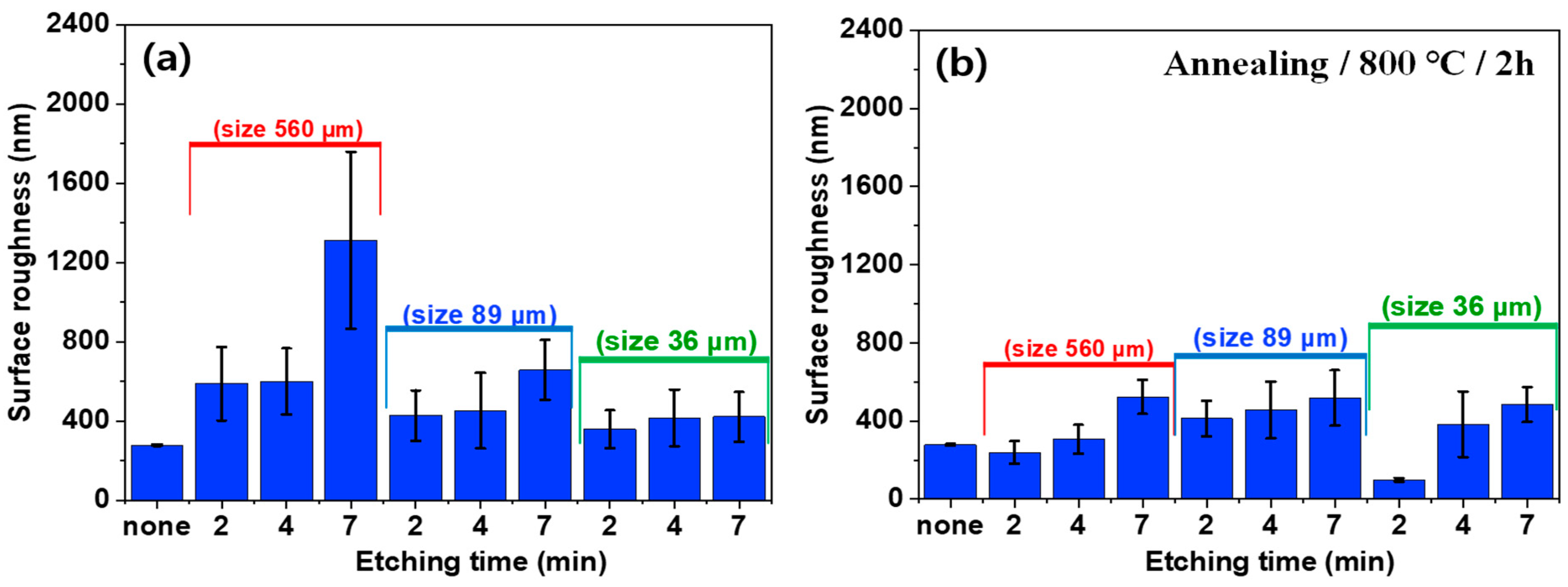

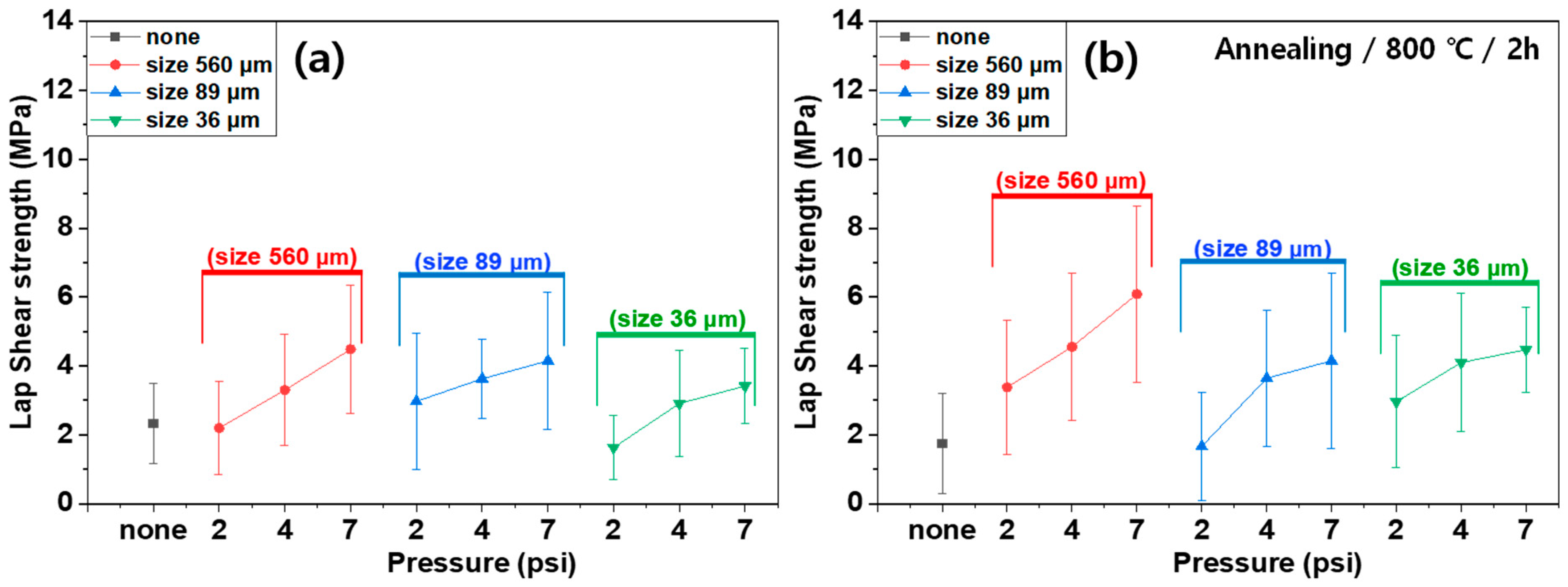

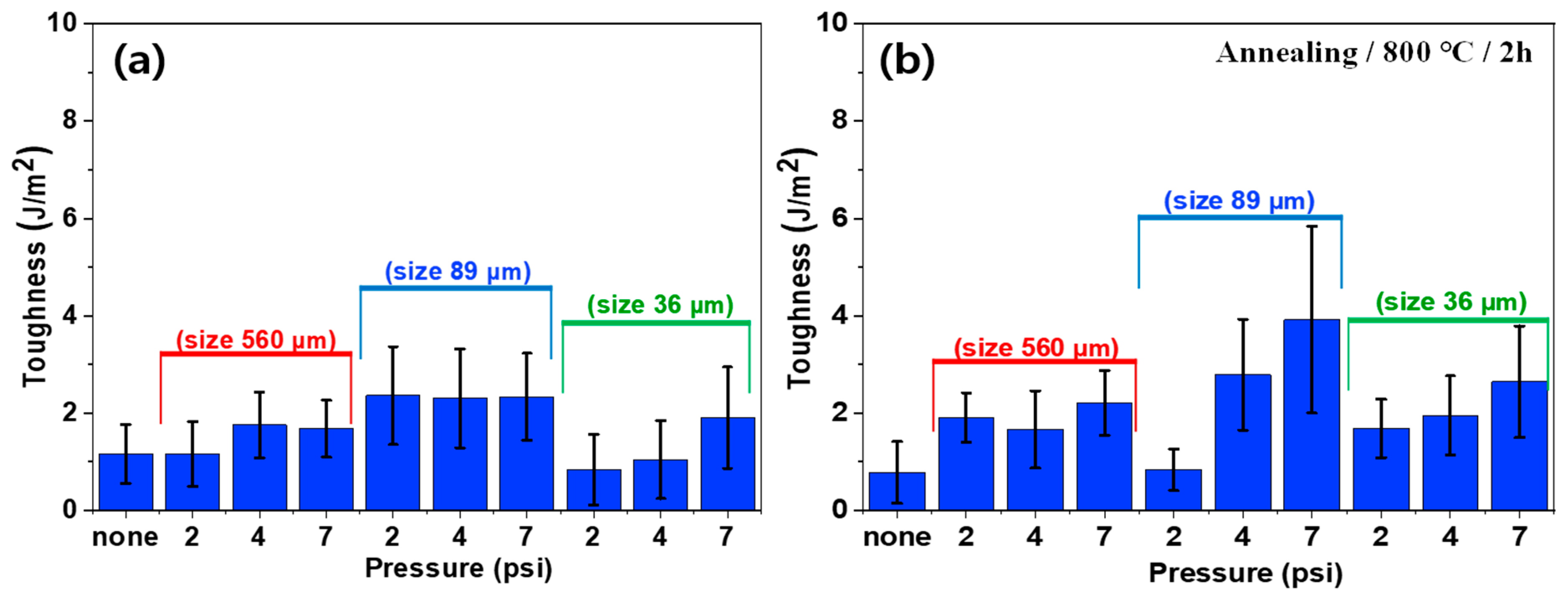

| Aluminum Oxide (Size) | Pressure (psi) | ||

|---|---|---|---|

| WA 30 (560 μm) | 2 | 4 | 7 |

| WA 150 (89 μm) | 2 | 4 | 7 |

| WA 320 (36 μm) | 2 | 4 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, S.-S.; Yoon, W.; Jang, K.-S. Optimizing Surface Characteristics of Stainless Steel (SUS) for Enhanced Adhesion in Heterojunction Bilayer SUS/Polyamide 66 Composites. Polymers 2024, 16, 2737. https://doi.org/10.3390/polym16192737

Yun S-S, Yoon W, Jang K-S. Optimizing Surface Characteristics of Stainless Steel (SUS) for Enhanced Adhesion in Heterojunction Bilayer SUS/Polyamide 66 Composites. Polymers. 2024; 16(19):2737. https://doi.org/10.3390/polym16192737

Chicago/Turabian StyleYun, Sang-Seok, Wanjun Yoon, and Keon-Soo Jang. 2024. "Optimizing Surface Characteristics of Stainless Steel (SUS) for Enhanced Adhesion in Heterojunction Bilayer SUS/Polyamide 66 Composites" Polymers 16, no. 19: 2737. https://doi.org/10.3390/polym16192737

APA StyleYun, S.-S., Yoon, W., & Jang, K.-S. (2024). Optimizing Surface Characteristics of Stainless Steel (SUS) for Enhanced Adhesion in Heterojunction Bilayer SUS/Polyamide 66 Composites. Polymers, 16(19), 2737. https://doi.org/10.3390/polym16192737