Abstract

The search for alternatives to petroleum-based thermoplastic polyamide elastomers (TPAEs) has recently drawn great interest. In this study, a bio-massed TPAE, PA12,36, was synthesized using 1,12-dodecanediamine (DDA) and fatty dimer acid (FDA, PripolTM1009) precursors via catalyst and solvent-free melt polycondensation. The molecular structure and molecular weight of the PA12,36 were characterized by 1H NMR, FTIR, and GPC. PA12,36 displayed a low melting temperature of 85.8 °C, an initial degradation temperature of 425 °C, and a glass-transition temperature of 30.4 °C, whereas it sustained satisfactory tensile strength (10.0 MPa) and superior strain at break (1378%). Furthermore, PA12,36 was foamed by supercritical CO2, and the cell size, cell density, and porosity were determined. The entangled long-chained FDA component generated a physically crosslinked network, which promoted the melt viscosity of PA12,36 against elongations of foam cell growth and increased foamability significantly. As a result, uniform structured cellular foams with a cell diameter of 15–24 µm and high cell density (1011 cells/cm3–1012 cells/cm3) were successfully achieved. The foaming window was widened from 76 to 81 °C, and the expansion ratio was increased from 4.8 to 9.6. Additionally, PA12,36 foam with a physically crosslinked structure presented a better creep shape recovery percentage (92–97.9%) and sturdier dimensional stability. This bio-based PA12,36 foam is a promising candidate to replace petroleum-based thermoplastic elastomer foams for engineering applications, particularly shoe soles.

1. Introduction

Polymer foams, as a sort of lightweight plastic product, cover all sectors of life and industrial manufacture owing to their outstanding attributes, comprising low costs, higher cushioning performance, excellent noise reduction, heat insulation, shock dissipation, and great specific strength. Due to these characteristics, they are used worldwide in numerous areas, such as construction, impact resistance, logistics packing, aerospace, and transport materials [1,2,3]. The growth and utilization of polymer foams can considerably improve energy efficacy and diminish energy consumption, contributing greatly to carbon neutrality and peaking [4,5,6].

Currently, thermoplastic polyamide elastomer (TPE) foams are emerging as candidates in the footwear industry. Polyamide, also known as PA, is a noteworthy semi-crystalline thermoplastic engineering plastic, and is extensively utilized in fiber textiles, automobile engineering, electronics, electrical components, and other industries, owing to its satisfactory flexibility, superior mechanical strength, resistance, and self-lubrication [7,8,9]. PA foams coalesce the benefits of both foaming products and PA; consequently, they have drawn emerging interest in academic research and industrial use in recent years [10,11]. General techniques for fabricating PA foams comprise extrusion foaming, injection molding foaming, bead foaming, and microcellular supercritical carbon dioxide foaming (scCO2). Among these foaming techniques, based on the need for ecological safety, PA foams made using the scCO2 foaming method are encouraged [12,13]. Compared with conventional blowing agents such as chlorofluorocarbons and alkanes, scCO2 is green, inflammable, nonhazardous, and solvable in polymer matrix [14]. Moreover, PA foams achieved by the scCO2 foaming method can benefit from polymer weight reduction and material savings, and can offer advantages such as improved flexibility, thermal insulation, elasticity, and energy absorption [15,16,17]. Because of this, more recently, thermoplastic microcellular PA foam has garnered prodigious interest for its utility in the footwear production industry [18]. It circumvents the drawbacks of other elastomer foams, such as the great density of thermoplastic polyurethane (TPU) [19] and inferior durability of ethylene-vinyl acetate (EVA) [20], owing to its distinctive soft- and hard-segment architecture.

Presently, PA12-based thermoplastic PA elastomer (TPAE) is the best known TPAE for footwear foams, namely PEBAX. The exorbitant costs of TPAE foams only apply to high-end footwear [21]. Among TPAE foams, PA6-based foam offers the substantial possibility of large-scale uses owing to its broad raw material sources [22]. However, traditional PA6 or other PAs generally comprise linear networks, poor melt strength, and low viscosity, which are insufficient to preserve foam cell texture and ultimately result in foam cell rupture [22]. Moreover, these features limit its uses in foaming operations, where strain deformity is common. General approaches used to improve PA melt strength comprise nanofiller blending, chain extension, and chemical crosslinking [23,24,25]. However, owing to fillers’ large surface area, melt blending of polymers with nanofillers mostly creates accumulation, especially in high filler loading conditions, making it complex to disperse homogeneously in the polymer system [26]. The effect of extending chains to toughen the material is minimal and thus cannot prevent bubble deformation, and polymers altered by chemical crosslinking may become gelled and nonrecyclable, leading to environmental pollution and resource waste [22].

In addition, large footwear manufacturers using PA foams increase PA waste [27]. The shoe industry is a huge and rapidly developing industry [28]. According to statistics, the worldwide footwear market was evaluated to be worth 373 billion USD in 2021, and that value is set to reach 430 billion USD in 2030 [29,30]. With the rapid development of the shoe industry, polymeric foam waste has also increased considerably [31]. Traditionally, shoe foams are made from fossil-based resources [32]. Developing thermoplastic PA foams from bio-based and ecofriendly feedstock without the use of exogenous additives (crosslinkers, chain extenders, and fillers) is challenging and, due to sustainability and other ecological concerns, is critical to their development. Based on the above consideration, we hypothesize that the synthesis of PA is advantageous using a vegetable oil-based fatty acid monomer with a branched structure. This fatty acid monomer has a long- branched, hanging-chain structure, which can provide the PA with high viscosity, modulus, a crosslink-like structure, and low foaming temperature, which is expected to significantly improve melt viscosity and foamability. Plant oils are an especially promising substitute raw material for the preparation of PA because they are degradable, obtainable in huge quantities, and relatively inexpensive [33]. Noteworthy literature on the manufacture of PAs from vegetable oil is readily obtainable [34]. However, the foaming of PA derived from bio-based fatty dimer acid (FDA) and 1,12-dodecane diamine (DDA), and its potential application, have not yet been studied.

This work aims to solve the cell collapse, extreme volume shrinkage, cell rupture, and poor recovery of PA-foamed materials resulting from their low melt strength, low linear molecular chain stiffness, and low elasticity. In this study, we synthesized a fully bio-based thermoplastic polyamide elastomer (TPAE), PA12,36, using DDA diamine and FDA (PripolTM 1009) monomers to improve melt strength without the contribution of chemical crosslinkers, by simple melt polymerization. The PA12,36 was comprehensively analyzed in terms of its molecular structure, thermal attributes, and mechanical attributes. In this study, PA12,36 microcellular foams were produced utilizing green scCO2. The low melting temperature and melting enthalpy indicated less crystallinity of PA12,36, which was favorable for improving gas permeability and reducing the effect of pressure variance inside and outside the cell on foam contraction. FDA monomers formed physical crosslinks such as chain entanglement, hydrogen, and/or van der Waals bonding, owing to the great number of nonpolar and polar side chains, which increased the foaming melt strength, creep recovery, and structural stability. This approach could reduce footwear pollution and advance the development of bioresource-based PA foams.

2. Experimental Section

2.1. Materials

Tetrahydrofuran (THF, HPLC grade, 99.9%), 1,12-dodecanediamine (DDA), and chloroform-d (≥99.8%, CDCl3) were purchased from Sigma Aldrich. Fatty dimer diacid (FDA, PripolTM 1009; molecular weight ~570; 100% renewable carbon content; ~1.0% tricarboxylic acid and ~98.7% dicarboxylic acid; iodine value 4.5 g/100 g and acid value 196 mg·g−1) were procured from Croda International Ltd. (The Netherlands, Gouda city).

2.2. Synthesis of PA12,36

Wholly renewable PA12,36 was synthesized via one-step melt polycondensation in a 2L polymerization reactor equipped with a mechanical stirrer, vacuum pump, nitrogen gas inlet, and reflux condenser. FDA (1000 mmol) and DDA (1010 mmol) were introduced into the reactor and mixed at 50 °C for 30 min. Subsequently, the reaction temperature was augmented by 25 °C every 20 min until attaining 250 °C, to avert unnecessary foaming or bubbling. The polymerization was performed at 250 °C for 12 h and further under 0.7 kPa reduced pressure until the rod climbing phenomenon occurred. After polymerization, the product was poured into ice-cold water. After cooling it to ambient temperature, a transparent PA12,36 was obtained.

2.3. Foaming Process

First, PA12,36 specimens for foaming experiment were prepared using a hot-pressing method. The PA12,36 powder was placed in a metal plate, which was placed in a hot-press instrument and heated to 110 °C for 15 min to melt the powder. Afterwards, pressure was applied using a force of 6.3 T. After 15 min of molding, the sample was permitted to cool to 30 °C, then detached from the mold and immediately cut into small pieces of ~5 cm in area. PA12,36 foamed specimens were fabricated using a batch foaming technique employing scCO2 as the green-blowing agent. The PA12,36 specimens (~5 cm area) were then placed in a high-pressure vessel. After attaining the needed saturation pressure (SP), the foaming system was heated to different temperatures (Tfoamings) of 70 °C, 76 °C, 79 °C, 81 °C, and 84 °C for 90 min to ensure that all the specimens were completely saturated with scCO2. Eventually, PA12,36 foaming was stimulated through rapid depressurization.

2.4. Characterization

The comprehensive instrumentation and analysis techniques (FTIR, 1H NMR, TGA, DSC, tensile properties, DMA, SEM, cell density, expansion ratio, and creep recovery measurements) are described in the Supporting Information.

3. Results and Discussion

3.1. Structure Characterization

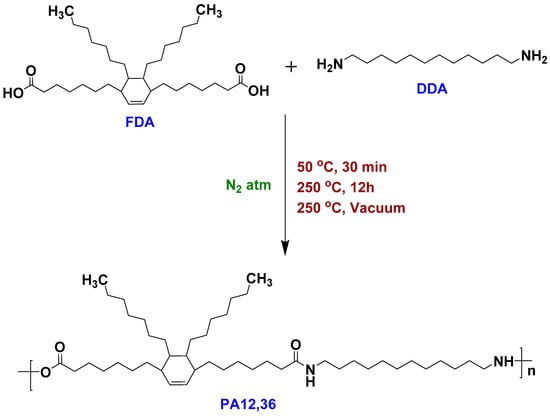

The primary objective of this study was to synthesize and characterize bio-massed PA12,36 elastomer from renewable monomers and utilize them for foaming applications. PA12,36 was synthesized successfully via simple one-step catalyst and solvent-free melt-polycondensation of renewable FDA and excessive DDA (Scheme 1). PA12,36 is a faint yellowish, transparent, and flexible solid (Figure 1a). PA12,36 films show an excellent transmission of 88.9%, are in the UV region of 500 nm, and their cut-off wavelength (λ0 [nm]) is formed at 278 nm (Figure S1). The molecular structure of PA12,36 was confirmed by FTIR and 1H NMR spectroscopy. The FTIR spectrograph of PA12,36 (Figure 1b) shows characteristic amide bands at 3293 cm−1 (amide-I, N–H vibration), 1637 cm−1 (amide II, C=O stretching), 1538 cm−1 (amide III, N–H deformation coupled with C–N), and 1260 cm−1 (amide IV, N–H bending), created by the reaction of DDA with FDA. Furthermore, the vanishing IR signals at 3005 cm−1 and 1707 cm−1 indicate that all COOH groups of FDA reacted with DDA amine groups [35].

Scheme 1.

Synthesis of PA12,36 from the polycondensation of DDA and FDA.

Figure 1.

(a) Photograph of the synthesized, compression-molded, transparent PA12,36 and (b) FTIR spectrographs of FDA and PA12,36.

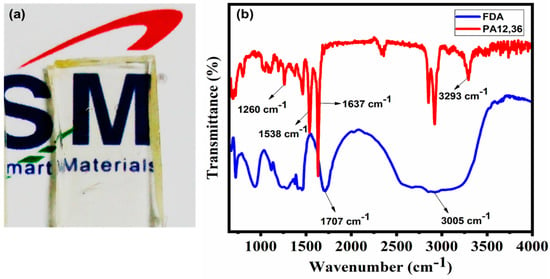

Originally, we analyzed the FDA 1H NMR spectrum, which was highly suitable for the comparative examination of the resulting PA12.36 (Figure 2). The proton signals at 0.8–1.0 ppm, 1.2 ppm, 1.6–1.7 ppm, 2.3 ppm, 4.7–5.6 ppm, and 6.6–7.1 ppm were assigned to the dangling –CH3 (labeled a), −CH2– (labeled b), −CH2–CH2–COOH (labeled c), −CH2–COOH (labeled d), and −CH=CH− (labeled e and f) groups, respectively. The 1HNMR spectrograph of PA12,36 clearly revealed the polymerization of DDA with FDA. Originally, the −CH2–COOH (2.37ppm) proton signal of the original FDA shifted to 2.17 ppm of the –CONH− groups (labeled d) in PA12,36. This chemical shift was associated with the formation of amide bonds. Additionally, new proton signals at 1.4–1.8 ppm resembled the −CH2– protons (labeled g and g’) existing in the DDA unit of PA12,36, while the new generated proton signal at 3.26 ppm belonged to the −CH2– group adjacent to the –CONH− groups (labeled h) in PA12,36. In the end, the −CH=CH– protons were still present, the double bonds were not activated during polymerization, and no radical crosslinking ensued amid the molecules [36]. These outcomes sufficiently indicated that the polymerization of FDA with DDA was completed, and PA12,36 was successfully manufactured.

Figure 2.

1H NMR spectrographs of FDA and PA12,36.

The weight-average molecular weight (Mw), polydispersity index (Ð), and number-average molecular weight (Mn) of synthesized PA12,36 were determined by GPC using THF as the solvent. The resulting Mw, Mn, and Ð values were 52,900 g mol−1, 31,400 g mol−1, and 1.6, respectively.

3.2. Thermal Properties

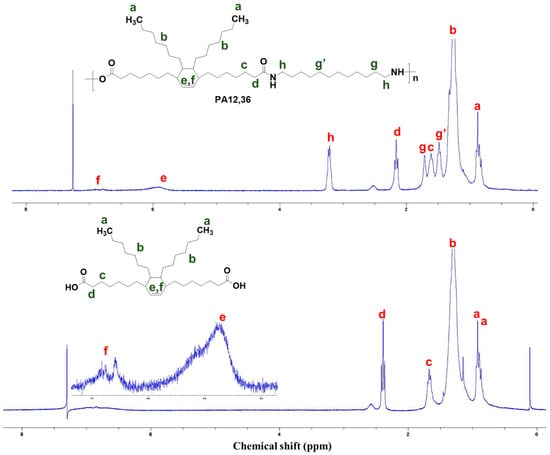

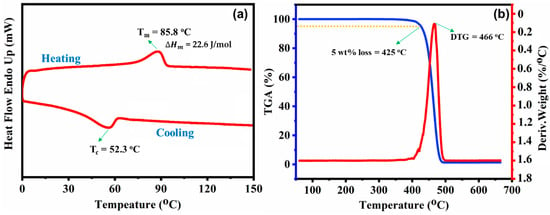

Figure 3a displays the DSC heating and cooling thermograms to determine the melting temperature (Tm) and crystallization temperature (Tc) of PA12,36. The Tm of PA12,36 was recorded to be 85.8 °C and the was 22.6 J/mol. This Tm value is lower than the Tms of traditional PAs, such as PA10,12 (Tm = 190 °C) [37], PA6,10 (Tm = 221 °C) [37], and PA6,6 (Tm = 262 °C) [38], chiefly due to the lower –CONH– linkage concentration and there being more methylene units in the repeating unit of PA12,36. The crystallinity (Xc) of PA12,36 was estimated to be ca. 11% with Supplementary Equation (S1). Two aspects influenced the low Tm and Xc of PA12,36. Primarily, PA12,36 comprised entangled methyl long chains in its repeating unit, which escalated chain disorder and prevented the formation of an ordered crystalline segment. Secondly, amid the ordered and disordered phases, the lengthy repeating network of PA12,36 structured kinetic obstacles of conformational entropy, which were hard to surpass [27]. As shown in the DSC cooling trace in Figure 3a, PA12,36 had an exothermic peak at 52.3 °C, labeled as Tc.

Figure 3.

(a) The DSC heating and cooling curves and (b) TGA (blue) and DTG (red) curves of PA12,36.

The thermal stability of PA is crucial in the foaming process and its practical uses. The TGA result of PA12,36 is illustrated in Figure 3b. Unlike traditional Pas, where the initial weight loss owing to the vaporization of water occurs at ca. 100 °C, the decomposition of PA12,36 began at ca. 425 °C (temperature at 5% weight loss). As PA12,36 comprises numerous nonpolar groups and is water repellent in its molecular structure, no degradation signal of water was seen in the TGA trace. The temperature at the maximum weight loss of PA12,36 was recorded from the DTG trace, at 466 °C. The great thermal permanency (468 °C) of PA12,36 supports its foaming process and engineering uses. The high thermal stability of PA12,36 may be due to physical crosslinking, such as chain, hydrogen, and/or van der Waals bonding. The augmented crosslinking networks can decrease the chain segmentation mobility of PA12,36, which can increase its thermal stability.

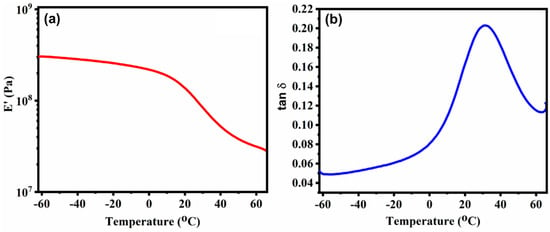

The DMA traces of PA12,36 are displayed in Figure 4. The storage modulus (G′) indicates the elastic behavior of PA12,36, and is connected to segmental movement. In the G′ curve of PA12,36, the glass-to-rubber shift region began at −4.4 °C, and G′ decreased gradually with increasing temperature (Figure 4a). Subsequently, before attaining the liquid phase, PA12,36 underwent a narrow rubbery plateau at ca. 53.1 °C. The tan δ signal (Figure 4b) shows the molecular mobility (viscoelasticity) of PA12,36, and can be used to assess glass-transition temperature (Tg). The PA12,36 elastomer showed a Tg value of 30.4 °C, higher than that of PA6,36, PA2,36, PA4,36, and PA9,36 [27,36]. FDA comprises an aliphatic ring and a low –CONH– linkage concentration, which augment the degree of conformational free-volume disarray and subsequently promote molecular chain movement, accounting for the Tg tendency. These results are in good agreement with prior reports [39].

Figure 4.

(a) storage modulus (E′) and (b) tan δ trace of PA12,36.

3.3. Tensile Properties

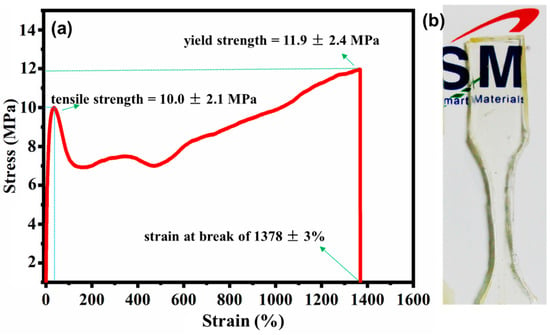

The stress-strain (s-s) trace of PA12,36, illustrated in Figure 5a, has a curve resembling that of TPEs comprising PA components [39]. The tensile curvature is not very smooth, possibly owing to driftage in chain entanglements during elongating. Comparable s-s curves have been formerly documented for a few other PAs, such as PA6,20, PA6,16, PA4,36, and PA6,36 [27,40,41]. PA12,36 had a yield strength of 11.9 ± 2.4 MPa, tensile strength of 10.0 ± 2.1 MPa, and strain at break of 1378 ± 3%. The tensile strength of PA12,36 is inferior to that of PA4,36 due to a lower –CONH– linkage concentration in PA12,36 [27]. The –CONH– linkage concentration affected intermolecular interlinkages and chain rigidity. For instance, H–bonding formation via –CONH– linkages led to a reduction in elongation at break and increased tensile strength.

Figure 5.

(a) Tensile s-s curve and (b) photograph of PA12,36 tensile test specimen.

3.4. Foaming Performance

After analyzing structural, thermal, and mechanical attributes, the foamability of bio-based PA12,36 elastomer was further explored. A green scCO2 batch foaming technique was implemented in this work, and it entailed two steps: (i) absorption of scCO2 into the PA matrix in a supercritical fluid phase, and (ii) development of cells using nucleation and a saturation pressure release procedure. Several factors, such as saturation temperature (Tfoaming), saturation pressure (Spressure), and foaming time (Ftime) could affect the foaming performance. The Tfoaming setting is a pivotal factor in the development of foam structure. T variance in Tfoaming and Tm determines the polymer’s crystalline structure, which could directly influence the stability of foam’s cellular texture and the growth and nucleation mechanisms of bubbles in the scCO2 foaming operation.

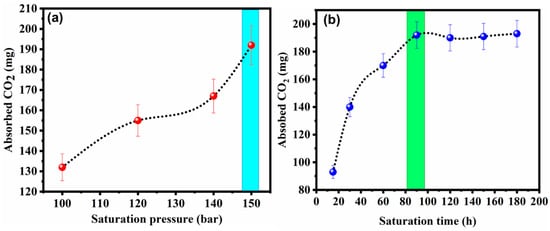

To find the optimal Spressure and Ftime conditions for the scCO2 foaming process, we first investigated the CO2 absorption properties in terms of Spressure and Ftime. The measurement procedure for CO2 absorption has been explained in detail in our previous research [42]. The CO2 absorption of PA12,36 upsurged as the applied Spressure increased, and reached a peak at 150 bar (at Tfoaming = 79 °C; Ftime = 90 min), as displayed in Figure 6a, which demonstrated that an Spressure of 150 bar was suitable for CO2 absorption and foaming attributes. The interaction between amide groups in PA12,36 and oxygen groups in CO2 resulted in a plasticization effect and H-bonds, which augmented the movement of PA12,36 networks and absorbed more CO2 [43]. In general, polymeric foams produced at higher Spressure would have smaller cell sizes because more CO2 is dissolved in the polymer matrix, which affords greater driving energy for cell nucleation compared with lower Spressure and results in more nuclei [44]. In Figure 6b, the CO2 absorption tendency plotted against the saturated Ftime of PA12,36 specimens under 79 °C and 150 bar conditions is shown. After soaking for 90 min, the CO2 absorption of PA12,36 reached a saturation level, so using an Ftime of 90 min was adequate for this work.

Figure 6.

(a) CO2 absorption of PA12,36 at different Spressures and (b) CO2 absorption of PA12,36 at 79 °C.

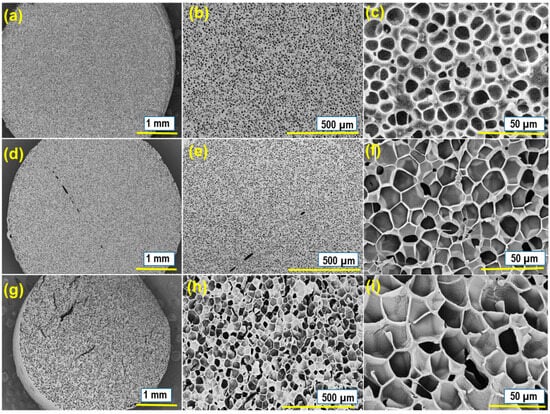

To further validate the above measurements and aid in the development of microcellular foam structure, the PA12,36 specimen was foamed at different Tfoamings under 150 bar (Ftime = 90 min). Foaming temperatures of 70 °C, 76 °C, 79 °C, 81 °C, and 84 °C were applied to study the foaming performance. The cellular topography of the PA12,36 foam at diverse Tfoamings is presented in Figure 7. When the Tfoaming was 70 °C, the PA12,36 specimen had a poor foam texture with a large nonfoaming area (Figure S2). Furthermore, at an Spressure of 150 bar, the unfoamed region reduced as the Tfoaming increased from 76 °C to 81 °C, and all foams showed uniform cell textures (Figure 7a–i). Under constant Spressure (150 bar), when the Tfoaming was comparatively low (i.e., 70 °C), numerous unmelted hard-phase crystals led to high melt strength and were thought to be a major barrier to the foam cell growth of PA12,36, as displayed in Figure S2. With an escalation in Tfoaming, the melt strength of PA12,36 decreased, thereby reducing the barrier to nucleation and growth of foam cells. Also, when the Tfoaming was 83 °C, the foam cells collapsed, as shown in Figure S3. The worsened melt strength of PA12,36 at high Tfoaming might be a reason for the contraction of foams. The coalescence and rupture of cells and contraction have pivotal impacts on the cellular texture of PA foams, enlarging cells, reducing density and surface area, and deteriorating resilience and hardness. Hence, Tfoaming must be controlled to prevent microcellular material being produced by insufficient foaming temperature, as well as exorbitant cell growth caused by high foaming temperature. Foams prepared at Tfoamings ranging from 76 °C to 81 °C had a uniform cell texture, indicating that the PA12,36 synthesized in this study had a wide processing window in the scCO2 foaming process.

Figure 7.

Different magnification SEM cellular micrographs of PA12,36 foams prepared under various Tfoamings: (a–c) 76 °C, (d–f) 79 °C, and (g–i) 81 °C.

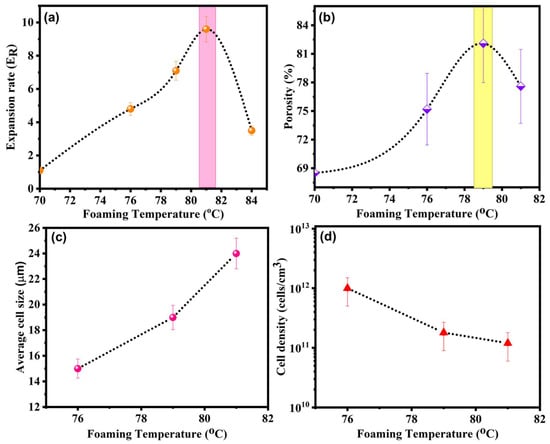

3.5. Expansion Ratio (ER), Average Cell Diameter (D), and Cell Density

The statistical results for the ER, D, and cell density of prepared foams are shown in Figure 8. As Figure 8a displays, the ER initially increased and then decreased with increasing Tfoaming, creating a characteristic bell curve that is common for microcellular polymer foaming. The maximum ER for PA12,36 foams was reached at a Tfoaming of 81 °C. An increasing Tfoaming could decline the melt viscosity of PA12,36, which could greatly limit bubbles’ growth. A higher Tfoaming can promote the diffusion of CO2 and prolong bubble growth duration [45]. Increasing the Tfoaming further to 84 °C led to excessive foam cell growth due to low melt viscosity, and then caused foam shrinkage. Figure 8b illustrates the porosity of PA12,36 foams as a function of Tfoaming. The porosity of PA12,36 foams foamed at 84 °C cannot be calculated due to foam shrinkage. The porosity of PA12,36 foams initially increased and subsequently decreased with Tfoaming, which was consistent with the changing tendency of ER, as shown in Figure 8a.

Figure 8.

(a) ER, (b) porosity, (c) average cell diameter (D), and (d) cell density of PA12,36 foams prepared at different Tfoamings (Spressure = 150 bar, Ftime = 90 min).

Figure 8c shows the D of PA12,36 foams over various Tfoamings (Spressure = 150 bar, Ftime = 90 min). It can be seen that the D of PA12,36 foams ranged from 15 to 24 µm, signifying the D could be controlled by regulating the Tfoaming [46]. Figure 8d plots the cell density of PA12,36 foams prepared at different Tfoamings (Spressure = 150 bar, Ftime = 90 min). The cell densities of PA12,36 foams attained varied between 1011 cells/cm3 and 1012 cells/cm3, mostly within an order of magnitude, demonstrating that the influence of Tfoaming conditions on cell density was minimal. This might be associated with the high melt viscosity of PA12,36.

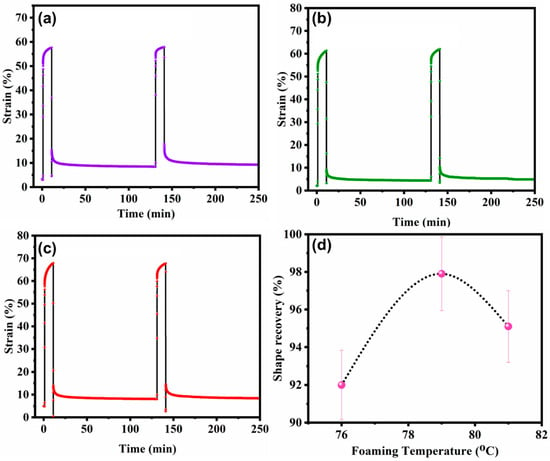

3.6. Cyclic Creep Recovery and Dimensional Stability

The polymer foam specimens’ dimensional stability under tensile/compression cyclic loading or unloading is pivotal for practical uses, especially in footwear. Therefore, a creep recovery experiment was conducted to further investigate the shape recovery (RV (%)) attributes of PA12,36 foams, as shown in Figure 9a–c, and the foaming temperature-dependent RV (%) was plotted in Figure 9d. PA12,36 foam distorted its shape under force and creep strain rose with time, owing to PA12,36 chain networks stretching. Elastic retrieval of the stretched PA12,36 chains ensued, related to a reduction in strain [47]. However, all of the PA12,36 showed an excellent RV (%); specifically, PA12,36 foamed at 79 °C had an RV of 97.9%. The RV (%) variance between PA12,36 foams foamed at different Tfoamings might be due to the D and ER of the individual foams. As shown clearly in Figure 9, the cyclic creep recovery curves had very little distortion after loading–unloading cycles, indicating the outstanding elasticity of manufactured PA12,36 foams. Importantly, the creep experiment results demonstrated that the fabricated foams were stiffer, sturdier, and more resilient, and had better elasticity.

Figure 9.

Cyclic creep recovery traces of PA12,36 foams prepared under different Tfoamings: (a) 76 °C, (b) 79 °C, and (c) 81 °C; (d) Creep recovery percentage of PA12,36 foams prepared under different Tfoamings.

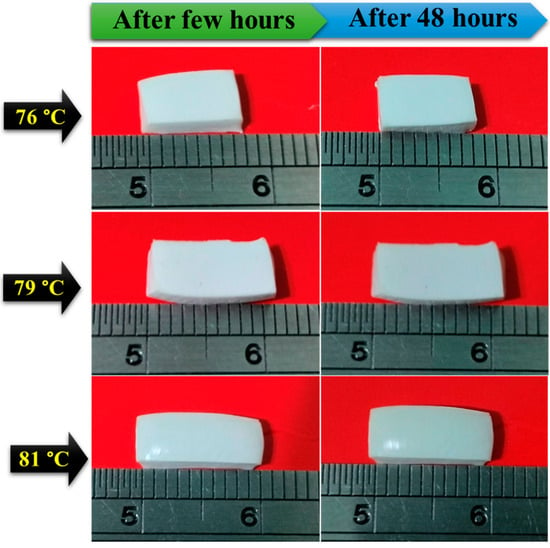

3.7. Dimensional Stability

Shrinkage is common in foam materials. Significant foam shrinkage occurs within seconds or minutes, completely affecting the use of foamed materials. Figure S4 shows the growth of ER and average cell size with time under different Tfoamings. There were no obvious changes in the expansion rate and average cell size of PA12,36 foams with different times, indicating excellent dimensional stability.

Therefore, the foams prepared at 73 °C, 76 °C, and 81 °C had good dimensional stability with no shrinkage, which might be attributed to cell structure, scCO2 diffusivity, and rheological features. In summary, the phenomenon appearing in Figure S4 indicates that the stability of PA12,36 foam has several benefits. The chain-entanglement network of long-chain branched FDA and the augmented physical crosslink density obstructed PA12,36 chain relaxation and combated foam contraction. Figure 10 shows the dimensional stability behavior of PA12,36 foams recorded by an optical camera. After 24 h of aging, all foam samples foamed under different Tfoamings had better foam structure stability. Hence, the better structural constancy and foamability of PA12,36 circumvents the foaming complications of inadequate melt viscosity and high crystallinity in traditional PAs.

Figure 10.

Photographs of PA12,36 foams prepared at different Tfaomings and the dimensional stability of the foams at different periods.

4. Conclusions

A green method was used to synthesize wholly bio-based PA12,36 by catalyst- and solvent-free melt polycondensation using DDA and FDA precursors derived from sustainable resources. The as-prepared PA12,36 showed an Mw of 52,900 g mol−1, Mn of 31,400 g mol−1, Tm of 85.8 °C with a low Xc of 11%, Tg of 30.4 °C, and Td5% of 425 °C. The tensile stress and strain at break of PA12,36 were 10.0 ± 2.1 MPa and 1378 ± 3%, respectively. Moreover, PA12,36 with low Tm and low Xc was foamed using the scCO2 method. The as-prepared foams unveiled a narrow and low Tfoaming window of 73–81 °C. The greatest foam ER of 9.6 was achieved at 76 °C, and the increased Tfoaming tended to induce foam cell coalescence owing to the inferior melt viscosity (strength) of PA12,36, resulting in a significant reduction of ER (5.5). Lastly, structure-tunable PA12,36 foams were prepared with an ER of 4.8–9.6, an average cell diameter range of 15–24 μm, and a high cell density of up to 1011–1012 cells/cm3. Moreover, PA12,36 foams showed excellent creep shape recovery performance (92–97.9%) and sturdier dimensional stability. The findings of this study reveal a promising, sustainable way to utilize bio-massed resources in the fabrication of PA foam materials in the polymer industry.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/polym16010159/s1, Figure S1. UV-Visible spectrum of PA12,36 film, Figure S2. SEM micrographs of PA12,36 foamed at 66 °C (SP = 150 bar, Ftime = 90 min), Figure S3. SEM micrographs of PA12,36 foamed at 83 °C (SP = 150 bar, Ftime = 90 min), and Figure S4. (a) Evaluation of (a) ER and (b) average cell size of the PA12,36 foams foamed at different Tfoaming under time variance: title. Ref. [48] is cited in the Supplementary File.

Author Contributions

Conceptualization, P.R., B.M., S.-P.R. and F.-C.C.; Methodology, P.R.; Validation, P.R.; Formal analysis, P.R. and B.M.; Resources, S.-P.R.; Data curation, P.R. and B.M.; Writing—original draft, P.R. and B.M.; Writing—review & editing, C.-W.C.; Supervision, S.-P.R. and F.-C.C.; Project administration, C.-W.C., J.-W.S. and Y.-H.C.; Funding acquisition, S.-P.R. and F.-C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fang-Chyou Chiu (CMRPD2N0011); Syang-Peng Rwei (NSTC 111-2634-F-027-001); Chin-Wen Chen (NSTC 111-2222-E-027-005).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors gratefully acknowledge financial support from the National Science and Technology Council of Taiwan (NSTC 111-2634-F-027-001 and NSTC 111-2222-E-027-005). F.C. Chiu acknowledges financial support (CMRPD2N0011) from Chang Gung Memorial Hospital (Taoyuan, Taiwan) to carry out this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Forest, C.; Chaumont, P.; Cassagnau, P.; Swoboda, B.; Sonntag, P. Polymer Nano-Foams for Insulating Applications Prepared from CO2 Foaming. Prog. Polym. Sci. 2015, 41, 122–145. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Wang, C.; Park, C.B. Ultra-Lightweight, Super Thermal-Insulation and Strong Pp/CNT Microcellular Foams. Compos. Sci. Technol. 2020, 191, 108084. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Y.; Wang, G.; Qiao, Y.; Chen, Z.; Zhang, A.; Park, C.B. Fabrication of Outstanding Thermal-Insulating, Mechanical Robust and Superhydrophobic PP/CNT/Sorbitol Derivative Nanocomposite Foams for Efficient Oil/Water Separation. J. Hazard. Mater. 2021, 418, 126295. [Google Scholar] [CrossRef] [PubMed]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A Review and Evaluation of Thermal Insulation Materials and Methods for Thermal Energy Storage Systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Dickson, T.; Pavía, S. Energy Performance, Environmental Impact and Cost of A Range Of Insulation Materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A Review on Insulation Materials for Energy Conservation in Buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Gong, S.; Zhao, S.; Chen, X.; Liu, H.; Deng, J.; Li, S.; Feng, X.; Li, Y.; Wu, X.; Pan, K. Thermoplastic Polyamide Elastomers: Synthesis, Structures/Properties, and Applications. Macromol. Mater. Eng. 2021, 306, 100568. [Google Scholar] [CrossRef]

- Marchildon, K. Polyamides–still strong after seventy years. Macromol. React. Eng. 2011, 5, 22–54. [Google Scholar] [CrossRef]

- Pervaiz, M.; Faruq, M.; Jawaid, M.; Sain, M. Polyamides: Developments and Applications towards Next-Generation Engineered Plastics. Curr. Org. Synth. 2017, 14, 146–155. [Google Scholar] [CrossRef]

- Xu, M.; Liu, Y.; Ge, Y.; Zhao, C.; Wei, L.; Hu, D.; Liu, T.; Zhang, L.; Zhao, L.; Park, C.B. Microcellular Extrusion Foaming of Long-Chain Branched Polyamide 6 Composites. J. Supercrit. Fluids 2023, 199, 105953. [Google Scholar] [CrossRef]

- Li, S.; Jiang, S.; Gong, S.; Ma, S.; Yang, H.; Pan, K.; Deng, J. Preparation Methods, Performance Improvement Strategies, and Typical Applications of Polyamide Foams. Ind. Eng. Chem. Res. 2021, 60, 17365–17378. [Google Scholar] [CrossRef]

- Lima, G.M.; Bose, R.K. Production and Application of Polymer Foams Employing Supercritical Carbon Dioxide. Adv. Polym. Technol. 2022, 2022, 8905115. [Google Scholar] [CrossRef]

- Li, Y.; Gong, P.; Liu, Y.; Niu, Y.; Park, C.B.; Li, G. Environmentally Friendly and Zero-Formamide EVA/LDPE Microcellular Foams Via Supercritical Carbon Dioxide Solid Foaming. ACS Appl. Polym. Mater. 2021, 3, 4213–4222. [Google Scholar] [CrossRef]

- Zhou, Y.; Tian, Y.; Peng, X. Applications and Challenges of Supercritical Foaming Technology. Polymers 2023, 15, 402. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhao, J.; Ge, C.; Zhao, G.; Park, C.B. Nanocellular Poly (Ether-Block-Amide)/MWCNT Nanocomposite Films Fabricated by Stretching-Assisted Microcellular Foaming for High-Performance EMI Shielding Applications. J. Mater. Chem. C 2021, 9, 1245–1258. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A.; Lee, R.E. Multi-Objective Optimization of Heat Transfer Mechanisms of Microcellular Polymeric Foams from Thermal-Insulation Point of View. Therm. Sci. Eng. Prog. 2019, 9, 21–29. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, G.; Zhao, J.; Zhang, A.; Zhao, G. Super-Elastic and Structure-Tunable Poly (Ether-Block-Amide) Foams Achieved by Microcellular Foaming. J. CO2 Util. 2022, 55, 101807. [Google Scholar] [CrossRef]

- Li, X.; Lai, J.; Wei, J.; Peng, X.; Wu, J.; Geng, L. Structure and Morphology of Thermoplastic Polyamide 6 Elastomers with Different Soft Segment Content and Their Foaming Behavior Using Supercritical CO2. Polym Eng Sci. 2022, 62, 103–115. [Google Scholar] [CrossRef]

- Ito, S.; Matsunaga, K.; Tajima, M.; Yoshida, Y. Generation of Microcellular Polyurethane with Supercritical Carbon Dioxide. J. Appl. Polym. Sci. 2007, 106, 3581–3586. [Google Scholar] [CrossRef]

- Jacobs, M.A.; Kemmere, M.F.; Keurentjes, J.T. Foam processing of Poly (Ethylene-Co-Vinyl Acetate) Rubber Using Supercritical Carbon Dioxide. Polymer 2004, 45, 7539–7547. [Google Scholar] [CrossRef]

- Barzegari, M.R.; Hossieny, N.; Jahani, D.; Park, C.B. Characterization of Hard-Segment Crystalline Phase of Poly (Ether-Block-Amide) (PEBAX®) Thermoplastic Elastomers in The Presence of Supercritical CO2 and Its Impact on Foams. Polymer 2017, 114, 15–27. [Google Scholar] [CrossRef]

- Yeh, S.K.; Liu, W.H.; Huang, Y.M. Carbon Dioxide-Blown Expanded Polyamide Bead Foams with Bimodal Cell Structure. Ind. Eng. Chem. Res. 2019, 58, 2958–2969. [Google Scholar] [CrossRef]

- Xu, M.; Lu, J.; Zhao, J.; Wei, L.; Liu, T.; Zhao, L.; Park, C.B. Rheological and Foaming Behaviors of Long-Chain Branched Polyamide 6 With Controlled Branch Length. Polymer 2021, 224, 123730. [Google Scholar] [CrossRef]

- Xu, M.; Chen, Y.; Liu, T.; Zhao, L.; Park, C.B. Determination of Modified Polyamide 6’s Foaming Windows by Bubble Growth Simulations Based on Rheological Measurements. J. Appl. Polym. Sci. 2019, 136, 48138. [Google Scholar] [CrossRef]

- Faridirad, F.; Ahmadi, S.; Barmar, M. Polyamide/Carbon Nanoparticles Nanocomposites: A Review. Polym Eng Sci. 2017, 57, 475–494. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Zhang, C.; Liu, T. 2D Nanosheet-Constructed Hybrid Nanofillers for Polymer Nanocomposites with Synergistic Dispersion and Function. APL Mater. 2019, 7, 080904. [Google Scholar] [CrossRef]

- Ranganathan, P.; Chen, C.W.; Tasi, M.C.; Rwei, S.P.; Lee, Y.H. Biomass Thermoplastic (Co) polyamide Elastomers Synthesized from a Fatty Dimer Acid: A Sustainable Route toward a New Era of Uniform and Bimodal Foams. Ind. Eng. Chem. Res. 2021, 60, 12139–12154. [Google Scholar] [CrossRef]

- Munny, A.A.; Ali, S.M.; Kabir, G.; Moktadir, M.A.; Rahman, T.; Mahtab, Z. Enablers of Social Sustainability in The Supply Chain: An Example of Footwear Industry from An Emerging Economy. Sustain. Prod. Consum. 2019, 20, 230–242. [Google Scholar] [CrossRef]

- Lunchev, A.V.; Tham, S.C.; Lipik, V.; Tok, A.L.Y. Carbon Nanomaterials as Additives to Ethylene Vinyl Acetate Copolymer Foams for Sport Footwear Applications. Polym. Adv. Technol. 2022, 33, 863–869. [Google Scholar] [CrossRef]

- Ikram, M. Transition Toward Green Economy: Technological Innovation’s Role in the Fashion Industry. Curr. Opin. Green Sustain. Chem. 2022, 37, 100657. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Zhou, B.; Zhang, X. Upcycling of textile and footwear wastes for synergistical reinforcement of cement mortar. Compos. Commun. 2023, 41, 101646. [Google Scholar] [CrossRef]

- Júnior, C.P.; Mendonca, A.V.; Fim, F.C.; Silva, L.B. Recycling EVA Waste: An Opportunity for the Footwear Industry-Rheological Properties of EVA Waste Composites Using Torque Rheometry. J. Polym. Environ. 2022, 30, 2155–2164. [Google Scholar] [CrossRef]

- Meier, M.A. Plant-Oil-Based Polyamides and Polyurethanes: Toward Sustainable Nitrogen-Containing Thermoplastic Materials. Macromol. Rapid Commun. 2019, 40, 1800524. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Liu, W.; Cai, L.; Jiang, T.; Wang, Z. Castor Oil-Based Multi-Functional Monomers and their Application in Polyamide Design. Ind. Crops Prod. 2023, 203, 117188. [Google Scholar] [CrossRef]

- Ranganathan, P.; Chen, C.W.; Rwei, S.P. Highly Stretchable Fully Biomass Autonomic Self-Healing Polyamide Elastomers and Their Foam for Selective Oil Absorption. Polymers 2021, 13, 3089. [Google Scholar] [CrossRef] [PubMed]

- Nurhamiyah, Y.; Amir, A.; Finnegan, M.; Themistou, E.; Edirisinghe, M.; Chen, B. Wholly Biobased, Highly Stretchable, Hydrophobic, and Self-Healing Thermoplastic Elastomer. ACS Appl. Mater. Interfaces 2021, 13, 6720–6730. [Google Scholar] [CrossRef] [PubMed]

- Pagacz, J.; Raftopoulos, K.N.; Leszczyńska, A.; Pielichowski, K. Bio-Polyamides Based on Renewable Raw Materials: Glass Transition and Crystallinity Studies. J. Therm. Anal. Calorim. 2016, 123, 1225–1237. [Google Scholar] [CrossRef]

- Lu, H.; Xu, X.; Li, X.; Zhang, Z. Morphology, Crystallization and Dynamic Mechanical Properties of PA66/Nano-SiO2 Composites. Bull. Mater. Sci. 2006, 29, 485–490. [Google Scholar] [CrossRef]

- Hablot, E.; Donnio, B.; Bouquey, M.; Avérous, L. Dimer Acid-Based Thermoplastic Bio-Polyamides: Reaction Kinetics, Properties and Structure. Polymer 2010, 51, 5895–5902. [Google Scholar] [CrossRef]

- Nguyen, P.H.; Spoljaric, S.; Seppälä, J. Redefining Polyamide Property Profiles Via Renewable Long-Chain Aliphatic Segments: Towards Impact Resistance and Low Water Absorption. Eur. Polym. J. 2018, 109, 16–25. [Google Scholar] [CrossRef]

- Nurhamiyah, Y.; Chen, B. Biobased Polyamide 4, 36 Thermoplastic Elastomer and its Cellulose Nanocomposites. Macromol. Chem. Phys. 2023, 224, 2300013. [Google Scholar] [CrossRef]

- Ranganathan, P.; Chen, C.W.; Chou, Y.L.; Rwei, S.P.; Ramaraj, S.K. Biomass Chemical Upcycling of Waste rPET for the Fabrication of Formamide-Free TPEE Microcellular Foams Via ScCO2 Foaming. J. CO2 Util. 2022, 65, 102199. [Google Scholar] [CrossRef]

- Ranganathan, P.; Chen, Y.H.; Rwei, S.P.; Lee, Y.H. Biomass Upcycling of Waste rPET to Higher-Value New-Easy-Recyclable Microcellular Thermoplastic (Co) Polyamide Foams and Hot-Melt Adhesives. Mater. Today Chem. 2022, 26, 101101. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Zhao, J.; Xu, Z.; Li, S.; Zhao, G. Corrugated Thermoplastic Polyurethane Foams with High Mechanical Strength Fabricated by Integrating Fused Filament Fabrication and Microcellular Foaming Using Supercritical CO2. J. CO2 Util. 2022, 66, 102293. [Google Scholar] [CrossRef]

- Li, B.; Zhao, G.; Wang, G.; Zhang, L.; Gong, J. Fabrication of High-Expansion Microcellular PLA Foams Based on Pre-Isothermal Cold Crystallization and Supercritical CO2 Foaming. Polym. Degrad. Stab. 2018, 156, 75–88. [Google Scholar] [CrossRef]

- Zheng, H.; Pan, G.; Huang, P.; Xu, D.; Zhai, W. Fundamental Influences of Crosslinking Structure on The Cell Morphology, Creep Property, Thermal Property, and Recycling Behavior of Microcellular EPDM Foams Blown with Compressed CO2. Ind. Eng. Chem. Res. 2020, 59, 1534–1548. [Google Scholar] [CrossRef]

- Wang, X.C.; Zhu, Q.S.; Dong, B.B.; Wu, H.H.; Liu, C.T.; Shen, C.Y.; Turng, L.S.; Geng, T. The Effects of Nanoclay and Deformation Conditions on the Inelastic Behavior of Thermoplastic Polyurethane Foams. Polym. Test. 2019, 79, 106043. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lee, C.W.; Chou, C.H.; Lin, C.H.; Chen, Y.H.; Chen, C.W.; Way, T.F.; Rwei, S.P. Sustainable Polyamide Elastomers From a Bio-Based Dimer Diamine for Fabricating Highly Expanded and Facilely Recyclable Microcellular Foams via Supercritical CO2 Foaming. Eur. Polym. J. 2021, 160, 110765. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).