3D and 4D Printing of PETG–ABS–Fe3O4 Nanocomposites with Supreme Remotely Driven Magneto-Thermal Shape-Memory Performance

Abstract

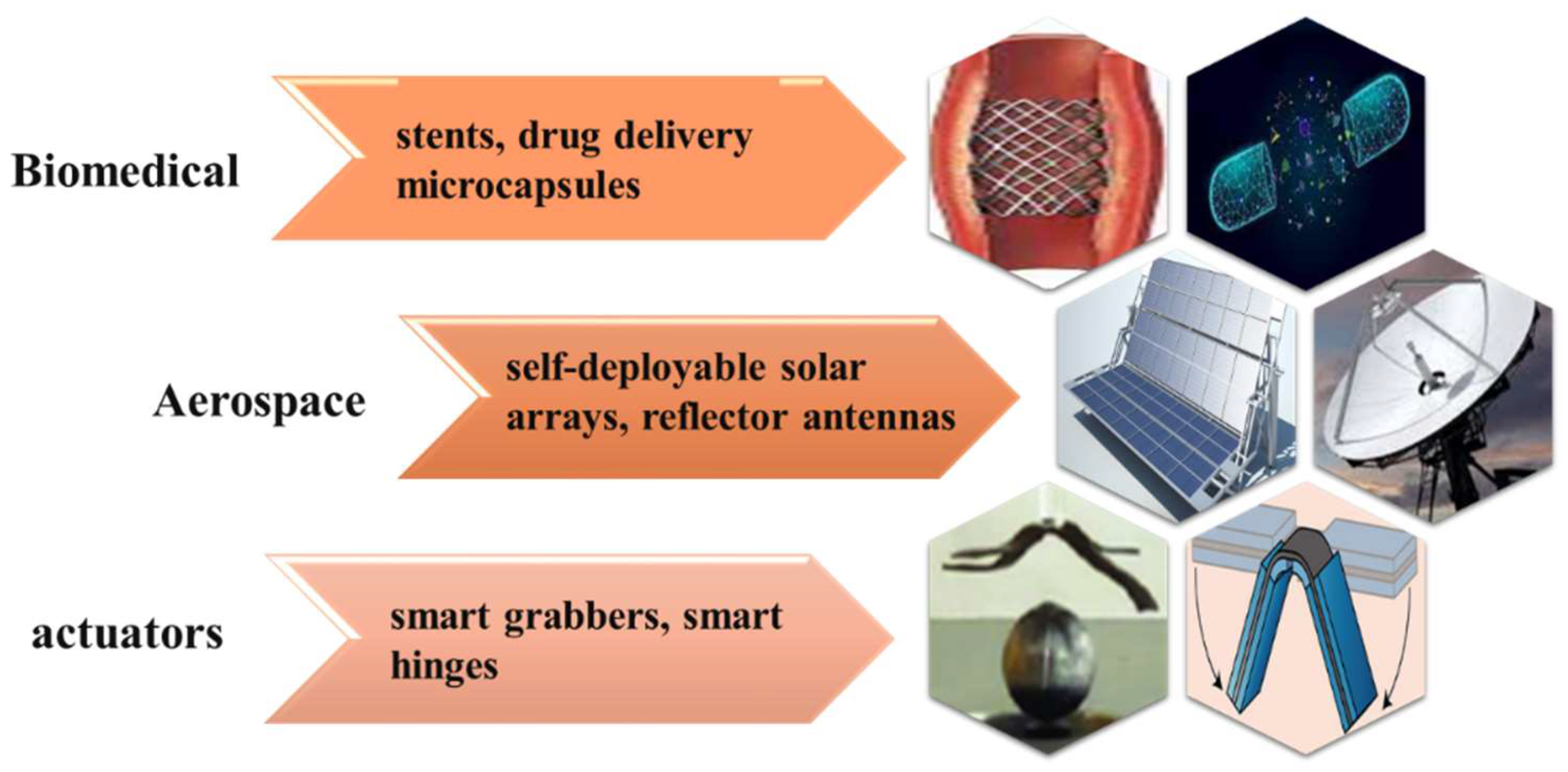

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing of PETG–ABS–Fe3O4 Nanocomposites

2.3. 3D Printing

2.4. Characterizations

2.4.1. DMTA

2.4.2. Microstructure Evaluation

2.4.3. Mechanical Properties

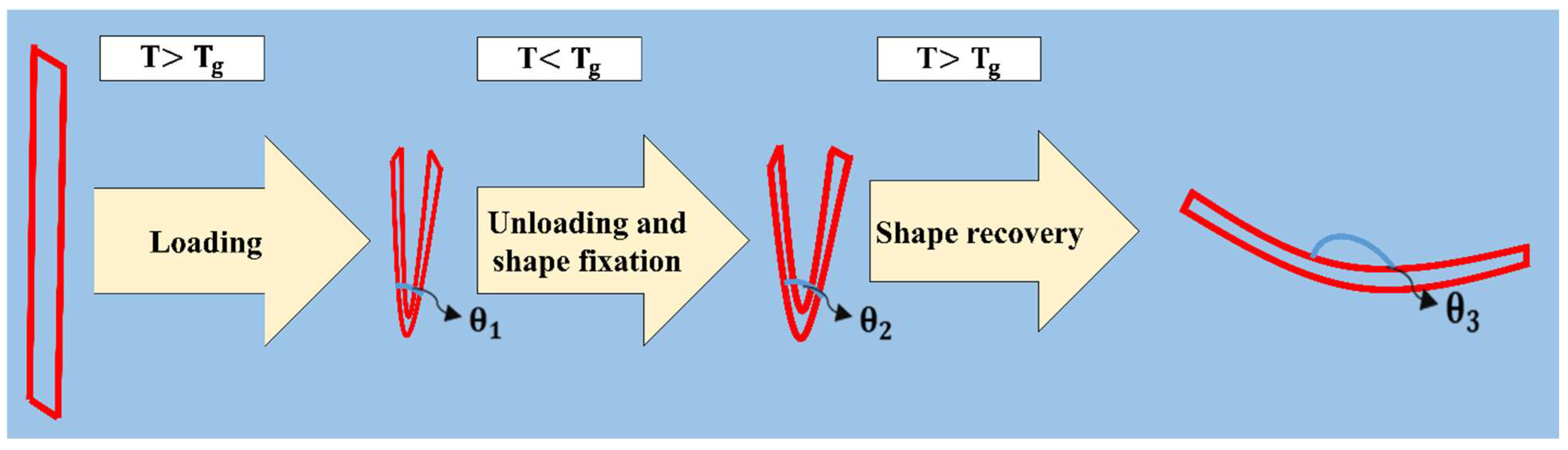

2.4.4. Shape-Memory Effect (SME)

3. Results and Discussion

3.1. Thermal Analysis

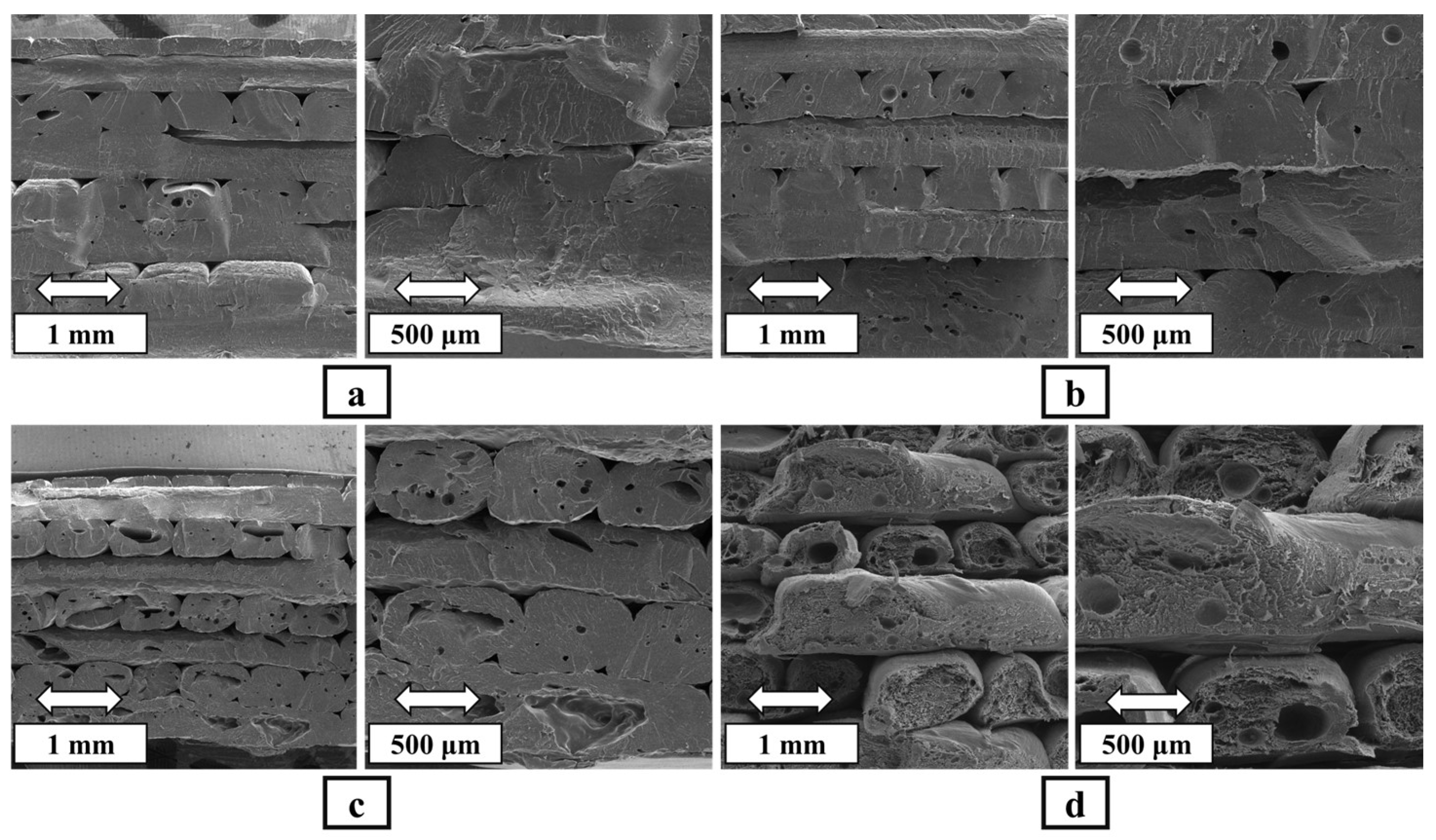

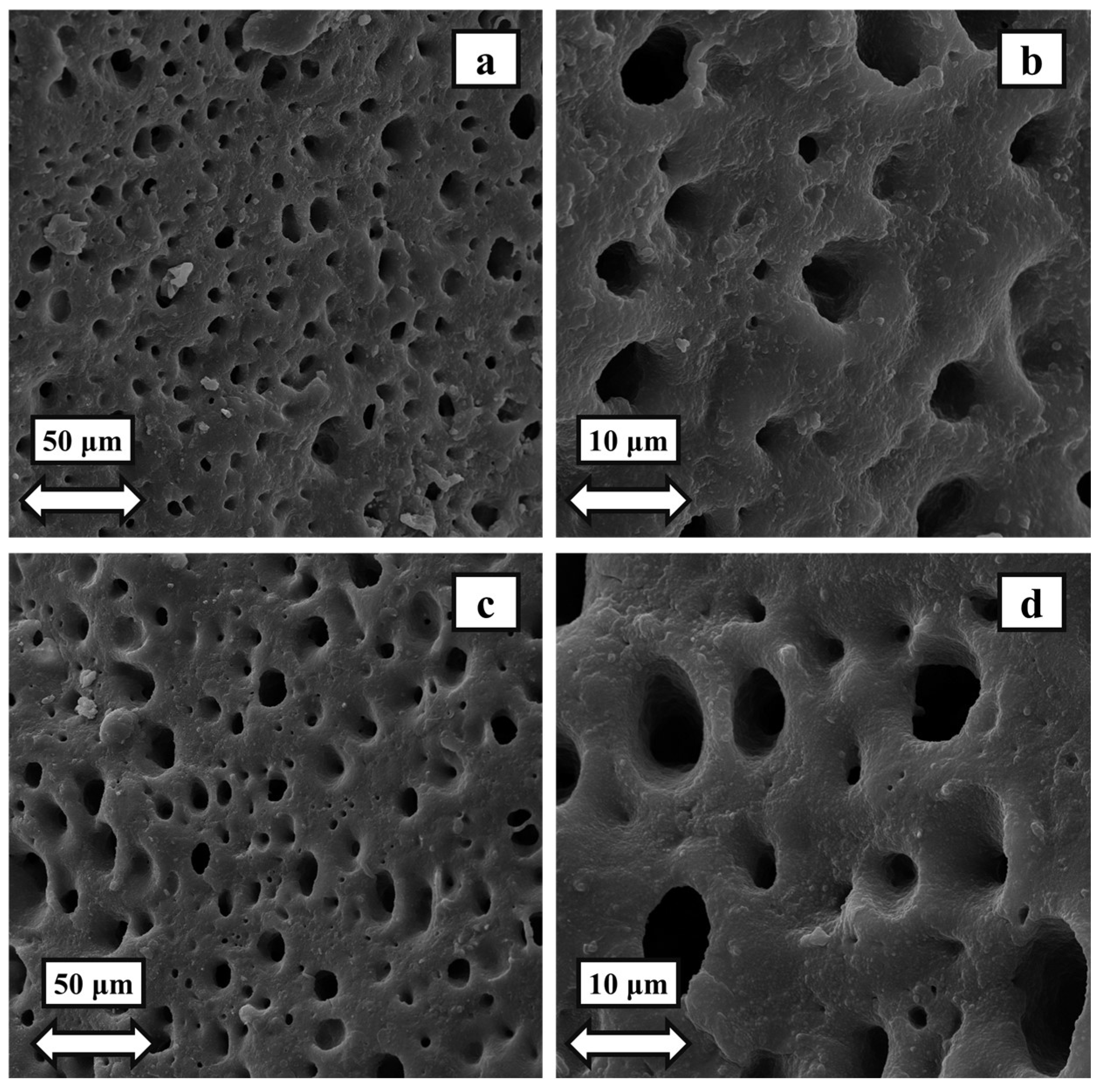

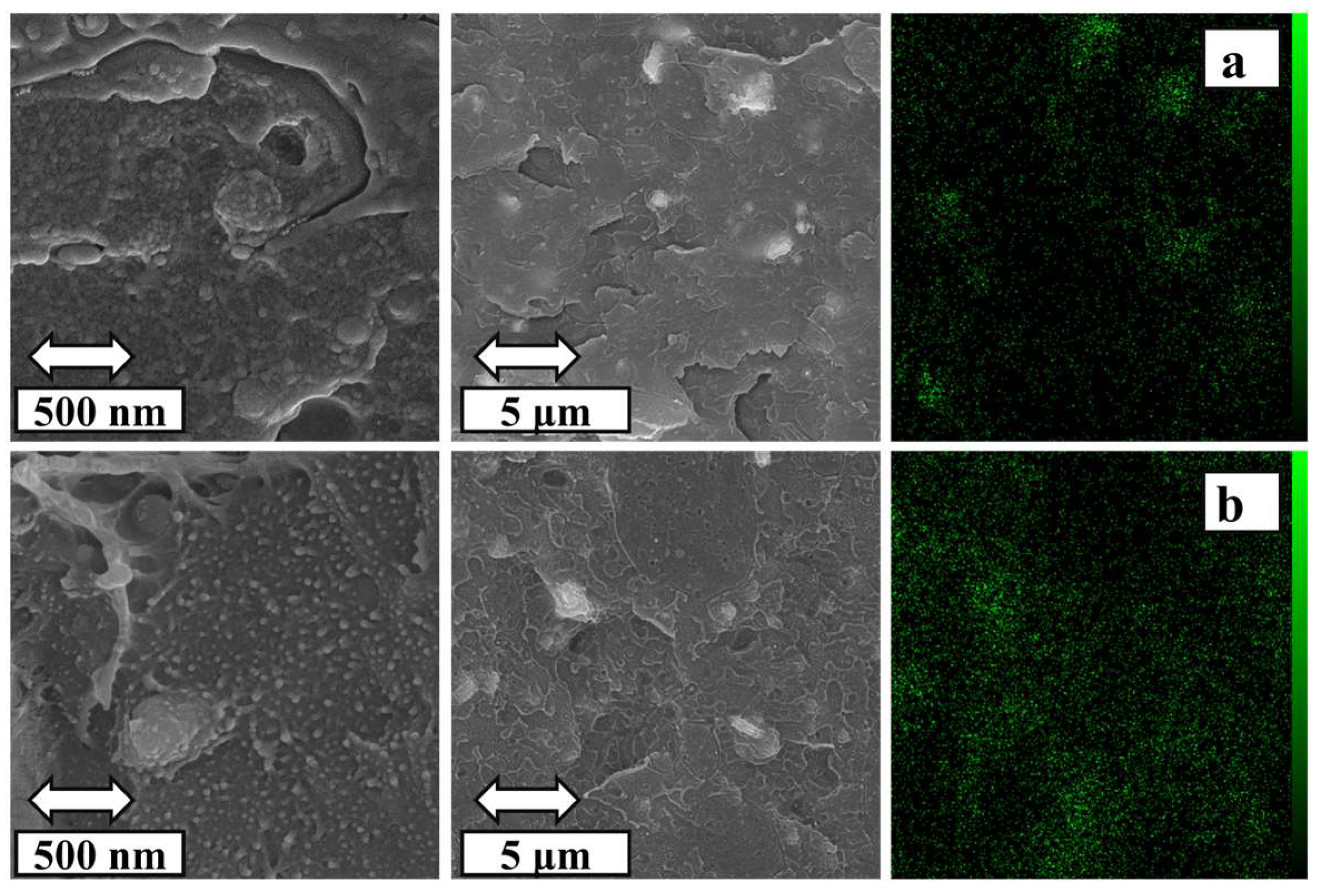

3.2. SEM Observation

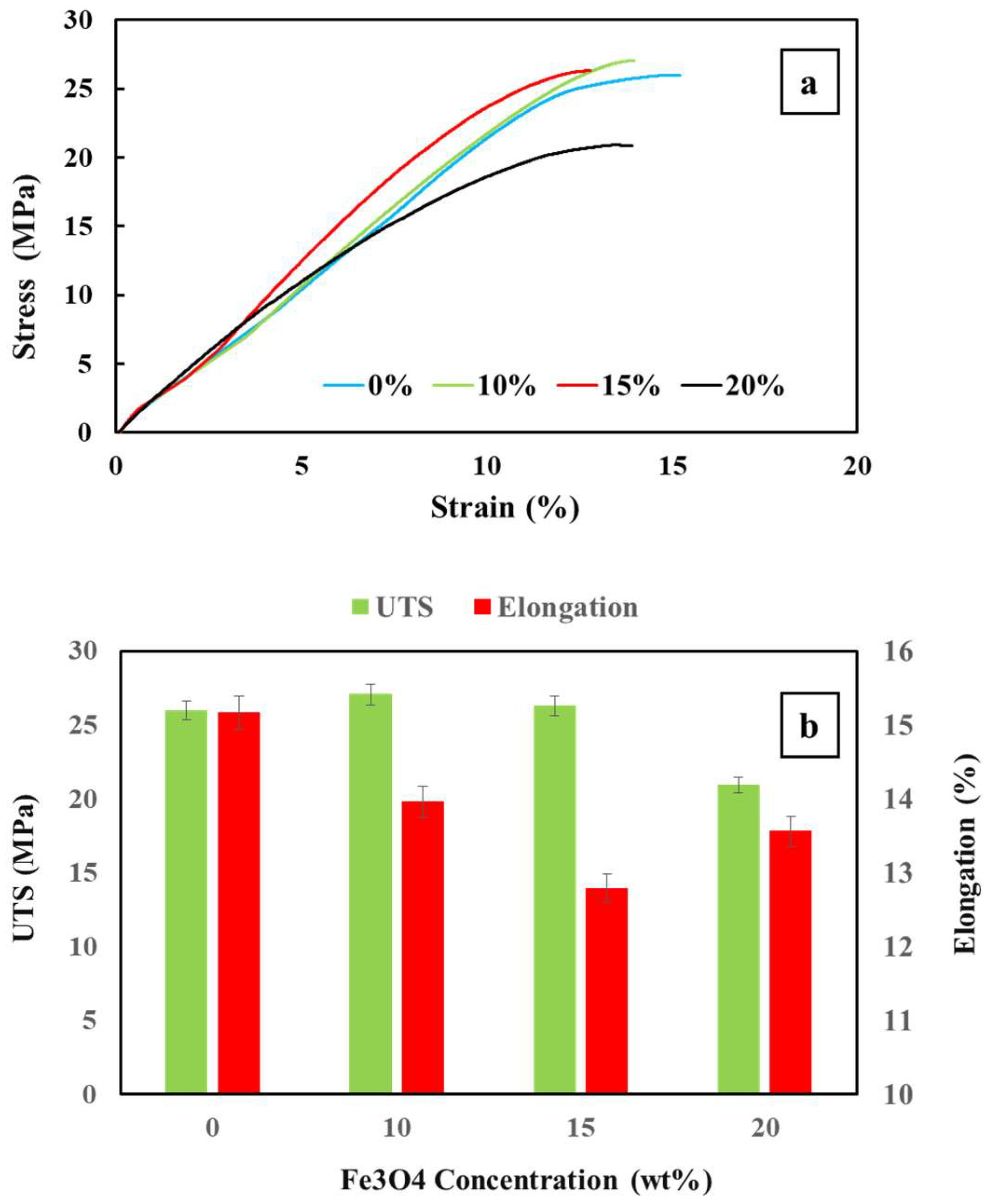

3.3. Mechanical Properties

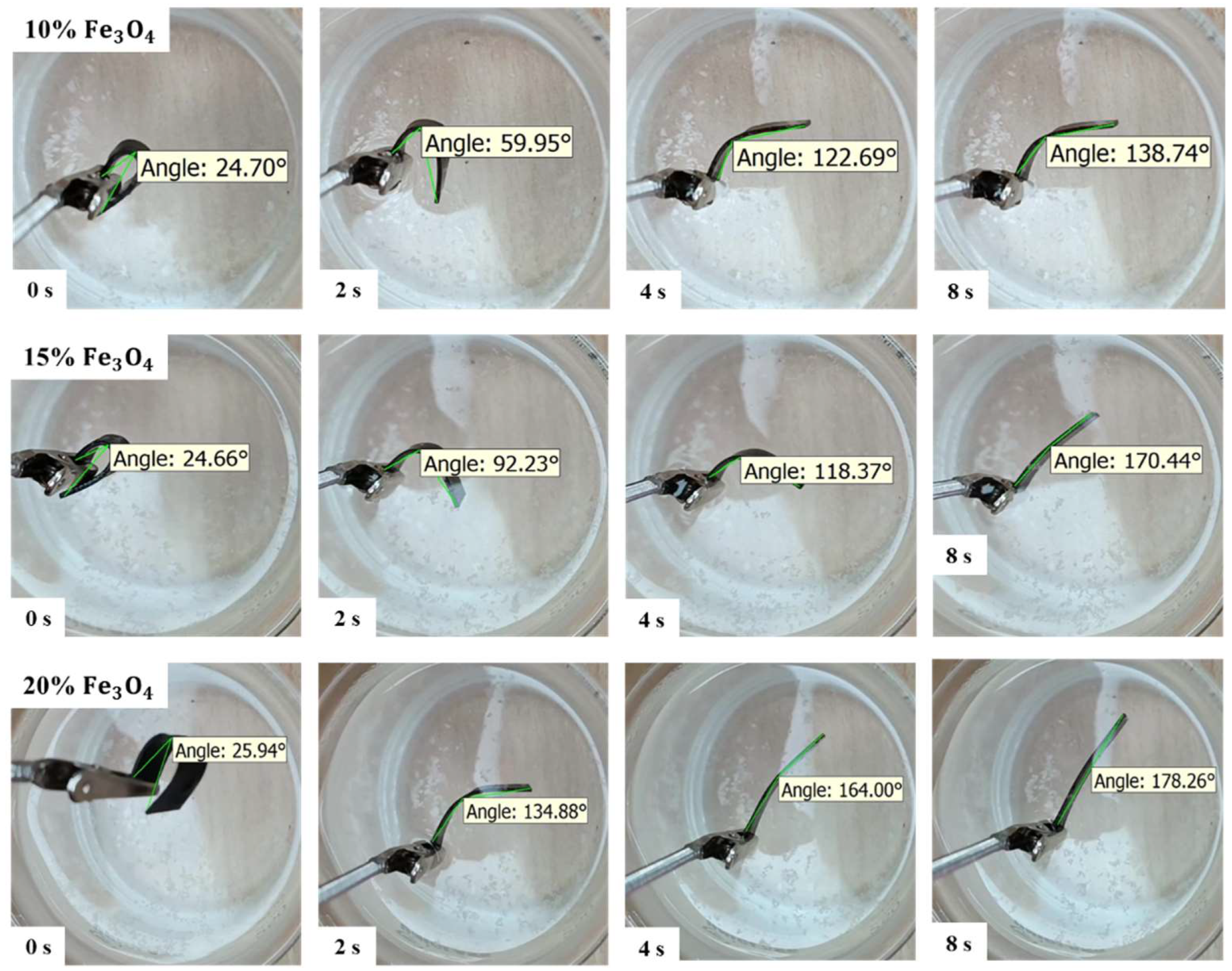

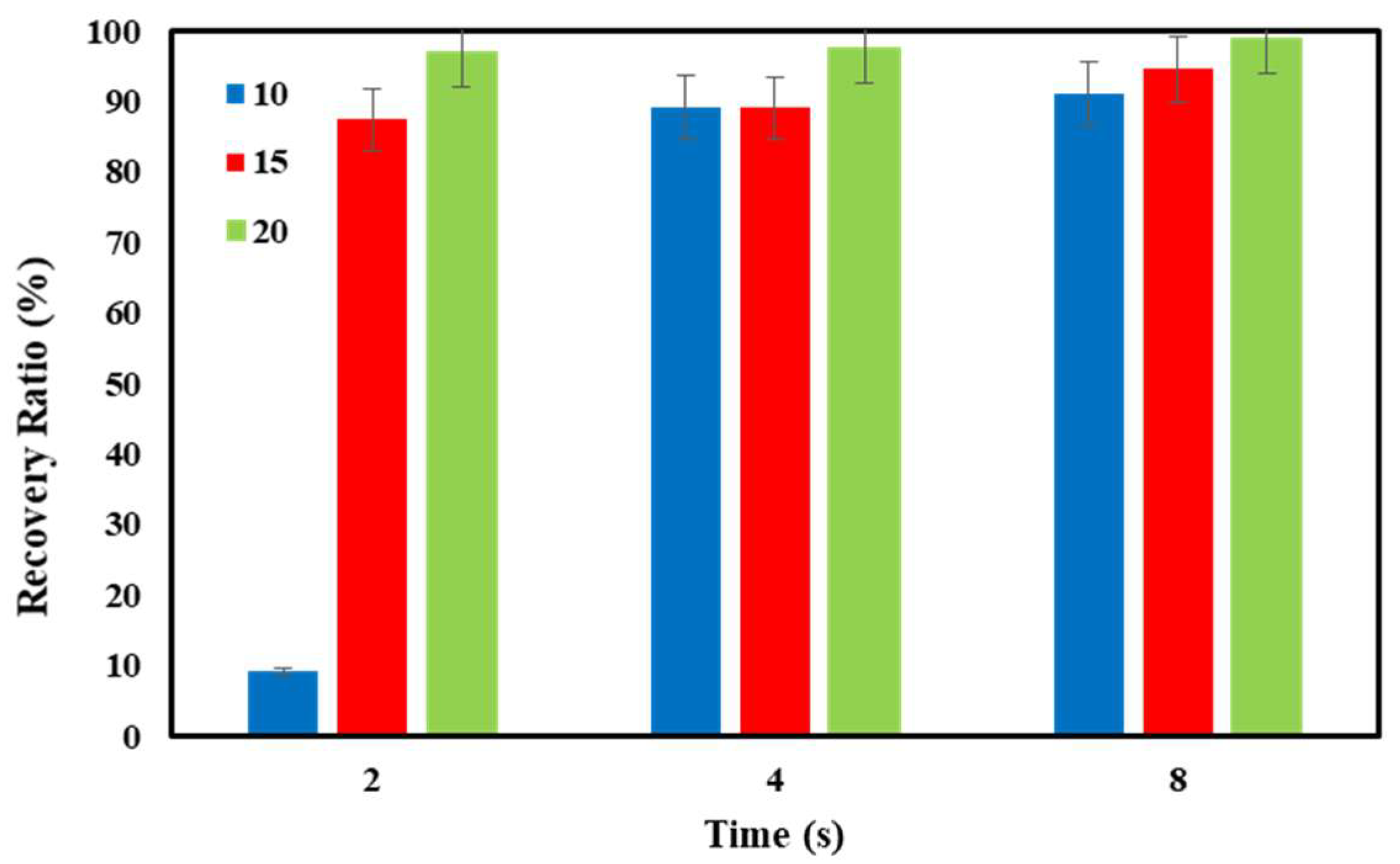

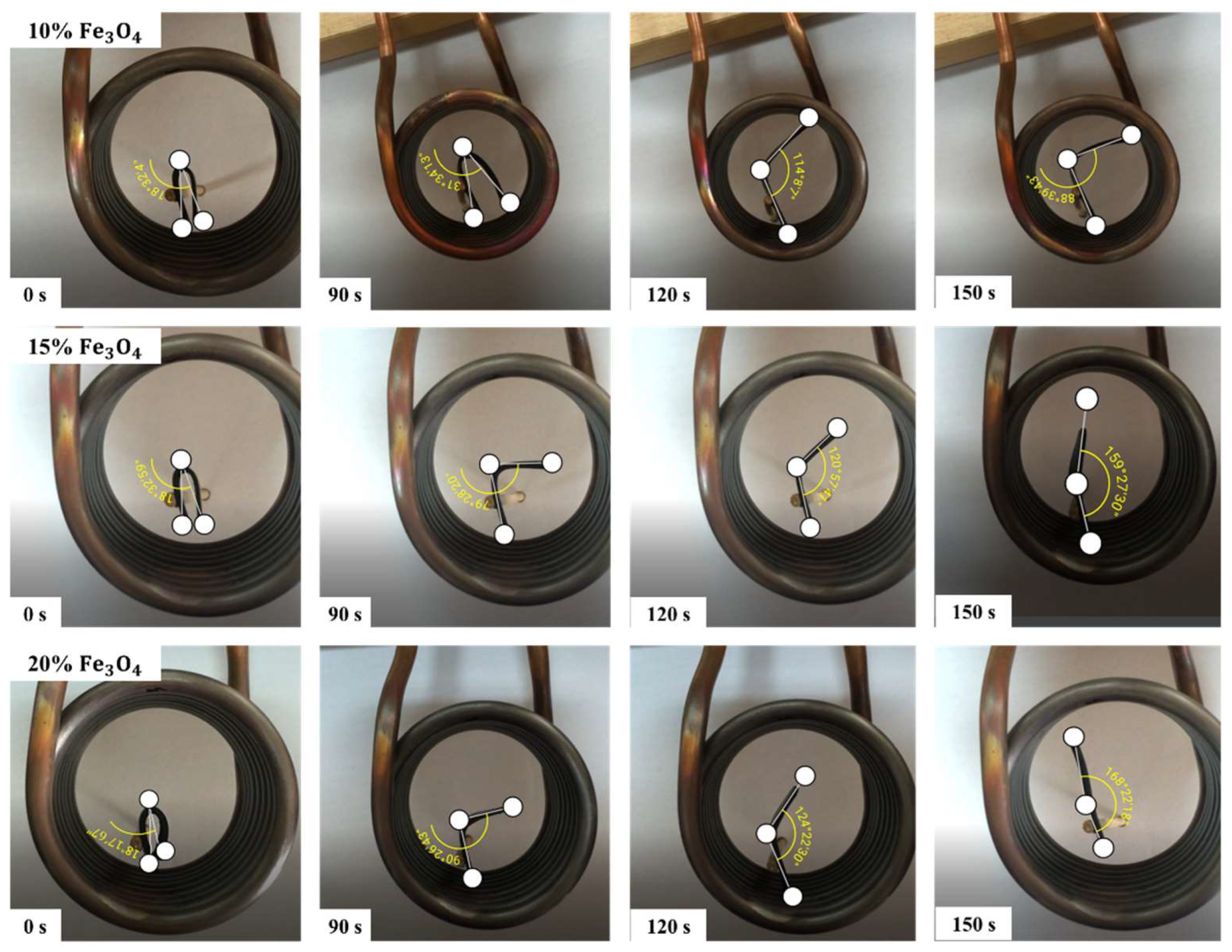

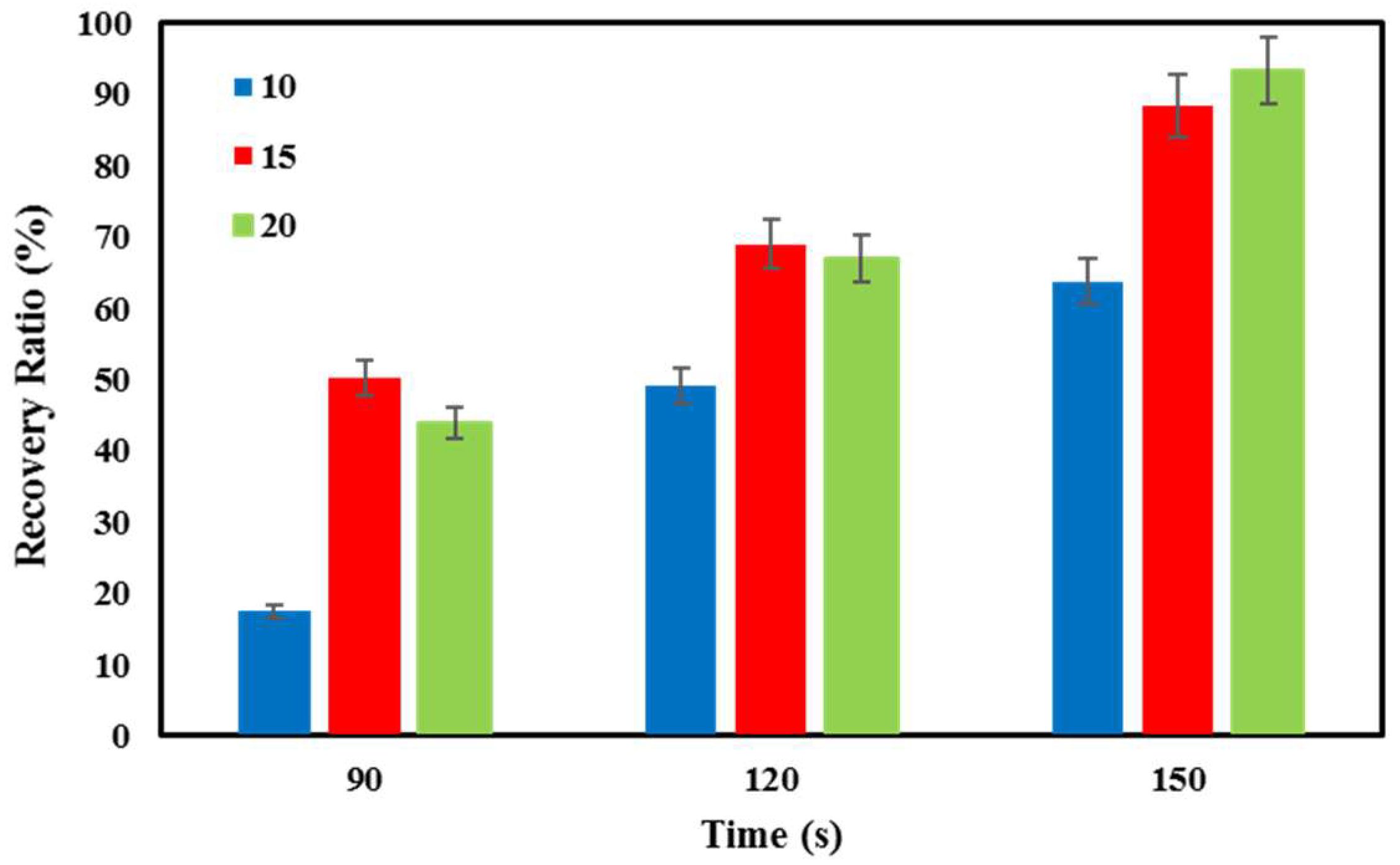

3.4. Shape-Memory Effect

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Various FDM Mechanisms Used in the Fabrication of Continuous-Fiber Reinforced Composites: A Review. Polymers 2024, 16, 831. [Google Scholar] [CrossRef]

- Ren, L.; Li, B.; Song, Z.; Liu, Q.; Ren, L.; Zhou, X. 3D printing of structural gradient soft actuators by variation of bioinspired architectures. J. Mater. Sci. 2019, 54, 6542–6551. [Google Scholar]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Zolfagharian, A.; Bodaghi, M.; Baghani, M. A New Strategy for Achieving Shape Memory Effects in 4D Printed Two-Layer Composite Structures. Polymers 2022, 14, 5446. [Google Scholar] [CrossRef]

- Ikram, H.; Al Rashid, A.; Koç, M. Additive manufacturing of smart polymeric composites: Literature review and future perspectives. Polym. Compos. 2022, 43, 6355–6380. [Google Scholar] [CrossRef]

- Ren, L.; Wang, Z.; Ren, L.; Xu, C.; Li, B.; Shi, Y.; Liu, Q. Understanding the role of process parameters in 4D printing: A review. Compos. Part B Eng. 2023, 265, 110938. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, W.M.; Kang, S.F.; Wu, X.L.; Lu, H.B.; Fu, J.; Cui, H. From 3D to 4D printing: Approaches and typical applications. J. Mech. Sci. Technol. 2015, 29, 4281–4288. [Google Scholar] [CrossRef]

- Ma, S.Q.; Zhang, Y.P.; Wang, M.; Liang, Y.H.; Ren, L.; Ren, L.Q. Recent progress in 4D printing of stimuli-responsive polymeric materials. Sci. China Technol. Sci. 2020, 63, 532–544. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Pahlavani, M.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Shape memory performance assessment of FDM 3D printed PLA-TPU composites by Box-Behnken response surface methodology. Int. J. Adv. Manuf. Technol. 2023, 127, 935–950. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Bian, W.; Liu, Y.; Leng, J. 4D printed electro-induced continuous carbon fiber reinforced shape memory polymer composites with excellent bending resistance. Compos. Part B Eng. 2020, 194, 108034. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Wu, W.; Dong, X.; Sang, L. 4D printing of mechanically robust PLA/TPU/Fe3O4 magneto-responsive shape memory polymers for smart structures. Compos. Part B Eng. 2023, 248, 110382. [Google Scholar] [CrossRef]

- Hu, X.; Ge, Z.; Wang, X.; Jiao, N.; Tung, S.; Liu, L. Multifunctional thermo-magnetically actuated hybrid soft millirobot based on 4D printing. Compos. Part B Eng. 2022, 228, 109451. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Woo, B.H.; Kim, N.; Jun, Y.C. Multicolor 4D printing of shape-memory polymers for light-induced selective heating and remote actuation. Sci. Rep. 2020, 10, 6258. [Google Scholar] [CrossRef]

- Du, W.; Jin, Y.; Lai, S.; Shi, L.; Fan, W.; Pan, J. Near-infrared light triggered shape memory and self-healable polyurethane/functionalized graphene oxide composites containing diselenide bonds. Polymer 2018, 158, 120–129. [Google Scholar] [CrossRef]

- Sharma, R.; Singh, R.; Batish, A. Study on barium titanate and graphene reinforced PVDF matrix for 4D applications. J. Thermoplast. Compos. Mater. 2021, 34, 1234–1253. [Google Scholar] [CrossRef]

- Wang, L.; Razzaq, M.Y.; Rudolph, T.; Heuchel, M.; Nöchel, U.; Mansfeld, U.; Jiang, Y.; Gould, O.E.C.; Behl, M.; Kratz, K.; et al. Reprogrammable, magnetically controlled polymeric nanocomposite actuators. Mater. Horizons 2018, 5, 861–867. [Google Scholar] [CrossRef]

- Melly, S.K.; Liu, L.; Liu, Y.; Leng, J. Active composites based on shape memory polymers: Overview, fabrication methods, applications, and future prospects. J. Mater. Sci. 2020, 55, 10975–11051. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic Shape Memory Polymers with Integrated Multifunctional Shape Manipulation. Adv. Mater. 2020, 32, e1906657. [Google Scholar] [CrossRef]

- Banobre-Lopez, M.; Pineiro-Redondo, Y.; Sandri, M.; Tampieri, A.; De Santis, R.; Dediu, V.A.; Rivas, J. Hyperthermia induced in magnetic scaffolds for bone tissue engineering. IEEE Trans. Magn. 2014, 50, 1–7. [Google Scholar] [CrossRef]

- Zhang, F.H.; Zhang, Z.C.; Luo, C.J.; Lin, I.T.; Liu, Y.; Leng, J.; Smoukov, S.K. Remote, fast actuation of programmable multiple shape memory composites by magnetic fields. J. Mater. Chem. C 2015, 3, 11290–11293. [Google Scholar] [CrossRef]

- Kumar, U.N.; Kratz, K.; Wagermaier, W.; Behl, M.; Lendlein, A. Non-contact actuation of triple-shape effect in multiphase polymer network nanocomposites in alternating magnetic field. J. Mater. Chem. 2010, 20, 3404–3415. [Google Scholar] [CrossRef]

- Mohr, R.; Kratz, K.; Weigel, T.; Lucka-Gabor, M.; Moneke, M.; Lendlein, A. Initiation of shape-memory effect by inductive heating of magnetic nanoparticles in thermoplastic polymers. Proc. Natl. Acad. Sci. USA 2006, 103, 3540–3545. [Google Scholar] [CrossRef]

- Yue, C.; Li, M.; Liu, Y.; Fang, Y.; Song, Y.; Xu, M.; Li, J. Three-dimensional printing of cellulose nanofibers reinforced PHB/PCL/Fe3O4 magneto-responsive shape memory polymer composites with excellent mechanical properties. Addit. Manuf. 2021, 46, 102146. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Zheng, Z.; Liu, Y.; Leng, J. Magnetic programming of 4D printed shape memory composite structures. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105571. [Google Scholar] [CrossRef]

- Zhao, W.; Huang, Z.; Liu, L.; Wang, W.; Leng, J.; Liu, Y. Porous bone tissue scaffold concept based on shape memory PLA/Fe3O4. Compos. Sci. Technol. 2020, 203, 108563. [Google Scholar] [CrossRef]

- Huang, J.; Cao, L.; Yuan, D.; Chen, Y. Design of Multi-Stimuli-Responsive Shape Memory Biobased PLA/ENR/Fe3O4 TPVs with Balanced Stiffness-Toughness Based on Selective Distribution of Fe3O4. ACS Sustain. Chem. Eng. 2019, 7, 2304–2315. [Google Scholar] [CrossRef]

- Mahesh, V.; Joseph, A.S.; Mahesh, V.; Harursampath, D.; Chethan, V.N. Investigation on the mechanical properties of additively manufactured PETG composites reinforced with OMMT nanoclay and carbon fibers. Polym. Compos. 2021, 42, 2380–2395. [Google Scholar] [CrossRef]

- Soleyman, E.; Aberoumand, M.; Soltanmohammadi, K.; Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 4D printing of PET-G via FDM including tailormade excess third shape. Manuf. Lett. 2022, 33, 1–4. [Google Scholar] [CrossRef]

- Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. A comprehensive experimental investigation on 4D printing of PET-G under bending. J. Mater. Res. Technol. 2022, 18, 2552–2569. [Google Scholar] [CrossRef]

- Mirasadi, K.; Rahmatabadi, D.; Ghasemi, I.; Khodaei, M.; Baniassadi, M.; Baghani, M. Investigating the Effect of ABS on the Mechanical Properties, Morphology, Printability, and 4D Printing of PETG-ABS Blends. Macromol. Mater. Eng. 2024, 2400038. [Google Scholar] [CrossRef]

- ASTM D4065-01; Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM D 638-02a; Standard Test Method for Tensile Properties of Plastics. ASTM International: Conshohocken, PA, USA, 2003.

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A Review on Voids of 3D Printed Parts by Fused Filament Fabrication; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Ghorbani, J.; Koirala, P.; Shen, Y.-L.; Tehrani, M. Eliminating voids and reducing mechanical anisotropy in fused filament fabrication parts by adjusting the filament extrusion rate. J. Manuf. Process. 2022, 80, 651–658. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D printing of PLA-TPU with different component ratios: Fracture toughness, mechanical properties, and morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Aberoumand, M.; Soltanmohammadi, K.; Rahmatabadi, D.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing of Polyvinyl Chloride (PVC): A Detailed Analysis of Microstructure, Programming, and Shape Memory Performance. Macromol. Mater. Eng. 2023, 308, 2200677. [Google Scholar] [CrossRef]

| Printing Parameters | Values |

|---|---|

| Velocity (mm/min) | 250 |

| Nozzle Temperature (°C) | 230 ± 10 |

| Bed Temperature (°C) | 50 |

| Nozzle Diameter (mm) | 0.6 |

| Layer Thickness (mm) | 0.45 |

| Printing Direction | 0–90 |

| Air Pressure (Bar) | 2.5–4 |

| Infill Density (%) | 100 |

| Samples | Tensile | |

|---|---|---|

| UTS (MPa) | El (%) | |

| 10% Fe3O4 | 27.05 | 13.9 |

| 15% Fe3O4 | 26.30 | 12.8 |

| 20% Fe3O4 | 20.94 | 13.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirasadi, K.; Rahmatabadi, D.; Ghasemi, I.; Khodaei, M.; Baniassadi, M.; Bodaghi, M.; Baghani, M. 3D and 4D Printing of PETG–ABS–Fe3O4 Nanocomposites with Supreme Remotely Driven Magneto-Thermal Shape-Memory Performance. Polymers 2024, 16, 1398. https://doi.org/10.3390/polym16101398

Mirasadi K, Rahmatabadi D, Ghasemi I, Khodaei M, Baniassadi M, Bodaghi M, Baghani M. 3D and 4D Printing of PETG–ABS–Fe3O4 Nanocomposites with Supreme Remotely Driven Magneto-Thermal Shape-Memory Performance. Polymers. 2024; 16(10):1398. https://doi.org/10.3390/polym16101398

Chicago/Turabian StyleMirasadi, Kiandokht, Davood Rahmatabadi, Ismaeil Ghasemi, Mohammad Khodaei, Majid Baniassadi, Mahdi Bodaghi, and Mostafa Baghani. 2024. "3D and 4D Printing of PETG–ABS–Fe3O4 Nanocomposites with Supreme Remotely Driven Magneto-Thermal Shape-Memory Performance" Polymers 16, no. 10: 1398. https://doi.org/10.3390/polym16101398

APA StyleMirasadi, K., Rahmatabadi, D., Ghasemi, I., Khodaei, M., Baniassadi, M., Bodaghi, M., & Baghani, M. (2024). 3D and 4D Printing of PETG–ABS–Fe3O4 Nanocomposites with Supreme Remotely Driven Magneto-Thermal Shape-Memory Performance. Polymers, 16(10), 1398. https://doi.org/10.3390/polym16101398