Nanofiber Space-Confined Fabrication of High-Performance Perovskite Films for Flexible Conversion of Fluorescence Quantum Yields in LED Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization

3. Results and Discussion

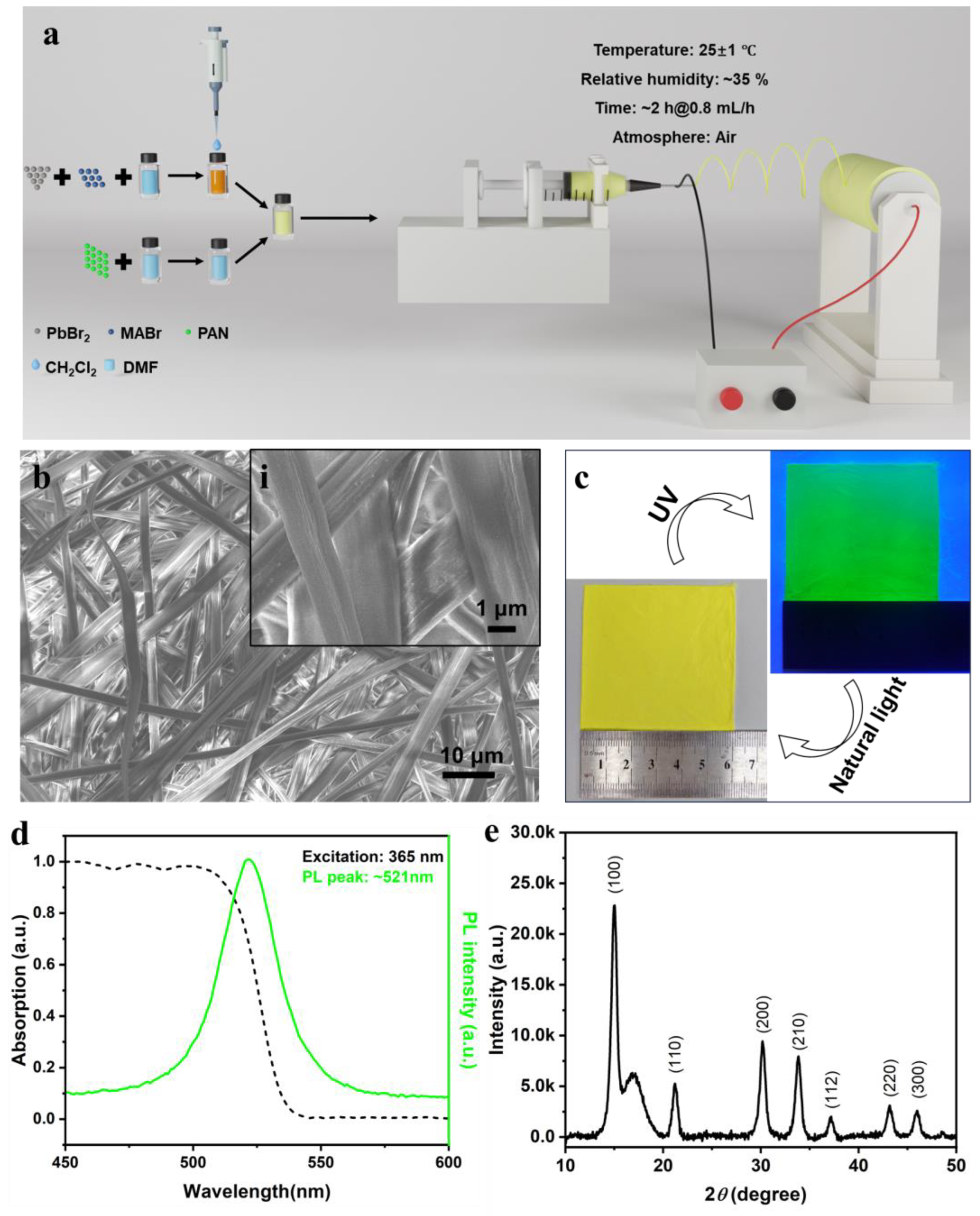

3.1. Preparation of QCMs

3.2. Structural and Optical Properties of QCMs

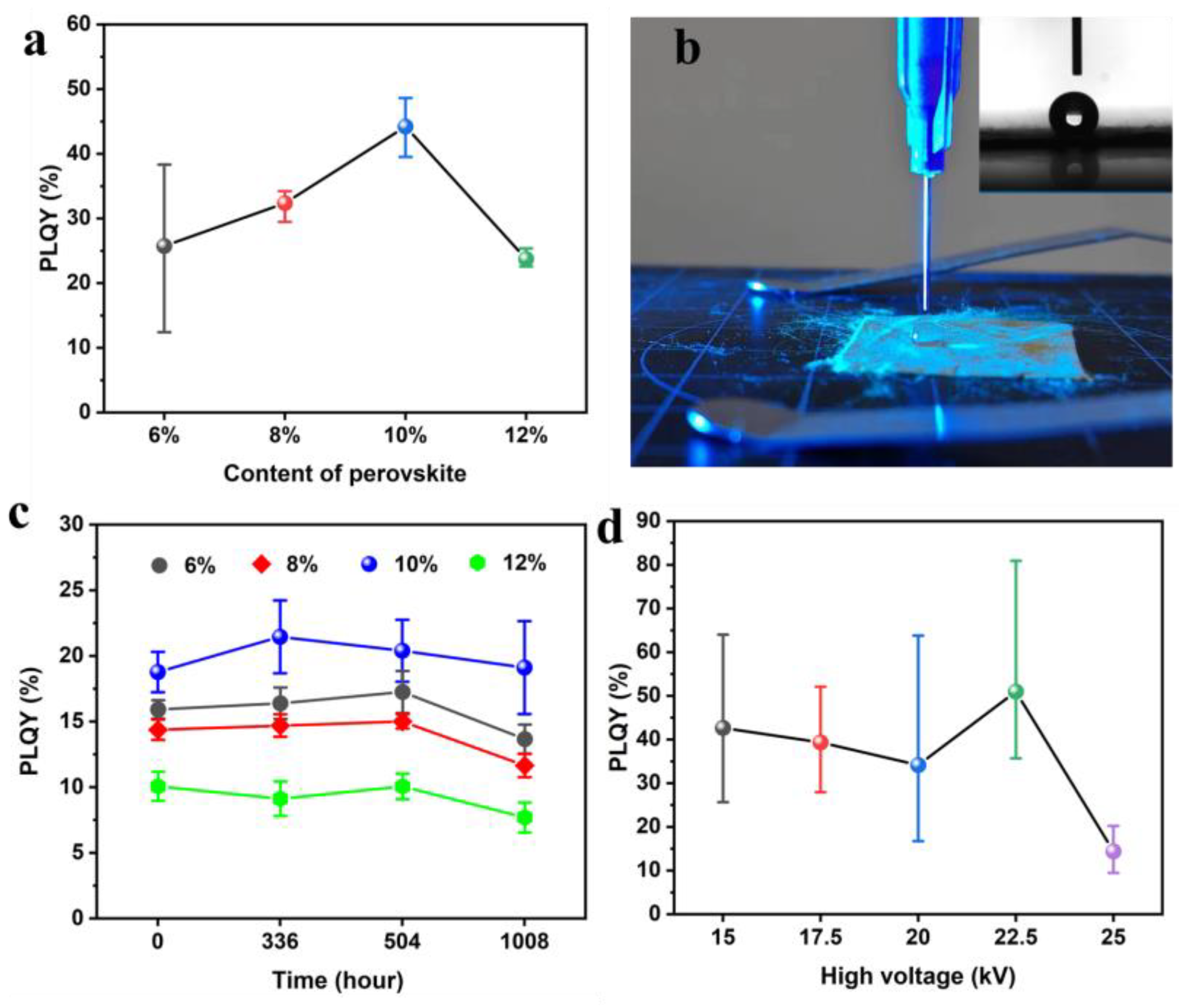

3.3. Optimization and Characteristics of QCMs

Optimization of QCM Composition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Su, Z.; Canil, L.; Hughes, D.; Aldamasy, M.H.; Dagar, J.; Trofimov, S.; Wang, L.; Zuo, W.; Jerónimo-Rendon, J.J.; et al. Highly efficient pin perovskite solar cells that endure temperature variations. Science 2023, 379, 399–403. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Ye, F.; Wang, X.; Chen, R.; Zhang, H.; Zhan, L.; Jiang, X.; Li, Y.; Ji, X.; Liu, S.; et al. Minimizing buried interfacial defects for efficient inverted perovskite solar cells. Science 2023, 380, 404–409. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Vasilopoulou, M.; Fakharuddin, A.; Gao, F.; Yusoff, A.R.b.M.; Friend, R.H.; Di, D. Light management for perovskite light-emitting diodes. Nat. Nanotechnol. 2023, 18, 981–992. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Song, B.; Zhang, Z.; Wang, K.-L.; Li, Y.-H.; Li, N.; Chen, C.-H.; Chen, J.; Xing, G.; Wang, Z.-K. Vertically Concentrated Quantum Wells Enabling Highly Efficient Deep-Blue Perovskite Light-Emitting Diodes. Angew. Chem. Int. Ed. 2024, 63, e202403739. [Google Scholar] [CrossRef]

- He, L.; Hu, G.; Jiang, J.; Wei, W.; Xue, X.; Fan, K.; Huang, H.; Shen, L. Highly sensitive tin-lead perovskite photodetectors with over 450 days stability enabled by synergistic engineering for pulse oximetry system. Adv. Mater. 2023, 35, 2210016. [Google Scholar] [CrossRef]

- Wang, K.; Huang, C.; Ruan, Q.; Zhou, Y.; Chen, Y.; Liu, H.; Xiao, S.; Song, Q. Emission Control in Metal Halide Perovskite Lasers. ACS Photonics 2023, 10, 2091–2101. [Google Scholar] [CrossRef]

- Jin, L.; Liu, Z.; Zhang, Y.; Wu, Y.; Liu, Y.; Deng, H.; Song, Q.; Xiao, S. Lanthanide-doped nanocrystals in high-Q microtoroids for stable on-chip white-light lasers. Photonics Res. 2022, 10, 1594–1601. [Google Scholar] [CrossRef]

- Pan, Z.; Zhu, X.; Xu, T.; Xie, Q.; Chen, H.; Xu, F.; Lin, H.; Wang, J.; Liu, Y. Highly stable CsPbI3 perovskite quantum dots enabled by single SiO2 coating toward down-conversion light-emitting diodes. Appl. Sci. 2023, 13, 7529. [Google Scholar] [CrossRef]

- Smith, I.C.; Hoke, E.T.; Solis-Ibarra, D.; McGehee, M.D.; Karunadasa, H.I. A layered hybrid perovskite solar-cell absorber with enhanced moisture stability. Angew. Chem. Int. Ed. 2014, 53, 11232–11235. [Google Scholar] [CrossRef]

- Pan, J.-L.; Yu, Y.-J.; Wang, Y.-K.; Liao, L.-S. Lanthanide Ion-Doped Perovskite Nanocrystals in Electroluminescent Device. Adv. Funct. Mater. 2024, 34, 2401327. [Google Scholar] [CrossRef]

- Nestoklon, M.O.; Kirstein, E.; Yakovlev, D.R.; Zhukov, E.A.; Glazov, M.M.; Semina, M.A.; Ivchenko, E.L.; Kolobkova, E.V.; Kuznetsova, M.S.; Bayer, M. Tailoring the electron and hole Landé factors in lead halide perovskite nanocrystals by quantum confinement and halide exchange. Nano Lett. 2023, 23, 8218–8224. [Google Scholar] [CrossRef] [PubMed]

- Protesescu, L.; Yakunin, S.; Bodnarchuk, M.I.; Krieg, F.; Caputo, R.; Hendon, C.H.; Yang, R.X.; Walsh, A.; Kovalenko, M.V. Nanocrystals of cesium lead halide perovskites (CsPbX3, X= Cl, Br, and I): Novel optoelectronic materials showing bright emission with wide color gamut. Nano Lett. 2015, 15, 3692–3696. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhong, H.; Chen, C.; Wu, X.-G.; Hu, X.; Huang, H.; Han, J.; Zou, B.; Dong, Y. Brightly luminescent and color-tunable colloidal CH3NH3PbX3 (X= Br, I, Cl) quantum dots: Potential alternatives for display technology. ACS Nano 2015, 9, 4533–4542. [Google Scholar] [CrossRef]

- Lignos, I.; Stavrakis, S.; Nedelcu, G.; Protesescu, L.; Demello, A.J.; Kovalenko, M.V. Synthesis of cesium lead halide perovskite nanocrystals in a droplet-based microfluidic platform: Fast parametric space mapping. Nano Lett. 2016, 16, 1869–1877. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Bai, S.; Kim, V.; Lamboll, R.; Shivanna, R.; Auras, F.; Richter, J.M.; Yang, L.; Dai, L.; Alsari, M.; et al. High-efficiency perovskite–polymer bulk heterostructure light-emitting diodes. Nat. Photonics 2018, 12, 783–789. [Google Scholar] [CrossRef]

- Geng, Y.; Guo, J.; Wang, H.; Da Ling, S.; Chen, Z.; Chen, S.; Xu, J. Large-Scale Production of Ligand-Engineered Robust Lead Halide Perovskite Nanocrystals by a Droplet-Based Microreactor System. Small 2022, 18, 2200740. [Google Scholar] [CrossRef]

- Bi, D.; Yi, C.; Luo, J.; Décoppet, J.-D.; Zhang, F.; Zakeeruddin, S.M.; Li, X.; Hagfeldt, A.; Grätzel, M. Polymer-templated nucleation and crystal growth of perovskite films for solar cells with efficiency greater than 21%. Nat. Energy 2016, 1, 16142. [Google Scholar] [CrossRef]

- Song, T.-B.; Chen, Q.; Zhou, H.; Jiang, C.; Wang, H.-H.; Yang, Y.; Liu, Y.; You, J.; Yang, Y. Perovskite solar cells: Film formation and properties. J. Mater. Chem. A 2015, 3, 9032–9050. [Google Scholar] [CrossRef]

- Semenistaya, T.V. Polyacrylonitrile-based materials: Properties, Methods and Applications. In Advanced Materials: Manufacturing, Physics, Mechanics and Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 61–77. [Google Scholar]

- Rahaman, M.S.A.; Ismail, A.F.; Mustafa, A. A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 2007, 92, 1421–1432. [Google Scholar] [CrossRef]

- Tsai, P.-C.; Chen, J.-Y.; Ercan, E.; Chueh, C.-C.; Tung, S.-H.; Chen, W.-C. Uniform luminous perovskite nanofibers with color-tunability and improved stability prepared by one-step core/shell electrospinning. Small 2018, 14, 1704379. [Google Scholar] [CrossRef]

- Schmidt, L.C.; Pertegás, A.; González-Carrero, S.; Malinkiewicz, O.; Agouram, S.; Espallargas, G.M.; Bolink, H.J.; Galian, R.E.; Pérez-Prieto, J. Nontemplate synthesis of CH3NH3PbBr3 perovskite nanoparticles. J. Am. Chem. Soc. 2014, 136, 850–853. [Google Scholar] [CrossRef] [PubMed]

- Pistor, P.; Borchert, J.; Fränzel, W.; Csuk, R.; Scheer, R. Monitoring the phase formation of coevaporated lead halide perovskite thin films by in situ x-ray diffraction. J. Phys. Chem. Lett. 2014, 5, 3308–3312. [Google Scholar] [CrossRef]

- Jyothi, N.K.; Kumar, K.V.; Murthy, P.N. FTIR, XRD and DC conductivity studies of proton conducting gel polymer electrolytes based on polyacrylonitrile (PAN). Int. J. Chem. Tech. Res. 2014, 6, 5214–5219. [Google Scholar]

- Anghelina, V.F.; Popescu, I.V.; Gaba, A.; Popescu, I.N.; Despa, V.; Ungureanu, D.A.N. Structural analysis of PAN fiber by X-ray diffraction. J. Sci. Arts 2010, 10, 89. [Google Scholar]

- Peng, M.; Guan, X.; Wu, Y.; Zhang, N.; Feng, Q.; Tian, L.; Wu, Y.; Zhang, Y.; Gan, F.; Deng, F.; et al. Embedding Perovskite in Polymer Matrix Achieved Positive Temperature Response with Inversed Temperature Crystallization. Energy Environ. Mater. 2024, 7, e12713. [Google Scholar] [CrossRef]

- Zhidkov, I.S.; Boukhvalov, D.W.; Akbulatov, A.F.; Frolova, L.A.; Finkelstein, L.D.; Kukharenko, A.I.; Cholakh, S.O.; Chueh, C.-C.; Troshin, P.A.; Kurmaev, E.Z. XPS spectra as a tool for studying photochemical and thermal degradation in APbX3 hybrid halide perovskites. Nano Energy 2021, 79, 105421. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Y.; Liu, B.; He, X.; Yuan, H.; Xin, Y. In-situ synthesis of MAPbBr3 perovskite quantum dot-polycaprolactone composites with enhanced photoluminescence quantum yield and stability. Mater. Today Commun. 2023, 35, 106220. [Google Scholar] [CrossRef]

- Chen, Q.; Fu, H.; Wang, N.; Gao, F.; Yang, W.; Liu, W.; Zheng, J. Enhanced thermal stability of MAPbBr3 nanocrystals by ligand modification. Mater. Res. Bull. 2023, 157, 112009. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, F.; Tai, J.; Li, Y.; Yang, Y.; Wang, H.; Zhang, J.; Xie, Z.; Xu, B.; Zhong, H.; et al. A detour strategy for colloidally stable block-copolymer grafted MAPbBr3 quantum dots in water with long photoluminescence lifetime. Nanoscale 2018, 10, 5820–5826. [Google Scholar] [CrossRef]

- Sorokin, V.M.; Konoshchuk, N.V.; Khmil, D.M.; Posudievsky, O.Y.; Koshechko, V.G.; Pokhodenko, V.D. CH3NH3PbBr3 nanocrystals formed in situ in polystyrene used for increasing the color rendering index of white LEDs. Theor. Exp. Chem. 2019, 55, 223–231. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, Y.; Kothalawala, N.L.; Wen, X.; Kim, D.Y.; Yang, F. MAPbBr3 nanocrystals from aqueous solution for poly (methyl methacrylate)-MAPbBr3 nanocrystal films with compression-resistant photoluminescence. Nanotechnology 2022, 33, 235605. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Lin, H.; Piao, X.; Tian, P.; Fang, M.; An, X.; Luo, C.; Qi, R.; Chen, Y.; Peng, H. Organometal halide perovskite nanocrystals embedded in silicone resins with bright luminescence and ultrastability. J. Mater. Chem. C 2017, 5, 12044–12049. [Google Scholar] [CrossRef]

- Li, X.; Xue, Z.; Luo, D.; Huang, C.; Liu, L.; Qiao, X.; Liu, C.; Song, Q.; Yan, C.; Li, Y.; et al. A stable lead halide perovskite nanocrystals protected by PMMA. Sci. China Mater. 2018, 61, 363–370. [Google Scholar] [CrossRef]

- Wang, Y.; He, J.; Chen, H.; Chen, J.; Zhu, R.; Ma, P.; Towers, A.; Lin, Y.; Gesquiere, A.J.; Wu, S.-T.; et al. Ultrastable, highly luminescent organic–inorganic perovskite–polymer composite films. Adv. Mater. 2016, 28, 10710–10717. [Google Scholar] [CrossRef]

- Zhao, X.; Jia, W.; Wang, H.; Yan, G.; Sun, Y.; Tang, X.; Zeng, X.; Lin, L. One-step preparation of excellent flexible ethyl cellulose composite film for LED. Mater. Chem. Phys. 2021, 270, 124798. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, N.; Guan, X.; Chen, X.; Xie, L.; Zhang, N.; Liao, J.; Su, L.; Wu, Y.; Gan, F.; Chang, G.; et al. Nanofiber Space-Confined Fabrication of High-Performance Perovskite Films for Flexible Conversion of Fluorescence Quantum Yields in LED Applications. Polymers 2024, 16, 2563. https://doi.org/10.3390/polym16182563

Yi N, Guan X, Chen X, Xie L, Zhang N, Liao J, Su L, Wu Y, Gan F, Chang G, et al. Nanofiber Space-Confined Fabrication of High-Performance Perovskite Films for Flexible Conversion of Fluorescence Quantum Yields in LED Applications. Polymers. 2024; 16(18):2563. https://doi.org/10.3390/polym16182563

Chicago/Turabian StyleYi, Ningbo, Xue Guan, Xiaoting Chen, Luojia Xie, Nan Zhang, Jinfeng Liao, Long Su, Yancheng Wu, Feng Gan, Guoqiang Chang, and et al. 2024. "Nanofiber Space-Confined Fabrication of High-Performance Perovskite Films for Flexible Conversion of Fluorescence Quantum Yields in LED Applications" Polymers 16, no. 18: 2563. https://doi.org/10.3390/polym16182563

APA StyleYi, N., Guan, X., Chen, X., Xie, L., Zhang, N., Liao, J., Su, L., Wu, Y., Gan, F., Chang, G., Tian, L., & Zhang, Y. (2024). Nanofiber Space-Confined Fabrication of High-Performance Perovskite Films for Flexible Conversion of Fluorescence Quantum Yields in LED Applications. Polymers, 16(18), 2563. https://doi.org/10.3390/polym16182563