Electromagnetic Interference (EMI) Shielding and Thermal Management of Sandwich-Structured Carbon Fiber-Reinforced Composite (CFRC) for Electric Vehicle Battery Casings

Abstract

1. Introduction

2. Experiment

2.1. Materials

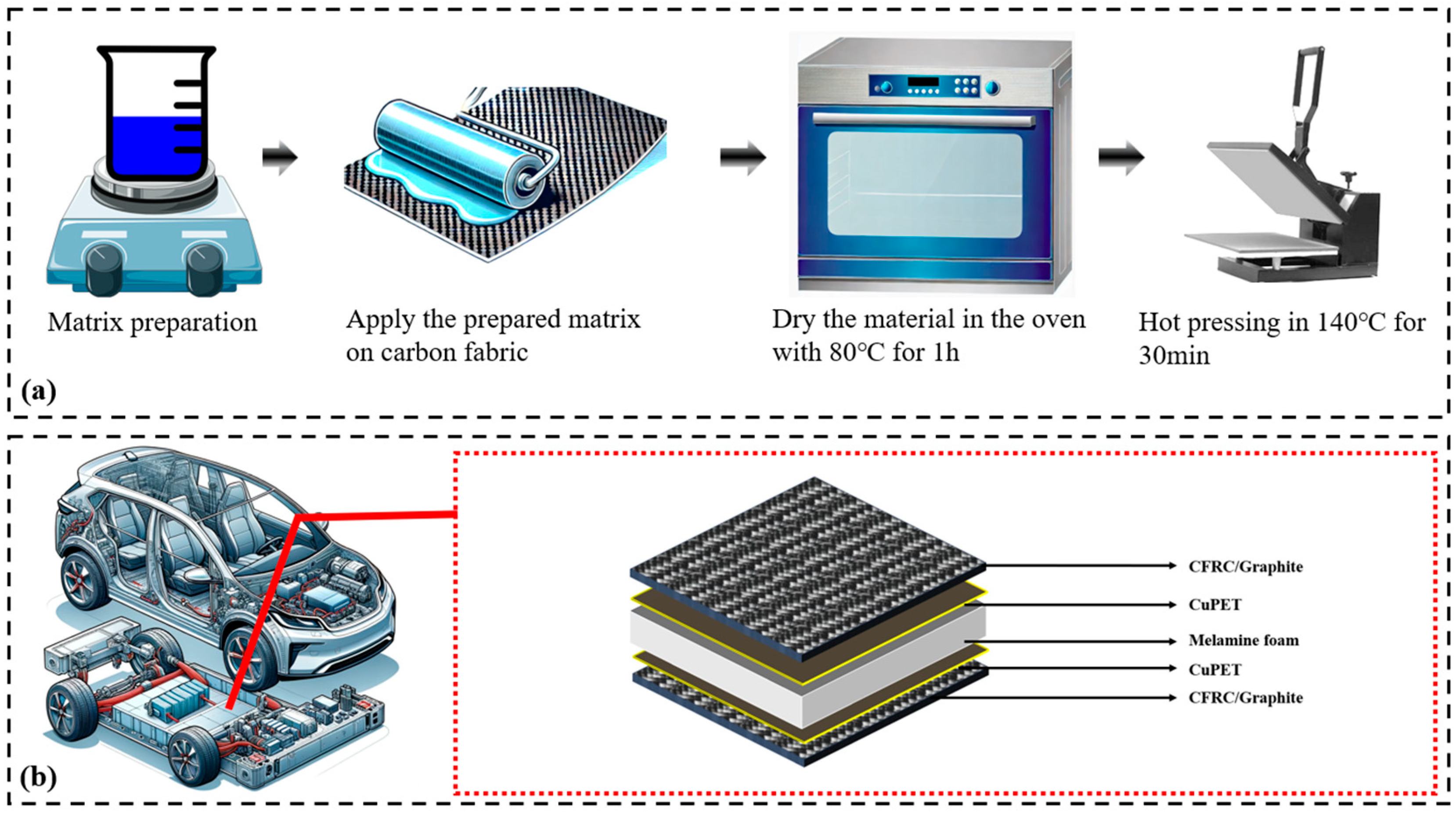

2.2. Fabrication of the Composites

3. Methods

3.1. Density

3.2. EMI Shielding

3.3. Thermal Properties

3.4. DMA 3-Points Bending Testing

3.5. Tensile Strength Test

3.6. Joule Heating Test

4. Results and Discussion

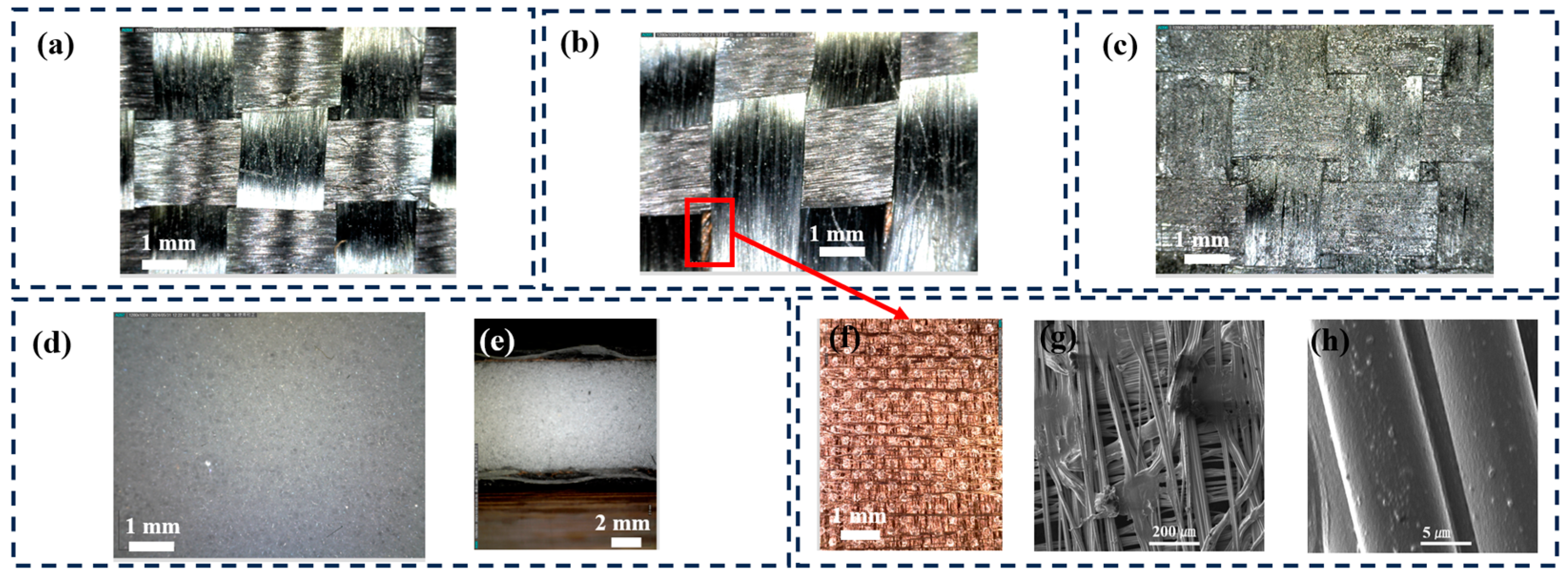

4.1. Basic Physical and Morphology Characterization

4.2. Mechanical Properties

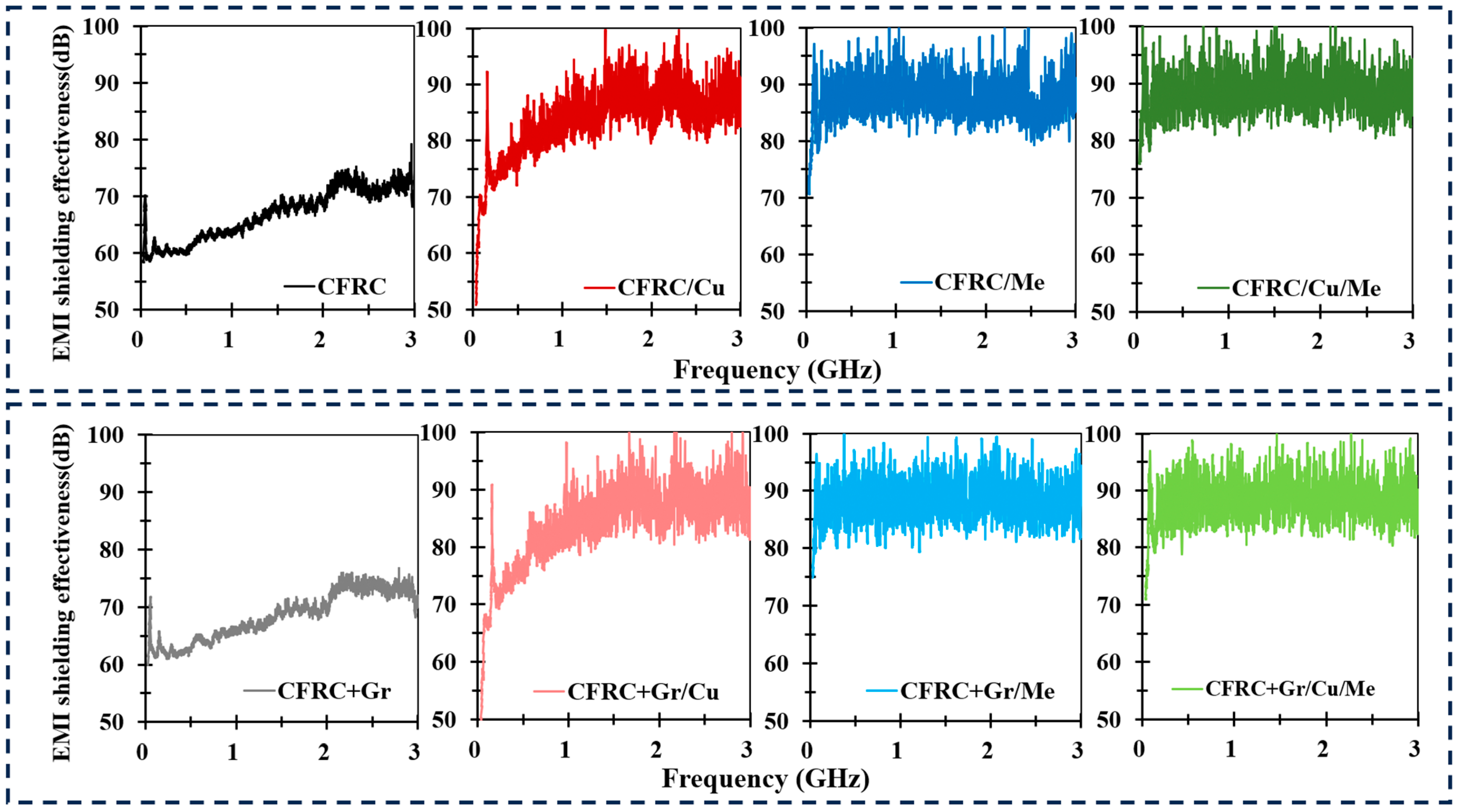

4.3. EMI Shielding Performance

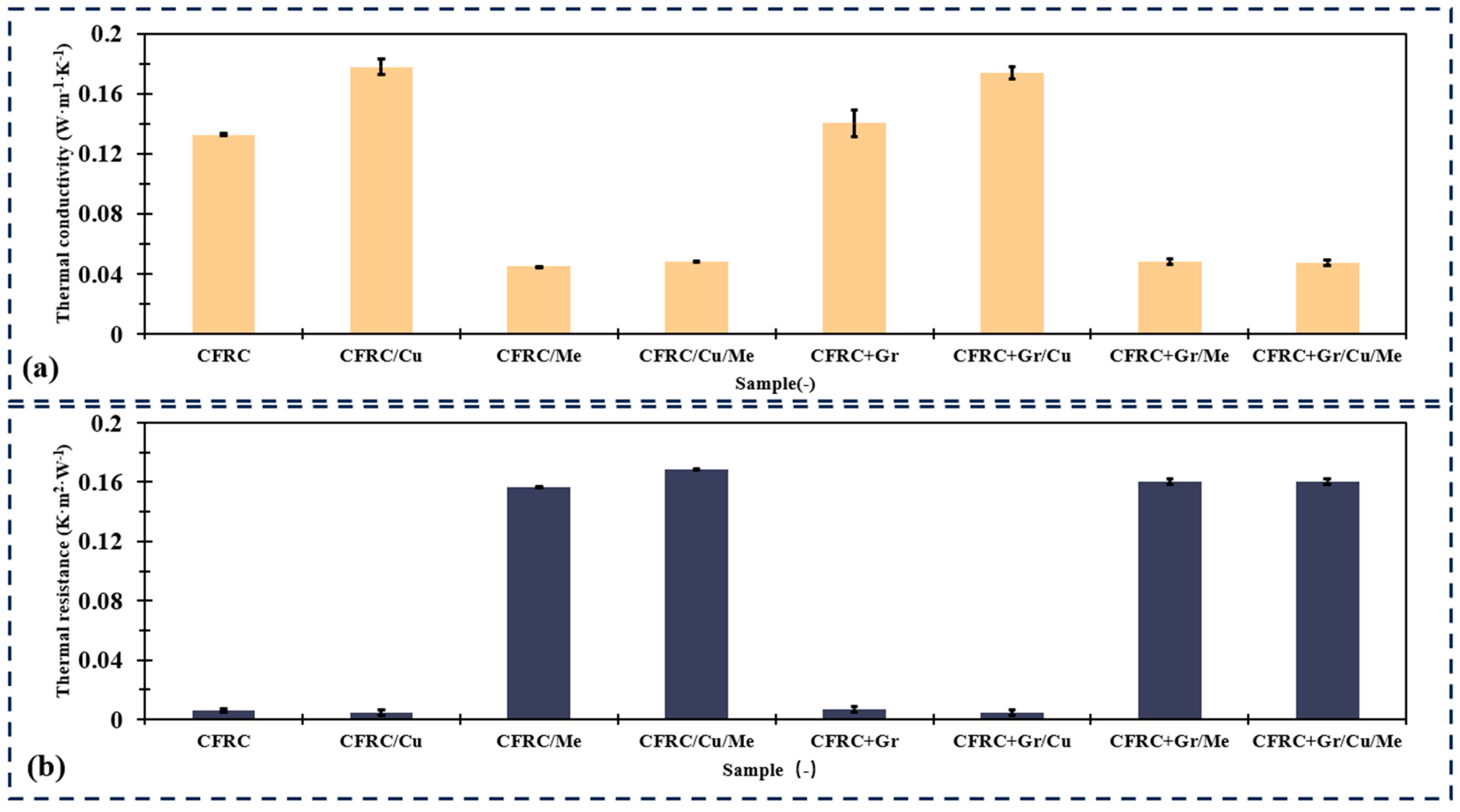

4.4. Thermal Conductivity and Resistance

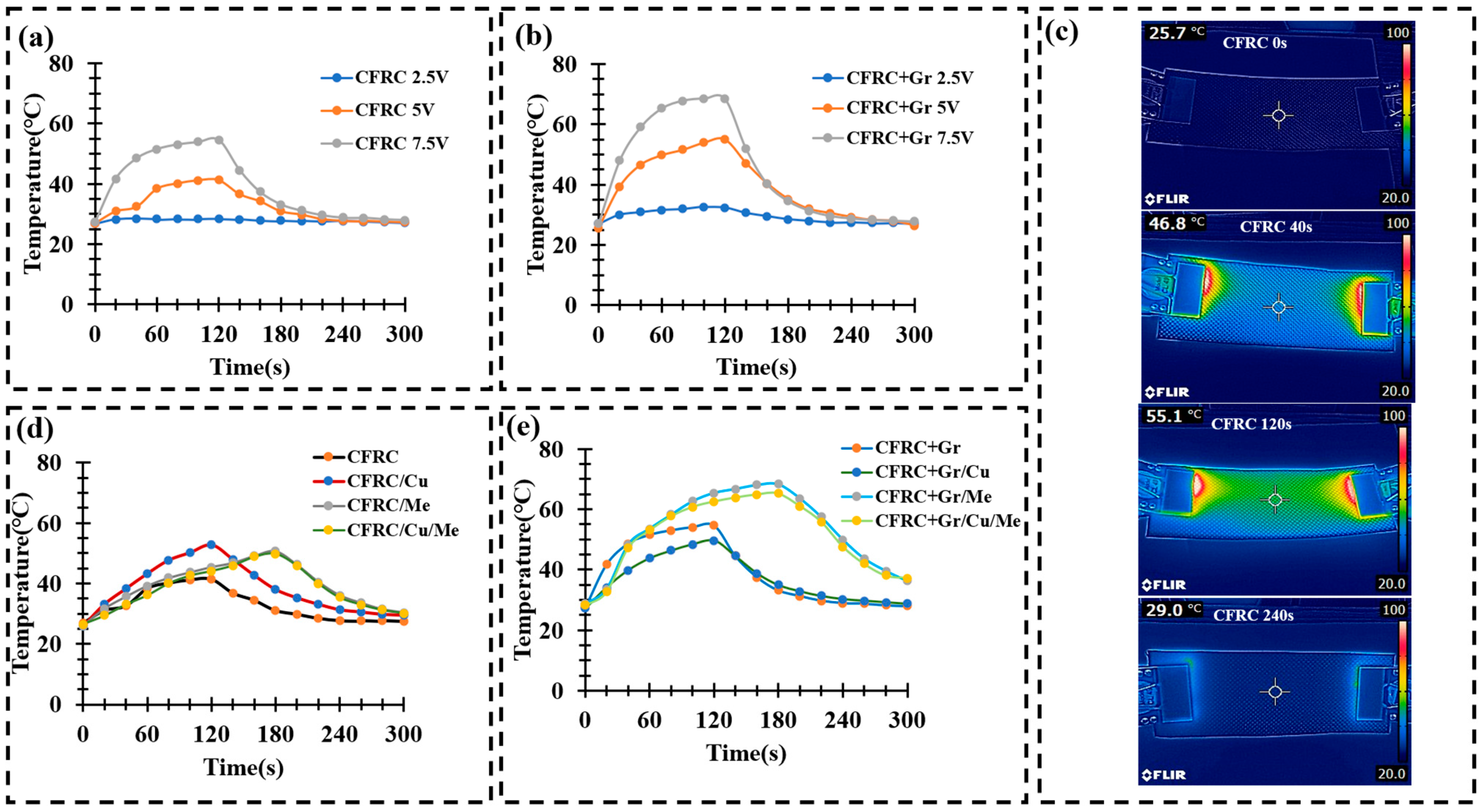

4.5. Joule Heating Material

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goswami, M.; Kumar, S.; Siddiqui, H.; Chauhan, V.; Singh, N.; Sathish, N.; Ashiq, M.; Kumar, S. 22—Electric Vehicles: A Step toward Sustainability. In Emerging Trends in Energy Storage Systems and Industrial Applications; Prabhansu, Kumar, N., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 619–640. ISBN 978-0-323-90521-3. [Google Scholar]

- Gupta, P.; Toksha, B.; Patel, B.; Rushiya, Y.; Das, P.; Rahaman, M. Recent Developments and Research Avenues for Polymers in Electric Vehicles. Chem. Rec. 2022, 22, e202200186. [Google Scholar] [CrossRef] [PubMed]

- Maske, P.; Chel, P.A.; Goyal, P.K.; Kaushik, D.G. Sustainable Perspective of Electric Vehicles and Its Future Prospects. J. Sustain. Mater. Process. Manag. 2021, 1, 17–32. [Google Scholar] [CrossRef]

- Kumar, P.; Srivastava, K.N.; Dhar, A. Role of Electric Vehicles in Future Road Transport. In Sustainable Energy and Transportation: Technologies and Policy; Gautam, A., De, S., Dhar, A., Gupta, J.G., Pandey, A., Eds.; Energy, Environment, and Sustainability; Springer: Singapore, 2018; pp. 43–60. ISBN 978-981-10-7509-4. [Google Scholar]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A Comprehensive Study of Key Electric Vehicle (EV) Components, Technologies, Challenges, Impacts, and Future Direction of Development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Van Mierlo, J.; Berecibar, M.; El Baghdadi, M.; De Cauwer, C.; Messagie, M.; Coosemans, T.; Jacobs, V.A.; Hegazy, O. Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electr. Veh. J. 2021, 12, 20. [Google Scholar] [CrossRef]

- Rizzoni, G.; Ahmed, Q.; Arasu, M.; Oruganti, P.S. Transformational Technologies Reshaping Transportation—An Academia Perspective; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Buckingham, R.; Asset, T.; Atanassov, P. Aluminum-Air Batteries: A Review of Alloys, Electrolytes and Design. J. Power Sources 2021, 498, 229762. [Google Scholar] [CrossRef]

- Sadeghian, A.; Iqbal, N. A Review on Dissimilar Laser Welding of Steel-Copper, Steel-Aluminum, Aluminum-Copper, and Steel-Nickel for Electric Vehicle Battery Manufacturing. Opt. Laser Technol. 2022, 146, 107595. [Google Scholar] [CrossRef]

- Sun, G.; Jia, C.; Zhang, J.; Yang, W.; Ma, Z.; Shao, G.; Qin, X. Effectively Enhance High Voltage Stability of LiNi1/3Co1/3Mn1/3O2 Cathode Material with Excellent Energy Density via La2O3 Surface Modified. Ionics 2019, 25, 2007–2016. [Google Scholar] [CrossRef]

- Cherat, N.; Rijnkels, M.; Godthi, V.; Sharma, H.; P, A.; Bobba, S. Thermoplastic Solution for Electric Vehicle Battery Protection; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- Choi, C.-H.; Cho, J.-M.; Kil, Y.; Yoon, Y. Development of Polymer Composite Battery Pack Case for an Electric Vehicle; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Lim, G.J.H.; Chan, K.K.; Sutrisnoh, N.A.A.; Srinivasan, M. Design of Structural Batteries: Carbon Fibers and Alternative Form Factors. Mater. Today Sustain. 2022, 20, 100252. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; Tunáková, V.; Niamlang, S.; Chvojka, J.; Venkataraman, M.; Militký, J.; Khan, M.Z.; Ali, A. Carbon Felt from Acrylic Dust Bags as Flexible EMI Shielding Layer and Resistive Heater. J. Mater. Res. Technol. 2024, 28, 4417–4427. [Google Scholar] [CrossRef]

- Sayam, A.; Rahman, A.N.M.M.; Rahman, M.S.; Smriti, S.A.; Ahmed, F.; Rabbi, M.F.; Hossain, M.; Faruque, M.O. A Review on Carbon Fiber-Reinforced Hierarchical Composites: Mechanical Performance, Manufacturing Process, Structural Applications and Allied Challenges. Carbon Lett. 2022, 32, 1173–1205. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Venkataraman, M.; Křemenáková, D.; Militký, J.; Yang, K.; Wang, Y.; Palanisamy, S. Enhanced Electromagnetic Shielding of Lightweight Copper-Coated Nonwoven Laminate with Carbon Filament Reinforcement. J. Eng. Fibers Fabr. 2023, 18, 15589250231199970. [Google Scholar] [CrossRef]

- Silva, F.; Aragón, M. Electromagnetic Interferences from Electric/Hybrid Vehicles. In Proceedings of the 2011 XXXth URSI General Assembly and Scientific Symposium, Istanbul, Turkey, 13–20 August 2011; pp. 1–4. [Google Scholar]

- Wang, D.; Hu, S.; Vecernik, J.; Kremenakova, D.; Militky, J.; Novotna, J. Impact of Different Matrix Systems on Mechanical, Thermal, and Electrical Properties of Carbon Fiber Reinforced Epoxy Resin Matrix Composites. Polym. Compos. 2024. early view. [Google Scholar] [CrossRef]

- Santhosh, M.S.; Sasikumar, R.; Natarajan, E. E-Glass/Phenolic Matrix/APP Laminate as a Potential Candidate for Battery Casing of e-Vehicle—Experimental Investigations. Mater. Res. Express 2021, 8, 045310. [Google Scholar] [CrossRef]

- Malik, M.; Dincer, I.; Rosen, M.A. Review on Use of Phase Change Materials in Battery Thermal Management for Electric and Hybrid Electric Vehicles. Int. J. Energy Res. 2016, 40, 1011–1031. [Google Scholar] [CrossRef]

- Gryz, K.; Karpowicz, J.; Zradziński, P. Complex Electromagnetic Issues Associated with the Use of Electric Vehicles in Urban Transportation. Sensors 2022, 22, 1719. [Google Scholar] [CrossRef]

- Moreno-Torres, P.; Lafoz, M.; Blanco, M.; R.Arribas, J.; Moreno-Torres, P.; Lafoz, M.; Blanco, M.; Arribas, J.R. Passenger Exposure to Magnetic Fields in Electric Vehicles. In Modeling and Simulation for Electric Vehicle Applications; IntechOpen: London, UK, 2016; ISBN 978-953-51-2637-9. [Google Scholar]

- Aiello, O. Electromagnetic Susceptibility of Battery Management Systems’ ICs for Electric Vehicles: Experimental Study. Electronics 2020, 9, 510. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S. A Review of Power Battery Thermal Energy Management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A Critical Review of Battery Thermal Performance and Liquid Based Battery Thermal Management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. A Review on Thermal Management of Lithium-Ion Batteries for Electric Vehicles. Energy 2022, 238, 121652. [Google Scholar] [CrossRef]

- Jaguemont, J.; Van Mierlo, J. A Comprehensive Review of Future Thermal Management Systems for Battery-Electrified Vehicles. J. Energy Storage 2020, 31, 101551. [Google Scholar] [CrossRef]

- ASTM D1895-17; Standard Test Methods for Apparent Density, Bulk Factor, and Pourability of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/d1895-17.html (accessed on 31 August 2022).

- ASTM International D09.12 ASTM D 4935-18; Standard Test Method for Measuring the Electromagnetic Shielding Effectiveness of Planar Materials. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ISO 11092:2014; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hotplate Test). ISO Technical Committee: Geneva, Switzerland, 2014.

- D30.04 ASTM D3039M-17; Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International Standard: West Conshohocken, PA, USA, 2017.

- Tan, C.; Said, M.R.; Chen, W. The Tensile Strength Effects on Precipitation Heat Treatment of 6061-T6 Aluminum Alloy. In Proceedings of the ASME 2009 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, San Diego, CA, USA, 30 August–2 September 2009; pp. 839–845. [Google Scholar]

- Pei, H.-W.; Zhang, S.-G.; Guo, H.-M.; He, W.; Liu, X.-B. Forming and Properties of 7075 Aluminum Alloy by Rheological Squeeze Casting with Transverse Mobile Injection Feed. Int. J. Adv. Manuf. Technol. 2022, 119, 7969–7981. [Google Scholar] [CrossRef]

- Maraveas, C.; Fasoulakis, Z.C.; Tsavdaridis, K.D. Mechanical Properties of High and Very High Steel at Elevated Temperatures and after Cooling Down. Fire Sci. Rev. 2017, 6, 3. [Google Scholar] [CrossRef]

- Tian, J.; Jiang, Z. Exploring New Strategies for Ultrahigh Strength Steel via Tailoring the Precipitates. Front. Mater. 2021, 8, 797798. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Lv, X. Simulation Study on the Influence of the Shielding Mechanism of the Battery Pack Shell on the Vehicle Radiation Emission; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Mariscotti, A. Harmonic and Supraharmonic Emissions of Plug-In Electric Vehicle Chargers. Smart Cities 2022, 5, 496–521. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S.; Colicelli, A. Overview on Battery Charging Systems for Electric Vehicles. Electronics 2023, 12, 4295. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Křemenáková, D.; Militký, J. Washable and Breathable Ultrathin Copper-Coated Nonwoven Polyethylene Terephthalate (PET) Fabric with Chlorinated Poly-Para-Xylylene (Parylene-C) Encapsulation for Electromagnetic Interference Shielding Application. Text. Res. J. 2023, 93, 3982–3998. [Google Scholar] [CrossRef]

- Wang, D.; Hu, S.; Kremenakova, D.; Militky, J. The Electromagnetic Shielding Effectiveness of the Copper Plated Nonwoven Fabric and Its’ Related Comfort Properties. J. Eng. Fibers Fabr. 2022, 17, 15589250221133462. [Google Scholar] [CrossRef]

- Wang, D.; Hu, S.; Kremenakova, D.; Militky, J. Evaluation of the Wearing Comfort Properties for Winter Used Electromagnetic Interference Shielding Sandwich Materials. J. Ind. Text. 2023, 53, 15280837231159869. [Google Scholar] [CrossRef]

| Greige Sample | Structure | GSM (g/m2) | Thickness (mm) | Density (g/cm3) | Supplier |

|---|---|---|---|---|---|

| Carbon fabric (CF) | Plain weave carbon | 245 | 0.428 | 0.53 | Havel composite |

| Meftex 30 (CuPET) | Nonwoven Cu coated PET fabric | 34.88 | 0.135 | 0.25 | Bochemie |

| Basotect (Melamine) | Melamine foam | 68.87 | 5.94 | 0.01 | BASF |

| Graphite particle | Particle size < 45 μm | - | - | 8.94 | Sigma Aldrich |

| Sample Code. | Description | Structure | GSM (g/m2) | Thickness (mm) | Density (g/cm3) |

|---|---|---|---|---|---|

| CFRC | Carbon fiber-reinforced composite | Two layers | 613.15 | 0.8 ± 0.08 | 0.76 |

| CFRC/Cu | Carbon composite with Cu-coated PET as the center layer | Sandwich structure | 717.89 | 0.77 ± 0.1 | 0.92 |

| CFRC/Me | Carbon composite with melamine foam as the center layer | Sandwich structure | 787.57 | 7.02 ± 0.2 | 0.1 |

| CFRC/Cu/Me | Carbon composite integrated with Cu-coated PET and melamine foam in the center | Sandwich structure | 828.83 | 8.1 ± 1.2 | 0.11 |

| CFRC+Gr | Carbon fiber-reinforced composite with a graphite particles-mixed matrix | Two layers | 651.24 | 0.98 ± 0.1 | 0.67 |

| CFRC+Gr/Cu | Carbon fiber-reinforced composite with a graphite particles-mixed matrix and Cu-coated PET as the center layer | Sandwich structure | 718.74 | 0.78 ± 0.06 | 0.92 |

| CFRC+Gr/Me | Carbon fiber-reinforced composite with a graphite particles-mixed matrix and melamine foam as the center layer | Sandwich structure | 735.07 | 7.73 ± 0.2 | 0.1 |

| CFRC+Gr/Cu/Me | Carbon fiber-reinforced composite with a graphite particles-mixed matrix and Cu-coated PET and melamine foam in the center | Sandwich structure | 824.05 | 7.62 ± 0.03 | 0.11 |

| Material | Tensile Strength (MPa) | Tensile Modules (GPa) | Specific Stength (MPa/(g/cm3)) | Specific Modulus (GPa/(g/cm3)) |

|---|---|---|---|---|

| CFRC | 207.1 ± 11.4 | 3.8 ± 0.03 | 272.5 | 5 |

| CFRC/Cu | 197.6 ± 20.6 | 2.7 ± 0.3 | 182.1 | 2.9 |

| CFRC/Me | 18.3 ± 1.3 | 0.4 ± 0.03 | 182.7 | 4 |

| CFRC/Cu/Me | 17.6 ± 0.3 | 0.3 ± 0.03 | 160.2 | 2.7 |

| CFRC+Gr | 232.4 ± 7.7 | 4.2 ± 0.2 | 346.8 | 6.3 |

| CFRC+Gr/Cu | 295 ± 32.2 | 5.5 ± 0.3 | 320.7 | 6 |

| CFRC+Gr/Me | 17.8 ± 1.4 | 0.3 ± 0.01 | 178.2 | 3 |

| CFRC+Gr/Cu/Me | 14.1 ± 2.1 | 0.3 ± 0.05 | 128.2 | 2.7 |

| 6061-T6 aluminum alloy [34] | 310–350 | 68–70 | 114.8–129.6 | 25.2–25.9 |

| 7075 High-strength aluminum alloy [35] | 560–590 | 72–80 | 200–210.7 | 25.71–28.57 |

| High-strength steel (HSS) [36] | 500–1200 | 190–210 | 64.1–153.8 | 24.7–26.9 |

| Ultra-high-strength steel [37] | 1000–1750 | 190–220 | 128.2–224.4 | 24.36–28.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Wang, D.; Večerník, J.; Křemenáková, D.; Militký, J. Electromagnetic Interference (EMI) Shielding and Thermal Management of Sandwich-Structured Carbon Fiber-Reinforced Composite (CFRC) for Electric Vehicle Battery Casings. Polymers 2024, 16, 2291. https://doi.org/10.3390/polym16162291

Hu S, Wang D, Večerník J, Křemenáková D, Militký J. Electromagnetic Interference (EMI) Shielding and Thermal Management of Sandwich-Structured Carbon Fiber-Reinforced Composite (CFRC) for Electric Vehicle Battery Casings. Polymers. 2024; 16(16):2291. https://doi.org/10.3390/polym16162291

Chicago/Turabian StyleHu, Shi, Dan Wang, Josef Večerník, Dana Křemenáková, and Jiří Militký. 2024. "Electromagnetic Interference (EMI) Shielding and Thermal Management of Sandwich-Structured Carbon Fiber-Reinforced Composite (CFRC) for Electric Vehicle Battery Casings" Polymers 16, no. 16: 2291. https://doi.org/10.3390/polym16162291

APA StyleHu, S., Wang, D., Večerník, J., Křemenáková, D., & Militký, J. (2024). Electromagnetic Interference (EMI) Shielding and Thermal Management of Sandwich-Structured Carbon Fiber-Reinforced Composite (CFRC) for Electric Vehicle Battery Casings. Polymers, 16(16), 2291. https://doi.org/10.3390/polym16162291