Modulation of Mechanical Properties of Silica-Filled Silicone Rubber by Cross-Linked Network Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Gel Permeation Chromatography Characterization

2.3. Sample Preparation

2.4. Vulcanization Characteristic Testing

2.5. Cross-Link Density Testing

2.6. Mechanical Properties Testing

2.7. Friction Testing

2.8. Rubber Process Analysis

2.9. Scanning Electron Microscopy Testing

3. Results and Discussion

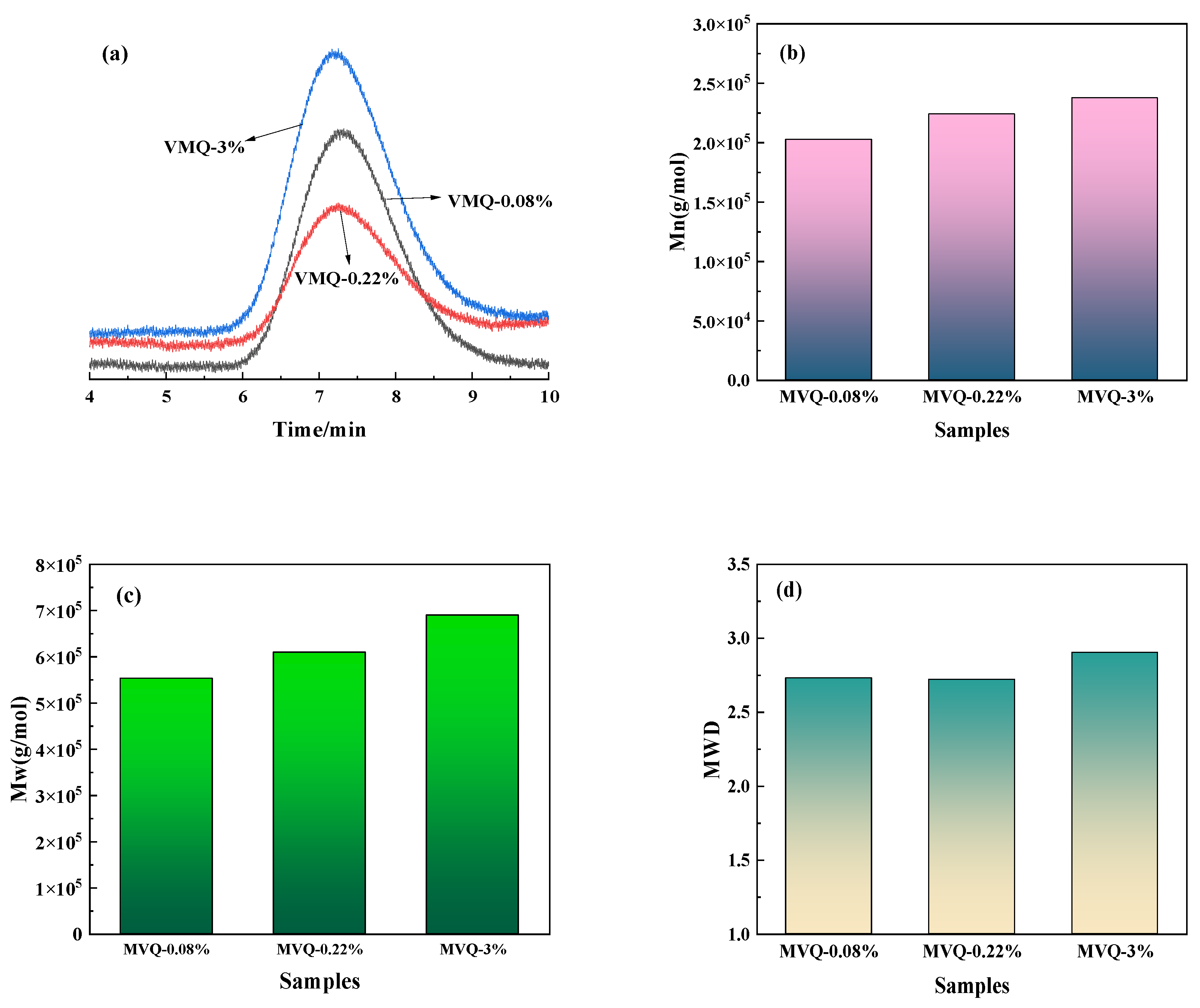

3.1. Molecular Weight and Molecular Weight Distribution

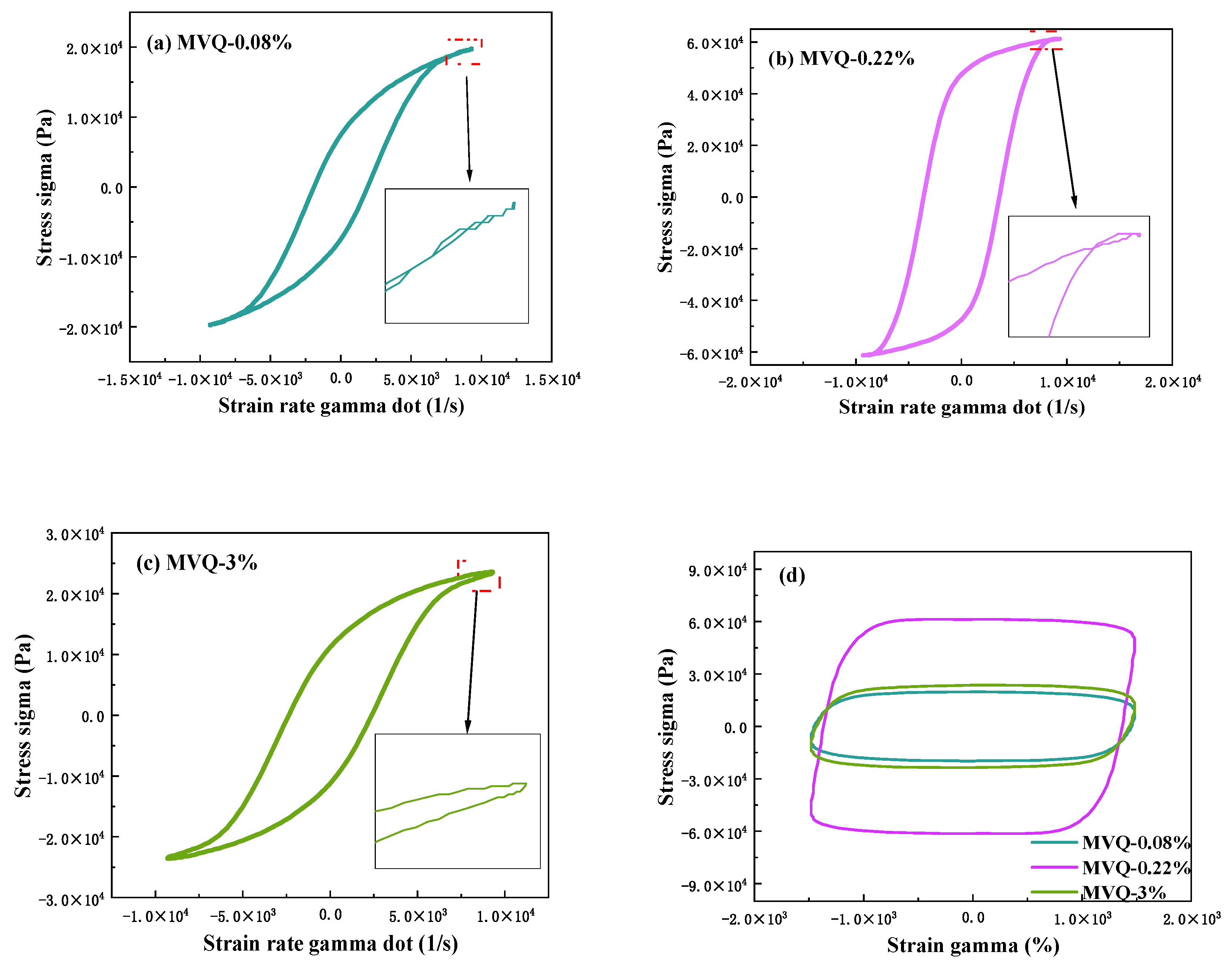

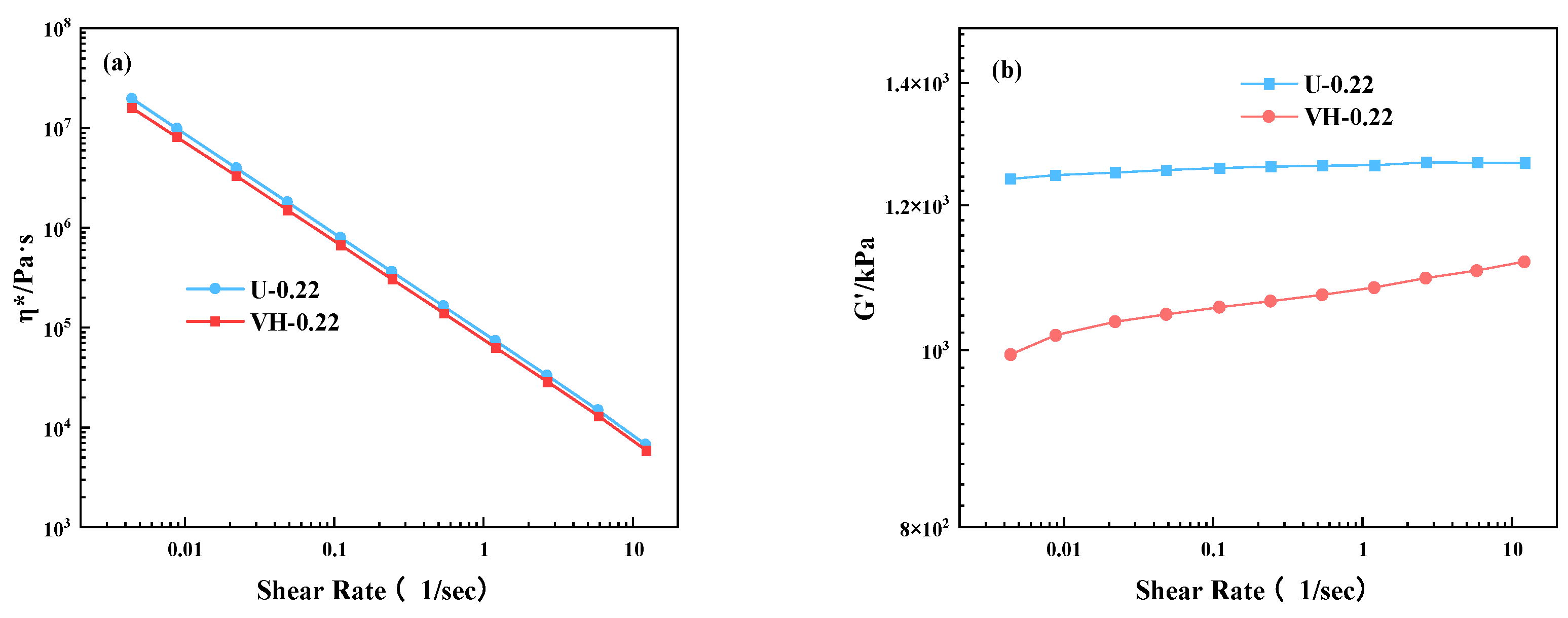

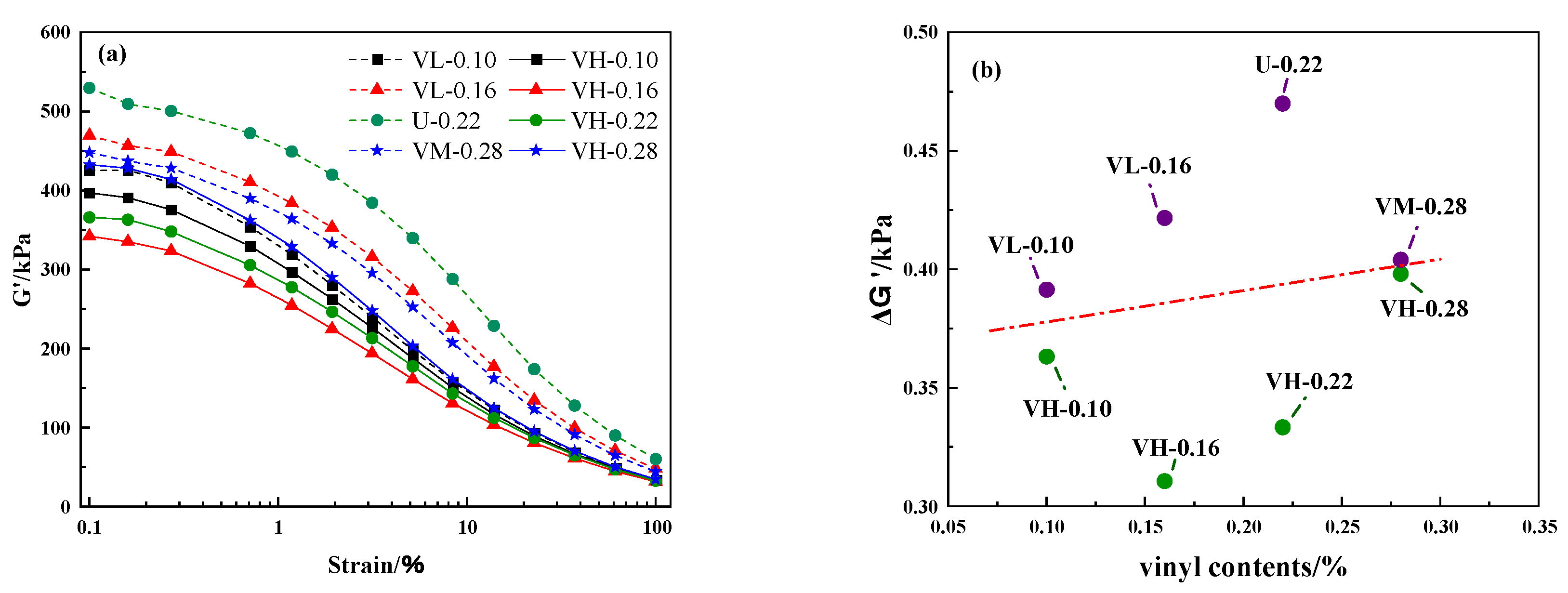

3.2. LAOS Analysis

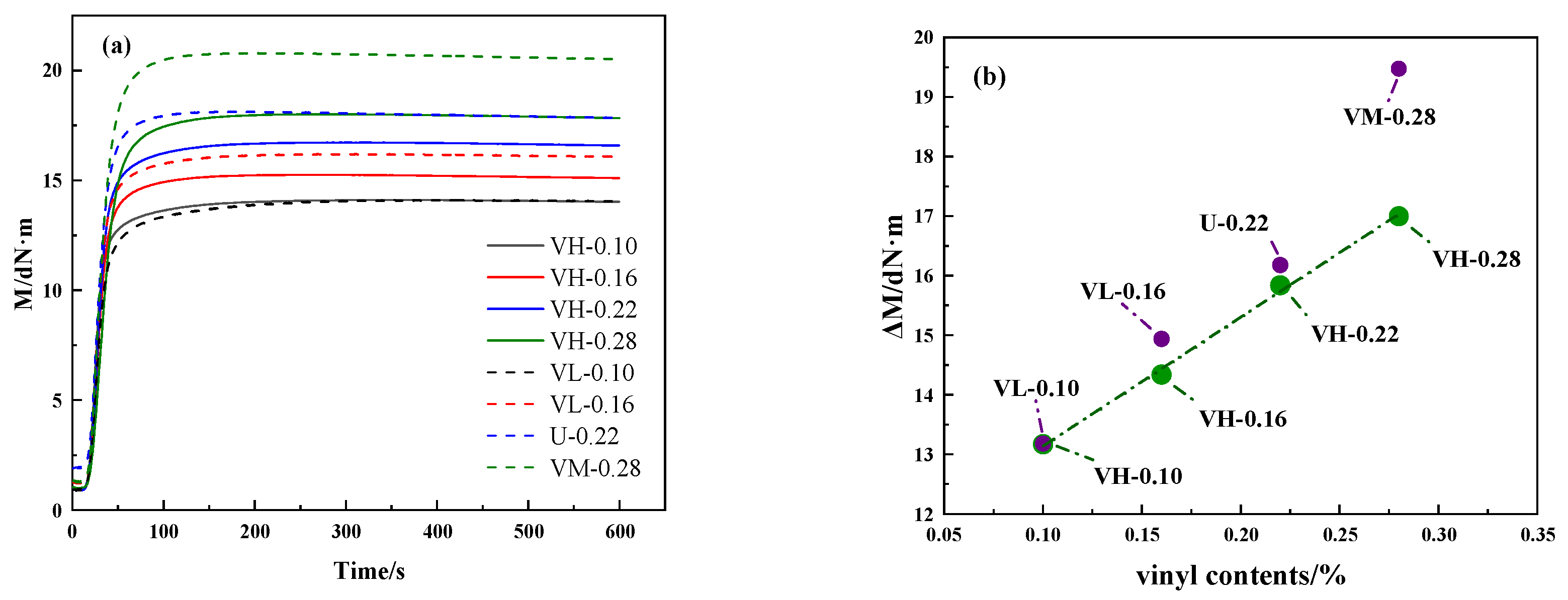

3.3. Vulcanization Properties

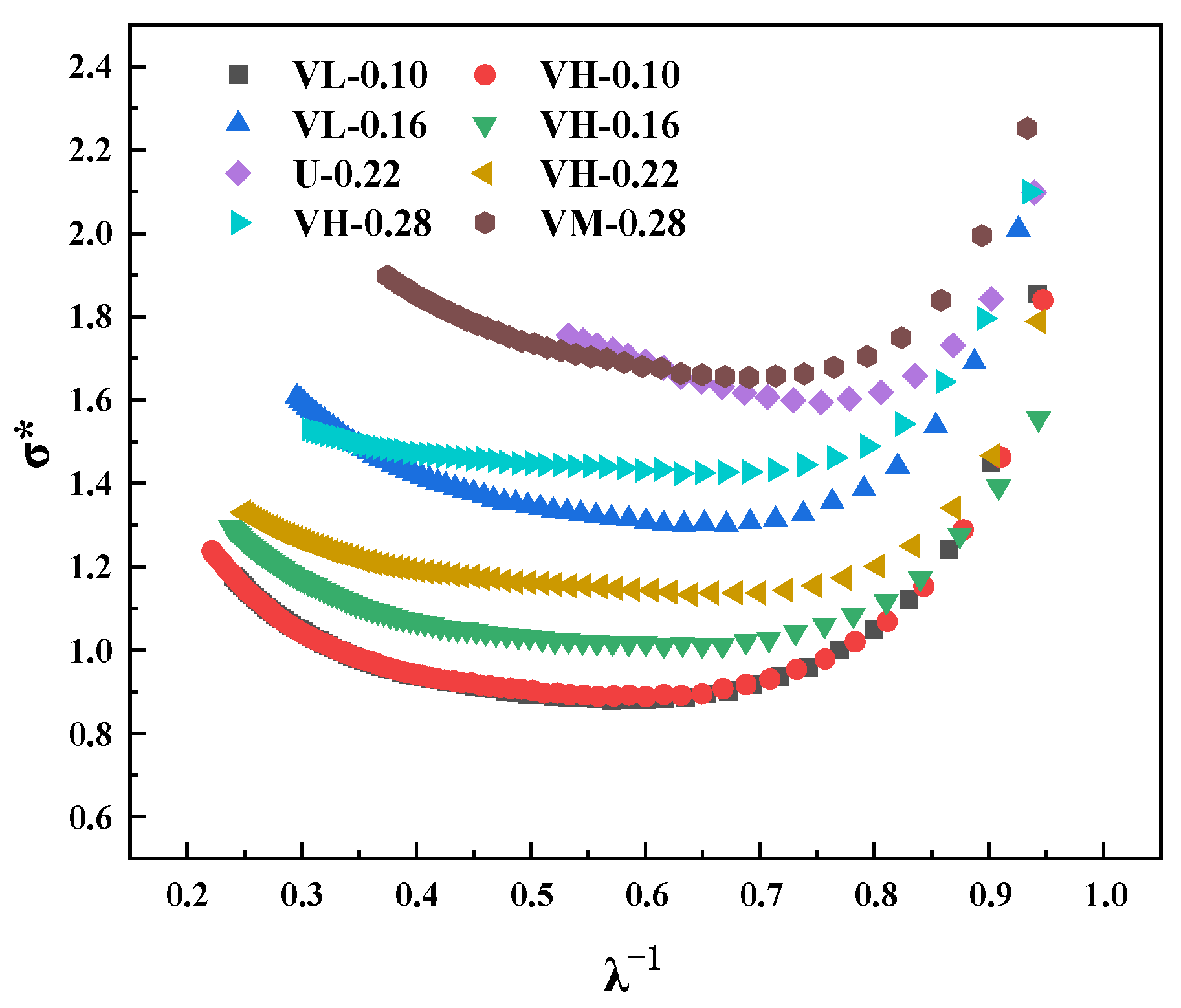

3.4. Network Structure Analysis

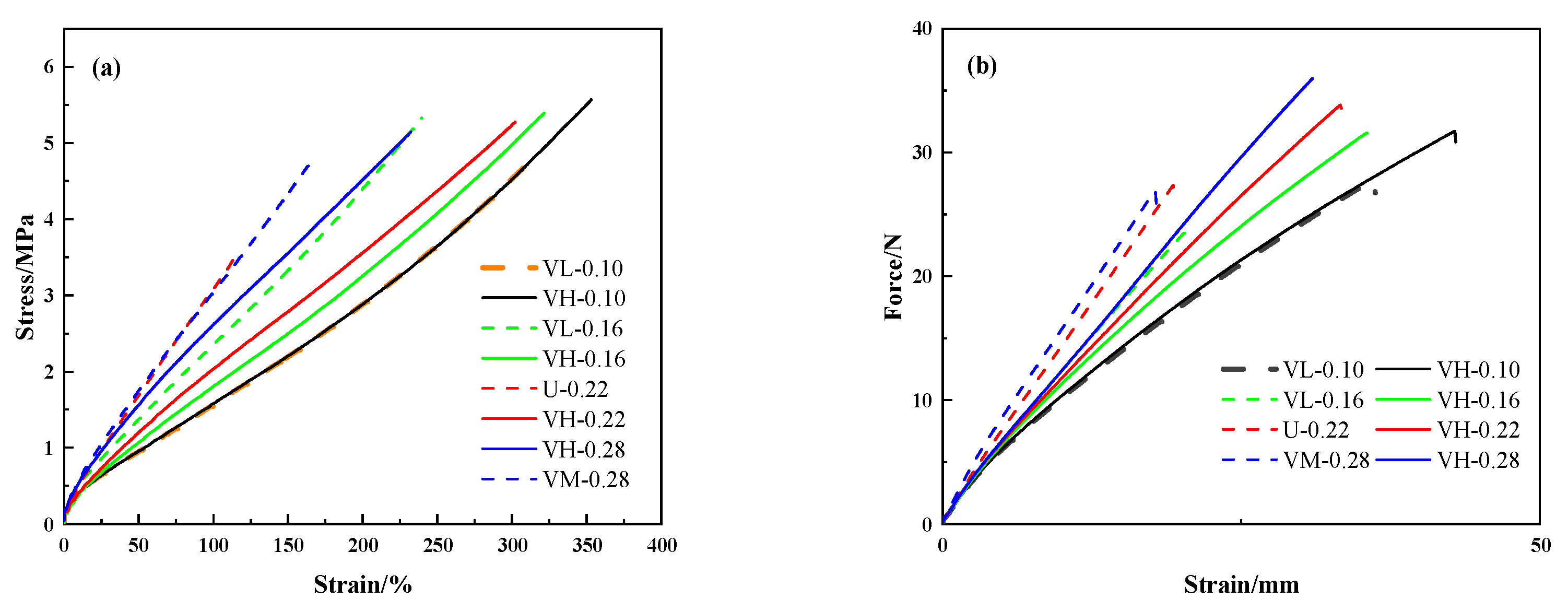

3.5. Mechanical Properties Analysis

3.6. Friction Properties Analysis

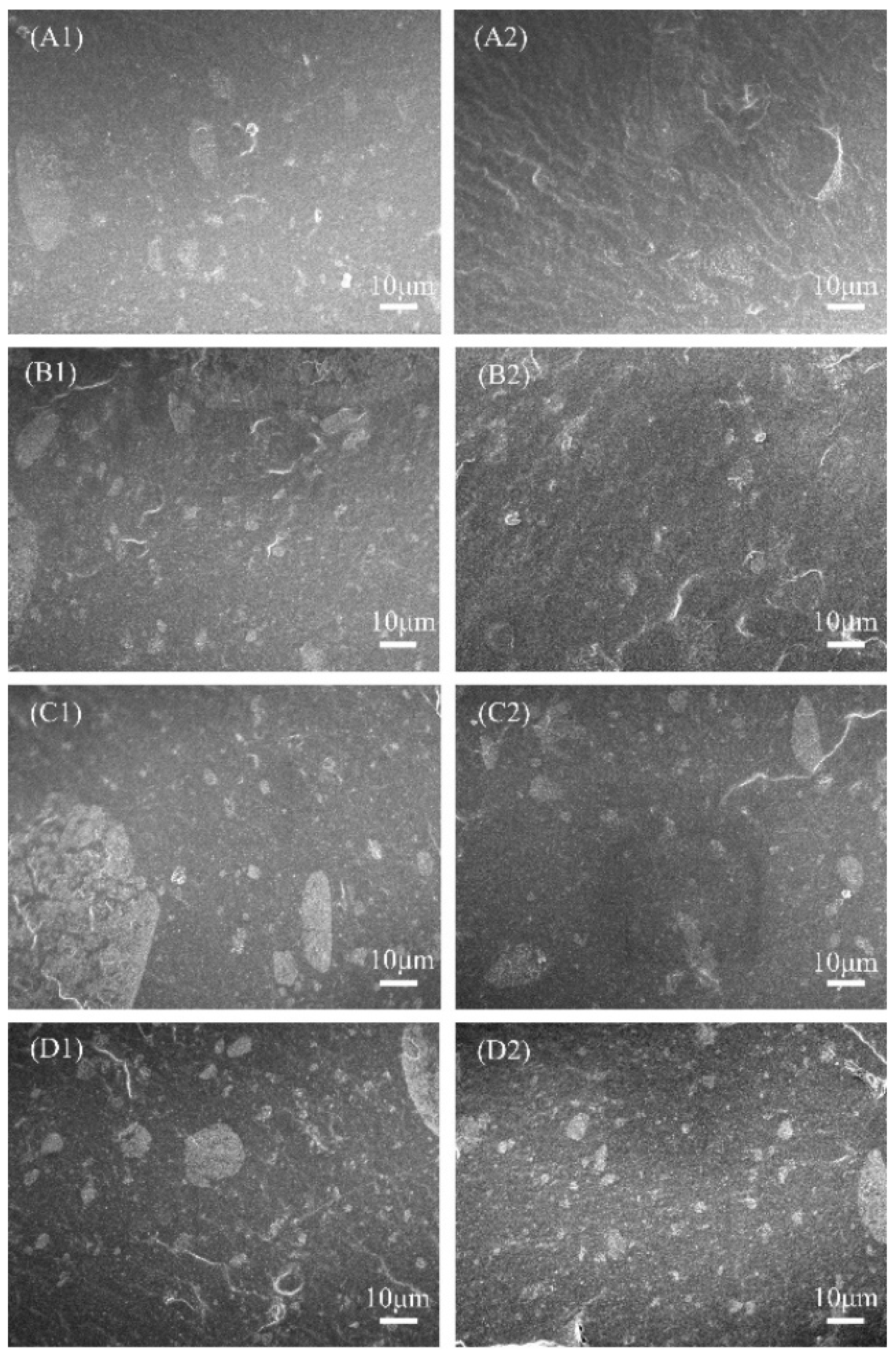

3.7. Filler Networks and Dispersion Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Feng, D.; Guan, H.; Guo, Y.; Liu, X.; Yan, C.; Zhang, L.; Gu, J. Highly efficient thermal conductivity of polydimethylsiloxane composites via introducing “Line-Plane”-like hetero-structured fillers. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106911. [Google Scholar] [CrossRef]

- Tang, W.; Liao, X.; Zhang, Y.; Li, J.; Wang, G.; Li, G. Mechanical–Microstructure Relationship and Cellular Failure Mechanism of Silicone Rubber Foam by the Cell Microstructure Designed in Supercritical CO2. J. Phys. Chem. C 2019, 123, 26947–26956. [Google Scholar] [CrossRef]

- Song, P.; Liu, B.; Liang, C.; Ruan, K.; Qiu, H.; Ma, Z.; Guo, Y.; Gu, J. Lightweight, Flexible Cellulose-Derived Carbon Aerogel@Reduced Graphene Oxide/PDMS Composites with Outstanding EMI Shielding Performances and Excellent Thermal Conductivities. Nano-Micro Lett. 2021, 13, 91. [Google Scholar] [CrossRef]

- Xu, Q.; Pang, M.; Zhu, L.; Zhang, Y.; Feng, S. Mechanical properties of silicone rubber composed of diverse vinyl content silicone gums blending. Mater. Des. 2010, 31, 4083–4087. [Google Scholar] [CrossRef]

- Huang, L.; Yu, F.; Liu, Y.; Lu, A.; Song, Z.; Liu, W.; Xiong, Y.; He, H.; Li, S.; Zhao, X.; et al. Understanding the Reinforcement Effect of Fumed Silica on Silicone Rubber: Bound Rubber and Its Entanglement Network. Macromolecules 2023, 56, 323–334. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.; Zhang, C.; Yang, W.; Qiao, B.; Yin, L. The Effect of Various Fillers on the Properties of Methyl Vinyl Silicone Rubber. Polymers 2023, 15, 1584. [Google Scholar] [CrossRef]

- Cao, K.; Li, B.; Jiao, Y.; Lu, Y.; Wang, L.; Guo, Y.; Dai, P. Enhancement of thermal and mechanical properties of silicone rubber with γ-ray irradiation-induced polysilane-modified graphene oxide/carbon nanotube hybrid fillers. RSC Adv. 2021, 11, 33354–33360. [Google Scholar] [CrossRef]

- Zhao, R.; Yin, Z.; Zou, W.; Yang, H.; Yan, J.; Zheng, W.; Li, H. Preparation of High-Strength and Excellent Compatibility Fluorine/Silicone Rubber Composites under the Synergistic Effect of Fillers. ACS Omega 2023, 8, 3905–3916. [Google Scholar] [CrossRef]

- Saville, B.; Watson, A.A. Structural Characterization of Sulfur-Vulcanized Rubber Networks. Rubber Chem. Technol. 1967, 40, 100–148. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the Crosslink Characteristics and Mechanical Properties of Natural Rubber Compound via Accelerators and Reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef]

- Huang, Y.-T.; Zhou, Y.; Yu, W.-W.; Liao, S.; Luo, M.-C. Nonprestretching double-network enabled by physical interaction-induced aggregation. Polymer 2022, 256, 125245. [Google Scholar] [CrossRef]

- Fukao, K.; Nakajima, T.; Nonoyama, T.; Kurokawa, T.; Kawai, T.; Gong, J.P. Effect of Relative Strength of Two Networks on the Internal Fracture Process of Double Network Hydrogels As Revealed by in Situ Small-Angle X-ray Scattering. Macromolecules 2020, 53, 1154–1163. [Google Scholar] [CrossRef]

- Gan, L.; Shang, S.; Jiang, S. Impact of vinyl concentration of a silicone rubber on the properties of the graphene oxide filled silicone rubber composites. Compos. Part B Eng. 2016, 84, 294–300. [Google Scholar] [CrossRef]

- Cai, J.-H.; Huang, M.-L.; Chen, X.-D.; Wang, M. Controllable construction of cross-linking network for regulating on the mechanical properties of polydimethylsiloxane and polydimethylsiloxane/carbon nanotubes composites. J. Appl. Polym. Sci. 2022, 139, 52113. [Google Scholar] [CrossRef]

- Genesky, G.D.; Aguilera-Mercado, B.M.; Bhawe, D.M.; Escobedo, F.A.; Cohen, C. Experiments and Simulations: Enhanced Mechanical Properties of End-Linked Bimodal Elastomers. Macromolecules 2008, 41, 8231–8241. [Google Scholar] [CrossRef]

- Wang, B.; Tang, W.; Zou, F.; Liu, S.; Li, G.; Liao, X. Foaming behavior regulation of silicone rubber via evolution of crosslinked structure. Sustain. Mater. Technol. 2023, 38, e00764. [Google Scholar] [CrossRef]

- Wei, W.; Zou, H.-W.; Liu, P.; Fan, P.; Xu, W. Mechanical properties and thermal conductivity of silicone rubber crosslinked through electron beam irradiation. Gaofenzi Cailiao Kexue Yu Gongcheng/Polym. Mater. Sci. Eng. 2008, 24, 113–115+120. [Google Scholar]

- Flory, P.J.; Rehner, J., Jr. Statistical Mechanics of Cross-Linked Polymer Networks II. Swelling. J. Chem. Phys. 1943, 11, 521–526. [Google Scholar] [CrossRef]

- Hajiali, F.; Shojaei, A. Network structure and mechanical properties of polydimethylsiloxane filled with nanodiamond—Effect of degree of silanization of nanodiamond. Compos. Sci. Technol. 2017, 142, 227–234. [Google Scholar] [CrossRef]

- ISO 37:2024; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 34-1:2022; Rubber, Vulcanized or Thermoplastic—Determination of Tear Strength. International Organization for Standardization: Geneva, Switzerland, 2022.

- ASTM D 2240-2005; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2005.

- Das, C.; Li, W.; Read, D.J.; Soulages, J.M. Coupled models for polymer synthesis and rheology to determine branching architectures and predict flow properties. Rheol. Acta 2019, 58, 159–172. [Google Scholar] [CrossRef]

- Pole, S.S.; Isayev, A.I. Correlations in rheological behavior between large amplitude oscillatory shear and steady shear flow of silica-filled star-shaped styrene-butadiene rubber compounds: Experiment and simulation. J. Appl. Polym. Sci. 2021, 138, 50660. [Google Scholar] [CrossRef]

- Hirayama, S.; Kurokawa, T.; Gong, J.P. Non-linear rheological study of hydrogel sliding friction in water and concentrated hyaluronan solution. Tribol. Int. 2020, 147, 106270. [Google Scholar] [CrossRef]

- Suárez, I.; Coto, B. GPC-VIS-MALS study of EVA copolymers: Quantification and interactions of SCB and LCB. Polym. Test. 2016, 52, 265–271. [Google Scholar] [CrossRef]

- Mooney, M. A Theory of Large Elastic Deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Rivlin, R.S.; Taylor, G.I. Large elastic deformations of isotropic materials. I. Fundamental concepts. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1997, 240, 459–490. [Google Scholar] [CrossRef]

- Fukahori, Y. New progress in the theory and model of carbon black reinforcement of elastomers. J. Appl. Polym. Sci. 2005, 95, 60–67. [Google Scholar] [CrossRef]

- James, H.M.; Guth, E. Theory of the Elastic Properties of Rubber. J. Chem. Phys. 1943, 11, 455–481. [Google Scholar] [CrossRef]

- Yoo, S.H.; Cohen, C.; Hui, C.-Y. Mechanical and swelling properties of PDMS interpenetrating polymer networks. Polymer 2006, 47, 6226–6235. [Google Scholar] [CrossRef]

- Şerbescu, A.; Saalwächter, K. Particle-induced network formation in linear PDMS filled with silica. Polymer 2009, 50, 5434–5442. [Google Scholar] [CrossRef]

- Feng, L.; Li, S.; Feng, S. Preparation and characterization of silicone rubber with high modulus via tension spring-type crosslinking. RSC Adv. 2017, 7, 13130–13137. [Google Scholar] [CrossRef]

- Deam, R.T.; Edwards, S.F. The theory of rubber elasticity. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1997, 280, 317–353. [Google Scholar] [CrossRef]

- Boyce, M.C.; Arruda, E.M. Constitutive Models of Rubber Elasticity: A Review. Rubber Chem. Technol. 2000, 73, 504–523. [Google Scholar] [CrossRef]

- Miehe, C.; Göktepe, S.; Lulei, F. A micro-macro approach to rubber-like materials—Part I: The non-affine micro-sphere model of rubber elasticity. J. Mech. Phys. Solids 2004, 52, 2617–2660. [Google Scholar] [CrossRef]

- Chen, G.; Wang, B.; Lin, H.; Peng, W.; Zhang, F.; Li, G.; Ke, D.; Liao, J.; Liao, L. Effect of Nonisoprene Degradation and Naturally Occurring Network during Maturation on the Properties of Natural Rubber. Polymers 2022, 14, 2180. [Google Scholar] [CrossRef]

- Al-Assi, M.; Kassem, E. Evaluation of Adhesion and Hysteresis Friction of Rubber–Pavement System. Appl. Sci. 2017, 7, 1029. [Google Scholar] [CrossRef]

- Klaassen, M.; de Vries, E.G.; Masen, M.A. Friction in the contact between skin and a soft counter material: Effects of hardness and surface finish. J. Mech. Behav. Biomed. Mater. 2019, 92, 137–143. [Google Scholar] [CrossRef]

- Chu, H.Z.; Liu, D.; Cui, Z.W.; Wang, K.; Qiu, G.X.; Liu, G.Y. Effect of crosslink density on solubility parameters of styrene butadiene rubber and the application in pre-screening of new potential additives. Polym. Test. 2020, 81, 106253. [Google Scholar] [CrossRef]

- Marzocca, A.J.; Cerveny, S.; Raimondo, R.B. Analysis of the variation of molecular parameters of NR during vulcanization in the frame of the conformational tube model. J. Appl. Polym. Sci. 1997, 66, 1085–1092. [Google Scholar] [CrossRef]

- Xu, H.; Song, Y.; Zhang, Q.; Zheng, Q. Contributions of silica network and interfacial fraction in reinforcement and Payne effect of polypropylene glycol nanocomposites. Polymer 2018, 138, 139–145. [Google Scholar] [CrossRef]

- Hou, F.; Song, Y.; Zheng, Q. Payne effect of thermo-oxidatively aged isoprene rubber vulcanizates. Polymer 2020, 195, 122432. [Google Scholar] [CrossRef]

- Han, Q.; Zhang, L.; Wu, Y. Relationship between dynamic fatigue crack propagation properties and viscoelasticity of natural rubber/silicone rubber composites. RSC Adv. 2019, 9, 29813–29820. [Google Scholar] [CrossRef] [PubMed]

| Samples | Different Vinyl Contents | |||

|---|---|---|---|---|

| MVQ-0.08%/phr | MVQ-0.22%/phr | MVQ-3%/phr | Total | |

| VL-0.10 | 85.7 | 14.3 | 0.10 | |

| VH-0.10 | 99.3 | 0.7 | 0.10 | |

| VL-0.16 | 42.8 | 57.2 | 0.16 | |

| VH-0.16 | 97.2 | 2.8 | 0.16 | |

| U-0.22 | 100 | 0.22 | ||

| VH-0.22 | 95.2 | 4.8 | 0.22 | |

| VH-0.28 | 93.2 | 6.8 | 0.28 | |

| VM-0.28 | 97.8 | 2.2 | 0.28 | |

| Samples | LCB Indexes | Lissajous Curves |

|---|---|---|

| VMQ-0.08% | −0.37 | Secondary double rings |

| VMQ-0.22% | −0.05 | Secondary double rings |

| VMQ-3% | 0.19 | No secondary double rings |

| Samples | υc × 10−4 (mol·cm−3) (Swelling) | υc × 10−4 (mol·cm−3) (Mooney–Rivlin) |

|---|---|---|

| VL-0.10 | 3.562 | 0.692 |

| VH-0.10 | 3.473 | 0.408 |

| VL-0.16 | 4.779 | 1.712 |

| VH-0.16 | 4.154 | 1.291 |

| U-0.22 | 6.106 | 2.409 |

| VH-0.22 | 5.015 | 1.735 |

| VM-0.28 | 6.468 | 2.561 |

| VH-0.28 | 5.848 | 2.059 |

| Samples | Tensile Strength (MPa) | Tearing Strength (kN/mm) | Elongation at Break (%) | Hardness |

|---|---|---|---|---|

| VL-0.10 | 4.881 | 14.06 | 319.83 | 54 |

| VH-0.10 | 5.568 | 15.91 | 353.23 | 52 |

| VL-0.16 | 5.329 | 14.33 | 239.67 | 60 |

| VH-0.16 | 5.393 | 16.04 | 321.79 | 56 |

| U-0.22 | 3.536 | 12.76 | 115.14 | 64 |

| VH-0.22 | 5.277 | 17.05 | 302.53 | 59 |

| VM-0.28 | 4.839 | 13.12 | 168.35 | 65 |

| VH-0.28 | 5.144 | 18.34 | 232.34 | 62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Yong, Z. Modulation of Mechanical Properties of Silica-Filled Silicone Rubber by Cross-Linked Network Structure. Polymers 2024, 16, 2304. https://doi.org/10.3390/polym16162304

Jiang S, Yong Z. Modulation of Mechanical Properties of Silica-Filled Silicone Rubber by Cross-Linked Network Structure. Polymers. 2024; 16(16):2304. https://doi.org/10.3390/polym16162304

Chicago/Turabian StyleJiang, Shuangyan, and Zhanfu Yong. 2024. "Modulation of Mechanical Properties of Silica-Filled Silicone Rubber by Cross-Linked Network Structure" Polymers 16, no. 16: 2304. https://doi.org/10.3390/polym16162304

APA StyleJiang, S., & Yong, Z. (2024). Modulation of Mechanical Properties of Silica-Filled Silicone Rubber by Cross-Linked Network Structure. Polymers, 16(16), 2304. https://doi.org/10.3390/polym16162304