Coniferous Bark as Filler for Polylactic Acid-Based Biocomposites

Abstract

1. Introduction

2. Materials and Methods

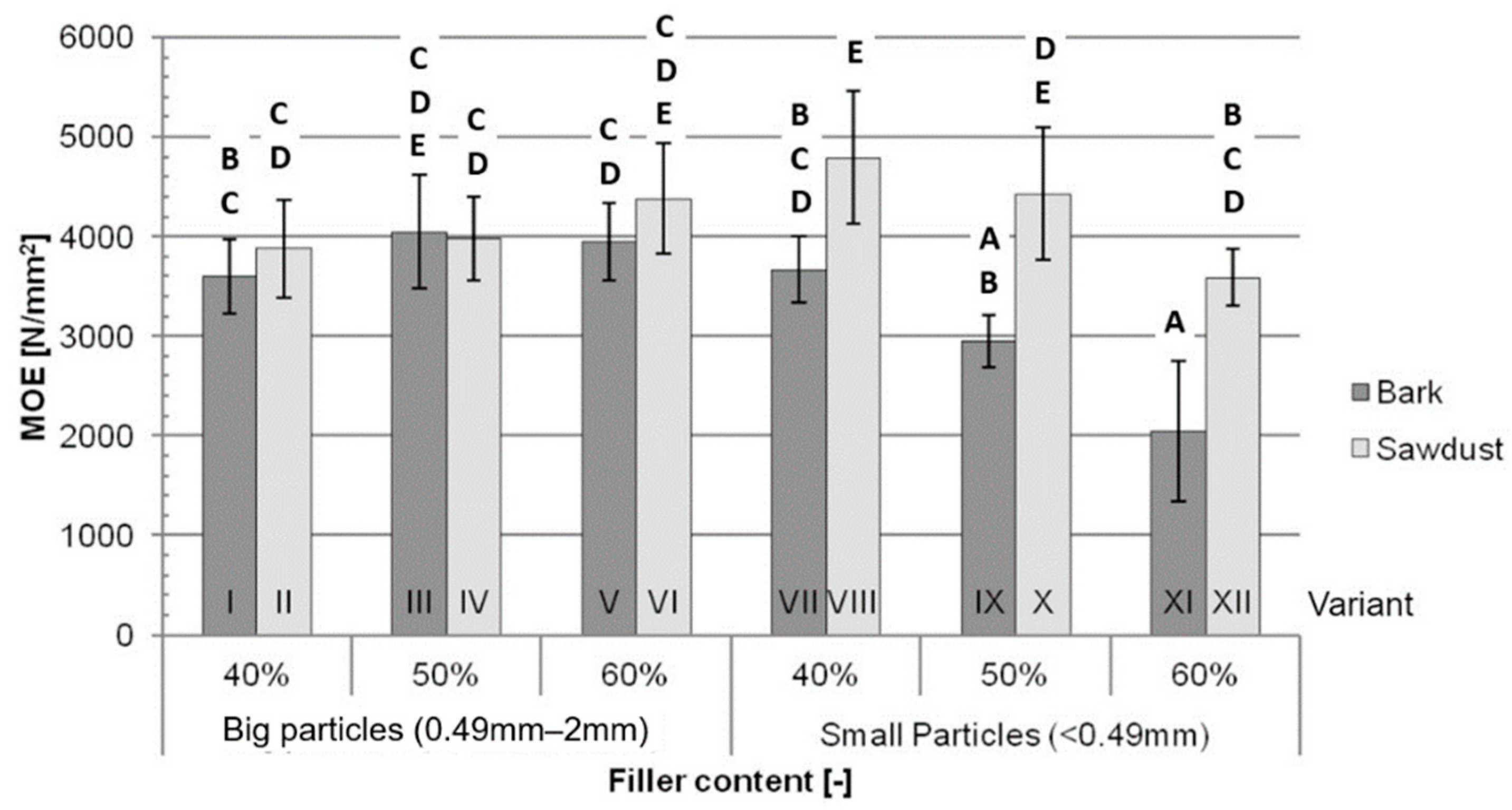

- Modulus of rupture (MOR) and modulus of elasticity (MOE) using 3-point flatwise bending tests according to EN 310 [25].

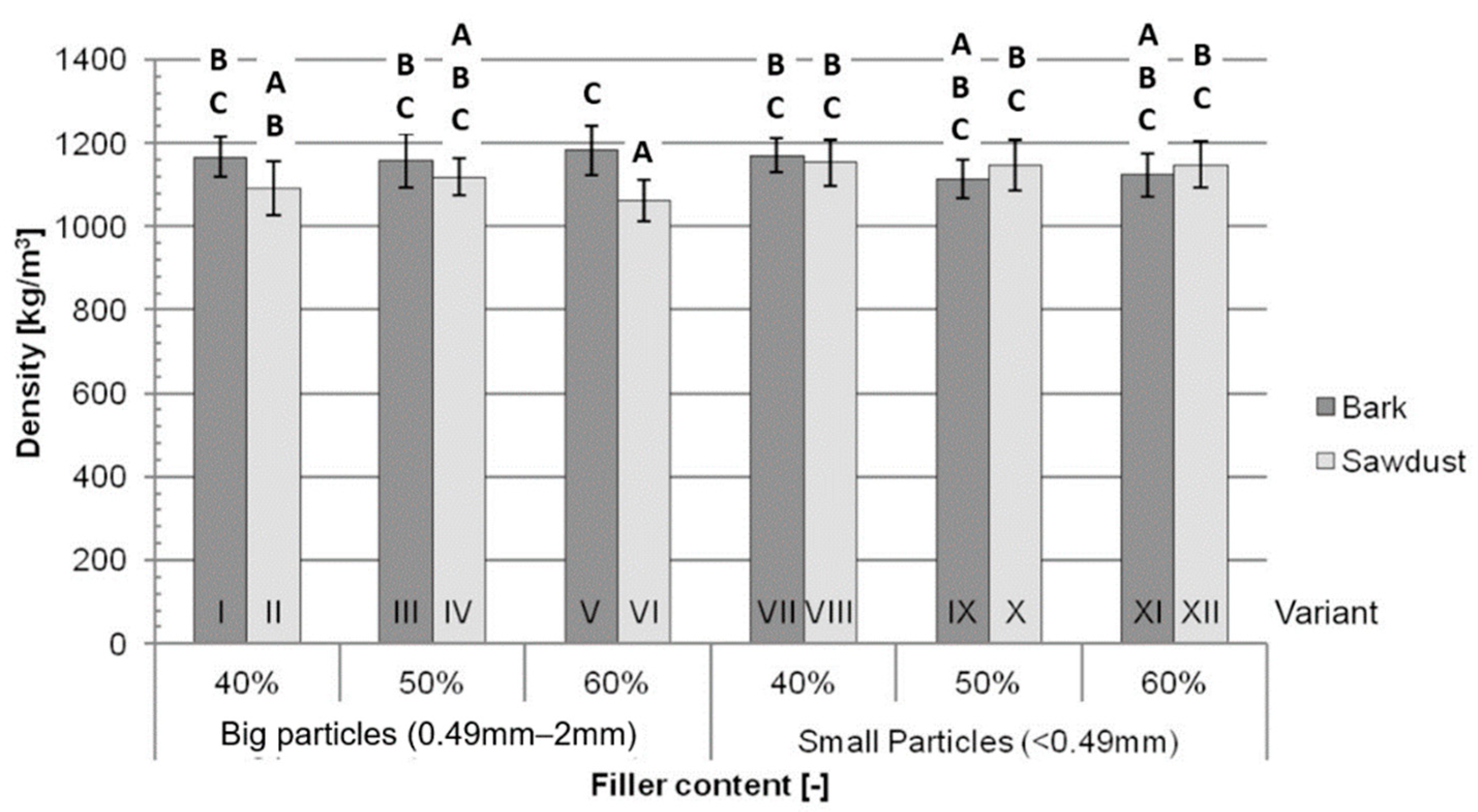

- Density according to EN 323 [26].

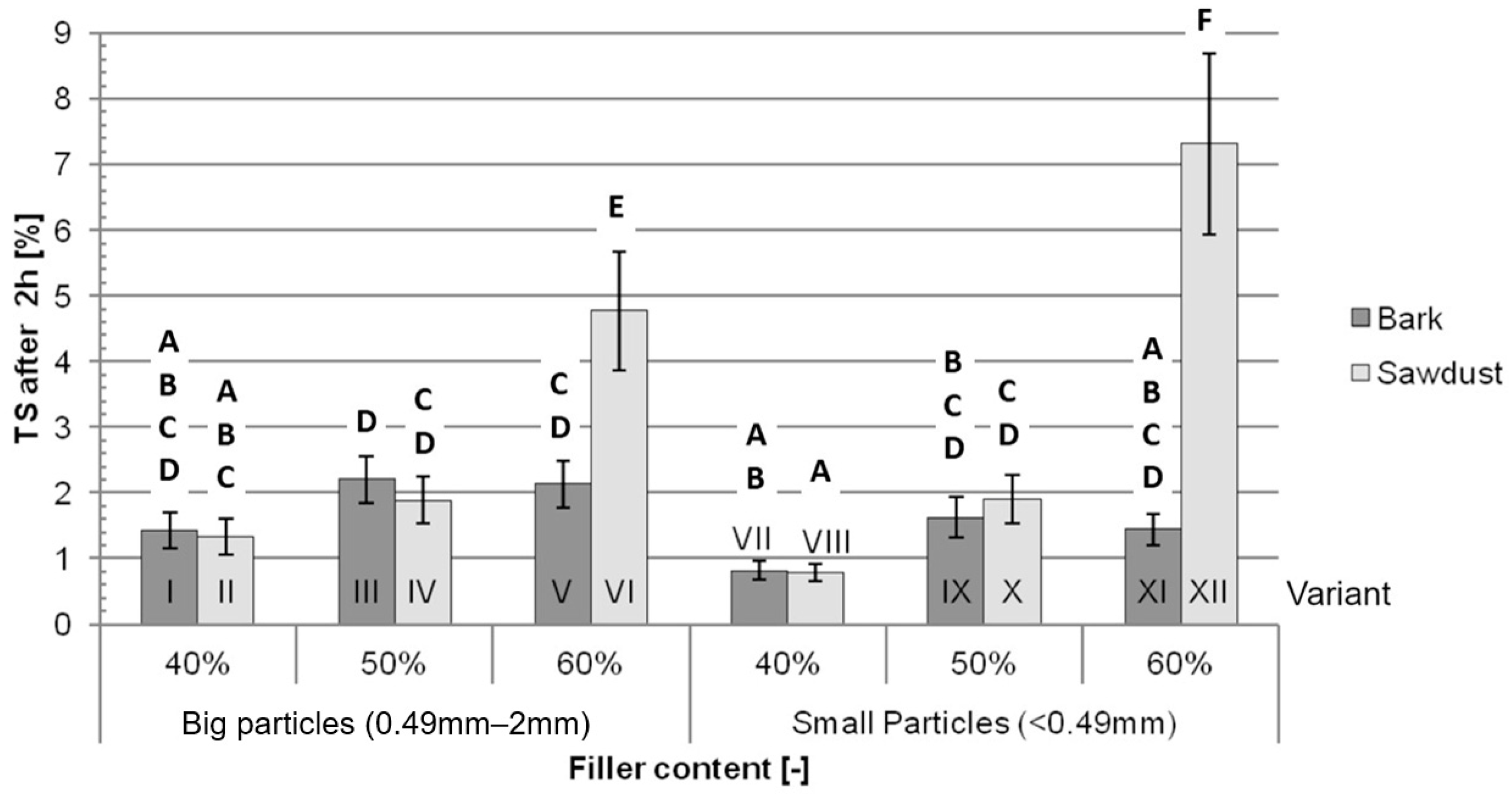

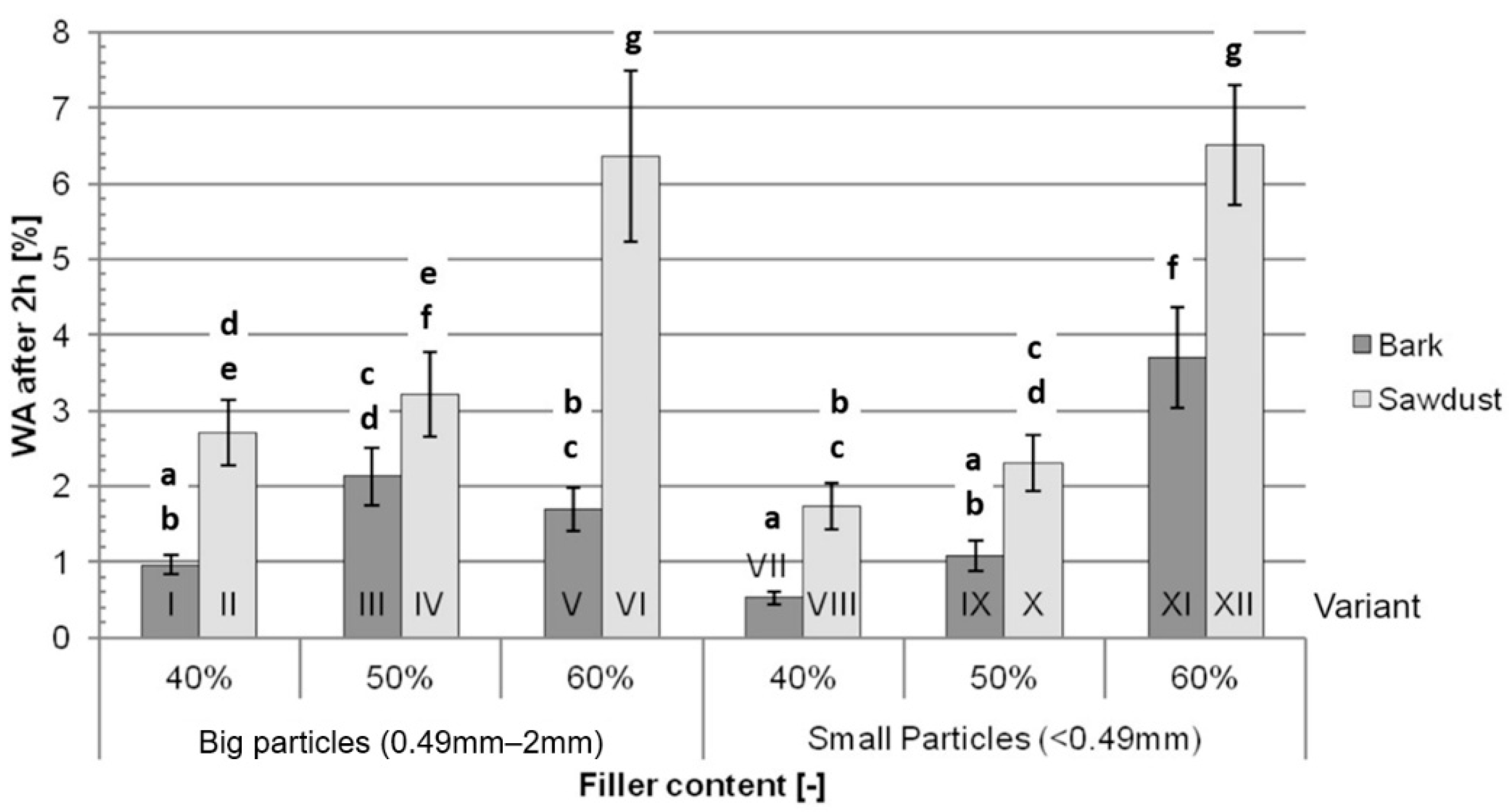

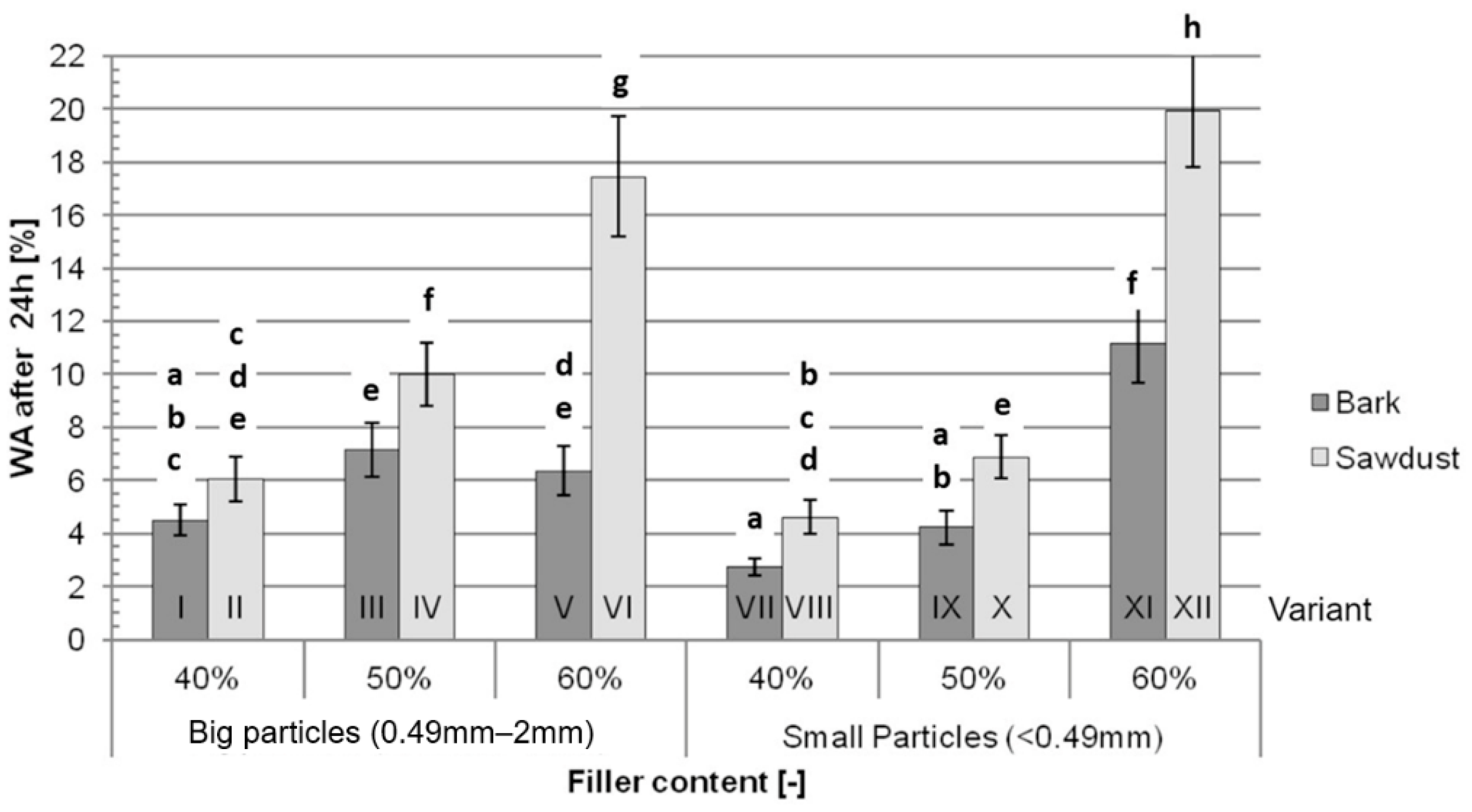

- Thickness swelling (TS) and water absorption (WA) after 2 h and 24 h of immersion in water according to EN 317 [27]. Samples were immersed in water with their faces vertical and separated from the edges of the container, as well as each other. The water temperature was maintained at 20 ± 1 °C for the whole duration of the test. After the test time had elapsed, excess water was removed and the samples were weighed and measured.

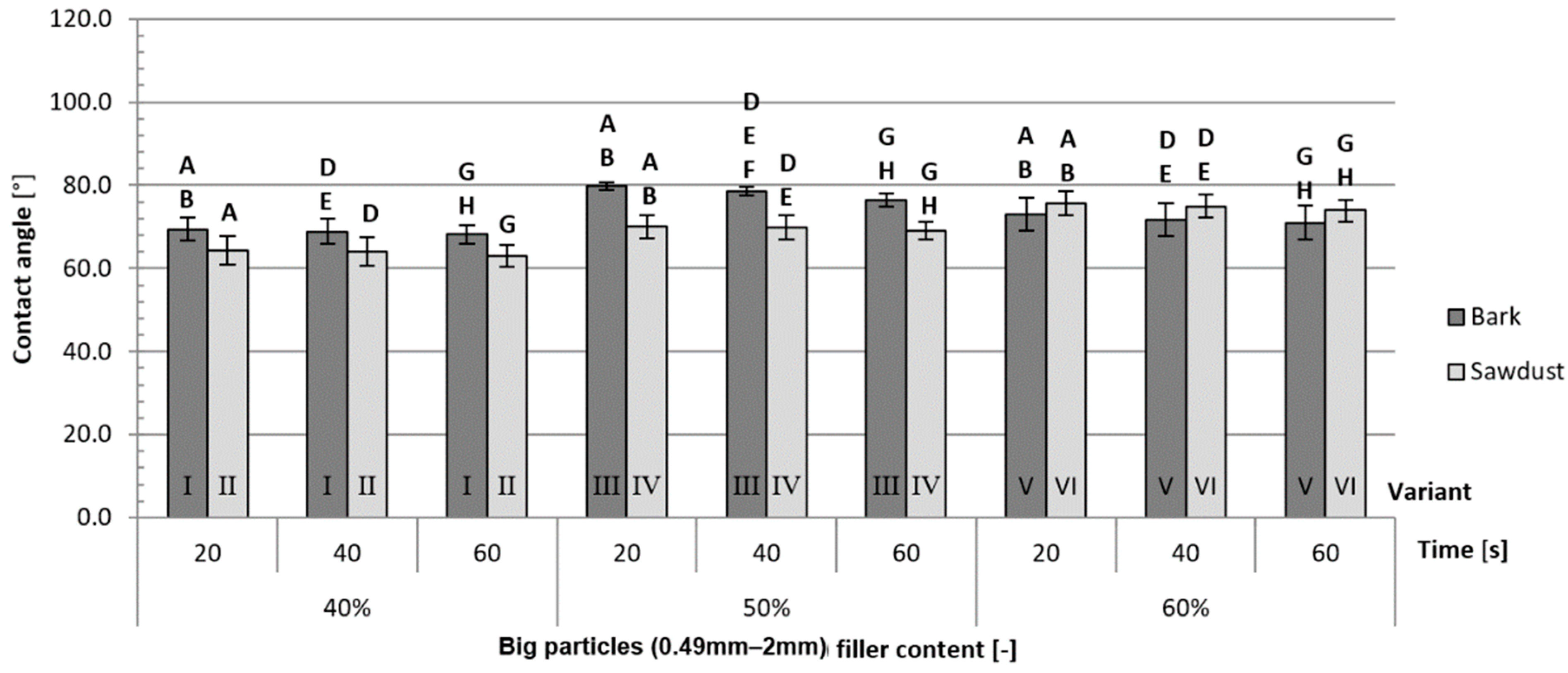

- Wettability (contact angle) was determined by the sessile drop method using a Phoenix 300 (Surface Electro Optics, Suwon City, Korea) contact angle analyser, equipped with microscopic lenses and a digital camera. The contact angles were measured after 20, 40 and 60 s of distilled water droplets touching the surface. Three replicates of these tests were performed.

- Surface free energy was determined by measuring the contact angles of distilled water and diiodomethane after 5 s using the same procedure. The Owens–Wendt [28] method was used to calculate the free surface energy.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jian, B.; Mohrmann, S.; Li, H.; Li, Y.; Ashraf, M.; Zhou, J.; Zheng, X. A Review on Flexural Properties of Wood-Plastic Composites. Polymers 2022, 14, 3942. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of Wood and Biodegradable Thermoplastics: A Review. Polym. Rev. 2018, 58, 444–494. [Google Scholar] [CrossRef]

- El-Haggar, S.M.; Kamel, M.A. Wood Plastic Composites. Adv. Compos. Mater. Anal. Nat. Man-Made Mater. 2011, 325–344. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Falk, R.H.; Vos, D.; Cramer, S.M. The comparative performance of woodfiber-plastic and wood-based panels. In Proceedings of the 5th International Conference on Woodfiber-Plastic Composites, Madison, WI, USA, 26–27 May 1999. [Google Scholar]

- EN 15534-1+A1; Composites Made from Cellulose-Based Materials and Thermoplastics (Usually Called Wood-Polymer Composites (WPC) or Natural Fibre Composites (NFC))—Part 1: Test Methods for Characterisation of Compounds and Products. BSI: London, UK, 2017.

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Partanen, A.; Carus, M. Biocomposites, find the real alternative to plastic—An examination of biocomposites in the market. Reinf. Plast. 2019, 63, 317–321. [Google Scholar] [CrossRef]

- Quitadamo, A.; Massardier, V.; Valente, M. Eco-Friendly Approach and Potential Biodegradable Polymer Matrix for WPC Composite Materials in Outdoor Application. Int. J. Polym. Sci. 2019, 2019, 3894370. [Google Scholar] [CrossRef]

- Balart, J.F.; García-Sanoguera, D.; Balart, R.; Boronat, T.; Sánchez-Nacher, L. Manufacturing and properties of biobased thermoplastic composites from poly(lactid acid) and hazelnut shell wastes. Polym. Compos. 2018, 39, 848–857. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Das, P.P.; Chaudhary, V. Moving towards the era of bio fibre based polymer composites. Clean. Eng. Technol. 2021, 4, 100182. [Google Scholar] [CrossRef]

- Włodarczyk-Fligier, A.; Polok-Rubiniec, M.; Chmielnicki, B. Kompozyty polimerowe z napełniaczem naturalnym. Przetwórstwo Tworzyw 2018, 24, 50–57. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Kuciel, S.; Liber-Kneć, A.; Mikuła, J.S.; Kuźniar, P.; Korniejenko, K.; Łagan, S.D.; Zajchowski, S. Kompozyty Polimerowe na Osnowie Recyklatów z Włóknami Naturalnymi: Praca Zbiorowa; Politechnika Krakowska: Kraków, Poland, 2010. [Google Scholar]

- Kim, J.-W.; Harper, D.P.; Taylor, A.M. Effect of wood species on the mechanical and thermal properties of wood-plastic composites. J. Appl. Polym. Sci. 2009, 112, 1378–1385. [Google Scholar] [CrossRef]

- Gozdecki, C.; Kociszewski, M.; Mirowski, J.; Wilczynski, A.; Zajchowski, S. Effect of wood bark on wood-plastic composite properties. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2009, 68, 278–282. [Google Scholar]

- Avci, E.; Acar, M.; Gonultas, O.; Candan, Z. Manufacturing biocomposites using black pine bark and oak bark. BioResources 2018, 13, 15–26. [Google Scholar] [CrossRef]

- Çetin, N.S.; Özmen, N.; Narlıoğlu, N.; Çavuş, V. Effect of bark flour on the mechanical properties of HDPE composites. Usak Univ. J. Mater. Sci. 2014, 3, 23. [Google Scholar] [CrossRef][Green Version]

- Kazemi Najafi, S.; Kiaefar, A.; Tajvidi, M. Effect of bark flour content on the hygroscopic characteristics of wood-polypropylene composites. J. Appl. Polym. Sci. 2008, 110, 3116–3120. [Google Scholar] [CrossRef]

- Farsi, M. Effect of Nano-SiO2 and Bark Flour Content on the Physical and Mechanical Properties of Wood–Plastic Composites. J. Polym. Environ. 2017, 25, 308–314. [Google Scholar] [CrossRef]

- Obuch, J.; Hecl, D. Using SRC Poplar to Produce Bark-Enriched Wood Plastic Composite Profiles; Dendromass4Europe.eu: Tharandt, Germany, 2022. [Google Scholar]

- EN 310; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. CEN: Brussele, Belgium, 1994.

- EN 323; Wood-Based Panels—Determination of Density. CEN: Brussele, Belgium, 1999.

- EN 317; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water. CEN: Brussele, Belgium, 1999.

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Shah, B.L.; Selke, S.E.; Walters, M.B.; Heiden, P.A. Effects of wood flour and chitosan on mechanical, chemical, and thermal properties of polylactide. Polym. Compos. 2008, 29, 655–663. [Google Scholar] [CrossRef]

- Gozdecki, C.; Kociszewski, M.; Wilczyński, A.; Mirowski, J. Effect of wood bark content on mechanical properties of wood-polyethylene composite. Ann. Warsaw Univ. Life Sci. For. Wood Technol. 2010, 71, 203–206. [Google Scholar]

- Safdari, V.; Khodadadi, H.; Hosseinihashemi, S.K.; Ganjian, E. The Effects of Poplar Bark and Wood Content on the Mechanical Properties of Wood-Polypropylene Composites. BioResources 2011, 6, 5180–5192. [Google Scholar] [CrossRef]

- Tang, Q.; Fang, L.; Guo, W. UHD fiberboard reinforcement. BioResources 2017, 12, 6749–6762. [Google Scholar]

- Radoor, S.; Karayil, J.; Shivanna, J.M.; Siengchin, S. Water Absorption and Swelling Behaviour of Wood Plastic Composites. Wood Polym. Compos. Recent Adv. Appl. 2021, 195–212. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A. Effects of fiber characteristics on the physical and mechanical properties of wood plastic composites. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 1975–1981. [Google Scholar] [CrossRef]

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. Part B Eng. 2019, 176, 10734. [Google Scholar] [CrossRef]

- Tamrakar, S.; Lopez-Anido, R.A. Water absorption of wood polypropylene composite sheet piles and its influence on mechanical properties. Constr. Build. Mater. 2011, 25, 3977–3988. [Google Scholar] [CrossRef]

| Variant | Share of PLA Matrix | Size of Particles | Kind of Particles |

|---|---|---|---|

| I | 60% | (0.49–2 mm) | Bark |

| II | Sawdust | ||

| III | 50% | Bark | |

| IV | Sawdust | ||

| V | 40% | Bark | |

| VI | Sawdust | ||

| VII | 60% | (<0.49 mm) | Bark |

| VIII | Sawdust | ||

| IX | 50% | Bark | |

| X | Sawdust | ||

| XI | 40% | Bark | |

| XII | Sawdust |

| Factor | MOR | MOE | Density | |||

|---|---|---|---|---|---|---|

| p | P | p | P | p | P | |

| a | 0.000 | 42.57% | 0.009 | 3.72% | 0.361 | 1.32% |

| b | 0.000 | 15.86% | 0.000 | 23.86% | 0.001 | 7.24% |

| c | 0.000 | 2.58% | 0.002 | 3.72% | 0.204 | 1.05% |

| a × b | 0.000 | 6.40% | 0.510 | 0.51% | 0.122 | 2.75% |

| a × c | 0.000 | 13.27% | 0.000 | 16.71% | 0.258 | 1.77% |

| b × c | 0.000 | 5.67% | 0.000 | 12.39% | 0.000 | 13.96% |

| a × b × c | 0.000 | 3.06% | 0.340 | 0.82% | 0.361 | 1.32% |

| Error | 10.58% | 38.29% | 69.43% | |||

| Factor | TS after 2 h | TS after 24 h | WA after 2 h | WA after 24 h | ||||

|---|---|---|---|---|---|---|---|---|

| p | P | p | P | p | P | p | P | |

| a | 0.000 | 40.05% | 0.000 | 37.51% | 0.000 | 46.45% | 0.000 | 54.56% |

| b | 0.000 | 13.79% | 0.000 | 18.63% | 0.000 | 30.04% | 0.000 | 20.66% |

| c | 0.835 | 0.00% | 0.430 | 0.06% | 0.038 | 0.28% | 0.144 | 0.10% |

| a × b | 0.000 | 29.15% | 0.000 | 20.39% | 0.000 | 8.80% | 0.000 | 12.10% |

| a × c | 0.000 | 3.04% | 0.000 | 7.54% | 0.000 | 5.48% | 0.000 | 7.38% |

| b × c | 0.000 | 2.93% | 0.020 | 0.58% | 0.000 | 0.94% | 0.101 | 0.12% |

| a × b × c | 0.000 | 3.43% | 0.000 | 4.13% | 0.000 | 1.15% | 0.041 | 0.29% |

| Error | 7.60% | 11.15% | 6.87% | 4.80% | ||||

| Factor | Contact Angle after 20 s | Contact Angle after 40 s | Contact Angle after 60 s | |||

|---|---|---|---|---|---|---|

| p | P | p | P | p | P | |

| a | 0.002 | 12.98% | 0.004 | 11.93% | 0.005 | 10.68% |

| b | 0.000 | 30.56% | 0.000 | 29.35% | 0.000 | 29.66% |

| c | 0.003 | 11.55% | 0.004 | 11.62% | 0.002 | 13.00% |

| a × b | 0.327 | 2.45% | 0.404 | 2.20% | 0.378 | 2.28% |

| a × c | 0.086 | 3.36% | 0.093 | 3.57% | 0.093 | 3.45% |

| b × c | 0.019 | 9.80% | 0.028 | 9.76% | 0.022 | 10.05% |

| a × b × c | 0.159 | 4.16% | 0.236 | 3.58% | 0.197 | 3.91% |

| Error | 25.14% | 27.99% | 26.96% | |||

| Filler Content | Variant | Surface Free Energy [mJ × m−2] | ||

|---|---|---|---|---|

| γtot | γD | γP | ||

| 40% L | I | 51.68 | 45.60 | 6.07 |

| II | 52.23 | 43.24 | 8.99 | |

| 50% L | III | 44.33 | 41.18 | 3.15 |

| IV | 52.59 | 47.45 | 5.14 | |

| 60% L | V | 47.36 | 42.17 | 5.20 |

| VI | 48.75 | 45.18 | 3.57 | |

| 40% S | VII | 49.40 | 44.31 | 5.10 |

| VIII | 49.50 | 41.84 | 7.66 | |

| 50% S | IX | 38.29 | 36.53 | 1.77 |

| X | 47.22 | 40.55 | 6.67 | |

| 60% S | XI | 37.76 | 37.75 | 0.00 |

| XII | 50.24 | 49.17 | 1.07 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasiński, W.; Auriga, R.; Lee, S.H.; Adamik, Ł.; Borysiuk, P. Coniferous Bark as Filler for Polylactic Acid-Based Biocomposites. Polymers 2024, 16, 2669. https://doi.org/10.3390/polym16182669

Jasiński W, Auriga R, Lee SH, Adamik Ł, Borysiuk P. Coniferous Bark as Filler for Polylactic Acid-Based Biocomposites. Polymers. 2024; 16(18):2669. https://doi.org/10.3390/polym16182669

Chicago/Turabian StyleJasiński, Wojciech, Radosław Auriga, Seng Hua Lee, Łukasz Adamik, and Piotr Borysiuk. 2024. "Coniferous Bark as Filler for Polylactic Acid-Based Biocomposites" Polymers 16, no. 18: 2669. https://doi.org/10.3390/polym16182669

APA StyleJasiński, W., Auriga, R., Lee, S. H., Adamik, Ł., & Borysiuk, P. (2024). Coniferous Bark as Filler for Polylactic Acid-Based Biocomposites. Polymers, 16(18), 2669. https://doi.org/10.3390/polym16182669