Effect of Bi2O3 Particle Size on the Radiation-Shielding Performance of Free-Lead Epoxide Materials against Ionizing Radiation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Epoxy Resin (ER)

2.1.2. Bismuth Oxide (Bi2O3)

2.2. Methods

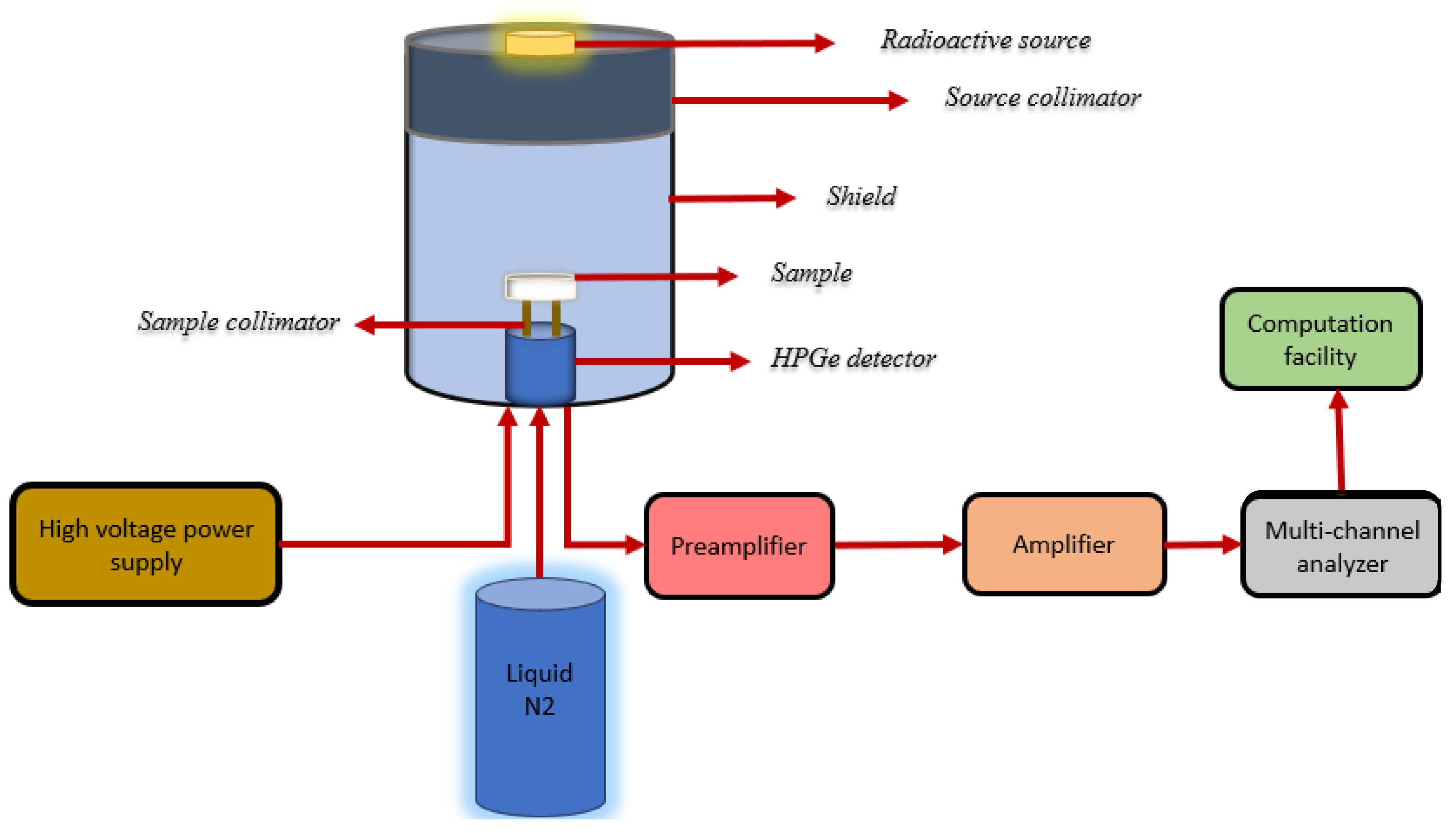

2.3. Shielding Measurements

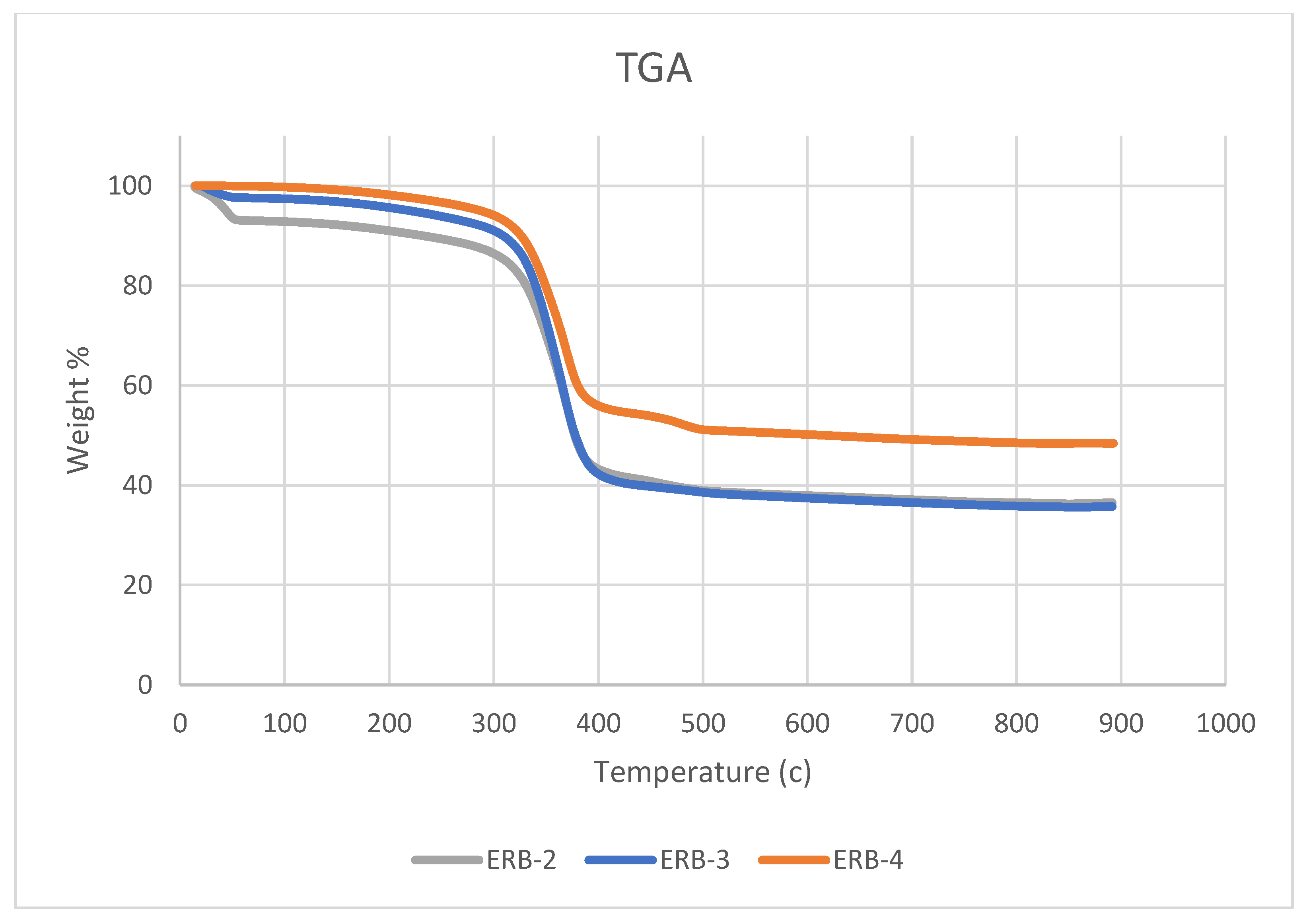

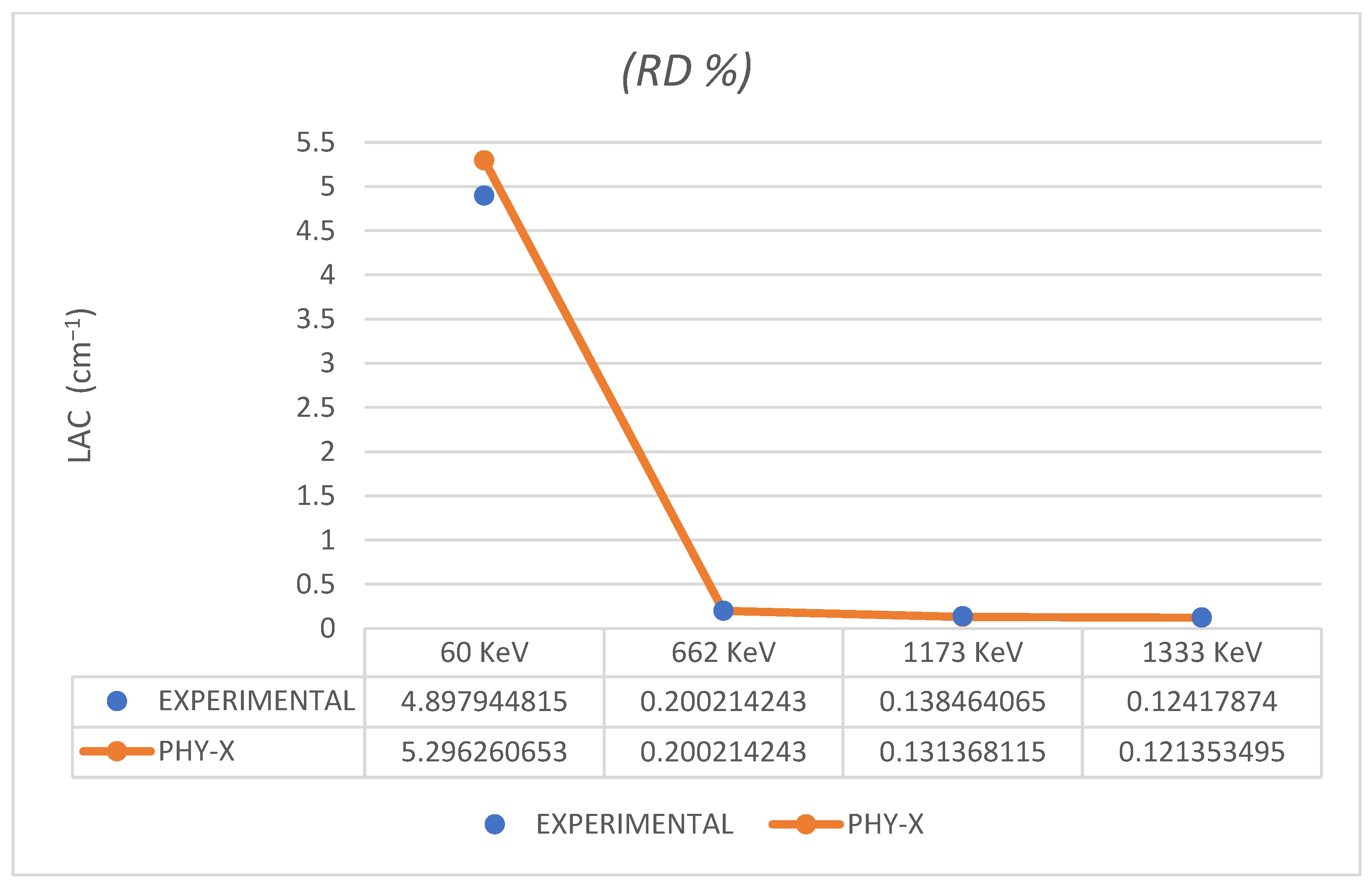

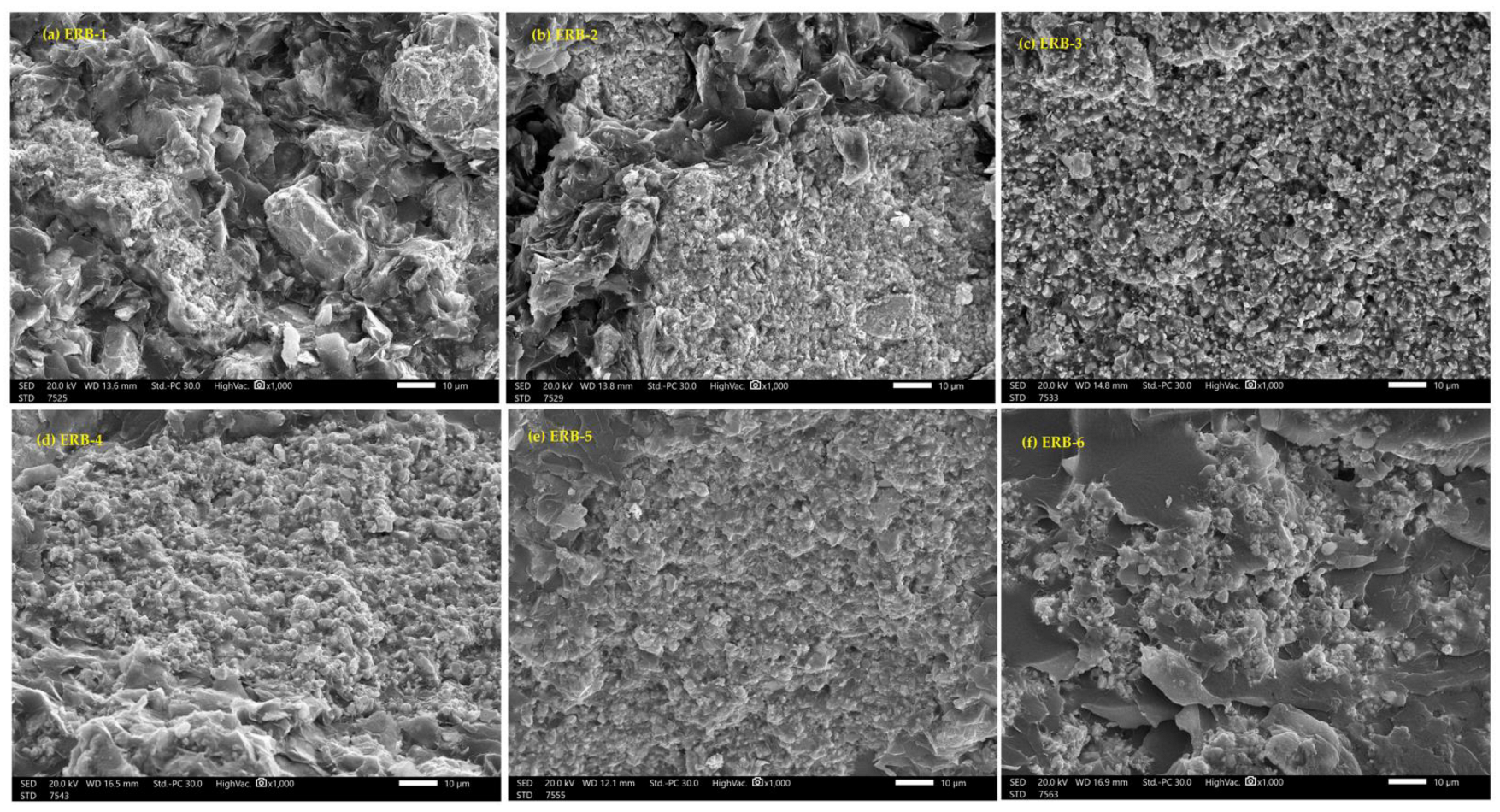

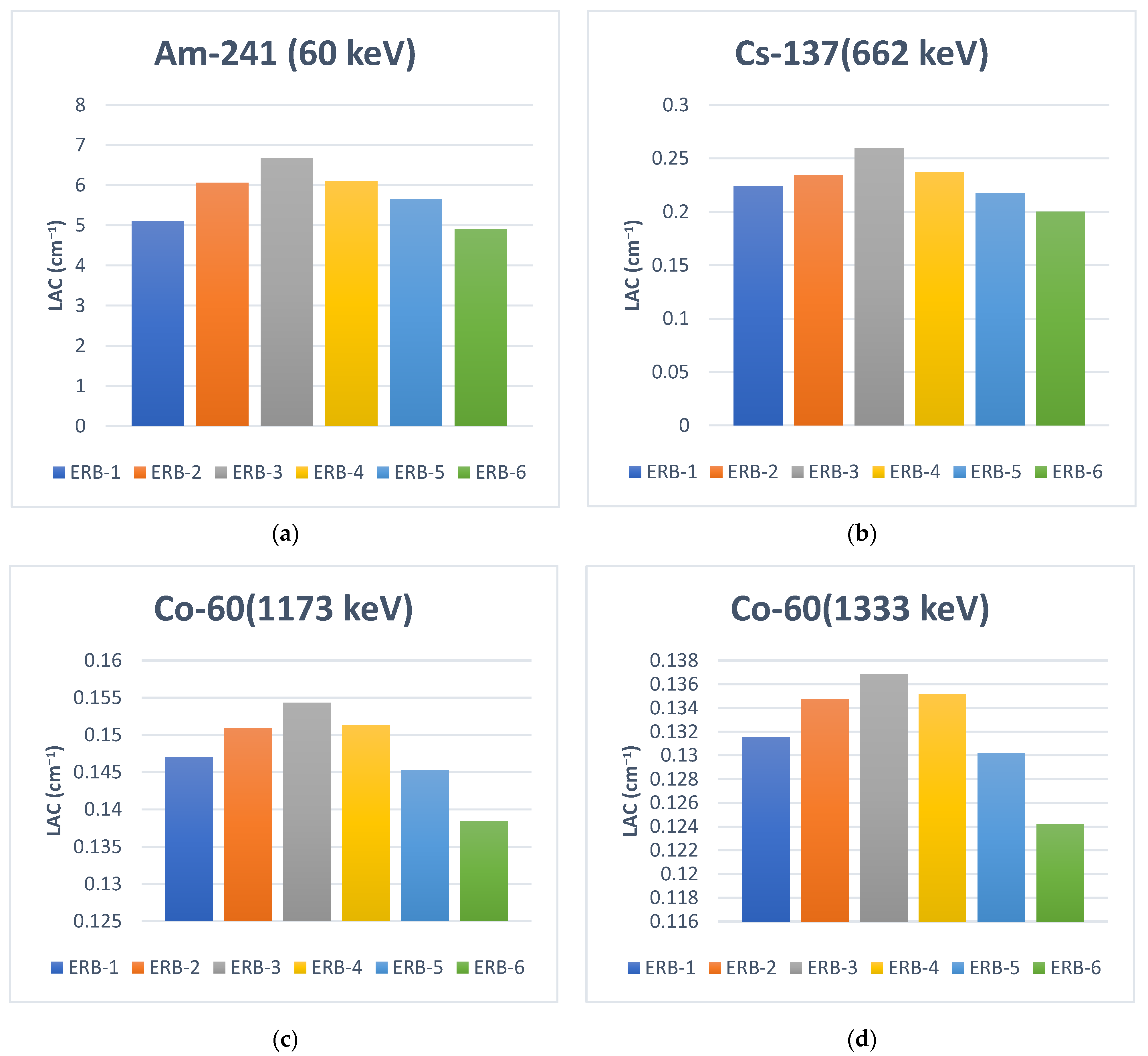

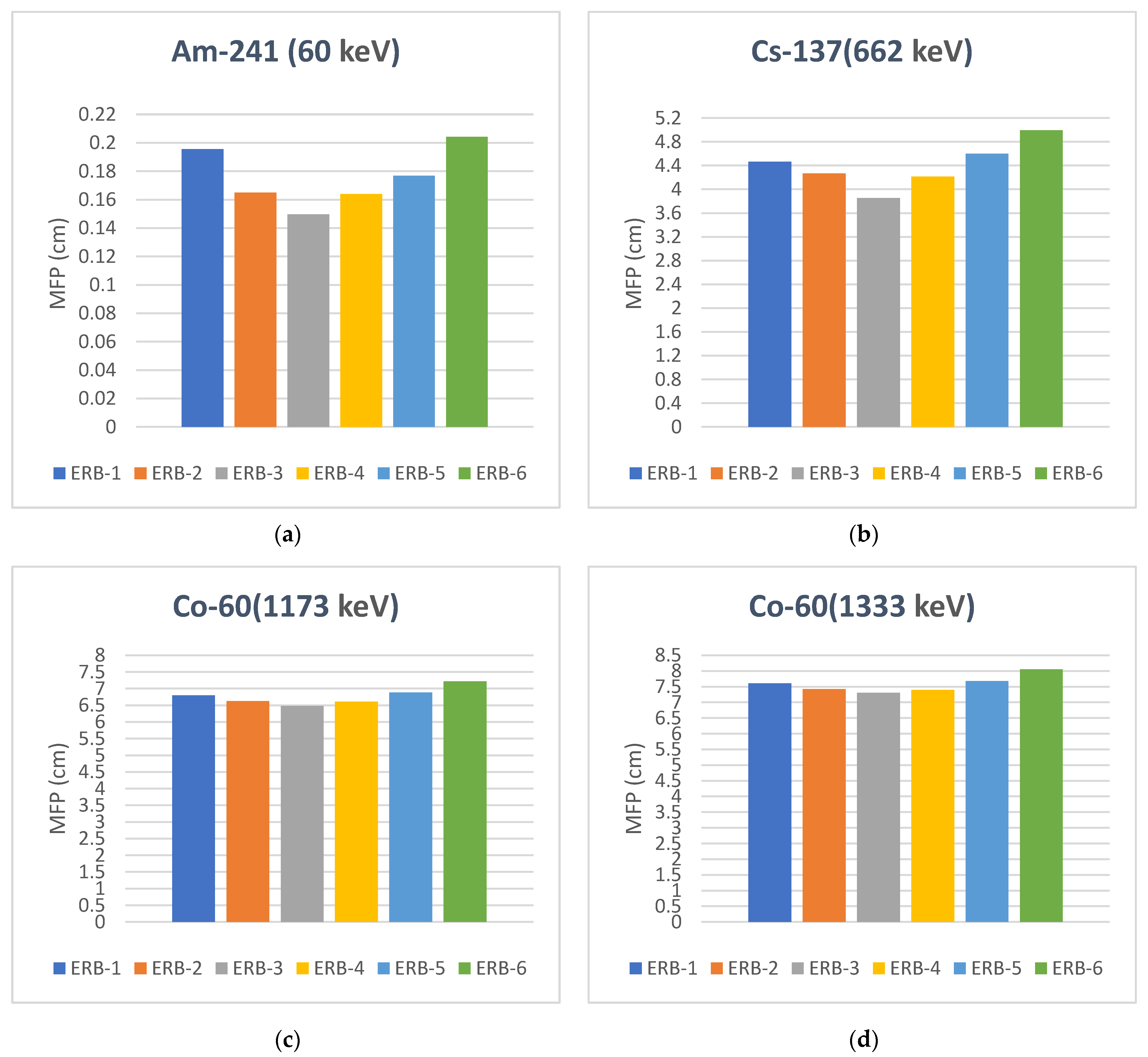

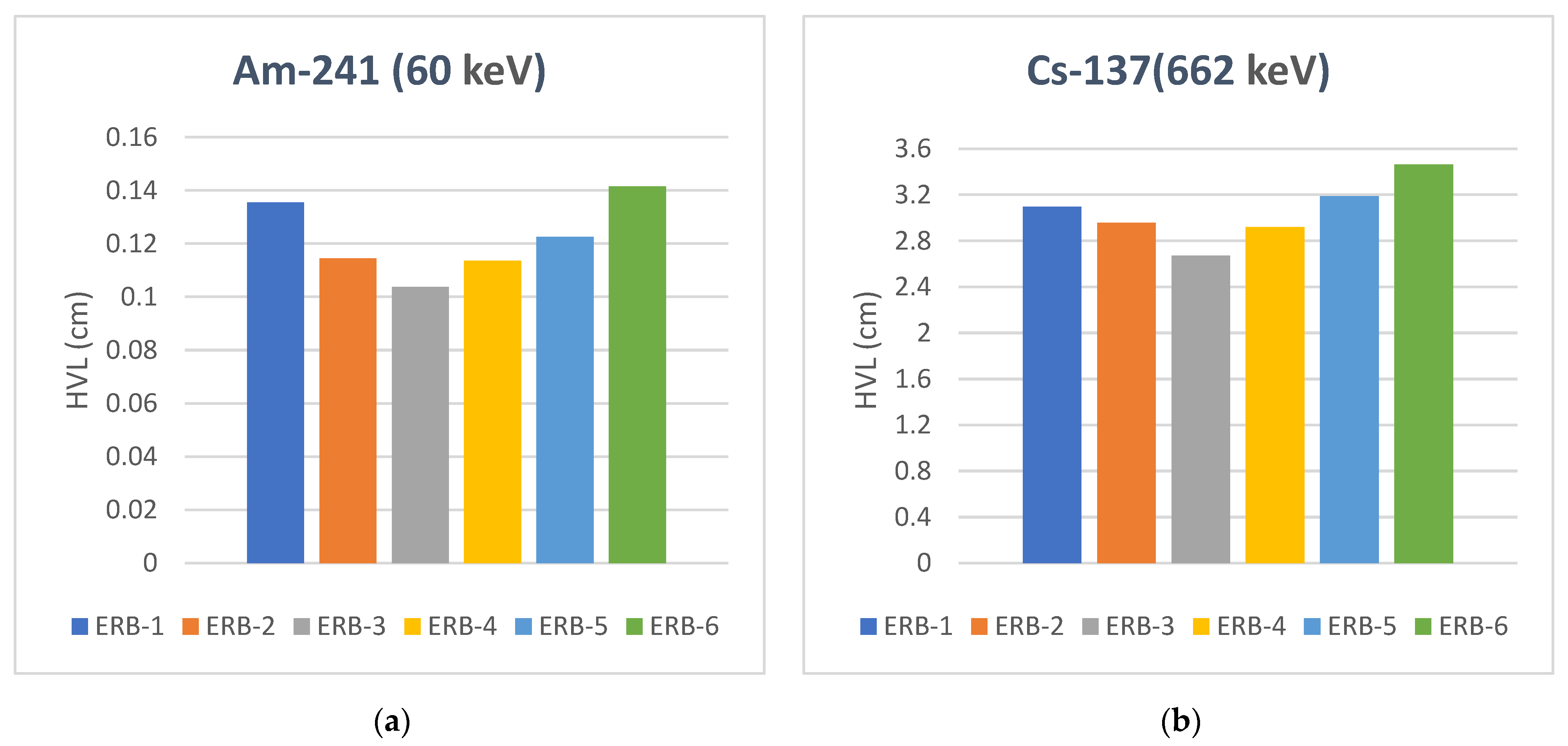

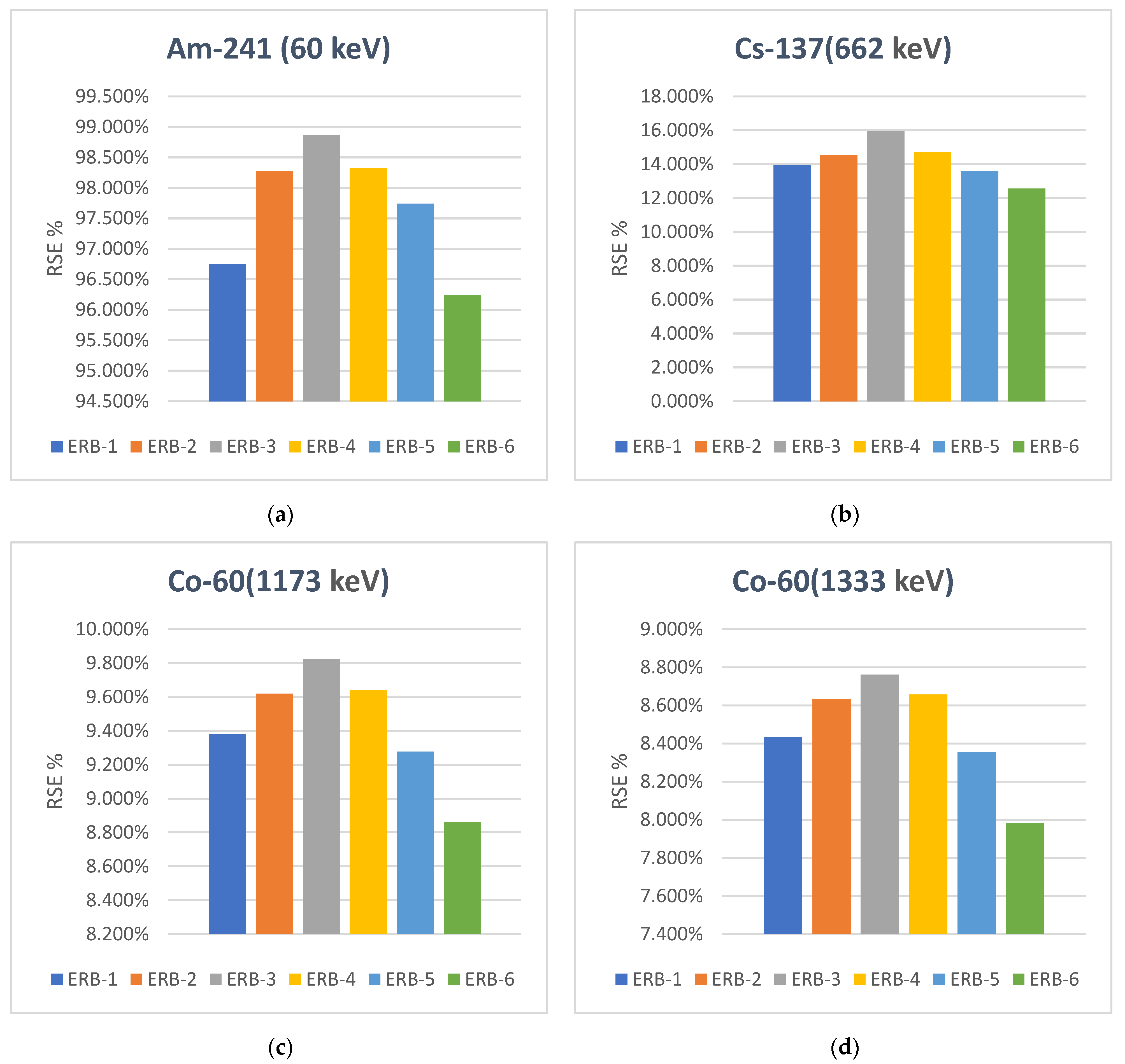

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tijani, S.A.; Al-Hadeethi, Y. The use of isophthalic-bismuth polymer composites as radiation shielding barriers in nuclear medicine. Mater. Res. Express 2019, 6, 055323. [Google Scholar] [CrossRef]

- Karmakar, A.; Wang, J.; Prinzie, J.; De Smedt, V.; Leroux, P. A review of semiconductor based ionising radiation sensors used in Harsh radiation environments and their applications. Radiation 2021, 1, 194–217. [Google Scholar] [CrossRef]

- Kaewjaeng, S.; Kothan, S.; Chaiphaksa, W.; Chanthima, N.; Rajaramakrishna, R.; Kim, H.J.; Kaewkhao, J. High transparency La2O3-CaO-B2O3-SiO2 glass for diagnosis X-rays shielding material application. Radiat. Phys. Chem. 2019, 160, 41–47. [Google Scholar] [CrossRef]

- Udalova, A.A. Nonpower applications of nuclear technology. In Nuclear Reactor Technology Development and Utilization; Woodhead Publishing: Sawston, UK, 2020; pp. 319–341. [Google Scholar]

- Verdipoor, K.; Alemi, A.; Mesbahi, A. Photon mass attenuation coefficients of a silicon resin loaded with WO3, PbO, and Bi2O3 Micro and Nanoparticles for radiation shielding. Radiat. Phys. Chem. 2018, 147, 85–90. [Google Scholar] [CrossRef]

- Tumwong, A.; Wimolmala, E.; Markpin, T.; Sombatsompop, N.; Saenboonruang, K. Enhanced X-ray shielding properties of NRL gloves with nano-Bi2O3 and their mechanical properties under aging conditions. Radiat. Phys. Chem. 2021, 186, 109530. [Google Scholar] [CrossRef]

- Oliver, N.; Ramli, R.M.; Azman, N.Z.N. An empirical study on the X-ray attenuation capability of n-WO3/nBi2O3/PVA with added starch. Nucl. Eng. Technol. 2022, 54, 3459–3469. [Google Scholar] [CrossRef]

- Aral, N.; Banu Nergis, F.; Candan, C. An Alternative X-ray Shielding Material Based on Coated Textiles. Text. Res. J. 2015, 86, 803–811. [Google Scholar] [CrossRef]

- Dubey, K.A.; Chaudhari, C.V.; Suman, S.K.; Raje, N.; Mondal, R.K.; Grover, V.; Murali, S.; Bhardwaj, Y.K.; Varshney, L. Synthesis of Flexible Polymeric Shielding Materials for Soft Gamma Rays: Physicomechanical and Attenuation Characteristics of Radiation Crosslinked Polydimethylsiloxane/Bi2O3 Composites. Polym. Compos. 2016, 37, 756–762. [Google Scholar] [CrossRef]

- Kadyrzhanov, K.K.; Kozlovskiy, A.A.; Konuhova, M.; Popov, A.I.; Shlimas, D.D.; Borgekov, D.B. Determination of gamma radiation shielding efficiency by radiation-resistant composite ZrO2-Al2O3-TiO2-WO3-Nb2O5 ceramics. Opt. Mater. 2024, 154, 115752. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Shlimas, D.I.; Zdorovets, M.V.; Elsts, E.; Konuhova, M.; Popov, A.I. Investigation of the Effect of PbO Doping on Telluride Glass Ceramics as a Potential Material for Gamma Radiation Shielding. Materials 2023, 16, 2366. [Google Scholar] [CrossRef]

- Mahmoud, I.S.; Issa, S.A.; Saddeek, Y.B.; Tekin, H.O.; Kilicoglu, O.; Alharbi, T.; Sayyed, M.I.; Erguzel, T.T.; Elsaman, R. Gamma, neutron shielding and mechanical parameters for lead vanadate glasses. Ceram. Int. 2019, 45, 14058–14072. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.I. Radiation attenuation properties of Bi2O3–Na2O–V2O5–TiO2–TeO2 glass system using Phy-X/PSD software. Ceram. Int. 2020, 46, 4795–4800. [Google Scholar] [CrossRef]

- Prasad, R.; Pai, A.R.; Oyadiji, S.O.; Tomas, S.; Parashar, S.K.S. Utilization of hazardous red mud in silicone rubber/MWCNT nanocomposites for high performance electromagnetic interference shielding. J. Clean. Prod. 2022, 377, 134290. [Google Scholar] [CrossRef]

- Plangpleng, N.; Charoenphun, P.; Polpanich, D.; Sakulkaew, K.; Buasuwan, N.; Onjun, O.; Chuamsaamarkkee, K. Flexible gamma ray shielding based on natural Rubber/BaSO4 nanocomposites. Radiat. Phys. Chem. 2022, 199, 110311. [Google Scholar] [CrossRef]

- Nunez-Briones, A.G.; Benavides, R.; Bolaina-Lorenzo, E.D.; Martínez-Pardo, M.E.; Kotzian-Pereira-Benavides, C.; Mendoza-Mendoza, E.; Bentacourt-Galindo, R.; Garcia-Cerda, L.A. Nontoxic fexible PVC nanocomposites with Ta2O5 and Bi2O3 nanoparticles for shielding diagnostic X-rays. Radiat. Phys. Chem. 2023, 202, 110512. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Y.; Yuan, Y.; Cui, K.; Wei, W.; Wu, J.; Qin, W.; Wu, X. Spatially confned Bi2O3–Ti3C2Tx hybrids reinforced epoxy composites for gamma radiation shielding. Compos. Commun. 2022, 34, 101252. [Google Scholar] [CrossRef]

- Aldhuhaibat, M.J.R.; Amana, M.S.; Jubier, N.J.; Salim, A.A. Improved gamma radiation shielding traits of epoxy composites: Evaluation of mass attenuation coefficient, effective atomic and electron number. Radiat. Phys. Chem. 2021, 179, 1083. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Zhang, G.; Yang, Z.; Li, M.; Zhang, Z. Radiation shielding property of structural polymer composite: Continuous basalt fiber reinforced epoxy matrix composite containing erbium oxide. Compos. Sci. Technol. 2017, 143, 67–74. [Google Scholar] [CrossRef]

- Rotkovich, A.A.; Tishkevich, D.I.; German, S.A.; Bondaruk, A.A.; Dashkevich, E.S.; Trukhanov, A.V. A study of the morphological, structural, and shielding properties of epoxy-W composite materials. Nexus Future Mater. 2024, 1, 13–19. [Google Scholar]

- Saleh, I.H.; Ibrahim, N.M.; Hassaan, M.A.; Ghatass, Z.F.; Arayro, J.; Mezher, R.; Ibosayyed, M.; Elsafi, M. Using 7Be and 137Cs for Assessing the Land Stability of Alexandria Region, Egypt. Sustainability 2024, 16, 1692. [Google Scholar] [CrossRef]

- Alresheedi, M.T.; Elsafi, M.; Aladadi, Y.T.; Abas, A.F.; Ganam, A.B.; Sayyed, M.I.; Mahdi, M.A. Assessment of Silicone Rubber/Lead Oxide Composites Enriched with Bi2O3, WO3, BaO, and SnO2 Nanoparticles for Radiation Shielding Applications. Polymers 2023, 15, 2160. [Google Scholar] [CrossRef] [PubMed]

- Alsafi, K.; El-Nahal, M.A.; Al-Saleh, W.M.; Almutairi, H.M.; Abdel-Gawad, E.H.; Elsafi, M. Utilization of Waste Marble and Bi2O3-NPs as a Sustainable Replacement for Lead Materials for Radiation Shielding Applications. Ceramics 2024, 7, 639–651. [Google Scholar] [CrossRef]

- Hannachi, E.; Sayyed, M.I.; Slimani, Y.; Elsafi, M. Gamma radiation shielding efficiency of some different ceramic composites: A comparative study. Radiat. Phys. Chem. 2024, 220, 111695. [Google Scholar] [CrossRef]

- Aloraini, D.A.; Elsafi, M.; Almuqrin, A.H.; Yasmin, S.; Sayyed, M.I. Synergistic Effect in Ionizing Radiation Shielding with Recent Tile Composites Blended with Marble Dust and BaO Micro/Nanoparticles. Crystals 2023, 13, 1057. [Google Scholar] [CrossRef]

- Muthamma, M.V.; Prabhu, S.; Bubbly, S.G.; Gudennavar, S.B. Micro and nano Bi2O3 flled epoxy composites: Termal, mechanical and γ-ray attenuation properties. Appl. Radiat. Isot. 2021, 174, 1080. [Google Scholar] [CrossRef]

- Demirbay, T.; Çağlar, M.; Karabul, Y.; Kılıç, M.; İçelli, O.; Güven Özdemir, Z. Availability of water glass/Bi2O3 composites in dielectric and gamma-ray screening applications. Radiat. Ef. Defects Solids 2019, 174, 419–434. [Google Scholar] [CrossRef]

- Alkan, Ü.; Kılıç, M.; Karabul, Y.; Çağlar, M.; İçelli, O.; Güven Özdemir, Z. X-ray irradiated LDPE/PP blends with high mechanical and dielectric performance. J. Appl. Polym. Sci. 2018, 135, 46571. [Google Scholar] [CrossRef]

- Çağlar, M.; Kayacık, H.; Karabul, Y.; Kılıç, M.; Özdemir, Z.G.; İçelli, O. Na2Si3O7/BaO composites for the gamma-ray shielding in medical applications: Experimental, MCNP5, and WinXCom studies. Progr. Nucl. Energy. 2019, 117, 0149–1970. [Google Scholar] [CrossRef]

- Şakar, E.; Özpolat, Ö.F.; Alım, B.; Sayyed, M.I.; Kurudirek, M. Phy-X/PSD: Development of a user-friendly online software for calculation of parameters relevant to radiation shielding and dosimetry. Radiat. Phys. Chem. 2020, 166, 108496. [Google Scholar] [CrossRef]

- Farquharson, M.J.; Spyrou, N.M.; Al-Bahri, J.; Highgate, D.J. Low energy photon attenuation measurements of hydrophilic materials for tissue equivalent phantoms. Appl. Radiat. Isot. 1995, 46, 783–790. [Google Scholar] [CrossRef]

- Cheewasukhanont, W.; Limkitjaroenporn, P.; Kothan, S.; Kedkaew, C.; Kaewkhao, J. The effect of particle size on radiation shielding properties for bismuth borosilicate glass. Radiat. Phys. Chem. 2020, 172, 108791. [Google Scholar] [CrossRef]

- Abbas, M.I.; Alahmadi, A.H.; Elsafi, M.; Alqahtani, S.A.; Yasmin, S.; Sayyed, M.I.; Gouda, M.M.; El-Khatib, A.M. Effect of Kaolin Clay, and ZnO-Nanoparticles on the Radiation Shielding Properties of Epoxy Resin Composites. Polymers 2022, 14, 4801. [Google Scholar] [CrossRef] [PubMed]

- Elsafi, M.; Almuqrin, A.H.; Almutairi, H.M.; Al-Saleh, W.M.; Sayyed, M.I. Grafting red clay with Bi2O3 nanoparticles into epoxy resin for gamma-ray shielding applications. Sci. Rep. 2023, 13, 5472. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | Percentage (wt.%) | Density (g cm−3) | ||

|---|---|---|---|---|

| Epoxy Resin | Micro-Bi2O | Nano-Bi2O3 | ||

| ERB-1 | 50 | 0 | 50 | 2.013 ± 0.005 |

| ERB-2 | 50 | 10 | 40 | 1.808 ± 0.010 |

| ERB-3 | 50 | 20 | 30 | 2.254 ± 0.008 |

| ERB-4 | 50 | 30 | 20 | 1.938 ± 0.005 |

| ERB-5 | 50 | 40 | 10 | 2.130 ± 0.009 |

| ERB-6 | 50 | 50 | 0 | 1.836 ± 0.007 |

| Composite Name | MAC, g cm−2 | |||

|---|---|---|---|---|

| 60 keV | 662 keV | 1173 keV | 1333 keV | |

| ERB-1 | 2.5408 ± 0.0016 | 0.1113 ± 0.0010 | 0.0730 ± 0.0015 | 0.0653 ± 0.0018 |

| ERB-2 | 3.3514 ± 0.0010 | 0.1296 ± 0.0023 | 0.0835 ± 0.0013 | 0.0745 ± 0.0009 |

| ERB-3 | 2.9651 ± 0.0009 | 0.1152 ± 0.0009 | 0.0685 ± 0.0021 | 0.0607 ± 0.0015 |

| ERB-4 | 3.1480 ± 0.0014 | 0.1225 ± 0.0018 | 0.0781 ± 0.0018 | 0.0697 ± 0.0011 |

| ERB-5 | 2.6560 ± 0.0019 | 0.1021 ± 0.0013 | 0.0682 ± 0.0019 | 0.0611 ± 0.0017 |

| ERB-6 | 2.6677 ± 0.0021 | 0.1090 ± 0.0020 | 0.0754 ± 0.0011 | 0.0676 ± 0.0021 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hedaya, A.; Elsafi, M.; Al-Saleh, W.M.; Saleh, I.H. Effect of Bi2O3 Particle Size on the Radiation-Shielding Performance of Free-Lead Epoxide Materials against Ionizing Radiation. Polymers 2024, 16, 2125. https://doi.org/10.3390/polym16152125

Hedaya A, Elsafi M, Al-Saleh WM, Saleh IH. Effect of Bi2O3 Particle Size on the Radiation-Shielding Performance of Free-Lead Epoxide Materials against Ionizing Radiation. Polymers. 2024; 16(15):2125. https://doi.org/10.3390/polym16152125

Chicago/Turabian StyleHedaya, Ali, Mohamed Elsafi, Wafa M. Al-Saleh, and Ibrahim H. Saleh. 2024. "Effect of Bi2O3 Particle Size on the Radiation-Shielding Performance of Free-Lead Epoxide Materials against Ionizing Radiation" Polymers 16, no. 15: 2125. https://doi.org/10.3390/polym16152125

APA StyleHedaya, A., Elsafi, M., Al-Saleh, W. M., & Saleh, I. H. (2024). Effect of Bi2O3 Particle Size on the Radiation-Shielding Performance of Free-Lead Epoxide Materials against Ionizing Radiation. Polymers, 16(15), 2125. https://doi.org/10.3390/polym16152125