A Current Trend in Efficient Biopolymer Coatings for Edible Fruits to Enhance Shelf Life

Abstract

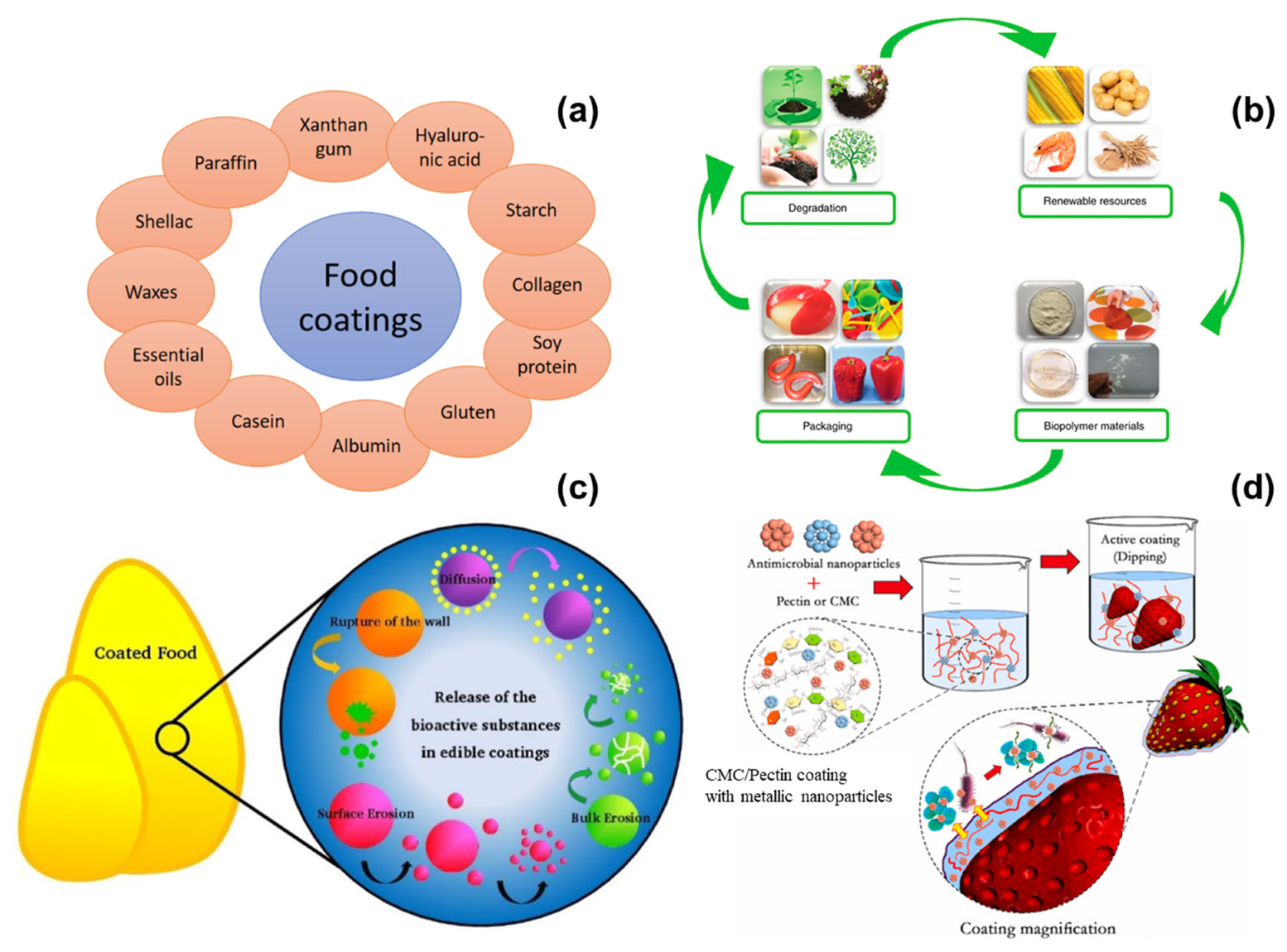

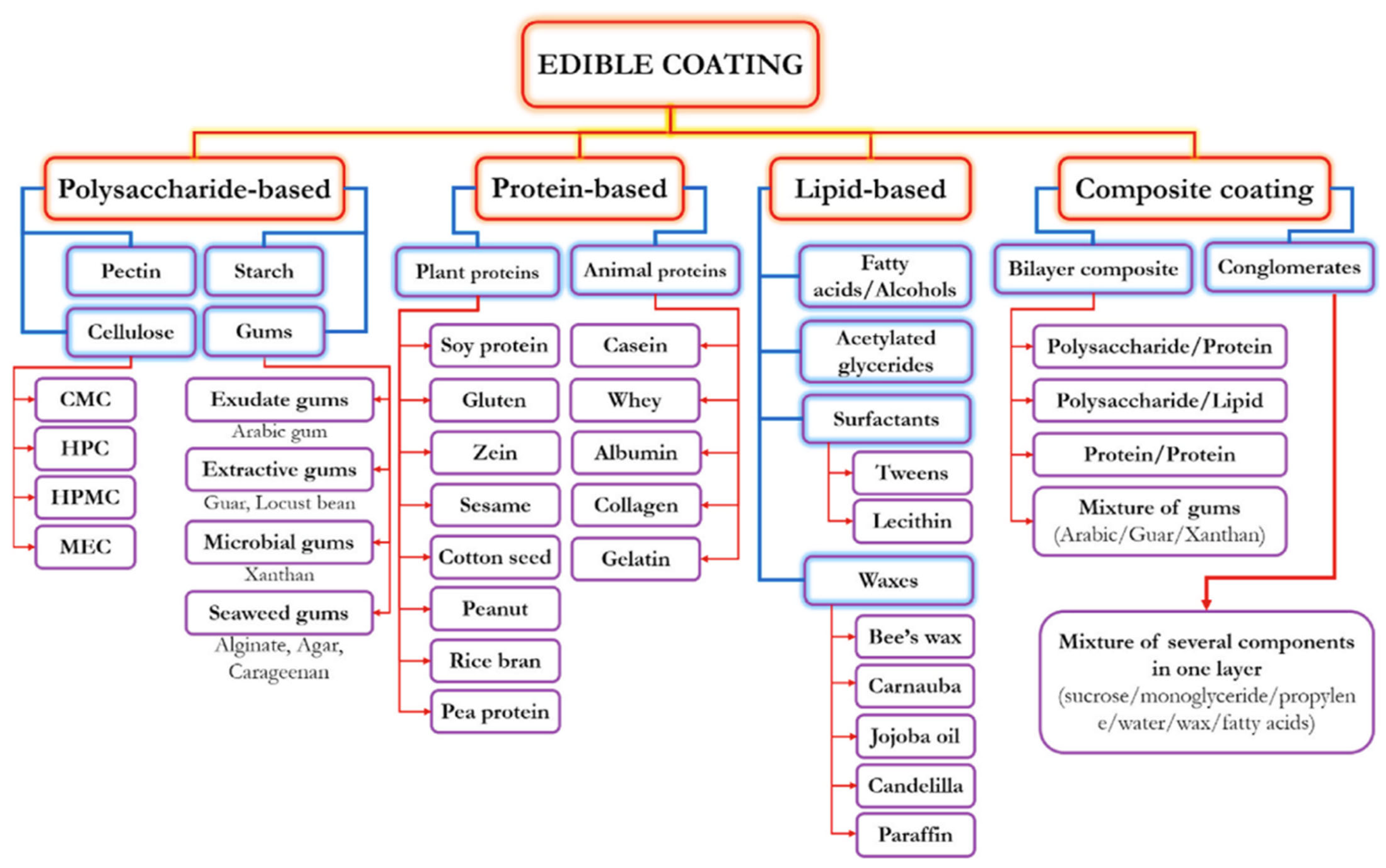

1. Introduction

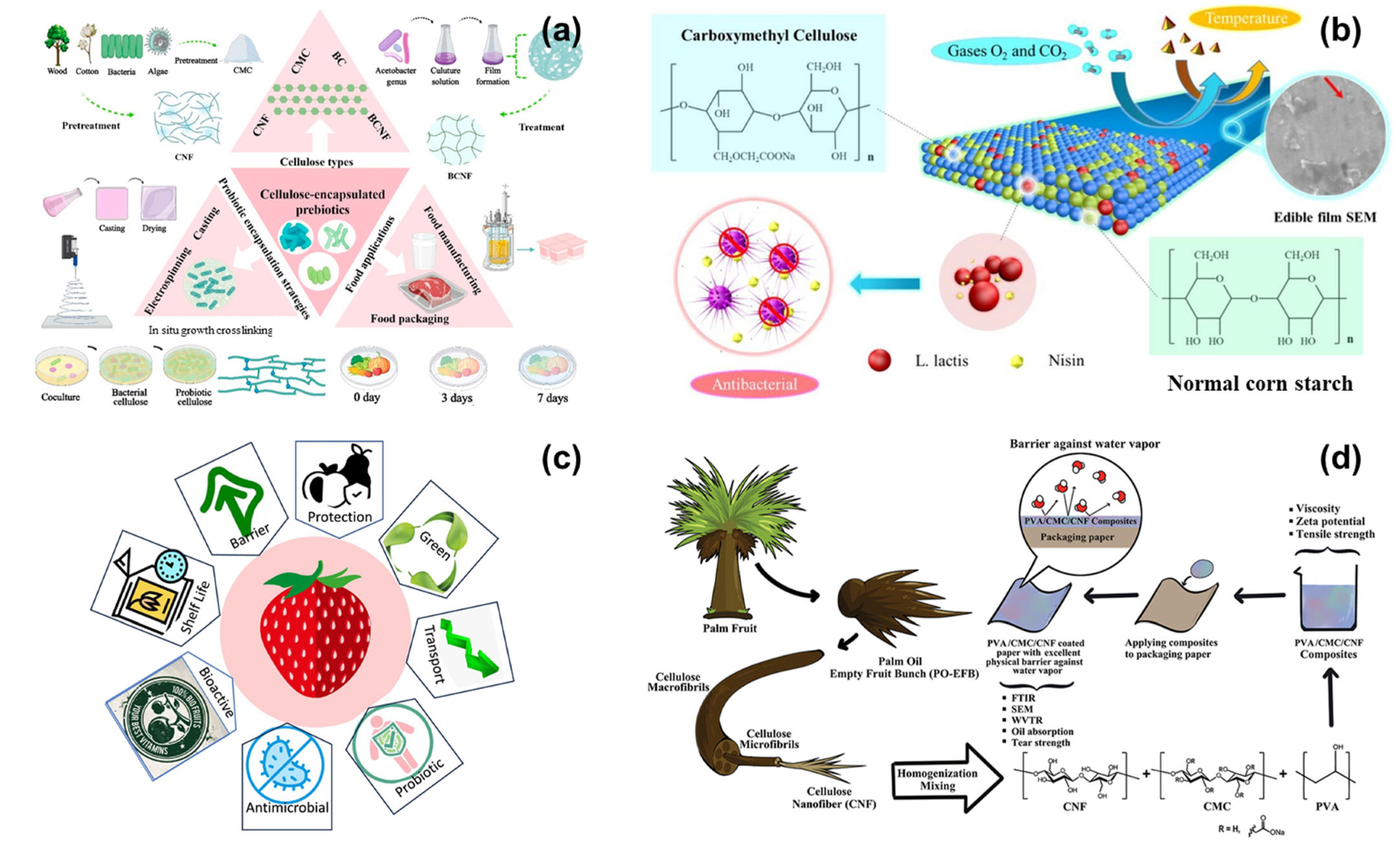

2. Cellulose-Based Biopolymers for Food Coating Applications

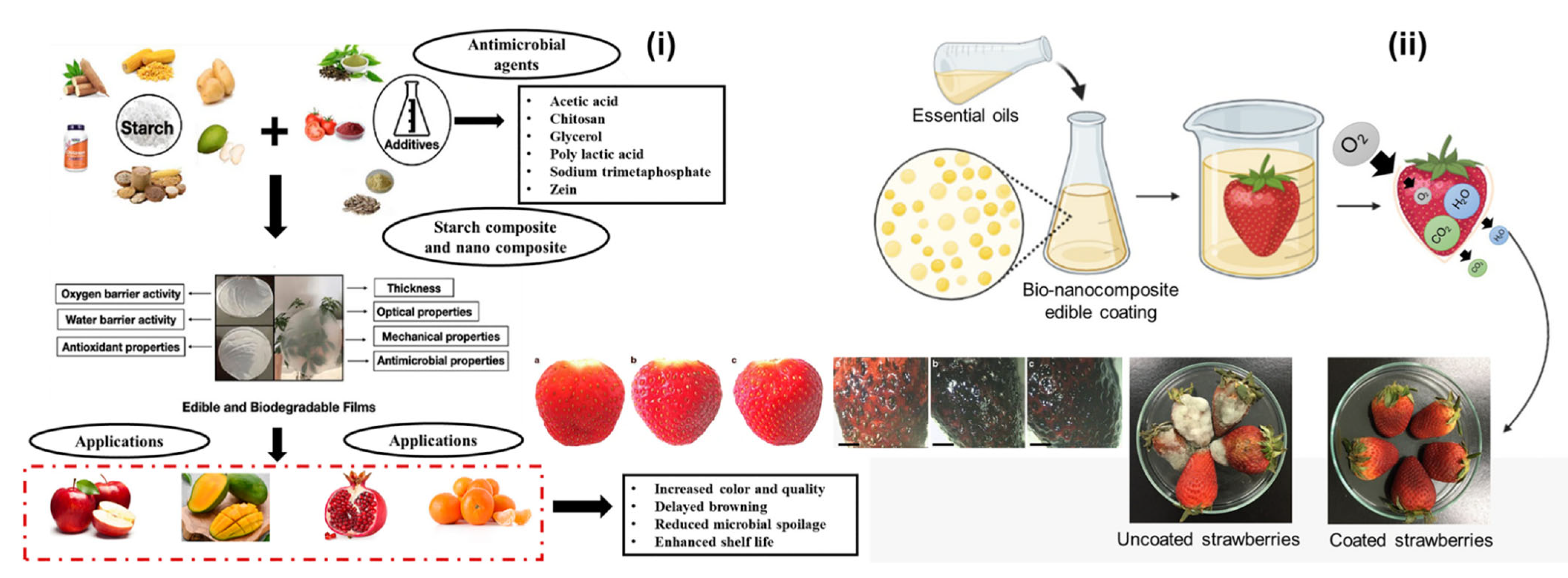

3. Starch-Based Biopolymers for Food Coating Applications

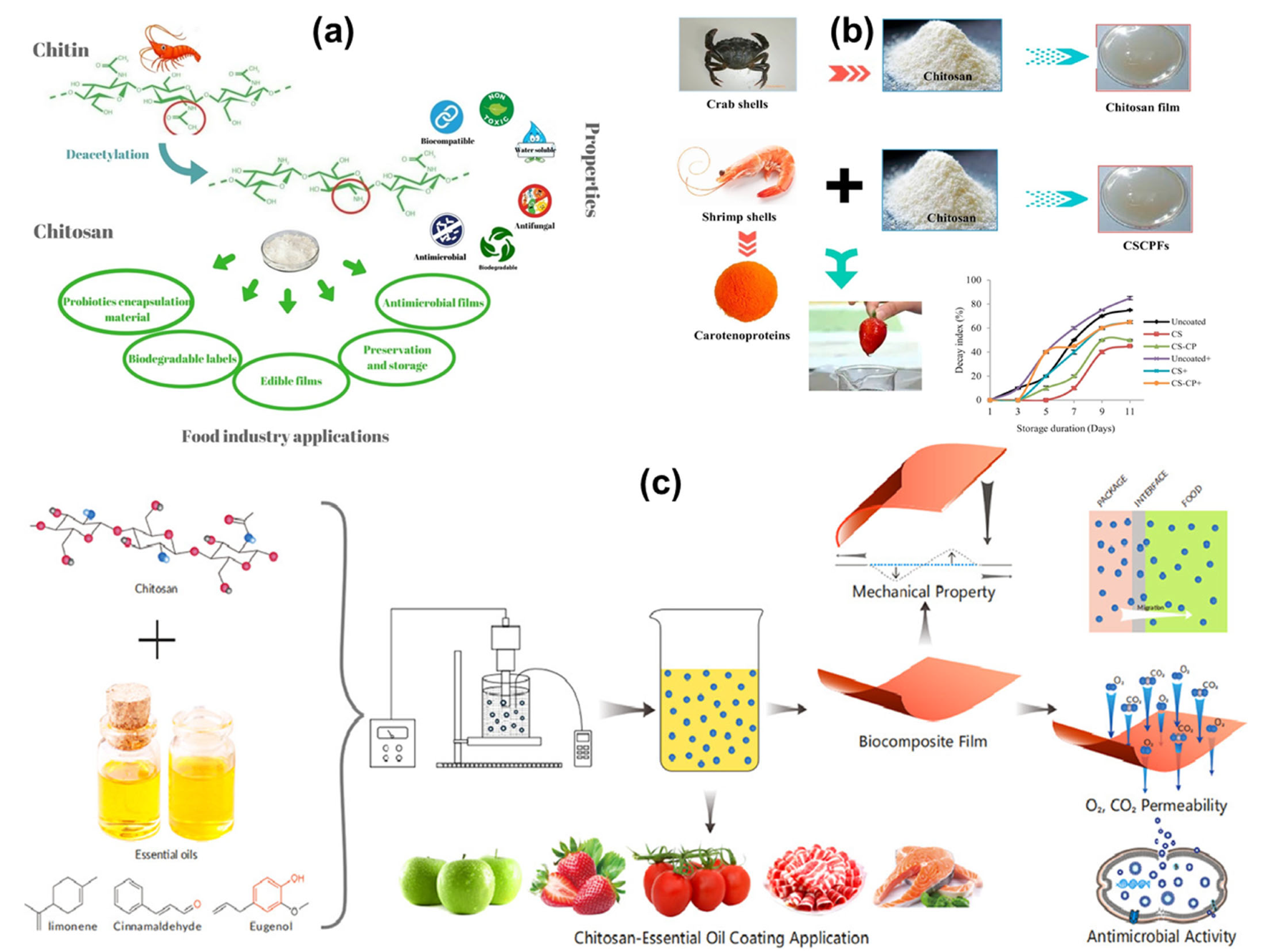

4. Chitosan-Based Biopolymers for Food Coating Applications

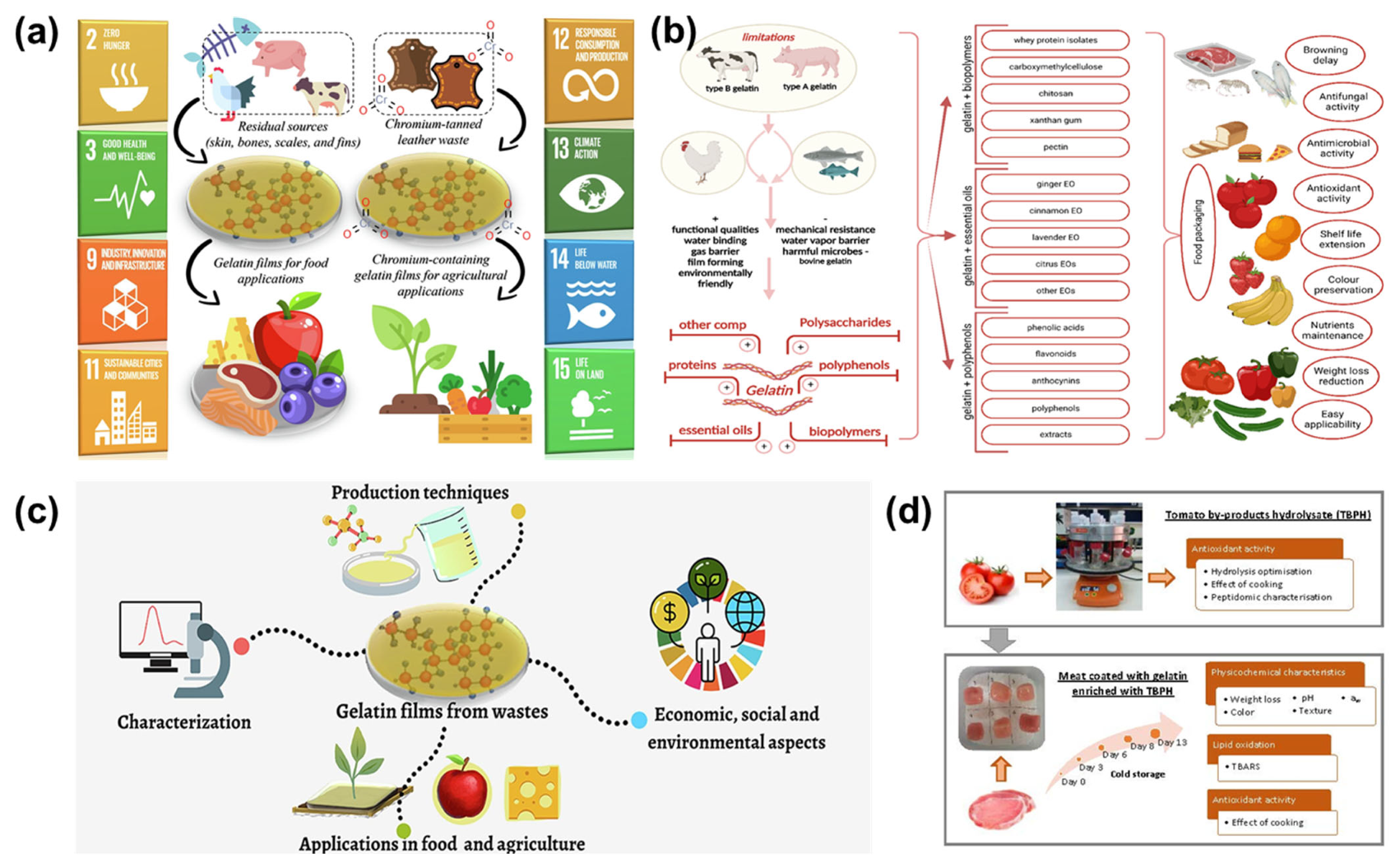

5. Gelatin-Based Biopolymers for Food Coating Applications

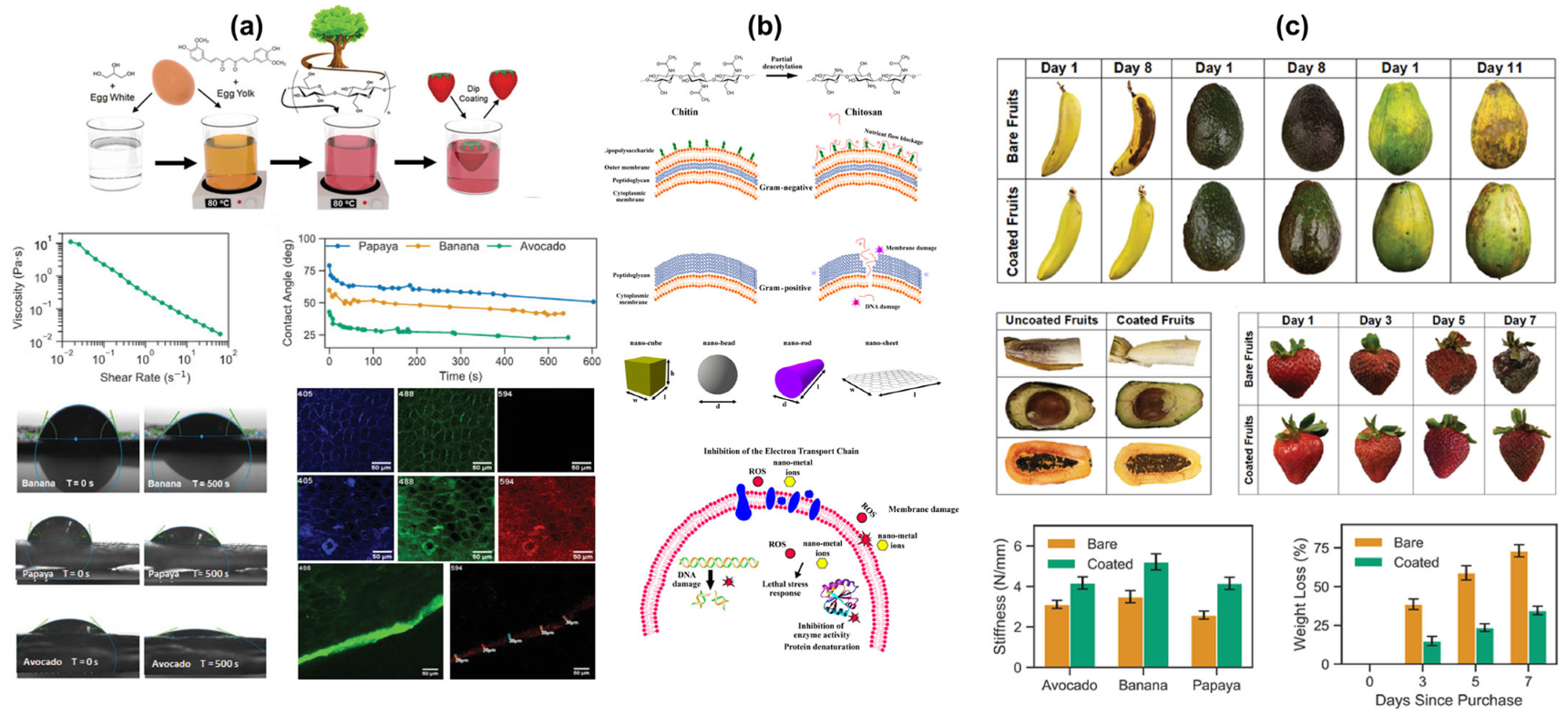

6. Fatty Acid and Wax Coatings for Extending Shelf Life of Food Materials

7. Biopolymer Nanocomposite Materials for Food Coating Applications

8. Removal of Biopolymers from Food Materials and Quantitative Features of Biopolymer Coating

9. The Structural Properties Relationship of Biopolymers for Edible Food Coatings

10. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rozin, P. The Meaning of Food in Our Lives: A Cross-Cultural Perspective on Eating and Well-Being. J. Nutr. Educ. Behav. 2005, 37, S107–S112. [Google Scholar] [CrossRef] [PubMed]

- Lusk, J.L.; Briggeman, B.C. Food Values. Am. J. Agric. Econ. 2009, 91, 184–196. [Google Scholar] [CrossRef]

- Sugimura, T. Food and cancer. Toxicology 2002, 181–182, 17–21. [Google Scholar] [CrossRef] [PubMed]

- Ranadheera, R.; Baines, S.; Adams, M. Importance of food in probiotic efficacy. Food Res. Int. 2009, 43, 1–7. [Google Scholar] [CrossRef]

- Oliver, M.A.; Gregory, P.J. Soil, food security and human health: A review. Eur. J. Soil Sci. 2015, 66, 257–276. [Google Scholar] [CrossRef]

- Pandey, S.; Sharma, K.; Gundabala, V. Antimicrobial bio-inspired active packaging materials for shelf life and safety development: A review. Food Biosci. 2022, 48, 101730. [Google Scholar] [CrossRef]

- Pellegrino, M.; Elechi, J.O.; Plastina, P.; Loizzo, M.R. Application of Natural Edible Coating to Enhance the Shelf Life of Red Fruits and Their Bioactive Content. Appl. Sci. 2023, 14, 4552. [Google Scholar] [CrossRef]

- Basavegowda, N.; Baek, K. Advances in Functional Biopolymer-Based Nanocomposites for Active Food Packaging Applications. Polymers 2020, 13, 4198. [Google Scholar] [CrossRef]

- No, H.K.; Meyers, S.P.; Prinyawiwatkul, W.; Xu, Z. Applications of Chitosan for Improvement of Quality and Shelf Life of Foods: A Review. J. Food Sci. 2007, 72, R87–R100. [Google Scholar] [CrossRef]

- Arturo, J. An Extensive Review of Natural Polymers Used as Coatings for Postharvest Shelf-Life Extension: Trends and Challenges. Polymers 2020, 13, 3271. [Google Scholar] [CrossRef]

- Priya, K.; Thirunavookarasu, N.; Chidanand, D. Recent advances in edible coating of food products and its legislations: A review. J. Agric. Food Res. 2023, 12, 100623. [Google Scholar] [CrossRef]

- Pratap Singh, D.; Packirisamy, G. Biopolymer based edible coating for enhancing the shelf life of horticulture products. Food Chem. Mol. Sci. 2022, 4, 100085. [Google Scholar] [CrossRef] [PubMed]

- Pillai, A.R.; Eapen, A.S.; Zhang, W.; Roy, S. Polysaccharide-Based Edible Biopolymer-Based Coatings for Fruit Preservation: A Review. Foods 2023, 13, 1529. [Google Scholar] [CrossRef] [PubMed]

- Perdones, Á.; Tur, N.; Chiralt, A.; Vargas, M. Effect on tomato plant and fruit of the application of biopolymer–oregano essential oil coatings. J. Sci. Food Agric. 2016, 96, 4505–4513. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, M.; Singh, A.K. Potential of engineered nanostructured biopolymer-based coatings for perishable fruits with Coronavirus safety perspectives. Prog. Org. Coat. 2022, 163, 106632. [Google Scholar] [CrossRef]

- Yuan, L.; Liu, R.; Zhou, Y.; Zhang, R.; Chen, S.; Yang, Q.; Gu, Y.; Han, L.; Yan, B. Janus biopolymer nanocomposite coating with excellent antibacterial and water/oxygen barrier performance for fruit preservation. Food Hydrocoll. 2024, 149, 109528. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, M.; Bhandari, B.; Gao, Z. Recent developments in novel shelf life extension technologies of fresh-cut fruits and vegetables. Trends Food Sci. Technol. 2017, 64, 23–38. [Google Scholar] [CrossRef]

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Chettri, S.; Sharma, N.; Mohite, A.M. Edible coatings and films for shelf-life extension of fruit and vegetables. Biomater. Adv. 2023, 154, 213632. [Google Scholar] [CrossRef]

- Gull, A.; Bhat, N.; Wani, S.M.; Masoodi, F.A.; Amin, T.; Ganai, S.A. Shelf life extension of apricot fruit by application of nanochitosan emulsion coatings containing pomegranate peel extract. Food Chem. 2021, 349, 129149. [Google Scholar] [CrossRef]

- Taylor, T.M.; Ravishankar, S.; Bhargava, K.; Juneja, V.K. Chemical Preservatives and Natural Food Antimicrobials. In Food Microbiology: Fundamentals and Frontiers, 5th ed.; ASM Press: Washington, DC, USA, 2019; pp. 705–731. [Google Scholar] [CrossRef]

- Carocho, M.; Morales, P.; Ferreira, I.C. Antioxidants: Reviewing the chemistry, food applications, legislation and role as preservatives. Trends Food Sci. Technol. 2017, 71, 107–120. [Google Scholar] [CrossRef]

- Davidson, P.M.; Taylor, T.M.; Schmidt, S.E. Chemical Preservatives and Natural Antimicrobial Compounds. In Food Microbiology: Fundamentals and Frontiers, 4th ed.; ASM Press: Washington, DC, USA, 2012; pp. 765–801. [Google Scholar] [CrossRef]

- Falleh, H.; Ben Jemaa, M.; Saada, M.; Ksouri, R. Essential oils: A promising eco-friendly food preservative. Food Chem. 2020, 330, 127268. [Google Scholar] [CrossRef] [PubMed]

- Gokoglu, N. Novel natural food preservatives and applications in seafood preservation: A review. J. Sci. Food Agric. 2019, 99, 2068–2077. [Google Scholar] [CrossRef] [PubMed]

- Balart, R.; Fombuena, V.; Arrieta, M.P. Biopolymers from Natural Resources. Polymers 2020, 13, 2532. [Google Scholar] [CrossRef] [PubMed]

- Schnepp, Z. Biopolymers as a Flexible Resource for Nanochemistry. Angew. Chem. Int. Ed. 2013, 52, 1096–1108. [Google Scholar] [CrossRef] [PubMed]

- Flaris, V.; Singh, G. Recent developments in biopolymers. J. Vinyl Addit. Technol. 2009, 15, 1–11. [Google Scholar] [CrossRef]

- Ramesan, M.T.; Surya, K. Fabrication and characterization of biopolymer nanocomposites from natural resource materials. Polym. Compos. 2017, 38, E66–E73. [Google Scholar] [CrossRef]

- Bayer, I.S. Biopolymers in Multilayer Films for Long-Lasting Protective Food Packaging: A Review. In Sustainable Food Packaging Technology; Wiley-VCH: Weinheim, Germany, 2021; pp. 395–426. [Google Scholar] [CrossRef]

- Calambas, H.L.; Fonseca, A.; Adames, D.; Caicedo, C. Physical-Mechanical Behavior and Water-Barrier Properties of Biopolymers-Clay Nanocomposites. Molecules 2020, 26, 6734. [Google Scholar] [CrossRef]

- Cherpinski, A.; Torres-Giner, S.; Cabedo, L.; Méndez, J.A.; Lagaron, J.M. Multilayer structures based on annealed electrospun biopolymer coatings of interest in water and aroma barrier fiber-based food packaging applications. J. Appl. Polym. Sci. 2018, 135, 45501. [Google Scholar] [CrossRef]

- Khwaldia, K.; Arab-Tehrany, E.; Desobry, S. Biopolymer Coatings on Paper Packaging Materials. Compr. Rev. Food Sci. Food Saf. 2009, 9, 82–91. [Google Scholar] [CrossRef]

- Akhter, R.; Masoodi, F.; Wani, T.A.; Rather, S.A. Functional characterization of biopolymer based composite film: Incorporation of natural essential oils and antimicrobial agents. Int. J. Biol. Macromol. 2019, 137, 1245–1255. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Du, G.; Jia, H.; Fan, Q.; Wang, Z.; Gao, Z.; Yue, T.; Yuan, Y. Essential oils encapsulated by biopolymers as antimicrobials in fruits and vegetables: A review. Food Biosci. 2021, 44, 101367. [Google Scholar] [CrossRef]

- Varghese, S.A.; Siengchin, S.; Parameswaranpillai, J. Essential oils as antimicrobial agents in biopolymer-based food packaging—A comprehensive review. Food Biosci. 2020, 38, 100785. [Google Scholar] [CrossRef]

- Da Silva Rios, D.A.; Nakamoto, M.M.; Braga, A.R.C.; da Silva, E.M.C. Food coating using vegetable sources: Importance and industrial potential, gaps of knowledge, current application, and future trends. Appl. Food Res. 2022, 2, 100073. [Google Scholar] [CrossRef]

- Gupta, I.; Cherwoo, L.; Bhatia, R.; Setia, H. Biopolymers: Implications and application in the food industry. Biocatal. Agric. Biotechnol. 2022, 46, 102534. [Google Scholar] [CrossRef]

- Chen, K.; Tian, R.; Jiang, J.; Xiao, M.; Wu, K.; Kuang, Y.; Deng, P.; Zhao, X.; Jiang, F. Moisture loss inhibition with biopolymer films for preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2024, 263, 130337. [Google Scholar] [CrossRef]

- Ruggeri, E.; Farè, S.; Nardo, L.D.; Marelli, B. Edible Biopolymers for Food Preservation. In Sustainable Food Packaging Technology; Wiley-VCH: Weinheim, Germany, 2021; pp. 57–105. [Google Scholar] [CrossRef]

- Kumar, S.; Basumatary, I.B.; Mukherjee, A.; Dutta, J. An Overview of Natural Biopolymers in Food Packaging. In Biopolymer-Based Food Packaging: Innovations and Technology Applications; John Wiley & Sons, Inc.: New York, NY, USA, 2022; pp. 1–28. [Google Scholar] [CrossRef]

- Khan, M.R.; Di Giuseppe, F.A.; Torrieri, E.; Sadiq, M.B. Recent advances in biopolymeric antioxidant films and coatings for preservation of nutritional quality of minimally processed fruits and vegetables. Food Packag. Shelf Life 2021, 30, 100752. [Google Scholar] [CrossRef]

- Yuan, Y.; Tian, H.; Huang, R.; Liu, H.; Wu, H.; Guo, G.; Xiao, J. Fabrication and characterization of natural polyphenol and ZnO nanoparticles loaded protein-based biopolymer multifunction electrospun nanofiber films, and application in fruit preservation. Food Chem. 2023, 418, 135851. [Google Scholar] [CrossRef]

- Md Nor, S.; Ding, P. Trends and advances in edible biopolymer coating for tropical fruit: A review. Food Res. Int. 2020, 134, 109208. [Google Scholar] [CrossRef]

- Volpe, S.; Cavella, S.; Torrieri, E. Biopolymer Coatings as Alternative to Modified Atmosphere Packaging for Shelf Life Extension of Minimally Processed Apples. Coatings 2019, 9, 569. [Google Scholar] [CrossRef]

- Díaz-Montes, E.; Castro-Muñoz, R. Trends in Chitosan as a Primary Biopolymer for Functional Films and Coatings Manufacture for Food and Natural Products. Polymers 2020, 13, 767. [Google Scholar] [CrossRef] [PubMed]

- Mahmud, N.; Islam, J.; Tahergorabi, R. Marine Biopolymers: Applications in Food Packaging. Processes 2021, 9, 2245. [Google Scholar] [CrossRef]

- Kraśniewska, K.; Galus, S.; Gniewosz, M. Biopolymers-Based Materials Containing Silver Nanoparticles as Active Packaging for Food Applications—A Review. Int. J. Mol. Sci. 2019, 21, 698. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, P.; Nath, D.; Hoque, M.; Sarkar, P.; Hati, S.; Mishra, B.K. Biopolymer-Based antimicrobial coatings for aquatic food products: A review. J. Food Process. Preserv. 2022, 46, e16465. [Google Scholar] [CrossRef]

- Flórez, M.; Cazón, P.; Vázquez, M. Selected Biopolymers’ Processing and Their Applications: A Review. Polymers 2023, 15, 641. [Google Scholar] [CrossRef] [PubMed]

- Folentarska, A.; Łagiewka, J.; Krystyjan, M.; Ciesielski, W. Biodegradable Binary and Ternary Complexes from Renewable Raw Materials. Polymers 2020, 13, 2925. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Cheng, Y.; Wang, C.; Liu, H.; Bian, H.; Pan, Y.; Sun, J.; Han, W. Application of Protein-Based Films and Coatings for Food Packaging: A Review. Polymers 2019, 11, 2039. [Google Scholar] [CrossRef]

- González-Reza, R.M.; García-Betanzos, C.I.; Sánchez-Valdes, L.I.; Quintanar-Guerrero, D.; Cornejo-Villegas, M.A.; Zambrano-Zaragoza, M.L. The Functionalization of Nanostructures and Their Potential Applications in Edible Coatings. Coatings 2018, 8, 160. [Google Scholar] [CrossRef]

- Panahirad, S.; Dadpour, M.; Peighambardoust, S.H.; Soltanzadeh, M.; Gullón, B.; Alirezalu, K.; Lorenzo, J.M. Applications of carboxymethyl cellulose- and pectin-based active edible coatings in preservation of fruits and vegetables: A review. Trends Food Sci. Technol. 2021, 110, 663–673. [Google Scholar] [CrossRef]

- Mesgari, M.; Aalami, A.H.; Sahebkar, A. Antimicrobial activities of chitosan/titanium dioxide composites as a biological nanolayer for food preservation: A review. Int. J. Biol. Macromol. 2021, 176, 530–539. [Google Scholar] [CrossRef]

- Kumar, A.; Yadav, S.; Pramanik, J.; Sivamaruthi, B.S.; Jayeoye, T.J.; Prajapati, B.G.; Chaiyasut, C. Chitosan-Based Composites: Development and Perspective in Food Preservation and Biomedical Applications. Polymers 2023, 15, 3150. [Google Scholar] [CrossRef] [PubMed]

- Dutta, P.; Tripathi, S.; Mehrotra, G.; Dutta, J. Perspectives for chitosan based antimicrobial films in food applications. Food Chem. 2009, 114, 1173–1182. [Google Scholar] [CrossRef]

- Duguma, H.T. Potential applications and limitations of edible coatings for maintaining tomato quality and shelf life. Int. J. Food Sci. Technol. 2022, 57, 1353–1366. [Google Scholar] [CrossRef]

- Sapper, M.; Chiralt, A. Starch-Based Coatings for Preservation of Fruits and Vegetables. Coatings 2018, 8, 152. [Google Scholar] [CrossRef]

- Oyom, W.; Zhang, Z.; Bi, Y.; Tahergorabi, R. Application of starch-based coatings incorporated with antimicrobial agents for preservation of fruits and vegetables: A review. Prog. Org. Coat. 2022, 166, 106800. [Google Scholar] [CrossRef]

- Niu, B.; Zhan, L.; Shao, P.; Xiang, N.; Sun, P.; Chen, H.; Gao, H. Electrospinning of zein-ethyl cellulose hybrid nanofibers with improved water resistance for food preservation. Int. J. Biol. Macromol. 2019, 142, 592–599. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, H.; Shi, Z.; Liu, Y.; Liu, L.; Yu, J.; Fan, Y. Preparation of amino cellulose nanofiber via ε-poly-L-lysine grafting with enhanced mechanical, anti-microbial and food preservation performance. Ind. Crops Prod. 2023, 194, 116288. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, S.; Xia, X.; Tan, M.; Lv, Y.; Cheng, Y.; Tao, Y.; Lu, J.; Du, J.; Wang, H. High-Performance carboxymethyl cellulose-based hydrogel film for food packaging and preservation system. Int. J. Biol. Macromol. 2022, 223, 1126–1137. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M. Bacterial cellulose as a biodegradable food packaging material: A review. Food Hydrocoll. 2021, 113, 106530. [Google Scholar] [CrossRef]

- Boonsupthip, W.; Lee, C. Application of Antifreeze Protein for Food Preservation: Effect of Type III Antifreeze Protein for Preservation of Gel-Forming of Frozen and Chilled Actomyosin. J. Food Sci. 2003, 68, 1804–1809. [Google Scholar] [CrossRef]

- Na, X.; Zou, B.; Zheng, X.; Yu, X.; Zhang, L.; Xu, X.; Du, M.; Wu, C. One-Step spraying of protein-anchored chitosan oligosaccharide antimicrobial coating for food preservation. Int. J. Biol. Macromol. 2024, 275, 133330. [Google Scholar] [CrossRef] [PubMed]

- Mihalca, V.; Kerezsi, A.D.; Weber, A.; Schmucker, J.; Vodnar, D.C.; Dulf, F.V.; Socaci, S.A.; Fărcaș, A.; Mureșan, C.I.; Suharoschi, R.; et al. Protein-Based Films and Coatings for Food Industry Applications. Polymers 2020, 13, 769. [Google Scholar] [CrossRef] [PubMed]

- López-Carballo, G.; Hernández-Muñoz, P.; Gavara, R.; Ocio, M. Photoactivated chlorophyllin-based gelatin films and coatings to prevent microbial contamination of food products. Int. J. Food Microbiol. 2008, 126, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Ou, Y.; Tsay, F.; Lai, H.; Weng, M. Using gelatin-based antimicrobial edible coating to prolong shelf-life of tilapia fillets. J. Food Qual. 2002, 25, 213–222. [Google Scholar] [CrossRef]

- Armghan Khalid, M.; Niaz, B.; Saeed, F.; Afzaal, M.; Islam, F.; Hussain, M.; Al-Farga, A. Edible coatings for enhancing safety and quality attributes of fresh produce: A comprehensive review. Int. J. Food Prop. 2022, 25, 1817–1847. [Google Scholar] [CrossRef]

- Magri, A.; Petriccione, M.; Cerqueira, M.A.; Gutiérrez, T.J. Self-Assembled lipids for food applications: A review. Adv. Colloid Interface Sci. 2020, 285, 102279. [Google Scholar] [CrossRef]

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2018, 109, 1095–1107. [Google Scholar] [CrossRef]

- Rhim, J.W.; Shellhammer, T.H. Lipid-based edible films and coatings. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2004; pp. 362–383. [Google Scholar] [CrossRef]

- Ceylan, Z.; Meral, R.; Cavidoglu, I.; Karakas, C.Y.; Yilmaz, M.T. A new application on fatty acid stability of fish fillets: Coating with probiotic bacteria-loaded polymer-based characterized nanofibers. J. Food Saf. 2018, 38, e12547. [Google Scholar] [CrossRef]

- Cagri, A.; Ustunol, Z.; Ryser, E.T. Antimicrobial Edible Films and Coatings. J. Food Prot. 2004, 67, 833–848. [Google Scholar] [CrossRef]

- Hu, Z.; Zen, X.; Gong, J.; Deng, Y. Water resistance improvement of paper by superhydrophobic modification with microsized CaCO3 and fatty acid coating. Colloids Surf. A Physicochem. Eng. Asp. 2009, 351, 65–70. [Google Scholar] [CrossRef]

- Soliman, H.M.; Zahran, H.A. Synthesis of a new hydrophobic coating film from stearic acid of buffalo fat. Sci. Rep. 2022, 12, 18465. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Ye, F.; Dobretsov, S.; Dutta, J. Chitosan Nanocomposite Coatings for Food, Paints, and Water Treatment Applications. Appl. Sci. 2018, 9, 2409. [Google Scholar] [CrossRef]

- Qu, B.; Luo, Y. A review on the preparation and characterization of chitosan-clay nanocomposite films and coatings for food packaging applications. Carbohydr. Polym. Technol. Appl. 2021, 2, 100102. [Google Scholar] [CrossRef]

- Kritchenkov, A.S.; Egorov, A.R.; Volkova, O.V.; Artemjev, A.A.; Kurliuk, A.V.; Anh Le, T.; Hieu Truong, H.; Le-Nhat-Thuy, G.; Van Tran Thi, T.; Van Tuyen, N.; et al. Novel biopolymer-based nanocomposite food coatings that exhibit active and smart properties due to a single type of nanoparticles. Food Chem. 2021, 343, 128676. [Google Scholar] [CrossRef]

- Arora, A.; Padua, G.W. Review: Nanocomposites in Food Packaging. J. Food Sci. 2009, 75, R43–R49. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Mohammadi Nafchi, A.; Salehabadi, A.; Oladzad-abbasabadi, N.; Jafari, S.M. Application of bio-nanocomposite films and edible coatings for extending the shelf life of fresh fruits and vegetables. Adv. Colloid Interface Sci. 2021, 291, 102405. [Google Scholar] [CrossRef]

- Ozcalik, O.; Tihminlioglu, F. Barrier properties of corn zein nanocomposite coated polypropylene films for food packaging applications. J. Food Eng. 2013, 114, 505–513. [Google Scholar] [CrossRef]

- Garcia, C.V.; Shin, G.H.; Kim, J.T. Metal oxide-based nanocomposites in food packaging: Applications, migration, and regulations. Trends Food Sci. Technol. 2018, 82, 21–31. [Google Scholar] [CrossRef]

- Huang, J.; Li, X.; Zhou, W. Safety assessment of nanocomposite for food packaging application. Trends Food Sci. Technol. 2015, 45, 187–199. [Google Scholar] [CrossRef]

- Hernández-Muñoz, P.; Almenar, E.; Valle, V.D.; Velez, D.; Gavara, R. Effect of chitosan coating combined with postharvest calcium treatment on strawberry (Fragaria × ananassa) quality during refrigerated storage. Food Chem. 2008, 110, 428–435. [Google Scholar] [CrossRef]

- Ghaouth, A.E.; Arul, J.; Ponnampalam, R.; Boulet, M. Chitosan Coating Effect on Storability and Quality of Fresh Strawberries. J. Food Sci. 1991, 56, 1618–1620. [Google Scholar] [CrossRef]

- Vu, K.; Hollingsworth, R.; Leroux, E.; Salmieri, S.; Lacroix, M. Development of edible bioactive coating based on modified chitosan for increasing the shelf life of strawberries. Food Res. Int. 2010, 44, 198–203. [Google Scholar] [CrossRef]

- Randazzo, W.; Fabra, M.J.; Falcó, I.; López-Rubio, A.; Sánchez, G. Polymers and Biopolymers with Antiviral Activity: Potential Applications for Improving Food Safety. Compr. Rev. Food Sci. Food Saf. 2018, 17, 754–768. [Google Scholar] [CrossRef] [PubMed]

- Taherimehr, M.; YousefniaPasha, H.; Tabatabaeekoloor, R.; Pesaranhajiabbas, E. Trends and challenges of biopolymer-based nanocomposites in food packaging. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5321–5344. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Roy, S.; Rhim, W. Copper-Based nanoparticles for biopolymer-based functional films in food packaging applications. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1933–1952. [Google Scholar] [CrossRef]

- Sobhan, A.; Muthukumarappan, K.; Wei, L. Biosensors and biopolymer-based nanocomposites for smart food packaging: Challenges and opportunities. Food Packag. Shelf Life 2021, 30, 100745. [Google Scholar] [CrossRef]

- Pinto, L.; Bonifacio, M.A.; De Giglio, E.; Santovito, E.; Cometa, S.; Bevilacqua, A.; Baruzzi, F. Biopolymer hybrid materials: Development, characterization, and food packaging applications. Food Packag. Shelf Life 2021, 28, 100676. [Google Scholar] [CrossRef]

- Baranwal, J.; Barse, B.; Fais, A.; Delogu, G.L.; Kumar, A. Biopolymer: A Sustainable Material for Food and Medical Applications. Polymers 2021, 14, 983. [Google Scholar] [CrossRef]

- Moeini, A.; Germann, N.; Malinconico, M.; Santagata, G. Formulation of secondary compounds as additives of biopolymer-based food packaging: A review. Trends Food Sci. Technol. 2021, 114, 342–354. [Google Scholar] [CrossRef]

- Bhaskar, R.; Zo, S.M.; Narayanan, K.B.; Purohit, S.D.; Gupta, M.K.; Han, S.S. Recent development of protein-based biopolymers in food packaging applications: A review. Polym. Test. 2023, 124, 108097. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Packag. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Klein, M.; Poverenov, E. Natural biopolymer-based hydrogels for use in food and agriculture. J. Sci. Food Agric. 2020, 100, 2337–2347. [Google Scholar] [CrossRef] [PubMed]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-Based Sustainable Food Packaging Materials: Challenges, Solutions, and Applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Sivakanthan, S.; Rajendran, S.; Gamage, A.; Madhujith, T.; Mani, S. Antioxidant and antimicrobial applications of biopolymers: A review. Food Res. Int. 2020, 136, 109327. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Li, C. Delivery of Probiotics with Cellulose-Based Films and Their Food Applications. Polymers 2023, 16, 794. [Google Scholar] [CrossRef]

- Makam, R.M.M.; Wan Omar, W.N.N.; bin Jihat, D.A.; Nor, N.U.M.; Shamjuddin, A.; Amin, N.A.S. The potential of carboxylmethyl cellulose from empty fruit bunch as versatile material in food coating: A review. Carbohydr. Polym. 2024, 338, 122194. [Google Scholar] [CrossRef]

- Nizardo, N.M.; Sugandi, N.A.D.; Handayani, A.S. Poly(vinyl alcohol)/Carboxymethyl Cellulose/Cellulose nanofibrils nanocomposite as coating for food packaging paper. Polym.-Plast. Technol. Mater. 2023, 63, 447–458. [Google Scholar] [CrossRef]

- Singh, A.; Singh, J.; Singh, N.; Kaur, N. Development and characterization of gelatin/carboxymethyl cellulose based polymeric film with inclusion of ionic liquid to enhance the shelf life of food. Food Packag. Shelf Life 2024, 42, 101251. [Google Scholar] [CrossRef]

- Bangar, S.P.; Whiteside, W.S.; Suri, S.; Barua, S.; Phimolsiripol, Y. Native and modified biodegradable starch-based packaging for shelf-life extension and safety of fruits/vegetables. Int. J. Food Sci. Technol. 2023, 58, 862–870. [Google Scholar] [CrossRef]

- Oliveira Filho, J.G.D.; Albiero, B.R.; Calisto, Í.H.; Bertolo, M.R.V.; Oldoni, F.C.A.; Egea, M.B.; Bogusz Junior, S.; De Azeredo, H.M.C.; Ferreira, M.D. Bio-Nanocomposite edible coatings based on arrowroot starch/cellulose nanocrystals/carnauba wax nanoemulsion containing essential oils to preserve quality and improve shelf life of strawberry. Int. J. Biol. Macromol. 2022, 219, 812–823. [Google Scholar] [CrossRef] [PubMed]

- Garcia, L.C.; Pereira, L.M.; de Luca Sarantópoulos, C.I.G.; Hubinger, M.D. Selection of an Edible Starch Coating for Minimally Processed Strawberry. Food Bioprocess Technol. 2010, 3, 834–842. [Google Scholar] [CrossRef]

- Versino, F.; Lopez, O.V.; Garcia, M.A.; Zaritzky, N.E. Starch-Based films and food coatings: An overview. Starch-Stärke 2016, 68, 1026–1037. [Google Scholar] [CrossRef]

- Luciano, C.G.; Caicedo Chacon, W.D.; Valencia, G.A. Starch-Based Coatings for Food Preservation: A Review. Starch-Stärke 2022, 74, 2100279. [Google Scholar] [CrossRef]

- Călinoiu, L.; Ştefănescu, B.E.; Pop, I.D.; Muntean, L.; Vodnar, D.C. Chitosan Coating Applications in Probiotic Microencapsulation. Coatings 2019, 9, 194. [Google Scholar] [CrossRef]

- Hajji, S.; Younes, I.; Affes, S.; Boufi, S.; Nasri, M. Optimization of the formulation of chitosan edible coatings supplemented with carotenoproteins and their use for extending strawberries postharvest life. Food Hydrocoll. 2018, 83, 375–392. [Google Scholar] [CrossRef]

- Zhang, X.; Ismail, B.B.; Cheng, H.; Jin, T.Z.; Qian, M.; Arabi, S.A.; Liu, D.; Guo, M. Emerging chitosan-essential oil films and coatings for food preservation—A review of advances and applications. Carbohydr. Polym. 2021, 273, 118616. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Dong, Q.; Xu, C.; Deng, S.; Kang, Y.; Fan, M.; Li, L. Application of functionalized chitosan in food: A review. Int. J. Biol. Macromol. 2023, 235, 123716. [Google Scholar] [CrossRef]

- Ashfaq, A.; Khursheed, N.; Fatima, S.; Anjum, Z.; Younis, K. Application of nanotechnology in food packaging: Pros and Cons. J. Agric. Food Res. 2022, 7, 100270. [Google Scholar] [CrossRef]

- Chandrababu, V.; Parameswaranpillai, J.; Gopi, J.A.; Pathak, C.; Midhun Dominic, C.; Feng, N.L.; Krishnasamy, S.; Muthukumar, C.; Hameed, N.; Ganguly, S. Progress in food packaging applications of biopolymer-nanometal composites—A comprehensive review. Biomater. Adv. 2024, 162, 213921. [Google Scholar] [CrossRef]

- Ștefănescu, B.E.; Socaciu, C.; Vodnar, D.C. Recent Progress in Functional Edible Food Packaging Based on Gelatin and Chitosan. Coatings 2022, 12, 1815. [Google Scholar] [CrossRef]

- Toniciolli Rigueto, C.V.; Rosseto, M.; Alessandretti, I.; De Oliveira, R.; Wohlmuth, D.A.R.; Ferreira Menezes, J.; Loss, R.A.; Dettmer, A.; Pizzutti, I.R. Gelatin films from wastes: A review of production, characterization, and application trends in food preservation and agriculture. Food Res. Int. 2022, 162, 112114. [Google Scholar] [CrossRef] [PubMed]

- Gallego, M.; Arnal, M.; Talens, P.; Toldrá, F.; Mora, L. Effect of Gelatin Coating Enriched with Antioxidant Tomato By-Products on the Quality of Pork Meat. Polymers 2020, 12, 1032. [Google Scholar] [CrossRef] [PubMed]

- Ramos, M.; Valdés, A.; Beltrán, A.; Garrigós, M.C. Gelatin-Based Films and Coatings for Food Packaging Applications. Coatings 2016, 6, 41. [Google Scholar] [CrossRef]

- Abdelhedi, O.; Salem, A.; Nasri, R.; Nasri, M.; Jridi, M. Food applications of bioactive marine gelatin films. Curr. Opin. Food Sci. 2022, 43, 206–215. [Google Scholar] [CrossRef]

- Luo, Q.; Hossen, M.A.; Zeng, Y.; Dai, J.; Li, S.; Qin, W.; Liu, Y. Gelatin-Based composite films and their application in food packaging: A review. J. Food Eng. 2021, 313, 110762. [Google Scholar] [CrossRef]

- Khwaldia, K. Water vapor barrier and mechanical properties of paper-sodium caseinate and paper-sodium caseinate-paraffin wax films. J. Food Biochem. 2010, 34, 998–1013. [Google Scholar] [CrossRef]

- Prudnikov, E.; Polishchuk, I.; Sand, A.; Hamad, H.A.; Massad-Ivanir, N.; Segal, E.; Pokroy, B. Self-Assembled fatty acid crystalline coatings display superhydrophobic antimicrobial properties. Mater. Today Bio 2023, 18, 100516. [Google Scholar] [CrossRef]

- De Freitas, C.A.S.; De Sousa, P.H.M.; Soares, D.J.; Da Silva, J.Y.G.; Benjamin, S.R.; Guedes, M.I.F. Carnauba wax uses in food—A review. Food Chem. 2019, 291, 38–48. [Google Scholar] [CrossRef]

- Díaz-Montes, E.; Castro-Muñoz, R. Edible Films and Coatings as Food-Quality Preservers: An Overview. Foods 2021, 10, 249. [Google Scholar] [CrossRef]

- Yamanaka, Y.; Kobayashi, I.; Neves, M.A.; Ichikawa, S.; Uemura, K.; Nakajima, M. Formulation of W/O/W emulsions loaded with short-chain fatty acid and their stability improvement by layer-by-layer deposition using dietary fibers. LWT-Food Sci. Technol. 2017, 76, 344–350. [Google Scholar] [CrossRef]

- Jung, S.; Cui, Y.; Barnes, M.; Satam, C.; Zhang, S.; Chowdhury, R.A.; Adumbumkulath, A.; Sahin, O.; Miller, C.; Sajadi, S.M.; et al. Multifunctional Bio-Nanocomposite Coatings for Perishable Fruits. Adv. Mater. 2020, 32, 1908291. [Google Scholar] [CrossRef] [PubMed]

- Acharya, B.; Korber, D.R. Antimicrobial Biodegradable Food Packaging Based on Chitosan and Metal/Metal-Oxide Bio-Nanocomposites: A Review. Polymers 2020, 13, 2790. [Google Scholar] [CrossRef]

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Banat, F.; Sivamani, S.; Sivakumar, N.; Hosseini-Bandegharaei, A.; Show, P.L. Biopolymers and composites: Properties, characterization and their applications in food, medical and pharmaceutical industries. J. Environ. Chem. Eng. 2021, 9, 105322. [Google Scholar] [CrossRef]

- Carvalho, A.P.A.D.; Conte-Junior, C.A. Food-Derived biopolymer kefiran composites, nanocomposites and nanofibers: Emerging alternatives to food packaging and potentials in nanomedicine. Trends Food Sci. Technol. 2021, 116, 370–386. [Google Scholar] [CrossRef]

- Khezerlou, A.; Tavassoli, M.; Alizadeh Sani, M.; Mohammadi, K.; Ehsani, A.; McClements, D.J. Application of Nanotechnology to Improve the Performance of Biodegradable Biopolymer-Based Packaging Materials. Polymers 2020, 13, 4399. [Google Scholar] [CrossRef]

- Mallakpour, S.; Sirous, F.; Hussain, C.M. A journey to the world of fascinating ZnO nanocomposites made of chitosan, starch, cellulose, and other biopolymers: Progress in recent achievements in eco-friendly food packaging, biomedical, and water remediation technologies. Int. J. Biol. Macromol. 2021, 170, 701–716. [Google Scholar] [CrossRef]

- Min, T.; Zhou, L.; Sun, X.; Du, H.; Zhu, Z.; Wen, Y. Electrospun functional polymeric nanofibers for active food packaging: A review. Food Chem. 2022, 391, 133239. [Google Scholar] [CrossRef]

- Wang, L.; Rhim, J.; Hong, S. Preparation of poly(lactide)/poly(butylene adipate-co-terephthalate) blend films using a solvent casting method and their food packaging application. LWT-Food Sci. Technol. 2016, 68, 454–461. [Google Scholar] [CrossRef]

- Lee, J.H.; Jeong, D.; Kanmani, P. Study on physical and mechanical properties of the biopolymer/silver based active nanocomposite films with antimicrobial activity. Carbohydr. Polym. 2019, 224, 115159. [Google Scholar] [CrossRef]

- Barra, A.; Santos, J.D.; Silva, M.R.; Nunes, C.; Gonçalves, I.; Yildirim, S.; Ferreira, P.; Marques, P.A. Graphene Derivatives in Biopolymer-Based Composites for Food Packaging Applications. Nanomaterials 2020, 10, 2077. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Lin, Z.; Goddard, J.M. Performance of photo-curable metal-chelating active packaging coating in complex food matrices. Food Chem. 2019, 286, 154–159. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Liu, N.; Chen, Y.; Zhang, W.; Qu, R.; Zhang, Q.; Feng, L.; Wei, Y. A versatile CeO2/Co3O4 coated mesh for food wastewater treatment: Simultaneous oil removal and UV catalysis of food additives. Water Res. 2018, 137, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Suhag, R.; Kumar, N.; Petkoska, A.T.; Upadhyay, A. Film formation and deposition methods of edible coating on food products: A review. Food Res. Int. 2020, 136, 109582. [Google Scholar] [CrossRef]

- Dos Passos Braga, S.; Magnani, M.; Madruga, M.S.; De Souza Galvão, M.; De Medeiros, L.L.; Batista, A.U.D.; Dias, R.T.A.; Fernandes, L.R.; De Medeiros, E.S.; De Souza, E.L. Characterization of edible coatings formulated with chitosan and Mentha essential oils and their use to preserve papaya (Carica papaya L.). Innov. Food Sci. Emerg. Technol. 2020, 65, 102472. [Google Scholar] [CrossRef]

- Emragi, E.; Kalita, D.; Jayanty, S.S. Effect of edible coating on physical and chemical properties of potato tubers under different storage conditions. LWT 2021, 153, 112580. [Google Scholar] [CrossRef]

- Antonino, C.; Difonzo, G.; Faccia, M.; Caponio, F. Effect of edible coatings and films enriched with plant extracts and essential oils on the preservation of animal-derived foods. J. Food Sci. 2024, 89, 748–772. [Google Scholar] [CrossRef]

- Pelaes Vital, A.C.; Guerrero, A.; Guarnido, P.; Cordeiro Severino, I.; Olleta, J.L.; Blasco, M.; Maggi, F.; Campo, M.D. Effect of Active-Edible Coating and Essential Oils on Lamb Patties Oxidation during Display. Foods 2021, 10, 263. [Google Scholar] [CrossRef]

- Andriani, V.; Abyor Handayani, N. Recent technology of edible coating production: A review. Mater. Today Proc. 2023, 87, 200–206. [Google Scholar] [CrossRef]

- Carneiro-da-Cunha, M.G.; Cerqueira, M.A.; Souza, B.W.; Souza, M.P.; Teixeira, J.A.; Vicente, A.A. Physical properties of edible coatings and films made with a polysaccharide from Anacardium occidentale L. J. Food Eng. 2009, 95, 379–385. [Google Scholar] [CrossRef]

- Pacheco Pineda, I.Y.; Méndez-Lagunas, L.L.; Balbuena Ortega, A.; Guerrero Martínez, L.; Pérez-Orozco, J.P.; Del Río, J.A.; Nair, P.K. Optical and thermal properties of edible coatings for application in solar drying. Sci. Rep. 2021, 11, 10051. [Google Scholar] [CrossRef]

- Donjio, R.T.; Nguemezi, J.A.; Anoumaa, M.; Phounzong, E.T.; Kenfack, J.O.; Fonkou, T. Using Response Surface Methodology to Optimize Edible Coating Formulations to Delay Ripening and Preserve Postharvest Quality of Tomatoes. J. Food Qual. 2023, 2023, 1019310. [Google Scholar] [CrossRef]

- Nunes, C.; Silva, M.; Farinha, D.; Sales, H.; Pontes, R.; Nunes, J. Edible Coatings and Future Trends in Active Food Packaging–Fruits’ and Traditional Sausages’ Shelf Life Increasing. Foods 2023, 12, 3308. [Google Scholar] [CrossRef] [PubMed]

- Janowicz, M.; Galus, S.; Ciurzyńska, A.; Nowacka, M. The Potential of Edible Films, Sheets, and Coatings Based on Fruits and Vegetables in the Context of Sustainable Food Packaging Development. Polymers 2023, 15, 4231. [Google Scholar] [CrossRef]

- Falcó, I.; Flores-Meraz, P.L.; Randazzo, W.; Sánchez, G.; López-Rubio, A.; Fabra, M.J. Antiviral activity of alginate-oleic acid-based coatings incorporating green tea extract on strawberries and raspberries. Food Hydrocoll. 2019, 87, 611–618. [Google Scholar] [CrossRef]

- Yashaswini, M.; Iyer, P.R. Chitosan Based Films Incorporated with Turmeric/Clove/Ginger Essential Oil for Food Packaging. J. Nanomed. Nanotechnol. 2019, 10, 537. [Google Scholar] [CrossRef]

- Sergio Contreras Saavedra, Rosa Isela Ventura-Aguilar, Silvia Bautista-Baños and Laura Leticia BarreraNecha, Biodegradable chitosan coating for improving quality and controlling Alternaria alternata growth in figs. World J. Adv. Res. Rev. 2020, 7, 115–125. [CrossRef]

- Nair, M.S.; Tomar, M.; Punia, S.; Kukula-Koch, W.; Kumar, M. Enhancing the functionality of chitosan- and alginate-based active edible coatings/films for the preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2020, 164, 304–320. [Google Scholar] [CrossRef]

- Arnon-Rips, H.; Porat, R.; Poverenov, E. Enhancement of agricultural produce quality and storability using citral-based edible coatings; the valuable effect of nano-emulsification in a solid-state delivery on fresh-cut melons model. Food Chem. 2019, 277, 205–212. [Google Scholar] [CrossRef]

- Beristain-Bauza, S.D.C.; Mani-López, E.; Palou, E.; López-Malo, A. Antimicrobial activity of whey protein films supplemented with Lactobacillus sakei cell-free supernatant on fresh beef. Food Microbiol. 2017, 62, 207–211. [Google Scholar] [CrossRef]

- Hao, R.; Liu, Y.; Sun, L.; Xia, L.; Jia, H.; Li, Q.; Pan, J. Sodium alginate coating with plant extract affected microbial communities, biogenic amine formation and quality properties of abalone (Haliotis discus hannai Ino) during chill storage. LWT-Food Sci. Technol. 2017, 81, 1–9. [Google Scholar] [CrossRef]

- Chawla, R.; Sivakumar, S.; Kaur, H. Antimicrobial edible films in food packaging: Current scenario and recent nanotechnological advancements- a review. Carbohydr. Polym. Technol. Appl. 2021, 2, 100024. [Google Scholar] [CrossRef]

- Göksen, G.; Fabra, M.J.; Ekiz, H.I.; López-Rubio, A. Phytochemical-Loaded electrospun nanofibers as novel active edible films: Characterization and antibacterial efficiency in cheese slices. Food Control 2020, 112, 107133. [Google Scholar] [CrossRef]

- de Vargas, V.H.; Marczak, L.D.F.; Flôres, S.H.; Mercali, G.D. Advanced Technologies Applied to Enhance Properties and Structure of Films and Coatings: A Review. Food Bioprocess Technol. 2022, 15, 1224–1247. [Google Scholar] [CrossRef]

- Khan, M.R.; Volpe, S.; Valentino, M.; Miele, N.A.; Cavella, S.; Torrieri, E. Active Casein Coatings and Films for Perishable Foods: Structural Properties and Shelf-Life Extension. Coatings 2021, 11, 899. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Oleyaei, S.A.; Almasi, H. Nanostructured Materials Utilized in Biopolymer-Based Plastics for Food Packaging Applications. Crit. Rev. Food Sci. Nutr. 2015, 55, 1699–1723. [Google Scholar] [CrossRef]

- Hoque, M.; Gupta, S.; Santhosh, R.; Syed, I.; Sarkar, P. Biopolymer-Based edible films and coatings for food applications. In Food, Medical, and Environmental Applications of Polysaccharides; Elsevier: Amsterdam, The Netherlands, 2020; pp. 81–107. [Google Scholar] [CrossRef]

- Fabra, M.J.; Busolo, M.A.; Lopez-Rubio, A.; Lagaron, J.M. Nanostructured biolayers in food packaging. Trends Food Sci. Technol. 2013, 31, 79–87. [Google Scholar] [CrossRef]

| Scheme | Edible Coating Material | Technique | Observations and Shelf-Life Effectiveness | Food Product | Ref. |

|---|---|---|---|---|---|

| 1 | Alginate-oleic acid | Spreading | Antiviral activity | Strawberries and raspberries | [151] |

| 2 | Essential oil of turmeric/ginger/clove | Heating and Drying | Coated tomatoes and Amla remained fresh for a longer time as compared to non-coated samples | Tomatoes and Amla | [152] |

| 3 | Chitosan | Dipping | The color change was delayed, and Alternaria alternata growth was inhibited | Figs | [153] |

| 4 | Alginate | Blending | Inhibition of the growth of the fungal pathogen Colletotrichumgloeosporioides at 10 °C storage | Capsicum | [154] |

| 5 | Chitosan/Carboxy methyl cellulose | Nano-emulsified coatings | Antibacterial protection (~5 log reduction) and extended storability (13 days) | Fresh-cut melons | [155] |

| 6 | Whey protein | Spreading | Inhibition action against E. Coli/L. Monocytogenes | Beef | [156] |

| 7 | Alginate | Spreading | Improved microbial activity | Abalone | [157] |

| 8 | Corn starch | Spreading | Enhanced activity towards Bacillus cereus and Aspergillus Niger | Sweet meat/Doda Burfi | [158] |

| 9 | Zein nanofibers | Coating | Outstanding antibacterial activity against S. Aureus and L/Mmonocytogenes, over ~28 days | Cheese | [159] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanaraj, R.; Suresh Kumar, S.M.; Mayakrishnan, G.; Rathinam, B.; Kim, S.C. A Current Trend in Efficient Biopolymer Coatings for Edible Fruits to Enhance Shelf Life. Polymers 2024, 16, 2639. https://doi.org/10.3390/polym16182639

Vanaraj R, Suresh Kumar SM, Mayakrishnan G, Rathinam B, Kim SC. A Current Trend in Efficient Biopolymer Coatings for Edible Fruits to Enhance Shelf Life. Polymers. 2024; 16(18):2639. https://doi.org/10.3390/polym16182639

Chicago/Turabian StyleVanaraj, Ramkumar, Subburayan Manickavasagam Suresh Kumar, Gopiraman Mayakrishnan, Balamurugan Rathinam, and Seong Cheol Kim. 2024. "A Current Trend in Efficient Biopolymer Coatings for Edible Fruits to Enhance Shelf Life" Polymers 16, no. 18: 2639. https://doi.org/10.3390/polym16182639

APA StyleVanaraj, R., Suresh Kumar, S. M., Mayakrishnan, G., Rathinam, B., & Kim, S. C. (2024). A Current Trend in Efficient Biopolymer Coatings for Edible Fruits to Enhance Shelf Life. Polymers, 16(18), 2639. https://doi.org/10.3390/polym16182639