Scleroglucan-Based Foam Incorporating Recycled Rigid Polyurethane Waste for Novel Insulation Material Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Production

2.2. Dimension, Mass and Density Determination

2.3. Macro and Micrographs

2.4. Mechanical Testing

2.5. Thermal Conductivity Determination

2.6. Sound Absorption Measurements

3. Results and Discussion

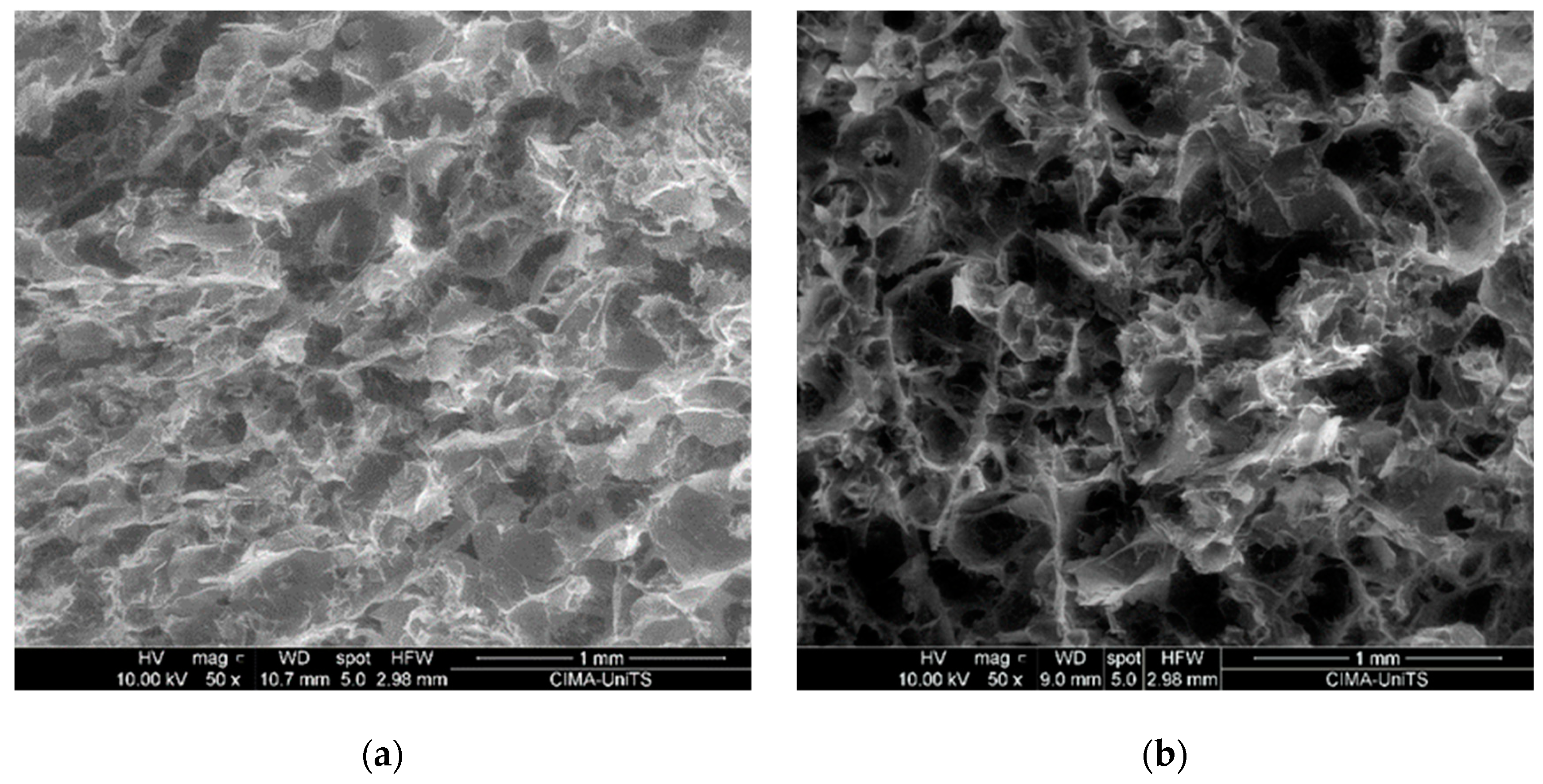

3.1. Foam Structure

3.2. Sample Density

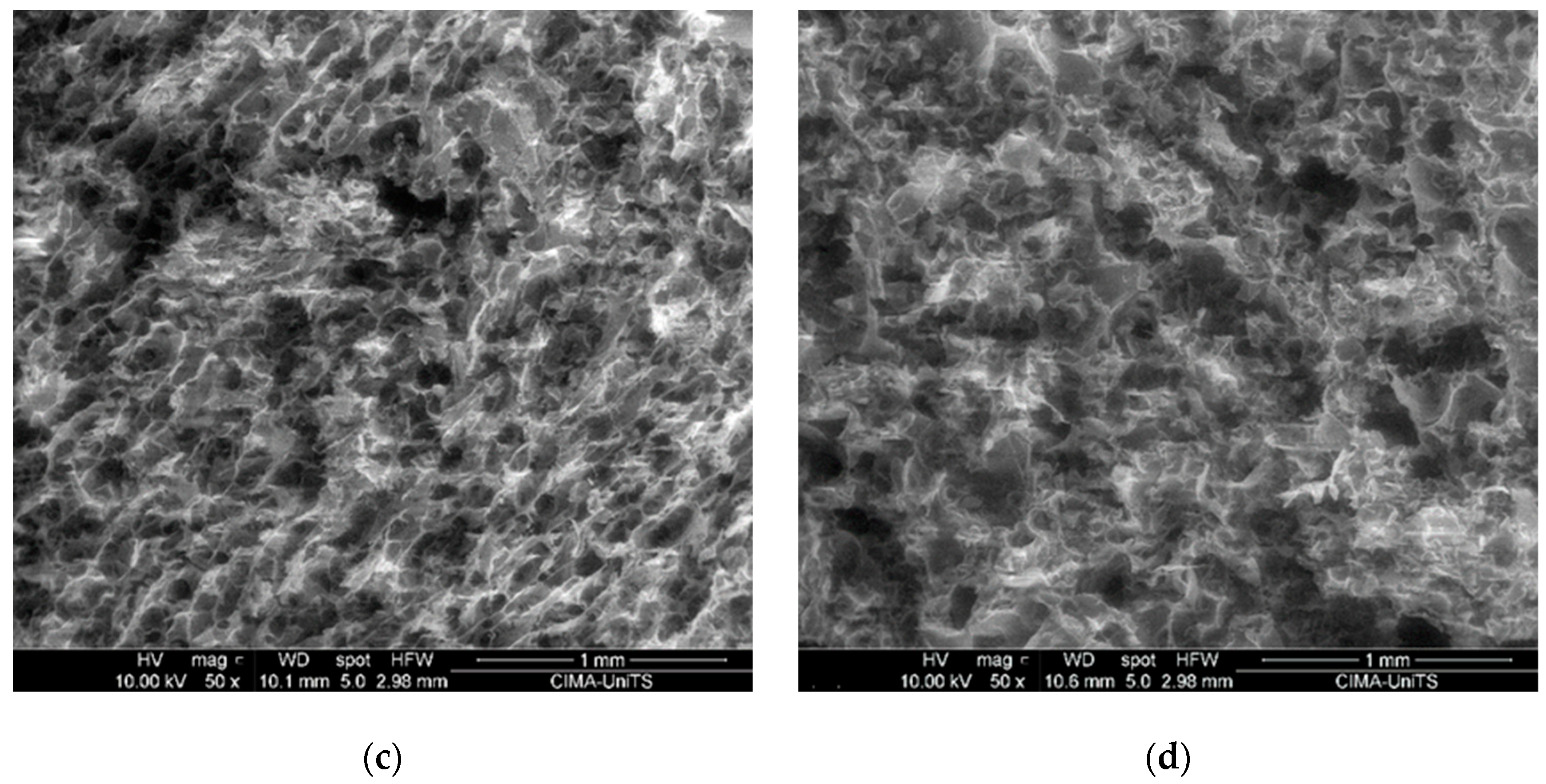

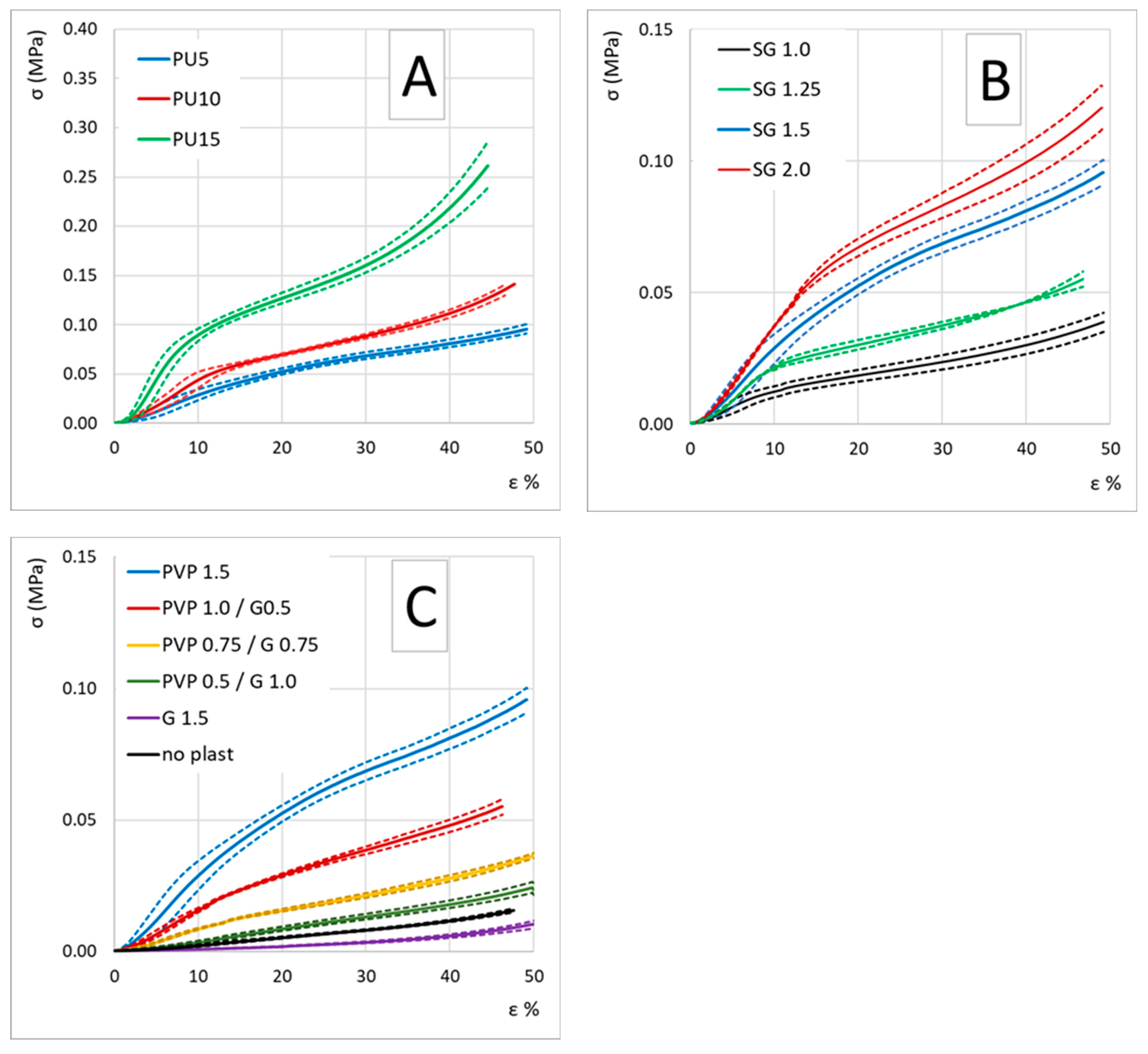

3.3. Mechanical Properties

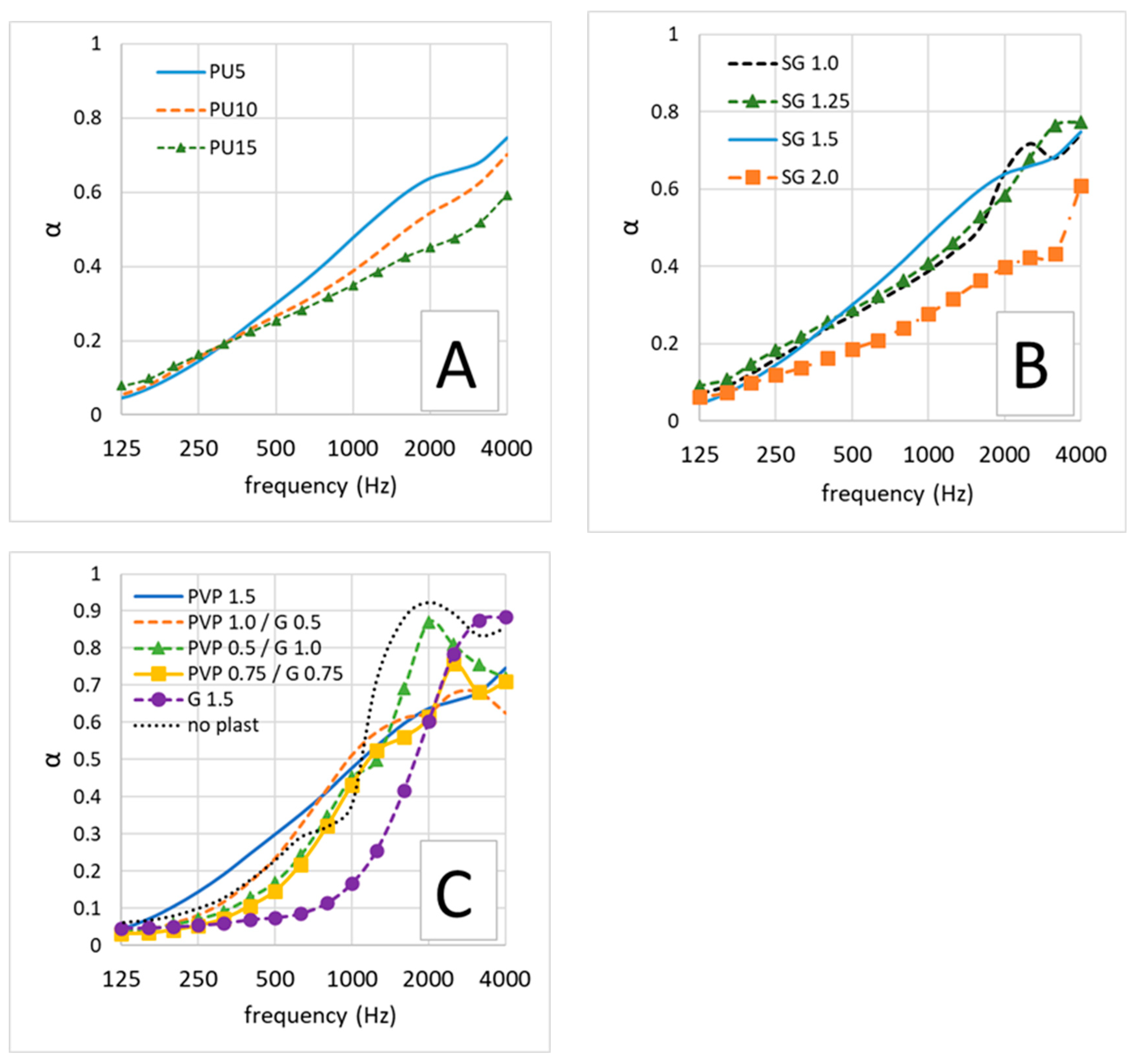

3.4. Sound Absorption Properties

3.5. Thermal Insulation Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Energy Efficiency in Buildings; European Commission: Luxembourg, 2020. [Google Scholar]

- US Department of Energy. Building Energy Data Book; US Department of Energy: New York, NY, USA, 2012.

- UN Environ. Program. Sustainable Buildings and Climate Initiative; UN Environ. Program: Nairobi, Kenya, 2013. [Google Scholar]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Papadopoulos, A.M.; Giama, E. Environmental performance evaluation of thermal insulation materials and its impact on the building. Build. Environ. 2007, 42, 2178–2187. [Google Scholar] [CrossRef]

- Harrison, P.; Holmes, P.; Bevan, R.; Kamps, K.; Levy, L.; Greim, H. Regulatory risk assessment approaches for synthetic mineral fibres. Regul. Toxicol. Pharmacol. 2015, 73, 425–441. [Google Scholar] [CrossRef] [PubMed]

- Cozzarini, L.; De Lorenzi, L.; Fortuna, L.; Bevilacqua, P. Recycling of glass waste and spent alkaline batteries cathodes into insulation materials. Sustain. Mater. Technol. 2023, 38, e00767. [Google Scholar] [CrossRef]

- Cozzarini, L.; De Lorenzi, L.; Barago, N.; Sbaizero, O.; Bevilacqua, P. Expanded Glass for Thermal and Acoustic Insulation from Recycled Post-Consumer Glass and Textile Industry Process Waste. Materials 2023, 16, 1721. [Google Scholar] [CrossRef] [PubMed]

- Sonnenschein, M.F. Polyurethane Rigid Foams. In Polyurethanes: Science, Technology, Markets, and Trends, 1st ed.; Wiley: Hoboken, NJ, USA, 2021; pp. 273–314. [Google Scholar]

- Szycher, M. Rigid Polyurethane Foams. In Szycher’s Handbook of Polyurethanes, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Sonnenschein, M.F. Recycling of Polyurethanes. In Polyurethanes: Science, Technology, Markets, and Trends, 1st ed.; Wiley: Hoboken, NJ, USA, 2021; pp. 465–480. [Google Scholar]

- Yang, W.; Dong, Q.; Liu, S.; Xie, H.; Liu, L.; Li, J. Recycling and Disposal Methods for Polyurethane Foam Wastes. Procedia Environ. Sci. 2012, 16, 167–175. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef]

- He, P.; Lu, H.; Ruan, H.; Wang, C.; Zhang, Q.; Huang, Z.; Liu, J. Mechanochemistry: An Efficient Way to Recycle Thermoset Polyurethanes. Polymers 2022, 14, 3277. [Google Scholar] [CrossRef]

- Heiran, R.; Ghaderian, A.; Reghunadhan, A.; Sedaghati, F.; Thomas, S.; Haghighi, A.H. Glycolysis: An efficient route for recycling of end of life polyurethane foams. J. Polym. Res. 2021, 28, 22. [Google Scholar] [CrossRef]

- Eling, B.; Tomović, Ž; Schädler, V. Current and Future Trends in Polyurethanes: An Industrial Perspective. Macromol. Chem. Phys. 2020, 221, 2000114. [Google Scholar] [CrossRef]

- Cozzarini, L.; Marsich, L.; Ferluga, A. Innovative Thermal and Acoustic Insulation Foams from Recycled Fiberglass Waste. Adv. Mater. Technol. 2020, 8, 2201953. [Google Scholar] [CrossRef]

- Cozzarini, L.; Marsich, L.; Ferluga, A.; Schmid, C. Life cycle analysis of a novel thermal insulator obtained from recycled glass waste. Dev. Built Environ. 2020, 3, 100014. [Google Scholar] [CrossRef]

- Kyawoo D’amore, G.; Caniato, M.; Schmid, C.; Marsich, L.; Ferluga, A.; Cozzarini, L.; Marinò, A. An Innovative Thermal and Acoustic Insulation Foam for Naval Fire Doors Characterization and Study with FEM Analysis; IOS Press: Amsterdam, The Netherlands, 2018; pp. 332–339. [Google Scholar]

- Morris, G.; Harding, S. Polysaccharides, Microbial. In Encyclopedia of Microbiology, 3rd ed.; Academic Press: Cambridge, MA, USA, 2009; pp. 482–494. [Google Scholar]

- Fariña, J.I.; Siñeriz, F.; Molina, O.E.; Perotti, N.I. Isolation and physicochemical characterization of soluble scleroglucan from Sclerotium rolfsii. Rheological properties, molecular weight and conformational characteristics. Carbohydr. Polym. 2001, 44, 41–50. [Google Scholar] [CrossRef]

- Park, J.K.; Khan, T. Other microbial polysaccharides: Pullulan, scleroglucan, elsinan, levan, alternant, dextran. In Handbook of Hydrocolloids; Elsevier: Amsterdam, The Netherlands, 2009; pp. 592–614. [Google Scholar]

- Coviello, T.; Grassi, M.; Rambone, G.; Santucci, E.; Carafa, M.; Murtas, E.; Riccieri, F.M.; Alhaique, F. Novel hydrogel system from scleroglucan: Synthesis and characterization. J. Control. Release 1999, 60, 367–378. [Google Scholar] [CrossRef]

- Schmid, J.; Meyer, V.; Sieber, V. Scleroglucan: Biosynthesis, production and application of a versatile hydrocolloid. Appl. Microbiol. Biotechnol. 2011, 91, 937–947. [Google Scholar] [CrossRef]

- Viñarta, S.C.; Yossen, M.M.; Vega, J.R.; Figueroa, L.I.C.; Fariña, J.I. Scleroglucan compatibility with thickeners, alcohols and polyalcohols and downstream processing implications. Carbohydr. Polym. 2013, 92, 1107–1115. [Google Scholar] [CrossRef] [PubMed]

- Coviello, T.; Grassi, M.; Lapasin, R.; Marino, A.; Alhaique, F. Scleroglucan/borax: Characterization of a novel hydrogel system suitable for drug delivery. Biomaterials 2003, 24, 2789–2798. [Google Scholar] [CrossRef]

- Giri, T.K. Hydrogels based on scleroglucan. In Polysaccharide Hydrogels for Drug Delivery and Regenerative Medicine; Giri, T.K., Ghosh, B., Badwaik, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 139–150. [Google Scholar]

- Coviello, T.; Alhaique, F.; Di Meo, C.; Matricardi, P.; Montanari, E.; Zoratto, N.; Grassi, M.; Abrami, M. Scleroglucan and guar gum: The synergistic effects of a new polysaccharide system. Express Polym. Lett. 2022, 16, 410–426. [Google Scholar] [CrossRef]

- Gidley, M.; Katsuyoshi, N. Physico-chemistry of (1,3)-β-Glucans. In Chemistry, Biochemistry, and Biology of 1-3 Beta Glucans and Related Polysaccharides; Bacic, A., Fincher, G.B., Stone, B.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 47–118. [Google Scholar]

- Miranda, L.F.; Lugão, A.B.; Machado, L.D.B.; Ramanathan, L.V. Crosslinking and degradation of PVP hydrogels as a function of dose and PVP concentration. Radiat. Phys. Chem. 1999, 55, 709–712. [Google Scholar] [CrossRef]

- ASTM C165; Standard Test Method for Measuring Compressive Properties of Thermal Insulations. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2017.

- ASTM C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- EN ISO 10534-2:2001; Acoustics-Determination of Sound Absorption Coefficient and Impedance in Impedances Tubes. International Organization for Standardization: Genève, Switzerland, 2001.

- ASTM C423; Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method. ASTM International: West Conshohocken, PA, USA, 2022.

- Buska, A.; Mačiulaitis, R. The compressive strength properties of mineral wool slabs: Influence of structure anisotropy and methodical factors. J. Civ. Eng. Manag. 2007, 13, 97–106. [Google Scholar] [CrossRef]

- ASTM C578-18; Standard, Specification for Rigid, Cellular Polystyrene Thermal Insulation. ASTM International: West Conshohocken, PA, USA, 2018.

- Gao, S.; Zeng, Y. Surface modification of ultrahigh molecular weight polyethylene fibers by plasma treatment. I. Improving surface adhesion. J. Appl. Polym. Sci. 1993, 47, 2065–2071. [Google Scholar] [CrossRef]

- Olivas, G.I.; Barbosa-Cánovas, G.V. Alginate–calcium films: Water vapor permeability and mechanical properties as affected by plasticizer and relative humidity. LWT Food Sci. Technol. 2008, 41, 359–366. [Google Scholar] [CrossRef]

- Travan, A.; Scognamiglio, F.; Borgogna, M.; Marsich, E.; Donati, I.; Tarusha, L.; Grassi, M.; Paoletti, S. Hyaluronan delivery by polymer demixing in polysaccharide-based hydrogels and membranes for biomedical applications. Carbohydr. Polym. 2016, 150, 408–418. [Google Scholar] [CrossRef]

- Allard, J.; Atalla, N. Propagation of Sound in Porous Media: Modelling Sound Absorbing Materials; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Shaid Sujon, M.A.; Islam, A.; Nadimpalli, V.K. Damping and sound absorption properties of polymer matrix composites: A review. Polym. Test. 2021, 104, 107388. [Google Scholar] [CrossRef]

- ASTM C1029-20; Standard Specification for Spray-Applied Rigid Cellular Polyurethane Thermal Insulation. ASTM International: West Conshohocken, PA, USA, 2020.

- Holman, J.P. Heat Transfer; McGraw-Hill Education: New York, NY, USA, 2012. [Google Scholar]

| Sample Nr. | SG (% wt./vol.) | PVP (% wt./vol.) | G (% wt./vol.) | Filler (% wt./vol.) | Filler Type |

|---|---|---|---|---|---|

| 1 | 1.5 | 1.5 | - | 5 | PU powder |

| 2 | 1.5 | 1.5 | - | 10 | PU powder |

| 3 | 1.5 | 1.5 | - | 15 | PU powder |

| 4 | 1.5 | 0.75 | 0.75 | 5 | PU powder |

| 5 | 1.5 | 1.00 | 0.50 | 5 | PU powder |

| 6 | 1.5 | 0.50 | 1.00 | 5 | PU powder |

| 7 | 1.5 | - | 1.50 | 5 | PU powder |

| 8 | 1.5 | - | - | 5 | PU powder |

| 9 | 1.00 | 1.5 | - | 5 | PU powder |

| 10 | 1.25 | 1.5 | - | 5 | PU powder |

| 11 | 2.00 | 1.5 | - | 5 | PU powder |

| 12 | 1.5 | 1.5 | - | 5 | glass powder |

| 13 | 1.5 | 1.5 | - | 5 | brick powder |

| 14 | 1.5 | 1.5 | - | 5 | carbon fibers powder |

| Sample Nr. | Density (kg m−3) | E (kPa) | σc at ε = 25% (kPa) | σc at ε = 50% (kPa) | NRC | λ (mW m−1 K−1) |

|---|---|---|---|---|---|---|

| 1 | 55.2 ± 0.5 | 384 ± 38 | 61 ± 3 | 97 ± 4 | 0.40 | 36.5 ± 1.0 |

| 2 | 77.5 ± 1.4 | 500 ± 64 | 79 ± 2 | 152 ± 6 | 0.35 | 36.7 ± 1.5 |

| 3 | 105.4 ± 1.4 | 1273 ± 226 | 138 ± 4 | 296 ± 11 | 0.30 | 38.8 ± 1.3 |

| 4 | 58.8 ± 0.6 | 103 ± 11 | 19 ± 1 | 37 ± 1 | 0.40 | 36.9 ± 0.5 |

| 5 | 50.8 ± 0.8 | 187 ± 15 | 33 ± 0 | 58 ± 1 | 0.45 | 36.8 ± 2.0 |

| 6 | 55.7 ± 1.1 | 52 ± 3 | 11 ± 1 | 24 ± 2 | 0.40 | 37.2 ± 1.4 |

| 7 | 65.9 ± 1.6 | 16 ± 1 | 3 ± 0 | 10 ± 1 | 0.30 | 36.0 ± 0.6 |

| 8 | 42.5 ± 2.5 | 34 ± 3 | 7 ± 0 | 17 ± 1 | 0.45 | 41.2 ± 1.1 |

| 9 | 50.5 ± 1.1 | 184 ± 31 | 21 ± 1 | 40 ± 1 | 0.35 | 36.7 ± 1.5 |

| 10 | 50.7 ± 0.5 | 253 ± 10 | 34 ± 1 | 61 ± 1 | 0.40 | 36.5 ± 1.2 |

| 11 | 57.9 ± 1.1 | 445 ± 29 | 76 ± 9 | 125 ± 8 | 0.25 | 36.6 ± 1.0 |

| 12 | 60.5 ± 2.9 | 270 ± 31 | 38 ± 1 | 64 ± 1 | 0.35 | - |

| 13 | 62.2 ± 1.6 | 228 ± 10 | 35 ± 0 | 58 ± 1 | 0.30 | - |

| 14 | 74.8 ± 3.4 | 270 ± 10 | 50 ± 1 | 80 ± 0 | 0.30 | - |

| rock wool * | 151 ± 5.0 | 500 ± 20 | 60 ± 1 | 80 ± 1 | 0.30 | 37.7 ± 0.5 |

| EPS * | 18.5 ± 0.6 | ≈ 2.0 × 103 | 120 ± 3 | 180 ± 5 | 0.20 | 36.7 ± 2.5 |

| Rigid PU * | 52.1 ± 0.7 | ≈ 1.1 × 104 | 410 ± 10 | 470 ± 20 | 0.05 | 42.0 ± 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cozzarini, L.; Marsich, L.; Ferluga, A. Scleroglucan-Based Foam Incorporating Recycled Rigid Polyurethane Waste for Novel Insulation Material Production. Polymers 2024, 16, 1360. https://doi.org/10.3390/polym16101360

Cozzarini L, Marsich L, Ferluga A. Scleroglucan-Based Foam Incorporating Recycled Rigid Polyurethane Waste for Novel Insulation Material Production. Polymers. 2024; 16(10):1360. https://doi.org/10.3390/polym16101360

Chicago/Turabian StyleCozzarini, Luca, Lucia Marsich, and Alessio Ferluga. 2024. "Scleroglucan-Based Foam Incorporating Recycled Rigid Polyurethane Waste for Novel Insulation Material Production" Polymers 16, no. 10: 1360. https://doi.org/10.3390/polym16101360

APA StyleCozzarini, L., Marsich, L., & Ferluga, A. (2024). Scleroglucan-Based Foam Incorporating Recycled Rigid Polyurethane Waste for Novel Insulation Material Production. Polymers, 16(10), 1360. https://doi.org/10.3390/polym16101360