Microbeam X-ray and Scanning Electron Microscopic Analyses on Sector-Banded Spherulites of Poly(p-dioxanone) Justified with Pixelated Iridescence

Abstract

1. Introduction

2. Experimental

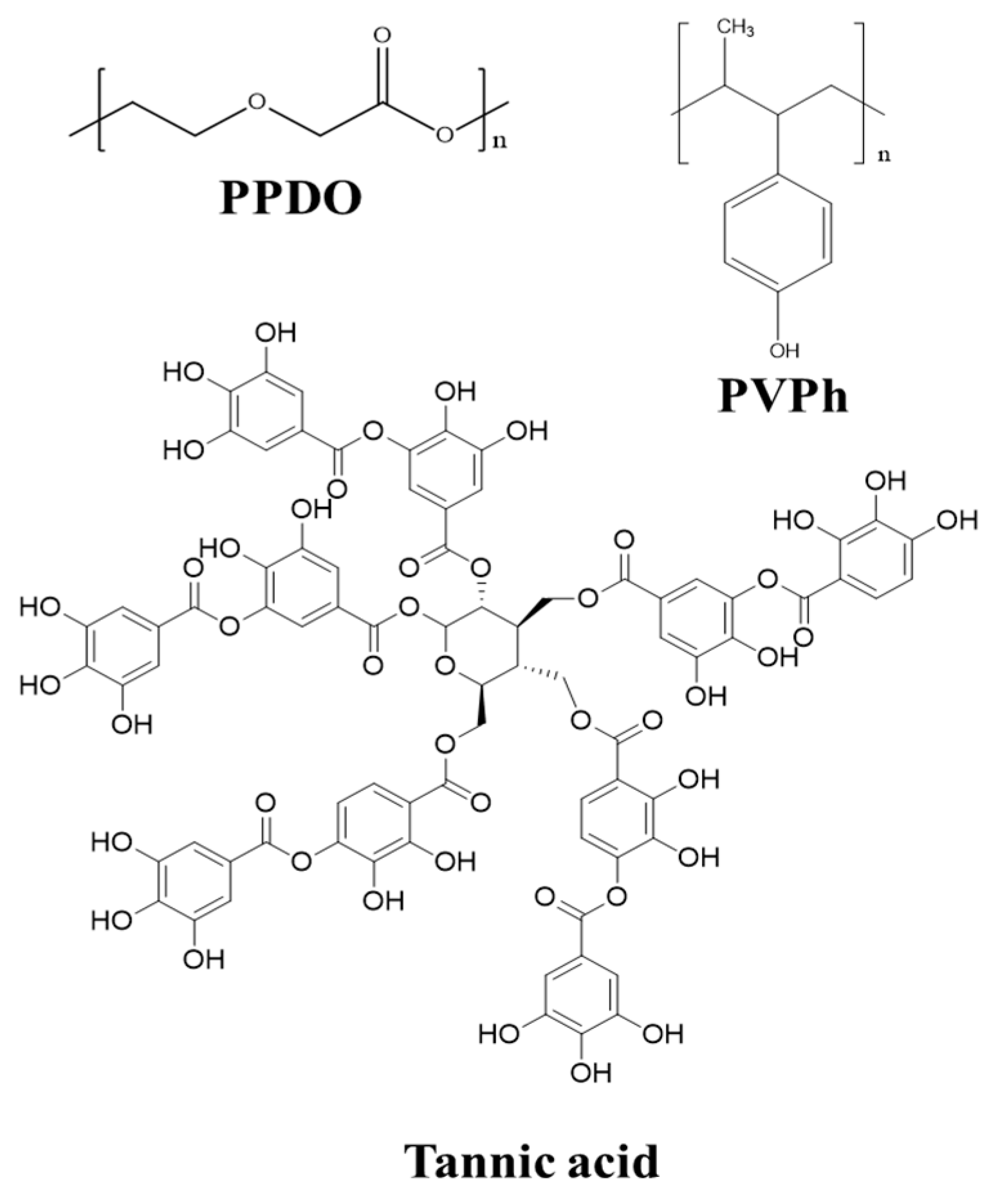

2.1. Materials and Preparation

2.2. Apparatus

3. Results and Discussion

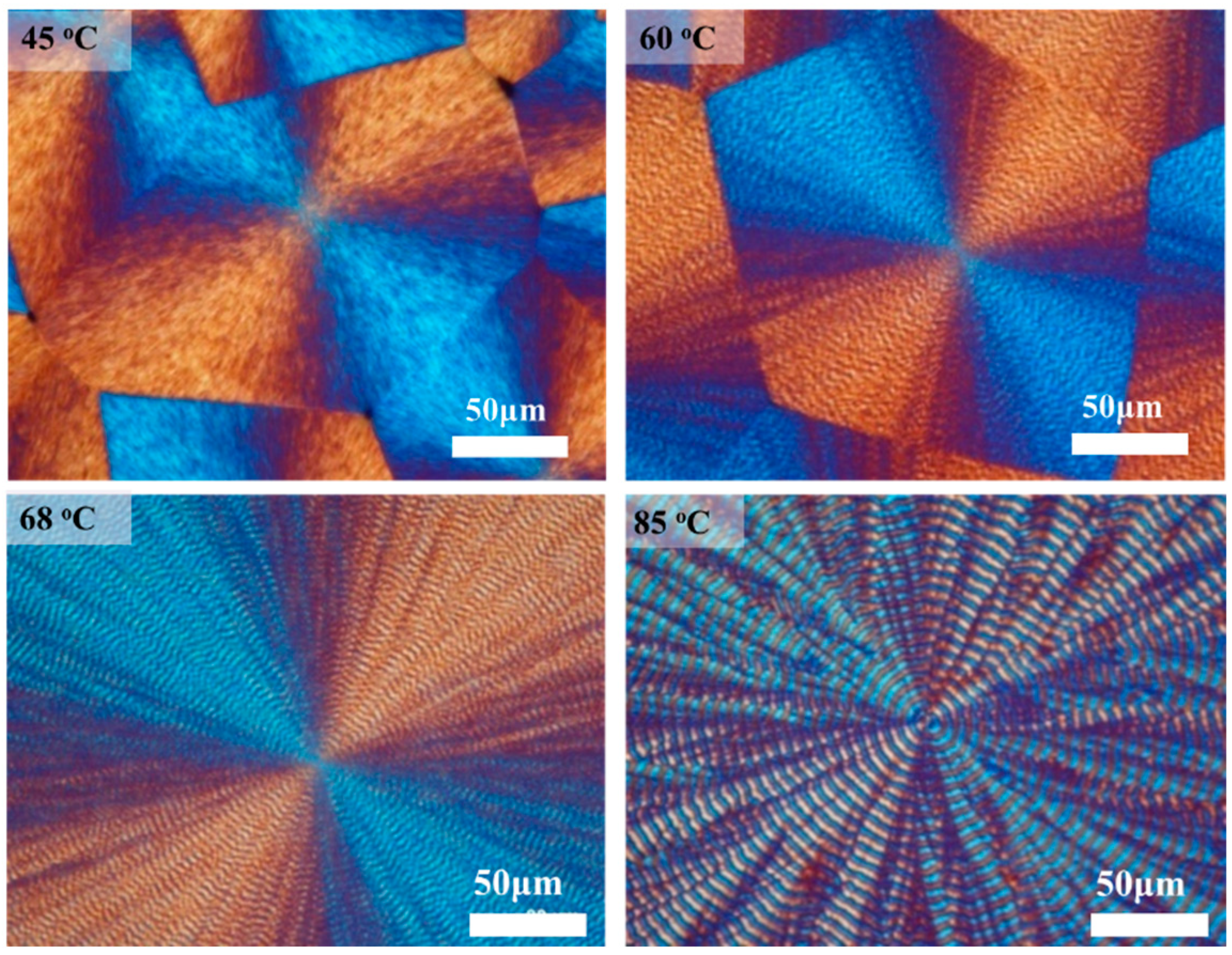

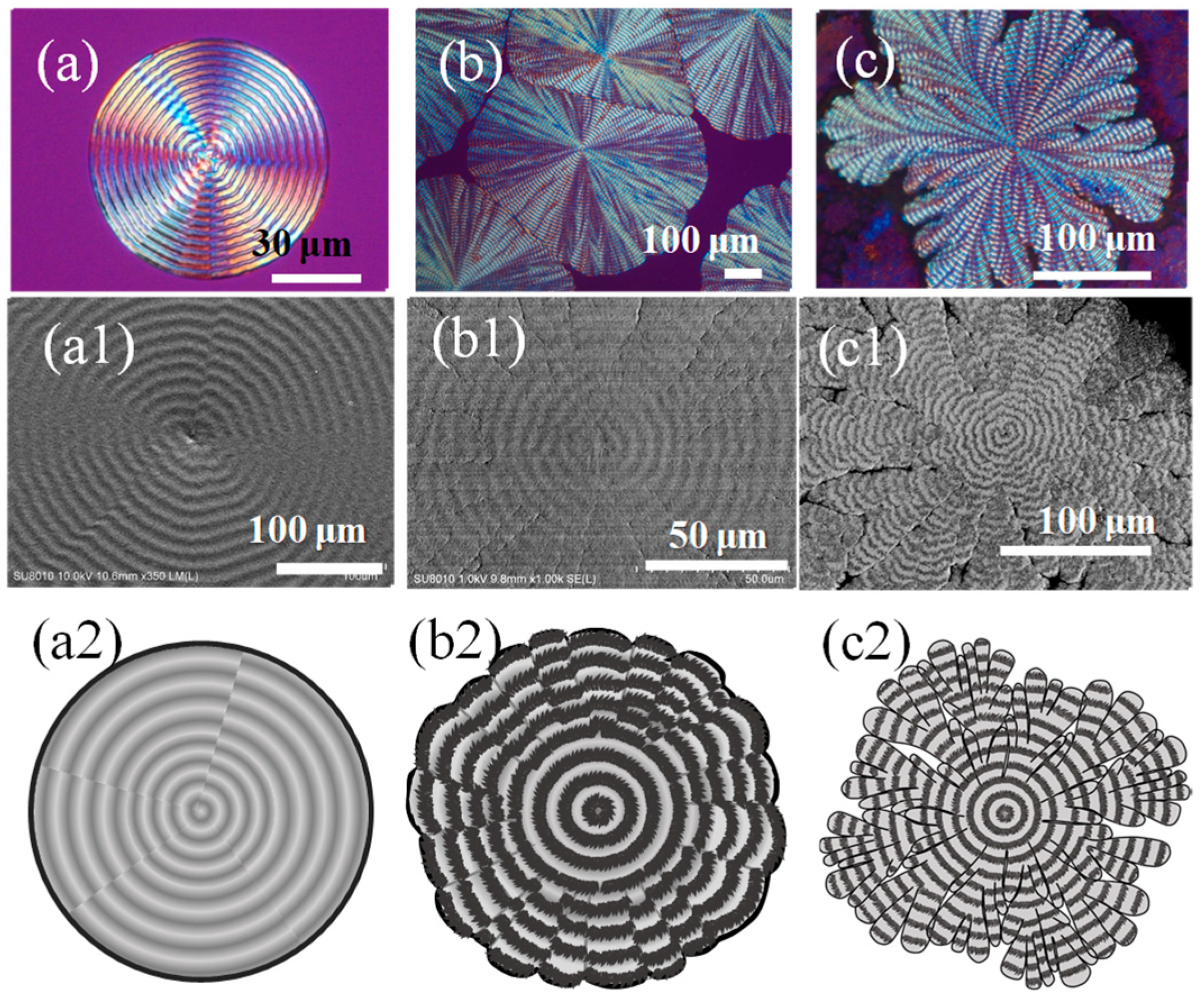

3.1. PPDO/PVPh Ring-Banded Spherulites

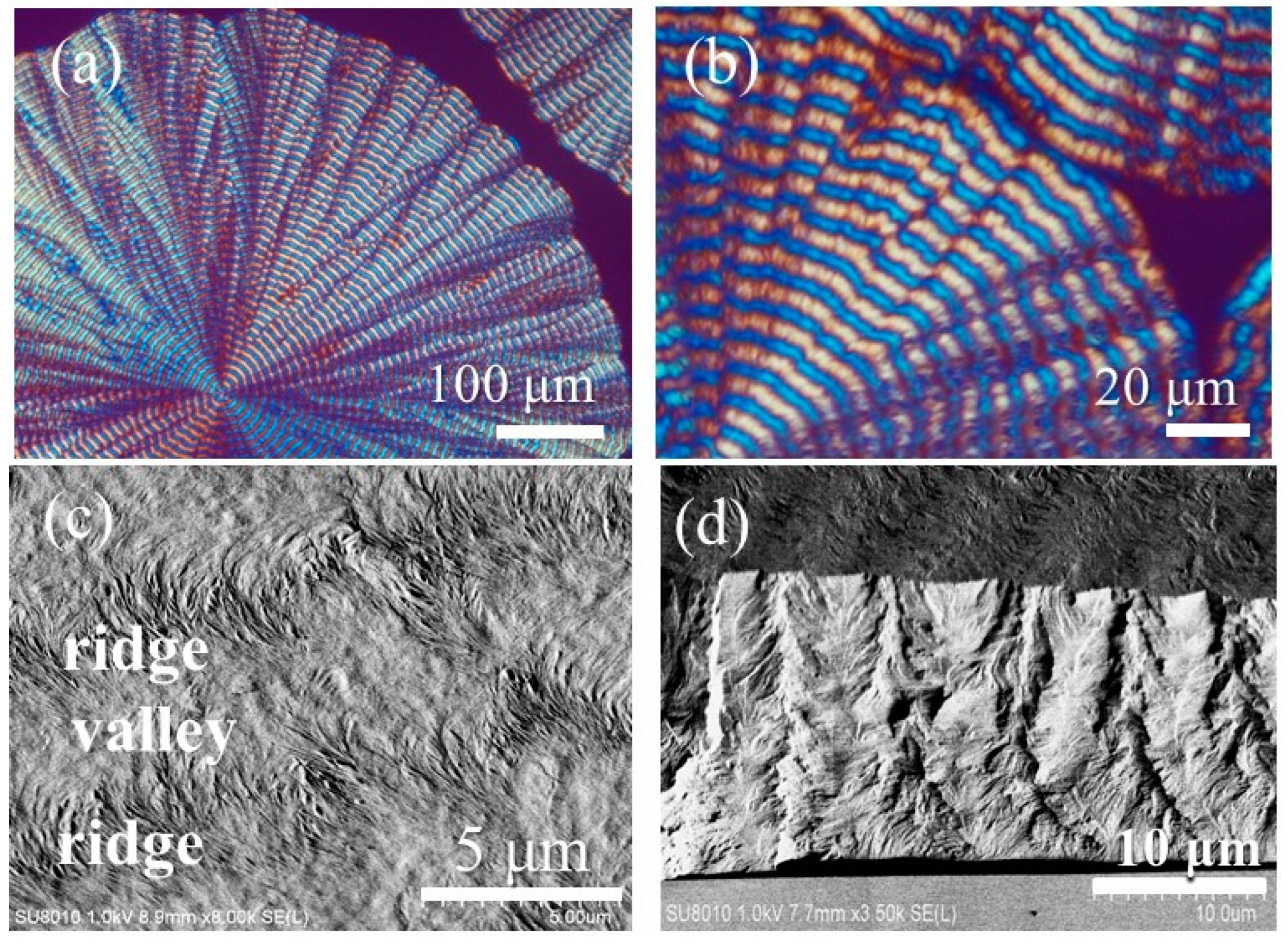

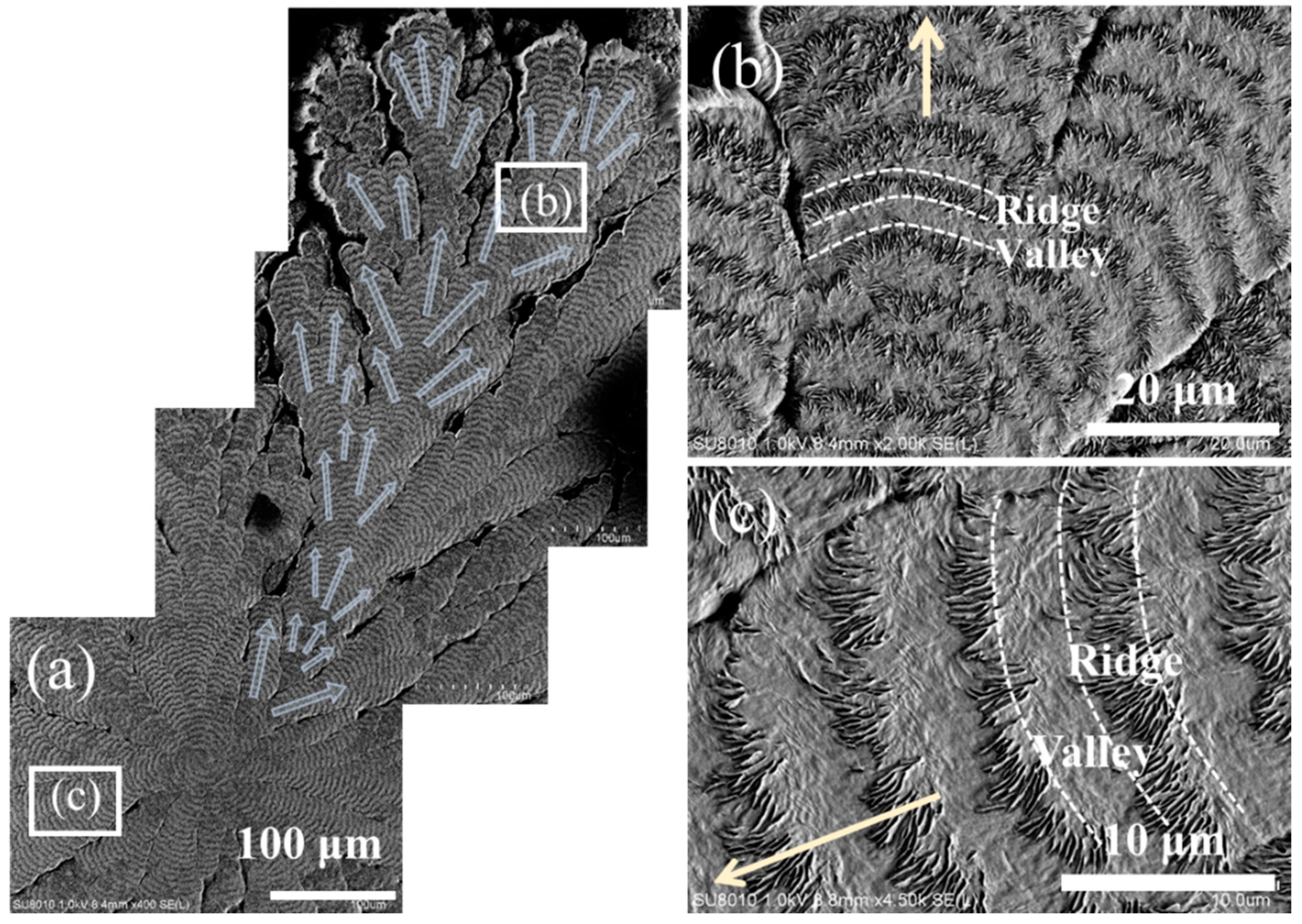

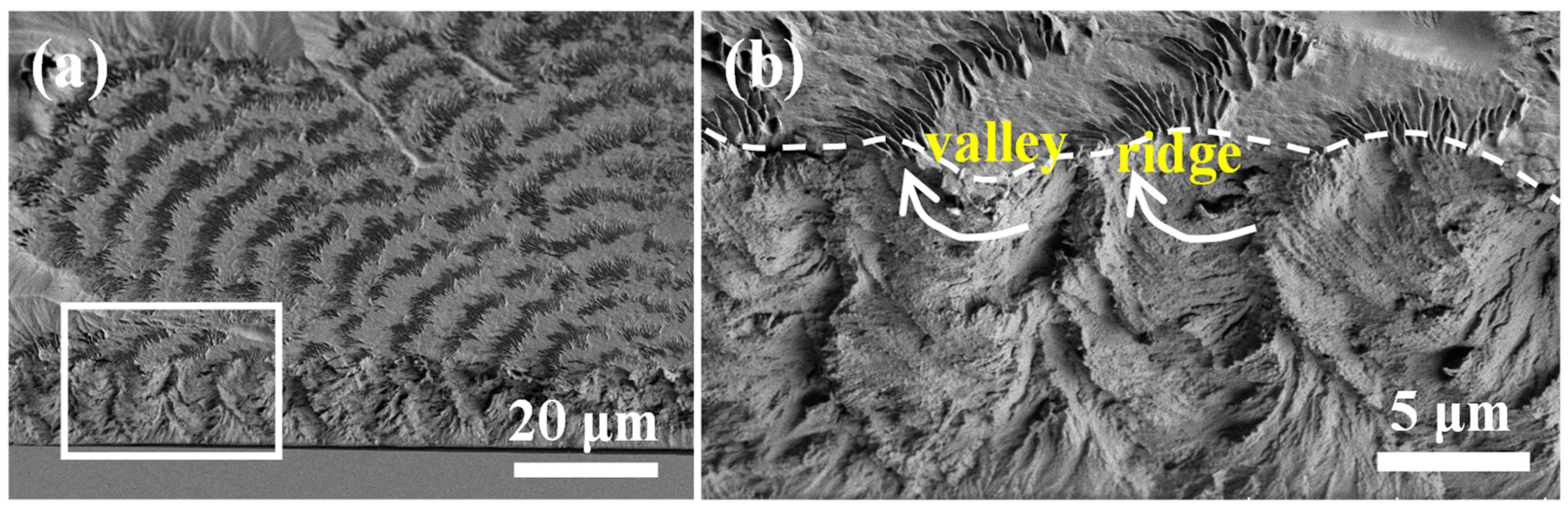

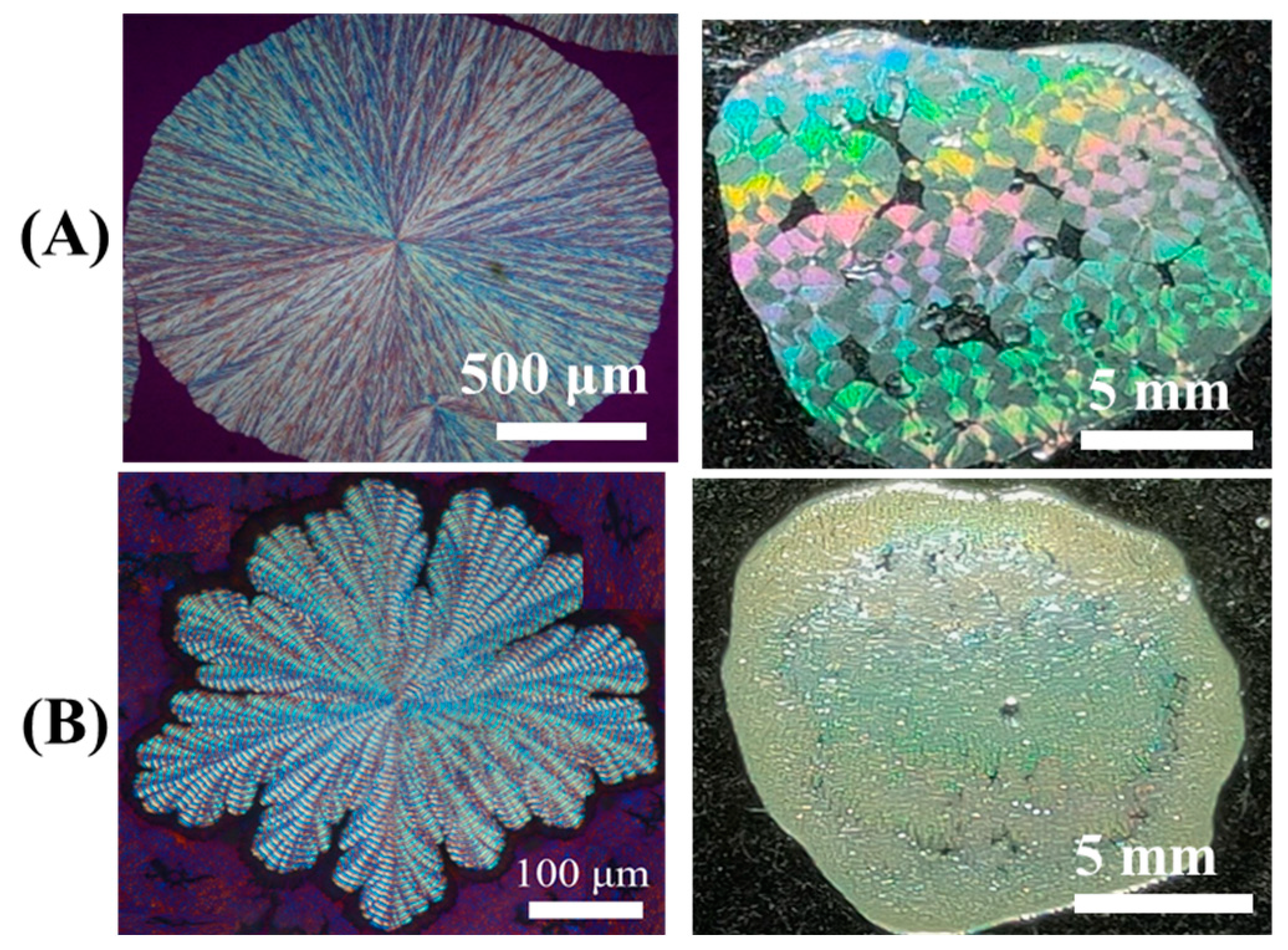

3.2. Spoke-Bands in PPDO Spherulites

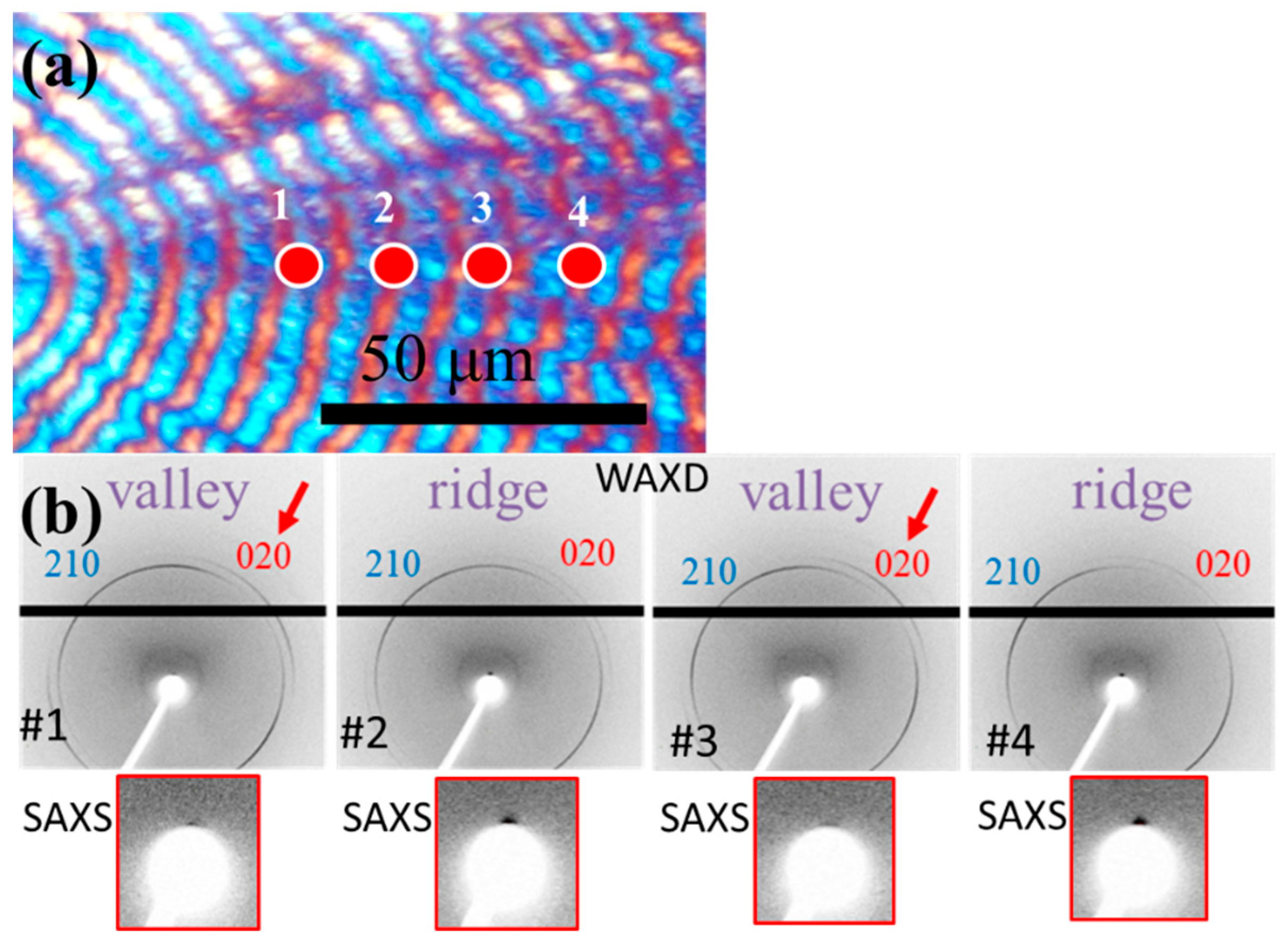

3.3. Synchrotron Microbeam X-ray Analysis on Spoke-Segregated Ring Bands

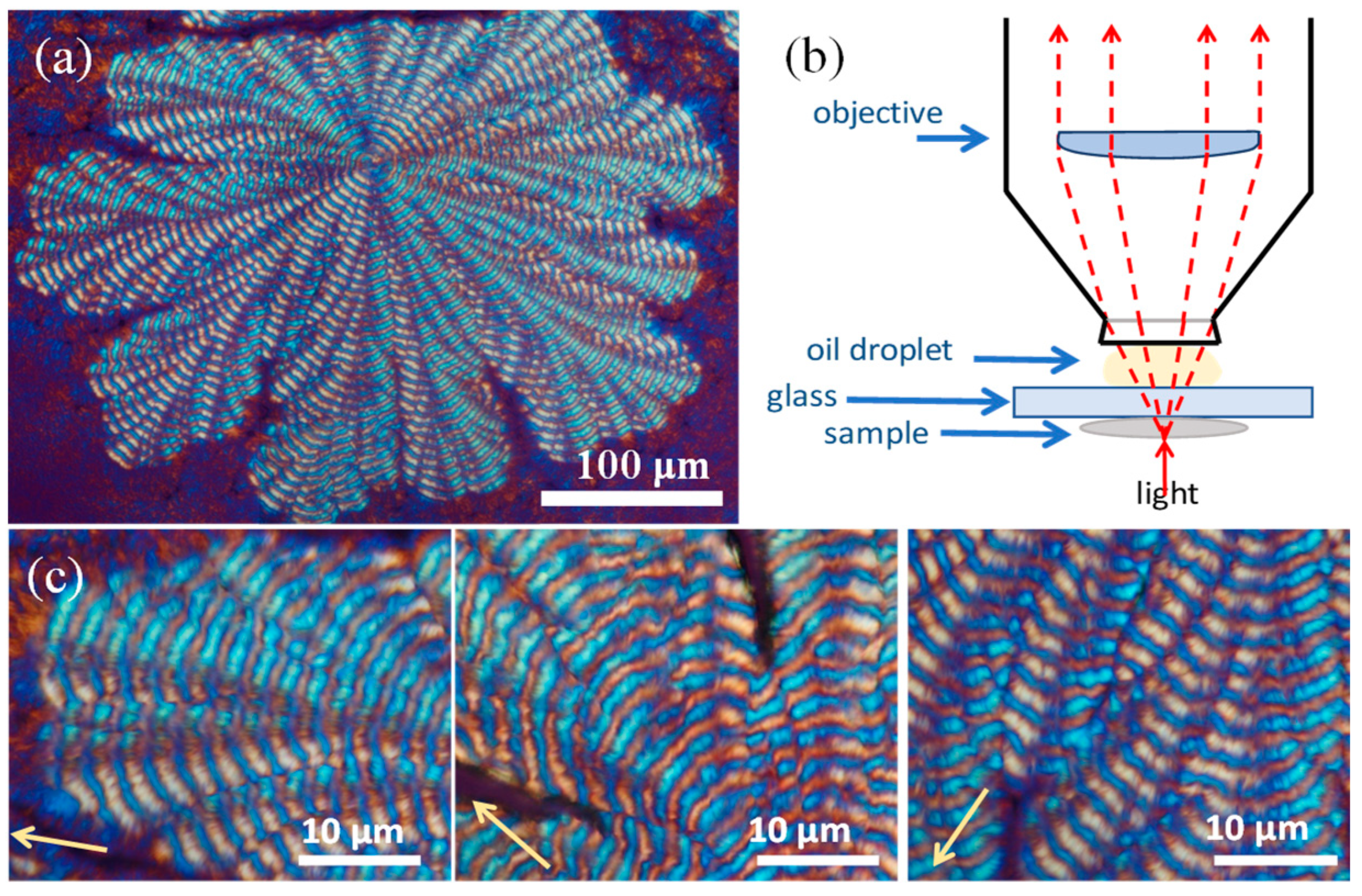

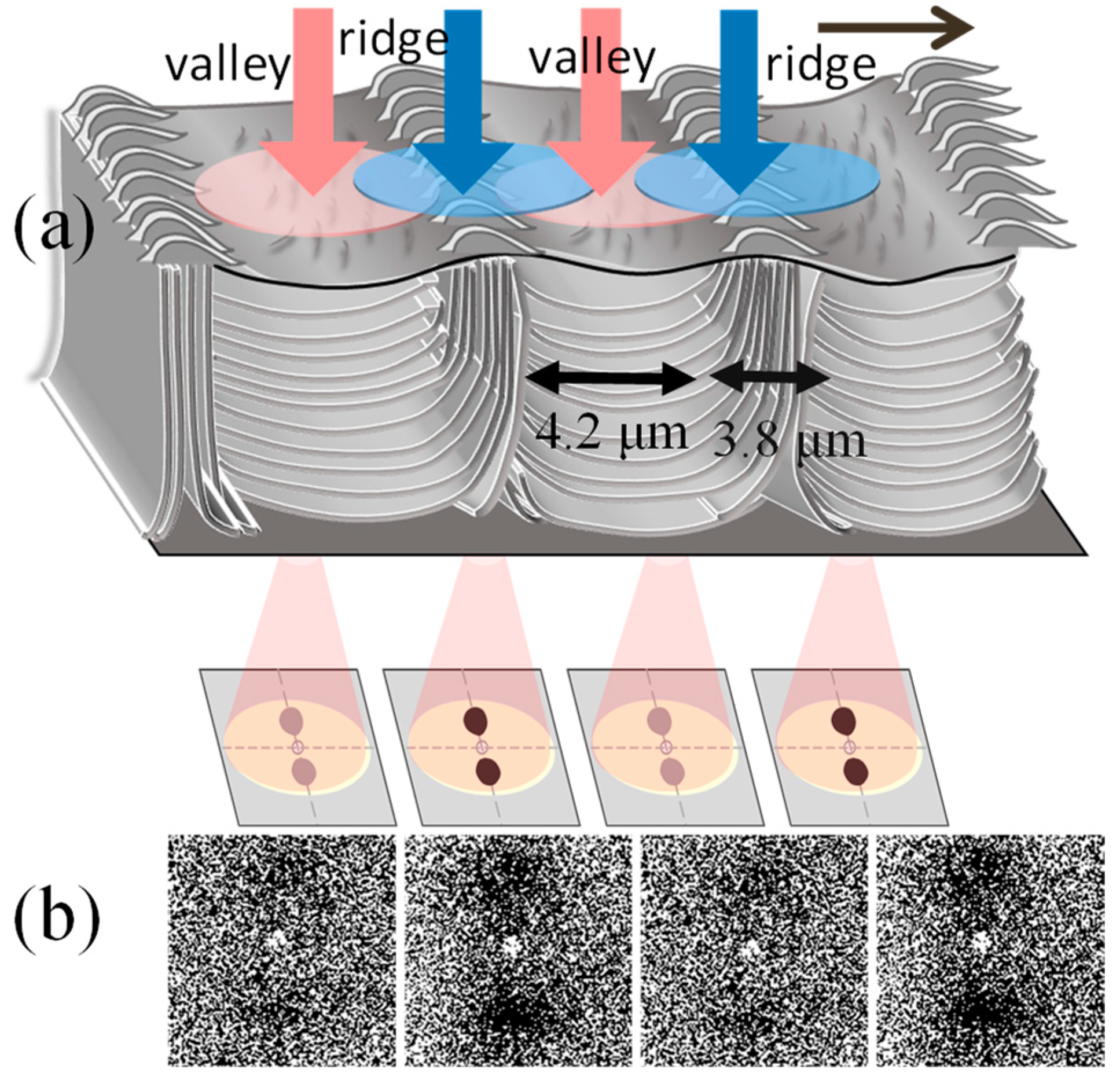

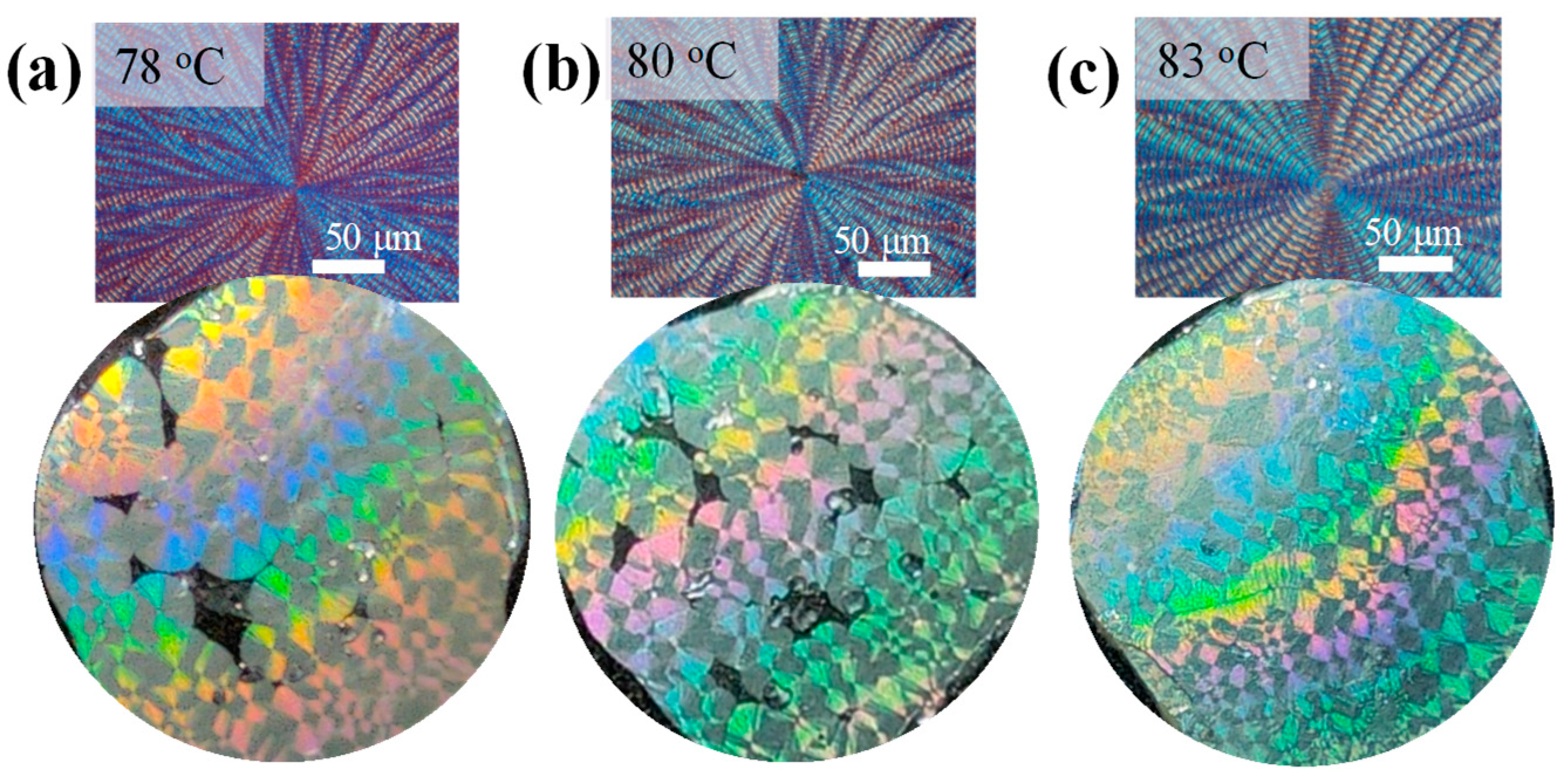

3.4. Pixelated Iridescence by Light Interference with Periodic Micro- or Nano-Structures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lugito, G.; Su, C.C.; Wang, Y.-H.; Woo, E.M. Nano-assembly of intertwining lamellae of opposite bending senses in poly(ethylene oxide) co-crystallizing with poly(p-vinyl phenol). J. Polym. Res. 2017, 24, 166. [Google Scholar] [CrossRef]

- Braun, D.; Jacobs, M.; Hellmann, G.P. On the morphology of poly(vinylidene fluoride) crystals in blends. Polymer 1994, 35, 706–717. [Google Scholar] [CrossRef]

- Gunn, E.; Wong, L.; Branham, C.W.; Marquardt, B.; Kahr, B. Extinction mapping of polycrystalline patterns. CrystEngComm 2011, 13, 1123–1126. [Google Scholar] [CrossRef]

- Yen, K.C.; Woo, E.M. Formation of dendrite crystals in poly(ethylene oxide) interacting with bioresourceful tannin. Polym. Bull. 2009, 62, 225–235. [Google Scholar] [CrossRef]

- Bassett, D.C.; Keller, A.; Mitsuhashi, S. New features in polymer crystal growth from concentrated solutions. J. Polym. Sci. Part A Gen. Pap. 1963, 1, 763–788. [Google Scholar] [CrossRef]

- Norton, D.R.; Keller, A. The spherulitic and lamellar morphology of melt-crystallized isotactic polypropylene. Polymer 1985, 26, 704–716. [Google Scholar] [CrossRef]

- Yeh, Y.T.; Woo, E.M. Anatomy into interior lamellar assembly in nuclei-dependent diversified morphologies of poly(L-lactic acid). Macromolecules 2018, 51, 7722–7733. [Google Scholar] [CrossRef]

- Weber, C.H.M.; Chiche, A.; Krausch, G.; Rosenfeldt, S.; Ballauff, M.; Harnau, L.; Göttker-Schnetmann, I.; Tong, Q.; Mecking, S. Single lamella nanoparticles of polyethylene. Nano Lett. 2007, 7, 2024–2029. [Google Scholar] [CrossRef]

- Minke, R.; Blackwell, J. Single crystals of poly(tetramethylene adipate). J. Macromol. Sci. Part B 1980, 18, 233–255. [Google Scholar] [CrossRef]

- Huang, I.H.; Chang, L.; Woo, E.M. Tannin induced single crystalline morphology in poly(ethylene succinate). Macromol. Chem. Phys. 2011, 212, 1155–1164. [Google Scholar] [CrossRef]

- Brener, E.; Müller-Krumbhaar, H.; Temkin, D. Structure formation and the morphology diagram of possible structures in two-dimensional diffusional growth. Phys. Rev. E 1996, 54, 2714–2722. [Google Scholar] [CrossRef] [PubMed]

- Mandala, Y.H.; Woo, E.M.; Ni’mah, H.; Nurkhamidah, S. Surface-relief and interior lamellar assembly in Janus-face spherulites of Poly(butylene succinate) crystallized with Poly(ethylene oxide). Polymer 2019, 176, 168–178. [Google Scholar] [CrossRef]

- Tseng, Y.-L.; Chuan, K.-N.; Woo, E.M. Unusual ringed/dendritic sector faces in poly(butylene succinate) crystallized with isomeric polymer. Ind. Eng. Chem. Res. 2020, 59, 7485–7494. [Google Scholar] [CrossRef]

- Toda, A. Rounded lateral habits of polyethylene single crystals. Polymer 1991, 32, 771–780. [Google Scholar] [CrossRef]

- Rosenthal, M.; Bar, G.; Burghammer, M.; Ivanov, D.A. On the nature of chirality imparted to achiral polymers by the crystallization process. Angew. Chem. Int. Ed. 2011, 50, 8881–8885. [Google Scholar] [CrossRef]

- Saracovan, I. Main-Chain Chirality and Crystalline Morphology in Optically Active Polyethers; McGill University: Montreal, QC, Canada, 2001. [Google Scholar]

- Rosenthal, M.; Burghammer, M.; Bar, G.; Samulski, E.T.; Ivanov, D.A. Switching chirality of hybrid left-right crystalline helicoids built of achiral polymer chains: When right to left becomes left to right. Macromolecules 2014, 47, 8295–8304. [Google Scholar] [CrossRef]

- Christ, B.; Schultz, J.M. Polymer spherulites: A critical review. Prog. Polym. Sci. 2016, 56, 1–63. [Google Scholar] [CrossRef]

- Lustiger, A.; Lotz, B.; Duff, T.S. The morphology of the spherulitic surface in polyethylene. J. Polym. Sci. Part B Polym. Phys. 1989, 27, 561–579. [Google Scholar] [CrossRef]

- Lotz, B.; Cheng, S.Z.D. A critical assessment of unbalanced surface stresses as the mechanical origin of twisting and scrolling of polymer crystals. Polymer 2005, 46, 577–610. [Google Scholar] [CrossRef]

- Zhang, Y.; Liao, X.; Luo, X.; Liu, S.; Yang, Q.; Li, G. Concentric ring-banded spherulites of six-arm star-shaped poly(ε-caprolactone) via subcritical CO2. RSC Adv. 2014, 4, 10144–10150. [Google Scholar] [CrossRef]

- Keith, H.D.; Padden, F.J. Banding in polyethylene and other spherulites. Macromolecules 1996, 29, 7776–7786. [Google Scholar] [CrossRef]

- Li, M.C.; Wang, H.F.; Chiang, C.H.; Lee, Y.D.; Ho, R.M. Lamellar-twisting-induced circular dichroism of chromophore moieties in banded spherulites with evolution of homochirality. Angew. Chem. 2014, 53, 4450–4455. [Google Scholar] [CrossRef] [PubMed]

- Lovinger, A.J. Twisted Crystals and the Origin of Banding in Spherulites of Semicrystalline Polymers. Macromolecules 2020, 53, 741–745. [Google Scholar] [CrossRef]

- Woo, E.M.; Lugito, G. Origins of periodic bands in polymer spherulites. Eur. Polym. J. 2015, 71, 27–60. [Google Scholar] [CrossRef]

- Stern, T. Transcrystalline Mechanism of Banded Spherulites Development in Melt-Crystallized Semicrystalline Polymers. Polymers 2024, 16, 2411. [Google Scholar] [CrossRef]

- Yakovlev, S.; Downing, K.H.; Brant, P. Cross hatched structure of polyethylene spherulites. Polym. Cryst. 2021, 4, e10174. [Google Scholar] [CrossRef]

- Sabino, M.A.; Albuerne, J.; Müller, A.J.; Brisson, J.; Prud’homme, R.E. Influence of in Vitro Hydrolytic Degradation on the Morphology and Crystallization Behavior of Poly(p-dioxanone). Biomacromolecules 2004, 5, 358–370. [Google Scholar] [CrossRef]

- Pezzin, A.P.T.; Van Ekenstein, G.O.R.A.; Zavaglia, C.A.C.; Ten Brinke, G.; Duek, E.A.R. Poly(para-dioxanone) and poly(L-lactic acid) blends: Thermal, mechanical, and morphological properties. J. Appl. Polym. Sci. 2003, 88, 2744–2755. [Google Scholar] [CrossRef]

- Zeng, J.; Zhu, Q.; Li, Y.; Qiu, Z.; Wang, Y. Unique Crystalline/Crystalline Polymer Blends of Poly(ethylene succinate) and Poly(p-dioxanone): Miscibility and Crystallization Behaviors. J. Phys. Chem. B 2010, 114, 14827–14833. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Wang, P.; Bai, W.; Zhang, L.; Li, Q.; Xiong, C. Miscibility, Thermal and Mechanical Properties of Poly(para-dioxanone)/Poly(lactic-co-glycolic acid) Blends. J. Polym. Environ. 2015, 23, 367–373. [Google Scholar] [CrossRef]

- Huang, K.-Y.; Woo, E.M.; Nagarajan, S. Unique Periodic Rings Composed of Fractal-Growth Dendritic Branching in Poly(p-dioxanone). Polymers 2022, 14, 805. [Google Scholar] [CrossRef] [PubMed]

- Sabino, M.A.; González, S.; Márquez, L.; Feijoo, J.L. Study of the hydrolytic degradation of polydioxanone PPDX. Polym. Degrad. Stab. 2000, 69, 209–216. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, Z.; Zhang, S.; Liu, C.; Gross, R.A.; Kyriakides, T.R.; Saltzman, W.M. Biodegradation, biocompatibility, and drug delivery in poly(ω-pentadecalactone-co-p-dioxanone) copolyesters. Biomaterials 2011, 32, 6646–6654. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.-K.; Wang, X.-L.; Wang, Y.-Z. Poly(p-dioxanone) and its copolymers. J. Macromol. Sci. Part C Polym. Rev. 2002, 42, 373–398. [Google Scholar] [CrossRef]

- Im, J.N.; Kim, J.K.; Kim, H.; Lee, K.Y.; Park, W.H. Characteristics of novel monofilament sutures prepared by conjugate spinning. J. Biomed. Mater. Res. Part B Appl. Biomater. 2007, 83B, 499–504. [Google Scholar] [CrossRef] [PubMed]

- Puttlitz, C.; Adams, B.; Brown, T. Bioabsorbable pin fixation of intercarpal joints: An evaluation of fixation stiffness. Clin. Biomech. 1997, 12, 149–153. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-H.; Woo, E.M. Kinetic Analysis on Effect of Poly(4-vinyl phenol) on Complex-Forming Blends of Poly(L-lactide) and Poly(D-lactide). Polym. J. 2009, 41, 374–382. [Google Scholar] [CrossRef]

- Ni’mah, H.; Woo, E.M.; Nurkhamidah, S. Diversification of spherulite patterns in poly(ethylene succinate) crystallized with strongly interacting poly(4-vinyl phenol). J. Polym. Res. 2014, 21, 339. [Google Scholar] [CrossRef]

- Park, S.Y.; Park, M.; Lee, H.H. Cooperative polymer gate dielectrics in organic thin-film transistors. Appl. Phys. Lett. 2004, 85, 2283–2285. [Google Scholar] [CrossRef]

- Bourara, H.; Hadjout, S.; Benabdelghani, Z.; Etxeberria, A. Miscibility and hydrogen bonding in blends of poly(4-vinylphenol)/Poly(vinyl methyl ketone). Polymers 2014, 6, 2752–2763. [Google Scholar] [CrossRef]

- Wang, S.-C.; Chen, Y.; Wang, Y.-C.; Wang, W.-J.; Yang, C.-S.; Tsai, C.-L.; Hou, M.-H.; Chen, H.-F.; Shen, Y.-C.; Hung, M.-C. Tannic acid suppresses SARS-CoV-2 as a dual inhibitor of the viral main protease and the cellular TMPRSS2 protease. Am. J. Cancer Res. 2020, 10, 4538–4546. [Google Scholar] [PubMed]

- Ahmad, T. Reviewing the Tannic Acid Mediated Synthesis of Metal Nanoparticles. J. Nanotechnol. 2014, 2014, 954206. [Google Scholar] [CrossRef]

- Velmurugan, P.; Singam, E.R.A.; Jonnalagadda, R.R.; Subramanian, V. Investigation on interaction of tannic acid with type I collagen and its effect on thermal, enzymatic, and conformational stability for tissue engineering applications. Biopolymers 2014, 101, 471–483. [Google Scholar] [CrossRef]

- Lee, L.-T.; Wu, M.-C.; Lee, M.-H. Novel miscible blends of biodegradable polymer and biocompatible polyphenol acquired from natural source. J. Polym. Res. 2013, 20, 282. [Google Scholar] [CrossRef]

- Slouf, M.; Pavlova, E.; Krejcikova, S.; Ostafinska, A.; Zhigunov, A.; Krzyzanek, V.; Sowinski, P.; Piorkowska, E. Relations between morphology and micromechanical properties of alpha, beta and gamma phases of iPP. Polym. Test. 2018, 67, 522–532. [Google Scholar] [CrossRef]

- Hao, M.-H.; Nagarajan, S.; Woo, E.M. Probing the Nano-Assembly Leading to Periodic Gratings in Poly(p-dioxanone). Nanomaterials 2023, 13, 2665. [Google Scholar] [CrossRef]

- Smith, G.S. Structural color of morpho butterflies. Am. J. Phys. 2009, 77, 1010–1019. [Google Scholar] [CrossRef]

- Rodríguez, R.E.; Agarwal, S.P.; An, S.; Kazyak, E.; Das, D.; Shang, W.; Skye, R.; Deng, T.; Dasgupta, N.P. Biotemplated Morpho Butterfly Wings for Tunable Structurally Colored Photocatalysts. ACS Appl. Mater. Interfaces 2018, 10, 4614–4621. [Google Scholar] [CrossRef] [PubMed]

- Prum, R.O.; Quinn, T.; Torres, R.H. Anatomically diverse butterfly scales all produce structural colours by coherent scattering. J. Exp. Biol. 2006, 209, 748–765. [Google Scholar] [CrossRef]

- Vukusic, P.; Sambles, J.R.; Ghiradella, H. Optical classification of microstructure in butterfly wing-scales. Photonics Sci. News 2000, 6, 61–66. [Google Scholar]

- Bartl, M.H.; Galusha, J.W.; Richey, L.R.; Gardner, J.S.; Cha, J.N. Discovery of a diamond-based photonic crystal structure in beetle scales. Phys. Rev. E—Stat. Nonlinear Soft Matter Phys. 2008, 77, 2–5. [Google Scholar] [CrossRef]

- Vignolini, S.; Rudall, P.J.; Rowland, A.V.; Reed, A.; Moyroud, E.; Faden, R.B.; Baumberg, J.J.; Glover, B.J.; Steiner, U. Pointillist structural color in Pollia fruit. Proc. Natl. Acad. Sci. USA 2012, 109, 15712–15715. [Google Scholar] [CrossRef] [PubMed]

- Dumanli, A.G.; Kamita, G.; Landman, J.; van der Kooij, H.; Glover, B.J.; Baumberg, J.J.; Steiner, U.; Vignolini, S. Controlled, bio-inspired self-assembly of cellulose-based chiral reflectors. Adv. Opt. Mater. 2014, 2, 646–650. [Google Scholar] [CrossRef] [PubMed]

- Kelly, J.A.; Shukaliak, A.M.; Cheung, C.C.Y.; Shopsowitz, K.E.; Hamad, W.Y.; MacLachlan, M.J. Responsive photonic hydrogels based on nanocrystalline cellulose. Angew. Chem. 2013, 52, 8912–8916. [Google Scholar] [CrossRef] [PubMed]

- Giese, M.; Blusch, L.K.; Khan, M.K.; MacLachlan, M.J. Functional materials from cellulose-derived liquid-crystal templates. Angew. Chem. Int. Ed. 2015, 54, 2888–2910. [Google Scholar] [CrossRef] [PubMed]

- Zi, J.; Yu, X.; Li, Y.; Hu, X.; Xu, C.; Wang, X.; Liu, X.; Fu, R. Coloration strategies in peacock feathers. Proc. Natl. Acad. Sci. USA 2003, 100, 12576–12578. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Kotov, N.A.; Magonov, S.; Ozturk, B. Nanostructured artificial nacre. Nat. Mater. 2003, 2, 413–418. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Q.; Tang, Z. Layered nanocomposites inspired by the structure and mechanical properties of nacre. Chem. Soc. Rev. 2012, 41, 1111–1129. [Google Scholar] [CrossRef]

- Kim, B.H.; Choi, Y.; Kim, J.Y.; Shin, H.; Kim, S.; Son, S.W.; Kim, S.O.; Kim, P. Wrinkle-directed self-assembly of block copolymers for aligning of nanowire arrays. Adv. Mater. 2014, 26, 4665–4670. [Google Scholar] [CrossRef] [PubMed]

- Mapas, J.K.D.; Thomay, T.; Cartwright, A.N.; Ilavsky, J.; Rzayev, J. Ultrahigh molecular weight linear block copolymers: Rapid access by reversible-deactivation radical polymerization and self-assembly into large domain nanostructures. Macromolecules 2016, 49, 3733–3738. [Google Scholar] [CrossRef]

- Chiang, Y.; Chou, C.; Wu, C.; Lin, E.; Yoon, J.; Thomas, E.L. Large-Area Block Copolymer Photonic Gel Films with Solvent-Evaporation-Induced Red- and Blue-Shift Reflective Bands. Macromolecules 2015, 48, 4004–4011. [Google Scholar] [CrossRef]

- Liberman-Martin, A.L.; Chu, C.K.; Grubbs, R.H. Application of Bottlebrush Block Copolymers as Photonic Crystals. Macromol. Rapid Commun. 2017, 38, 1700058. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, S.; Huang, K.; Chuang, W.; Lin, J.; Woo, E.M. Thermo-Sensitive Poly(p-dioxanone) Banded Spherulites with Controllable Patterns for Iridescence. J. Phys. Chem. C 2023, 127, 2628–2638. [Google Scholar] [CrossRef]

- Nagarajan, S.; Woo, E.M.; Su, C.; Yang, C. Microstructural periodic arrays in poly(butylene adipate) featured with photonic crystal aggregates. Macromol. Rapid Commun. 2021, 42, 2100202. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woo, E.M.; Lin, C.-H.; Nagarajan, S.; Su, C.-C. Microbeam X-ray and Scanning Electron Microscopic Analyses on Sector-Banded Spherulites of Poly(p-dioxanone) Justified with Pixelated Iridescence. Polymers 2024, 16, 2736. https://doi.org/10.3390/polym16192736

Woo EM, Lin C-H, Nagarajan S, Su C-C. Microbeam X-ray and Scanning Electron Microscopic Analyses on Sector-Banded Spherulites of Poly(p-dioxanone) Justified with Pixelated Iridescence. Polymers. 2024; 16(19):2736. https://doi.org/10.3390/polym16192736

Chicago/Turabian StyleWoo, Eamor M., Chia-Hui Lin, Selvaraj Nagarajan, and Chean-Cheng Su. 2024. "Microbeam X-ray and Scanning Electron Microscopic Analyses on Sector-Banded Spherulites of Poly(p-dioxanone) Justified with Pixelated Iridescence" Polymers 16, no. 19: 2736. https://doi.org/10.3390/polym16192736

APA StyleWoo, E. M., Lin, C.-H., Nagarajan, S., & Su, C.-C. (2024). Microbeam X-ray and Scanning Electron Microscopic Analyses on Sector-Banded Spherulites of Poly(p-dioxanone) Justified with Pixelated Iridescence. Polymers, 16(19), 2736. https://doi.org/10.3390/polym16192736