Cotton Fabric-Reinforced Hydrogels with Excellent Mechanical and Broad-Spectrum Photothermal Antibacterial Properties

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Synthesis of rGO@PDA

2.3. Preparation of Cotton Fabric-Reinforced Hydrogels

2.4. General Characterizations

2.5. Evaluation of Mechanical Properties

2.6. Evaluation of the Swelling Behavior

2.7. Evaluation of Photothermal Properties

2.8. Evaluation of In Vitro Antibacterial Efficiency

3. Results and Discussion

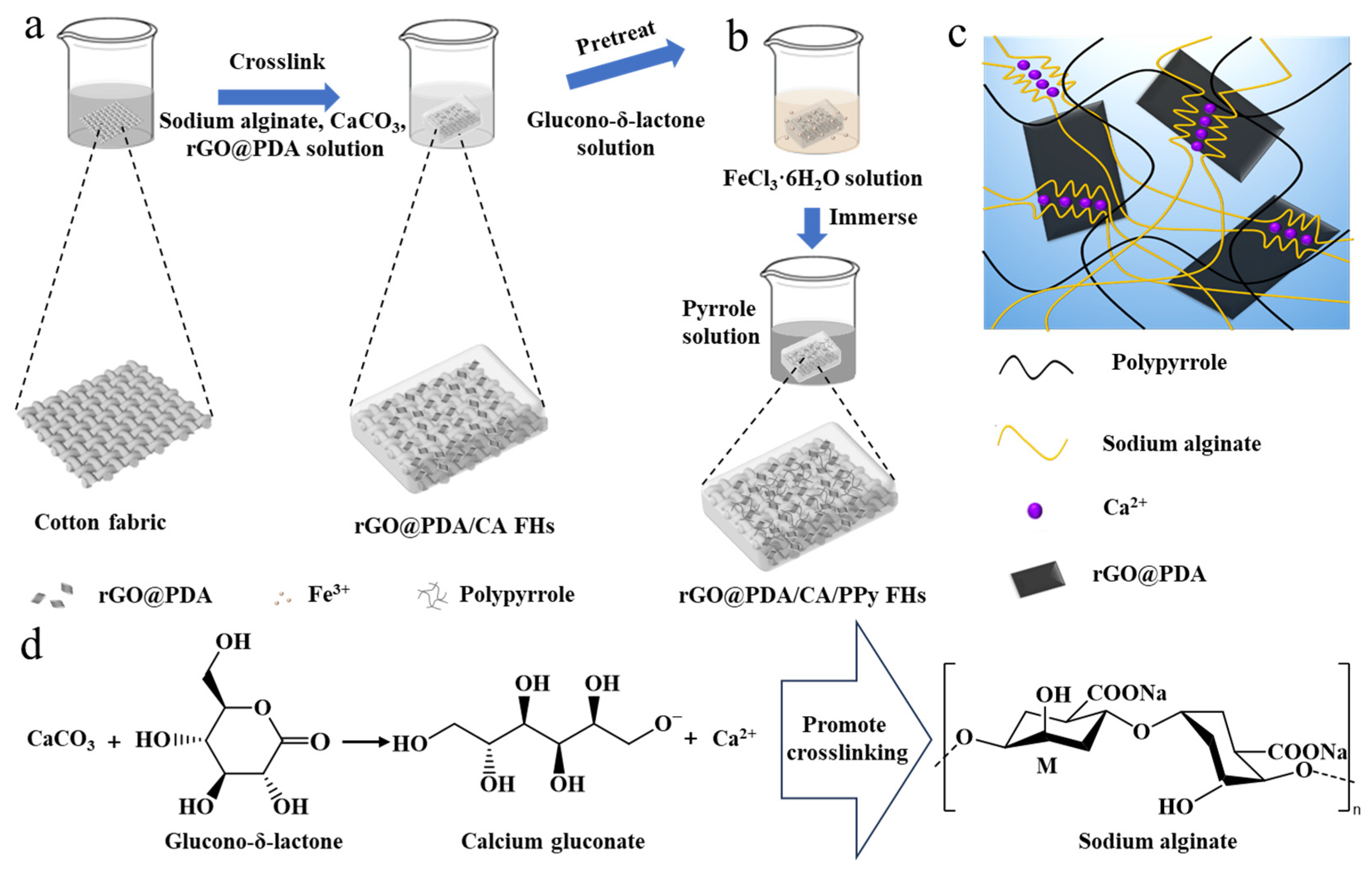

3.1. Design and Fabrication of rGO@PDA/CA/PPy FHs

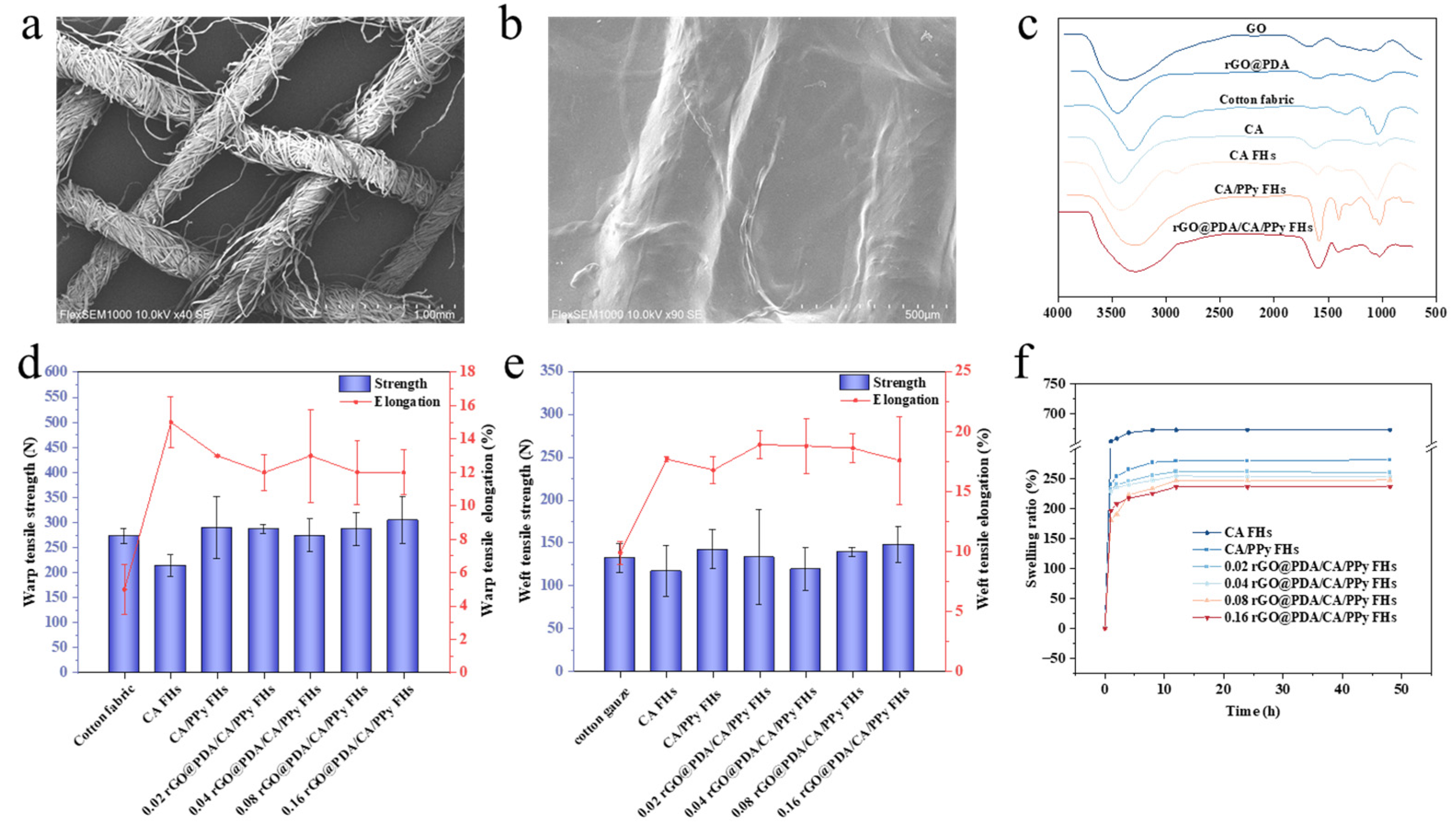

3.2. Structure and Mechanical Properties of Cotton Fabric-Reinforced CA Hydrogels

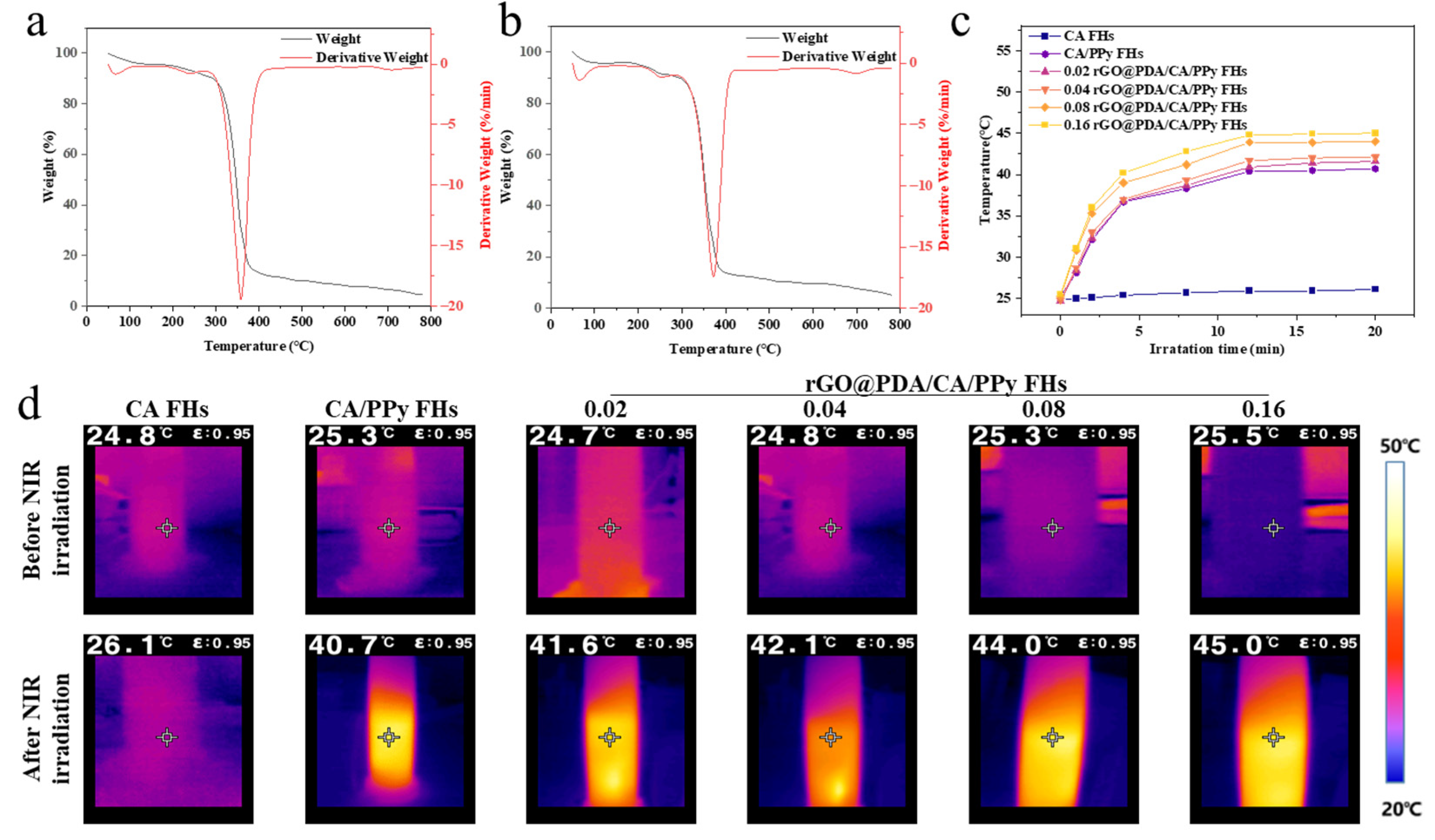

3.3. Thermal Properties of Cotton Fabric-Reinforced CA Hydrogels

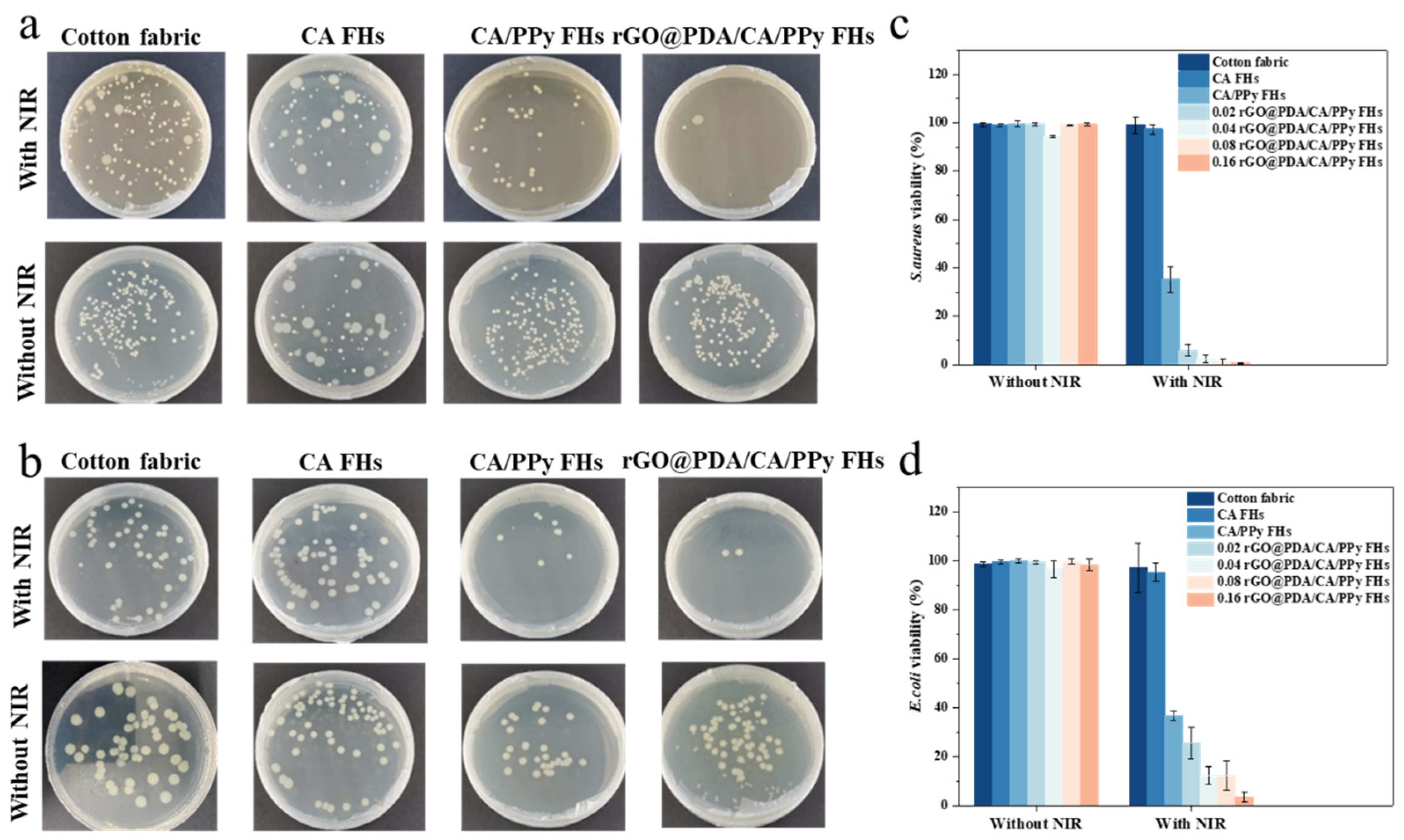

3.4. Photothermal Antibacterial Properties of Cotton Fabric-Reinforced CA Hydrogels

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fleischmann-Struzek, C.; Mellhammar, L.; Rose, N.; Cassini, A.; Rudd, K.E.; Schlattmann, P.; Allegranzi, B.; Reinhart, K. Incidence and mortality of hospital- and ICU-treated sepsis: Results from an updated and expanded systematic review and meta-analysis. Intensive Care Med. 2020, 46, 1552–1562. [Google Scholar] [CrossRef] [PubMed]

- Bauer, M.; Gerlach, H.; Vogelmann, T.; Preissing, F.; Stiefel, J.; Adam, D. Mortality in sepsis and septic shock in Europe, North America and Australia between 2009 and 2019—Results from a systematic review and meta-analysis. Crit. Care 2020, 24, 239. [Google Scholar] [CrossRef] [PubMed]

- Maitz, J.; Merlino, J.; Rizzo, S.; McKew, G.; Maitz, P. Burn wound infections microbiome and novel approaches using therapeutic microorganisms in burn wound infection control. Adv. Drug Deliv. Rev. 2023, 196, 114769. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Renick, P.; Senkowsky, J.; Nair, A.; Tang, L. Diagnostics for Wound Infections. Adv. Wound Care 2020, 10, 317–327. [Google Scholar] [CrossRef] [PubMed]

- Diacovich, L.; Gorvel, J.-P. Bacterial manipulation of innate immunity to promote infection. Nat. Rev. Microbiol. 2010, 8, 117–128. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Akakuru, O.U.; Ma, X.; Zheng, J.; Zheng, J.; Wu, A. Nanoparticle-Based Wound Dressing: Recent Progress in the Detection and Therapy of Bacterial Infections. Bioconjugate Chem. 2020, 31, 1708–1723. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Lin, F.; Zhou, M.; Li, Y.; Li, W.; Shan, G.; Xu, Y.; Xu, J.; Yang, J. Preparation of biocompatible wound dressings with dual release of antibiotic and platelet-rich plasma for enhancing infected wound healing. J. Biomater. Appl. 2021, 36, 219–236. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wu, J.; Wang, H.; Guan, C. Thermosensitive Cotton Textile Loaded with Cyclodextrin-complexed Curcumin as a Wound Dressing. Fibers Polym. 2021, 22, 2475–2482. [Google Scholar] [CrossRef]

- Gunes, O.C.; Ziylan Albayrak, A. Antibacterial Polypeptide nisin containing cotton modified hydrogel composite wound dressings. Polym. Bull. 2021, 78, 6409–6428. [Google Scholar] [CrossRef]

- Rosselle, L.; Cantelmo, A.R.; Barras, A.; Skandrani, N.; Pastore, M.; Aydin, D.; Chambre, L.; Sanyal, R.; Sanyal, A.; Boukherroub, R.; et al. An ‘on-demand’ photothermal antibiotic release cryogel patch: Evaluation of efficacy on an ex vivo model for skin wound infection. Biomater. Sci. 2020, 8, 5911–5919. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Wang, J.; Wang, Y.; Chen, A.; Wang, C.; Mo, W.; Li, Y.; Yuan, Q.; Zhang, Y. Photon-Responsive Antibacterial Nanoplatform for Synergistic Photothermal-/Pharmaco-Therapy of Skin Infection. ACS Appl. Mater. Interfaces 2019, 11, 300–310. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, Y.; Shi, Y.; Song, H.; Yu, C. Antibiotic-Free Antibacterial Strategies Enabled by Nanomaterials: Progress and Perspectives. Adv. Mater. 2020, 32, 1904106. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Gao, Y.; Chen, Y.; Liu, L.; Mo, A.; Peng, Q. Nanomaterials-based photothermal therapy and its potentials in antibacterial treatment. J. Control. Release 2020, 328, 251–262. [Google Scholar] [CrossRef] [PubMed]

- Borzenkov, M.; Pallavicini, P.; Taglietti, A.; D’Alfonso, L.; Collini, M.; Chirico, G. Photothermally active nanoparticles as a promising tool for eliminating bacteria and biofilms. Beilstein J. Nanotechnol. 2020, 11, 1134–1146. [Google Scholar] [CrossRef] [PubMed]

- Bhattarai, D.P.; Tiwari, A.P.; Maharjan, B.; Tumurbaatar, B.; Park, C.H.; Kim, C.S. Sacrificial template-based synthetic approach of polypyrrole hollow fibers for photothermal therapy. J. Colloid Interface Sci. 2019, 534, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Guan, G.; Win, K.Y.; Yao, X.; Yang, W.; Han, M.-Y. Plasmonically Modulated Gold Nanostructures for Photothermal Ablation of Bacteria. Adv. Healthc. Mater. 2021, 10, 2001158. [Google Scholar] [CrossRef] [PubMed]

- Peyravi, A.; Ahmadijokani, F.; Arjmand, M.; Hashisho, Z. Graphene oxide enhances thermal stability and microwave absorption/regeneration of a porous polymer. J. Hazard. Mater. 2022, 433, 128792. [Google Scholar] [CrossRef] [PubMed]

- Francolini, I.; Perugini, E.; Silvestro, I.; Lopreiato, M.; Scotto d’Abusco, A.; Valentini, F.; Placidi, E.; Arciprete, F.; Martinelli, A.; Piozzi, A. Graphene Oxide Oxygen Content Affects Physical and Biological Properties of Scaffolds Based on Chitosan/Graphene Oxide Conjugates. Materials 2019, 12, 1142. [Google Scholar] [CrossRef] [PubMed]

- Sima, H.; Sui, Y.; Zhang, C. Preparation of polysiloxane foam with graphene for promoting electromagnetic interference shielding performance and thermal stability. J. Appl. Polym. Sci. 2022, 139, e52376. [Google Scholar] [CrossRef]

- Gad, Y.H.; Nasef, S.M. Radiation synthesis of graphene oxide/composite hydrogels and their ability for potential dye adsorption from wastewater. J. Appl. Polym. Sci. 2021, 138, 51220. [Google Scholar] [CrossRef]

- Cheng, F.; Xu, L.; Zhang, X.; He, J.; Huang, Y.; Li, H. Generation of a photothermally responsive antimicrobial, bioadhesive gelatin methacryloyl (GelMA) based hydrogel through 3D printing for infectious wound healing. Int. J. Biol. Macromol. 2024, 260, 129372. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Mahmood, S.; Hilles, A.R.; Thomas, S.; Roy, S.; Provaznik, V.; Romero, E.L.; Ghosal, K. Cationic starch: A functionalized polysaccharide based polymer for advancement of drug delivery and health care system—A review. Int J Biol Macromol 2023, 248, 125757. [Google Scholar] [CrossRef] [PubMed]

- Rajakumari, R.; Saha, P.; Ghosal, K.; Tharayil, A.; Kalarikkal, N.; Thomas, S. Polysaccharide-based Scaffolds for Tissue Engineering Applications. In Polysaccharide-based Biomaterials: Delivery of Therapeutics and Biomedical Applications; Jana, S., Jana, S., Domb, A.J., Eds.; The Royal Society of Chemistry: London, UK, 2022. [Google Scholar] [CrossRef]

- Xiang, J.; Shen, L.; Hong, Y. Status and future scope of hydrogels in wound healing: Synthesis, materials and evaluation. Eur. Polym. J. 2020, 130, 109609. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, S.; Zhong, L.; Wang, B.; Wang, H.; Hong, F. Zn2+-loaded TOBC nanofiber-reinforced biomimetic calcium alginate hydrogel for antibacterial wound dressing. Int. J. Biol. Macromol. 2020, 143, 235–242. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Wang, L.; Jing, J.; Zhan, J.; Xu, C.; Xie, W.; Ye, S.; Zhao, Y.; Zhang, C.; Huang, F. Conductive Collagen-Based Hydrogel Combined With Electrical Stimulation to Promote Neural Stem Cell Proliferation and Differentiation. Front. Bioeng. Biotechnol. 2022, 10, 912497. [Google Scholar] [CrossRef] [PubMed]

- Bu, Y.; Xu, H.; Li, X.; Xu, W.; Yin, Y.; Dai, H.; Wang, X.; Huang, Z.; Xu, P. A conductive sodium alginate and carboxymethyl chitosan hydrogel doped with polypyrrole for peripheral nerve regeneration. RSC Adv. 2018, 8, 10806–10817. [Google Scholar] [CrossRef] [PubMed]

- Anamizu, M.; Tabata, Y. Design of injectable hydrogels of gelatin and alginate with ferric ions for cell transplantation. Acta Biomater. 2019, 100, 184–190. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Chen, W.; Ma, L.; Yang, J.; Gao, M.; Wang, K.; Yu, H.; Lv, R.; Fu, M. Robust double-network polyvinyl alcohol-polypyrrole hydrogels as high-performance electrodes for flexible supercapacitors. J. Colloid Interface Sci. 2023, 652, 540–548. [Google Scholar] [CrossRef]

- Ye, D.; Cheng, Q.; Zhang, Q.; Wang, Y.; Chang, C.; Li, L.; Peng, H.; Zhang, L. Deformation Drives Alignment of Nanofibers in Framework for Inducing Anisotropic Cellulose Hydrogels with High Toughness. ACS Appl. Mater. Interfaces 2017, 9, 43154–43162. [Google Scholar] [CrossRef]

- Zhang, R.; Wu, Y.; Lin, P.; Jia, Z.; Zhang, Y.; Liu, F.; Yu, B.; Zhou, F. Extremely Tough Hydrogels with Cotton Fibers Reinforced. Adv. Eng. Mater. 2020, 22, 2000508. [Google Scholar] [CrossRef]

- Li, B.; Li, D.; Yang, Y.; Zhang, L.; Xu, K.; Wang, J. Study of thermal-sensitive alginate-Ca2+/poly(N-isopropylacrylamide) hydrogels supported by cotton fabric for wound dressing applications. Text. Res. J. 2018, 89, 801–813. [Google Scholar] [CrossRef]

- Liu, H.; Yang, L.; Dou, B.; Lan, J.; Shang, J.; Lin, S. Zwitterionic hydrogel-coated cotton fabrics with underwater superoleophobic, self-healing and anti-fouling performances for oil-water separation. Sep. Purif. Technol. 2021, 279, 119789. [Google Scholar] [CrossRef]

- Estes Bright, L.M.; Griffin, L.; Mondal, A.; Hopkins, S.; Ozkan, E.; Handa, H. Biomimetic gasotransmitter-releasing alginate beads for biocompatible antimicrobial therapy. J. Colloid Interface Sci. 2022, 628, 911–921. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.T.; Tabakman, S.M.; Liang, Y.; Wang, H.; Sanchez Casalongue, H.; Vinh, D.; Dai, H. Ultrasmall Reduced Graphene Oxide with High Near-Infrared Absorbance for Photothermal Therapy. J. Am. Chem. Soc. 2011, 133, 6825–6831. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Lu, C.; Wang, Q.; Li, F. Biocompatibility and fabrication of RGO/chitosan film for cartilage tissue recovery. Environ. Toxicol. Pharmacol. 2017, 54, 199–203. [Google Scholar] [CrossRef] [PubMed]

- Panda, S.; Jeong, H.; Hajra, S.; Rajaitha, P.M.; Hong, S.; Kim, H.J. Biocompatible polydopamine based triboelectric nanogenerator for humidity sensing. Sens. Actuators B 2023, 394, 134384. [Google Scholar] [CrossRef]

- Cui, S.; Mao, J.; Rouabhia, M.; Elkoun, S.; Zhang, Z. A biocompatible polypyrrole membrane for biomedical applications. RSC Adv. 2021, 11, 16996–17006. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, X.; Zhang, J.; Shi, J.; Liu, W.; Kritchenkov, A.S.; Van Vlierberghe, S.; Wang, L.; Liu, W.; Gao, J. Cotton Fabric-Reinforced Hydrogels with Excellent Mechanical and Broad-Spectrum Photothermal Antibacterial Properties. Polymers 2024, 16, 1346. https://doi.org/10.3390/polym16101346

Yuan X, Zhang J, Shi J, Liu W, Kritchenkov AS, Van Vlierberghe S, Wang L, Liu W, Gao J. Cotton Fabric-Reinforced Hydrogels with Excellent Mechanical and Broad-Spectrum Photothermal Antibacterial Properties. Polymers. 2024; 16(10):1346. https://doi.org/10.3390/polym16101346

Chicago/Turabian StyleYuan, Xiangnan, Jun Zhang, Jiayin Shi, Wenfu Liu, Andreii S. Kritchenkov, Sandra Van Vlierberghe, Lu Wang, Wanjun Liu, and Jing Gao. 2024. "Cotton Fabric-Reinforced Hydrogels with Excellent Mechanical and Broad-Spectrum Photothermal Antibacterial Properties" Polymers 16, no. 10: 1346. https://doi.org/10.3390/polym16101346

APA StyleYuan, X., Zhang, J., Shi, J., Liu, W., Kritchenkov, A. S., Van Vlierberghe, S., Wang, L., Liu, W., & Gao, J. (2024). Cotton Fabric-Reinforced Hydrogels with Excellent Mechanical and Broad-Spectrum Photothermal Antibacterial Properties. Polymers, 16(10), 1346. https://doi.org/10.3390/polym16101346