Effect of UV Top Coating Microcapsules on the Coating Properties of Fiberboard Surfaces

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Preparation Method of UV Top Coating Microcapsules

2.3. Preparation Method of UV Coatings on the Fiberboard Surface

2.4. Testing and Characterization

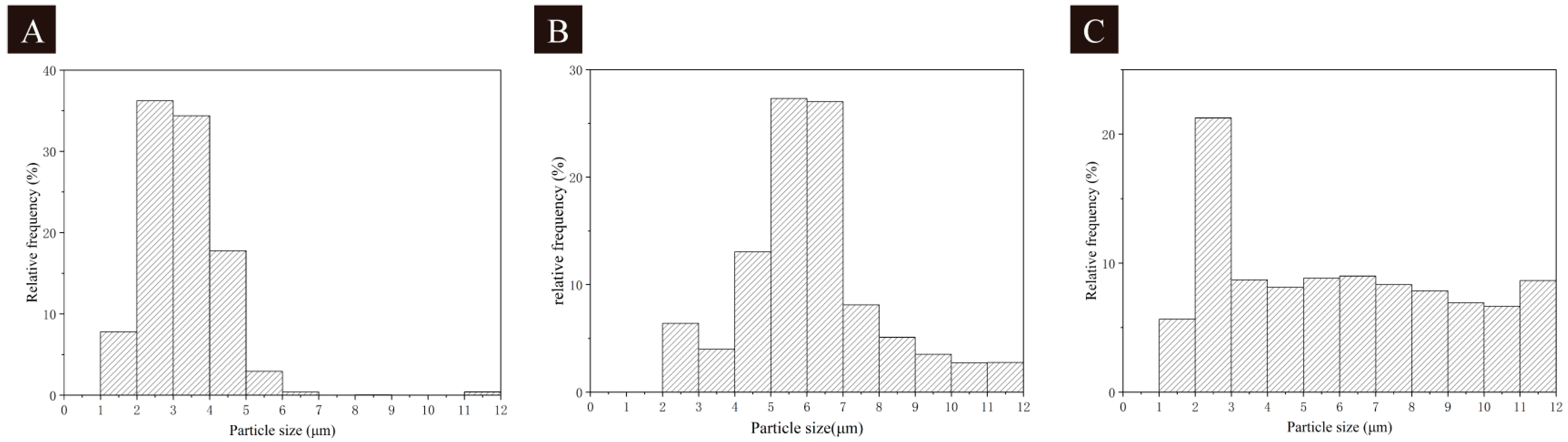

2.4.1. Microscopic Characterization

2.4.2. Chemical Composition

2.4.3. Optical Properties

2.4.4. Mechanical Properties

2.4.5. Self-Healing Properties Test

3. Results and Discussion

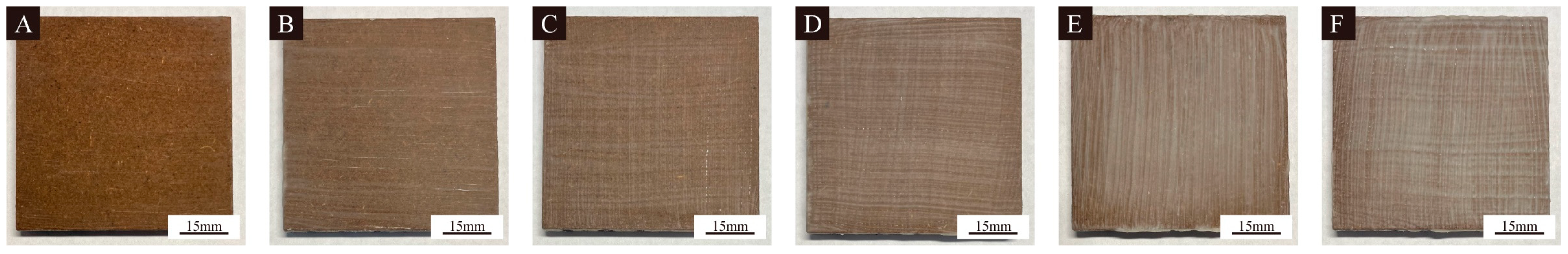

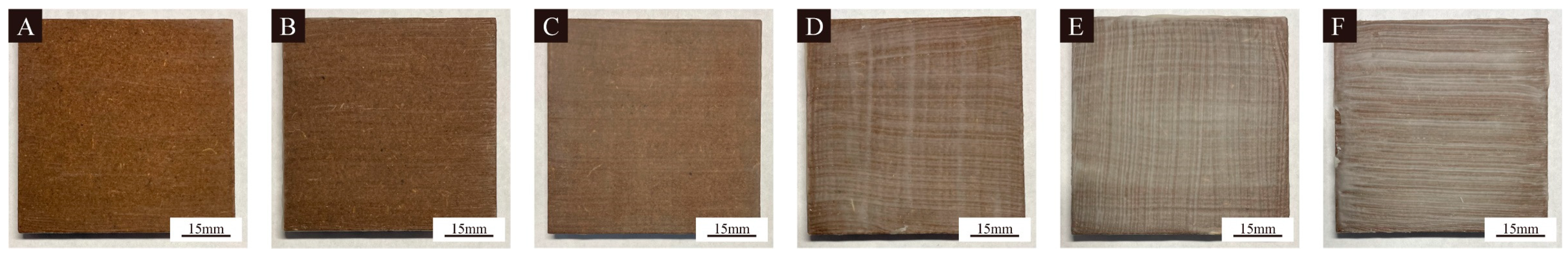

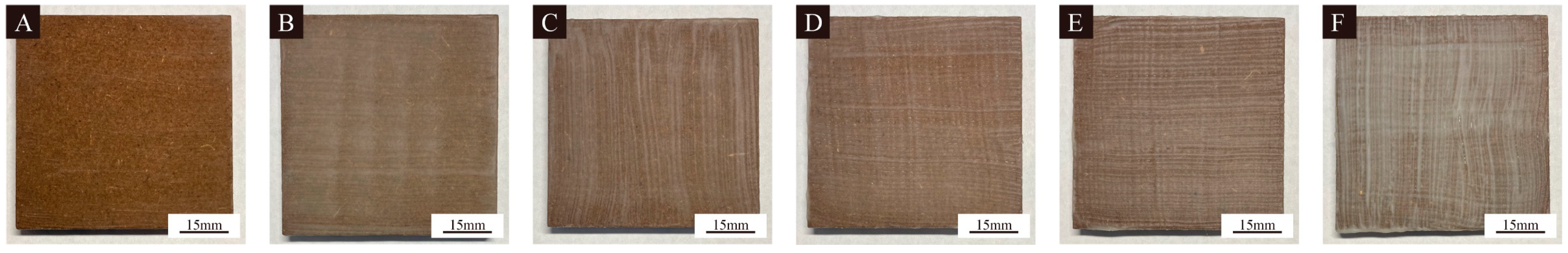

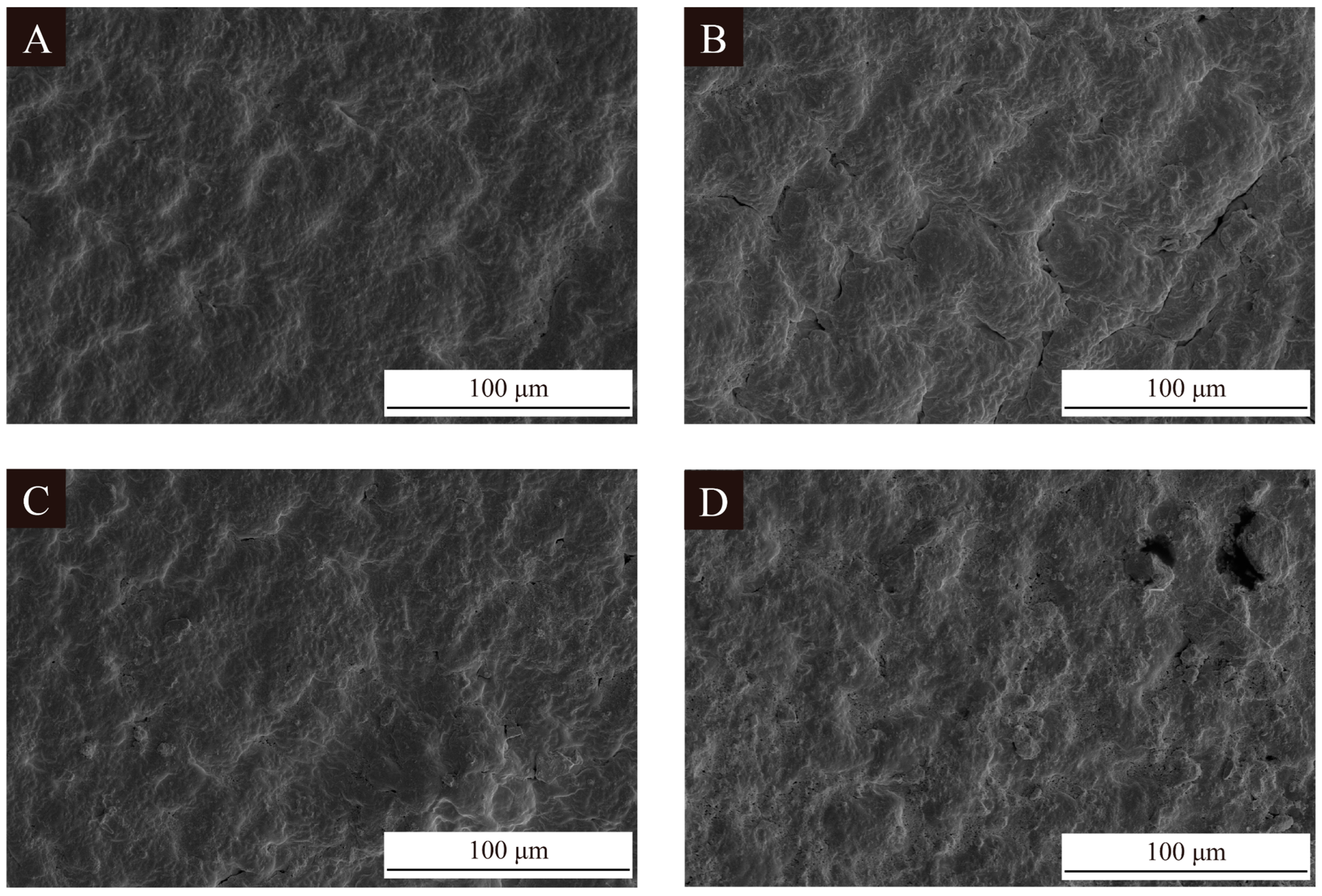

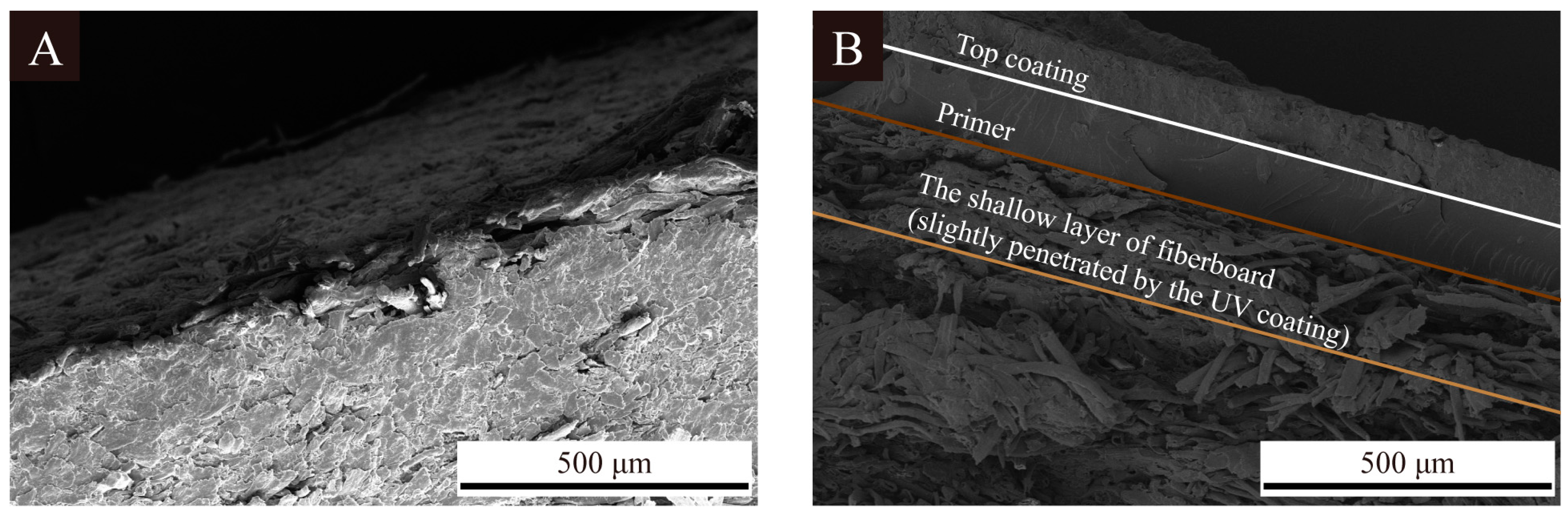

3.1. Macroscopic Analysis of the UV Coatings on Fiberboard Surfaces

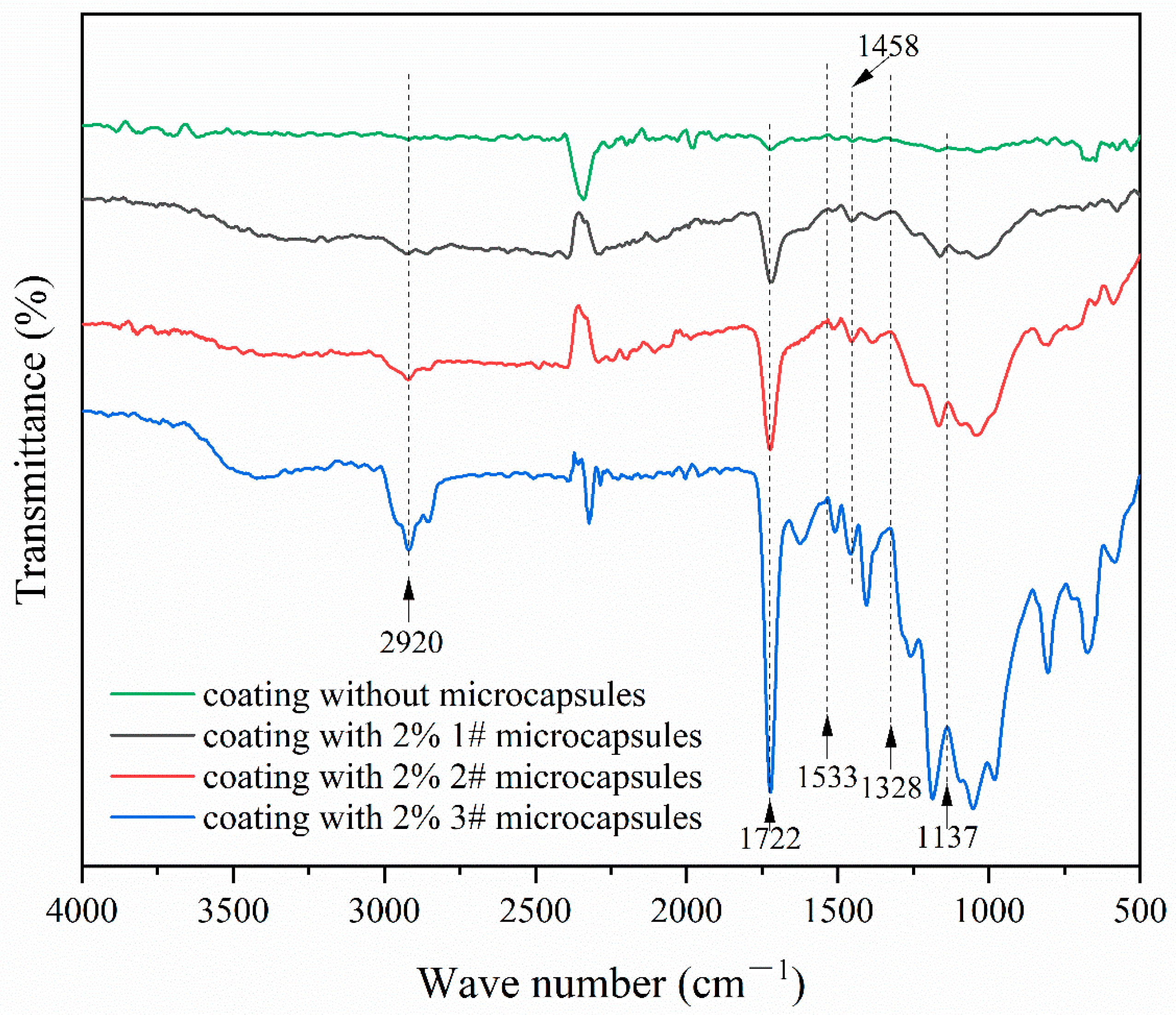

3.2. Chemical Analysis of the UV Coating on Fiberboard Surfaces

3.3. Optical Analysis of the UV Coating on Fiberboard Surfaces

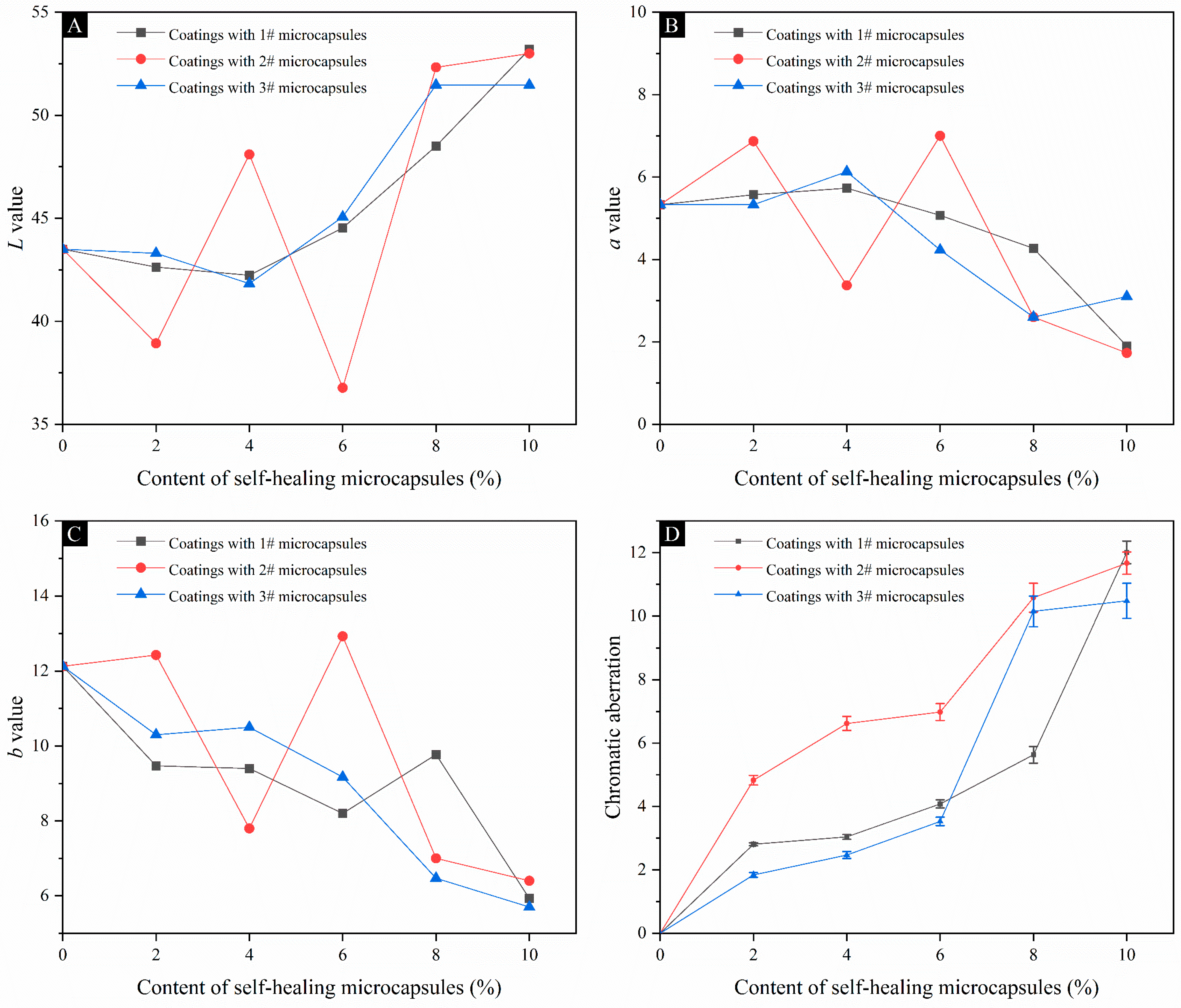

3.3.1. Analysis of Chromatic Aberration and Chromaticity Value of the UV Coating on Fiberboard Surfaces

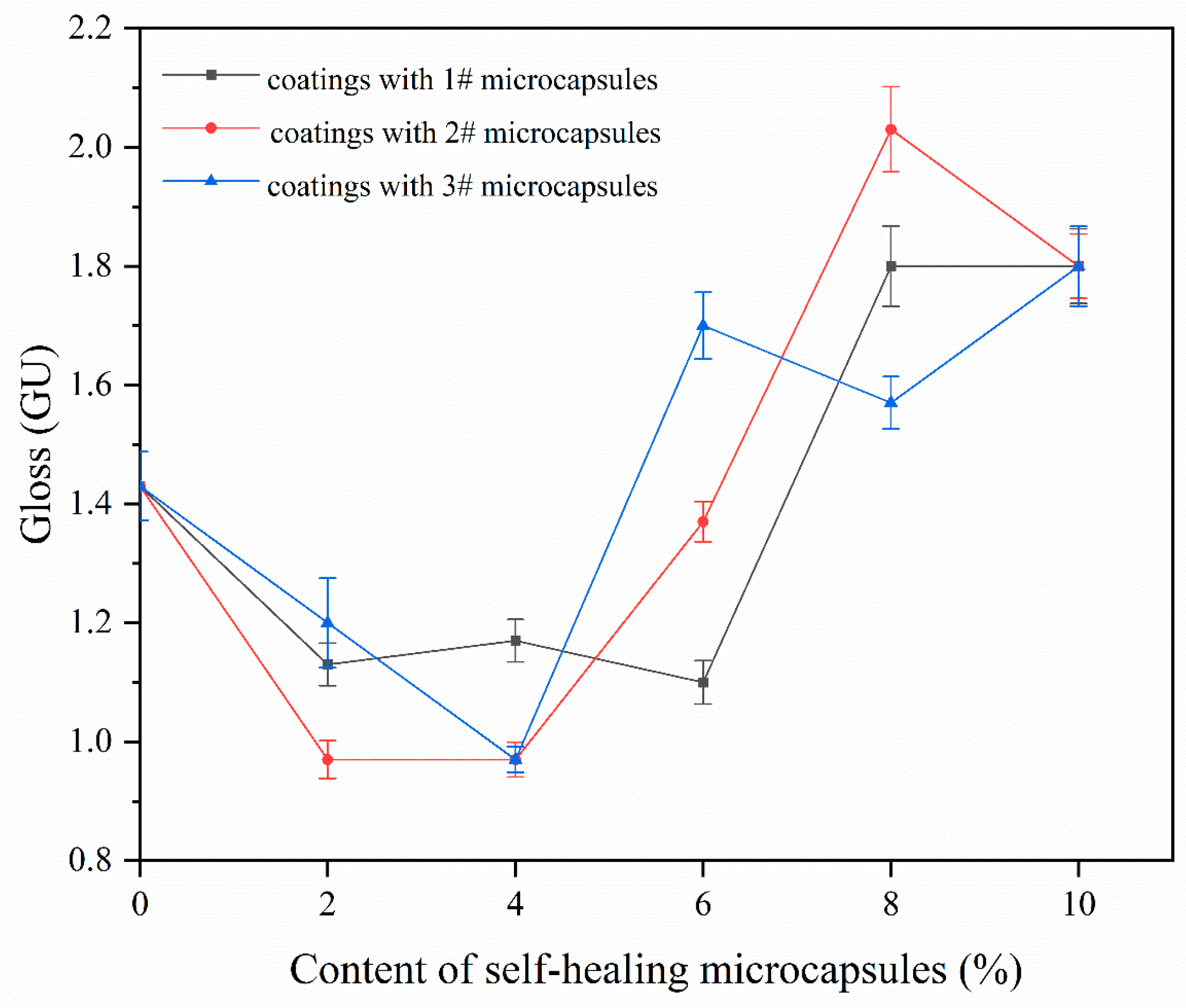

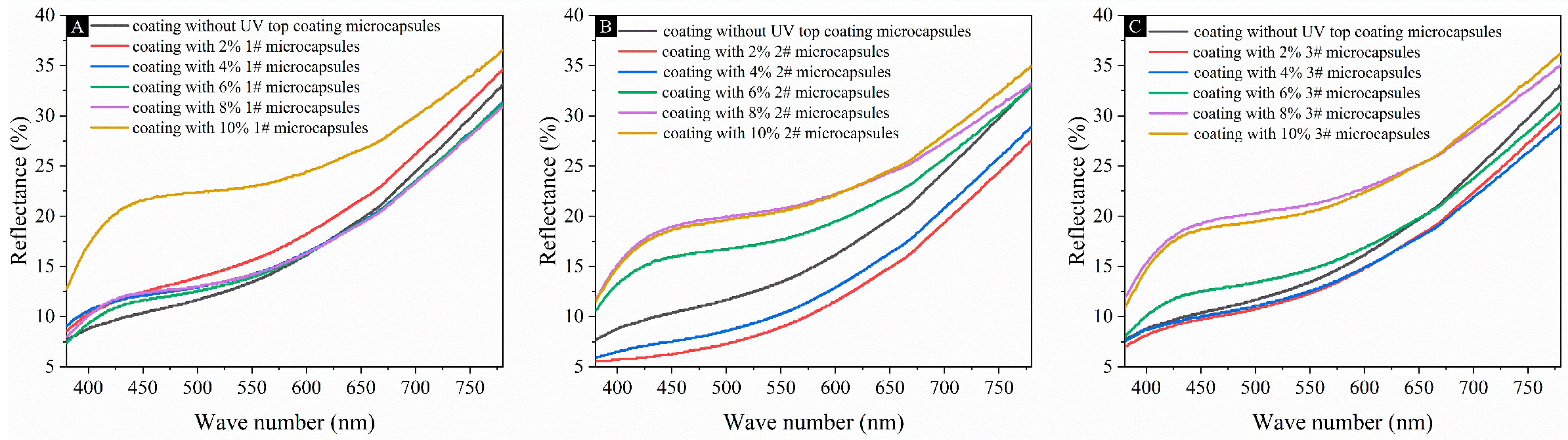

3.3.2. Gloss and Reflectance Analysis of the Coating on Fiberboard Surfaces

3.4. Mechanical Analysis of the UV Coating on Fiberboard Surfaces

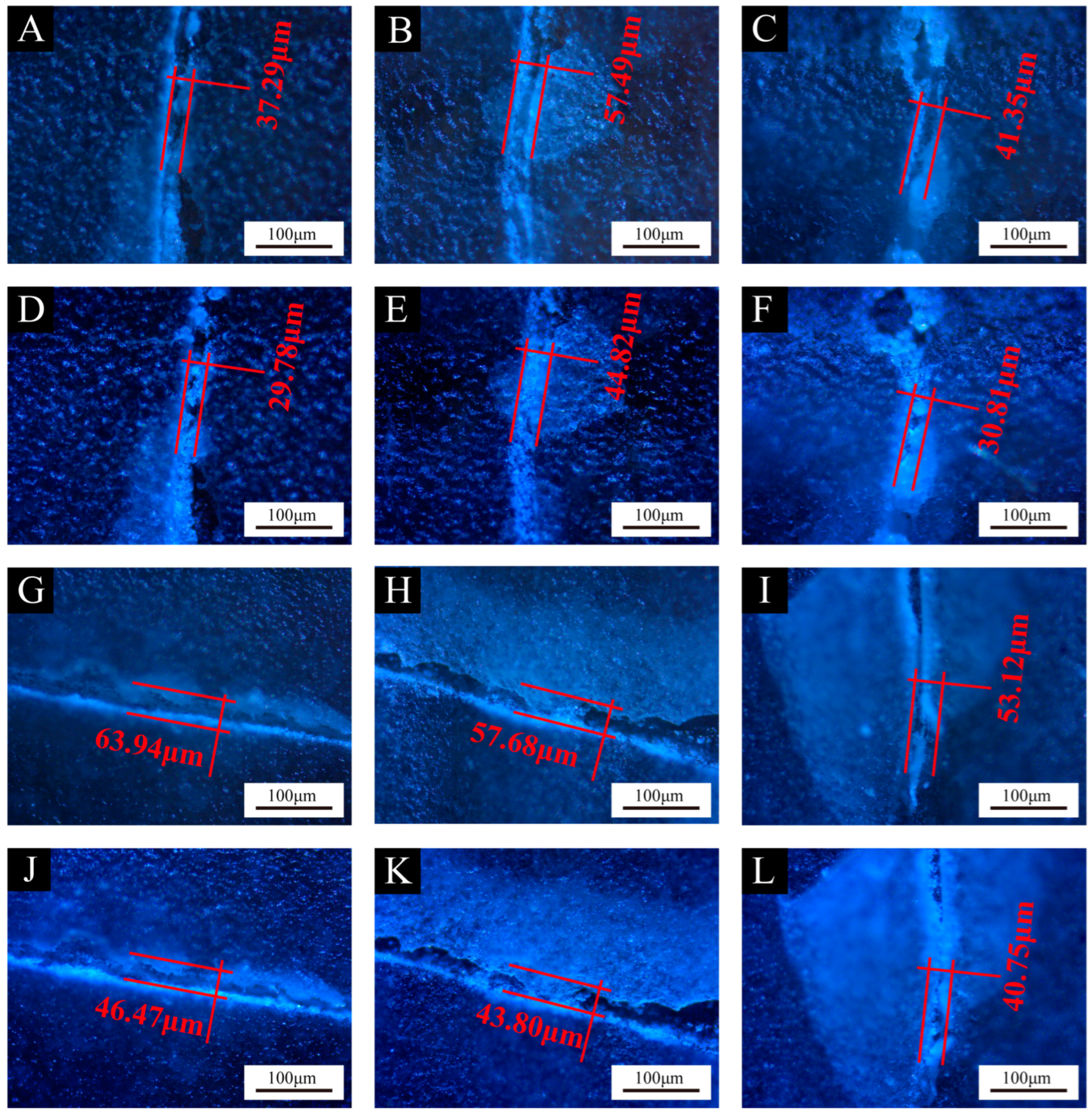

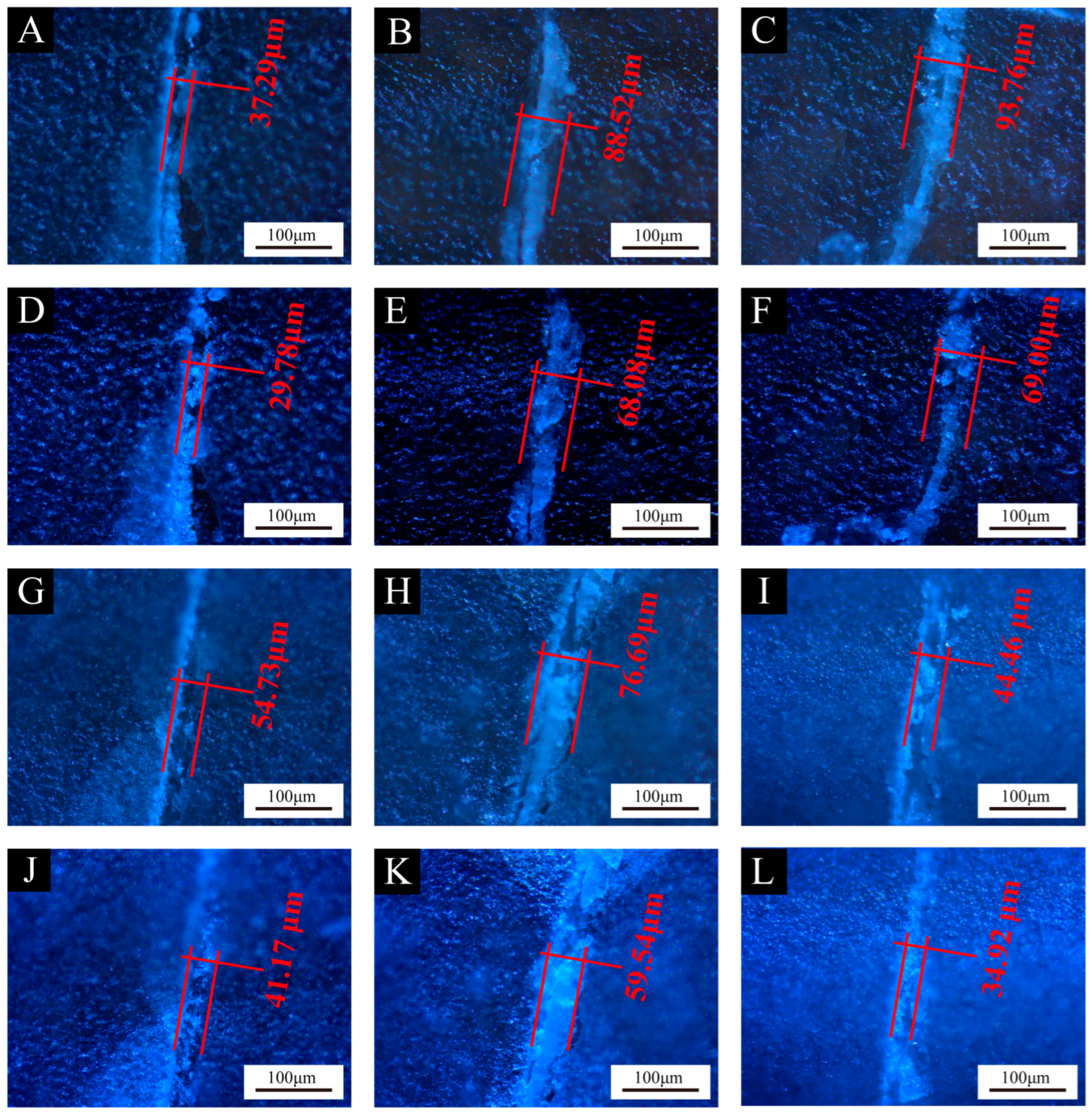

3.5. Self-Healing Property Analysis of the UV Coating on Fiberboard Surfaces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.G.; Niu, J.Y. Green Material Characteristics Applied to Office Desk Furniture. Bioresources 2022, 17, 2228–2242. [Google Scholar] [CrossRef]

- Zhu, H.L.; Luo, W.; Ciesielski, P.N.; Fang, Z.Q.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L.B. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Nicolau, A.; Pop, M.A.; Cosereanu, C. 3D Printing Application in Wood Furniture Components Assembling. Materials 2022, 15, 2907. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.Y.; Zhu, Y. Reverse design and additive manufacturing of furniture protective foot covers. Bioresources 2024, 19, 4670–4678. [Google Scholar] [CrossRef]

- Hu, W.G.; Liu, N.; Xu, L.; Guan, H.Y. Study on cold/warm sensation of materials used in desktop of furniture. Wood Res. 2020, 65, 497–506. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, W.; Tan, Y. Multi-attribute hierarchical clustering for product family division of customized wooden doors. Bioresources 2023, 18, 7889–7904. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Xu, W.; Li, R.R.; Zhou, J.C.; Luo, Z.Y. Study on sustainable lightweight design of airport waiting chair frame structure based on ANSYS workbench. Sustainability 2024, 16, 5350. [Google Scholar] [CrossRef]

- Li, S.D.; Yuan, Y.; Wang, J.M.; Guo, M.H. Do Novel Wooden Composites Provide an Environmentally Favorable Alternative for Panel-type Furniture? Bioresources 2019, 14, 2740–2758. [Google Scholar] [CrossRef]

- Ferdosian, F.; Pan, Z.H.; Gao, G.C.; Zhao, B.X. Bio-Based Adhesives and Evaluation for Wood Composites Application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef]

- Jin, S.C.; Li, K.; Zhang, X.W.; Gao, Q.; Zeng, L.; Shi, S.Q.; Li, J.Z. Phytic acid-assisted fabrication for soybean meal/nanofiber composite adhesive via bioinspired chelation reinforcement strategy. J. Hazard. Mater. 2020, 399, 123064. [Google Scholar] [CrossRef]

- Feng, X.H.; Wu, Z.H.; Sang, R.J.; Wang, F.; Zhu, Y.Y.; Wu, M.J. Surface Design of Wood-Based Board to Imitate Wood Texture Using 3D Printing Technology. Bioresources 2019, 14, 8196–8211. [Google Scholar] [CrossRef]

- Sang, R.J.; Yang, S.; Fan, Z.X. Effects of MDF Substrate Surface Coating Process on UV Inkjet Print Quality. Coatings 2023, 13, 970. [Google Scholar] [CrossRef]

- Nam, K.H.; Seo, K.; Seo, J.; Khan, S.B.; Han, H. Ultraviolet-curable polyurethane acrylate nanocomposite coatings based on surface-modified calcium carbonate. Prog. Org. Coat. 2015, 85, 22–30. [Google Scholar] [CrossRef]

- Sang, R.J.; Yang, F. Effect of TiO2@ CaCO3 Waterborne Primer on the Coloring Performance of Inkjet-Printed Wood Product Coatings. Coatings 2023, 13, 2071. [Google Scholar] [CrossRef]

- Latthe, S.S.; Sutar, R.S.; Kodag, V.S.; Bhosale, A.K.; Kumar, A.M.; Sadasivuni, K.K.; Xing, R.M.; Liu, S.H. Self—Cleaning superhydrophobic coatings: Potential industrial applications. Prog. Org. Coat. 2019, 128, 52–58. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Polyurethane Non-Transparent Coating Process on Paint Film Performance Applied on Modified Poplar. Coatings 2022, 12, 39. [Google Scholar] [CrossRef]

- Sang, R.J.; Yang, F.; Fan, Z.X. The Effect of Water-Based Primer Pretreatment on the Performance of Water-Based Inkjet Coatings on Wood Surfaces. Coatings 2023, 13, 1649. [Google Scholar] [CrossRef]

- Huang, T.; Zhou, C.M.; Wang, X.M.; Kaner, J. A Study of Visual Perception Based on Colour and Texture of Reconstituted Decorative Veneer. Coatings 2024, 14, 57. [Google Scholar] [CrossRef]

- Agnol, L.D.; Dias, F.T.G.; Ornaghi, H.L.; Sangermano, M.; Bianchi, O. UV-curable waterborne polyurethane coatings: A state-of-the-art and recent advances review. Prog. Org. Coat. 2021, 154, 106156. [Google Scholar] [CrossRef]

- Chen, X.Y.; Li, X.Y.; Hu, J.J.; Guo, X.; Zhang, Y.J.; Zhang, Y.; Sun, W.S. Influence of metal oxide doping on waterborne UV polyurethane coating. J. For. Eng. 2023, 8, 190–197. [Google Scholar]

- Sang, R.J.; Fan, Z.X. Effect of surface treatment of poplar substrate on the characterization performance of UV inkjet coating. J. For. Eng. 2022, 7, 177–182. [Google Scholar]

- Li, X.; Wang, D.; Zhao, L.Y.; Hou, X.Z.; Liu, L.; Feng, B.; Li, M.X.; Zheng, P.; Zhao, X.; Wei, S.Y. UV LED curable epoxy soybean-oil-based waterborne PUA resin for wood coatings. Prog. Org. Coat. 2021, 151, 105942. [Google Scholar] [CrossRef]

- Su, Y.P.; Zhang, S.T.; Chen, Y.W.; Yuan, T.; Yang, Z.H. One-step synthesis of novel renewable multi-functional linseed oil-based acrylate prepolymers and its application in UV-curable coatings. Prog. Org. Coat. 2020, 148, 105820. [Google Scholar] [CrossRef]

- Noè, C.; Tonda-Turo, C.; Carmagnola, I.; Hakkarainen, M.; Sangermano, M. UV-Cured Biodegradable Methacrylated Starch-Based Coatings. Coatings 2021, 11, 127. [Google Scholar] [CrossRef]

- Wu, Z.H.; Zhang, H.Q. Research progress on waterborne UV-curable coatings and their applications for furniture and wood products. J. For. Eng. 2023, 8, 1–12. [Google Scholar]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness Evaluation of Coated Wood Surfaces as Function of Varnish Type and Exposure to Different Conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Xue, J.X.; Xu, W.; Zhou, J.C.; Mao, W.G.; Wu, S.S. Effects of High-Temperature Heat Treatment Modification by Impregnation on Physical And Mechanical Properties of Poplar. Materials 2022, 15, 7334. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Liu, Y.; Wang, J.X.; Xu, W. Study of selective modification effect of constructed structural color layers on European beech wood surfaces. Forests 2024, 15, 261. [Google Scholar] [CrossRef]

- Wang, X.Y.; Liu, X.; Wu, S.S.; Xu, W. The influence of different impregnation factors on mechanical properties of silica sol-modified Populus tomentosa. Wood Fiber Sci. 2024, 56, 65–71. [Google Scholar]

- Hu, W.G.; Zhang, J.L. Bolt-Bearing Yield Strength of Three-Layered Cross-Laminated Timber Treated with Phenol Formaldehyde Resin. Forests 2020, 11, 551. [Google Scholar] [CrossRef]

- Gosavi, A.A.; Nandgude, T.D.; Mishra, R.K.; Puri, D.B. Exploring the Potential of Artificial Intelligence as a Facilitating Tool for Formulation Development in Fluidized Bed Processor: A Comprehensive Review. AAPS PharSciTech 2024, 25, 111. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Ettelaie, R.; Dong, L.L.; Li, X.L.; Li, T.; Zhang, X.M.; Binks, B.P.; Yang, H.Q. Pickering emulsion droplet-based biomimetic microreactors for continuous flow cascade reactions. Nat. Commun. 2022, 13, 475. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.L.; Zhang, L.; Yu, R.L.; Yuan, L.Y.; Yang, Y.H.; He, X.D.; Wang, J.M.; Li, Z.P. Microencapsulation of ethylenediamine and its application in binary self-healing system using dual-microcapsule. Mater. Design 2020, 189, 108535. [Google Scholar] [CrossRef]

- Mu, H.X.; Deng, Y.Q.; Zou, W.C.; Yang, X.D.; Zhao, Q. Dual Microcapsules Encapsulating Liquid Diamine and Isocyanate for Application in Self-Healing Coatings. Coatings 2024, 14, 410. [Google Scholar] [CrossRef]

- Pan, N.N.; Fan, C.L.; Quan, Q.; Zhu, M.H.; Zhou, X.Y.; Chen, M.Z. Preparation and performance of high energy storage cellulose-based phase change Pickering emulsion. J. For. Eng. 2023, 8, 101–112. [Google Scholar]

- Farzi, G.; Davoodi, A.; Ahmadi, A.; Neisiany, R.E.; Anwer, M.K.; Aboudzadeh, M.A. Encapsulation of Cerium Nitrate within Poly(urea-formaldehyde) Microcapsules for the Development of Self-healing Epoxy-based Coating. ACS Omega 2022, 6, 31147–31153. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Zhang, Q.; Wei, X.Y.; Sun, F.W. Preparation and characterization of modified polyethylene glycol/phenolic foam filled with phase change microcapsules. J. For. Eng. 2023, 8, 102–109. [Google Scholar]

- Yan, X.X.; Peng, W.W. Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating. Coatings 2020, 10, 764. [Google Scholar] [CrossRef]

- Tomasz, K.; Maja, Z.; Arkadiusz, J. The impact of ultrasound on Janus capsules at gel-liquid interface. Curr. Appl. Phys. 2022, 38, 22–29. [Google Scholar]

- Song, Y.K.; Kim, H.W.; Chung, C.M. Repeatable Self-Healing of a Protective Coating Based on Vegetable-Oil-Loaded Microcapsules. Polymers 2022, 14, 2013. [Google Scholar] [CrossRef]

- Liu, B.; Wu, M.L.; Du, W.; Jiang, L.; Li, H.J.; Wang, L.X.; Li, J.H.; Zuo, D.Y.; Ding, Q.J. The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers 2023, 15, 2718. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.X.; Liu, J.T.; Zhang, Y.R.; Ge, Y.; Wu, R.; Song, X.H.; Zhang, P.; Wu, J. Mechanical behavior and self-healing mechanism of polyurea-based double-walled microcapsule/epoxy composite films. Prog. Org. Coat. 2021, 157, 106283. [Google Scholar] [CrossRef]

- Thakur, T.; Gaur, B.; Singha, A.S. Bio-based epoxy/imidoamine encapsulated microcapsules and their application for high performance self-healing coatings. Prog. Org. Coat. 2021, 159, 106436. [Google Scholar] [CrossRef]

- Zotiadis, C.; Patrikalos, I.; Loukaidou, V.; Korres, D.M.; Karantonis, A.; Vouyiouka, S. Self-healing coatings based on poly(urea-formaldehyde) microcapsules: In situ polymerization, capsule properties and application. Prog. Org. Coat. 2021, 161, 106475. [Google Scholar] [CrossRef]

- Ullah, H.; Qureshi, K.S.; Khan, U.; Zaffar, M.; Yang, Y.J.; Rabat, N.E.; Khan, M.I.; Saqib, S.; Mukhtar, A.; Ullah, S.; et al. Self-healing epoxy coating synthesis by embedment of metal 2-methyl imidazole and acetylacetonate complexes with microcapsules. Chemosphere 2021, 285, 131492. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Xu, W. Effect of Coating Process on Properties of Two-Component Waterborne Polyurethane Coatings for Wood. Coatings 2022, 12, 1857. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Sanding Processes on the Surface Properties of Modified Poplar Coated by Primer Compared with Mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Xu, W. Influence of Cell Characteristics on the Construction of Structural Color Layers on Wood Surfaces. Forests 2024, 15, 676. [Google Scholar] [CrossRef]

- Weng, M.Y.; Zhu, Y.T.; Mao, W.G.; Zhou, J.C.; Xu, W. Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests 2023, 14, 1440. [Google Scholar] [CrossRef]

- GB/T 11186.3-1989; Methods for Measuring the Colour of Coating Films. Part III: Calculation of Colour Differences. Standardization Administration of the People’s Republic of China: Beijing, China, 1990.

- GB/T 4893.6-2013; Test of Surface Coatings of Furniture-Part 6: Determination of Gloss Value. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Wang, C.; Yu, J.H.; Jiang, M.H.; Li, J.Y. Effect of slicing parameters on the light transmittance of 3D-printed polyethylene terephthalate glycol products. Bioresources 2024, 19, 500–509. [Google Scholar] [CrossRef]

- GB/T 1732-2020; Determination of Impact Resistance of Coating Films. Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

- GB/T 6739-2022; Paints and Varnishes—Determination of Film Hardness by Pencil Test. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- Hu, W.G.; Liu, Y.; Konukcu, A.C. Study on withdrawal load resistance of screw in wood-based materials: Experimental and numerical. Wood Mater. Sci. Eng. 2023, 18, 334–343. [Google Scholar] [CrossRef]

- GB/T 4893.4-2013; Test of Surface Coatings of Furniture-Part 4: Determination of Adhesion-Cross Cut. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

| Test Materials | Molecular Mass (g/mol) | CAS | Producer |

|---|---|---|---|

| 37% formaldehyde | 30.03 | 50-00-0 | Shandong Xinjiuchenghuagong Technology Co., Ltd., Jinan, China |

| Melamine | 126.12 | 108-78-1 | Jiangning District Wanjuyi Experimental Equipment Firm, Nanjing, China |

| Triethanolamine | 149.19 | 102-71-6 | Nanjing Houxin Biotechnology Co., Ltd., Nanjing, China |

| Span-20 | 346.459 | 133-39-2 | Nanjing Houxin Biotechnology Co., Ltd., Nanjing, China |

| Triton X-100 | 646.85 | 9002-93-1 | Shandong Yousuo Chemical Technology Co., Ltd., Linyi, China |

| Absolute ethanol | 46.07 | 64-17-5 | Wuxi Jingke Chemical Co., Ltd., Wuxi, China |

| UV top coating | - | - | Jiangsu Himonia Technology Co., Ltd., Zhenjiang, China |

| Citric acid monohydrate | 210.139 | 5949-29-1 | Jinan Xiaoshi Chemical Co., Ltd., Jinan, China |

| Test Instruments | Model | Manufacturer |

|---|---|---|

| Water bath | LC-OB-5L | Hunan Yunyihui E-commerce Co., Ltd., Changsha, China |

| Scanning electron microscope (SEM) | OLS3000 | Jiangdong Jiecheng Electronic Components Store, Ningbo, China |

| Powder tablet press | HY-12 | Tianjin Tianguang Optical Instrument Co., Ltd., Tianjin, China |

| Infrared spectrometer | Cary630 | Shenyang Jasco Trading Co., Ltd., Shenyang, China |

| Chromatic aberration instrument | 3nhYS3010 | Shenzhen threenh Technology Co., Ltd., Shenzhen, China |

| Gloss meter | 3nhYG60S | Shenzhen threenh Technology Co., Ltd., Shenzhen, China |

| Ultraviolet spectrophotometer | U-3900 | Hitachi High-Tech Co., Ltd., Beijing, China |

| Coating roughness tester | SJ-411 | Dongguan Asktools Co., Ltd., Dongguan, China |

| Single-lamp curing machine | 620# | Huzhou Tongxu Machinery Equipment Co., Ltd., Huzhou, China |

| Sample (#) | Triton X-100 (g) | Span 20 (g) | Ethanol (mL) | UV Topcoat (g) | Formaldehyde (g) | Melamine (g) | Deionized Water (mL) |

|---|---|---|---|---|---|---|---|

| 1 | 0.08 | 0.22 | 78.90 | 8.80 | 13.52 | 6.00 | 30.00 |

| 2 | 0.15 | 0.15 | 78.90 | 8.80 | 13.52 | 6.00 | 30.00 |

| 3 | 0.20 | 0.10 | 78.90 | 8.80 | 13.52 | 6.00 | 30.00 |

| Content of UV Top Coating Microcapsules (%) | Mass of UV Top Coating Microcapsules (g) | Mass of UV Top Coating (g) |

|---|---|---|

| 0 | 0 | 0.800 |

| 2.0 | 0.016 | 0.784 |

| 4.0 | 0.032 | 0.768 |

| 6.0 | 0.048 | 0.752 |

| 8.0 | 0.064 | 0.736 |

| 10.0 | 0.080 | 0.720 |

| UV Coatings | Content of UV Top Coating Microcapsules (%) | L | a | b | ΔE |

|---|---|---|---|---|---|

| Coatings with 1# microcapsules | 0 | 43.50 | 5.33 | 12.13 | - |

| 2.0 | 42.63 | 5.57 | 9.47 | 2.81 | |

| 4.0 | 42.23 | 5.73 | 9.40 | 3.04 | |

| 6.0 | 44.53 | 5.07 | 8.20 | 4.08 | |

| 8.0 | 48.50 | 4.27 | 9.77 | 5.63 | |

| 10.0 | 53.20 | 1.90 | 5.93 | 12.01 | |

| Coatings with 2# microcapsules | 0 | 43.50 | 5.33 | 12.13 | - |

| 2.0 | 38.93 | 6.87 | 12.43 | 4.83 | |

| 4.0 | 48.10 | 3.37 | 7.80 | 6.62 | |

| 6.0 | 36.77 | 7.00 | 12.93 | 6.98 | |

| 8.0 | 52.33 | 2.60 | 7.00 | 10.58 | |

| 10.0 | 53.00 | 1.73 | 6.40 | 11.67 | |

| Coatings with 3# microcapsules | 0 | 43.50 | 5.33 | 12.13 | - |

| 2.0 | 43.30 | 5.33 | 10.30 | 1.84 | |

| 4.0 | 41.83 | 6.13 | 10.50 | 2.47 | |

| 6.0 | 45.07 | 4.23 | 9.17 | 3.53 | |

| 8.0 | 51.47 | 2.60 | 6.47 | 10.15 | |

| 10.0 | 51.47 | 3.10 | 5.70 | 10.48 |

| Coatings | Content of Self-Healing Microcapsules (%) | Gloss (GU) | Reflectance (%) | ||

|---|---|---|---|---|---|

| 20° | 60° | 85° | |||

| Coatings with 1# microcapsules | 0 | 0.20 | 1.43 | 5.13 | 17.10 |

| 2.0 | 0.20 | 1.13 | 3.90 | 19.01 | |

| 4.0 | 0.20 | 1.17 | 3.10 | 17.45 | |

| 6.0 | 0.20 | 1.10 | 4.50 | 17.13 | |

| 8.0 | 0.23 | 1.80 | 7.00 | 17.34 | |

| 10.0 | 0.33 | 1.80 | 2.00 | 25.11 | |

| Coatings with 2# microcapsules | 0 | 0.20 | 1.43 | 5.13 | 17.10 |

| 2.0 | 0.10 | 0.97 | 3.70 | 12.59 | |

| 4.0 | 0.20 | 0.97 | 5.00 | 13.89 | |

| 6.0 | 0.30 | 1.37 | 4.93 | 20.37 | |

| 8.0 | 0.33 | 2.03 | 3.53 | 22.68 | |

| 10.0 | 0.37 | 1.80 | 8.67 | 22.84 | |

| Coatings with 3# microcapsules | 0 | 0.20 | 1.43 | 5.13 | 17.10 |

| 2.0 | 0.20 | 1.20 | 2.77 | 15.72 | |

| 4.0 | 0.20 | 0.97 | 3.37 | 15.67 | |

| 6.0 | 0.20 | 1.70 | 8.93 | 17.71 | |

| 8.0 | 0.30 | 1.57 | 2.87 | 23.39 | |

| 10.0 | 0.33 | 1.80 | 2.30 | 23.17 | |

| Coatings | Content of Microcapsules (%) | Adhesion (Grade) | Hardness | Impact Resistance (Grade) | Roughness (μm) |

|---|---|---|---|---|---|

| Coatings with 1# microcapsules | 0 | 2 | 2H | 5 | 1.410 |

| 2.0 | 2 | 3H | 4 | 1.493 | |

| 4.0 | 2 | 3H | 4 | 1.443 | |

| 6.0 | 3 | 3H | 3 | 1.677 | |

| 8.0 | 3 | 3H | 3 | 1.867 | |

| 10.0 | 3 | 3H | 3 | 2.211 | |

| Coatings with 2# microcapsules | 0 | 2 | 2H | 5 | 1.410 |

| 2.0 | 2 | 2H | 4 | 1.507 | |

| 4.0 | 2 | 2H | 4 | 1.669 | |

| 6.0 | 3 | 2H | 4 | 1.927 | |

| 8.0 | 4 | 3H | 3 | 2.248 | |

| 10.0 | 4 | 3H | 3 | 2.847 | |

| Coatings with 3# microcapsules | 0 | 2 | 2H | 5 | 1.410 |

| 2.0 | 2 | 2H | 4 | 1.110 | |

| 4.0 | 2 | 3H | 4 | 1.254 | |

| 6.0 | 2 | 3H | 4 | 1.821 | |

| 8.0 | 3 | 3H | 4 | 2.180 | |

| 10.0 | 4 | 3H | 3 | 2.485 |

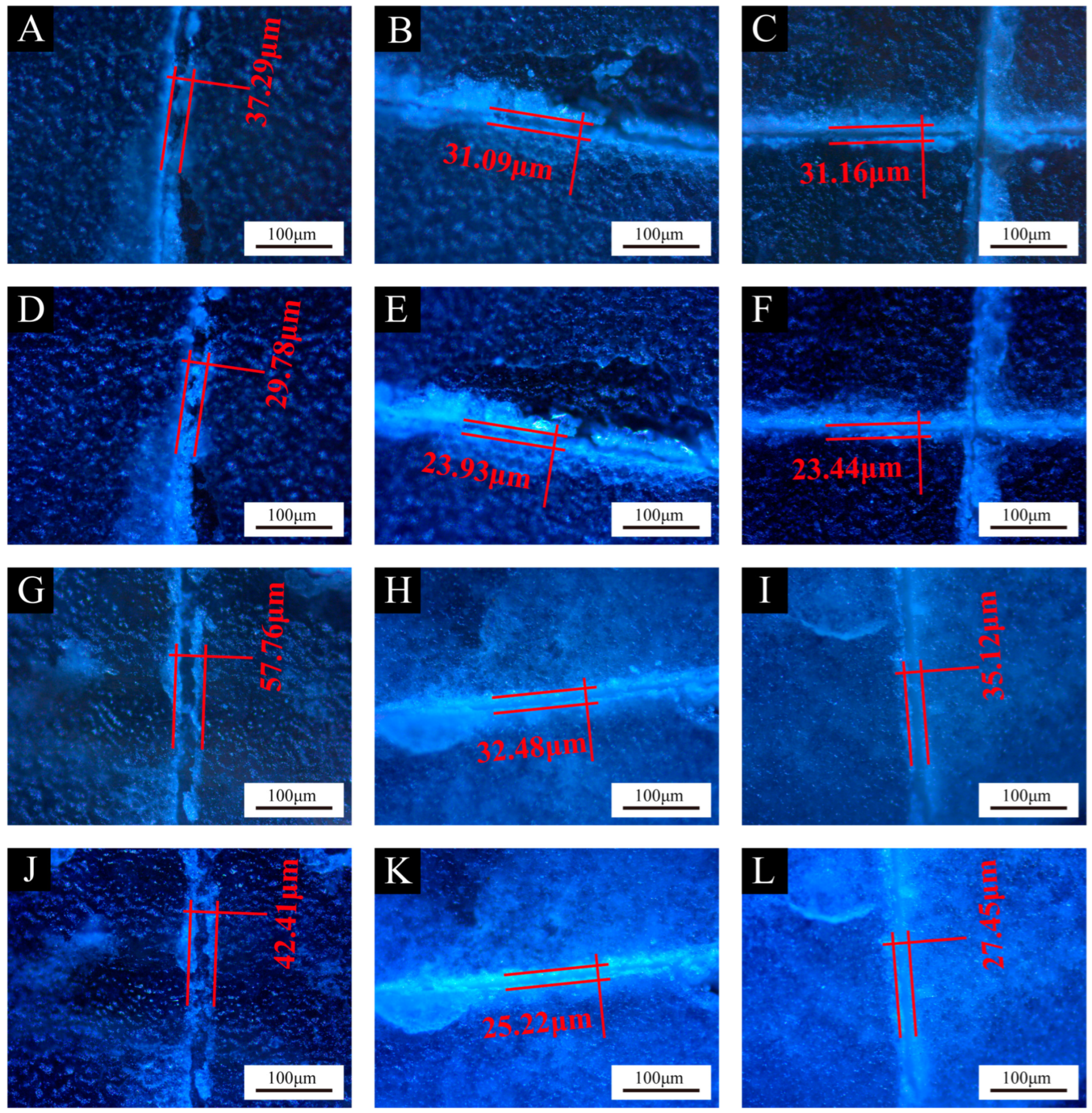

| Coatings | Content of Microcapsules (%) | Crack Width after Scratch (μm) | Crack Width after 1-Week Self-Healing (μm) | Self-Healing Rates (%) |

|---|---|---|---|---|

| Coatings with 1# microcapsules | 0 | 37.29 | 29.78 | 20.14 |

| 2.0 | 57.49 | 44.82 | 22.03 | |

| 4.0 | 41.35 | 30.81 | 25.49 | |

| 6.0 | 63.94 | 46.47 | 27.32 | |

| 8.0 | 57.68 | 43.80 | 24.07 | |

| 10.0 | 53.12 | 40.75 | 23.28 | |

| Coatings with 2# microcapsules | 0 | 37.29 | 29.78 | 20.14 |

| 2.0 | 88.52 | 68.08 | 23.09 | |

| 4.0 | 93.76 | 69.00 | 26.41 | |

| 6.0 | 54.73 | 41.17 | 24.78 | |

| 8.0 | 76.69 | 59.54 | 22.36 | |

| 10.0 | 44.46 | 34.92 | 21.45 | |

| Coatings with 3# microcapsules | 0 | 37.29 | 29.78 | 20.14 |

| 2.0 | 31.09 | 23.93 | 23.02 | |

| 4.0 | 31.16 | 23.44 | 24.79 | |

| 6.0 | 57.76 | 42.41 | 26.58 | |

| 8.0 | 32.48 | 25.22 | 22.35 | |

| 10.0 | 35.12 | 27.45 | 21.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Xia, Y.; Yan, X. Effect of UV Top Coating Microcapsules on the Coating Properties of Fiberboard Surfaces. Polymers 2024, 16, 2098. https://doi.org/10.3390/polym16152098

Zou Y, Xia Y, Yan X. Effect of UV Top Coating Microcapsules on the Coating Properties of Fiberboard Surfaces. Polymers. 2024; 16(15):2098. https://doi.org/10.3390/polym16152098

Chicago/Turabian StyleZou, Yuming, Yongxin Xia, and Xiaoxing Yan. 2024. "Effect of UV Top Coating Microcapsules on the Coating Properties of Fiberboard Surfaces" Polymers 16, no. 15: 2098. https://doi.org/10.3390/polym16152098

APA StyleZou, Y., Xia, Y., & Yan, X. (2024). Effect of UV Top Coating Microcapsules on the Coating Properties of Fiberboard Surfaces. Polymers, 16(15), 2098. https://doi.org/10.3390/polym16152098