4D-Printed Tool for Compressing a Shape Memory Polyurethane Foam during Programming

Abstract

1. Introduction

2. Materials and Methods

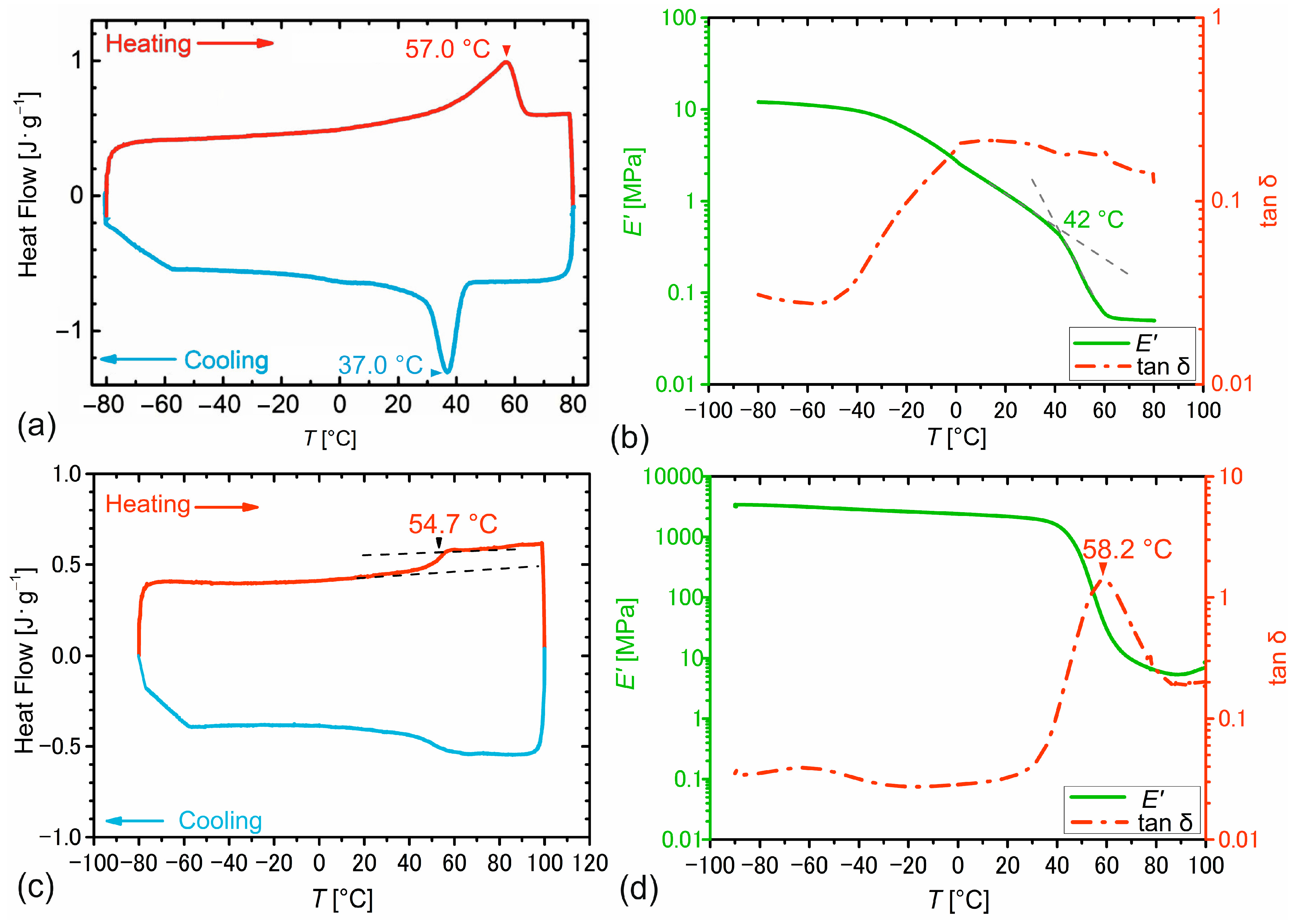

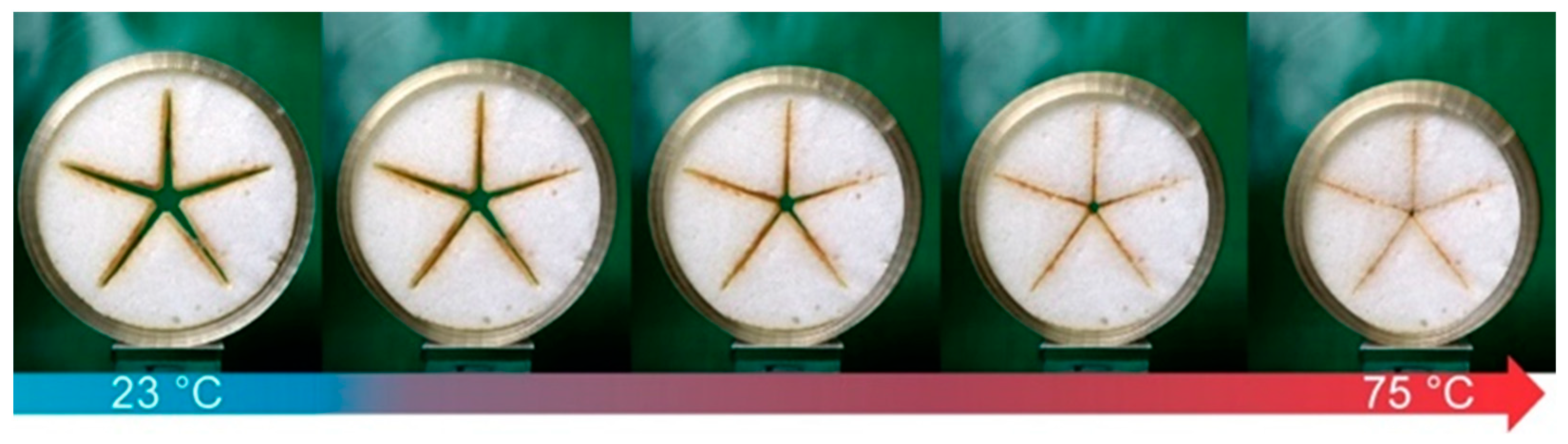

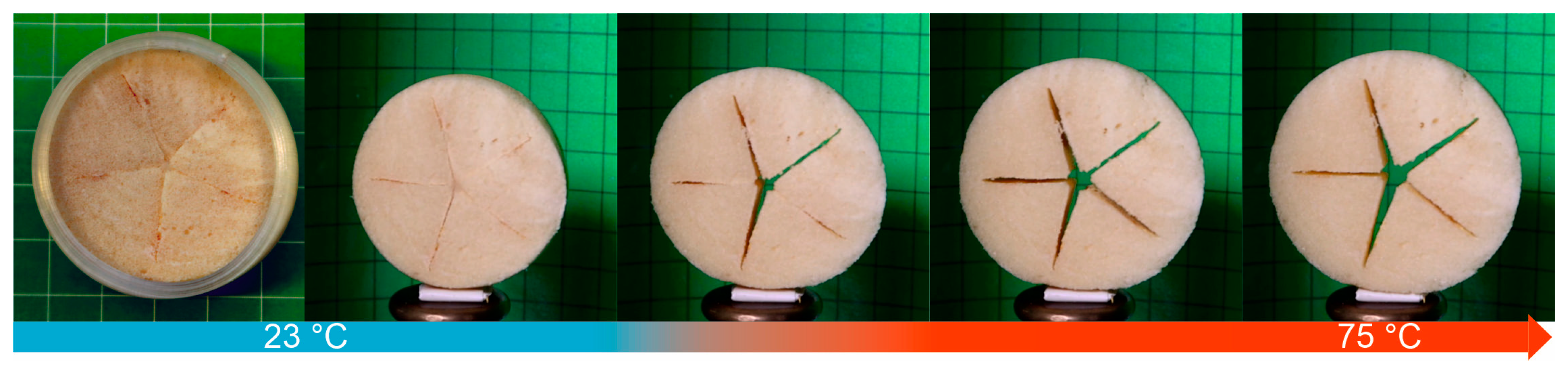

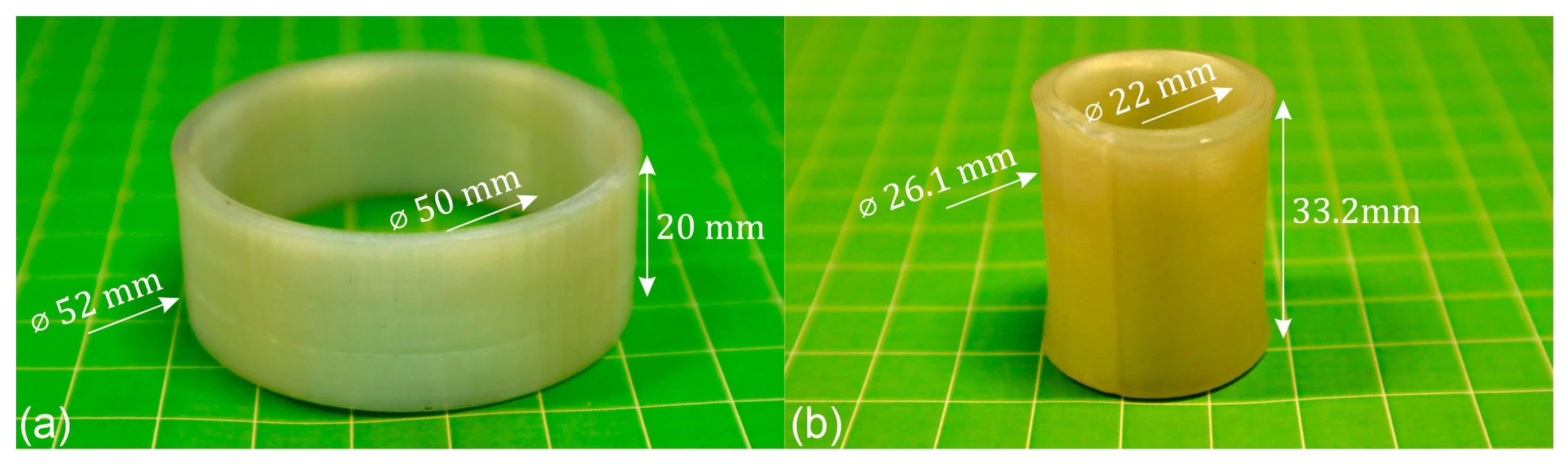

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pilate, F.; Toncheva, A.; Dubois, P.; Raquez, J.-M. Shape-memory polymers for multiple applications in the materials world. Eur. Polym. J. 2016, 80, 268–294. [Google Scholar] [CrossRef]

- Sun, L.; Wang, T.X.; Chen, H.M.; Salvekar, A.V.; Naveen, B.S.; Xu, Q.; Weng, Y.; Guo, X.; Chen, Y.; Huang, W.M. A Brief Review of the Shape Memory Phenomena in Polymers and Their Typical Sensor Applications. Polymers 2019, 11, 1049. [Google Scholar] [CrossRef]

- Yang, L.; Lou, J.; Yuan, J.; Deng, J. A review of shape memory polymers based on the intrinsic structures of their responsive switches. RSC Adv. 2021, 11, 28838–28850. [Google Scholar] [CrossRef]

- Zende, R.; Ghase, V.; Jamdar, V. A review on shape memory polymers. Polym. Plast. Technol. Mater. 2023, 62, 467–485. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.K.; Kant, R.; Bhattacharya, S. Shape Memory Polymers and Their Emerging Applications. In Trends in Applications of Polymers; Patel, V.K., Bhattacharya, S., Kant, R., Chauhan, P.S., Eds.; AIP Publishing: Melville, SK, Canada, 2022; pp. 1–18. ISBN 978-0-7354-2455-5. [Google Scholar]

- Kim, B.K.; Lee, S.Y.; Xu, M. Polyurethanes having shape memory effects. Polymer 1996, 37, 5781–5793. [Google Scholar] [CrossRef]

- Tobushi, H.; Hara, H.; Yamada, E.; Hayashi, S. Thermomechanical properties in a thin film of shape memory polymer of polyurethane series. Smart Mater. Struct. 1996, 5, 483–491. [Google Scholar] [CrossRef]

- Li, F.; Zhang, X.; Hou, J.; Xu, M.; Luo, X.; Ma, D.; Kim, B.K. Studies on thermally stimulated shape memory effect of segmented polyurethanes. J. Appl. Polym. Sci. 1997, 64, 1511–1516. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Ding, Z.; Zhao, Y.; Wang, C.C.; Purnawali, H.; Tang, C. Stimulus-responsive shape memory materials: A review. Mater. Des. 2012, 33, 577–640. [Google Scholar] [CrossRef]

- Fritzsche, N.; Pretsch, T. Programming of Temperature-Memory Onsets in a Semicrystalline Polyurethane Elastomer. Macromolecules 2014, 47, 5952–5959. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, W.M.; Kang, S.F.; Wu, X.L.; Lu, H.B.; Fu, J.; Cui, H. From 3D to 4D printing: Approaches and typical applications. J. Mech. Sci. Technol. 2015, 10, 4281–4288. [Google Scholar] [CrossRef]

- Li, G.; Wang, A. Cold, warm, and hot programming of shape memory polymers. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1319–1339. [Google Scholar] [CrossRef]

- Sáenz-Pérez, M.; Laza, J.M.; García-Barrasa, J.; Vilas, J.L.; León, L.M. Influence of the soft segment nature on the thermomechanical behavior of shape memory polyurethanes. Polym. Eng. Sci. 2018, 58, 238–244. [Google Scholar] [CrossRef]

- Chitrakar, C.; Torres, M.A.; Rocha-Flores, P.E.; Hu, Q.; Ecker, M. Multifaceted Shape Memory Polymer Technology for Biomedical Application: Combining Self-Softening and Stretchability Properties. Polymers 2023, 15, 4226. [Google Scholar] [CrossRef] [PubMed]

- Pei, E. 4D printing—Revolution or fad? Assem. Autom. 2014, 34, 123–127. [Google Scholar] [CrossRef]

- Momeni, F.; Mehdi, M.; Hassani, N.S.; Liu, X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-printing: A review on current smart materials, technologies, and applications. Int. J. Smart Nano Mater. 2019, 10, 205–224. [Google Scholar] [CrossRef]

- Ali, M.; Abilgaziyev, A.; Adair, D. 4D printing: A critical review of current developments, and future prospects. Int. J. Adv. Manufact. Technol. 2019, 105, 701–717. [Google Scholar] [CrossRef]

- Chu, H.; Yang, W.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D Printing: A Review of Recent Progress. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef]

- Subeshan, B.; Baddam, Y.; Asmatulu, E. Current progress of 4D-printing technology. Prog. Addit. Manuf. 2021, 6, 495–516. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W. 4D Printing: Technological and Manufacturing Renaissance. Macromol. Mater. Eng. 2022, 307, 2200003. [Google Scholar] [CrossRef]

- Joharji, L.; Mishra, R.B.; Alam, F.; Tytov, S.; Al-Modaf, F.; El-Atab, N. 4D printing: A detailed review of materials, techniques, and applications. Microelectron. Eng. 2022, 265, 111874. [Google Scholar] [CrossRef]

- McLellan, K.; Sun, Y.-C.; Naguib, H.E. A review of 4D printing: Materials, structures, and designs towards the printing of biomedical wearable devices. Bioprinting 2022, 27, e00217. [Google Scholar] [CrossRef]

- dos Santos, B.M.B.; Littlefair, G.; Singamneni, S. From 3D to 4D printing: A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Vatanparast, S.; Boschetto, A.; Bottini, L.; Gaudenzi, P. New Trends in 4D Printing: A Critical Review. Appl. Sci. 2023, 13, 7744. [Google Scholar] [CrossRef]

- Pingale, P.; Dawre, S.; Dhapte-Pawar, V.; Dhas, N.; Rajput, A. Advances in 4D printing: From stimulation to simulation. Drug Deliv. Transl. Res. 2023, 13, 164–188. [Google Scholar] [CrossRef]

- Tariq, A.; Arif, Z.U.; Khalid, M.Y.; Hossain, M.; Rasool, P.I.; Umer, R.; Ramakrishna, S. Recent Advances in the Additive Manufacturing of Stimuli-Responsive Soft Polymers. Adv. Eng. Mater. 2023, 25, 2301074. [Google Scholar] [CrossRef]

- Aldawood, F.K. A Comprehensive Review of 4D Printing: State of the Arts, Opportunities, and Challenges. Actuators 2023, 12, 101. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jäger, H.; Ettelaie, R.; Mohammadi, A.; Asghartabar Kashi, P. Multimaterial 3D printing of self-assembling smart thermo-responsive polymers into 4D printed objects: A review. Addit. Manuf. 2023, 71, 103598. [Google Scholar] [CrossRef]

- Tibbits, S. 4D Printing: Multi-Material Shape Change. Arch. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Zhang, Q.; Yan, D.; Zhang, K.; Hu, G. Pattern transformation of heat-shrinkable polymer by three-dimensional (3D) printing technique. Sci. Rep. 2015, 5, 8936. [Google Scholar] [CrossRef] [PubMed]

- van Manen, T.; Janbaz, S.; Zadpoor, A.A. Programming 2D/3D shape-shifting with hobbyist 3D printers. Mater. Horiz. 2017, 4, 1064–1069. [Google Scholar] [CrossRef] [PubMed]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Adaptive metamaterials by functionally graded 4D printing. Mater. Des. 2017, 135, 26–36. [Google Scholar] [CrossRef]

- Hu, G.F.; Damanpack, A.R.; Bodaghi, M.; Liao, W.H. Increasing dimension of structures by 4D printing shape memory polymers via fused deposition modeling. Smart Mater. Struct. 2017, 26, 125023. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Triple shape memory polymers by 4D printing. Smart Mater Struct 2018, 27, 065010. [Google Scholar] [CrossRef]

- Bodaghi, M.; Noroozi, R.; Zolfagharian, A.; Fotouhi, M.; Norouzi, S. 4D Printing Self-Morphing Structures. Materials 2019, 12, 1353. [Google Scholar] [CrossRef] [PubMed]

- Noroozi, R.; Bodaghi, M.; Jafari, H.; Zolfagharian, A.; Fotouhi, M. Shape-Adaptive Metastructures with Variable Bandgap Regions by 4D Printing. Polymers 2020, 12, 519. [Google Scholar] [CrossRef] [PubMed]

- Nezhad, I.S.; Golzar, M.; Behravesh, A.; Zare, S. Comprehensive Study on Shape Shifting Behaviors of Thermally Activated Hinges in FDM-Based 4D Printing. 2021. Available online: https://www.researchsquare.com/article/rs-791407/v1.pdf?c=1631891144000 (accessed on 13 March 2024).

- Rajkumar, A.R.; Shanmugam, K. Additive manufacturing-enabled shape transformations via FFF 4D printing. J. Mater. Res. 2018, 33, 4362–4376. [Google Scholar] [CrossRef]

- Chalissery, D.; Schönfeld, D.; Walter, M.; Shklyar, I.; Andrae, H.; Schwörer, C.; Amann, T.; Weisheit, L.; Pretsch, T. Highly Shrinkable Objects as Obtained from 4D Printing. Macromol. Mater. Eng. 2022, 307, 2100619. [Google Scholar] [CrossRef]

- Chalissery, D.; Pretsch, T.; Staub, S.; Andrä, H. Additive Manufacturing of Information Carriers Based on Shape Memory Polyester Urethane. Polymers 2019, 11, 1005. [Google Scholar] [CrossRef]

- Walter, M.; Friess, F.; Krus, M.; Zolanvari, S.M.H.; Grün, G.; Kröber, H.; Pretsch, T. Shape Memory Polymer Foam with Programmable Apertures. Polymers 2020, 12, 1914. [Google Scholar] [CrossRef] [PubMed]

- Ultimaker Cura: Powerful, Easy-to-Use 3D Printing Software. Available online: https://ultimaker.com/software/ultimaker-cura (accessed on 19 January 2022).

- CorelDRAW Graphics Suite 2021|Free Trial. Available online: https://www.coreldraw.com/en/product/coreldraw/index-price.html?pcuversion&segid=subscription30&topnav=false&sourceid=cdgs2021-xx-ppc_brkws&x-vehicle=ppc_brkws&trial=big&gclid=CjwKCAjw1uiEBhBzEiwAO9B_HTh3mPZJXfUkRCV9kkJKNZYxLM-alc3rbpcRe_8ooW8RMsZxIWC7FBoCch8QAvD_BwE (accessed on 18 April 2024).

- Kovacs, A.J. Transition Vitreuse dans les Polymeres. Etude Phenomelogique (Vitreous transition in amorphous polymers. Phenomenological study). Fortschritte Der Hochpolym. Forsch. 1963, 3, 394–507. [Google Scholar] [CrossRef]

- Struik, L.C.E. Physical Aging in Amorphous Polymers and Other Materials, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 1978. [Google Scholar]

- Hutchinson, J.M. Physical aging of polymers. Prog. Polym. Sci. 1995, 20, 703–760. [Google Scholar] [CrossRef]

- Sun, X.; Zhou, K.; Demoly, F.; Zhao, R.R.; Qi, H.J. Perspective: Machine Learning in Design for 3D/4D Printing. J. Appl. Mech. 2024, 91, 030801. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Hamel, C.M.; Yu, K.; Qi, H.J. Materials, design, and fabrication of shape programmable polymers. Multifunct. Mater. 2020, 3, 032002. [Google Scholar] [CrossRef]

- Schönfeld, D.; Chalissery, D.; Wenz, F.; Specht, M.; Eberl, C.; Pretsch, T. Actuating Shape Memory Polymer for Thermoresponsive Soft Robotic Gripper and Programmable Materials. Molecules 2021, 26, 522. [Google Scholar] [CrossRef]

- Wenz, F.; Schönfeld, D.; Fischer, S.C.L.; Pretsch, T.; Eberl, C. Controlling Malleability of Metamaterials through Programmable Memory. Adv. Eng. Mater. 2022, 25, 2201022. [Google Scholar] [CrossRef]

- Wu, R.Y.; Wu, L.W.; He, S.; Liu, S.; Cui, T.J. Programmable metamaterials. Program. Mater. 2023, 1, e4. [Google Scholar] [CrossRef]

- Chalissery, D.; Schönfeld, D.; Walter, M.; Ziervogel, F.; Pretsch, T. Fused Filament Fabrication of Actuating Objects. Macromol. Mater. Eng. 2022, 307, 2200214. [Google Scholar] [CrossRef]

- Uribe-Gomez, J.; Schönfeld, D.; Posada-Murcia, A.; Roland, M.-M.; Caspari, A.; Synytska, A.; Salehi, S.; Pretsch, T.; Ionov, L. Fibrous Scaffolds for Muscle Tissue Engineering Based on Touch-Spun Poly(Ester-Urethane) Elastomer. Macromol. Biosci. 2022, 22, e2100427. [Google Scholar] [CrossRef]

- Tauber, F.J.; Scheckenbach, F.; Walter, M.; Pretsch, T.; Speck, T. A 3D-Printed Thermoresponsive Artificial Venus Flytrap Lobe Based on a Multilayer of Shape Memory Polymers. In Biomimetic and Biohybrid Systems: 11th International Conference, Living; Meder, F., Hunt, A., Margheri, L., Mura, A., Mazzolai, B., Eds.; Springer International PU: Cham, Switzerland, 2023; pp. 91–108. ISBN 978-3-031-38856-9. [Google Scholar]

- Yang, D.; Zhang, H.; Zeng, H. Programmable shape memory polymers: Intermolecular and interfacial interaction mechanisms. Sci. China Mater. 2023, 66, 4519–4520. [Google Scholar] [CrossRef]

- Wang, K.; Man, L.; Zhang, M.; Jia, Y.-G.; Zhu, X.X. Programmable polymers with shape memory for biomedical applications. Prog. Mater. 2023, 1, e2. [Google Scholar] [CrossRef]

- Eberl, C. Programmable Materials. Program. Mater. 2023, 1, e3. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chalissery, D.; Pretsch, T. 4D-Printed Tool for Compressing a Shape Memory Polyurethane Foam during Programming. Polymers 2024, 16, 1393. https://doi.org/10.3390/polym16101393

Chalissery D, Pretsch T. 4D-Printed Tool for Compressing a Shape Memory Polyurethane Foam during Programming. Polymers. 2024; 16(10):1393. https://doi.org/10.3390/polym16101393

Chicago/Turabian StyleChalissery, Dilip, and Thorsten Pretsch. 2024. "4D-Printed Tool for Compressing a Shape Memory Polyurethane Foam during Programming" Polymers 16, no. 10: 1393. https://doi.org/10.3390/polym16101393

APA StyleChalissery, D., & Pretsch, T. (2024). 4D-Printed Tool for Compressing a Shape Memory Polyurethane Foam during Programming. Polymers, 16(10), 1393. https://doi.org/10.3390/polym16101393