Design of Biodegradable PU Textile Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Biodegradable PU Dispersion

2.3. Fabric Coating

2.4. Characterization

3. Results

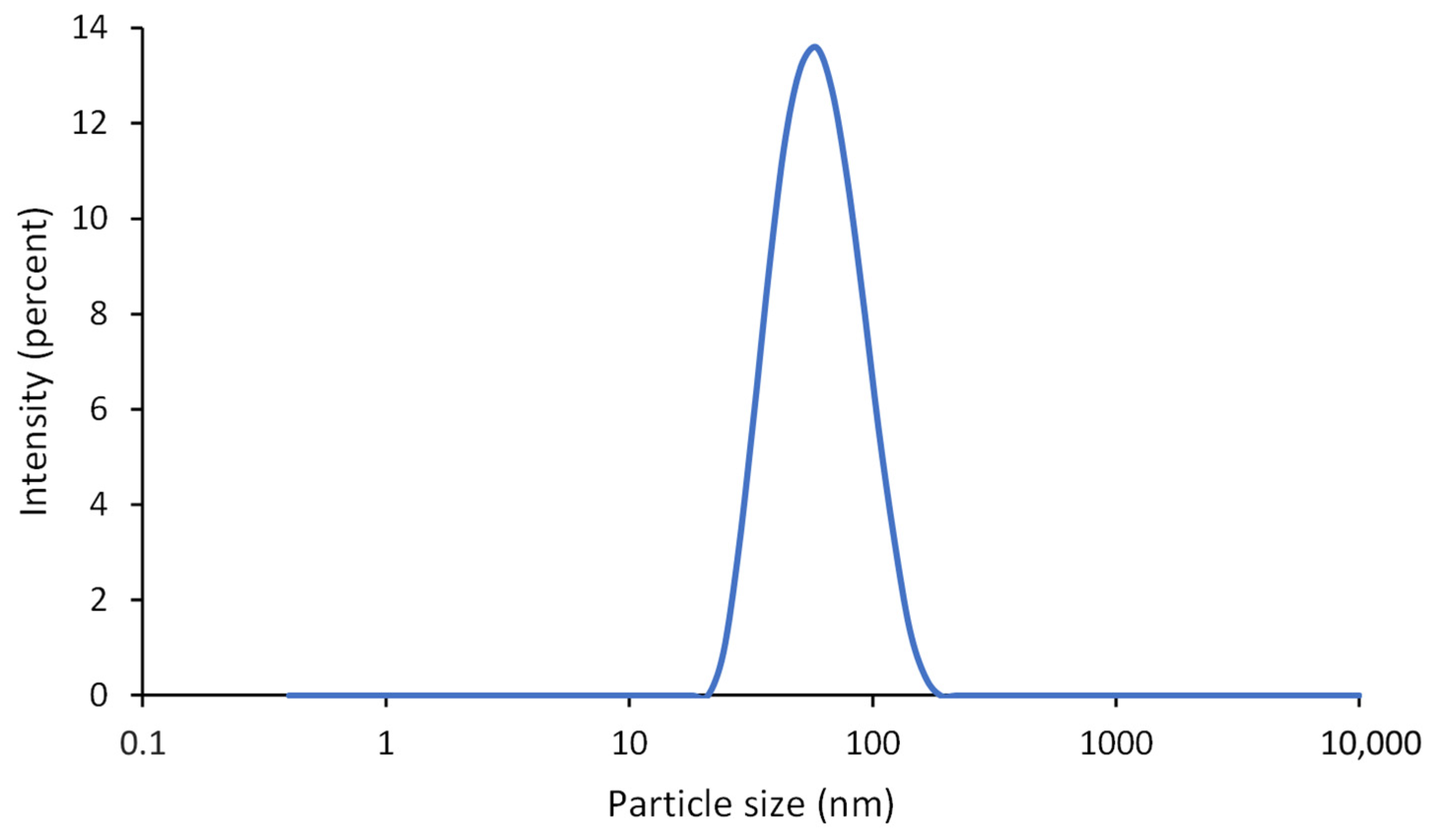

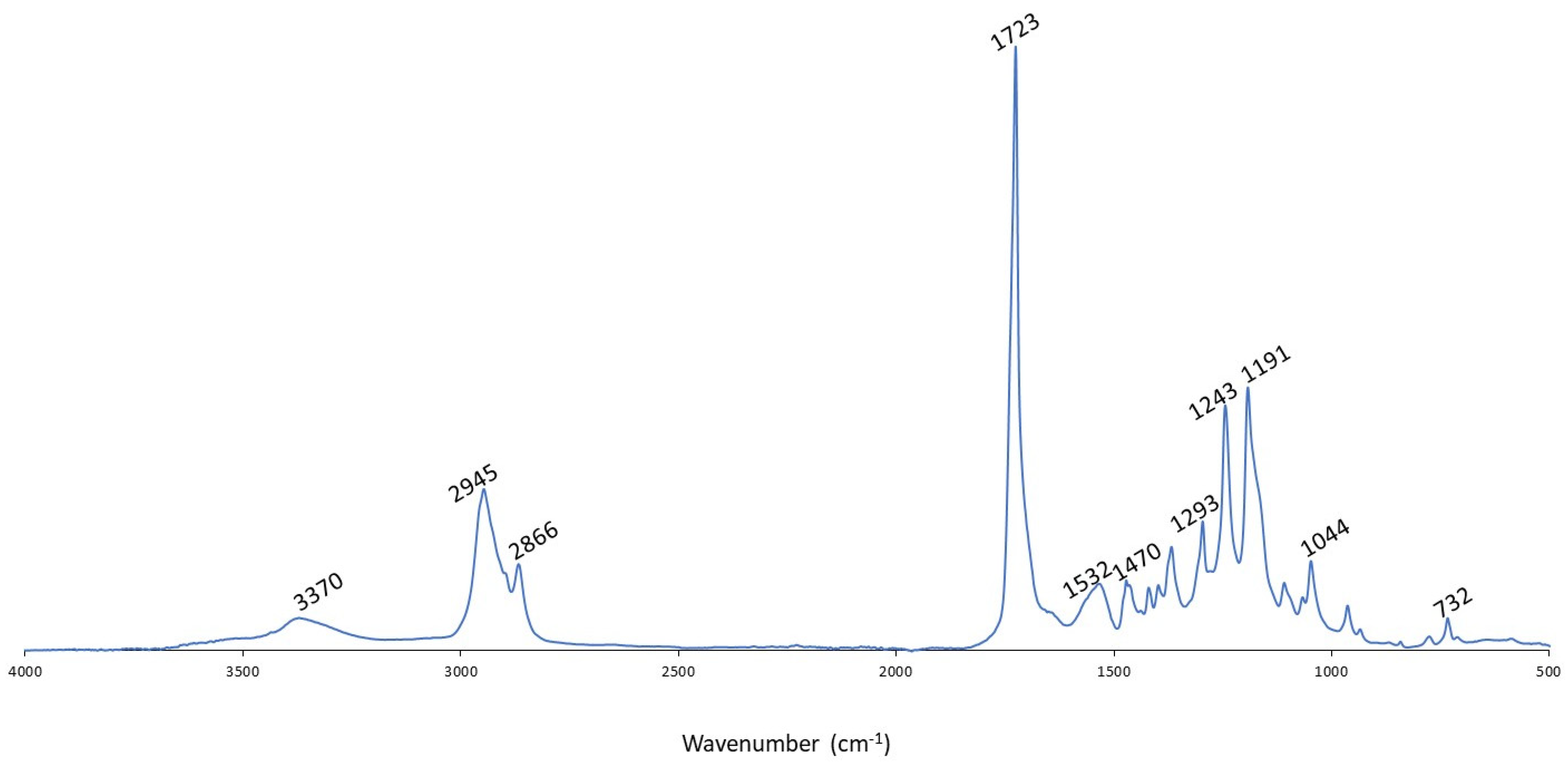

3.1. Characterization of PU Dispersion and Coating

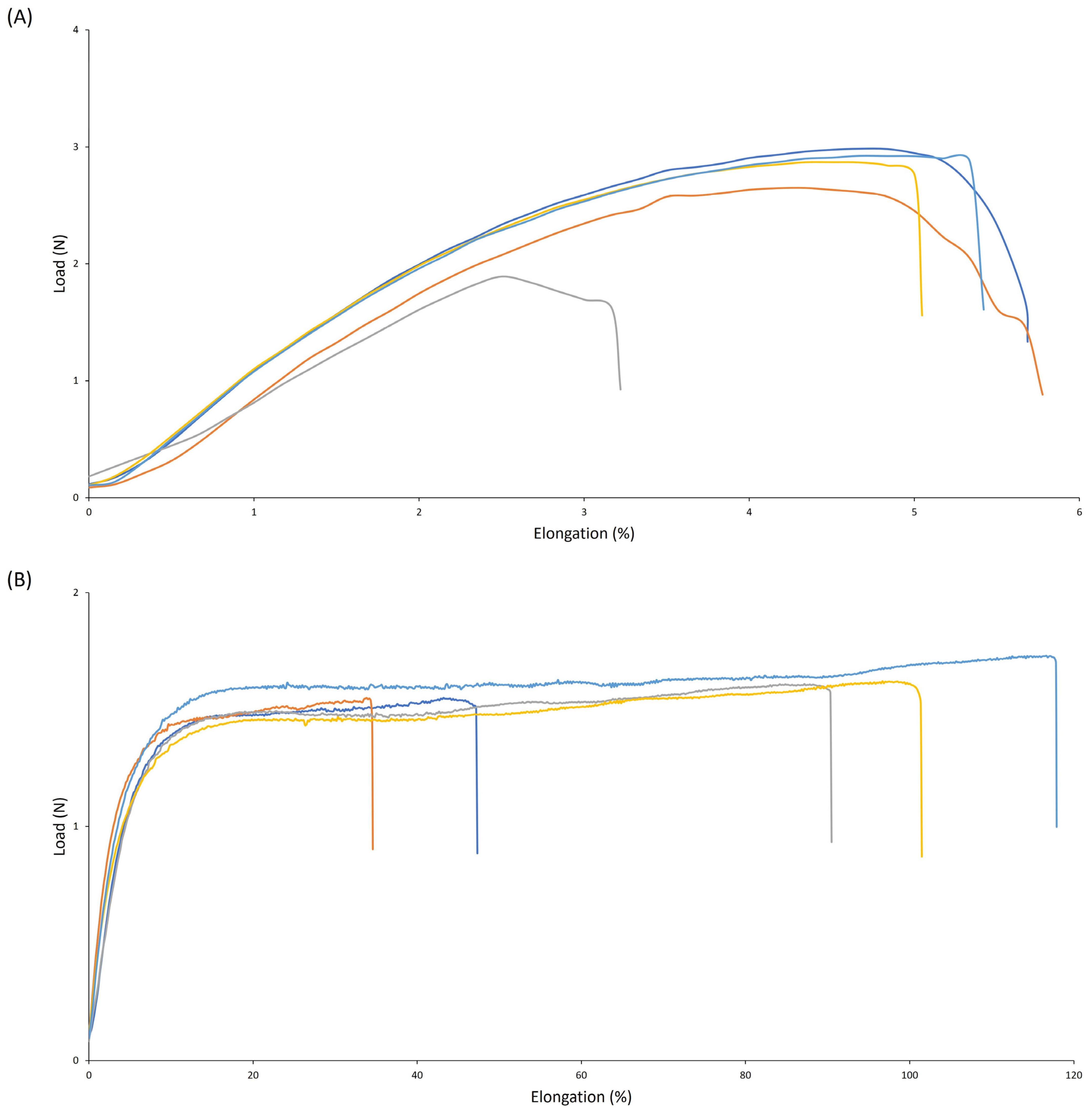

3.2. Mechanical Properties of the Coating

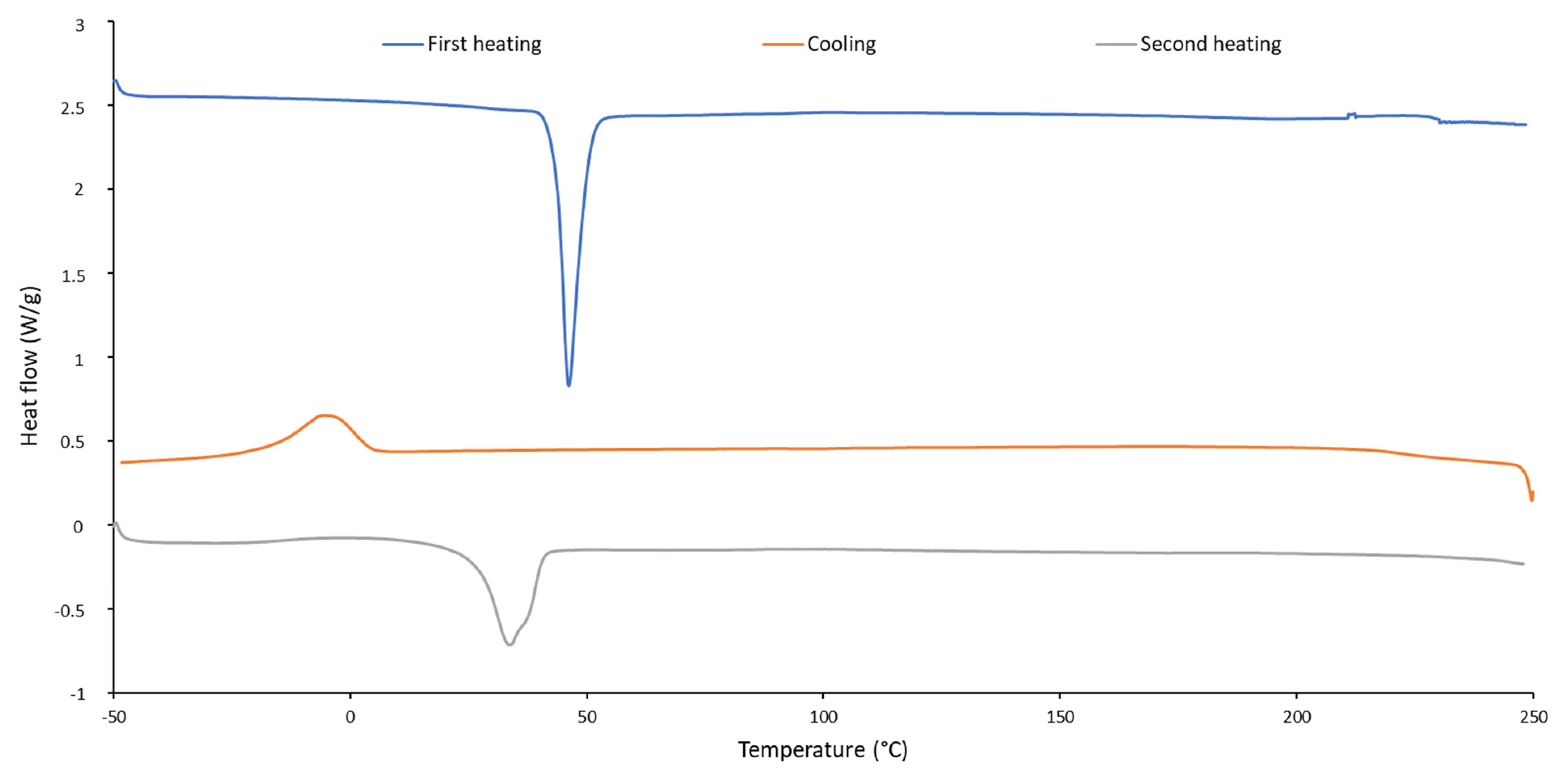

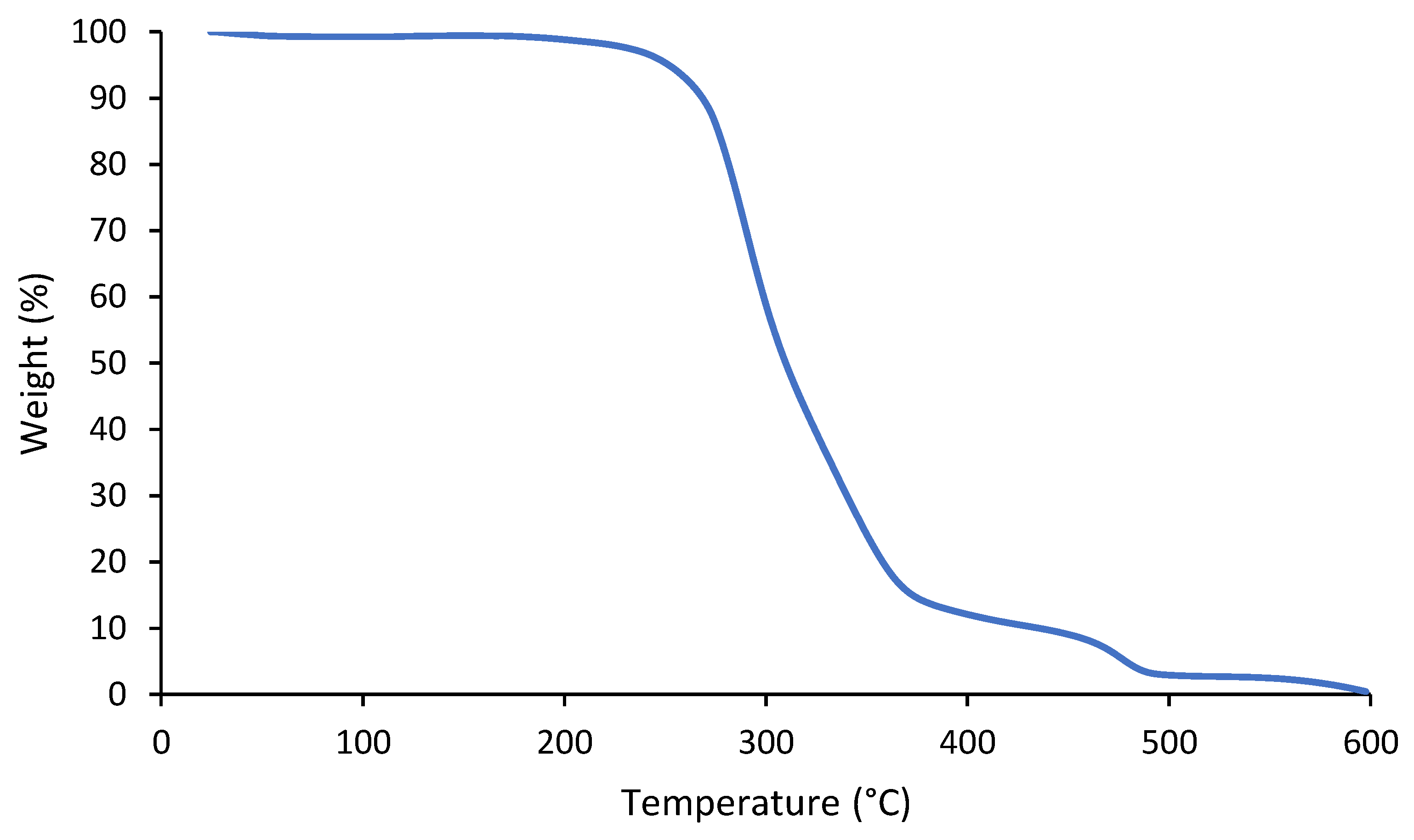

3.3. Thermal Properties of Biodegradable PU

3.4. Disintegration Study

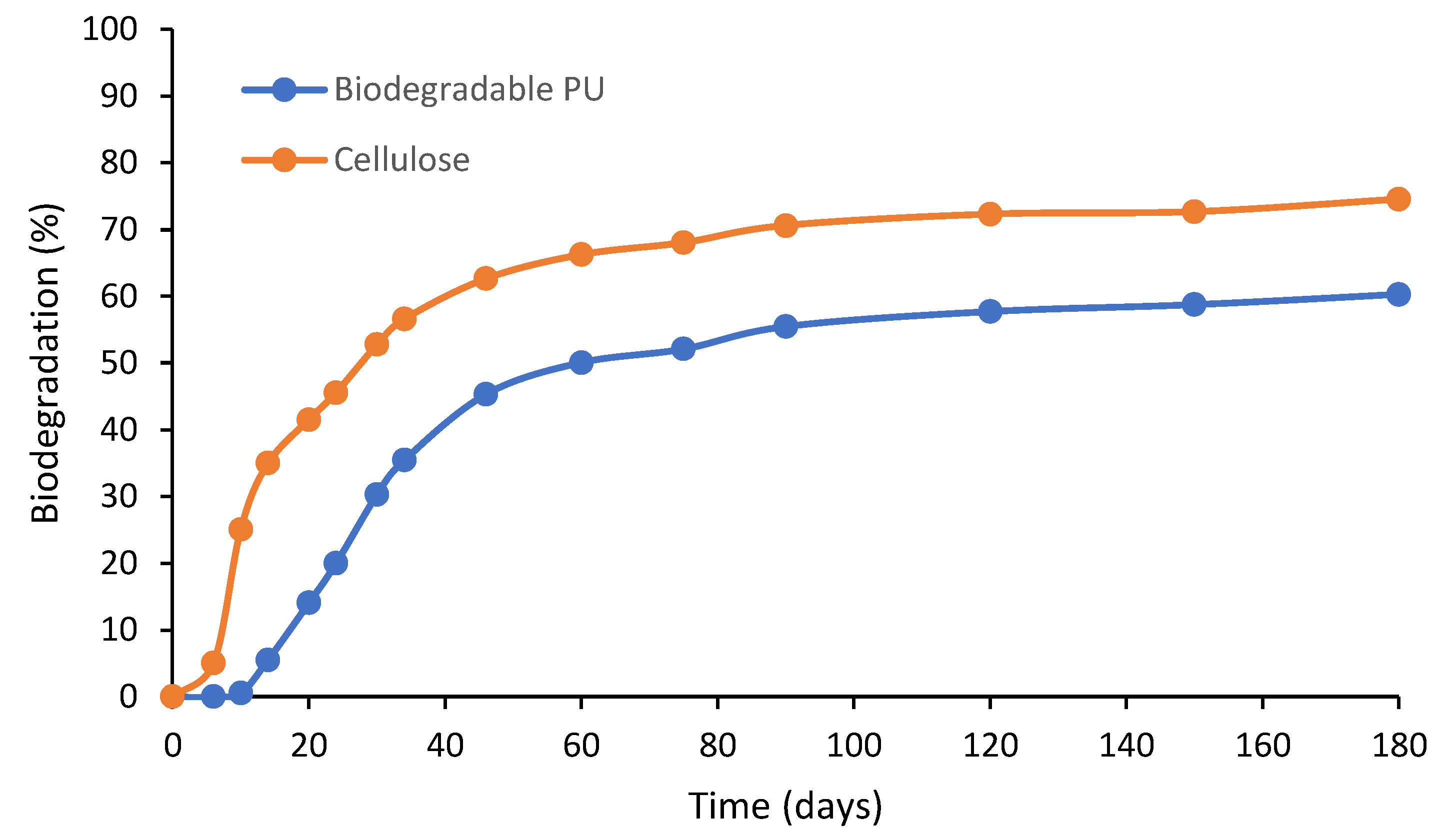

3.5. Soil Biodegradation of PU Coating

3.6. Toxicity Screening

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Song, H.; Wang, J.; Wang, Y.; Jia, S.; Deng, T.; Hou, X. Controllable degradation of polyurethane elastomer via selective cleavage of C-O and C-N bonds. J. Clean. Prod. 2018, 176, 873–879. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P.; Simón, D.; Rodríguez, J. Thermo-Chemical Decomposition Study of Polyurethane Elastomer through Glycerolysis Route with Using Crude and Refined Glycerine as a Transesterification Agent. J. Polym. Environ. 2018, 26, 166–174. [Google Scholar] [CrossRef]

- Zahedifar, P.; Pazdur, L.; Vande Velde, C.; Billen, P. Multistage chemical recycling of polyurethanes and dicarbamates: A glycolysis–hydrolysis demonstration. Sustainability 2021, 13, 3583. [Google Scholar] [CrossRef]

- Xu, Y.; Morado, E.; Zimmerman, S. Construction from destruction using a photo-triggered self-propagating degradable polyurethane as a one-pot epoxy. Polym. Chem. 2020, 11, 6215. [Google Scholar] [CrossRef]

- De Smet, D.; Verjans, J.; Vanneste, M. Selective Solvolysis of Bio-Based PU-Coated Fabric. Polymers 2022, 14, 5452. [Google Scholar] [CrossRef] [PubMed]

- Pkhakadze, G.; Grigorieva, M.; Gladir, I.; Momot, V. Biodegradable polyurethanes. J. Mater. Sci. Mater. Med. 1996, 7, 265. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef] [PubMed]

- Biffinger, J.; Barlow, D.; Cockrell, A.; Cusick, K.; Hervey, W.; Fitzgerald, L.; Nadeau, L.; Hung, C.; Crookes-Goodson, W.; Russell, J. The applicability of Impranil DLN for gauging the biodegradation of polyurethanes. Polym. Degrad. Stab. 2015, 120, 178. [Google Scholar] [CrossRef]

- Magnin, A.; Pollet, E.; Perrin, R.; Ullmann, C.; Persillon, C.; Phalip, V.; Avérous, L. Enzymatic recycling of thermoplastic polyurethanes: Synergistic effect of an esterase and an amidase and recovery of building blocks. Waste Manag. 2019, 85, 141. [Google Scholar] [CrossRef] [PubMed]

- Dupret, I.; David, C.; Colpaert, M.; Loutz, J.-M.; Vander Wauven, C. Biodegradation of poly(ester-urethane)s by a pure strain of micro-organisms. Macromol. Chem. Phys. 1999, 200, 2508. [Google Scholar] [CrossRef]

- Hettrich, W.; Becker, R. New isocyanates from amino acids. Polymer 1997, 38, 2437. [Google Scholar] [CrossRef]

- Tatai, L.; Moore, T.; Adhikari, R.; Malherbe, F.; Griffiths, I.; Gunatillake, T. Thermoplastic biodegradable polyurethanes: The effect of chain extender structure on properties and in-vitro degradation. Biomaterials 2007, 28, 5407. [Google Scholar] [CrossRef] [PubMed]

- Dahiyat, B.; Posadas, E.; Hirosue, S.; Hostin, E.; Leong, K. Degradable biomaterials with elastomeric characteristics and drug-carrier function. React. Polym. 1995, 25, 101–109. [Google Scholar] [CrossRef]

- Skarja, G.; Woodhouse, K. Synthesis and characterization of degradable polyurethane elastomers containing an amino acid-based chain extender. J. Biomater. Sci. Polym. Ed. 1998, 9, 271–295. [Google Scholar] [CrossRef] [PubMed]

- Elliott, S.; Fromstein, J.; Santerre, J.; Woodhous, K. Identification of biodegradation products formed by L-phenylalanine based segmented polyurethaneureas. J. Biomater. Sci. Polym. Ed. 2002, 13, 691. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-Y.; Hsu, S.-H. Fabrication of biodegradable polyurethane microspheres by a facile and green process. J. Biomed. Mater. Res. B 2015, 103, 878. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Silva, L.; Kloss, J.; Munaro, M.; de Souza, G.; Wada, M.; Gomez, J.; Zawadzki, S.; Akcelrud, L. Polycaprolactone based biodegradable polyurethanes. Macromol. Symp. 2003, 197, 255. [Google Scholar] [CrossRef]

- Gong, C.; Fu, S.; Gu, Y.; Liu, C.; Kan, B.; Deng, H.; Luo, F.; Qian, Z. Synthesis, characterization, and hydrolytic degradation of biodegradable poly(ether ester)-urethane copolymers based on ε-caprolactone and poly(ethylene glycol). J. Appl. Polym. Sci. 2009, 113, 1111. [Google Scholar] [CrossRef]

- Touchet, T.; Cosgriff-Hernandez, E. Hierarchal structure–property relationships of segmented polyurethanes. In Advances in Polyurethane Biomaterials; Woodhead Publishing: Sawston, UK, 2016; pp. 3–22. [Google Scholar]

- Available online: https://www.solutions.covestro.com/-/media/covestro/solution-center/brands/downloads/imported/1580485238.pdf (accessed on 26 March 2024).

- Blount, A.; Armstrong, S.; Yuan, F.; Burgess, S. Porous polyurethaneurea (Artelon) joint spacer compared to trapezium resection and ligament reconstruction. J. Hand Surg. Am. 2013, 38, 1741. [Google Scholar] [CrossRef] [PubMed]

- Dearman, B.; Li, A.; Greenwood, J. Optimization of a polyurethane dermal matrix and experience with a polymer-based cultured composite skin. J. Burn Care 2014, 35, 437. [Google Scholar] [CrossRef] [PubMed]

- Tatai, L. Evaluation of Novosorb™ Biodegradable Polyurethanes: Understanding Degradation Characteristics. 2015. Available online: https://researchbank.swinburne.edu.au/file/ba6e2aba-47ca-4990-9d4e-ed24a28061d5/1/Lisa%20Tatai%20Thesis.pdf (accessed on 26 March 2024).

- ISO 13321; Particle Size Analysis—Photon Correlation Spectroscopy. ISO: Geneva, Switzerland, 1996.

- ISO 13934-1; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. ISO: Geneva, Switzerland, 2013.

- ISO 811; Textiles—Determination of Resistance to Water Penetration—Hydrostatic Pressure Test. ISO: Geneva, Switzerland, 2018.

- ISO 6330; Textiles—Domestic Washing and Drying Procedures for Textile Testing. ISO: Geneva, Switzerland, 2021.

- BS 6085; Methods of Test for Determination of the Resistance of Textiles to Microbiological Deterioration. British Standards Institution: London, UK, 1981.

- ISO 17556; Plastics—Determination of the Ultimate Aerobic Biodegradability of Plastic Materials in Soil by Measuring the Oxygen Demand in a Respirometer or the Amount of Carbon Dioxide Evolved. ISO: Geneva, Switzerland, 2019.

- Wilhelm, C.; Gardette, J.-L. Infrared analysis of the photochemical behaviour of segmented polyurethanes: 1. Aliphatic poly(ester-urethane). Polymer 1997, 38, 4019. [Google Scholar] [CrossRef]

- Irusta, L.; Fernanadez-Berridi, J. Aromatic poly(ester-urethanes): Effect of the polyol molecular weight on the photochemical behavior. Polymer 2000, 41, 3297. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra: A Practical Approach in Encyclopedia of Analytical Chemistry; Mayers, R., Ed.; Wiley: Hoboken, NJ, USA, 2000; p. 10815. [Google Scholar]

- Kaushiva, B.; McCartney, S.; Rossmy, G.; Wilkes, G. Surfactant level influences on structure and properties of flexible slabstock polyurethane foams. Polymer 2000, 41, 285. [Google Scholar] [CrossRef]

- Molina, G.; Elizalde-Mata, A.; Hernández-Martínez, Á.; Fonseca, G.; Cruz Soto, M.; Rodríguez-Morales, Á.; Estevez, M. Synthesis and Characterization of Inulin-Based Responsive Polyurethanes for Breast Cancer Applications. Polymers 2020, 12, 865. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Zafar, F.; Sharmin, E.; Garg, N.; Kashif, M. Synthesis and characterization of corrosion protective polyurethane fatty amide/silica hybrid coating material. Prog. Org. Coat. 2012, 73, 112. [Google Scholar] [CrossRef]

- Anand, A.; Kulkarni, R.; Gite, V. Preparation and properties of eco-friendly two pack PU coatings based on renewable source (sorbitol) and its property improvement by nano ZnO. Prog. Org. Coat. 2012, 74, 764. [Google Scholar] [CrossRef]

- Marathe, R.; Tatiya, P.; Chaudhari, A.; Lee, J.; Mahulikar, P.; Sohn, D.; Gite, V. Neem acetylated polyester polyol—Renewable source based smart PU coatings containing quinoline (corrosion inhibitor) encapsulated polyurea microcapsules for enhance anticorrosive property. Ind. Crop. Prod. 2015, 77, 239. [Google Scholar] [CrossRef]

- De Smet, D.; Wéry, M.; Uyttendaele, W.; Vanneste, M. Bio-Based Waterborne PU for Durable Textile Coatings. Polymers 2021, 13, 4229. [Google Scholar] [CrossRef] [PubMed]

| Wavenumber (cm−1) | Corresponding Group |

|---|---|

| 732 | COO urethane (deformation vibration) |

| 1044 | C-O stretching |

| 1191 | C-O-C ester (elongation vibration) |

| 1243 | C-O-C urethane (elongation vibration) |

| 1293 | C-C stretching |

| 1470 | CH (deformation vibration) |

| 1532 | N-H and C-N amide |

| 1723 | C=O urethane and ester (elongation vibration) |

| 2866 | CH (elongation vibration) |

| 2945 | CH (elongation vibration) |

| 3370 | NH (elongation vibration) |

| Level in PU (ppm) | EN13432 Limit (ppm) | |

|---|---|---|

| Zn | 54.7 | 150 |

| Cu | n.d. | 50 |

| Ni | n.d. | 25 |

| Cd | n.d. | 0.5 |

| Pb | n.d. | 50 |

| Hg | n.d. | 0.5 |

| Cr | n.d. | 50 |

| Mo | n.d. | 1 |

| Se | n.d. | 0.75 |

| As | n.d. | 5 |

| F | 21 | 100 |

| 1st Day Seeding | 40th Day Seeding | |||

|---|---|---|---|---|

| Germination Rate (%) | Fresh Weight (g) | Germination Rate (%) | Fresh Weight (g) | |

| Soil + PU | 93.3 ± 6.7 | 0.73 ± 0.02 | 86.7 ± 6.7 | 0.69 ± 0.03 |

| Control Soil | 91.1 ± 3.8 | 0.66 ± 0.02 | 88.9 ± 3.8 | 0.86 ± 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Smet, D.; Verjans, J.; Bader, M.; Mondschein, A.; Vanneste, M. Design of Biodegradable PU Textile Coating. Polymers 2024, 16, 2236. https://doi.org/10.3390/polym16162236

De Smet D, Verjans J, Bader M, Mondschein A, Vanneste M. Design of Biodegradable PU Textile Coating. Polymers. 2024; 16(16):2236. https://doi.org/10.3390/polym16162236

Chicago/Turabian StyleDe Smet, David, Jente Verjans, Miriam Bader, Anke Mondschein, and Myriam Vanneste. 2024. "Design of Biodegradable PU Textile Coating" Polymers 16, no. 16: 2236. https://doi.org/10.3390/polym16162236

APA StyleDe Smet, D., Verjans, J., Bader, M., Mondschein, A., & Vanneste, M. (2024). Design of Biodegradable PU Textile Coating. Polymers, 16(16), 2236. https://doi.org/10.3390/polym16162236