3D-Printed Polycaprolactone-Based Containing Calcium Zirconium Silicate: Bioactive Scaffold for Accelerating Bone Regeneration

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. CZS Synthesis

2.3. PCL/CZS Composites Preparation

2.4. 3D Printed Scaffolds Fabrication

2.5. Scaffolds Characterisations

2.6. Mechanical Characterisation of the Scaffolds

2.7. Thermogravimetric Analysis (TGA)

2.8. Differential Scanning Calorimetry (DSC)

2.9. In Vitro Bioactivity Evaluation

2.10. Biodegradation Study

2.11. Cell Viability

3. Results

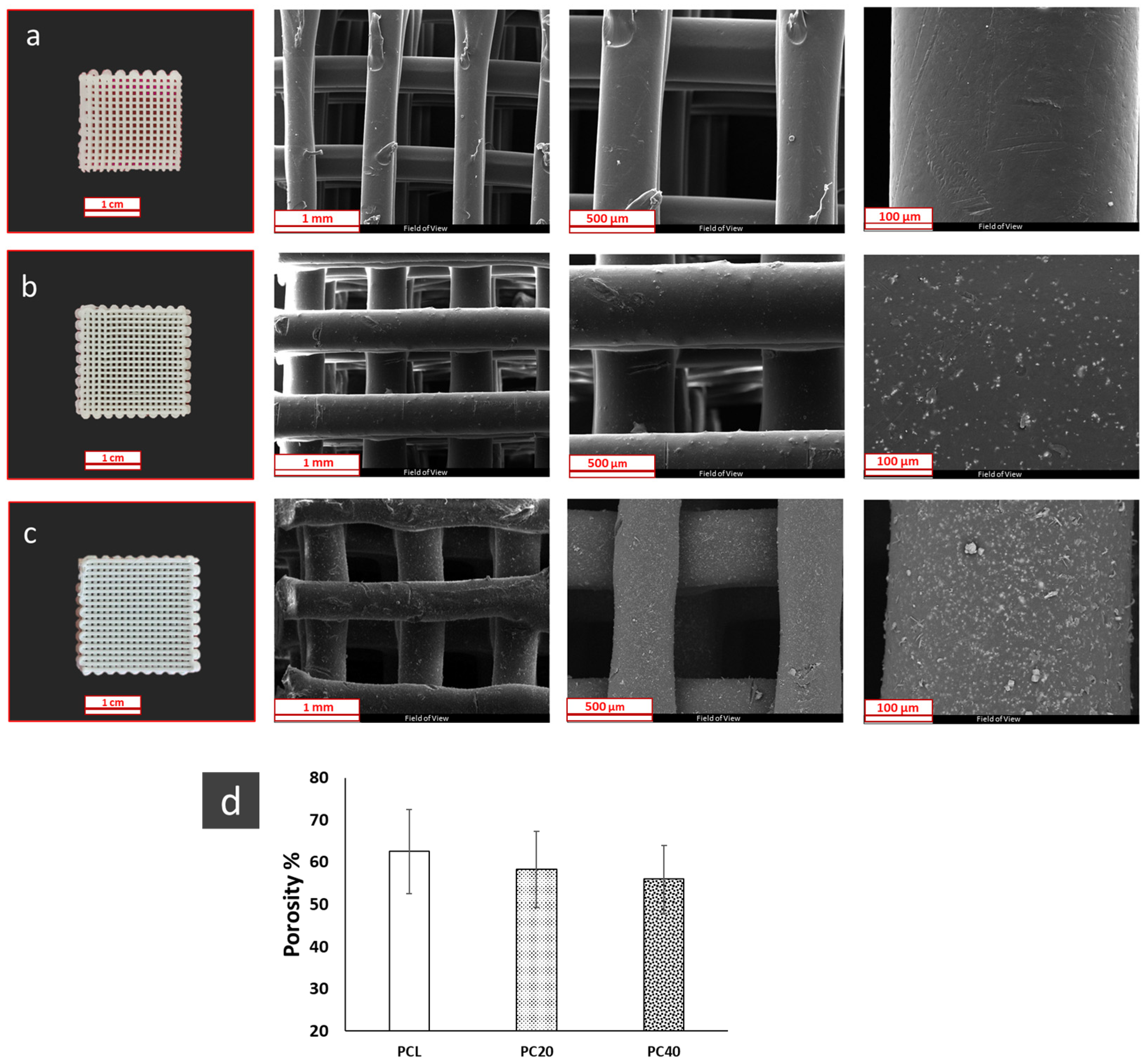

3.1. Morphological Properties

3.2. Mechanical Properties of the Scaffolds

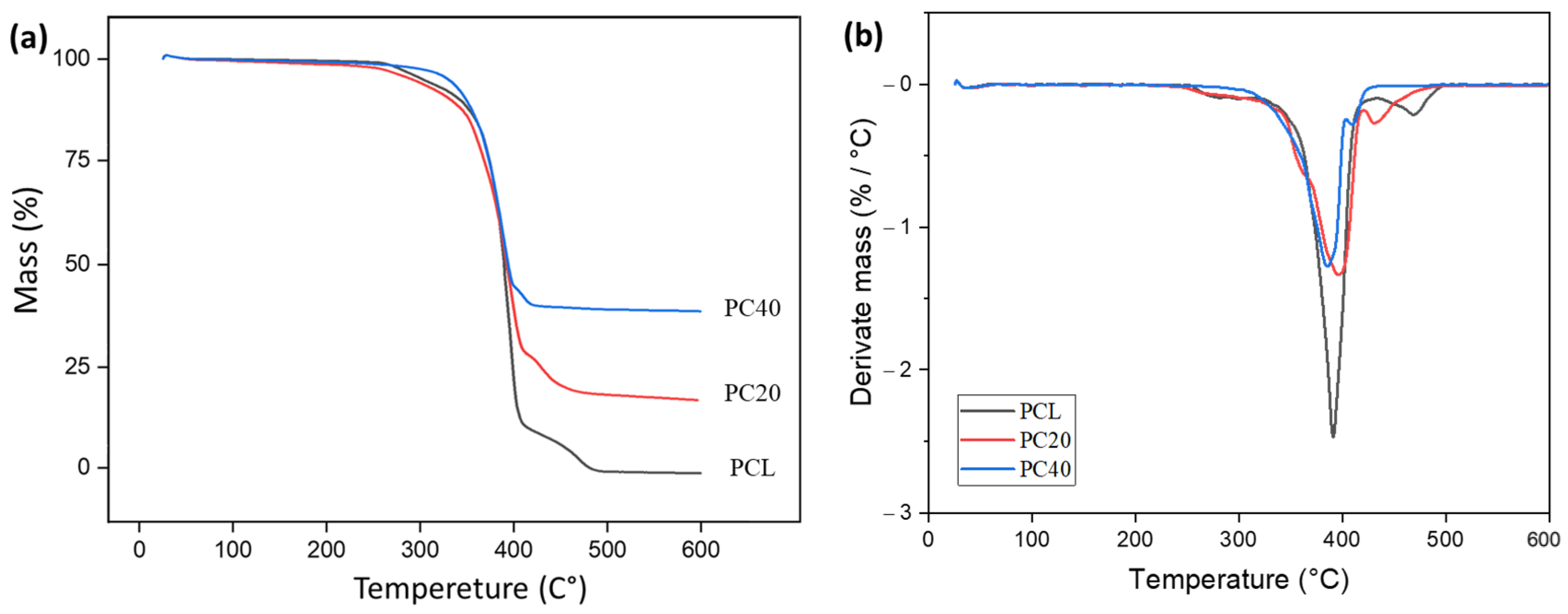

3.3. Thermal Properties

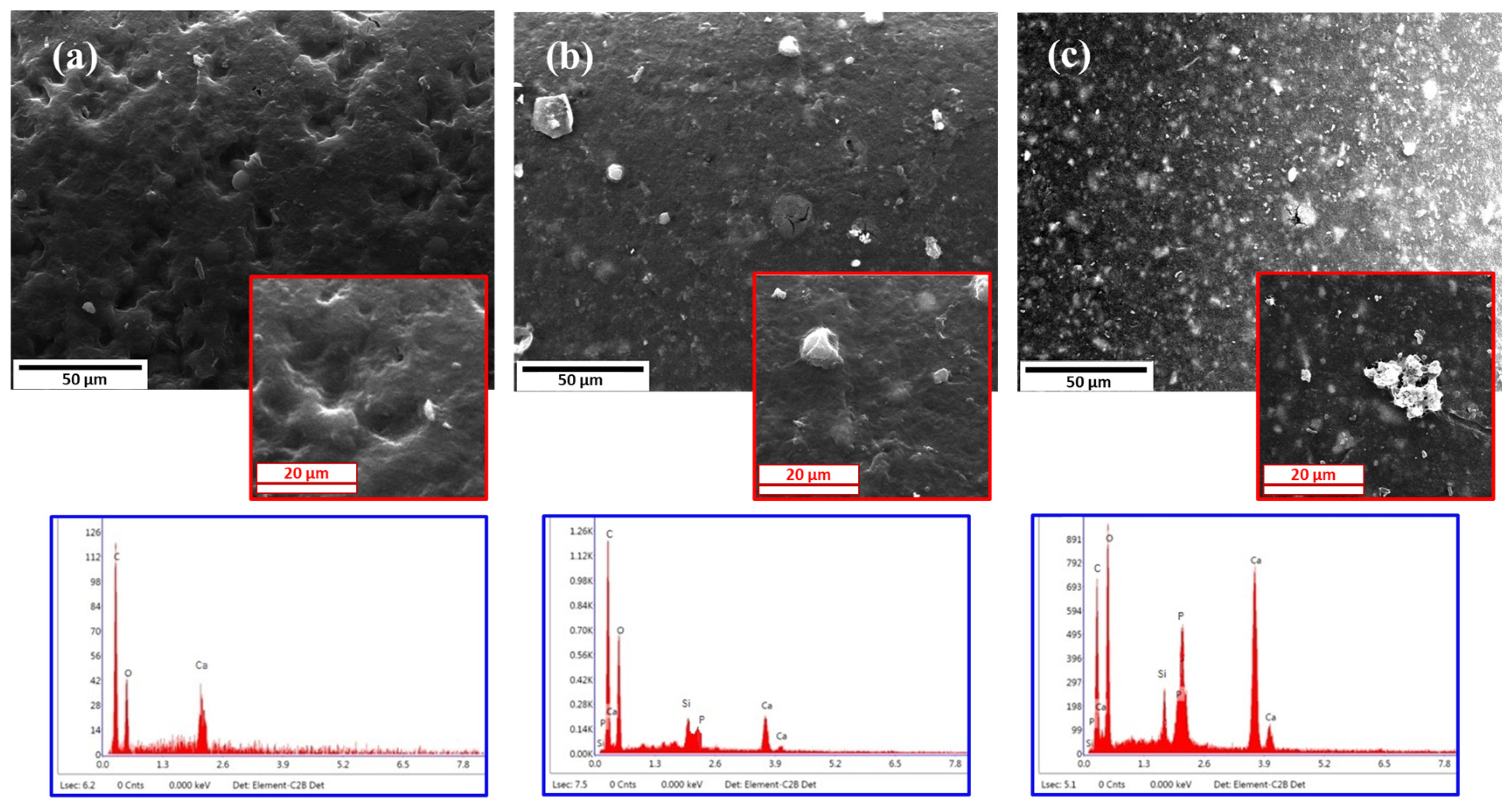

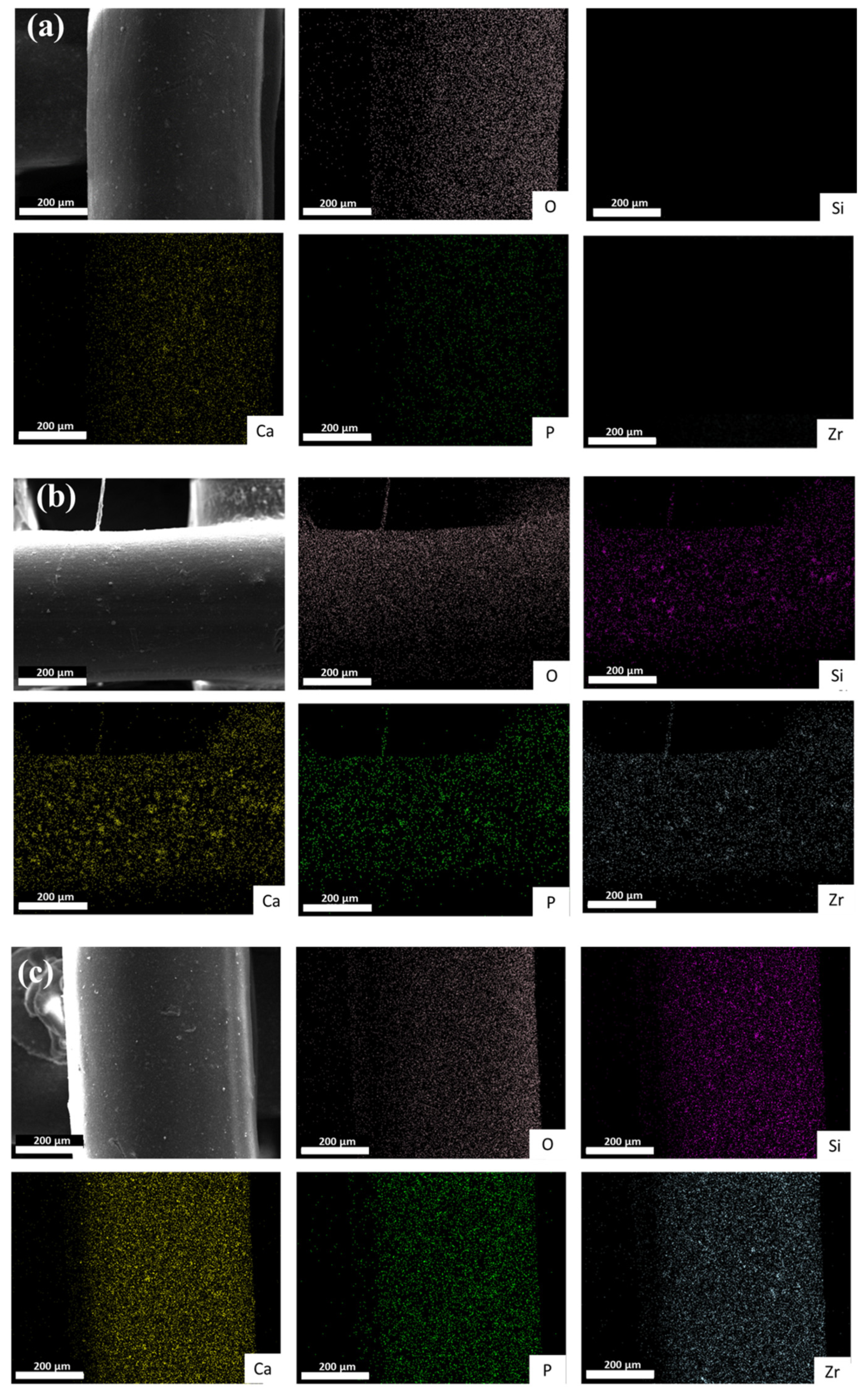

3.4. Biological Properties of the Scaffolds

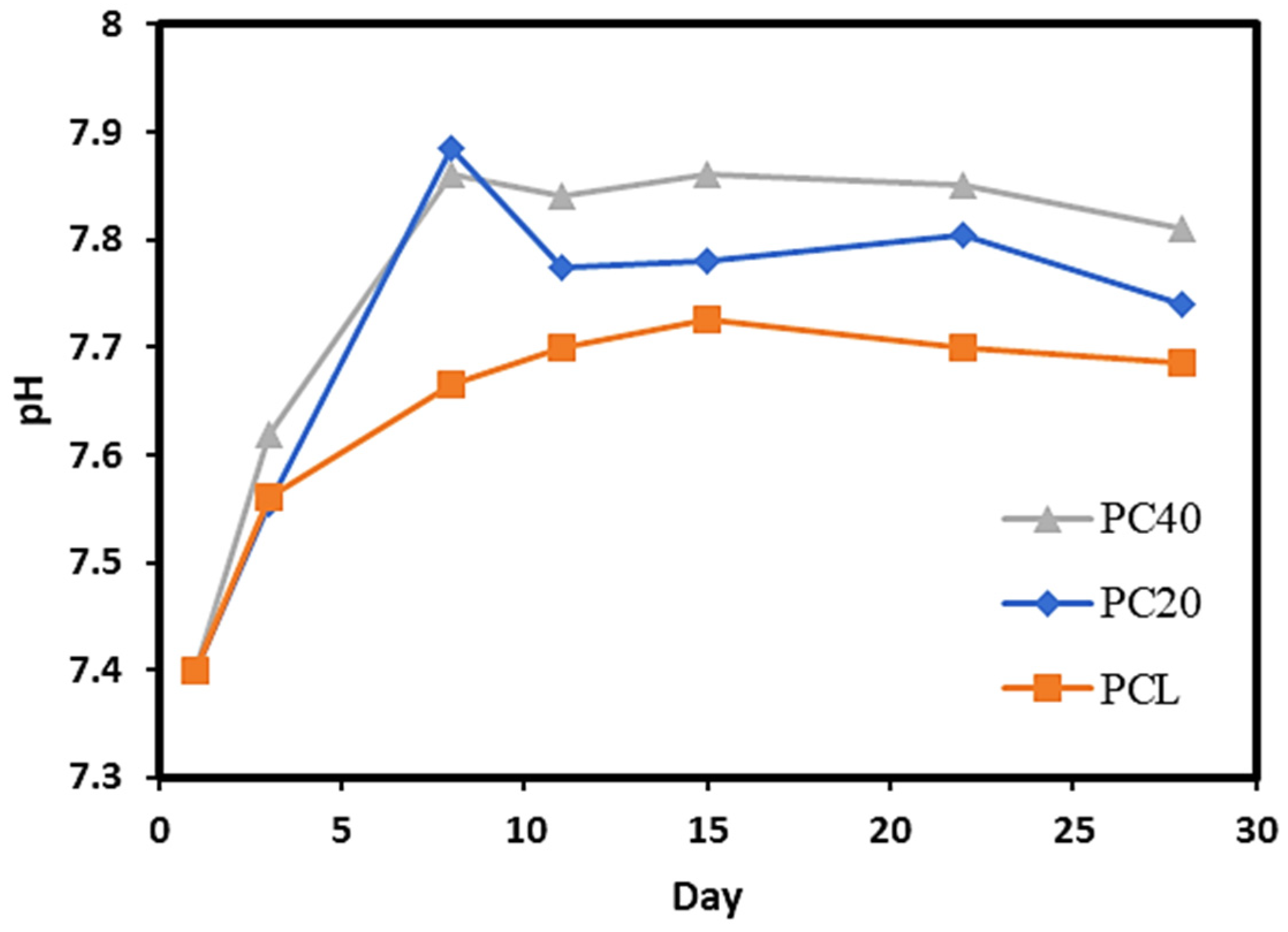

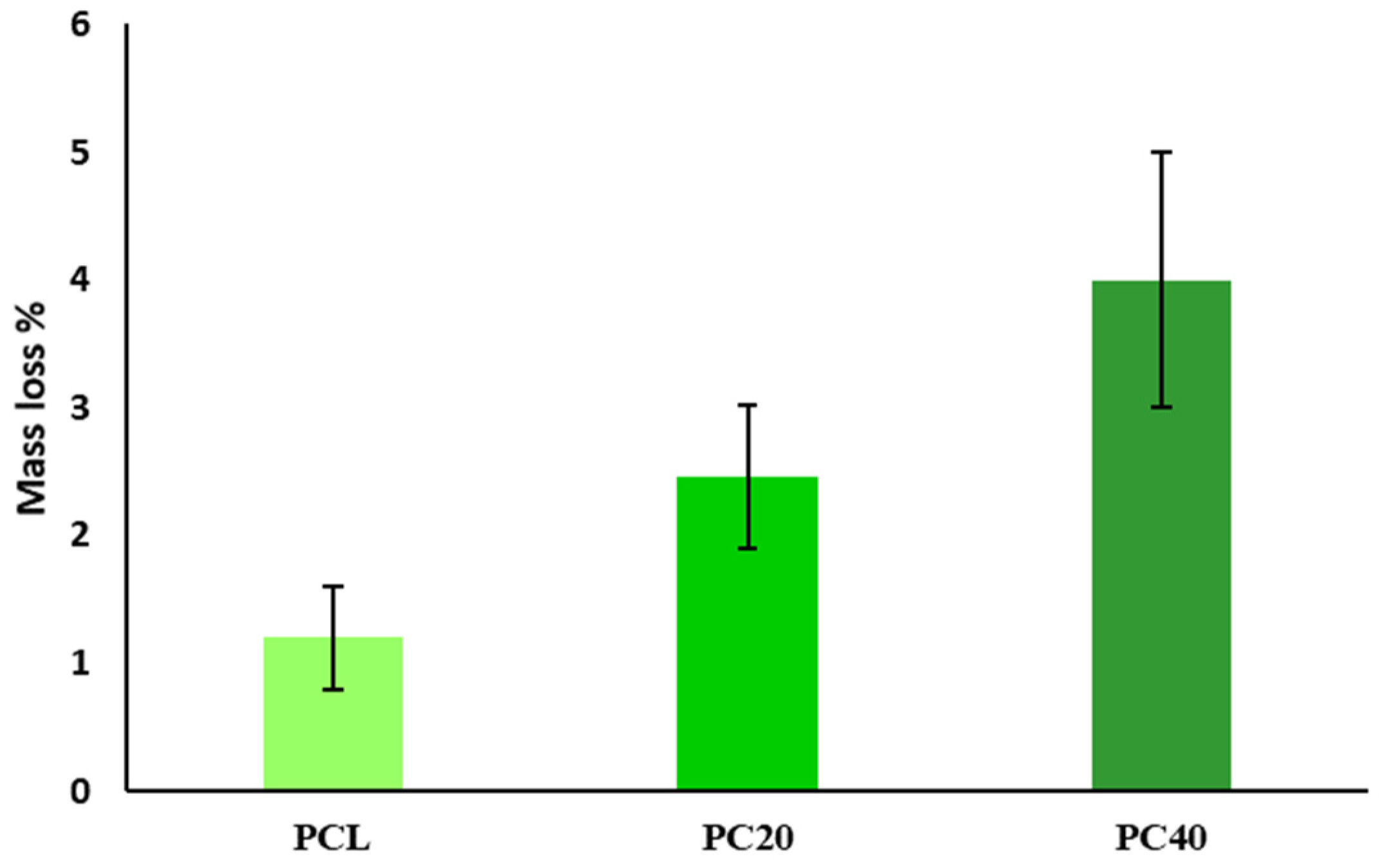

3.5. Biodegradation Evaluation

3.6. Cell Viability

4. Discussion

4.1. Morphological Properties

4.2. Mechanical Properties

4.3. Thermal Properties

4.4. Bioactivity Assessment

4.5. Biodegradation Evaluation

4.6. Cell Viability

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, S.; Chauhan, V.M.; Ghaemmaghami, A.M.; Aylott, J.W. New Generation of Bioreactors That Advance Extracellular Matrix Modelling and Tissue Engineering. Biotechnol. Lett. 2019, 41, 1–25. [Google Scholar] [CrossRef]

- Koons, G.L.; Diba, M.; Mikos, A.G. Materials Design for Bone-Tissue Engineering. Nat. Rev. Mater. 2020, 5, 584–603. [Google Scholar] [CrossRef]

- Ma, C.; Du, T.; Niu, X.; Fan, Y. Biomechanics and Mechanobiology of the Bone Matrix. Bone Res. 2022, 10, 59. [Google Scholar] [CrossRef]

- Parvizi, J.; Kim, G.K. Bone Grafting. In High Yield Orthopaedics; Elsevier: Amsterdam, The Netherlands, 2010; pp. 64–65. [Google Scholar]

- Valtanen, R.S.; Yang, Y.P.; Gurtner, G.C.; Maloney, W.J.; Lowenberg, D.W. Synthetic and Bone Tissue Engineering Graft Substitutes: What Is the Future? Injury 2021, 52, S72–S77. [Google Scholar] [CrossRef]

- Stevens, B.; Yang, Y.; Mohandas, A.; Stucker, B.; Nguyen, K.T. A Review of Materials, Fabrication Methods, and Strategies Used to Enhance Bone Regeneration in Engineered Bone Tissues. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 85, 573–582. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, S.; Singh, S.; Maiti, T.K.; Sharma, C.; Dutt, D.; Sharma, S.; Li, C.; Tag Eldin, E.M. Scaffold Fabrication Techniques of Biomaterials for Bone Tissue Engineering: A Critical Review. Bioengineering 2022, 9, 728. [Google Scholar] [CrossRef]

- Mohseni, M.; Castro, N.J.; Dang, H.P.; Nguyen, T.D.; Ho, H.M.; Tran, M.P.N.; Nguyen, T.H.; Tran, P.A. Adipose Tissue Regeneration. In Biomaterials in Translational Medicine; Elsevier: Amsterdam, The Netherlands, 2019; pp. 291–330. [Google Scholar]

- Pahlevanzadeh, F.; Emadi, R.; Kharaziha, M.; Poursamar, S.A.; Nejatidanesh, F.; Emadi, H.; Aslani, R.; Moroni, L.; Setayeshmehr, M. Amorphous Magnesium Phosphate-Graphene Oxide Nano Particles Laden 3D-Printed Chitosan Scaffolds with Enhanced Osteogenic Potential and Antibacterial Properties. Biomater. Adv. 2024, 158, 213760. [Google Scholar] [CrossRef]

- Nadgorny, M.; Ameli, A. Functional Polymers and Nanocomposites for 3D Printing of Smart Structures and Devices. ACS Appl. Mater. Interfaces 2018, 10, 17489–17507. [Google Scholar] [CrossRef]

- Petretta, M.; Gambardella, A.; Desando, G.; Cavallo, C.; Bartolotti, I.; Shelyakova, T.; Goranov, V.; Brucale, M.; Dediu, V.A.; Fini, M.; et al. Multifunctional 3D-Printed Magnetic Polycaprolactone/Hydroxyapatite Scaffolds for Bone Tissue Engineering. Polymers 2021, 13, 3825. [Google Scholar] [CrossRef]

- Lamnini, S.; Elsayed, H.; Lakhdar, Y.; Baino, F.; Smeacetto, F.; Bernardo, E. Robocasting of Advanced Ceramics: Ink Optimization and Protocol to Predict the Printing Parameters—A Review. Heliyon 2022, 8, e10651. [Google Scholar] [CrossRef]

- Löffler, R.; Koch, M. Innovative Extruder Concept for Fast and Efficient Additive Manufacturing. IFAC-PapersOnLine 2019, 52, 242–247. [Google Scholar] [CrossRef]

- Kholgh Eshkalak, S.; Rezvani Ghomi, E.; Dai, Y.; Choudhury, D.; Ramakrishna, S. The Role of Three-Dimensional Printing in Healthcare and Medicine. Mater. Des. 2020, 194, 108940. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Y.; Zhou, Y.; Chen, J.; Wan, Q. The Application of Polycaprolactone in Three-Dimensional Printing Scaffolds for Bone Tissue Engineering. Polymers 2021, 13, 2754. [Google Scholar] [CrossRef]

- Fazeli, N.; Arefian, E.; Irani, S.; Ardeshirylajimi, A.; Seyedjafari, E. 3D-Printed PCL Scaffolds Coated with Nanobioceramics Enhance Osteogenic Differentiation of Stem Cells. ACS Omega 2021, 6, 35284–35296. [Google Scholar] [CrossRef] [PubMed]

- Altunordu, G.; Tezcaner, A.; Evis, Z.; Keskin, D. Improvement of Bioactivity with Dual Bioceramic Incorporation to Nanofibrous PCL Scaffolds. Materialia 2023, 27, 101699. [Google Scholar] [CrossRef]

- Helaehil, J.V.; Lourenço, C.B.; Huang, B.; Helaehil, L.V.; de Camargo, I.X.; Chiarotto, G.B.; Santamaria-Jr, M.; Bártolo, P.; Caetano, G.F. In Vivo Investigation of Polymer-Ceramic PCL/HA and PCL/β-TCP 3D Composite Scaffolds and Electrical Stimulation for Bone Regeneration. Polymers 2021, 14, 65. [Google Scholar] [CrossRef] [PubMed]

- Arefpour, A.; Kasiri-Asgarani, M.; Monshi, A.; Karbasi, S.; Doostmohammadi, A. Baghdadite/Polycaprolactone Nanocomposite Scaffolds: Preparation, Characterisation, and in Vitro Biological Responses of Human Osteoblast-like Cells (Saos-2 Cell Line). Mater. Technol. 2020, 35, 421–432. [Google Scholar] [CrossRef]

- Soleymani, F.; Emadi, R.; Sadeghzade, S.; Tavangarian, F. Applying Baghdadite/PCL/Chitosan Nanocomposite Coating on AZ91 Magnesium Alloy to Improve Corrosion Behavior, Bioactivity, and Biodegradability. Coatings 2019, 9, 789. [Google Scholar] [CrossRef]

- Sadeghzade, S.; Shamoradi, F.; Emadi, R.; Tavangarian, F. Fabrication and Characterization of Baghdadite Nanostructured Scaffolds by Space Holder Method. J. Mech. Behav. Biomed. Mater. 2017, 68, 1–7. [Google Scholar] [CrossRef]

- Li, R.; Ying, B.; Wei, Y.; Xing, H.; Qin, Y.; Li, D. Comparative Evaluation of Sr-Incorporated Calcium Phosphate and Calcium Silicate as Bioactive Osteogenesis Coating Orthopedics Applications. Colloids Surf. A Physicochem. Eng. Asp. 2020, 600, 124834. [Google Scholar] [CrossRef]

- Yang, Y.; Kulkarni, A.; Soraru, G.D.; Pearce, J.M.; Motta, A. 3D Printed SiOC(N) Ceramic Scaffolds for Bone Tissue Regeneration: Improved Osteogenic Differentiation of Human Bone Marrow-Derived Mesenchymal Stem Cells. Int. J. Mol. Sci. 2021, 22, 13676. [Google Scholar] [CrossRef] [PubMed]

- Emadi, H.; Baghani, M.; Khodaei, M.; Baniassadi, M.; Tavangarian, F. Development of 3D-Printed PCL/Baghdadite Nanocomposite Scaffolds for Bone Tissue Engineering Applications. J. Polym. Environ. 2024, 1–19. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How Useful Is SBF in Predicting in Vivo Bone Bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef] [PubMed]

- Mokhtari, H.; Ghasemi, Z.; Kharaziha, M.; Karimzadeh, F.; Alihosseini, F. Chitosan-58S Bioactive Glass Nanocomposite Coatings on TiO2 Nanotube: Structural and Biological Properties. Appl. Surf. Sci. 2018, 441, 138–149. [Google Scholar] [CrossRef]

- Pahlevanzadeh, F.; Bakhsheshi-Rad, H.R.; Ismail, A.F.; Aziz, M. Apatite-forming Ability, Cytocompatibility, and Mechanical Properties Enhancement of Poly Methyl Methacrylate-based Bone Cements by Incorporating of Baghdadite Nanoparticles. Int. J. Appl. Ceram. Technol. 2019, 16, 2006–2019. [Google Scholar] [CrossRef]

- Motloung, M.P.; Mofokeng, T.G.; Ray, S.S. Viscoelastic, Thermal, and Mechanical Properties of Melt-Processed Poly (ε-Caprolactone) (PCL)/Hydroxyapatite (HAP) Composites. Materials 2021, 15, 104. [Google Scholar] [CrossRef] [PubMed]

- Trakoolwannachai, V.; Kheolamai, P.; Ummartyotin, S. Characterization of Hydroxyapatite from Eggshell Waste and Polycaprolactone (PCL) Composite for Scaffold Material. Compos. Part B Eng. 2019, 173, 106974. [Google Scholar] [CrossRef]

- Siauciunas, R.; Prichockiene, E.; Valancius, Z. The Influence of Mg-Impurities in Raw Materials on the Synthesis of Rankinite Clinker and the Strength of Mortar Hardening in CO2 Environment. Materials 2023, 16, 2930. [Google Scholar] [CrossRef] [PubMed]

- Sadreddini, S.; Jodati, H.; Evis, Z.; Keskin, D. Novel Barium-Doped-Baghdadite Incorporated PHBV-PCL Composite Fibrous Scaffolds for Bone Tissue Engineering. J. Mech. Behav. Biomed. Mater. 2023, 148, 106185. [Google Scholar] [CrossRef]

- Pezeshki-Modaress, M.; Zandi, M.; Rajabi, S. Tailoring the Gelatin/Chitosan Electrospun Scaffold for Application in Skin Tissue Engineering: An in Vitro Study. Prog. Biomater. 2018, 7, 207–218. [Google Scholar] [CrossRef]

- Jiankang, H.; Dichen, L.; Yaxiong, L.; Bo, Y.; Bingheng, L.; Qin, L. Fabrication and Characterization of Chitosan/Gelatin Porous Scaffolds with Predefined Internal Microstructures. Polymer 2007, 48, 4578–4588. [Google Scholar] [CrossRef]

- Pezeshki-Modaress, M.; Rajabi-Zeleti, S.; Zandi, M.; Mirzadeh, H.; Sodeifi, N.; Nekookar, A.; Aghdami, N. Cell-Loaded Gelatin/Chitosan Scaffolds Fabricated by Salt-Leaching/Lyophilization for Skin Tissue Engineering: In Vitro and in Vivo Study. J. Biomed. Mater. Res. Part A 2014, 102, 3908–3917. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, N.; Hamlet, S.; Love, R.M.; Nguyen, N.-T. Porous Scaffolds for Bone Regeneration. J. Sci. Adv. Mater. Devices 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Chhabra, H.; Kadam, S.S.; Londhe, K.; Soni, V.P.; Bellare, J.R. Hardystonite Improves Biocompatibility and Strength of Electrospun Polycaprolactone Nanofibers over Hydroxyapatite: A Comparative Study. Mater. Sci. Eng. C 2013, 33, 2926–2936. [Google Scholar] [CrossRef] [PubMed]

- Moeini, S.; Mohammadi, M.R.; Simchi, A. In-Situ Solvothermal Processing of Polycaprolactone/Hydroxyapatite Nanocomposites with Enhanced Mechanical and Biological Performance for Bone Tissue Engineering. Bioact. Mater. 2017, 2, 146–155. [Google Scholar] [CrossRef] [PubMed]

- Momeni, M.; Amini, K.; Heidari, A.; Khodaei, M. Evaluation the Properties of Polycaprolactone/Fluorapatite Nano-Biocomposite. J. Bionic Eng. 2022, 19, 179–187. [Google Scholar] [CrossRef]

- Sadeghzade, S.; Emadi, R.; Labbaf, S. Hardystonite-Diopside Nanocomposite Scaffolds for Bone Tissue Engineering Applications. Mater. Chem. Phys. 2017, 202, 95–103. [Google Scholar] [CrossRef]

- Huang, L.; Meng, Y.; Ren, A.; Han, X.; Bai, D.; Bao, L. Response of Cementoblast-like Cells to Mechanical Tensile or Compressive Stress at Physiological Levels in Vitro. Mol. Biol. Rep. 2009, 36, 1741–1748. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Fang, G.; Zhou, J. Additively Manufactured Scaffolds for Bone Tissue Engineering and the Prediction of Their Mechanical Behavior: A Review. Materials 2017, 10, 50. [Google Scholar] [CrossRef]

- Weber, A.F.; Monteiro, R.S.; Malmonge, S.M.; Souza, M.T.; Petil, O.; Daguano, J.K.M.B. Mechanical Evaluation of Poly-ε-Caprolactone and Biosilicate® Composites. In Proceedings of the XXVI Brazilian Congress on Biomedical Engineering, Armação de Buzios, RJ, Brazil, 21–25 October 2018; pp. 89–92. [Google Scholar]

- Mokhtari, S.; Eftekhari Yekta, B.; Marghussian, V.; Ahmadi, P.T. Synthesis and Characterization of Biodegradable AZ31/Calcium Phosphate Glass Composites for Orthopedic Applications. Adv. Compos. Hybrid Mater. 2020, 3, 390–401. [Google Scholar] [CrossRef]

- Liu, C.; Wan, P.; Tan, L.L.; Wang, K.; Yang, K. Preclinical Investigation of an Innovative Magnesium-Based Bone Graft Substitute for Potential Orthopaedic Applications. J. Orthop. Transl. 2014, 2, 139–148. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Pei, N.; Chen, Z.; Li, R.; Fu, L.; Zhang, P.; Zhao, J. The Critical Role of Fillers in Composite Polymer Electrolytes for Lithium Battery. Nano-Micro Lett. 2023, 15, 74. [Google Scholar] [CrossRef] [PubMed]

- Moldoveanu, S.C. Chapter 2 Thermal Decomposition of Polymers. In Techniques and Instrumentation in Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2005; pp. 31–107. [Google Scholar]

- Uliasz, M.; Zima, G.; Błaż, S.; Jasiński, B. Enzymatic and Oxidizing Agents for the Decomposition of Polymers Used in the Composition of Drilling Muds. Energies 2021, 14, 5032. [Google Scholar] [CrossRef]

- Biscaia, S.; Branquinho, M.V.; Alvites, R.D.; Fonseca, R.; Sousa, A.C.; Pedrosa, S.S.; Caseiro, A.R.; Guedes, F.; Patrício, T.; Viana, T.; et al. 3D Printed Poly(ε-Caprolactone)/Hydroxyapatite Scaffolds for Bone Tissue Engineering: A Comparative Study on a Composite Preparation by Melt Blending or Solvent Casting Techniques and the Influence of Bioceramic Content on Scaffold Properties. Int. J. Mol. Sci. 2022, 23, 2318. [Google Scholar] [CrossRef] [PubMed]

- Thijssen, Q.; Cornelis, K.; Alkaissy, R.; Locs, J.; Van Damme, L.; Schaubroeck, D.; Willaert, R.; Snelling, S.; Mouthuy, P.-A.; Van Vlierberghe, S. Tough Photo-Cross-Linked PCL-Hydroxyapatite Composites for Bone Tissue Engineering. Biomacromolecules 2022, 23, 1366–1375. [Google Scholar] [CrossRef]

- Korbut, A.; Włodarczyk, M.; Rudnicka, K.; Szwed, A.; Płociński, P.; Biernat, M.; Tymowicz-Grzyb, P.; Michalska, M.; Karska, N.; Rodziewicz-Motowidło, S.; et al. Three Component Composite Scaffolds Based on PCL, Hydroxyapatite, and L-Lysine Obtained in TIPS-SL: Bioactive Material for Bone Tissue Engineering. Int. J. Mol. Sci. 2021, 22, 13589. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Nie, W.; Li, D.; Wang, W.; Zheng, L.; Zhang, J.; Zhang, J.; Peng, C.; Mo, X.; He, C. 3D Printed PCL/SrHA Scaffold for Enhanced Bone Regeneration. Chem. Eng. J. 2019, 362, 269–279. [Google Scholar] [CrossRef]

- Aoyama, T.; Uto, K.; Shimizu, H.; Ebara, M.; Kitagawa, T.; Tachibana, H.; Suzuki, K.; Kodaira, T. Development of a New Poly-ε-Caprolactone with Low Melting Point for Creating a Thermoset Mask Used in Radiation Therapy. Sci. Rep. 2021, 11, 20409. [Google Scholar] [CrossRef] [PubMed]

- Baptista, C.; Azagury, A.; Shin, H.; Baker, C.M.; Ly, E.; Lee, R.; Mathiowitz, E. The Effect of Temperature and Pressure on Polycaprolactone Morphology. Polymer 2020, 191, 122227. [Google Scholar] [CrossRef]

- Woodruff, M.A.; Hutmacher, D.W. The Return of a Forgotten Polymer—Polycaprolactone in the 21st Century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef]

- Carotenuto, M.R.; Cavallaro, G.; Chinnici, I.; Lazzara, G.; Milioto, S. Hybrid Green Materials Obtained by PCL Melt Blending with Diatomaceous Earth. Molecules 2024, 29, 1203. [Google Scholar] [CrossRef] [PubMed]

- Papananou, H.; Perivolari, E.; Chrissopoulou, K.; Anastasiadis, S.H. Tuning Polymer Crystallinity via the Appropriate Selection of Inorganic Nanoadditives. Polymer 2018, 157, 111–121. [Google Scholar] [CrossRef]

- Cavallaro, G.; Milioto, S.; Parisi, F.; Lazzara, G. Halloysite Nanotubes Loaded with Calcium Hydroxide: Alkaline Fillers for the Deacidification of Waterlogged Archeological Woods. ACS Appl. Mater. Interfaces 2018, 10, 27355–27364. [Google Scholar] [CrossRef] [PubMed]

- Emadi, H.; Karevan, M.; Masoudi Rad, M.; Sadeghzade, S.; Pahlevanzadeh, F.; Khodaei, M.; Khayatzadeh, S.; Lotfian, S. Bioactive and Biodegradable Polycaprolactone-Based Nanocomposite for Bone Repair Applications. Polymers 2023, 15, 3617. [Google Scholar] [CrossRef] [PubMed]

- Sadeghzade, S.; Liu, J.; Wang, H.; Li, X.; Cao, J.; Cao, H.; Tang, B.; Yuan, H. Recent Advances on Bioactive Baghdadite Ceramic for Bone Tissue Engineering Applications: 20 Years of Research and Innovation (a Review). Mater. Today Bio 2022, 17, 100473. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Zhang, M.; Chen, X.; Pu, X.; Liao, X.; Huang, Z.; Yin, G. A Novel Akermanite/Poly (Lactic-Co-Glycolic Acid) Porous Composite Scaffold Fabricated via a Solvent Casting-Particulate Leaching Method Improved by Solvent Self-Proliferating Process. Regen. Biomater. 2017, 4, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Tajvar, S.; Hadjizadeh, A.; Samandari, S.S. Scaffold Degradation in Bone Tissue Engineering: An Overview. Int. Biodeterior. Biodegradation 2023, 180, 105599. [Google Scholar] [CrossRef]

- Sung, H.-J.; Meredith, C.; Johnson, C.; Galis, Z.S. The Effect of Scaffold Degradation Rate on Three-Dimensional Cell Growth and Angiogenesis. Biomaterials 2004, 25, 5735–5742. [Google Scholar] [CrossRef]

- Wang, F.; Cai, X.; Shen, Y.; Meng, L. Cell–Scaffold Interactions in Tissue Engineering for Oral and Craniofacial Reconstruction. Bioact. Mater. 2023, 23, 16–44. [Google Scholar] [CrossRef]

- Hoomehr, B.; Raeissi, K.; Ashrafizadeh, F.; Kharaziha, M.; Labbaf, S. Corrosion Performance and Biological Properties of Electrophoretically Deposited Bioactive Glass-Zirconia Core-Shell Composite Coating on Ti6Al4V Substrate. Surf. Coatings Technol. 2022, 434, 128209. [Google Scholar] [CrossRef]

- Montazerian, M.; Yekta, B.E.; Marghussian, V.K.; Bellani, C.F.; Siqueira, R.L.; Zanotto, E.D. Bioactivity and Cell Proliferation in Radiopaque Gel-Derived CaO–P2O5–SiO2–ZrO2 Glass and Glass–Ceramic Powders. Mater. Sci. Eng. C 2015, 55, 436–447. [Google Scholar] [CrossRef] [PubMed]

- Reffitt, D.; Ogston, N.; Jugdaohsingh, R.; Cheung, H.F.; Evans, B.A.; Thompson, R.P.; Powell, J.; Hampson, G. Orthosilicic Acid Stimulates Collagen Type 1 Synthesis and Osteoblastic Differentiation in Human Osteoblast-like Cells in Vitro. Bone 2003, 32, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Han, P.; Wu, C.; Xiao, Y. The Effect of Silicate Ions on Proliferation, Osteogenic Differentiation and Cell Signalling Pathways (WNT and SHH) of Bone Marrow Stromal Cells. Biomater. Sci. 2013, 1, 379–392. [Google Scholar] [CrossRef] [PubMed]

| Sample | Mass Loss at 150 °C (%) | Remained Mass at 150 °C (%) | Mass Loss at 600 °C (%) | Remained Mass at 600 °C (%) | Inflection Point (°C) |

|---|---|---|---|---|---|

| PCL | 0.3 | 99.7 | 99.1 | 0.9 | 390.5 |

| PC20 | 1.0 | 99.0 | 80.7 | 19.3 | 394.9 |

| PC40 | 0.6 | 99.4 | 61.3 | 38.7 | 386.6 |

| Sample | Tc Onset (°C) | Tc (°C) | (J/g) | Tm Onset (°C) | Tm (°C) | (J/g) |

|---|---|---|---|---|---|---|

| PCL | 38.2 | 36.1 | 31.15 | 54.0 | 57.5 | −21.45 |

| PB20 | 38.6 | 36.6 | 24.62 | 54.0 | 57.5 | −16.26 |

| PB40 | 41.5 | 40.2 | 20.79 | 54.0 | 56.8 | −12.47 |

| Sample | PCL | PC20 | PC40 | |

|---|---|---|---|---|

| Element (Weight %) | ||||

| C | 54.5 | 33.1 | 19.5 | |

| O | 41.3 | 31.2 | 23.1 | |

| Ca | 2.7 | 14.9 | 24.3 | |

| P | 1.5 | 7.5 | 13.3 | |

| Zr | - | 7.1 | 10.1 | |

| Si | - | 6.2 | 9.7 | |

| Specimen | SBF | PCL | PC20 | PC40 | |

|---|---|---|---|---|---|

| Ion Con. (mg/L) | |||||

| Ca | 104 | 80.1 | 63.3 | 59.9 | |

| P | 35 | 27.2 | 19.3 | 14.2 | |

| Si | 0 | 0 | 1.2 | 3.3 | |

| Specimen | PCL (mg/L) | PC20 (mg/L) | PC40 (mg/L) | |||

|---|---|---|---|---|---|---|

| Time | Ca | Si | Ca | Si | Ca | Si |

| Day1 | - | - | - | - | - | - |

| Day21 | - | - | 5.3 | 0 | 3.8 | 1.3 |

| Day42 | - | - | 4.8 | 1 | 3.3 | 4.0 |

| Day70 | - | - | 3.5 | 2.2 | 2.9 | 14.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emadi, H.; Baghani, M.; Masoudi Rad, M.; Hoomehr, B.; Baniassadi, M.; Lotfian, S. 3D-Printed Polycaprolactone-Based Containing Calcium Zirconium Silicate: Bioactive Scaffold for Accelerating Bone Regeneration. Polymers 2024, 16, 1389. https://doi.org/10.3390/polym16101389

Emadi H, Baghani M, Masoudi Rad M, Hoomehr B, Baniassadi M, Lotfian S. 3D-Printed Polycaprolactone-Based Containing Calcium Zirconium Silicate: Bioactive Scaffold for Accelerating Bone Regeneration. Polymers. 2024; 16(10):1389. https://doi.org/10.3390/polym16101389

Chicago/Turabian StyleEmadi, Hosein, Mostafa Baghani, Maryam Masoudi Rad, Bahareh Hoomehr, Majid Baniassadi, and Saeid Lotfian. 2024. "3D-Printed Polycaprolactone-Based Containing Calcium Zirconium Silicate: Bioactive Scaffold for Accelerating Bone Regeneration" Polymers 16, no. 10: 1389. https://doi.org/10.3390/polym16101389

APA StyleEmadi, H., Baghani, M., Masoudi Rad, M., Hoomehr, B., Baniassadi, M., & Lotfian, S. (2024). 3D-Printed Polycaprolactone-Based Containing Calcium Zirconium Silicate: Bioactive Scaffold for Accelerating Bone Regeneration. Polymers, 16(10), 1389. https://doi.org/10.3390/polym16101389