Investigating Additive Manufacturing Possibilities for an Unmanned Aerial Vehicle with Polymeric Materials

Abstract

1. Introduction

2. Materials and Research Methodology

2.1. The Raw Material Market Analysis

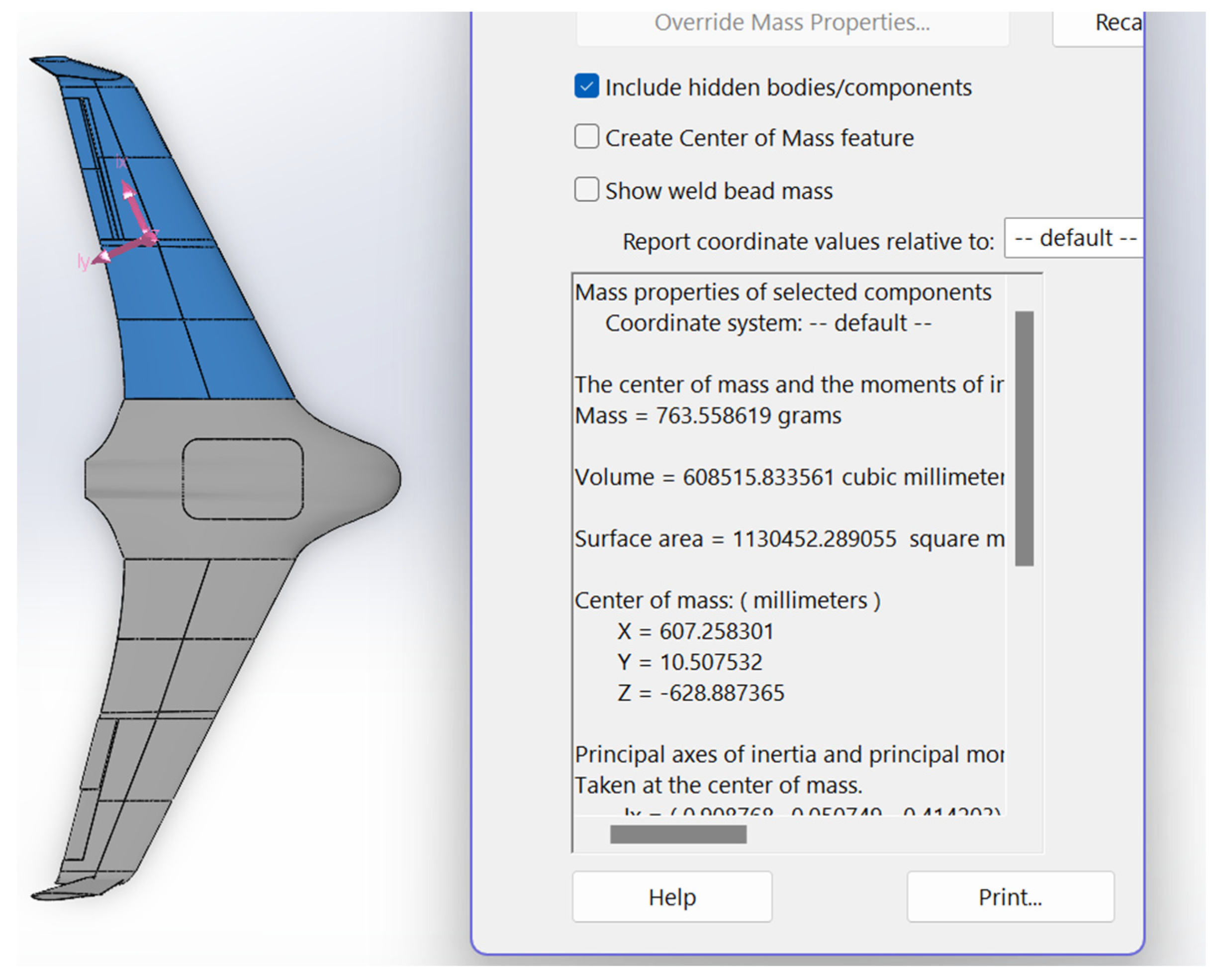

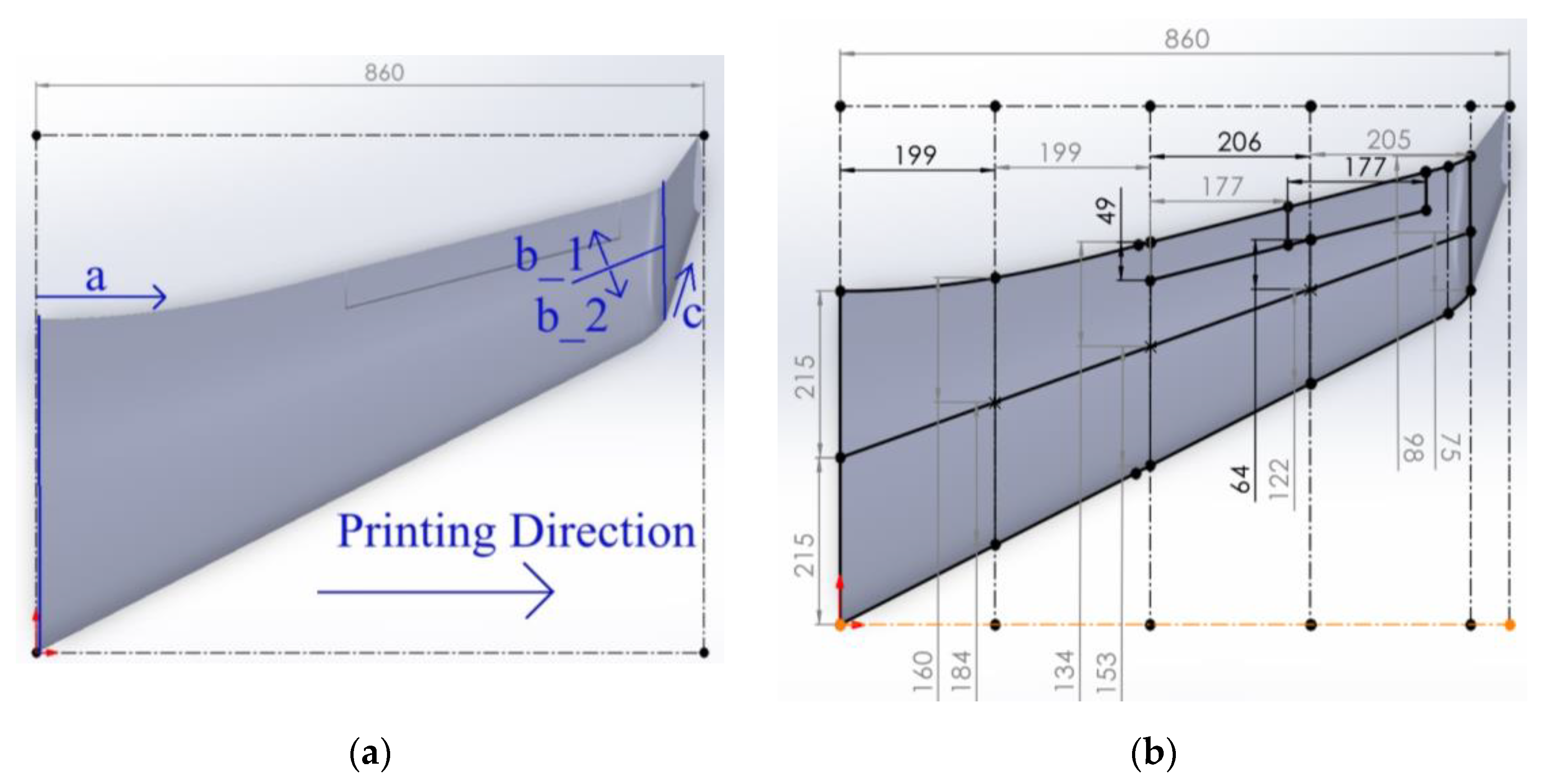

2.2. The Fabrication Object

- The valid payload should fit the 1 kg to 2 kg range to extend its application abilities.

- The proposed modification must empty as much space inside the UAV prototype as possible to substantiate the EPO replacement with a polymeric shell.

- The aerial vehicle should have minimal moving parts to reduce the number of servo mechanisms and increase the design reliability.

2.3. The Analysis Concept

2.3.1. The Theoretical Analysis of the Wing Bending Resistance

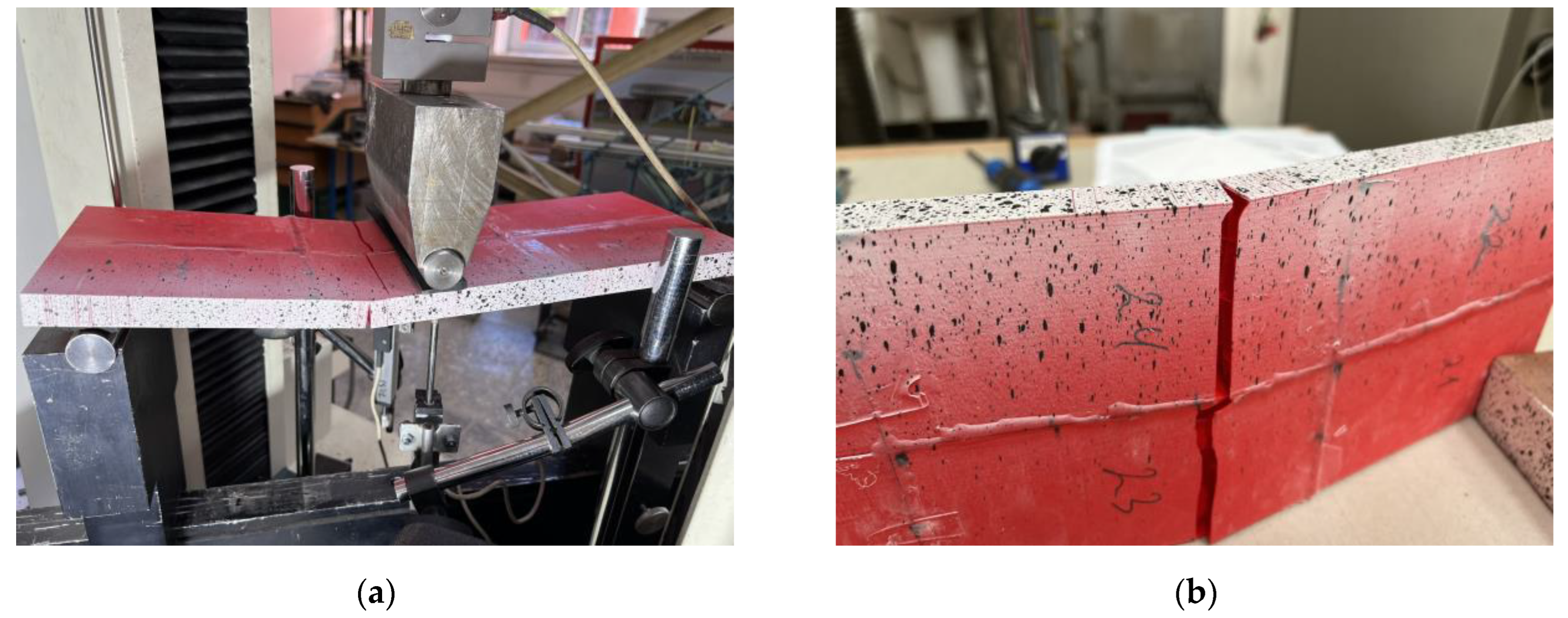

2.3.2. The Simplified Mechanical Test

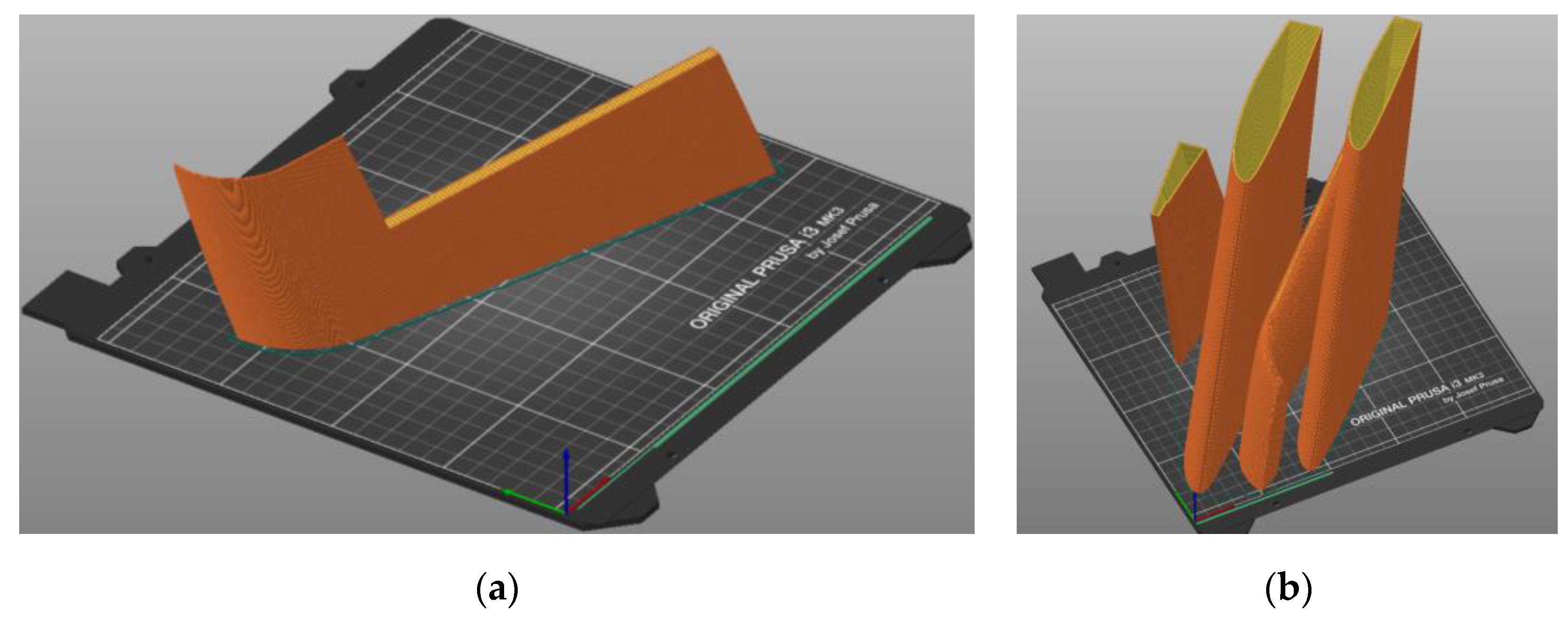

2.3.3. Prototyping the Exact Geometry Wing

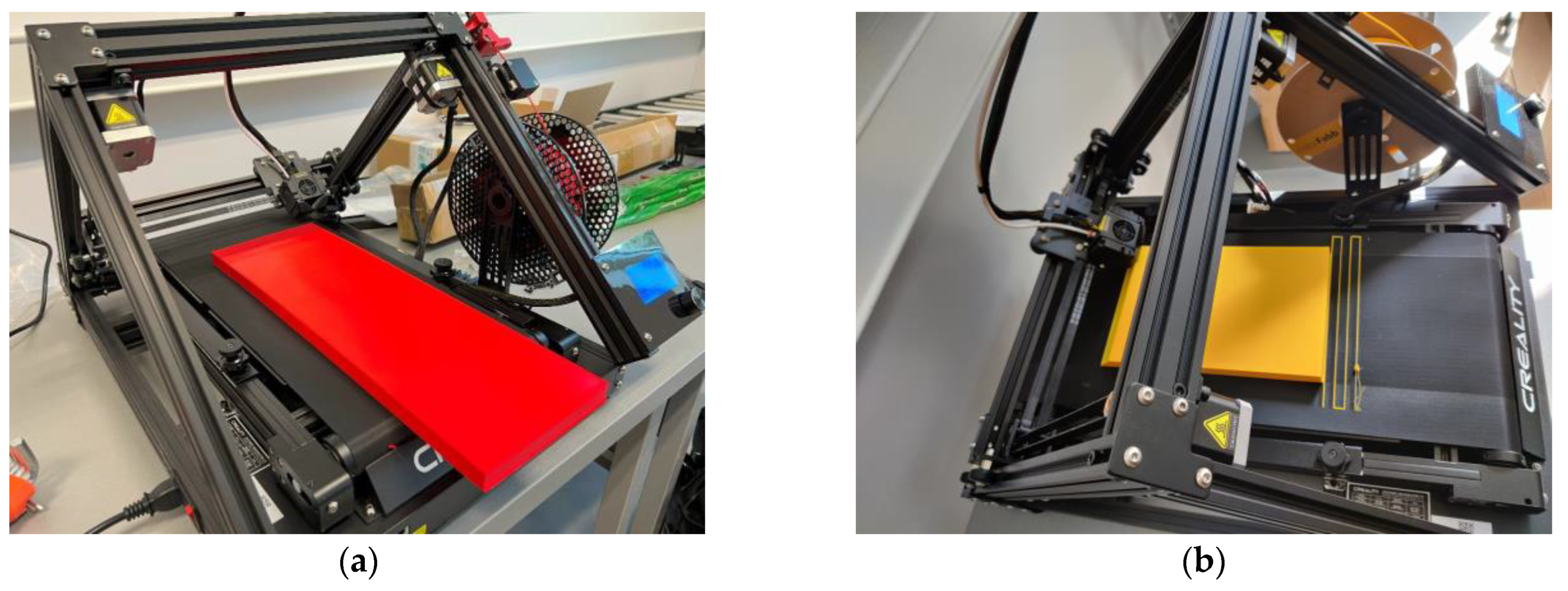

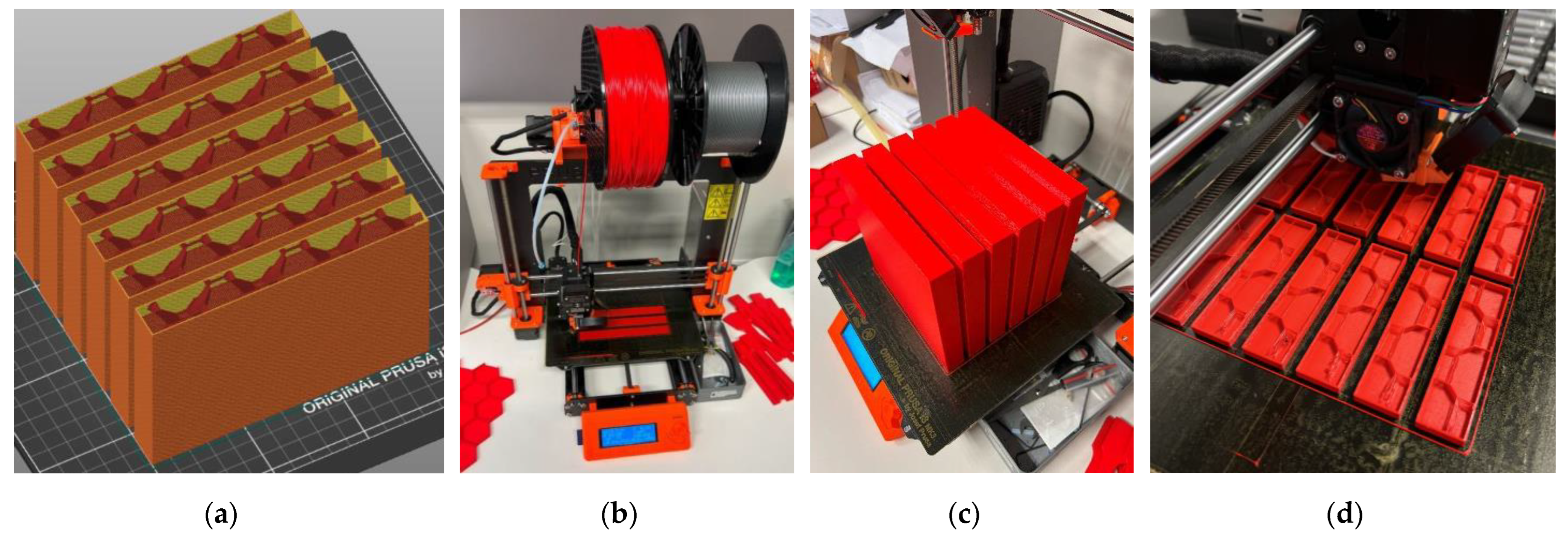

3. Prototyping Results and Discussion

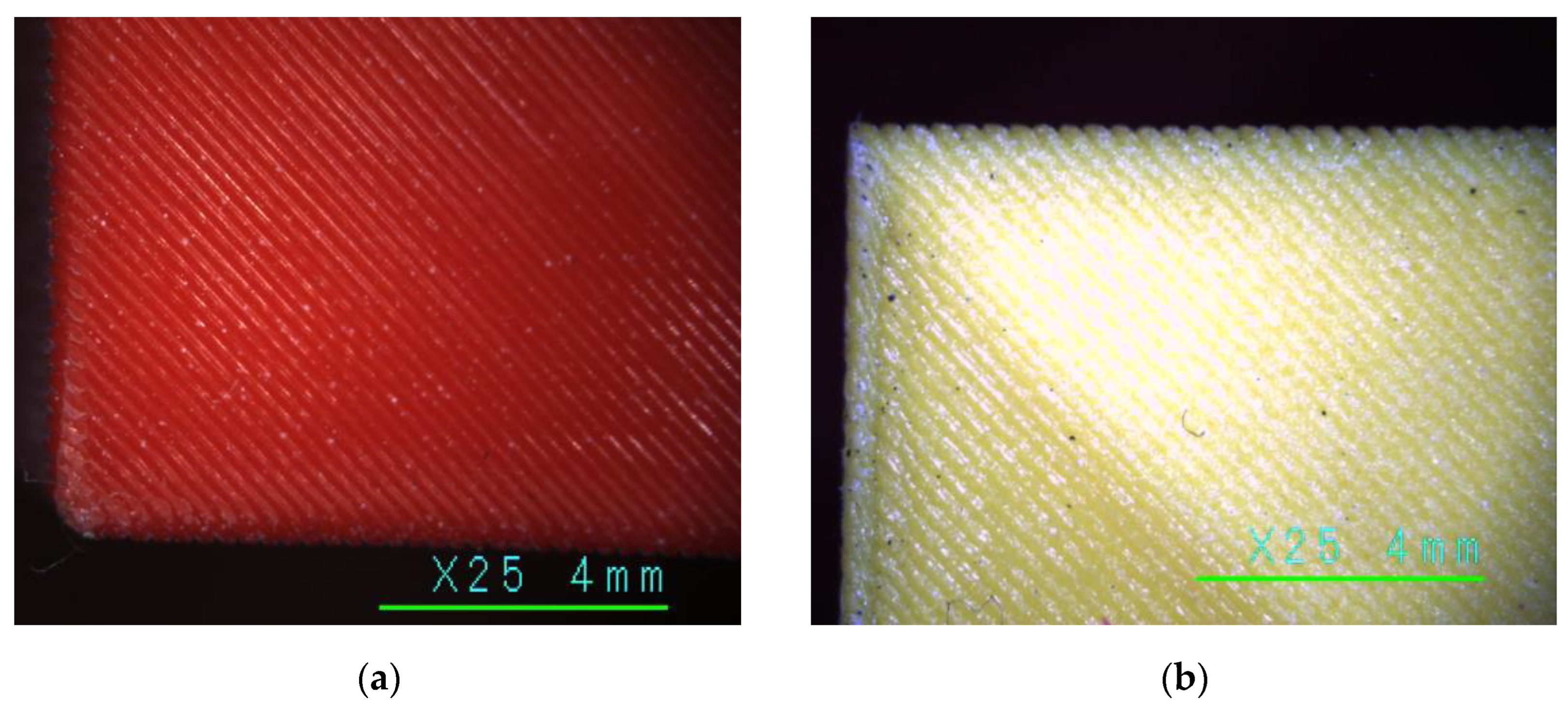

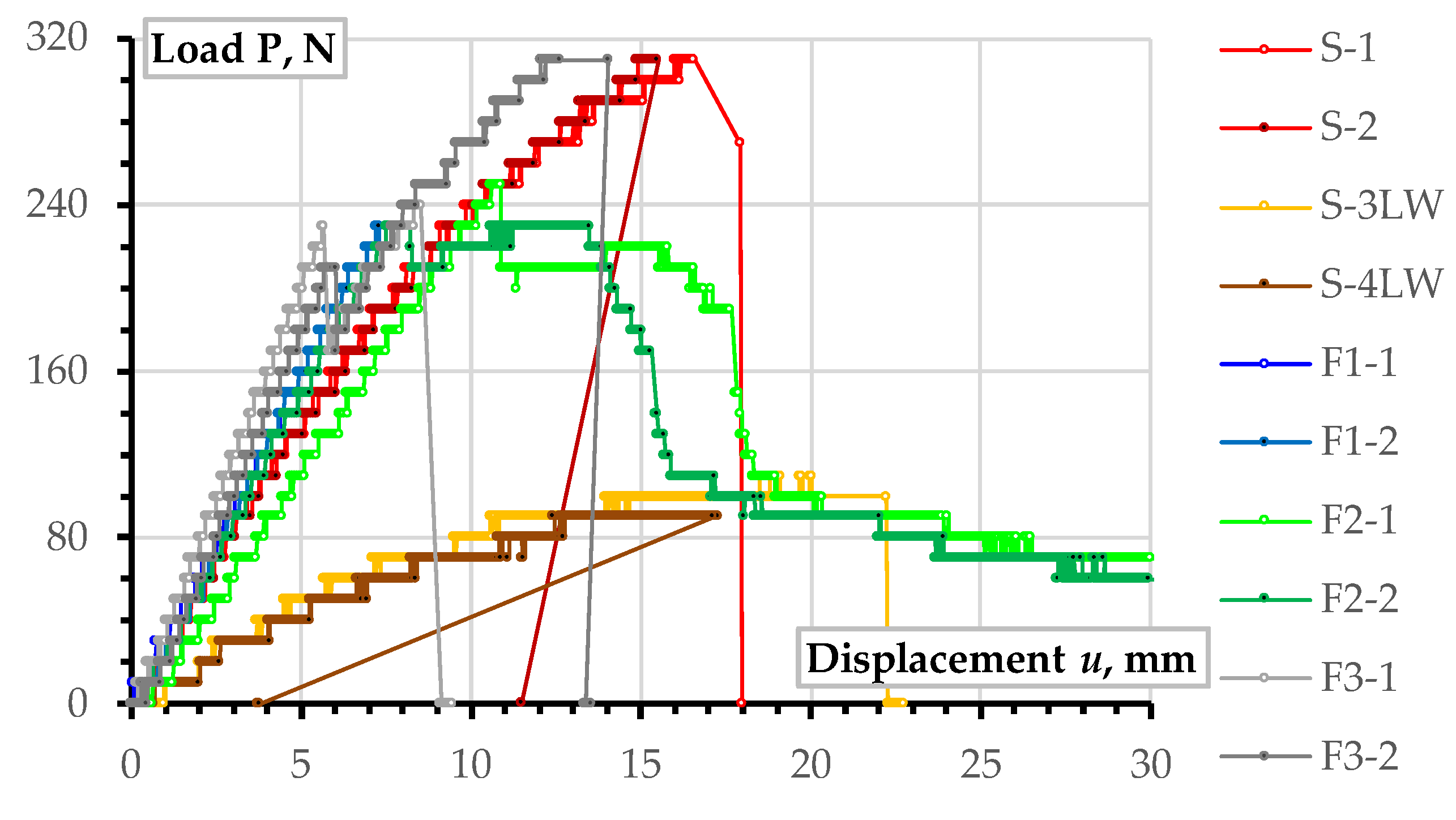

3.1. The Mechanical Performance of Printed PLA Elements

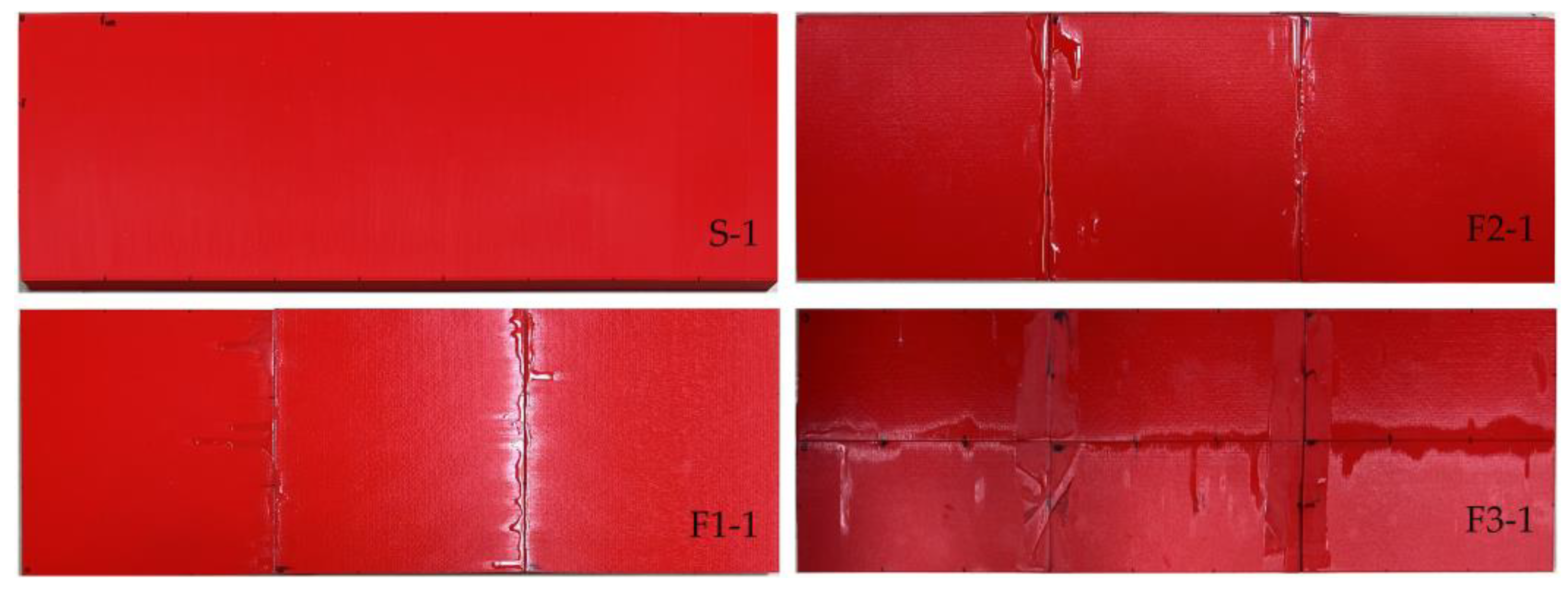

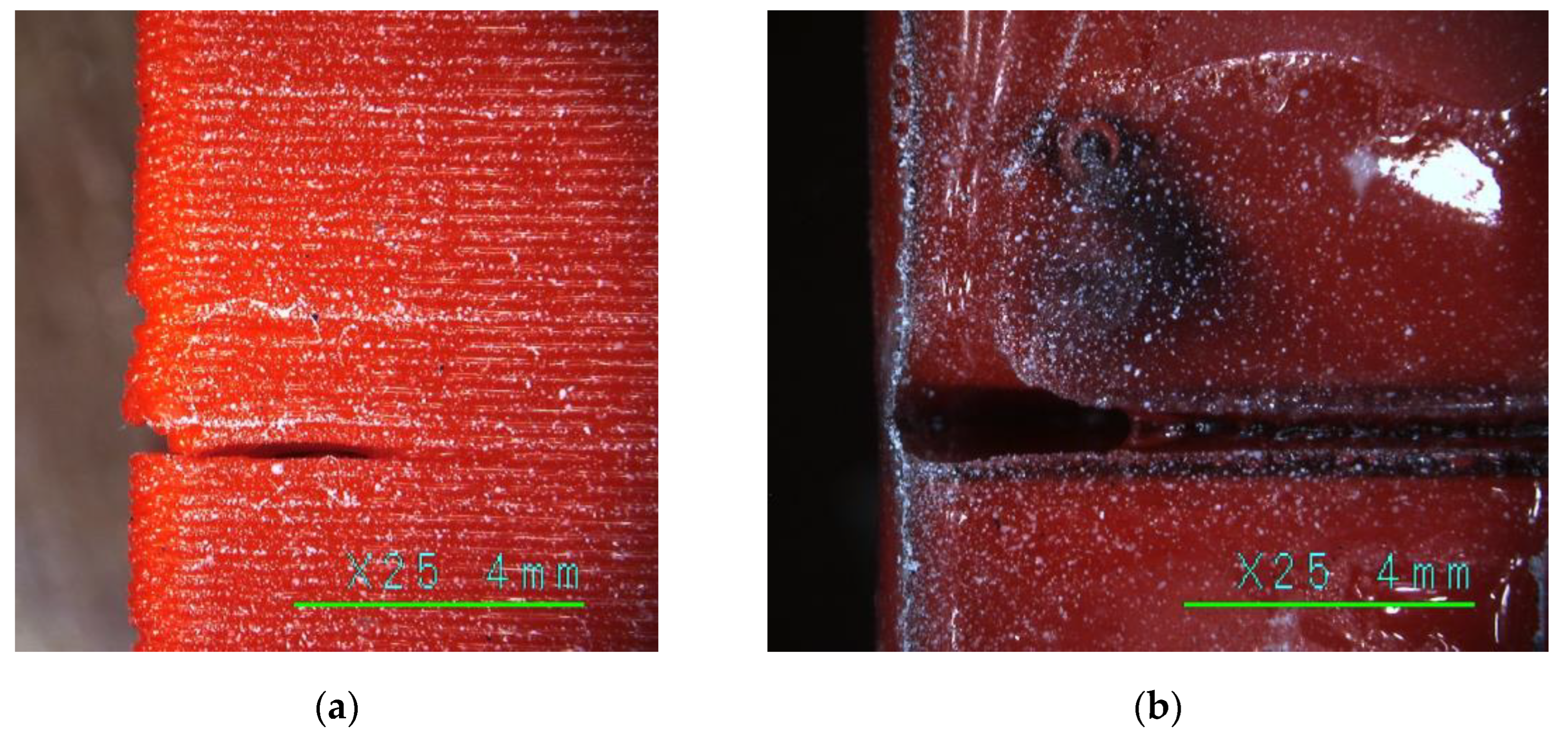

3.2. Fracture Mechanisms of the Bending Elements

3.3. Fabrication Example: The Exact Geometry Wing

3.4. Further Research

- Geometry optimization, including reduction of printing volume (shell thickness), object fragmentation, and parallel fabrication. These means will reduce the fabrication duration and UAV weight;

- The mass fabrication of optimized geometry shapes must combine different technologies (e.g., continuous filament reinforcement and injection molding), ensuring fabrication quality and speed;

- Continuous control is essential to prevent fabrication defects (Figure 17a) and terminate manufacturing errors (Figure 19a). This necessity requires the development of online visual monitoring systems, including artificial intelligence (AI) algorithms, which are becoming increasingly crucial in additive manufacturing.

- The mechanical resistance of the joints must ensure the target load-bearing capacity;

- The hardening time must ensure the ability to tailor the component position. Alternatively, a scaffold may speed up the assembly process and compensate for the hardening speed;

- The adhesive should fill empty spaces and voids but not flow out of the gluing space. These conditions determine the adhesive flowability optimization problem.

4. Conclusions

- Despite differences in mechanical performance, all bending samples demonstrated remarkable resistance to stress, substantially exceeding the theoretical limit of 0.369 MPa. This result provides reassurance about the reliability of the proposed EPO replacement concept with a 3D printed polymeric shell. The 10.7–10.9 MPa stresses reached in PLA samples, almost 30 times exceeding the theoretical limit, determine the structural optimization space for reducing the UAV weight and raising the valid payload efficiency.

- The potential of LW-PLA for manufacturing UAVs is a hopeful prospect. Raising the extruder temperature from 210 °C to 230 °C for LW-PLA reduced the sample weight by 20.6%, as expected from the literature review, but approximately four times reduced the estimated stresses and modulus of elasticity of the printed material (regarding the ordinary PLA). Still, estimated stresses have exceeded the theoretical limit eight times, which makes LW-PLA acceptable for manufacturing UAVs if deformation limits are satisfied. However, careful optimization of CAD slicing parameters and extrusion temperature is essential to ensure appropriate layer arrangement (overlapping) and particular material expansion to address the relatively weak interlayer bonding strength characteristic for lightweight materials.

- The bending samples with the perpendicular fragment printing pathway orientation regarding the bending plane demonstrated favorable ductile failure because of the compressive zone crushing. This failure mechanism ensured remarkable residual resistance even for vertical displacements exceeding 30 mm (i.e., 3/40 of the bending span). Thus, this arrangement is recommended for fabricating bending UAV components (i.e., wings).

- The slender details, printed in the vertical position (i.e., wing fragments, as recommended in this study), must have a sufficient bonding area with the printing bed. Empty profiles may not ensure reliable contact, so a solid base should be provided. It might be removed after the printing to reduce the structural weight if necessary.

- Avoid forming surfaces with less than 10% inclination is essential during CAD fragmentation. Due to limited printing resolution, these shapes can lead to unwanted perforations and may require additional surface finishing.

- The fabrication demonstrated acceptable precision, with a 0.6% error in the weight of the CAD model and fabricated prototype. However, to fully realize the fabrication potential, the existing CAD slicing software needs modification to reduce the weight of aerodynamic profiles.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Martínez-García, A.; Monzón, M.; Paz, R. Standards for additive manufacturing technologies: Structure and impact. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 395–408. [Google Scholar] [CrossRef]

- Rimkus, A.; Farh, M.M.; Gribniak, V. Continuously reinforced polymeric composite for additive manufacturing—Development and efficiency analysis. Polymers 2022, 14, 3471. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Rohru, P.; Babbar, A.; Kumar, R.; Ranjan, N.; Chohan, J.S.; Kumar, R.; Gupta, M. Fused filament fabrication: A state-of-the-art review of the technology, materials, properties and defects. Int. J. Interact. Des. Manuf. 2023, 17, 2867–2889. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A.M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Mishra, V.; Negi, S.; Kar, S.; Sharma, A.K.; Rajbahadur, Y.N.K.; Kumar, A. Recent advances in fused deposition modeling based additive manufacturing of thermoplastic composite structures: A review. J. Thermoplast. Compos. Mater. 2022, 36, 3094–3132. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Dimitrov, D.; van Wijck, W.; Schreve, K.; de Beer, N. Investigating the achievable accuracy of three dimensional printing. Rapid Prototyp. J. 2006, 12, 42–52. [Google Scholar] [CrossRef]

- Abdulaziz, A.; Tlija, M.; Abidi, M.H.; Anis, A.; Abd Elgawad, A.E. Material extrusion of multi-polymer structures utilizing design and shrinkage behaviors: A design of experiment study. Polymers 2023, 15, 2683. [Google Scholar] [CrossRef]

- Jiang, G.; Yang, T.; Xu, J.; Tao, D.; Luo, C.; Wang, C.; Dong, Q.; Wang, Y. Investigation into hydroxypropyl-methylcellulose-reinforced polylactide composites for fused deposition modelling. Ind. Crops Prod. 2020, 146, 112174. [Google Scholar] [CrossRef]

- Baca Lopez, D.M.; Ahmad, R. Tensile mechanical behaviour of multi-polymer sandwich structures via fused deposition modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef]

- Zhen, H.; Zhao, B.; Quan, L.; Fu, J. Effect of 3D printing process parameters and heat treatment conditions on the mechanical properties and microstructure of PEEK parts. Polymers 2023, 15, 2209. [Google Scholar] [CrossRef]

- Magazzù, A.; Marcuello, C. Investigation of soft matter nanomechanics by atomic force microscopy and optical tweezers: A comprehensive review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef] [PubMed]

- Nazir, A.; Gokcekaya, O.; Masum, B.K.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Islam, A.; Mobarak, H.; Rimon, I.H.; Al Mahmud, Z.; Ghosh, J.; Ahmed, M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Lee, B.; Abdullah, J.; Khan, Z. Optimization of rapid prototyping parameters for production of flexible ABS object. J. Mater. Process. Technol. 2005, 169, 54–61. [Google Scholar] [CrossRef]

- Chacón, J.; Caminero, M.; García-Plaza, E.; Núñez, P. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of polypropylene/short glass fiber composite as fused deposition modeling (FDM) filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Kumar, K.R.; Soms, N.; Kumar, M. Investigation of fused deposition modeling parameters on mechanical properties and characterization of ABS/carbon fiber composites. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 238, 1398–1408. [Google Scholar] [CrossRef]

- Patel, R.; Jani, S.; Joshi, A. Review on multi-objective optimization of FDM process parameters for composite materials. Int. J. Interact. Des. Manuf. 2023, 17, 2115–2125. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazancoglu, Y.; Sezer, M.D.; Top, N.; Sahin, I. Optimizing fused deposition modelling parameters based on the design for additive manufacturing to enhance product sustainability. Comput. Ind. 2023, 145, 103833. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, H.; Wu, X. Nanomaterials reinforced polymer filament for fused deposition modeling: A state-of-the-art review. Polymers 2023, 15, 2980. [Google Scholar] [CrossRef]

- Mallikarjuna, B.; Bhargav, P.; Hiremath, S.; Jayachristiyan, K.G.; Jayanth, N. A review on the melt extrusion-based fused deposition modeling (FDM): Background, materials, process parameters and military applications. Int. J. Interact. Des. Manuf. 2024. [Google Scholar] [CrossRef]

- Hernandez, D.D. Factors affecting dimensional precision of consumer 3D printing. Int. J. Aviat. Aeronaut. Aerosp. 2015, 2, 2. [Google Scholar] [CrossRef]

- Bodaghi, M.; Sadooghi, A.; Bakhshi, M.; Hashemi, S.J.; Rahmani, K.; Motamedi, M.K. Glass fiber reinforced acrylonitrile butadiene styrene composite gears by FDM 3D printing. Adv. Mater. Interfaces 2023, 10, 2300337. [Google Scholar] [CrossRef]

- Szafran, K.S.; Jeziorek, Ł.A. Using own algorithms to increase the quality and fatigue resistance of FDM printing for use in drones and small aircraft. Fatigue Aircr. Struct. 2023, 15, 28–43. [Google Scholar] [CrossRef]

- Kechagias, J.; Zaoutsos, S. Effects of 3D-printing processing parameters on FFF parts’ porosity: Outlook and trends. Mater. Manuf. Process. 2024, 39, 804–814. [Google Scholar] [CrossRef]

- Fu, X.; Lin, Y.; Yue, X.J.; XunMa; Hur, B.; Yue, X.Z. A review of additive manufacturing (3D printing) in aerospace: Technology, materials, applications, and challenges. In Mobile Wireless Middleware, Operating Systems and Applications: 10th International Conference on Mobile Wireless Middleware, Operating Systems and Applications (MOBILWARE 2021); Springer International Publishing: Cham, Switzerland, 2022; pp. 73–98. [Google Scholar] [CrossRef]

- Ravindrababu, S.; Govdeli, Y.; Wong, Z.W.; Kayacan, E. Evaluation of the influence of build and print orientations of unmanned aerial vehicle parts fabricated using fused deposition modeling process. J. Manuf. Process. 2018, 34, 659–666. [Google Scholar] [CrossRef]

- Azarov, A.V.; Antonov, F.K.; Golubev, M.V.; Khaziev, A.R.; Ushanov, S.A. Composite 3D printing for the small size unmanned aerial vehicle structure. Compos. Part B Eng. 2019, 169, 157–163. [Google Scholar] [CrossRef]

- Karkun, M.S.; Dharmalingam, S. 3D printing technology in aerospace industry—A review. Int. J. Aviat. Aeronaut. Aerosp. 2022, 9, 4. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Y.; Zhao, Y.F. A new part consolidation method to embrace the design freedom of additive manufacturing. J. Manuf. Process. 2015, 20, 444–449. [Google Scholar] [CrossRef]

- Gardner, J.M.; Sauti, G.; Kim, J.; Cano, R.J.; Wincheski, R.A.; Stelter, C.J.; Grimsley, B.W.; Working, D.C.; Siochi, E.J. 3-D printing of multifunctional carbon nanotube yarn reinforced components. Addit. Manuf. 2016, 12, 38–44. [Google Scholar] [CrossRef]

- Klippstein, H.; De Cerio Sanchez, A.D.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Fused deposition modeling for unmanned aerial vehicles (UAVs): A review. Adv. Eng. Mater. 2018, 20, 1700552. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- El Moumen, A.; Tarfaoui, M.; Lafdi, K. Additive manufacturing of polymer composites: Processing and modeling approaches. Compos. Part B Eng. 2019, 171, 166–182. [Google Scholar] [CrossRef]

- Giri, J.; Shahane, P.; Jachak, S.; Chadge, R.; Giri, P. Optimization of FDM process parameters for dual extruder 3D printer using artificial neural network. Mater. Today Proc. 2021, 43, 3242–3249. [Google Scholar] [CrossRef]

- Tiwary, V.K.; Arunkumar, P.; Malik, V.R. An overview on joining/welding as post-processing technique to circumvent the build volume limitation of an FDM-3D printer. Rapid Prototyp. J. 2021, 27, 808–821. [Google Scholar] [CrossRef]

- Spaggiari, A.; Denti, F. Mechanical strength of adhesively bonded joints using polymeric additive manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1851–1859. [Google Scholar] [CrossRef]

- Bergonzi, L.; Pirondi, A.; Moroni, F.; Frascio, M.; Avalle, M. A study on additive manufacturing build parameters as bonded joint design factors. J. Adhes. 2024, 100, 576–605. [Google Scholar] [CrossRef]

- Costa, A.P.D.; Botelho, E.C.; Costa, M.L.; Narita, N.E.; Tarpani, J.R. A review of welding technologies for thermoplastic composites in aerospace applications. J. Aerosp. Technol. Manag. 2012, 4, 255–265. [Google Scholar] [CrossRef]

- Ozturk, F.; Cobanoglu, M.; Ece, R.E. Recent advancements in thermoplastic composite materials in aerospace industry. J. Thermoplast. Compos. Mater. 2024, 37, 08927057231222820. [Google Scholar] [CrossRef]

- Totla, H.S.; Gupta, A.; Mishra, S.; Sharma, S.; Selvaraj, S.K. Resistance welding analysis of thermoplastic composite structures in aeronautical applications. Int. J. Interact. Des. Manuf. 2024. [Google Scholar] [CrossRef]

- Olasek, K.; Wiklak, P. Application of 3D printing technology in aerodynamic study. J. Phys. Conf. Ser. 2014, 530, 012009. [Google Scholar] [CrossRef]

- Udroiu, R. New methodology for evaluating surface quality of experimental aerodynamic models manufactured by polymer jetting additive manufacturing. Polymers 2022, 14, 371. [Google Scholar] [CrossRef] [PubMed]

- Fiberlab. Technical Data Sheet Fiberlogy ABS, v1.0. Fiberlab. Brzezie, Poland, 2022; 1p.

- 3Dxtech. Technical Data Sheet: 3DXMAX® ABS 3D Printing Filament, v3.0. 3Dxtech. Grand Rapids, MI, USA, 2024; 1p.

- Karahaliou, K.; Tarantili, P.A. Stability of ABS compounds subjected to repeated cycles of extrusion processing. Polym. Eng. Sci. 2009, 49, 2269–2275. [Google Scholar] [CrossRef]

- La Gala, A.; Fiorio, R.; Erkoç, M.; Cardon, L.; D’hooge, D.R. Theoretical evaluation of the melting efficiency for the single-screw micro-extrusion process: The case of 3D printing of ABS. Processes 2020, 8, 1522. [Google Scholar] [CrossRef]

- Rosli, A.A.; Shuib, R.K.; Ishak, K.M.K.; Hamid, Z.A.A.; Abdullah, M.K.; Rusli, A. Influence of bed temperature on warpage, shrinkage and density of various acrylonitrile butadiene styrene (ABS) parts from fused deposition modelling (FDM). AIP Conf. Proc. 2020, 2267, 020072. [Google Scholar] [CrossRef]

- Singh, P.; Katiyar, P.; Singh, H. Impact of compatibilization on polypropylene (PP) and acrylonitrile butadiene styrene (ABS) blend: A review. Mater. Today Proc. 2023, 78, 189–197. [Google Scholar] [CrossRef]

- Kopar, M.; Yildiz, A.R. Experimental investigation of mechanical properties of PLA, ABS, and PETG 3-D printing materials using fused deposition modeling technique. Mater. Test. 2023, 65, 1795–1804. [Google Scholar] [CrossRef]

- Gu, J.; Wensing, M.; Uhde, E.; Salthammer, T. Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environ. Int. 2019, 123, 476–485. [Google Scholar] [CrossRef]

- Wojnowski, W.; Marć, M.; Kalinowska, K.; Kosmela, P.; Zabiegała, B. Emission profiles of volatiles during 3D printing with ABS, ASA, Nylon, and PETG polymer filaments. Molecules 2022, 27, 3814. [Google Scholar] [CrossRef]

- Jipa, A.; Reiter, L.; Flatt, R.J.; Dillenburger, B. Environmental stress cracking of 3D-printed polymers exposed to concrete. Addit. Manuf. 2022, 58, 103026. [Google Scholar] [CrossRef]

- Bute, I.; Tarasovs, S.; Vidinejevs, S.; Vevere, L.; Sevcenko, J.; Aniskevich, A. Thermal properties of 3D printed products from the most common polymers. Int. J. Adv. Manuf. Technol. 2023, 124, 2739–2753. [Google Scholar] [CrossRef]

- Mohammadian, Y.; Nasirzadeh, N. Toxicity risks of occupational exposure in 3D printing and bioprinting industries: A systematic review. Toxicol. Ind. Health 2021, 37, 573–584. [Google Scholar] [CrossRef]

- Farcas, M.T.; Stefaniak, A.B.; Knepp, A.K.; Bowers, L.; Mandler, W.K.; Kashon, M.; Jackson, S.R.; Stueckle, T.A.; Sisler, J.D.; Friend, S.A.; et al. Acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) filaments three-dimensional (3-D) printer emissions-induced cell toxicity. Toxicol. Lett. 2019, 317, 1–12. [Google Scholar] [CrossRef]

- Prusa Polymers. Technical Datasheet Prusament PLA, v1.1. Prusa Polymers. Prague, Czech Republic, 2022; 3p.

- ColorFabb. Technical Datasheet PLA Economy, v2.0. ColorFabb. Belfeld, The Netherlands, 2023; 3p.

- Singh, S.; Rajeshkannan, A.; Feroz, S.; Jeevanantham, A. Effect of normalizing on the tensile strength, shrinkage and surface roughness of PLA plastic. Mater. Today Proc. 2019, 24, 1174–1182. [Google Scholar] [CrossRef]

- Bermudez, D.; Quiñonez, P.A.; Vasquez, E.J.; Carrete, I.A.; Word, T.J.; Roberson, D.A. A comparison of the physical properties of two commercial 3D printing PLA grades. Virtual Phys. Prototyp. 2021, 16, 178–195. [Google Scholar] [CrossRef]

- Taib, N.A.A.B.; Rahman, R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Julaihi, M.R.M.B.; Khan, A. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Johar, M.; Rosli, A.A.; Shuib, R.K.; Abdul Hamid, Z.A.; Abdullah, M.K.; Ku Ishak, K.M.; Rusli, A. Dimensional stability of poly (lactic acid) (PLA) parts fabricated using fused deposition modelling (FDM). Prog. Rubber Plast. Recycl. Technol. 2024, 14777606241262882. [Google Scholar] [CrossRef]

- Yousefi, K.A.; Rennie, A.E.; Abd Rahim, S.Z.B. Additively manufactured foamed polylactic acid for lightweight structures. Rapid Prototyp. J. 2023, 29, 50–66. [Google Scholar] [CrossRef]

- 3DLabPrint. PolyLight 1.0|Lightweight PLA, 3DLabPrint; Brno, Czech Republic, 2024; 2p.

- ColorFabb. Technical Datasheet Light Weight PLA (LW-PLA), v1.0. ColorFabb. Belfeld, The Netherlands, 2023; 3p.

- Ozdemir, M.; Doubrovski, Z. Foam2Form: 4D printing with programmable foaming. In Proceedings of the Extended Abstracts of the CHI Conference on Human Factors in Computing Systems, New Orleans, LA, USA, 29 April–5 May 2024; p. 164, 8p. [Google Scholar] [CrossRef]

- Prusa Polymers. Technical Datasheet Prusament PETG, v1.1. Prusa Polymers. Prague, Czech Republic, 2022; 3p.

- ColorFabb. Technical Datasheet PETG Economy, v1.0. ColorFabb. Belfeld, The Netherlands, 2023; 2p.

- Holcomb, G.; Caldona, E.B.; Cheng, X.; Advincula, R.C. On the optimized 3D printing and post-processing of PETG materials. MRS Commun. 2022, 12, 381–387. [Google Scholar] [CrossRef]

- Fiberlab. Technical Data Sheet Fiberlogy PEI 9085, v2.0. Fiberlab. Brzezie, Poland, 2024; 1p.

- 3Dxtech. Technical Data Sheet: ThermaX™ PEI [Made Using ULTEM™ 9085], v4.0. 3Dxtech. Grand Rapids, MI, USA, 2024; 1p.

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- Bambu Filament. Technical Data Sheet PC, v3.0. Bambu Lab Global. Frankfurt am Main, Germany, 2023; 5p.

- 3Dxtech. Technical Data Sheet: 3DXMAX® Polycarbonate 3D Printing Filament, v3.0. 3Dxtech. Grand Rapids, MI, USA, 2024; 1p.

- Kodali, D.; Umerah, C.O.; Idrees, M.O.; Jeelani, S.; Rangari, V.K. Fabrication and characterization of polycarbonate-silica filaments for 3D printing applications. J. Compos. Mater. 2021, 55, 4575–4584. [Google Scholar] [CrossRef]

- Yilmaz, M.; Yilmaz, N.F.; Kalkan, M.F. Rheology, crystallinity, and mechanical investigation of interlayer adhesion strength by thermal annealing of polyetherimide (PEI/ULTEM 1010) parts produced by 3D printing. J. Mater. Eng. Perform. 2022, 31, 9900–9909. [Google Scholar] [CrossRef]

- Colón Quintana, J.L.; Slattery, L.; Pinkham, J.; Keaton, J.; Lorez-Anido, R.A.; Sharp, K. Effects of fiber orientation on the coefficient of thermal expansion of fiber-filled polymer systems in large format polymer extrusion-based additive manufacturing. Materials 2022, 15, 2764. [Google Scholar] [CrossRef]

- ColorFabb. Technical Datasheet PA Neat, v1.0. ColorFabb. Belfeld, The Netherlands, 2023; 2p.

- 3Dxtech. Technical Data Sheet: AmideX™ PA6 Copolymer 3D Printing Filament, v1.0. 3Dxtech. Grand Rapids, MI, USA, 2024; 1p.

- Ichakpa, M.; Goodyear, M.; Duthie, J.; Duthie, M.; Wisely, R.; MacPherson, A.; Keyte, J.; Pancholi, K.; Njuguna, J. Investigation on mechanical and thermal properties of 3D-printed polyamide 6, graphene oxide and glass-fibre-reinforced composites under dry, wet and high temperature conditions. J. Compos. Sci. 2023, 7, 227. [Google Scholar] [CrossRef]

- Barber, J.; Revolinsky, P.; Spinelli, E.; Jamora, V.C.; Eisazadeh, H.; Kravchenko, O.G. Investigation of high temperature compaction on fracture toughness of 3D printed carbon fiber polyamide composites. Prog. Addit. Manuf. 2024, 9, 1119–1134. [Google Scholar] [CrossRef]

- Yilmaz, S. Comprehensive analysis of 3D printed PA6.6 and fiber-reinforced variants: Revealing mechanical properties and adhesive wear behavior. Polym. Compos. 2024, 45, 1446–1460. [Google Scholar] [CrossRef]

- ColorFabb. Technical Datasheet ASA, v1.0. ColorFabb. Belfeld, The Netherlands, 2023; 2p.

- Prusa Polymers. Technical Datasheet Prusament ASA, v1.1. Prusa Polymers. Prague, Czech Republic, 2024; 3p.

- Goyanes, A.; Buanz, A.B.; Hatton, G.B.; Gaisford, S.; Basit, A.W. 3D printing of modified-release aminosalicylate (4-ASA and 5-ASA) tablets. Eur. J. Pharm. Biopharm. 2014, 89, 157–162. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure, thermal and mechanical behavior of 3D printed acrylonitrile styrene acrylate. Macromol. Mater. Eng. 2019, 304, 1800793. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Aravind, R.S.; Kandasamy, J.; Shahzad, M.A.; Baghdadi, M.A. 3D Printing parameter optimization using Taguchi approach to examine acrylonitrile styrene acrylate (ASA) mechanical properties. Polymers 2021, 14, 3256. [Google Scholar] [CrossRef]

- Utomo, E.; Shen, T.; Picco, C.J.; Concheiro, A.; Donnelly, R.F.; Larrañeta, E. Use of 3D printing for the development of biodegradable antiplatelet materials for cardiovascular applications. Pharmaceuticals 2021, 14, 921. [Google Scholar] [CrossRef] [PubMed]

- Watson, M.; Gonzalez, F. Design and implementation of a low-cost folding-wing UAV for model rocket deployment. In Proceedings of the 2023 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2023. [Google Scholar] [CrossRef]

- Mohsan, S.A.; Khan, M.A.; Noor, F.; Ullah, I.; Alsharif, M.H. Towards the unmanned aerial vehicles (UAVs): A comprehensive review. Drones 2022, 6, 147. [Google Scholar] [CrossRef]

- UAV Model. Available online: https://www.uavmodel.com/products/skywalker-x8-2122mm-uav-fixed-wing (accessed on 23 July 2024).

- Airfoil Tools. Available online: http://airfoiltools.com/ (accessed on 23 July 2024).

- Gribniak, V.; Arnautov, A.K.; Rimkus, A. An innovative frictional anchorage system for flat CFRP ribbon strips. Compos. Struct. 2023, 303, 116369. [Google Scholar] [CrossRef]

- Misiūnaitė, I.; Rimkus, A.; Gribniak, V. Developing a lightweight hybrid profile concept with a steel shell and polymeric lattice core for optimal mechanical performance. Compos. Struct. 2024, 340, 118169. [Google Scholar] [CrossRef]

- JARUS. Limit and Ultimate loads CS-23.2230. In Recommendations for Certification Specification for Unmanned Aircraft Systems SC-UAS, JARUS International. 2019; 67p.

- Abbott, R. Analysis and Design of Composite and Metallic Flight Vehicle Structures, 3rd ed.; Abbott Aerospace SEZC Ltd.: Grand Cayman, British Overseas Territory, 2019; 299p. [Google Scholar]

- Miller, E.J.; Li, W.W.; Jordan, A.; Lung, S. X-57 wing structural load testing. In Proceedings of the AIAA Aviation 2020 Forum, Online, 15–19 June 2020. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Rimkus, A. The development of nature-inspired gripping system of a flat CFRP strip for stress-ribbon structural layout. J. Comput. Des. Eng. 2021, 8, 788–798. [Google Scholar] [CrossRef]

- de Freitas, F.; Pegado, H. Impact of nozzle temperature on dimensional and mechanical characteristics of low-density PLA. Int. J. Adv. Manuf. Technol. 2023, 126, 1629–1638. [Google Scholar] [CrossRef]

- Gribniak, V.; Rimkus, A.; Misiūnaitė, I.; Zakaras, T. Improving local stability of aluminium profile with low-modulus stiffeners: Experimental and numerical web buckling analysis. Thin-Walled Struct. 2022, 172, 108858. [Google Scholar] [CrossRef]

- Rimkus, A.; Šalna, R.; Gribniak, V. Evaluating the PLA aging effects on the mechanical performance of 3D-printed components. Proc. Int. Struct. Eng. Constr. 2024, 11, SUS-01. [Google Scholar] [CrossRef]

- Gribniak, V.; Rimkus, A.; Plioplys, L.; Misiūnaitė, I.; Boris, R.; Pravilonis, T. Evaluating mechanical efficiency of glass fibres in a polymer profile. Polym. Test. 2021, 102, 107338. [Google Scholar] [CrossRef]

- Gribniak, V.; Rimkus, A.; Plioplys, L.; Misiunaite, I.; Garnevičius, M.; Boris, R.; Šapalas, A. An efficient approach to describe the fiber effect on mechanical performance of pultruded GFRP profiles. Front. Mater. 2021, 8, 746376. [Google Scholar] [CrossRef]

- Šostakaitė, L. Optimizing Connection Joints of Additively Manufactured Polymeric Drone Components. Bachelor’s Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2024. [Google Scholar]

- Lee, H.; Park, S.; Hong, M.; Lee, H.; Kim, Y. A study on the manufacture of permanent magnet traction control valve for electronic stability control in electric vehicles. Appl. Sci. 2021, 11, 7794. [Google Scholar] [CrossRef]

| Material * | ABS | PLA | LW-PLA | PETG | PEI | PC | PA | ASA |

|---|---|---|---|---|---|---|---|---|

| References | [46,47,48,49,50,51,52,53,54,55,56,57,58] | [55,56,57,59,60,61,62,63,64] | [56,65,66,67,68] | [52,53,54,55,69,70,71] | [53,55,72,73,74] | [55,56,57,58,75,76,77,78,79] | [54,55,56,57,80,81,82,83,84] | |

| Advantages | Cheap, lightweight, flexible | Biodegradable, sustainable raw materials | Non-toxic, chemically resistant | Temperature, flammability, and chemically resistant, high strength | Temperature-resistant, high strength | High interlayer adhesion; resistant to abrasion and impact | UV resistant, durable | |

| Weakness | Temperature deformations, toxic gases | Low melting temperature, brittleness | Low melting temperature and modulus of elasticity | High water absorption, hardly printable | Expensive | High printing temperature, deformation instability | High water absorption, deformation instability | Deformation instability, high-precision printing demands |

| Density [g/cm3] | 1.04–1.12 | 1.20–1.26 | 0.42–1.20 ◊ | 1.27–1.28 | 1.17–1.34 | 1.19–1.20 | 1.10–1.25 | 1.05–1.07 |

| Tensile strength [MPa] | 32–52 | 31(11) ‡–71 | 10–43 | 47–50 | 54–104 | 55(19) ‡–62 | 55–63 | 42–50 |

| Elasticity modulus [GPa] | 1.8–2.0 | 2.3–4.5 | 0.86–3.4 | 1.5–1.9 | 2.1–3.1 | 2.1–2.4 | 2.0–3.0 | 1.6–2.1 |

| Glass transition temp. [°C] | 100–112 | 50–70 | 55–60 | 70–75 | 186–220 | 145–147 | 62–79 | 101–116 |

| Melting temperature [°C] | 125–150 | 150–160 | 150–160 | – | – | 228–280 | 189–194 | 130–141 |

| Shrinkage ‡ [%] | 0.5–11 | 0.3–8.1 | −5.8 △–7.8 | 0.3–12 | 20 | 0.8–1.0 | 0.5–8.1 | 0.5–0.8 |

| Toxic gas emission | Yes | No | No | No | No | Yes | Yes | Yes |

| Price [€/kg] | 25–33 | 17–60 | 35–43 | 28–30 | 202–273 | 43–85 | 66–71 | 32–35 |

| Material | E [GPa] | ft [MPa] | εu [%] | Ef [GPa] | fr [MPa] | Tg [°C] | Tm [°C] | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| xy | z | xy | z | xy | z | xy | z | xy | z | |||

| PLA | 3.30 | 3.35 | 70 | 71 | 3.5 | 3.5 | 2.40 | 2.20 | 97 | 85 | 55–60 | 150–160 |

| LW-PLA | 3.35 (0.86) ◊ | 43 (10) ◊ | 8.1 (12.8) ◊ | – | – | 55–60 | 150–160 | |||||

| Sample * | Adhesive | h [mm] | b [mm] | L [mm] | t ‡ [mm] | γmax [mm] | wexp [g] | Pmax [N] | uP [mm] | σP [MPa] | E [GPa] | Failure ◊ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-1 | – | 17.85 ± 0.29 | 149.96 ± 0.07 | 447.8 ± 0.5 | 1.32 ± 0.28 | 3.99 | 216.0 | 310 | 16.0 | 11.0 | 1.27 | B |

| S-2 | – | 17.86 ± 0.33 | 149.95 ± 0.19 | 448.3 ± 0.5 | 1.36 ± 0.37 | 2.81 | 216.0 | 310 | 15.0 | 11.1 | 1.32 | B |

| S-3LW | – | 17.58 ± 0.30 | 149.97 ± 0.03 | 447.6 ± 0.5 | 1.73 ± 0.73 | 2.15 | 171.5 | 110 | 18.5 | 3.54 | 0.356 | B |

| S-4LW | – | 17.59 ± 0.27 | 150.01 ± 0.05 | 447.8 ± 0.5 | 1.72 ± 0.70 | 1.67 | 171.5 | 90 | 12.2 | 2.92 | 0.358 | B |

| F1-1 | “1” | 18.63 ± 0.09 | 149.54 ± 0.08 | 449.3 ± 0.3 | – | – | 206.5 | 140 | 4.33 | 6.65 | 2.23 | J |

| F1-2 | “2” | 18.64 ± 0.09 | 149.34 ± 0.23 | 449.2 ± 0.3 | – | – | 210.0 | 230 | 7.22 | 10.7 | 1.96 | J |

| F2-1 | “1” | 18.61 ± 0.09 | 149.72 ± 0.06 | 448.6 ± 0.4 | 0.82 ± 0.00 | – | 208.5 | 250 | 10.7 | 11.6 | 1.37 | D |

| F2-2 | “2” | 18.70 ± 0.11 | 149.73 ± 0.09 | 448.1 ± 0.4 | 0.78 ± 0.02 | – | 211.5 | 230 | 7.43 | 10.9 | 1.98 | D |

| F3-1 | “1” | 18.70 ± 0.05 | 149.69 ± 0.07 | 450.1 ± 0.2 | 0.82 ± 0.01 | – | 233.0 | 240 | 8.78 | 10.7 | 2.17 | B |

| F3-2 | “1” | 18.70 ± 0.05 | 149.67 ± 0.13 | 450.0 ± 0.2 | 0.83 ± 0.01 | – | 227.0 | 310 | 11.6 | 13.7 | 1.89 | B |

| Fragment * | “1” | “2” | “3” | “4” | “5” | “6” | “7” | “8” | “W” | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Calculated [g] | 125.31 | 103.80 | 86.64 | 69.90 | 68.09 | 55.62 | 143.99 | 176.89 | 112.57 | 942.81 |

| Measured [g] | 126.3 | 102.3 | 86.0 | 70.7 | 68.7 | 55.9 | 146.3 | 177.8 | 114.0 | 948.0 |

| Time [h] | 10:14 | 8:27 | 7:09 | 5:45 | 3:45 | 4:44 | 8:16 | 9:52 | 6:16 | 64:28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šostakaitė, L.; Šapranauskas, E.; Rudinskas, D.; Rimkus, A.; Gribniak, V. Investigating Additive Manufacturing Possibilities for an Unmanned Aerial Vehicle with Polymeric Materials. Polymers 2024, 16, 2600. https://doi.org/10.3390/polym16182600

Šostakaitė L, Šapranauskas E, Rudinskas D, Rimkus A, Gribniak V. Investigating Additive Manufacturing Possibilities for an Unmanned Aerial Vehicle with Polymeric Materials. Polymers. 2024; 16(18):2600. https://doi.org/10.3390/polym16182600

Chicago/Turabian StyleŠostakaitė, Laura, Edvardas Šapranauskas, Darius Rudinskas, Arvydas Rimkus, and Viktor Gribniak. 2024. "Investigating Additive Manufacturing Possibilities for an Unmanned Aerial Vehicle with Polymeric Materials" Polymers 16, no. 18: 2600. https://doi.org/10.3390/polym16182600

APA StyleŠostakaitė, L., Šapranauskas, E., Rudinskas, D., Rimkus, A., & Gribniak, V. (2024). Investigating Additive Manufacturing Possibilities for an Unmanned Aerial Vehicle with Polymeric Materials. Polymers, 16(18), 2600. https://doi.org/10.3390/polym16182600