Smart Carbon Fiber-Reinforced Polymer Composites for Damage Sensing and On-Line Structural Health Monitoring Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Characterization of Epoxy-Based Nanocomposites

2.3. Manufacturing and Characterization of UD Prepreg Materials and Composites

3. Results and Discussion

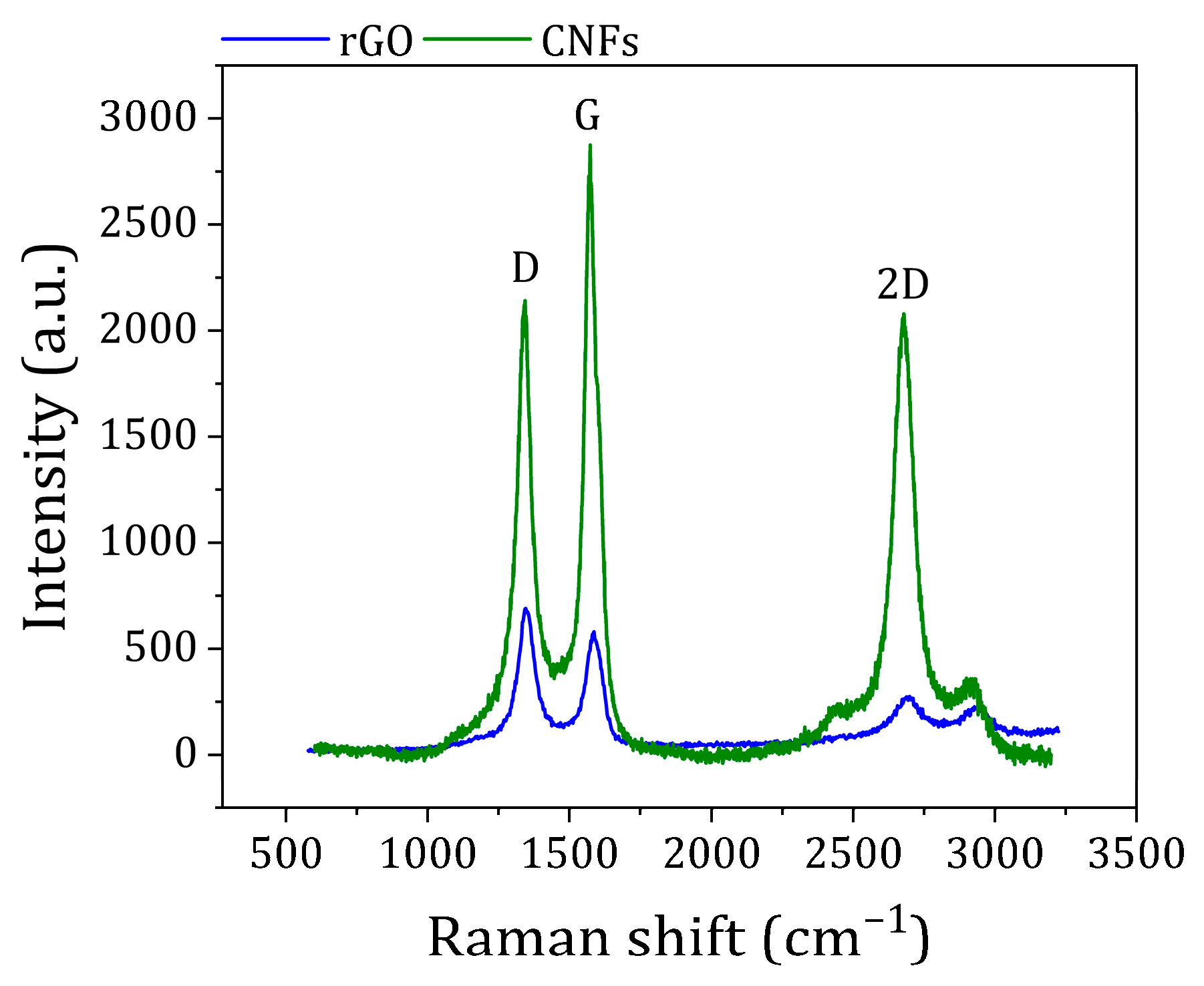

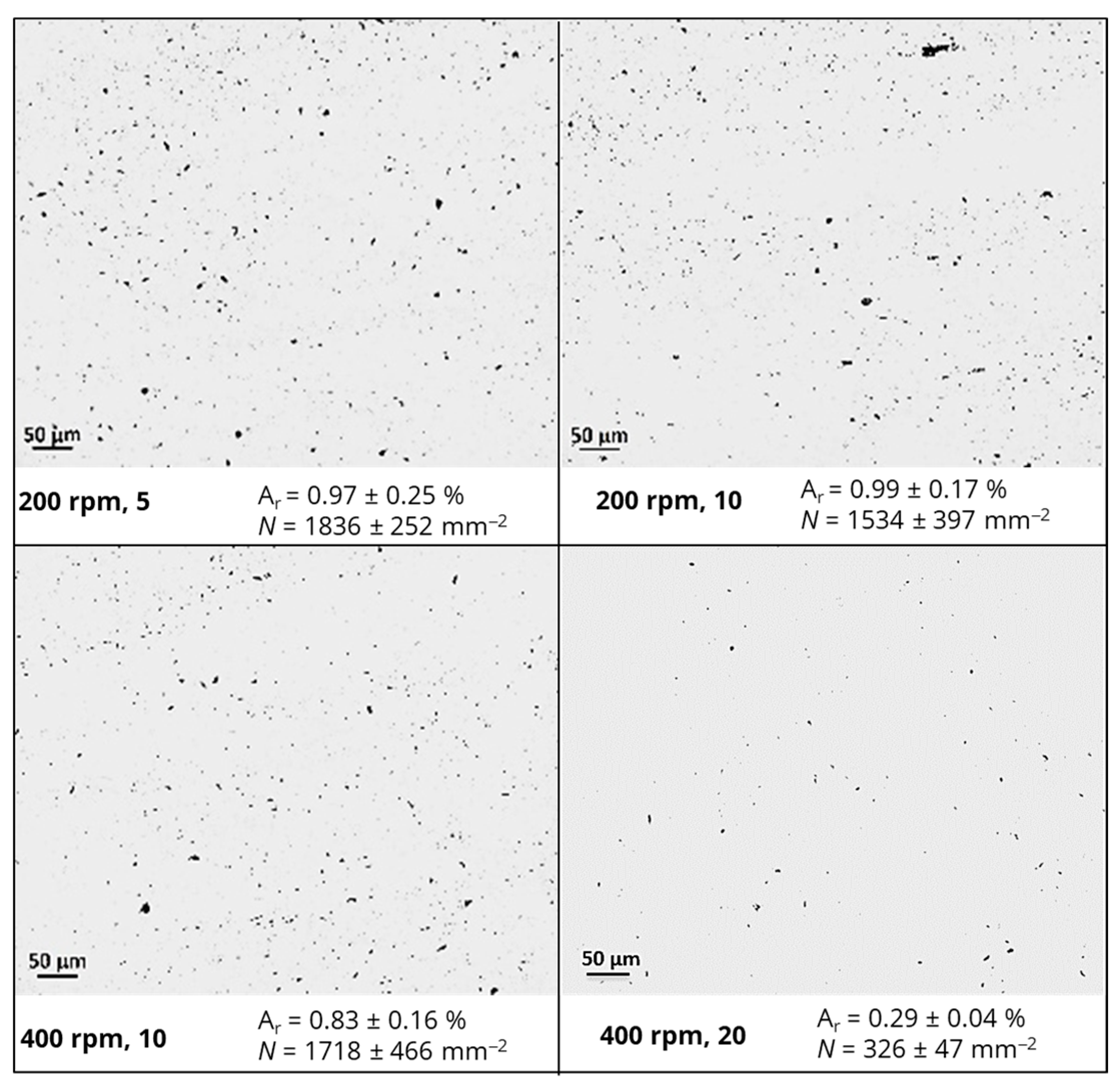

3.1. Morphology and Dispersion State Characterization

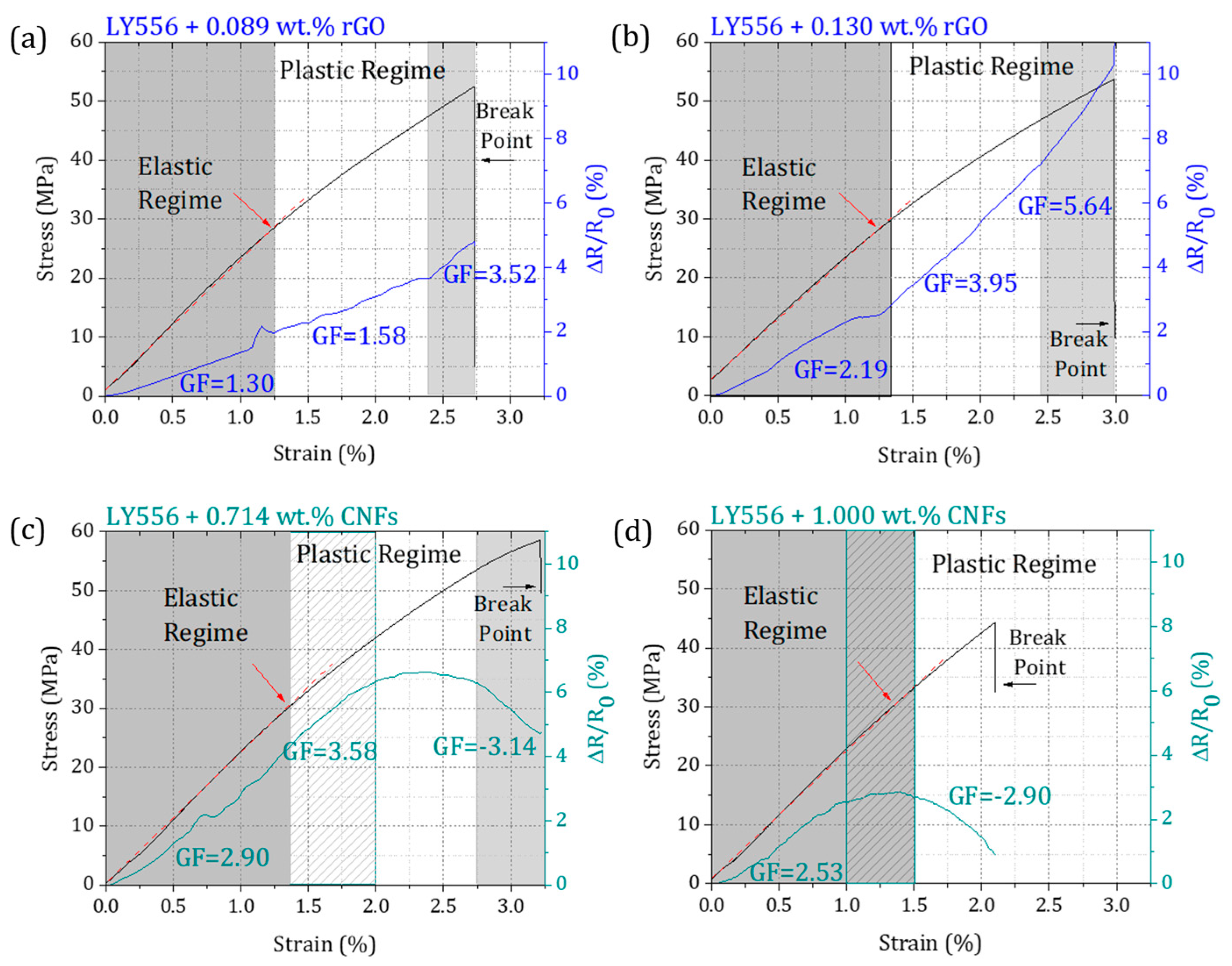

3.2. Electrical Conductivity and Strain-Sensing Capabilities of Epoxy-Based Nanocomposites

3.3. Electrical Conductivity and Strain-Sensing Capabilities of CFRP Composites

4. Conclusions

- (1)

- To promote the fragmentation of rGO or CNF agglomerates, high hydrodynamic shear stresses and long residence times are required (400 rpm and 20 passages per cycle).

- (2)

- An insulator-to-semi-conductive transition was attained with the incorporation of either rGO or CNFs, reaching maximum electrical conductivities at 0.714 wt.% of rGO or CNFs (5 5 × 10−2 or 2 × 10−4 S∙m−1, respectively).

- (3)

- The strain-sensing capabilities of epoxy-based nanocomposites are strongly dependent on the nanofiller concentration and geometric features. Although high electrical conductivity is required, the ductility of the final material must not be compromised.

- (4)

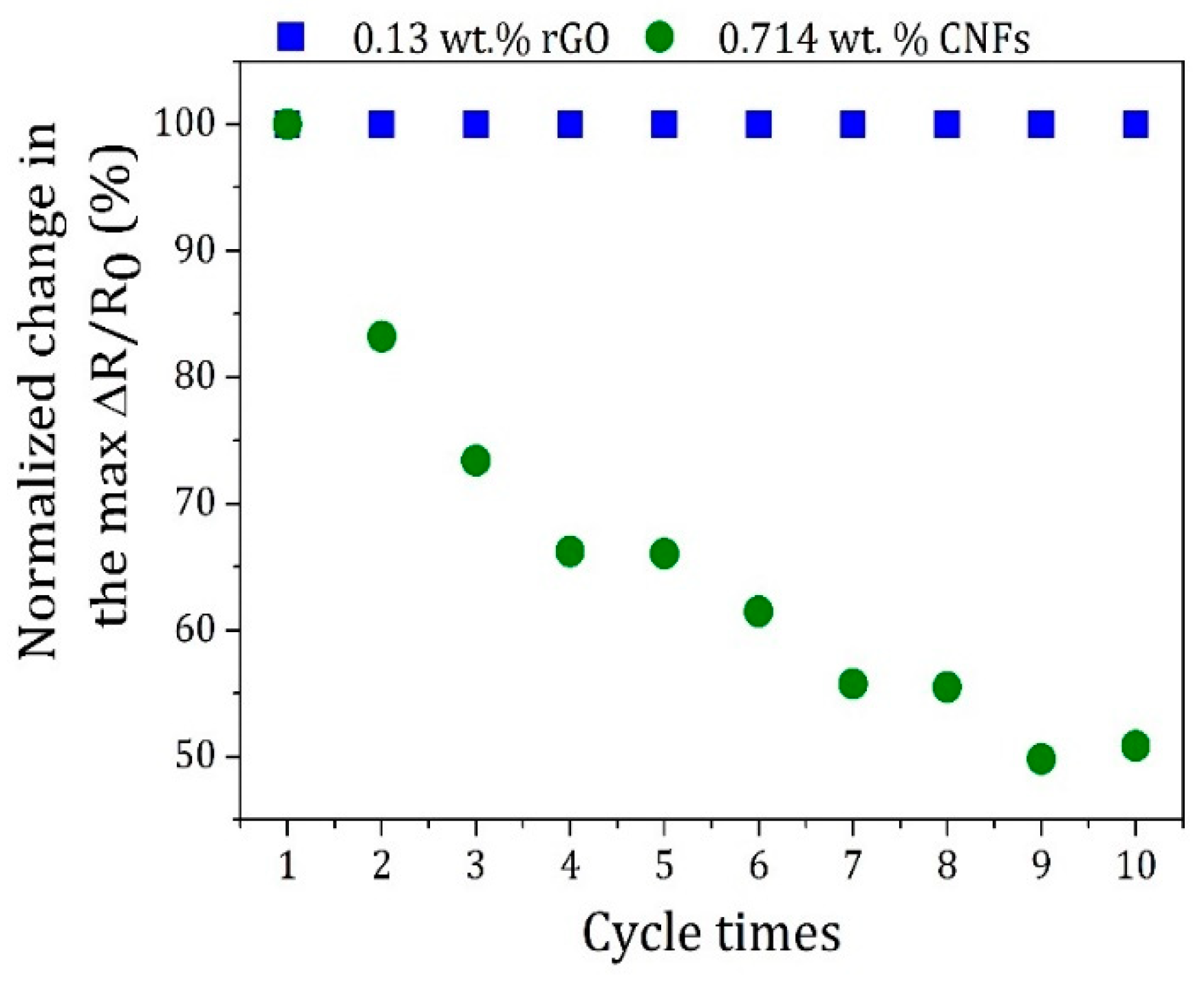

- Nanocomposites containing 0.13 wt.% of rGO showed remarkable sensing stability and reproducibility, a crucial behavior for real applications of strain sensors. An interesting behavior was found for modified counterparts with CNFs, where the electrical conductivity increased with an increasing number of tensile cycles, associated with the formation of new or alternative conductive pathways.

- (5)

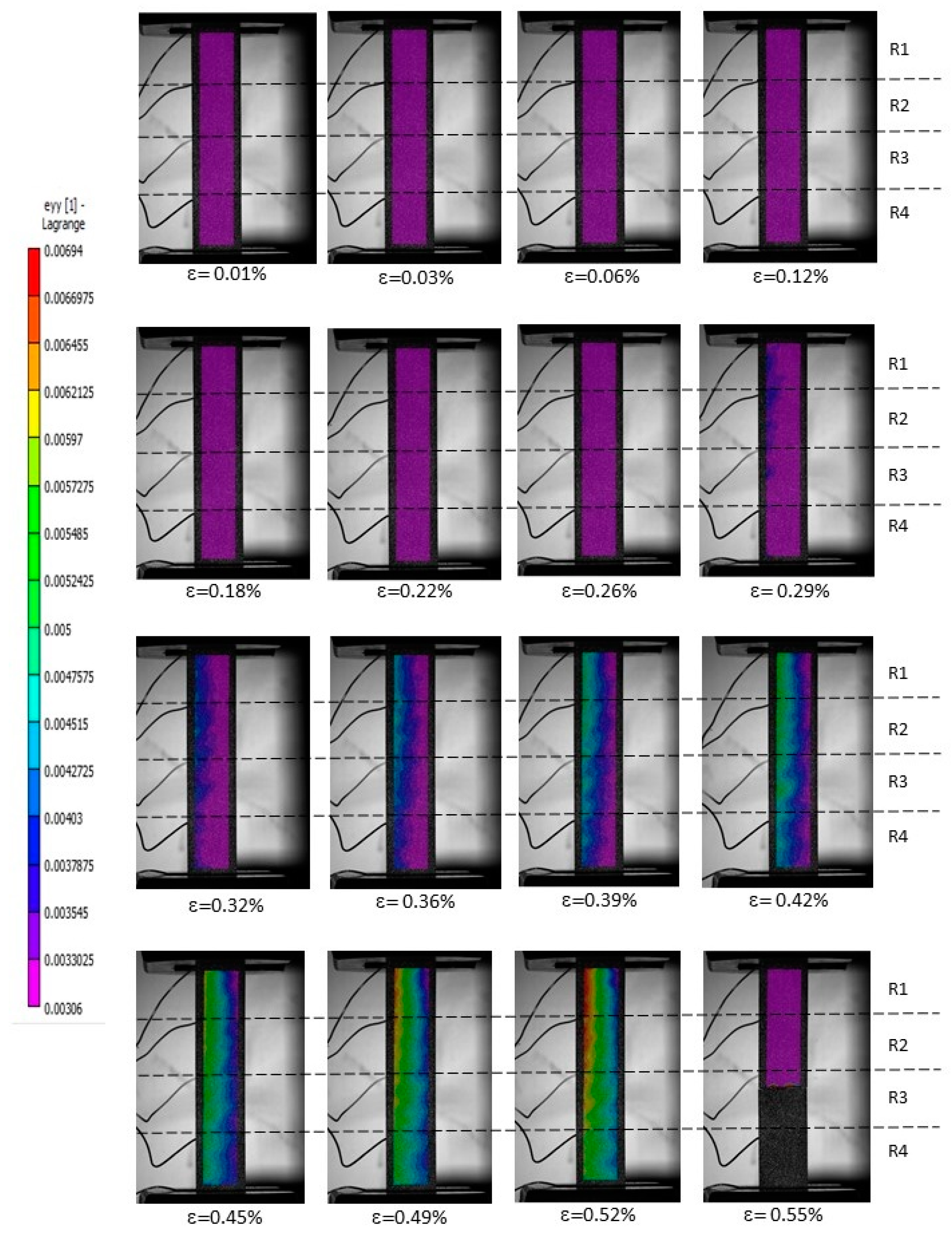

- DIC measurements allowed us to identify the damage pattern and progress, including location and width.

- (6)

- The electrical signal variation synchronized with DIC also showed three distinct stages, having tunable sensitivities, for modified CFRP composites with 0.13 wt.% of rGO.

- (7)

- A different behavior was found for CFRP composites containing CNFs, where a more linear relationship was established between strain deformation and electrical resistance.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alsaadi, A.; Meredith, J.; Swait, T.; Curiel-Sosa, J.; Jia, Y.; Hayes, S. Structural health monitoring for woven fabric CFRP laminates. Compos. Part B Eng. 2019, 174, 107048. [Google Scholar] [CrossRef]

- Ahmed, O.; Wang, X.; Tran, M.-V.; Ismadi, M.-Z. Advancements in fiber-reinforced polymer composite materials damage detection methods: Towards achieving energy-efficient SHM systems. Compos. Part B Eng. 2021, 223, 109136. [Google Scholar] [CrossRef]

- Oh, S.Y.; Lee, D.; Park, Y.-B. Impact Damage Characterization Approach for CFRP Pipes via Self-sensing. Int. J. Mech. Sci. 2024, 281, 109511. [Google Scholar] [CrossRef]

- Metaxa, S.; Kalkanis, K.; Psomopoulos, C.S.; Kaminaris, S.D.; Ioannidis, G. A review of structural health monitoring methods for composite materials. Procedia Struct. Integr. 2019, 22, 369–375. [Google Scholar] [CrossRef]

- Wan, W.; Shen, R.; Tang, J.; Xu, Y.; Zou, X.; Guo, H. Carbon fiber reinforced composites with self-sensing and self-healing capabilities enabled by CNT-modified nanofibers. Polym. Compos. 2024, 45, 7301–7315. [Google Scholar] [CrossRef]

- Zhang, H.; Bilotti, E.; Peijs, T. The use of carbon nanotubes for damage sensing and structural health monitoring in laminated composites: A review. Nanocomposites 2015, 1, 167–184. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Mongioì, F.; Selleri, G.; Maria Brugo, T.; Maccaferri, E.; Fabiani, D.; Zucchelli, A. Multifunctional composite material based on piezoelectric nanofibers and Cu-CFRP electrodes for sensing applications. Compos. Struct. 2024, 337, 118076. [Google Scholar] [CrossRef]

- Lee, I.Y.; Jang, J.; Park, Y.-B. Advanced structural health monitoring in carbon fiber-reinforced plastic using real-time self-sensing data and convolutional neural network architectures. Mater. Des. 2022, 224, 111348. [Google Scholar] [CrossRef]

- Avilés, F.; Oliva-Avilés, A.I.; Cen-Puc, M. Piezoresistivity, strain, and damage self-sensing of polymer composites filled with carbon nanostructures. Adv. Eng. Mater. 2018, 20, 1701159. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, K.; Zhu, S.; Xu, H.; Cao, D.; Zhao, L.; Zhang, R.; Yin, W. Review on the electrical resistance/conductivity of carbon fiber reinforced polymer. Appl. Sci. 2019, 9, 2390. [Google Scholar] [CrossRef]

- Shin, P.-S.; Baek, Y.-M.; Kim, J.-H.; Kwon, D.-J. The factor influencing self-sensing property of carbon fiber. Compos. Sci. Technol. 2023, 238, 110017. [Google Scholar] [CrossRef]

- Baltopoulos, A.; Polydorides, N.; Pambaguian, L.; Vavouliotis, A.; Kostopoulos, V. Exploiting carbon nanotube networks for damage assessment of fiber reinforced composites. Compos. Part B Eng. 2015, 76, 149–158. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Wan, B.; Han, B.; Cai, G.; Li, Z. Properties and mechanisms of self-sensing carbon nanofibers/epoxy composites for structural health monitoring. Compos. Struct. 2018, 200, 669–678. [Google Scholar] [CrossRef]

- Ouyang, Q.; Liu, L.; Wu, Z. In-situ damage self-sensing and strength recovery activated by self-electricity in carbon fibrous composites embedded with multi-functional interleaves. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107777. [Google Scholar] [CrossRef]

- Caradonna, A.; Badini, C.; Padovano, E.; Pietroluongo, M. Electrical and thermal conductivity of epoxy-carbon filler composites processed by calendaring. Materials 2019, 12, 1522. [Google Scholar] [CrossRef]

- Alig, I.; Pötschke, P.; Lellinger, D.; Skipa, T.; Pegel, S.; Kasaliwal, G.R.; Villmow, T. Establishment, morphology and properties of carbon nanotube networks in polymer melts. Polymer 2012, 53, 4–28. [Google Scholar] [CrossRef]

- Santos, R.; Vilaverde, C.; Cunha, E.; Paiva, M.; Covas, J. Probing dispersion and re-agglomeration phenomena upon melt-mixing of polymer-functionalized graphite nanoplates. Soft Matter 2016, 12, 77–86. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Real-time in situ sensing of damage evolution in advanced fiber composites using carbon nanotube networks. Nanotechnology 2008, 19, 215713. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T.W. Sensing of damage mechanisms in fiber-reinforced composites under cyclic loading using carbon nanotubes. Adv. Funct. Mater. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- Jain, R.; Kedir, N.; Hassan, H.; Chen, W.W.; Tallman, T.N. Self-sensing of pulsed laser ablation in carbon nanofiber-based smart composites. J. Intell. Mater. Syst. Struct. 2022, 34, 879–890. [Google Scholar] [CrossRef]

- Bhandari, M.; Wang, J.; Jang, D.; Nam, I.; Huang, B. A Comparative Study on the Electrical and Piezoresistive Sensing Characteristics of GFRP and CFRP Composites with Hybridized Incorporation of Carbon Nanotubes, Graphenes, Carbon Nanofibers, and Graphite Nanoplatelets. Sensors 2021, 21, 7291. [Google Scholar] [CrossRef]

- Duongthipthewa, A.; Zhou, H.; Wang, Q.; Zhou, L. Non-additive polymer matrix coated rGO/MXene inks for embedding sensors in prepreg enhancing smart FRP composites. Compos. Part B Eng. 2024, 270, 111108. [Google Scholar] [CrossRef]

- Ud Din, I.; Medhin, Y.; Aslam, N.; Bathusha, M.S.S.; Umer, R.; Khan, K.A. Rate dependent piezoresistive characterization of smart aerospace sandwich structures embedded with reduced graphene oxide (rGO) coated fabric sensors. Compos. Commun. 2022, 36, 101382. [Google Scholar] [CrossRef]

- Alahmed, N.; Ud Din, I.; Cantwell, W.J.; Umer, R.; Khan, K.A. Multi-scale characterization of self-sensing fiber reinforced composites. Sens. Actuators A Phys. 2024, 379, 115857. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, C.; Zhou, H.; Li, X.; Wang, X.; Zhou, X.; Xie, X.; Mai, Y.-W. In situ three-roll mill exfoliation approach for fabricating asphalt/graphite nanoplatelet composites as thermal interface materials. Compos. Sci. Technol. 2024, 252, 110627. [Google Scholar] [CrossRef]

- Araujo, A.; Vale, D.; Pappas, P.-N.; Koutroumanis, N.; Santos, R.M. Challenges and opportunities on nano-enabled multifunctional composites for aerostructures. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; p. 01007. [Google Scholar]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Wang, Y.; Alsmeyer, D.C.; McCreery, R.L. Raman spectroscopy of carbon materials: Structural basis of observed spectra. Chem. Mater. 1990, 2, 557–563. [Google Scholar] [CrossRef]

- Sato, K.; Saito, R.; Oyama, Y.; Jiang, J.; Cançado, L.; Pimenta, M.; Jorio, A.; Samsonidze, G.G.; Dresselhaus, G.; Dresselhaus, M. D-band Raman intensity of graphitic materials as a function of laser energy and crystallite size. Chem. Phys. Lett. 2006, 427, 117–121. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Cofano, R.; Garcia, A.; Sangermano, M.; Lanceros-Mendez, S. Photocurable 3D printed anisotropic electrically conductive materials based on bio-renewable composites. Addit. Manuf. 2023, 78, 103867. [Google Scholar] [CrossRef]

- ASTM D257-14(2021)e1; Standard Test Methods for DC Resistance or Conductance of Insulating Materials. ASTM: West Conshohocken, PA, USA, 2021.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- Sang, Z.; Ke, K.; Manas-Zloczower, I. Effect of carbon nanotube morphology on properties in thermoplastic elastomer composites for strain sensors. Compos. Part A Appl. Sci. Manuf. 2019, 121, 207–212. [Google Scholar] [CrossRef]

- ASTM D3529-16(2021); Standard Test Methods for Constituent Content of Composite Prepreg. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2014.

- Scurati, A.; Feke, D.; Manas-Zloczower, I. Analysis of the kinetics of agglomerate erosion in simple shear flows. Chem. Eng. Sci. 2005, 60, 6564–6573. [Google Scholar] [CrossRef]

- Sang, Z.; Ke, K.; Manas-Zloczower, I. Interface design strategy for the fabrication of highly stretchable strain sensors. ACS Appl. Mater. Interfaces 2018, 10, 36483–36492. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wei, B.; Farha, F.I.; Liu, W.; Li, W.; Qiu, Y.; Xu, F. Densely packed, highly strain sensitive carbon nanotube composites with sufficient polymer penetration. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105728. [Google Scholar] [CrossRef]

- Georgousis, G.; Pandis, C.; Kalamiotis, A.; Georgiopoulos, P.; Kyritsis, A.; Kontou, E.; Pissis, P.; Micusik, M.; Czanikova, K.; Kulicek, J.; et al. Strain sensing in polymer/carbon nanotube composites by electrical resistance measurement. Compos. Part B Eng. 2015, 68, 162–169. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Vavouliotis, A.; Karapappas, P.; Tsotra, P.; Paipetis, A. Damage monitoring of carbon fiber reinforced laminates using resistance measurements. Improving sensitivity using carbon nanotube doped epoxy matrix system. J. Intell. Mater. Syst. Struct. 2009, 20, 1025–1034. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Carbon nanotube networks: Sensing of distributed strain and damage for life prediction and self healing. Adv. Mater. 2006, 18, 2837–2841. [Google Scholar] [CrossRef]

| Component | Viscosity at 298.15 K (mPa.s) | Density (g·cm−3) | Mix Ratio (g) |

|---|---|---|---|

| Araldite LY 556® | 10,000–12,000 | 1.15–1.20 | 100 |

| Aradur 1571® | 28,000–40,000 | 1.20 | 23 |

| Accelerator 1573® | 60,000–90,000 | 1.08 | 5 |

| Hardener XB 3403® | 5–20 | 1.00 | 12 |

| Accelerator DY 070® | ≤50 | 0.95–1.05 | 2 |

| Hardener HY 906® | 175–350 | 1.20–1.25 | 95 |

| Dispersion Conditions | Velocity (rpm) | Number of Passages per Each Cycle | Maximum Nominal Shear Rate (s−1) |

|---|---|---|---|

| 200 rpm, 5 | 200 | 5 | 220,000 |

| 200 rpm, 10 | 200 | 10 | |

| 400 rpm, 10 | 400 | 10 | 440,000 |

| 400 rpm, 20 | 400 | 20 |

| Fiber Tension (N) | Winder Speed (rpm) | Squeeze Rolls Distance (cm) | Pitch (cm) | Bath Temperature (K) |

|---|---|---|---|---|

| 1.2 | 2 | 0.50 | 0.7 | 298.15 |

| Code | SM (g·m−2) | FAW (g·m−2) | FVF (%) |

|---|---|---|---|

| Unmodified prepreg | 151.83 ± 4.12 | 105.47 ± 1.18 | 60.5 ± 1.7 |

| rGO | 149.20 ± 4.69 | 105.68 ± 2.22 | 61.9 ± 2.0 |

| CNFs | 151.08 ± 2.56 | 104.94 ± 2.28 | 60.3 ± 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopes, C.; Araújo, A.; Silva, F.; Pappas, P.-N.; Termine, S.; Trompeta, A.-F.A.; Charitidis, C.A.; Martins, C.; Mould, S.T.; Santos, R.M. Smart Carbon Fiber-Reinforced Polymer Composites for Damage Sensing and On-Line Structural Health Monitoring Applications. Polymers 2024, 16, 2698. https://doi.org/10.3390/polym16192698

Lopes C, Araújo A, Silva F, Pappas P-N, Termine S, Trompeta A-FA, Charitidis CA, Martins C, Mould ST, Santos RM. Smart Carbon Fiber-Reinforced Polymer Composites for Damage Sensing and On-Line Structural Health Monitoring Applications. Polymers. 2024; 16(19):2698. https://doi.org/10.3390/polym16192698

Chicago/Turabian StyleLopes, Cláudia, Andreia Araújo, Fernando Silva, Panagiotis-Nektarios Pappas, Stefania Termine, Aikaterini-Flora A. Trompeta, Costas A. Charitidis, Carla Martins, Sacha T. Mould, and Raquel M. Santos. 2024. "Smart Carbon Fiber-Reinforced Polymer Composites for Damage Sensing and On-Line Structural Health Monitoring Applications" Polymers 16, no. 19: 2698. https://doi.org/10.3390/polym16192698

APA StyleLopes, C., Araújo, A., Silva, F., Pappas, P.-N., Termine, S., Trompeta, A.-F. A., Charitidis, C. A., Martins, C., Mould, S. T., & Santos, R. M. (2024). Smart Carbon Fiber-Reinforced Polymer Composites for Damage Sensing and On-Line Structural Health Monitoring Applications. Polymers, 16(19), 2698. https://doi.org/10.3390/polym16192698