Effects of Rare Earth Oxides on the Mechanical and Tribological Properties of Phenolic-Based Hybrid Nanocomposites

Abstract

:1. Introduction

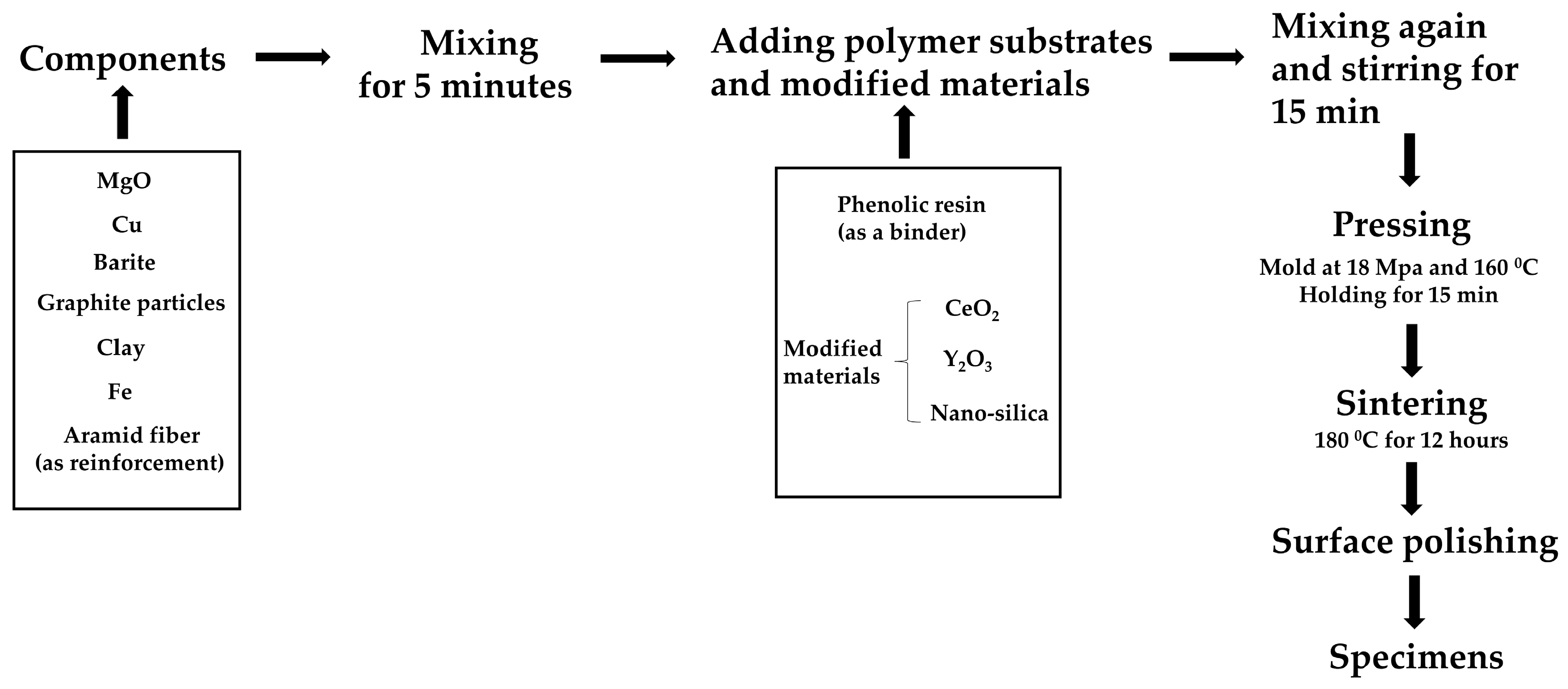

2. Materials and Methods

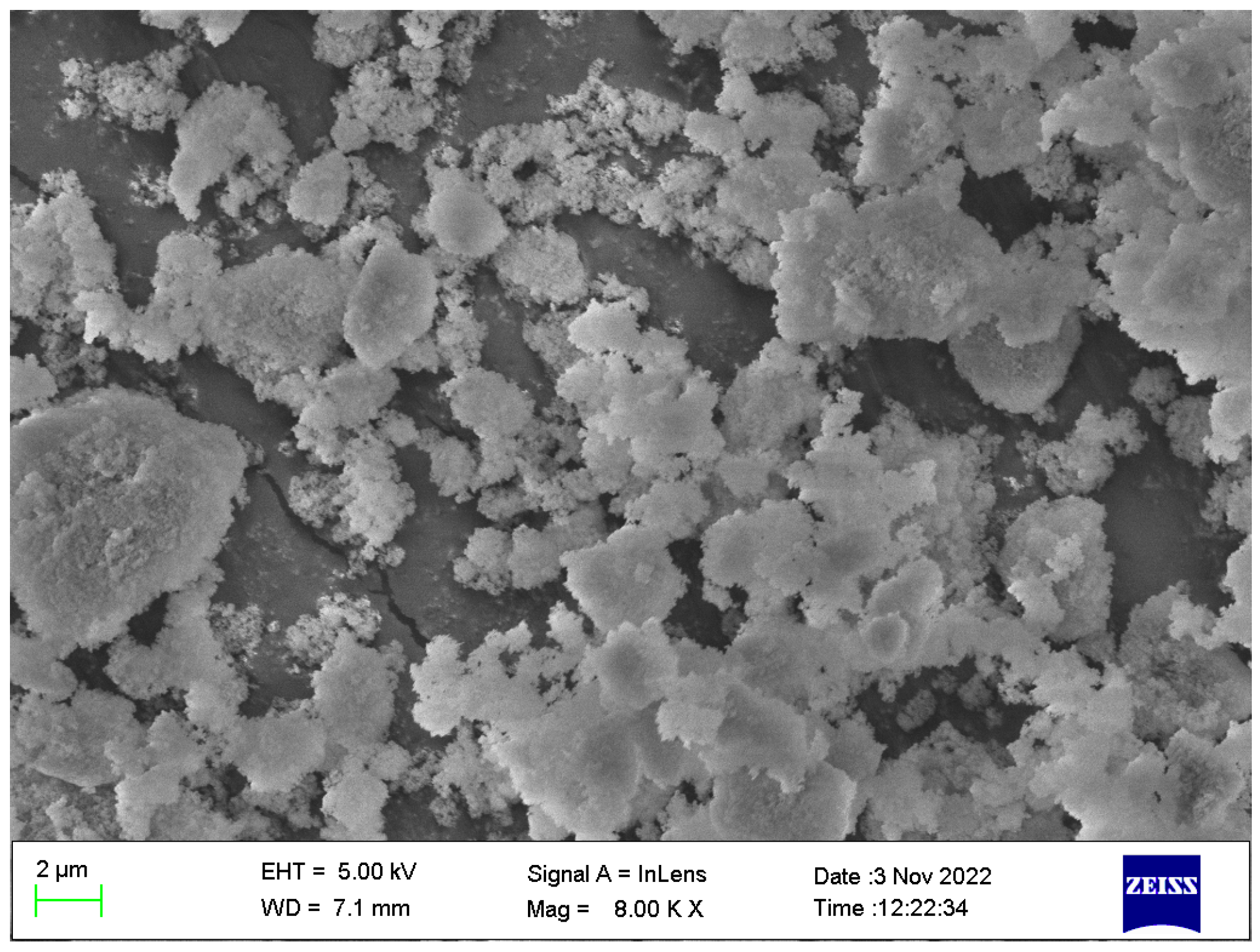

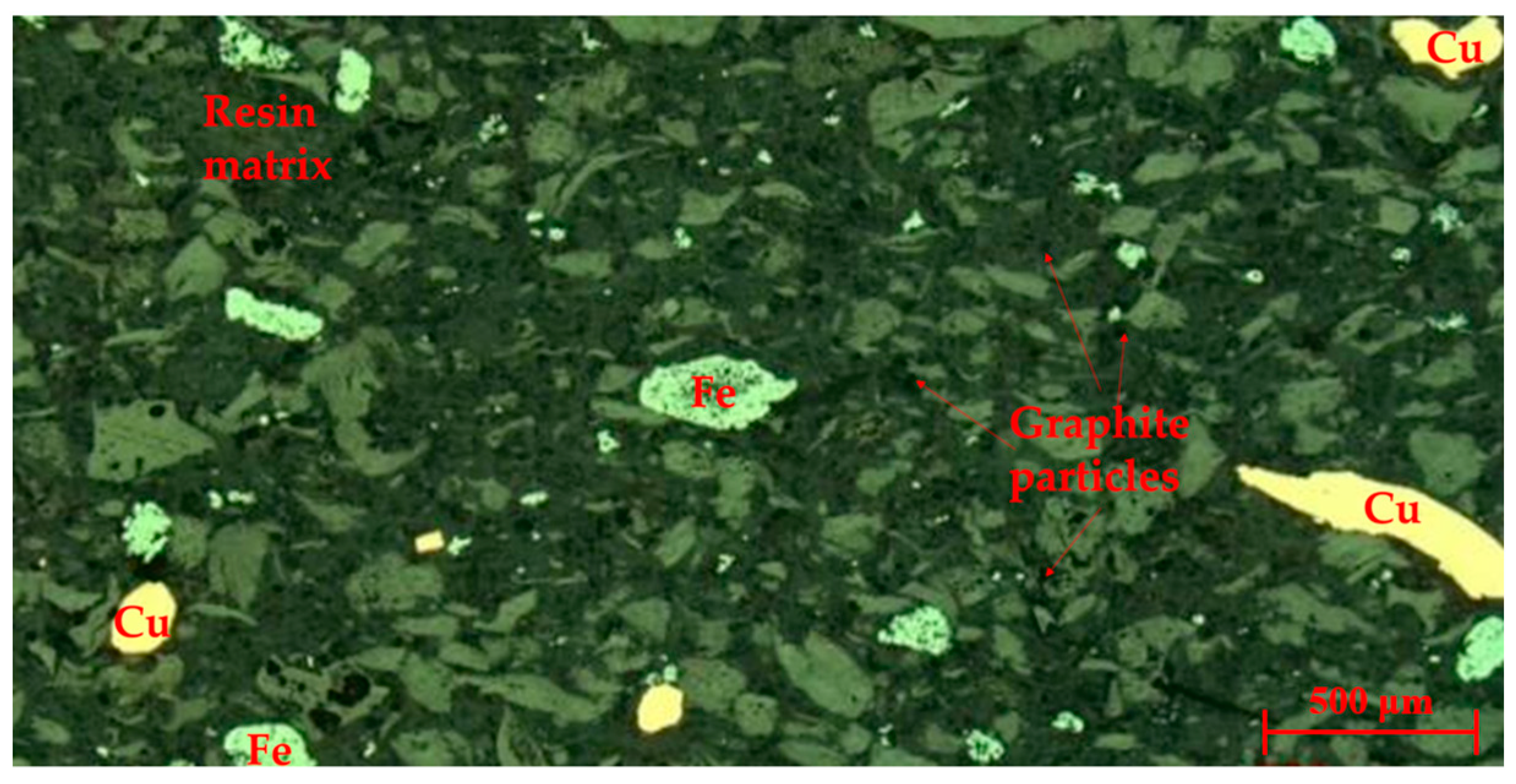

2.1. Experimental Materials

2.2. Methods

3. Results

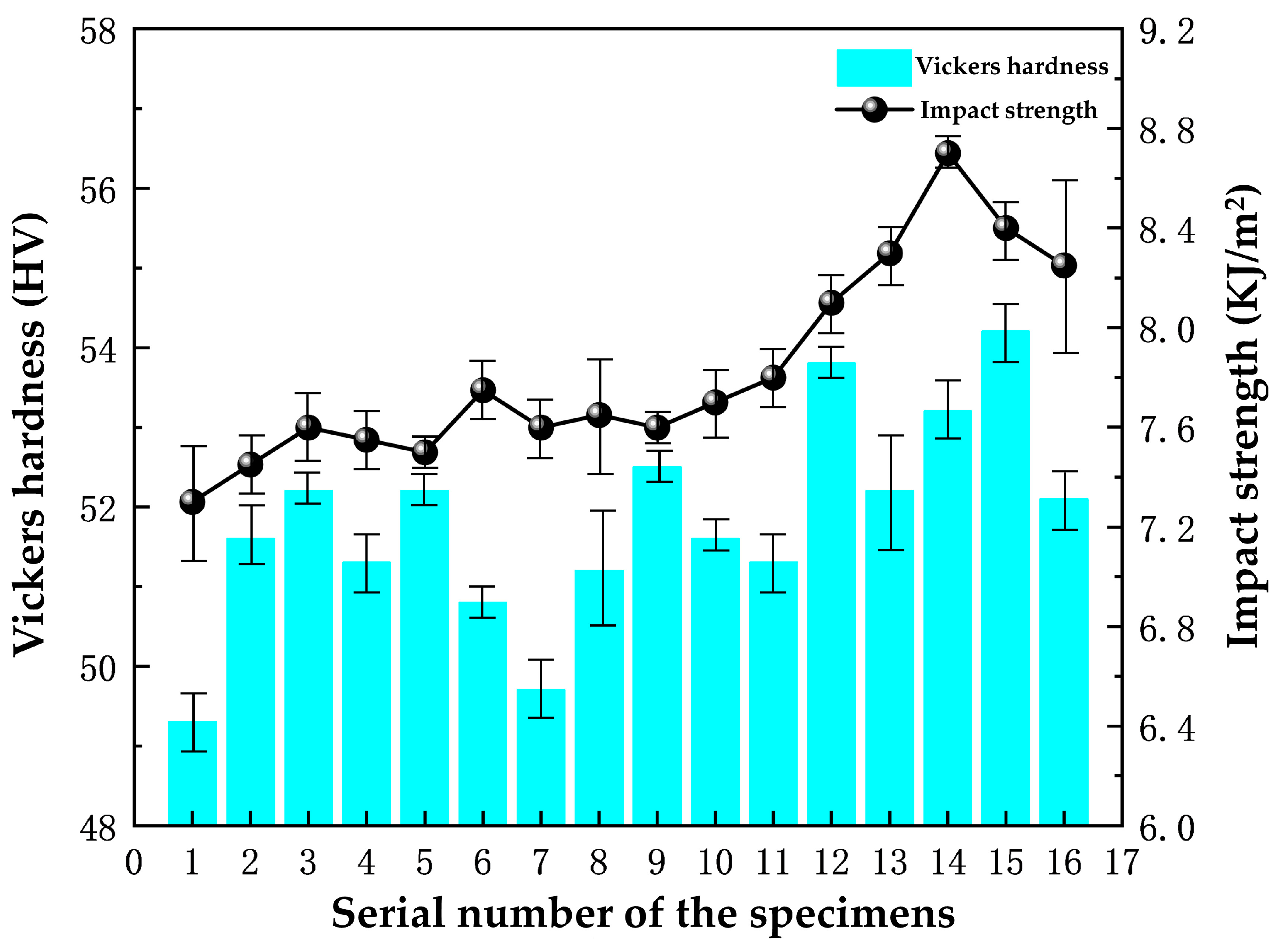

3.1. Mechanical Properties

3.1.1. Vickers Hardness and Impact Strength

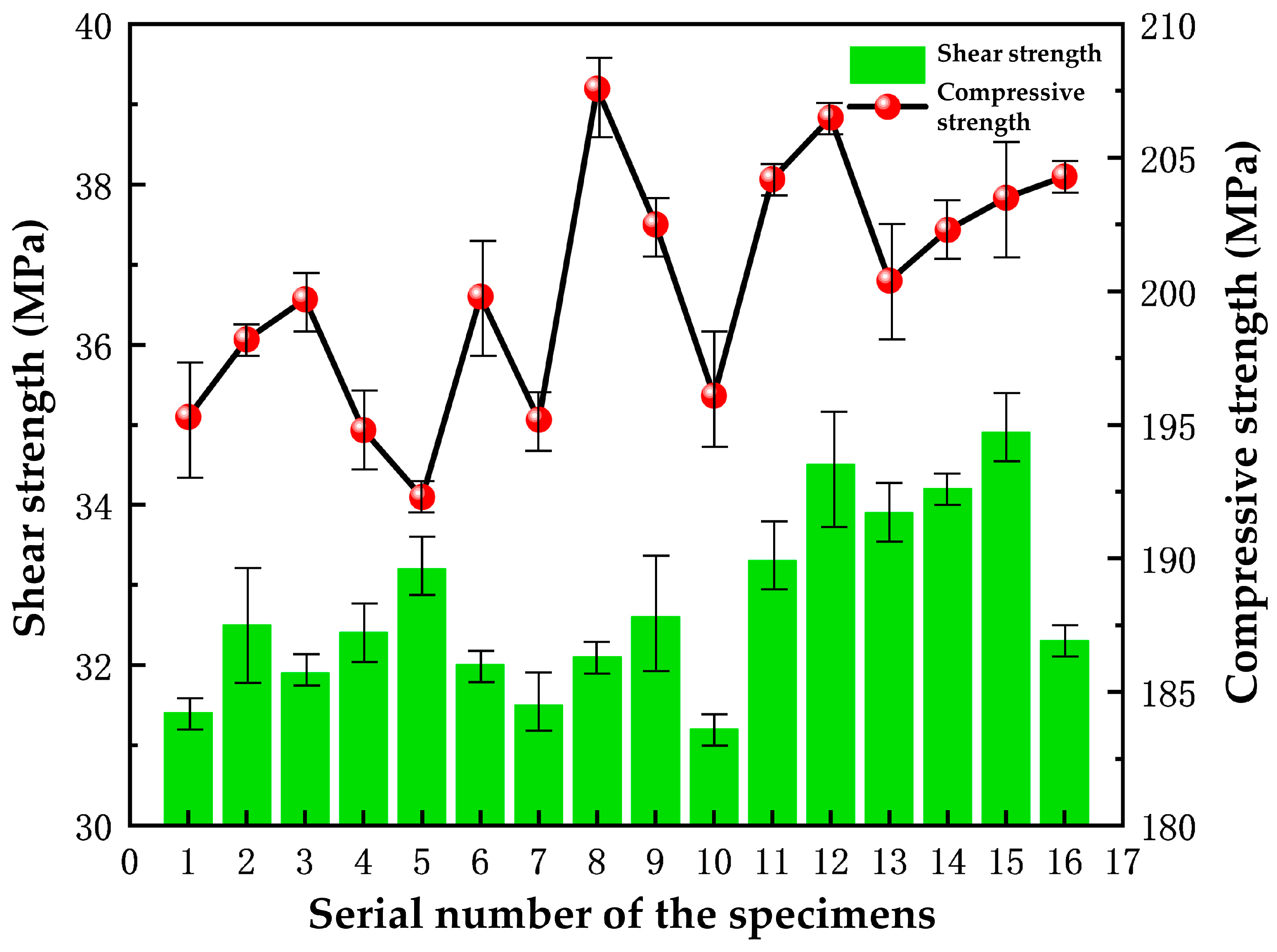

3.1.2. Compressive Strength and Shear Strength

3.2. Tribological Properties

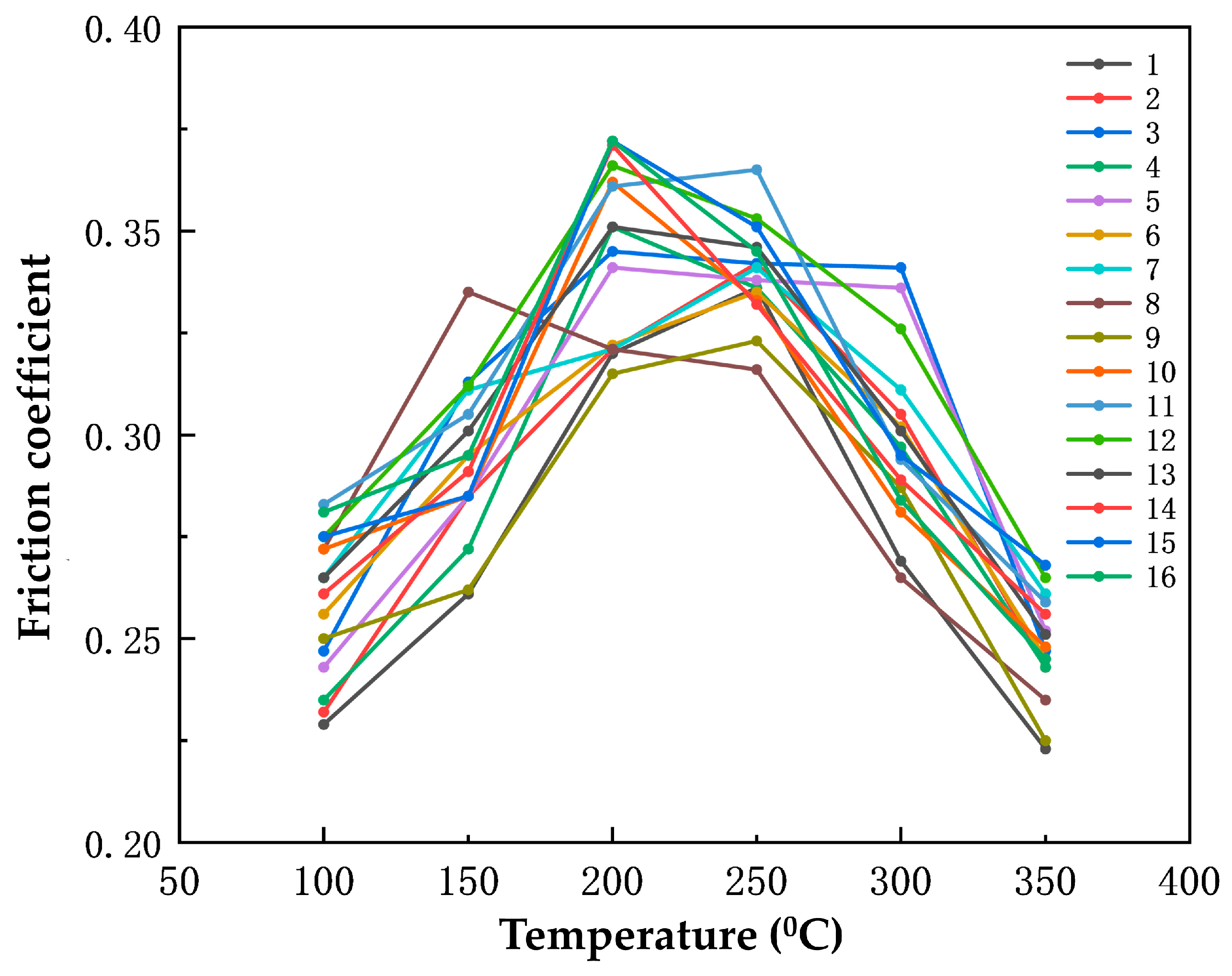

3.2.1. Effect of Rare Earth Oxides and Nanoparticles on the Friction Coefficient during the Heating Process

3.2.2. Effect of Rare Earth Oxides and Nanoparticles on the Friction Coefficient during the Cooling Process

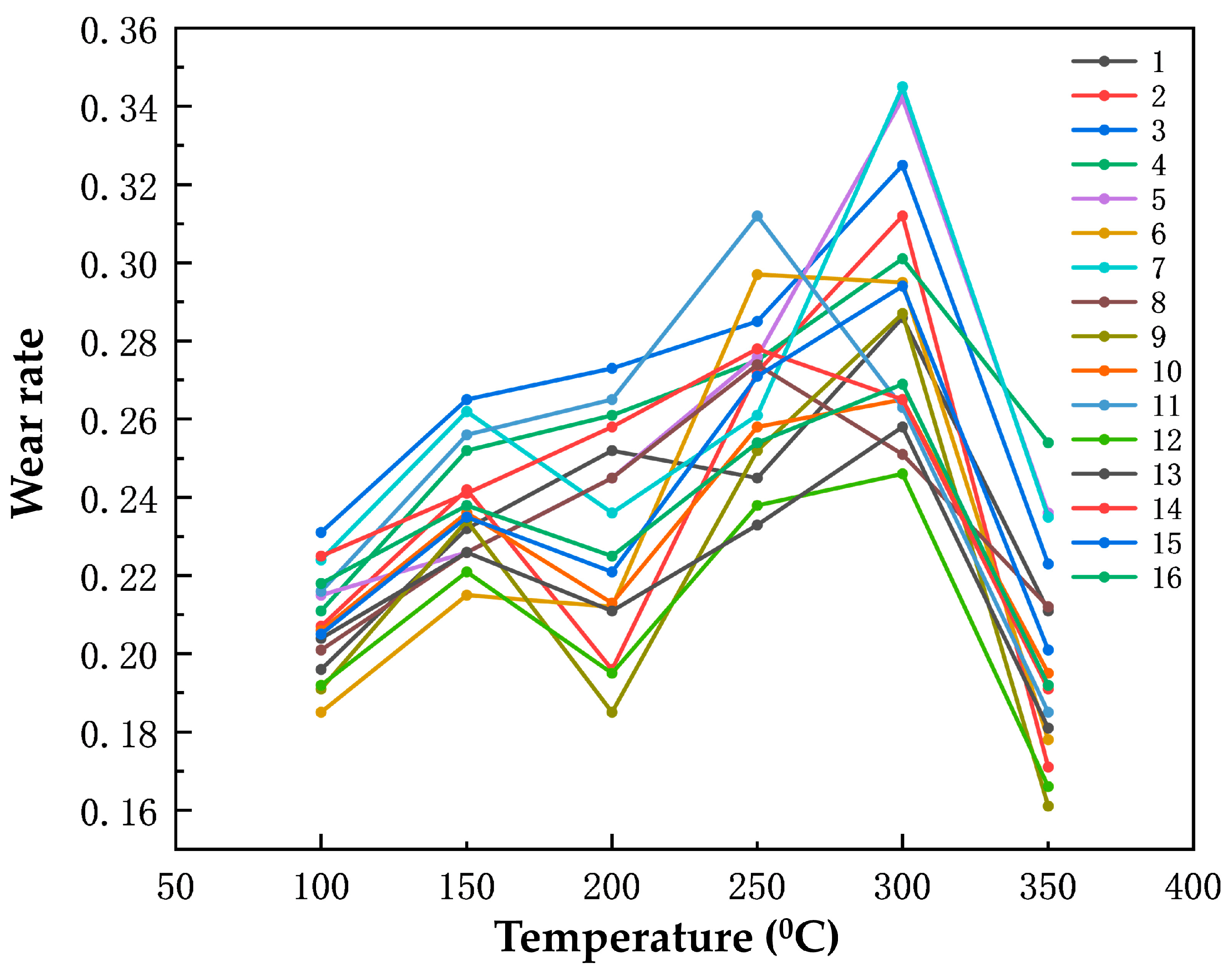

3.2.3. Effect of Rare Earth Oxides and Nanoparticles on the Wear Rate

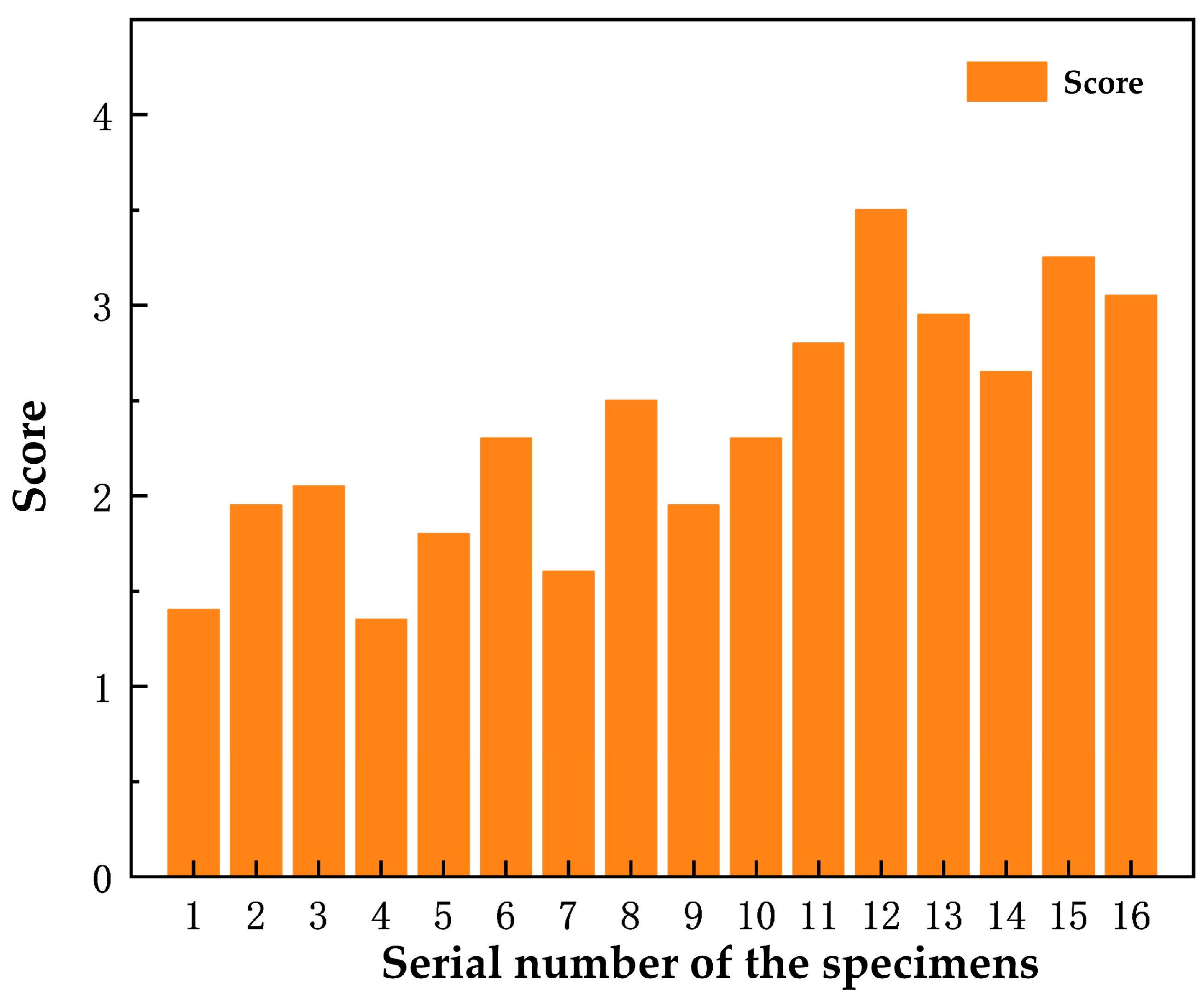

3.3. Fuzzy Comprehensive Evaluation

3.3.1. Fuzzy Evaluation of the Vickers Hardness and Impact Strength of Phenolic-Based Hybrid Nanocomposites

3.3.2. Fuzzy Evaluation of the Compressive Strength and Shear Strength of Phenolic-Based Hybrid Nanocomposites

3.3.3. Fuzzy Evaluation of the Friction Coefficient of Phenolic-Based Hybrid Nanocomposites

3.3.4. Fuzzy Evaluation of the Wear Rate of Phenolic-Based Hybrid Nanocomposites

4. Conclusions

- (1)

- Cerium oxide, yttrium oxide, and nano-silica cause different levels of enhancement of the mechanical properties and tribological properties of the phenolic-based hybrid nanocomposites.

- (2)

- When the levels of the three factors were changed, nano-silica had the greatest effect on the hardness and compressive strength. This mainly relies on the fact that nano-silica has a nano-size, which results in a large specific surface area and combines well with other component materials.

- (3)

- Rare earth cerium oxide and yttrium oxide have a greater influence on the impact strength, shear strength, friction coefficient, and wear rate. This phenomenon can be attributed to the unique electron layer configuration of rare earth elements, which in turn enhances the interfacial bonding characteristics between the resin and fibers when rare earth oxides are employed.

- (4)

- The material ratios of the phenolic-based hybrid nanocomposites were optimized through the orthogonal experimental design and fuzzy comprehensive evaluation method. The optimal formulation of the modified materials is 2% cerium oxide, 2.5% yttrium oxide, and 3% nano-silica.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Factor | Levels (Mass Fraction, %) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Serial Number of the Specimens | ||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| CeO2 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 |

| Y2O3 | 1 | 1.5 | 2 | 2.5 | 1 | 1.5 | 2 | 2.5 | 1 | 1.5 | 2 | 2.5 | 1 | 1.5 | 2 | 2.5 |

| Nano-silica | 2 | 3 | 4 | 5 | 3 | 2 | 5 | 4 | 4 | 5 | 2 | 3 | 5 | 4 | 3 | 2 |

References

- Yoo, C.H.; Park, J.H.; Park, S.S. Design and evaluation of performance tester for yaw brakes in wind turbines. Int. J. Precis. Eng. Manuf.-Green Tech. 2018, 5, 81–87. [Google Scholar] [CrossRef]

- Qazi, A.; Hussain, F.; Rahim, N.A.; Hardaker, G.; Alghazzawi, D.; Shaban, K.; Haruna, K. Towards sustainable energy: A systematic review of renewable energy sources, technologies, and public opinions. IEEE Access 2019, 7, 63837–63851. [Google Scholar] [CrossRef]

- Chandhan Kumar, V.; Rajesh Kannan, K.; Srivathsan, G.; Vignesh Ram, A.; Sravan, V.; Vaira Vignesh, R.; Govindaraju, M. Tribological characterization of functionally gradient composite (Cu–Fe–CeO2–Al2O3–Cg) for wind turbine brake pad. Tribol.-Mater. Surf. Interfaces 2023, 17, 3–21. [Google Scholar] [CrossRef]

- Joshi, A.G.; Bharath, K.N.; Basavarajappa, S. Recent progress in the research on natural composite brake pads: A comprehensive review. Tribol.-Mater. Surf. Interfaces 2023, 17, 237–259. [Google Scholar] [CrossRef]

- Mohamed, A.F.; Osman, O.O.; Ghazaly, N.M. Study of friction coefficient of wind turbine brake system under environmental conditions. Int. J. Adv. Sci. Technol. 2019, 28, 169–177. [Google Scholar]

- Sai Balaji, M.A.; Katiyar, J.K.; Eakambaram, A.; Baskara Sethupathi, P.; Kamalakannan, J.; Baskar, A. Comparative study of sintered and composite brake pad for wind turbine applications. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 11, 1117–1145. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J.; Friedrich, K. Tribology of Polymer Composites: Characterization, Properties, and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Lokesh, P.; Kumari, T.S.; Gopi, R.; Loganathan, G.B. A study on mechanical properties of bamboo fiber reinforced polymer composite. Mater. Today Proc. 2020, 22, 897–903. [Google Scholar] [CrossRef]

- Senthil Muthu Kumar, T.; Senthilkumar, K.; Chandrasekar, M.; Karthikeyan, S.; Ayrilmis, N.; Rajini, N.; Siengchin, S. Mechanical, thermal, tribological, and dielectric properties of biobased composites. Biobased Compos. Process. Charact. Prop-Erties Appl. 2021, 10, 53–73. [Google Scholar]

- Atiqah, A. Characterization and Interface of Natural and Synthetic Hybrid Composites. Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; Volume 4. [Google Scholar]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Shahroze, R.M.; Ishak, M.R.; Salit, M.S.; Leman, Z.; Asim, M.; Chandrasekar, M. Effect of organo-modified nanoclay on the mechanical properties of sugar palm fiber-reinforced polyester composites. BioResources 2018, 13, 7430–7444. [Google Scholar] [CrossRef]

- Gürgen, S.; Sert, A.; Kuşhan, M.C. An investigation on wear behavior of UHMWPE/carbide composites at elevated temperatures. J. Appl. Polym. Sci. 2021, 138, 50245. [Google Scholar] [CrossRef]

- Shanmugam, S.; Meenakshisundaram, O. Effect of graphene on tribology, mechanical, and thermal properties of flax/E-glass/epoxy hybrid nanocomposites. Polym. Compos. 2023, 44, 1940–1950. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Omran, A.A.B.; Singh, J.; Ilyas, R.A. Recent trends and developments in conducting polymer nanocomposites for multifunctional applications. Polymers 2021, 13, 2898. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Huang, C.; Wang, L.; Liang, L.; Cheng, Y.; Fei, W.; Li, Y. Recent progress in graphene/polymer nanocomposites. Adv. Mater. 2021, 33, 2001105. [Google Scholar] [CrossRef] [PubMed]

- Shameem, M.M.; Sasikanth, S.M.; Annamalai, R.; Raman, R.G. A brief review on polymer nanocomposites and its applications. Mater. Today Proc. 2021, 45, 2536–2539. [Google Scholar] [CrossRef]

- Yu, Y.; Song, J.; Zhao, G.; Ding, Q. Effect of rare earth oxide on the mechanical and tribological properties of polyimide nanocomposites. Ind. Lubr. Tribol. 2020, 72, 433–437. [Google Scholar] [CrossRef]

- Vasilev, A.P.; Lazareva, N.N.; Struchkova, T.S.; Okhlopkova, A.A.; Danilova, S.N. Mechanical and Tribological Properties of Polytetrafluoroethylene Modified with Combined Fillers: Carbon Fibers, Zirconium Dioxide, Silicon Dioxide and Boron Nitride. Polymers 2023, 15, 313. [Google Scholar] [CrossRef]

- Kumar, M.S.; Selvan, C.P.; Santhanam, K.; Kadirvel, A.; Chandraprabu, V.; SampathKumar, L. Effect of nanomaterials on tribological and mechanical properties of polymer nanocomposite materials. Adv. Mater. Sci. Eng. 2022, 2022, 1–16. [Google Scholar]

- Zheng, K.; Gao, C.; He, F.; Jiang, W. Development of a high-quality rare earth oxide modified resin-based brake material. Tribol.-Mater. Surf. Interfaces 2019, 13, 50–57. [Google Scholar] [CrossRef]

- Bilvatej, B.; Naveen, J.; Karthikeyan, N.; Norrrahim, M.N.F.; Knight, V.F.; Jawaid, M.; Loganathan, T.M. Progress in polymeric and metallic brake pads: A comprehensive review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 47, 796–815. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, T.; Chen, L.; Idziak, S.; Huang, Z.; Zhao, B. Effects of rare earth oxide additive on surface and tribological properties of polyimide composites. Appl. Surf. Sci. 2017, 416, 536–546. [Google Scholar] [CrossRef]

- Jiang, M.; Cheng, X. Effect of carbon nanotubes modified with different concentrations of rare earth lanthanum on the mechanical and tribological properties of epoxy composites. J. Compos. Mater. 2021, 55, 2197–2210. [Google Scholar] [CrossRef]

- Zheng, K.; Gao, C.; He, F.; Lin, Y. The role of rare earth lanthanum oxide in polymeric matrix brake composites to replace copper. Polymers 2018, 10, 1027. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.; Gao, C.; He, F.; Lin, Y.; Liu, M.; Lin, J. Study on the interfacial functionary mechanism of rare-earth-solution-modified bamboo-fiber-reinforced resin matrix composites. Materials 2018, 11, 1190. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Qin, Z.; Luo, H.; Yang, W.; Wang, Y.; Huang, Z. Nano-silica modified phenolic resin film: Manufacturing and properties. Nanotechnol. Rev. 2020, 9, 209–218. [Google Scholar] [CrossRef]

- Wang, S.; Cao, M.; Xue, H.; Cong, F.; Li, X.; Zhao, C.; Su, W. Nano-silica reinforced epoxy resin/nano-rubber composite material with a balance of stiffness and toughness. High Perform. Polym. 2021, 33, 685–694. [Google Scholar] [CrossRef]

- Dorieh, A.; Pour, M.F.; Movahed, S.G.; Pizzi, A.; Selakjani, P.P.; Kiamahalleh, M.V.; Aghaei, R. A review of recent progress in melamine-formaldehyde resin-based nanocomposites as coating materials. Prog. Org. Coat. 2022, 165, 106768. [Google Scholar] [CrossRef]

- Sun, Y.; Meng, X.; Liu, W.; Ren, Y. Study on the properties of CSH/epoxy nanocomposite structure doped with silica nanoparticles. J. Build. Eng. 2023, 74, 106894. [Google Scholar] [CrossRef]

- Chang, T.; Zhan, L.; Tan, W.; Li, S. Optimization of curing process for polymer-matrix composites based on orthogonal experimental method. Fibers Polym. 2017, 18, 148–154. [Google Scholar] [CrossRef]

- Qiu, K.; Chen, S.; Wang, C.; Yang, B.; Jiang, J. Optimal Design of Multi-Scale Fiber-Reinforced Cement-Matrix Composites Based on an Orthogonal Experimental Design. Polymers 2023, 15, 2898. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L. Research and application of AHP-fuzzy comprehensive evaluation model. Evol. Intell. 2022, 15, 2403–2409. [Google Scholar] [CrossRef]

- Xu, Q.; Zhao, J.; Ai, X.; Huang, W.; Wang, G. Optimum selection of tool materials for machining of high-strength steels based on fuzzy comprehensive evaluation method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 145–153. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, P.; Rochlani, M.; Falla, G.C.; Leischner, S.; Oeser, M. A fuzzy comprehensive evaluation method to select the optimal mineral filler for optimization of the performance of asphalt mastics. Constr. Build. Mater. 2021, 298, 123847. [Google Scholar] [CrossRef]

- Praveenkumara, J.; Madhu, P.; Yashas Gowda, T.G.; Sanjay, M.R.; Siengchin, S. A comprehensive review on the effect of syn-thetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 2022, 113, 1231–1239. [Google Scholar] [CrossRef]

- Sanghvi, M.R.; Tambare, O.H.; More, A.P. Performance of various fillers in adhesives applications: A review. Polym. Bull. 2022, 79, 10491–10553. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Kim, H.I. Synthesis, characterization, and hydrolytic degradation of polylactide/poly (ethylene glycol)/nano-silica composite films. J. Macromol. Sci. Part A 2012, 49, 348–354. [Google Scholar] [CrossRef]

- Yu, K.; Liang, Y.; Ma, G.; Yang, L.; Wang, T.J. Coupling of synthesis and modification to produce hydrophobic or functionalized nano-silica particles. Colloids Surf. A Physicochem. Eng. Asp. 2019, 574, 122–130. [Google Scholar] [CrossRef]

- Huang, C.; Yang, W.; Duan, K.; Fang, L.; Wang, L.; Bo, C. Mechanical behaviors of the brittle rock-like specimens with multi-non-persistent joints under uniaxial compression. Constr. Build. Mater. 2019, 220, 426–443. [Google Scholar] [CrossRef]

- Cong, M.; Zhang, S.; Sun, D.; Zhou, K. Optimization of preparation of foamed concrete based on orthogonal experiment and range analysis. Front. Mater. 2021, 8, 778173. [Google Scholar] [CrossRef]

- Petit, L.; Svane, A.; Szotek, Z.; Temmerman, W.M. First-principles study of rare-earth oxides. Phys. Rev. B 2005, 72, 205118. [Google Scholar] [CrossRef]

- Hossain, M.K.; Raihan, G.A.; Akbar, M.A.; Kabir Rubel, M.H.; Ahmed, M.H.; Khan, M.I. Current applications and future potential of rare earth oxides in sustainable nuclear, radiation, and energy devices: A review. ACS Appl. Electron. Mater. 2022, 4, 3327–3353. [Google Scholar] [CrossRef]

| Material | Purity (%) | Granularity (Mesh) | Melting Point (°C) | Density (g/cm3) |

|---|---|---|---|---|

| CeO2 | 99.9 | 200 | 2397 | 7.13 |

| Y2O3 | 99.9 | 200 | 2410 | 5.01 |

| Material | Purity (%) | Particle Size (nm) | Melting Point (°C) | PH | Specific Surface Area (m2/g) |

|---|---|---|---|---|---|

| Nano-silica | 99.8 | 30 ± 5 | 1750 | 5~7 | 150~300 |

| Components | |||||||

|---|---|---|---|---|---|---|---|

| MgO | Cu | Barite | Graphite Particles | Clay | Fe | Aramid Fiber | |

| Mass fraction (%) | 10 | 15 | 22 | 15 | 20 | 15 | 3 |

| Factor | Levels (Mass Fraction, %) | |||

|---|---|---|---|---|

| CeO2 | 1 | 1.5 | 2 | 2.5 |

| Y2O3 | 1 | 1.5 | 2 | 2.5 |

| Nano-silica | 2 | 3 | 4 | 5 |

| Factor | Mean Value (HV) | Range (HV) | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 51.100 | 50.975 | 52.300 | 52.925 | 1.950 |

| Y2O3 | 51.550 | 51.800 | 51.850 | 52.100 | 0.550 |

| Nano-silica | 50.875 | 52.950 | 52.275 | 51.200 | 2.075 |

| Factor | Mean Value (KJ/m2) | Range (KJ/m2) | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 7.480 | 7.572 | 7.620 | 7.818 | 0.338 |

| Y2O3 | 7.485 | 7.558 | 7.630 | 7.818 | 0.333 |

| Nano-silica | 7.675 | 7.595 | 7.555 | 7.665 | 0.120 |

| Factor | Compressive Strength (MPa) | Range (MPa) | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 197.000 | 198.725 | 202.325 | 202.625 | 5.625 |

| Y2O3 | 197.625 | 199.100 | 200.650 | 203.300 | 5.675 |

| Nano-silica | 200.900 | 200.125 | 203.025 | 196.625 | 6.400 |

| Factor | Shear Strength (MPa) | Range (MPa) | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 32.050 | 32.200 | 32.900 | 33.825 | 1.775 |

| Y2O3 | 32.775 | 32.475 | 32.900 | 32.825 | 0.425 |

| Nano-silica | 32.250 | 33.775 | 32.700 | 32.250 | 1.525 |

| Factor | Friction Coefficients | Range | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 0.289 | 0.296 | 0.300 | 0.304 | 0.015 |

| Y2O3 | 0.288 | 0.294 | 0.307 | 0.300 | 0.019 |

| Nano-silica | 0.295 | 0.303 | 0.293 | 0.298 | 0.010 |

| Factor | Friction Coefficients | Range | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 0.266 | 0.262 | 0.274 | 0.281 | 0.019 |

| Y2O3 | 0.262 | 0.267 | 0.276 | 0.278 | 0.016 |

| Nano-silica | 0.258 | 0.274 | 0.279 | 0.272 | 0.021 |

| Factor | Wear Rate | Range | |||

|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | R = Kmax − Kmin | |

| CeO2 | 0.249 | 0.246 | 0.227 | 0.233 | 0.022 |

| Y2O3 | 0.233 | 0.234 | 0.254 | 0.234 | 0.021 |

| Nano-silica | 0.237 | 0.234 | 0.241 | 0.242 | 0.008 |

| Vickers Hardness (HV) | 49~50.5 | 50.51~52 | 52.01~53.5 | 53.51~55 |

|---|---|---|---|---|

| Score | 1 | 2 | 3 | 4 |

| Impact Strength (KJ/m2) | 7.3~7.65 | 7.651~8.0 | 8.01~8.35 | 8.351~8.7 |

|---|---|---|---|---|

| Score | 1 | 2 | 3 | 4 |

| Compressive Strength (MPa) | 192~196 | 196~200 | 200~204 | 204~208 |

|---|---|---|---|---|

| Score | 1 | 2 | 3 | 4 |

| Shear Strength (MPa) | 31~32 | 32~33 | 33~34 | 34~35 |

|---|---|---|---|---|

| Score | 1 | 2 | 3 | 4 |

| Friction Coefficient | 0.264~0.277 | 0.277~0.290 | 0.290~0.303 | 0.303~0.316 |

|---|---|---|---|---|

| Score | 1 | 2 | 3 | 4 |

| Wear Rate | 0.255~0.270 | 0.240~0.255 | 0.225~0.240 | 0.210~0.225 |

|---|---|---|---|---|

| Score | 1 | 2 | 3 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Chen, S.; Sun, J.; Liu, Z.; He, D.; Xu, S. Effects of Rare Earth Oxides on the Mechanical and Tribological Properties of Phenolic-Based Hybrid Nanocomposites. Polymers 2024, 16, 131. https://doi.org/10.3390/polym16010131

Wang S, Chen S, Sun J, Liu Z, He D, Xu S. Effects of Rare Earth Oxides on the Mechanical and Tribological Properties of Phenolic-Based Hybrid Nanocomposites. Polymers. 2024; 16(1):131. https://doi.org/10.3390/polym16010131

Chicago/Turabian StyleWang, Shenglian, Shuang Chen, Jiachen Sun, Zimo Liu, Dingxiang He, and Shaofeng Xu. 2024. "Effects of Rare Earth Oxides on the Mechanical and Tribological Properties of Phenolic-Based Hybrid Nanocomposites" Polymers 16, no. 1: 131. https://doi.org/10.3390/polym16010131

APA StyleWang, S., Chen, S., Sun, J., Liu, Z., He, D., & Xu, S. (2024). Effects of Rare Earth Oxides on the Mechanical and Tribological Properties of Phenolic-Based Hybrid Nanocomposites. Polymers, 16(1), 131. https://doi.org/10.3390/polym16010131