Advancement of an Environmentally Friendly and Innovative Sustainable Rubber Wrap Film with Superior Sealing Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

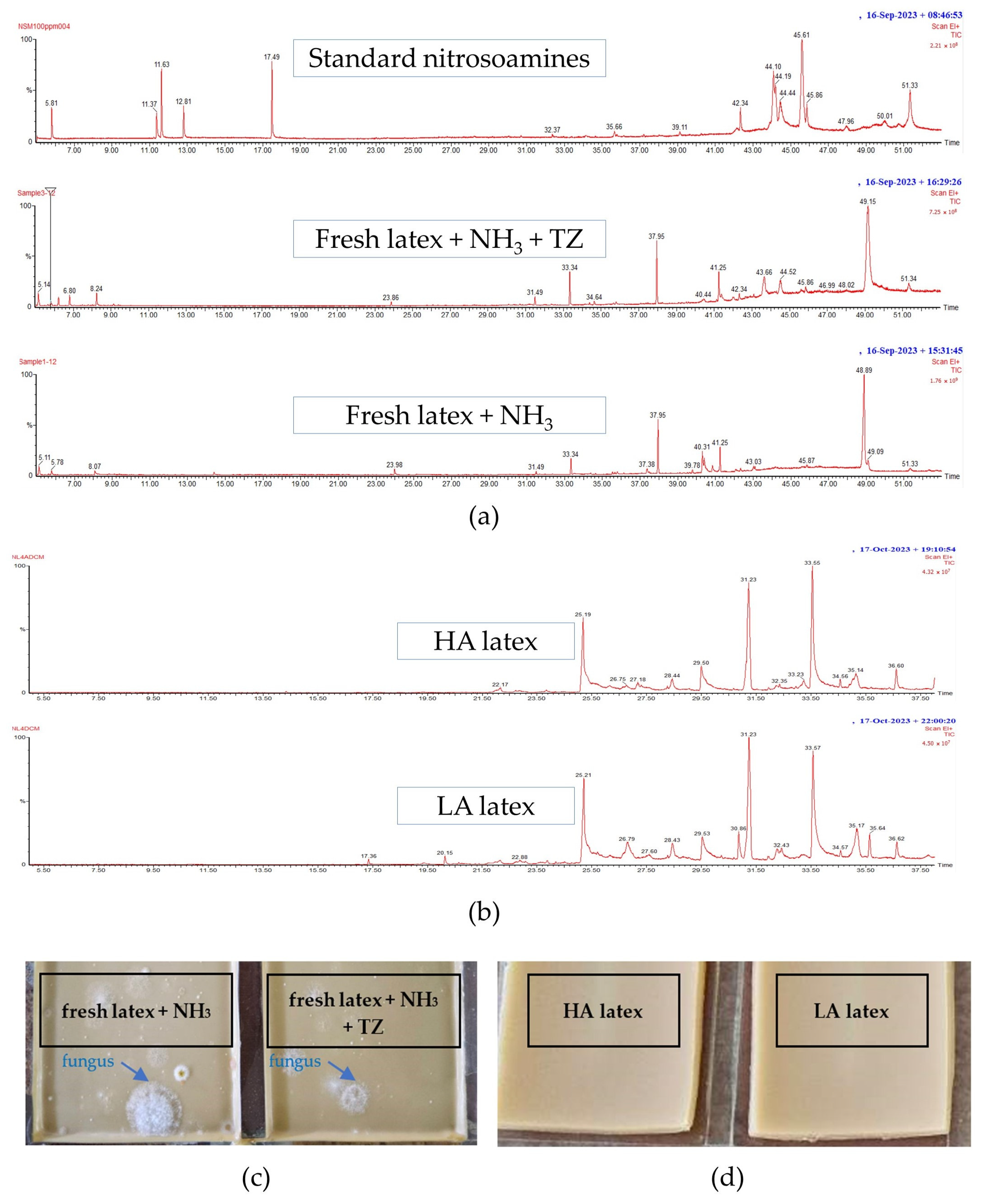

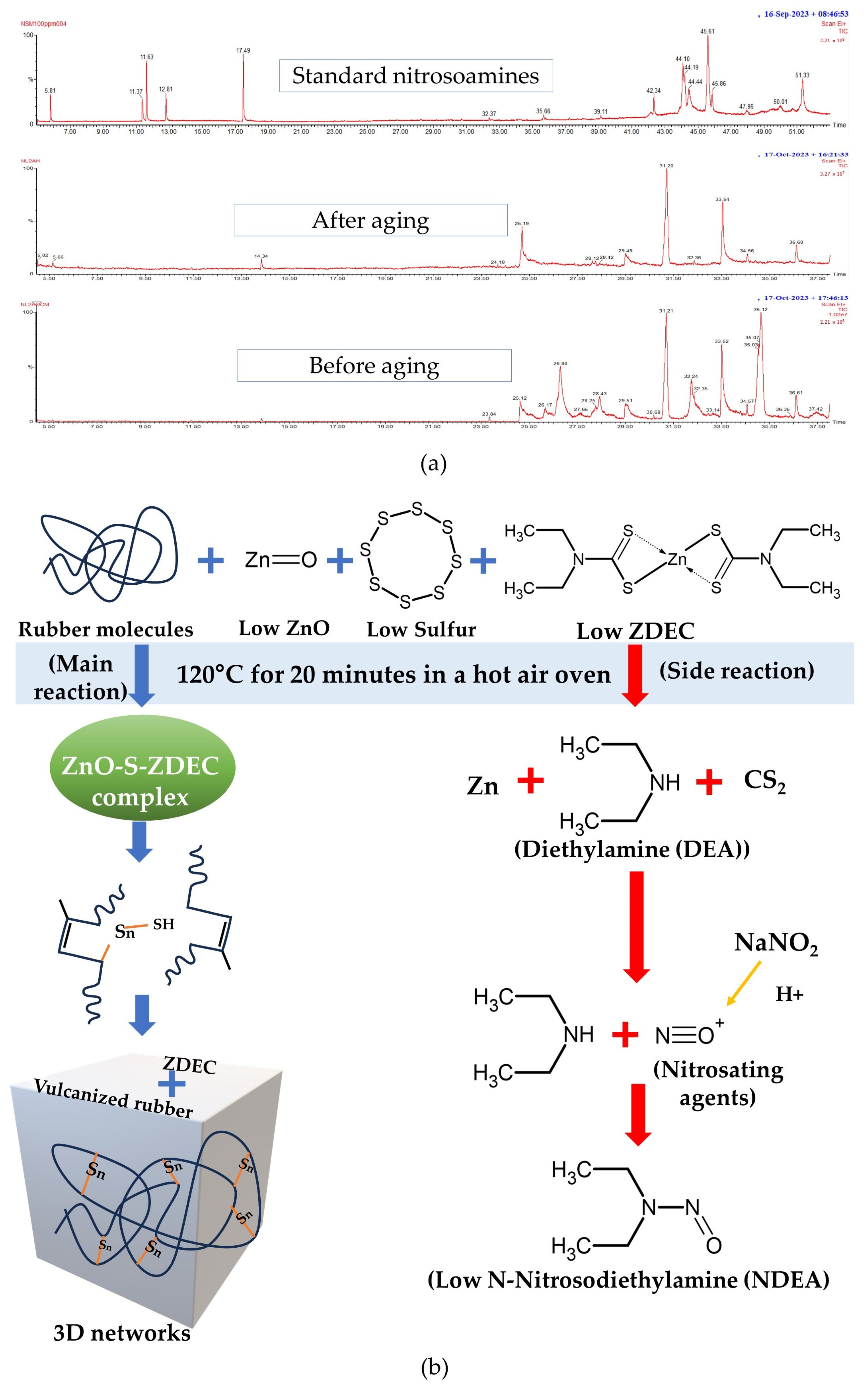

2.2. The Levels of Nitrosoamines in Fresh Latex and Concentrated Latex

2.3. Rubber Wrap Film: Preparation of the Rubber Compound

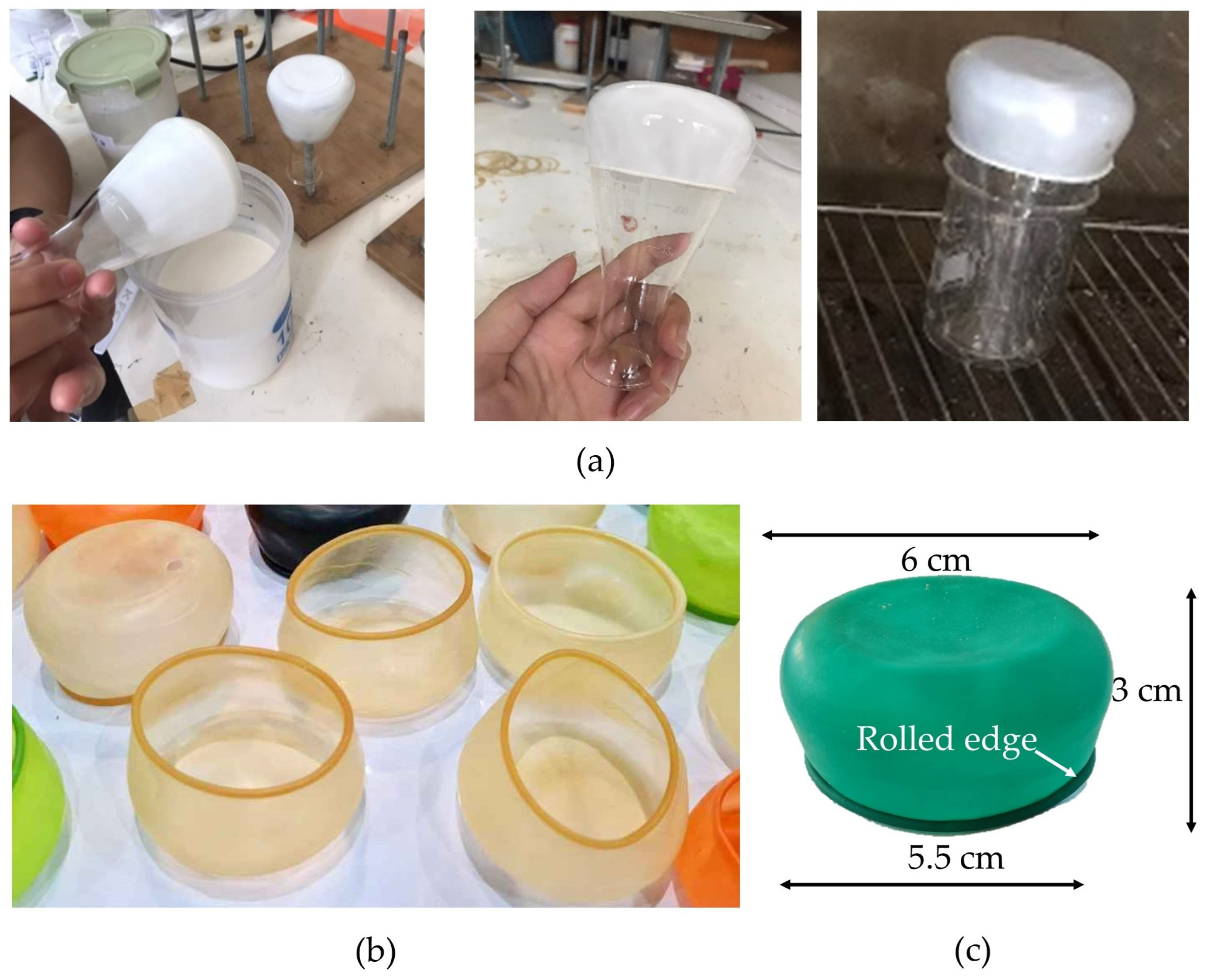

2.4. The Production of Rubber Wrap Film to Cover Containers

2.5. Nitrosamines Testing by Gas Chromatography–Mass Spectrometry (GC-MS)

2.6. Rubber Compound Properties

2.7. Mechanical Properties of Rubber Wrap Film

2.8. Performance Properties of Rubber Wrap Film

2.9. Statistical Analyses

3. Results and Discussion

3.1. The Levels of Nitrosoamines in Fresh Latex and Concentrated Latex

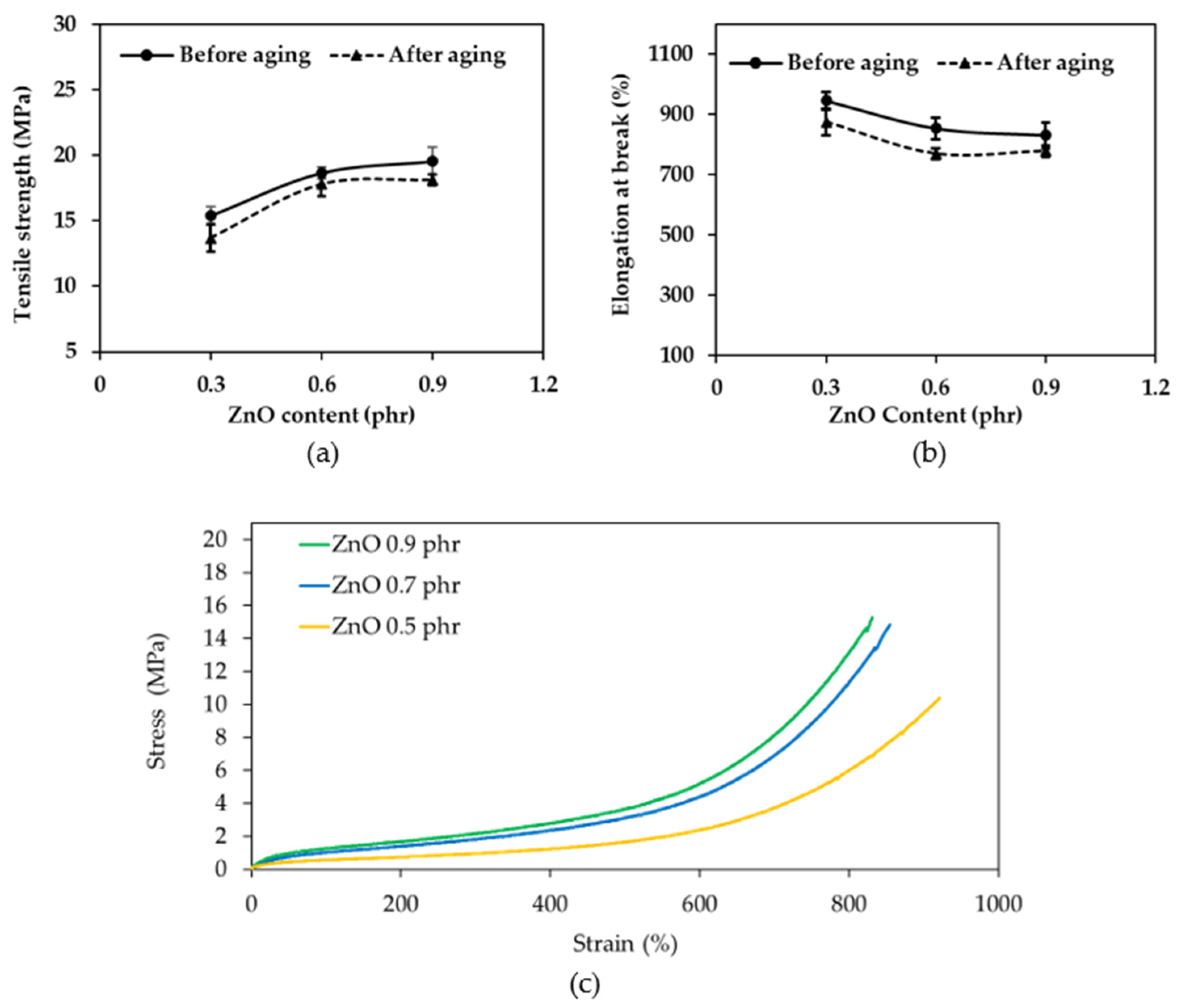

3.2. The Effect of Zinc Oxide (ZnO) Content on the Properties of Rubber Compounds and Mechanical Properties

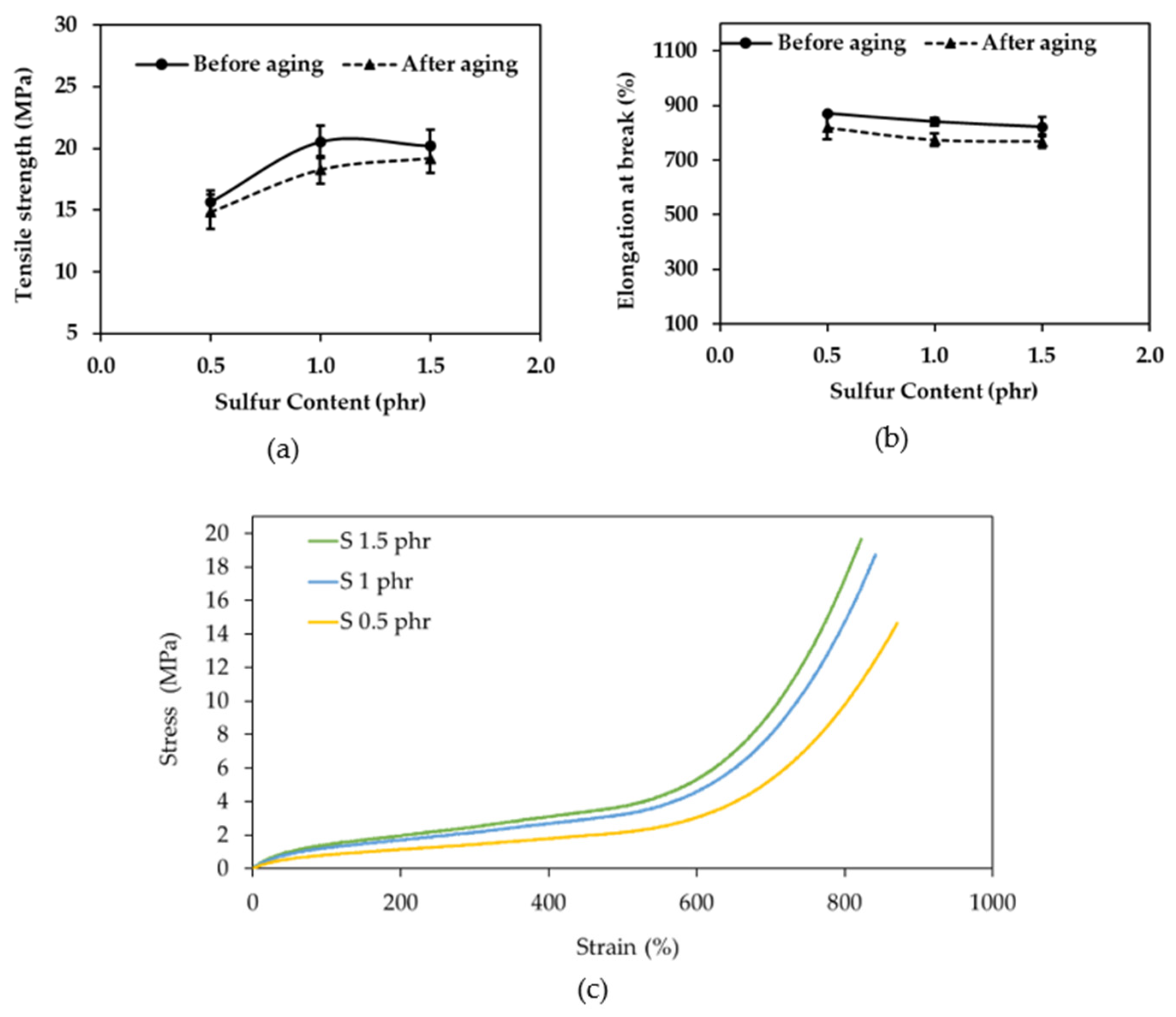

3.3. The Effect of Sulfur Content on the Properties of Rubber Compounds and Mechanical Properties

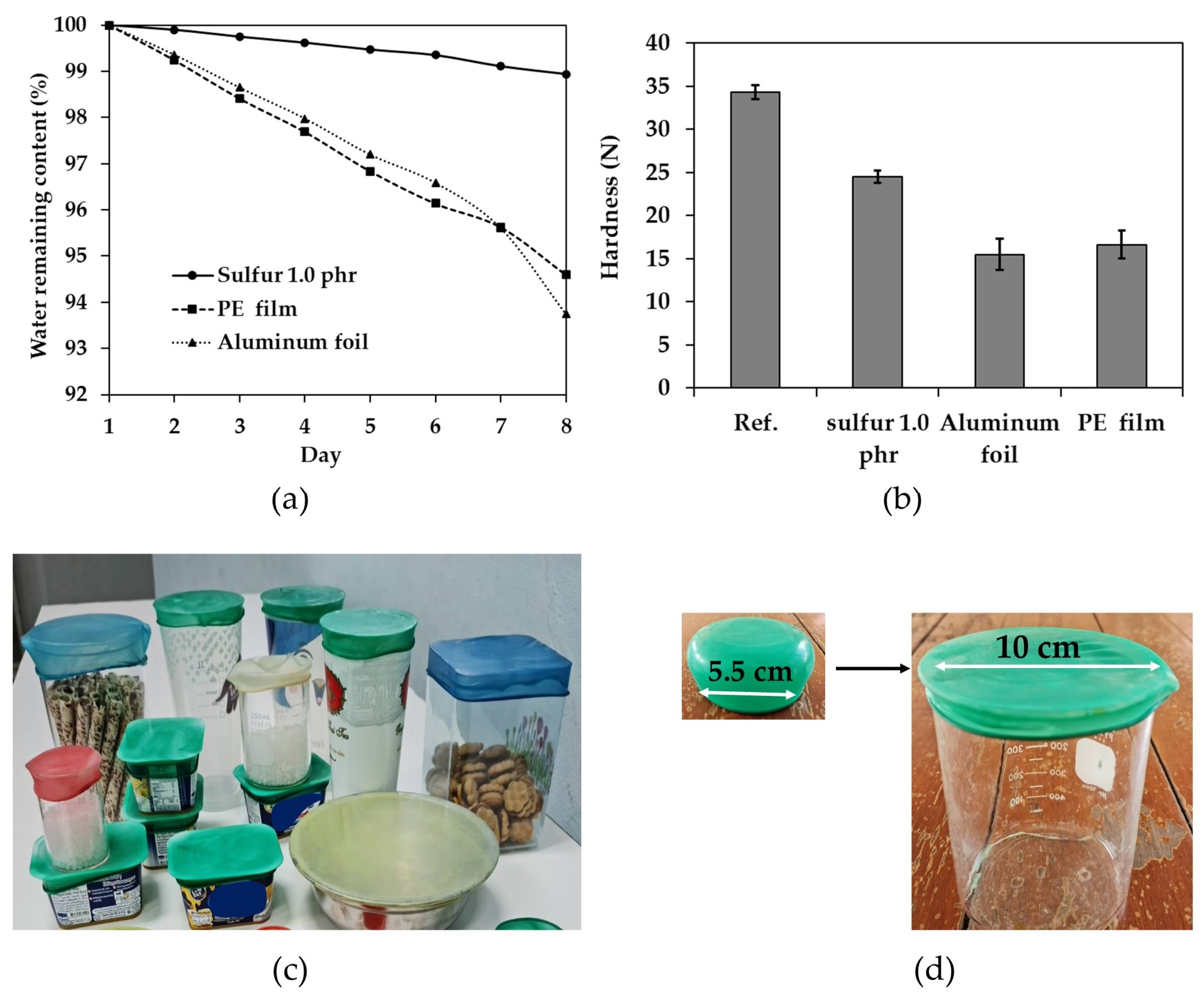

3.4. Results on the Performance of Rubber Wrap Films in Actual Use

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.-M.; Li, C.-Y.; Zhao, N.; Wang, Z.-H.; Lv, S.-W.; Liu, J.-C.; Chen, L.-J.; Wang, J.; Zhang, Y.; Wang, S. Migration regularity of phthalates in polyethylene wrap film of food packaging. J. Food Sci. 2020, 85, 2105–2113. [Google Scholar] [CrossRef] [PubMed]

- Viljoen, S.J.; Brailsford, F.L.; Murphy, D.V.; Hoyle, F.C.; Chadwick, D.R.; Jones, D.L. Leaching of phthalate acid esters from plastic mulch films and their degradation in response to UV irradiation and contrasting soil conditions. J. Hazard. Mater. 2023, 443, 130256. [Google Scholar] [CrossRef] [PubMed]

- Songue Same, O.; Nobosse, P.; Ngolong Ngea, G.L.; Piveteau, C.; Lemdani, M.; Kamga, R.; Deprez, B. Migration study of phthalates from non-food plastic containers used in food preservation. Heliyon 2023, 9, e20002. [Google Scholar] [CrossRef] [PubMed]

- Lamberti, M.; Escher, F. Aluminium Foil as a Food Packaging Material in Comparison with Other Materials. Food Rev. Int. 2007, 23, 407–433. [Google Scholar] [CrossRef]

- Bassioni, G.; Mohammed, F.S.; Al Zubaidy, E.; Kobrsi, I. Risk assessment of using aluminum foil in food preparation. Int. J. Electrochem. Sci. 2012, 7, 4498–4509. [Google Scholar] [CrossRef]

- Alabi, O.A.; Ologbonjaye, K.I.; Awosolu, O.; Alalade, O.E. Public and environmental health effects of plastic wastes disposal: A review. J. Toxicol. Risk Assess. 2019, 5, 21. [Google Scholar]

- MacLeod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The global threat from plastic pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef]

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M.N. Plastic waste and its management strategies for environmental sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Kachhawa, K.S.; Singh, T.P.; Awasthi, Y. Methods of detection of micro-plastic in environment with effect. JIMS8I Int. J. Inf. Commun. Comput. Technol. 2022, 10, 620–627. [Google Scholar] [CrossRef]

- Obebe, S.; Adamu, A. Plastic pollution: Causes, effects and preventions. Int. J. Eng. Appl. Sci. Technol. 2020, 4, 85–95. [Google Scholar]

- Boonrasri, S.; Sae–Oui, P.; Rachtanapun, P. Chitosan and Natural Rubber Latex Biocomposite Prepared by Incorporating Negatively Charged Chitosan Dispersion. Molecules 2020, 25, 2777. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Zheng, Z.; Li, X.; Park, S.; Zhang, W.; Diao, G.; Piao, Y. Design strategy for porous carbon nanomaterials from rational utilization of natural rubber latex foam scraps. Ind. Crop. Prod. 2023, 192, 116036. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, L.; Zhang, L.; Wang, Y.; Zhuang, Y.; Choi, Y.; Cho, Y.; Chen, T.; Yao, H.; Piao, Y. 3D Nanoconductive Network Based on the Microstructure of Latex Foam for Superior Performance Piezoresistive Sensors. ACS Appl. Polym. Mater. 2022, 4, 54–63. [Google Scholar] [CrossRef]

- Jiang, B. Effect of the microstructure of a filled rubber on its overall mechanical properties. Acta Mech. 2014, 225, 1121–1140. [Google Scholar] [CrossRef]

- Pinprayoon, O.; Mae, W. Migration of N-nitrosamines from rubber gloves for handling food-Effect of extraction media. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012022. [Google Scholar]

- Feng, D.; Liu, L.; Zhao, L.; Zhou, Q.; Tan, T. Evaluation of simulant migration of volatile nitrosamines from latex gloves and balloons by HS-SPME–GC–MS. J. Chromatogr. Sci. 2012, 50, 733–738. [Google Scholar] [CrossRef] [PubMed]

- Mutsuga, M.; Yamaguchi, M.; Kawamura, Y. Analysis of N-nitrosamine migration from rubber teats and soothers. Am. J. Anal. Chem. 2013, 4, 33424. [Google Scholar] [CrossRef]

- Rojruthai, P.; Sakdapipanich, J.; Wiriyanantawong, J.; Ho, C.-C.; Chaiear, N. Effect of Latex Purification and Accelerator Types on Rubber Allergens Prevalent in Sulphur Prevulcanized Natural Rubber Latex: Potential Application for Allergy-Free Natural Rubber Gloves. Polymers 2022, 14, 4679. [Google Scholar] [CrossRef]

- Travas-sejdic, J.; Jelencic, J.; Bravar, M.; Fröbe, Z. Characterization of the natural rubber vulcanizates obtained by different accelerators. Eur. Polym. J. 1996, 32, 1395–1401. [Google Scholar] [CrossRef]

- Sasidharan, K.K.; Joseph, R.; Palaty, S.; Gopalakrishnan, K.S.; Rajammal, G.; Pillai, P.V. Effect of the vulcanization time and storage on the stability and physical properties of sulfur-prevulcanized natural rubber latex. J. Appl. Polym. Sci. 2005, 97, 1804–1811. [Google Scholar] [CrossRef]

- Claramma, N.M.; Mathew, N.M. Effect of temperature on sulfur prevulcanization of natural rubber latex. J. Appl. Polym. Sci. 1997, 65, 1913–1920. [Google Scholar] [CrossRef]

- Boonrasri, S.; Sae-Oui, P.; Reungsang, A.; Rachtanapun, P. New Vegetable Oils with Different Fatty Acids on Natural Rubber Composite Properties. Polymers 2021, 13, 1108. [Google Scholar] [CrossRef] [PubMed]

- Blackley, D.C. Latex compounding ingredients. In Polymer Latices: Science and Technology Volume 3: Applications of Latices; Blackley, D.C., Ed.; Springer: Dordrecht, The Netherlands, 1997; pp. 34–154. [Google Scholar]

- Alam, M.N.; Kumar, V.; Park, S.-S. Advances in Rubber Compounds Using ZnO and MgO as Co-Cure Activators. Polymers 2022, 14, 5289. [Google Scholar] [CrossRef] [PubMed]

- Junkong, P.; Morimoto, R.; Miyaji, K.; Tohsan, A.; Sakaki, Y.; Ikeda, Y. Effect of fatty acids on the accelerated sulfur vulcanization of rubber by active zinc/carboxylate complexes. RSC Adv. 2020, 10, 4772–4785. [Google Scholar] [CrossRef] [PubMed]

- Anand, K.; Varghese, S.; Kurian, T. Effect of Micro and Nano Zinc Oxide on the Properties of Pre-Vulcanized Natural Rubber Latex Films. Prog. Rubber Plast. Recycl. Technol. 2015, 31, 145–156. [Google Scholar] [CrossRef]

- Mostoni, S.; Milana, P.; Di Credico, B.; D’Arienzo, M.; Scotti, R. Zinc-Based Curing Activators: New Trends for Reducing Zinc Content in Rubber Vulcanization Process. Catalysts 2019, 9, 664. [Google Scholar] [CrossRef]

- Sreethu, T.K.; Das, M.; Parathodika, A.R.; Bhattacharya, A.B.; Naskar, K. Understanding the role of ZnO as activator in SBR vulcanizates: Performance evaluation with active, nano, and functionalized ZnO. J. Appl. Polym. Sci. 2023, 140, e53257. [Google Scholar] [CrossRef]

- ISO 2004; Natural Rubber Latex Concentrate- Centrifuged or Creamed, Ammonia-Preserved Types—Specifications. International Organization for Standardization: Geneva, Switzerland, 2017.

- Somarathna, Y.R.; Samarasinghe, I.H.K.; Siriwardena, S.; de Silva, D.; Mallikarachchi, D.V.D. Effect of nanoZnO over conventional ZnO on preservation of concentrated natural rubber latex. J. Rubber Res. Inst. Sri Lanka 2018, 98, 65–79. [Google Scholar] [CrossRef]

- EN 12868; Child Use and Care Articles—Methods for Determining the Release of N-Nitrosamines and N-Nitrosatable Substances from Elastomer or Rubber Teats and Soothers. European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- ASTM F1313-90; Standard Specification for Volatile N-Nitrosamine Levels in Rubber Nipples on Pacifiers. ASTM International: West Conshohocken, PA, USA, 1999.

- ISO 29941; Condoms—Determination of Nitrosamines Migrating from Natural Rubber Latex Condoms. International Organization for Standardization (ISO): Geneva, Switzerland, 2010.

- EN 71-12; Safety of Toys—Part 12: N-Nitrosamines and N-Nitrosatable Substances. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- Martwong, E.; Thusanaphoom, P.; Naktham, A.; Jitcharoen, J.; Wongnongwa, Y.; Sukhawipat, N. Asymmetric Crosslinked Polyacrylamide/Natural Rubber Semi-IPN Hydrogel for Application of Methyl Orange Dye Removal: Combined Experimental and DFT Study. J. Polym. Environ. 2023. [Google Scholar] [CrossRef]

- ISO 124 (E); Latex, Rubber—Determination of Total Solids Content. International Organization for Standardization (ISO): Geneva, Switzerland, 2011.

- Boonrasri, S.; Thipchai, P.; Sae-Oui, P.; Thanakkasaranee, S.; Jantanasakulwong, K.; Rachtanapun, P. Property Improvements of Silica-Filled Styrene Butadiene Rubber/Butadiene Rubber Blend Incorporated with Fatty-Acid-Containing Palm Oil. Polymers 2023, 15, 3429. [Google Scholar] [CrossRef]

- ISO 37; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- Nun-Anan, P.; Suchat, S.; Mahathaninwong, N.; Chueangchayaphan, N.; Karrila, S.; Limhengha, S. Study of Aquilaria crassna Wood as an Antifungal Additive to Improve the Properties of Natural Rubber as Air-Dried Sheets. Polymers 2021, 13, 4178. [Google Scholar] [CrossRef]

- Feng, D.; Liu, L.; Zhao, L.; Zhou, Q.; Tan, T. Determination of volatile nitrosamines in latex products by HS-SPME–GC–MS. Chromatographia 2011, 74, 817–825. [Google Scholar] [CrossRef]

- Kim, Y.; Choi, S.-S.; Bae, J.W.; Kim, J.-S. Effects of ZnO content on microstructure and properties of maleated EPDM/zinc oxide composites. Polym. Bull. 2015, 72, 1163–1175. [Google Scholar] [CrossRef]

- T.K, S.; Naskar, K. Zinc oxide with various surface characteristics and its role on mechanical properties, cure-characteristics, and morphological analysis of natural rubber/carbon black composites. J. Polym. Res. 2021, 28, 183. [Google Scholar] [CrossRef]

- Hou, Z.-B.; Xie, W.-L.; Liu, G.-X.; Liao, S.; Luo, M.-C. Design of Vulcanization Intermediates with Low Steric Hindrance Contributing to Vulcanization Network Formation. ACS Appl. Polym. Mater. 2023, 5, 4509–4516. [Google Scholar] [CrossRef]

- Shi, F.; Li, X.; Bai, Y.; Li, L.; Pu, M.; Liu, L.; Lei, M. Mechanism of the Zinc Dithiocarbamate-Activated Rubber Vulcanization Process: A Density Functional Theory Study. ACS Appl. Polym. Mater. 2021, 3, 5188–5196. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, L.; Wang, R.; Yu, H.; Zheng, T.; Lian, Y.; Luo, M.; Liao, S.; Liu, H.; Peng, Z. Research of strain induced crystallization and tensile properties of vulcanized natural rubber based on crosslink densities. Ind. Crop. Prod. 2023, 202, 117070. [Google Scholar] [CrossRef]

- Carvalho, L.R.; Venturelli, L.G.; Lopes, T.C.; Filho, E.V.; Fontenelle, V.G.S.; de Lima, G.F.; Visconte, L.L.Y.; Tavares, E.d.C. Tetraphenylphosphonium Allyldithiocarbimates: A Novel Safe Amine Class of Morita–Baylis–Hillman-Derived NBR Vulcanization Accelerators. ACS Sustain. Chem. Eng. 2023, 11, 14507–14517. [Google Scholar] [CrossRef]

- Park, J.-E.; Seo, J.-E.; Lee, J.-Y.; Kwon, H. Distribution of seven N-nitrosamines in food. Toxicol. Res. 2015, 31, 279–288. [Google Scholar] [CrossRef]

- Boonying, P.; Boonpavanitchakul, K.; Kangwansupamonkon, W. Green Bio-composite Coating Film from Lignin/Pre-vulcanized Natural Rubber Latex for Controlled-release Urea Fertilizer. J. Polym. Environ. 2023, 31, 1642–1655. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Salleh, S.Z.; Ismail, H. Sustainable Use of Chloroprene Rubber Waste as Blend Component with Natural Rubber, Epoxidized Natural Rubber and Styrene Butadiene Rubber. J. Polym. Environ. 2019, 27, 2119–2130. [Google Scholar] [CrossRef]

- Abraham, E.; Thomas, M.S.; John, C.; Pothen, L.A.; Shoseyov, O.; Thomas, S. Green nanocomposites of natural rubber/nanocellulose: Membrane transport, rheological and thermal degradation characterisations. Ind. Crop. Prod. 2013, 51, 415–424. [Google Scholar] [CrossRef]

- de Lima, D.R.; Vieira, I.R.S.; Dutra da Rocha, E.B.; Furtado de Sousa, A.M.; Augusto da Costa, A.C.; Furtado, C.R.G. Biodegradation of natural rubber latex films by highlighting the crosslinked bond. Ind. Crop. Prod. 2023, 204, 117290. [Google Scholar] [CrossRef]

- Kaya, A.; Arafat, B.; Chichger, H.; Tolaymat, I.; Pierscionek, B.; Khoder, M.; Najlah, M. Preparation and Characterisation of Zinc Diethyldithiocarbamate–Cyclodextrin Inclusion Complexes for Potential Lung Cancer Treatment. Pharmaceutics 2024, 16, 65. [Google Scholar]

- Lim, J.Y.C.; Lin, Q.; Liu, C.K.; Guo, L.; Xue, K.; Loh, X.J. Zinc diethyldithiocarbamate as a catalyst for synthesising biomedically-relevant thermogelling polyurethanes. Mater. Adv. 2020, 1, 3221–3232. [Google Scholar] [CrossRef]

- Dirksen, A.; Nieuwenhuizen, P.J.; Hoogenraad, M.; Haasnoot, J.G.; Reedijk, J. New mechanism for the reaction of amines with zinc dithiocarbamates. J. Appl. Polym. Sci. 2001, 79, 1074–1083. [Google Scholar] [CrossRef]

- Hogarth, G. Metal-dithiocarbamate complexes: Chemistry and biological activity. Mini Rev. Med. Chem. 2012, 12, 1202–1215. [Google Scholar] [CrossRef] [PubMed]

- Weiss, B. Evidence for Mutagenesis by Nitric Oxide during Nitrate Metabolism in Escherichia coli. J. Bacteriol. 2006, 188, 829–833. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.D.; Zhong, R.G. Structure–activity relationship of nitrosating agents in the nitrosation reactions of ammonia: A theoretical study. Theor. Chem. Acc. 2009, 124, 261–268. [Google Scholar] [CrossRef]

- Ramesh, K.; Kim, H.Y.; Oh, K. Catalytic Aerobic N-Nitrosation by Secondary Nitroalkanes in Water: A Tandem Diazotization of Aryl Amines and Azo Coupling. Org. Lett. 2023, 25, 449–453. [Google Scholar] [CrossRef]

- Lv, M.; Fang, L.; Yu, H.; Rojruthai, P.; Sakdapipanich, J. Discoloration Mechanisms of Natural Rubber and Its Control. Polymers 2022, 14, 764. [Google Scholar] [CrossRef]

| Ingredient | Content, phr a | ||||

|---|---|---|---|---|---|

| in Formulation | 1 | 2 | 3 | 4 | 5 |

| 60% HA latex | 100 | 100 | 100 | 100 | 100 |

| 10%KOH | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| ZnO | 0.5 | 0.7 | 0.9 | 0.7 | 0.7 |

| Lowinox CPL | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| ZDEC | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sulfur | 0.5 | 0.5 | 0.5 | 1 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suchat, S.; Boonrasri, S. Advancement of an Environmentally Friendly and Innovative Sustainable Rubber Wrap Film with Superior Sealing Properties. Polymers 2024, 16, 1499. https://doi.org/10.3390/polym16111499

Suchat S, Boonrasri S. Advancement of an Environmentally Friendly and Innovative Sustainable Rubber Wrap Film with Superior Sealing Properties. Polymers. 2024; 16(11):1499. https://doi.org/10.3390/polym16111499

Chicago/Turabian StyleSuchat, Sunisa, and Siwarote Boonrasri. 2024. "Advancement of an Environmentally Friendly and Innovative Sustainable Rubber Wrap Film with Superior Sealing Properties" Polymers 16, no. 11: 1499. https://doi.org/10.3390/polym16111499

APA StyleSuchat, S., & Boonrasri, S. (2024). Advancement of an Environmentally Friendly and Innovative Sustainable Rubber Wrap Film with Superior Sealing Properties. Polymers, 16(11), 1499. https://doi.org/10.3390/polym16111499