Novel Epoxidized Brazil Nut Oil as a Promising Plasticizing Agent for PLA

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

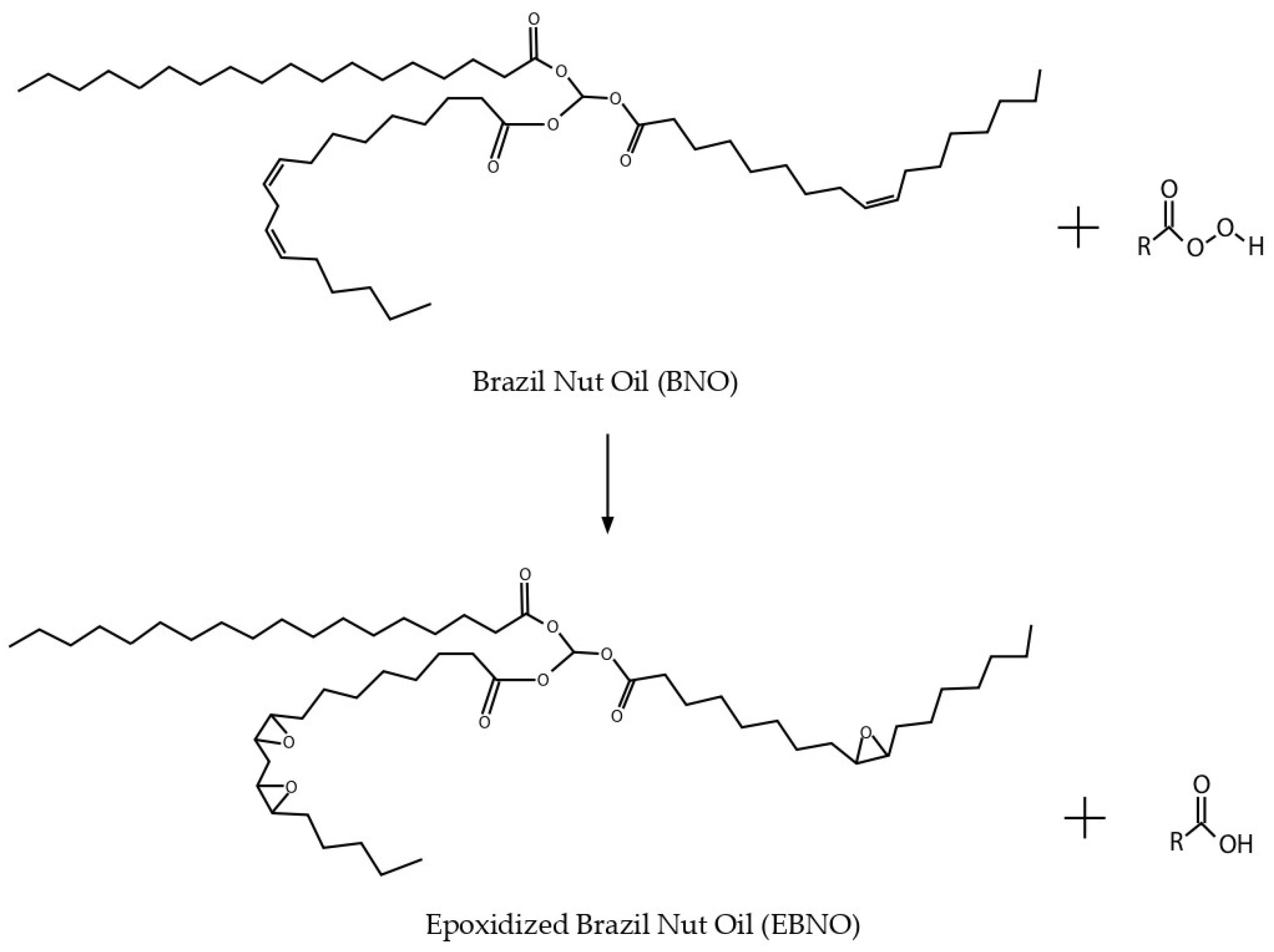

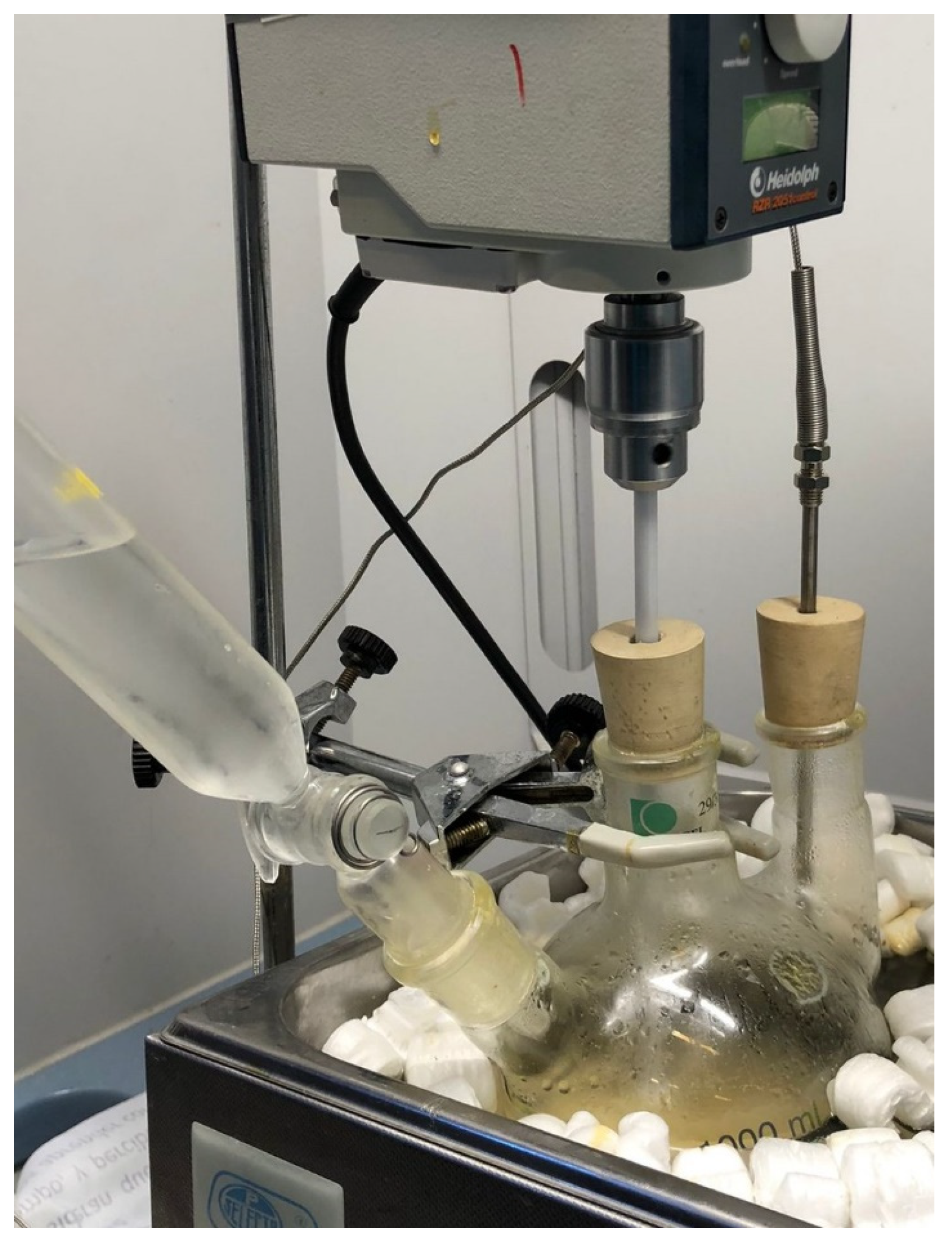

2.2. Epoxidation of Brazil Nut (Bertholletia excelsa) Oil

2.3. Manufacturing of PLA formulations with Epoxidized Brazil Nut Oil (EBNO)

2.4. Mechanical Characterization of PLA Formulations Plasticized with EBNO

2.5. Thermal Analysis of PLA Formulations Plasticized with EBNO

2.6. Thermomechanical Characterization of PLA Formulations Plasticized with EBNO

2.7. Morphology of PLA Plasticized with EBNO

2.8. Degree of Disintegration under Composting Conditions of PLA Formulations Plasticized with EBNO

3. Results

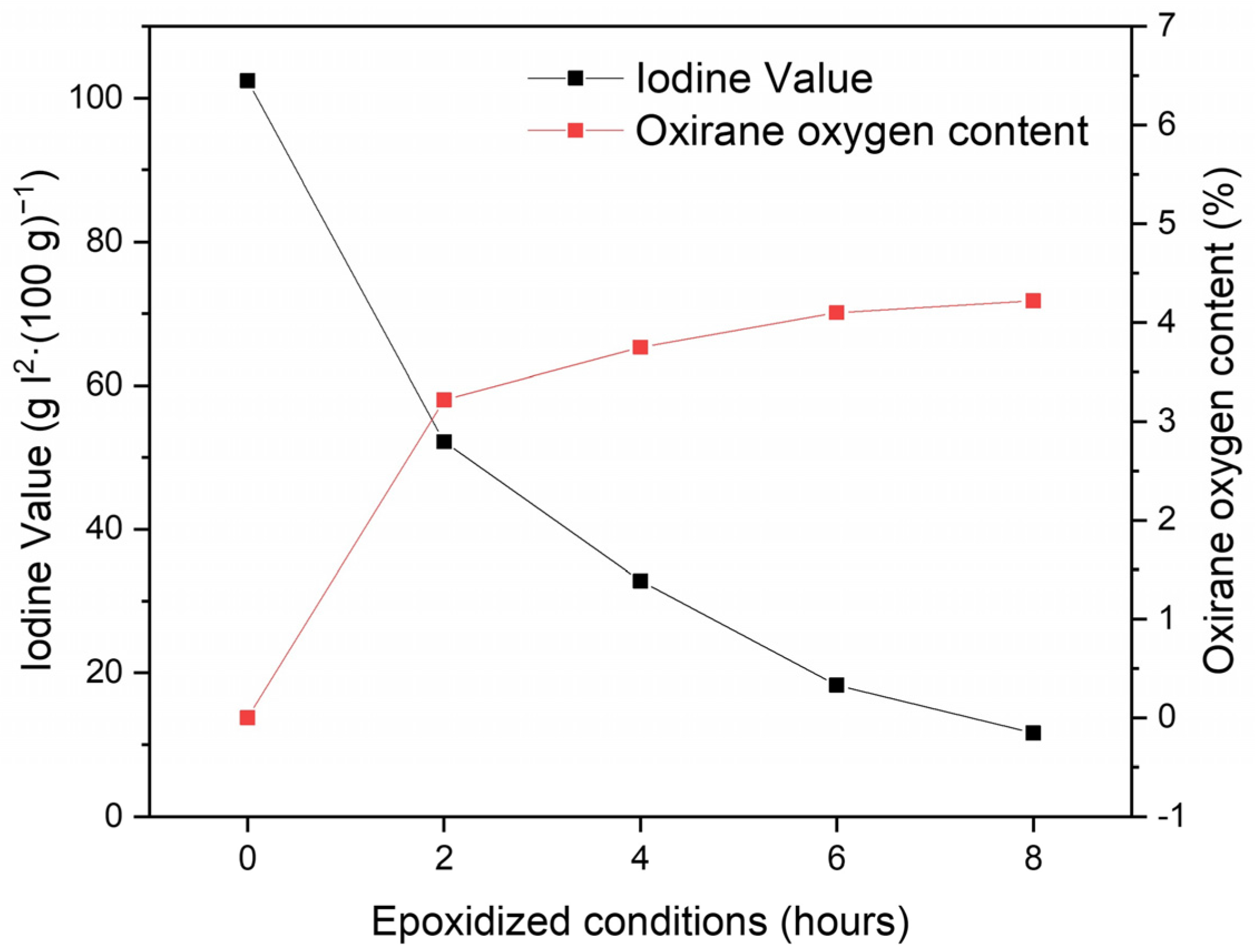

3.1. Syntesis of Epoxidized Brazil Nut Oil

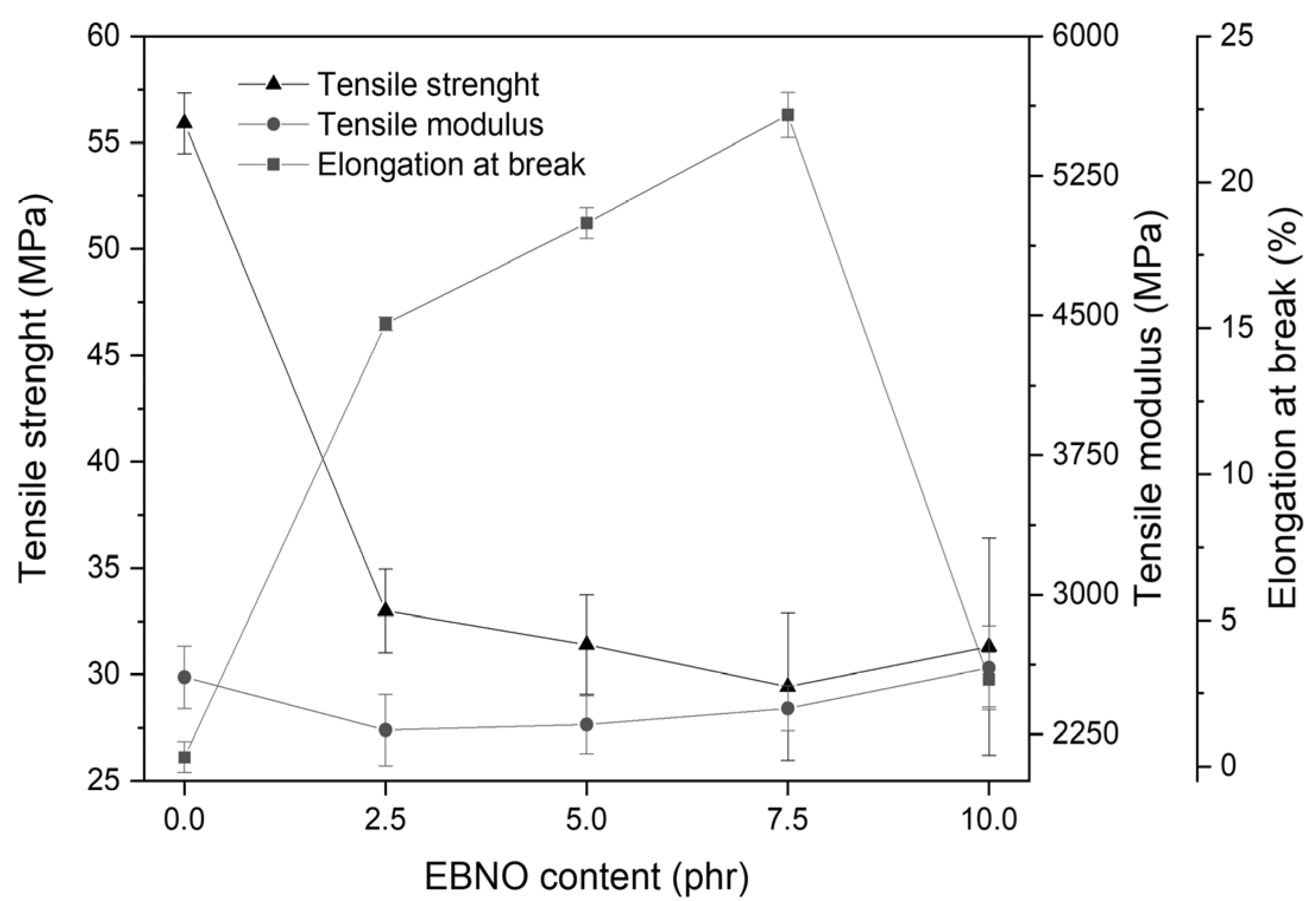

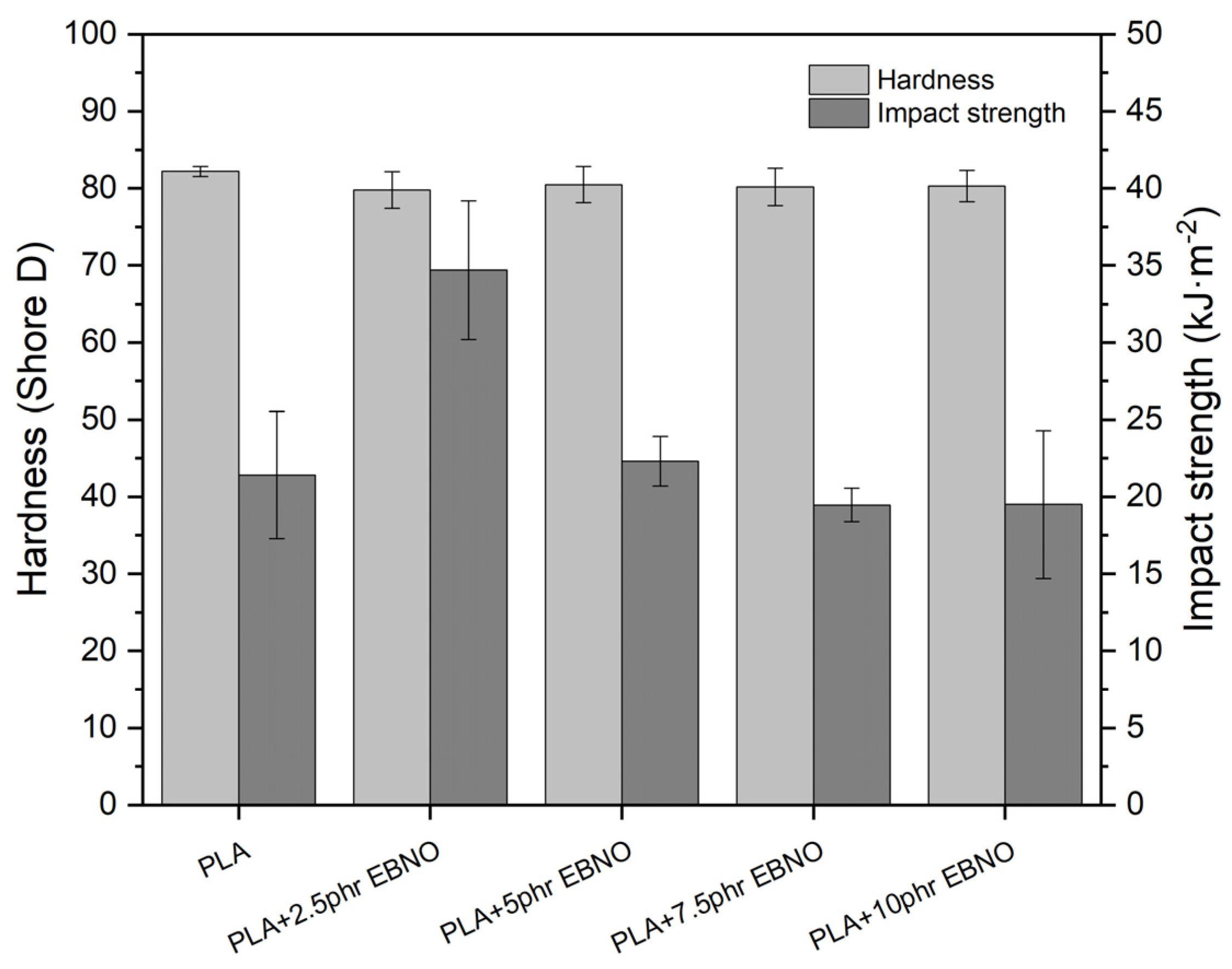

3.2. Effects of EBNO on Mechanical Properties of Plasticized PLA Formulations

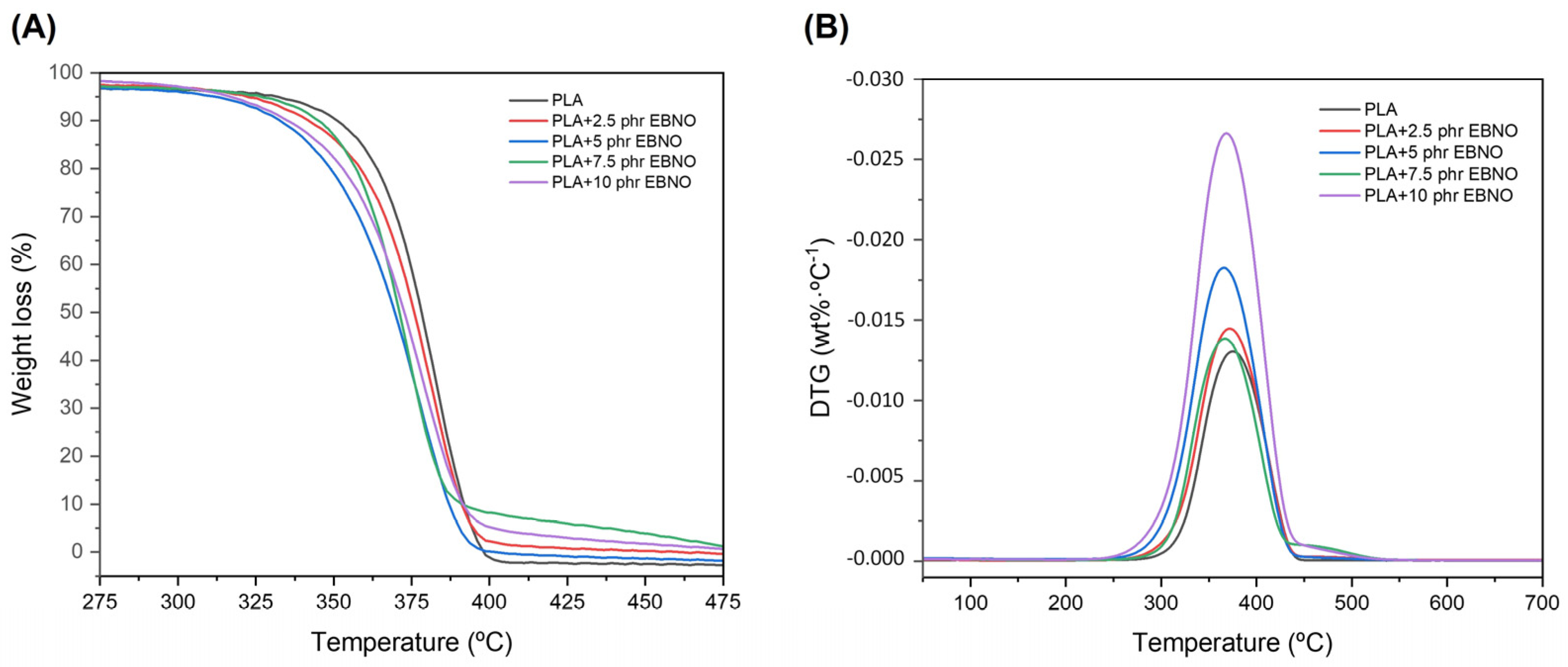

3.3. Effects of EBNO on Thermal Properties of Plasticized PLA Formulations

3.4. Effects of EBNO on Thermomechanical Properties of Plasticized PLA Formulations

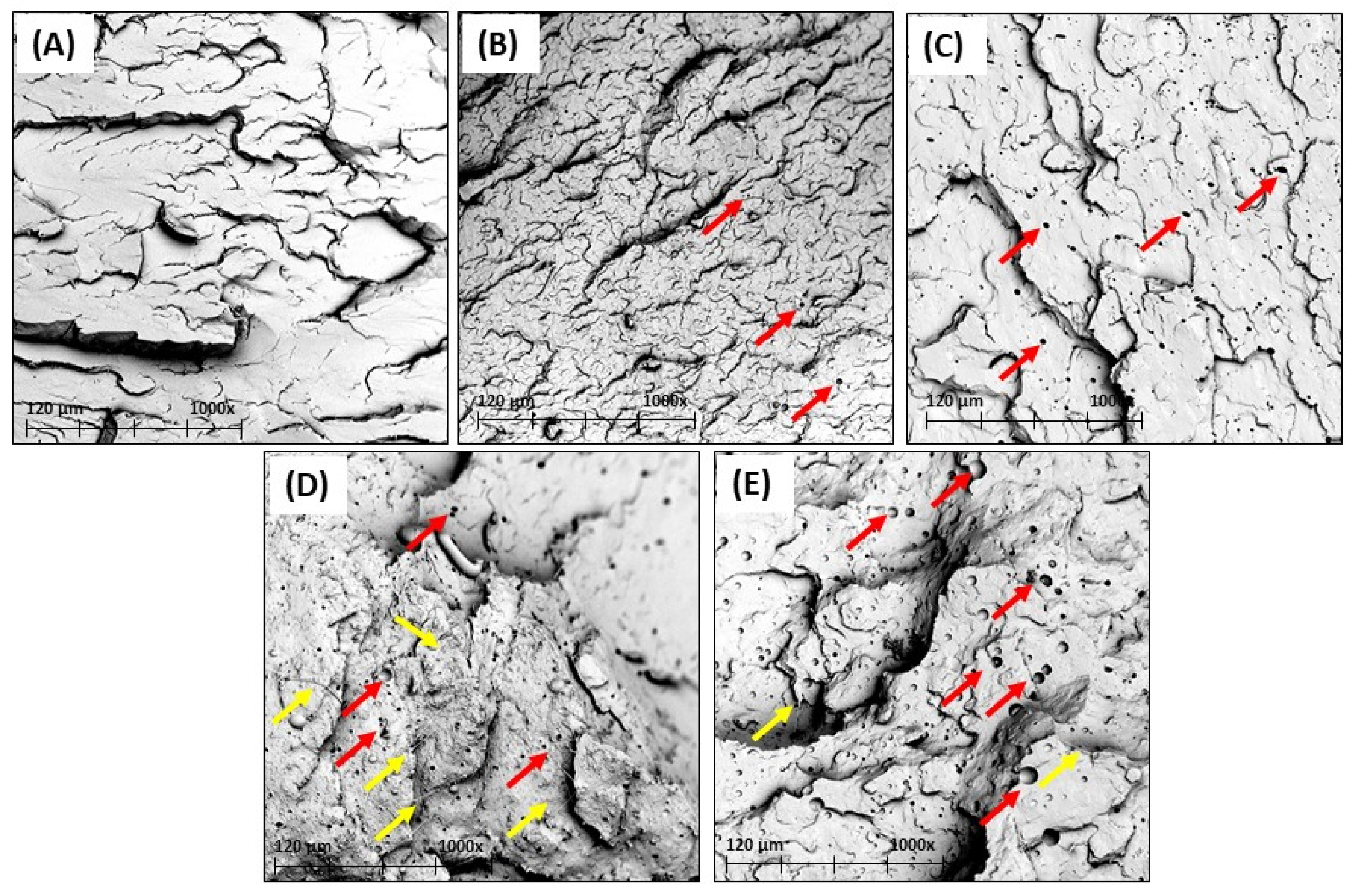

3.5. Morphology of PLA Formulations with EBNO

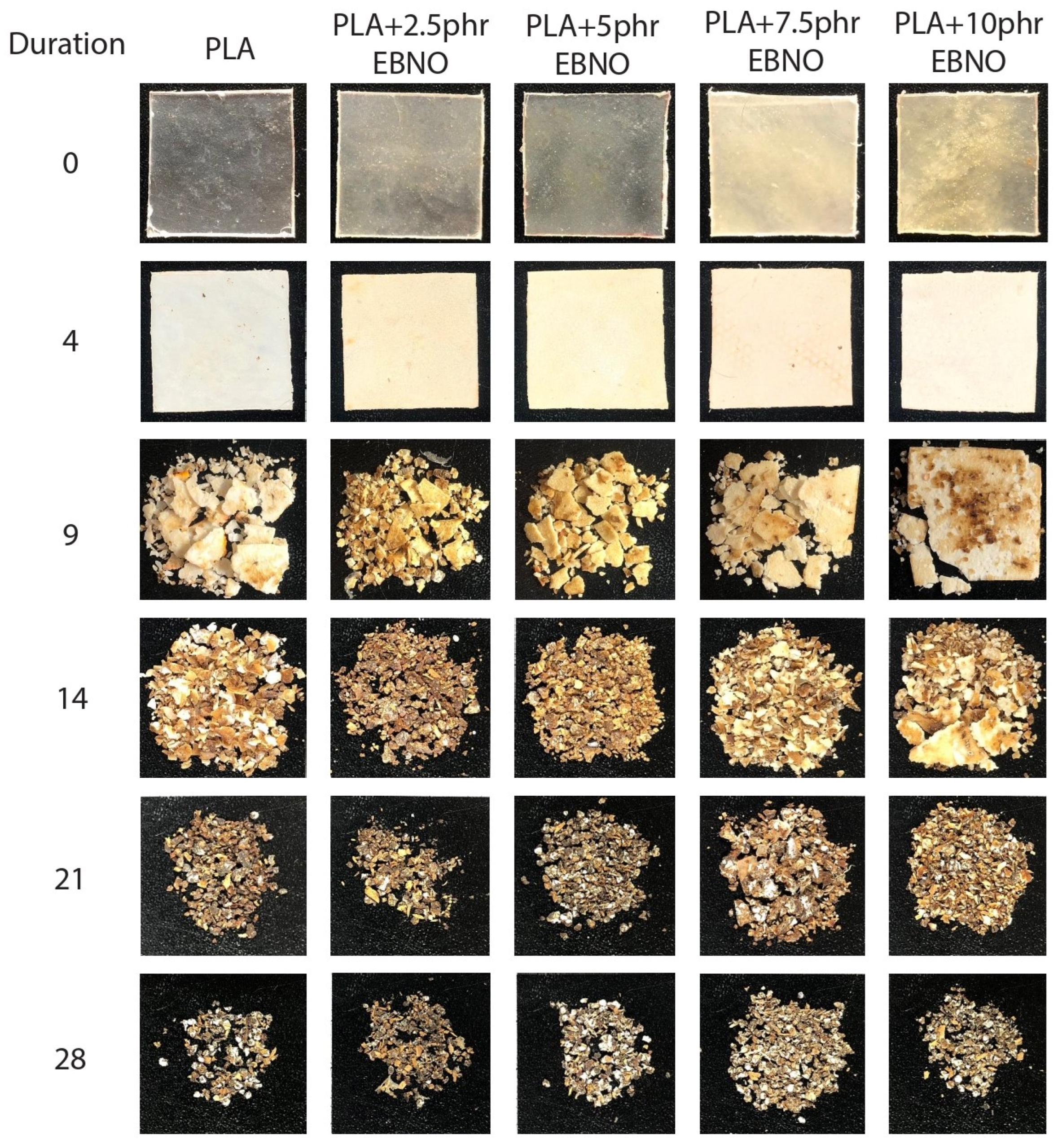

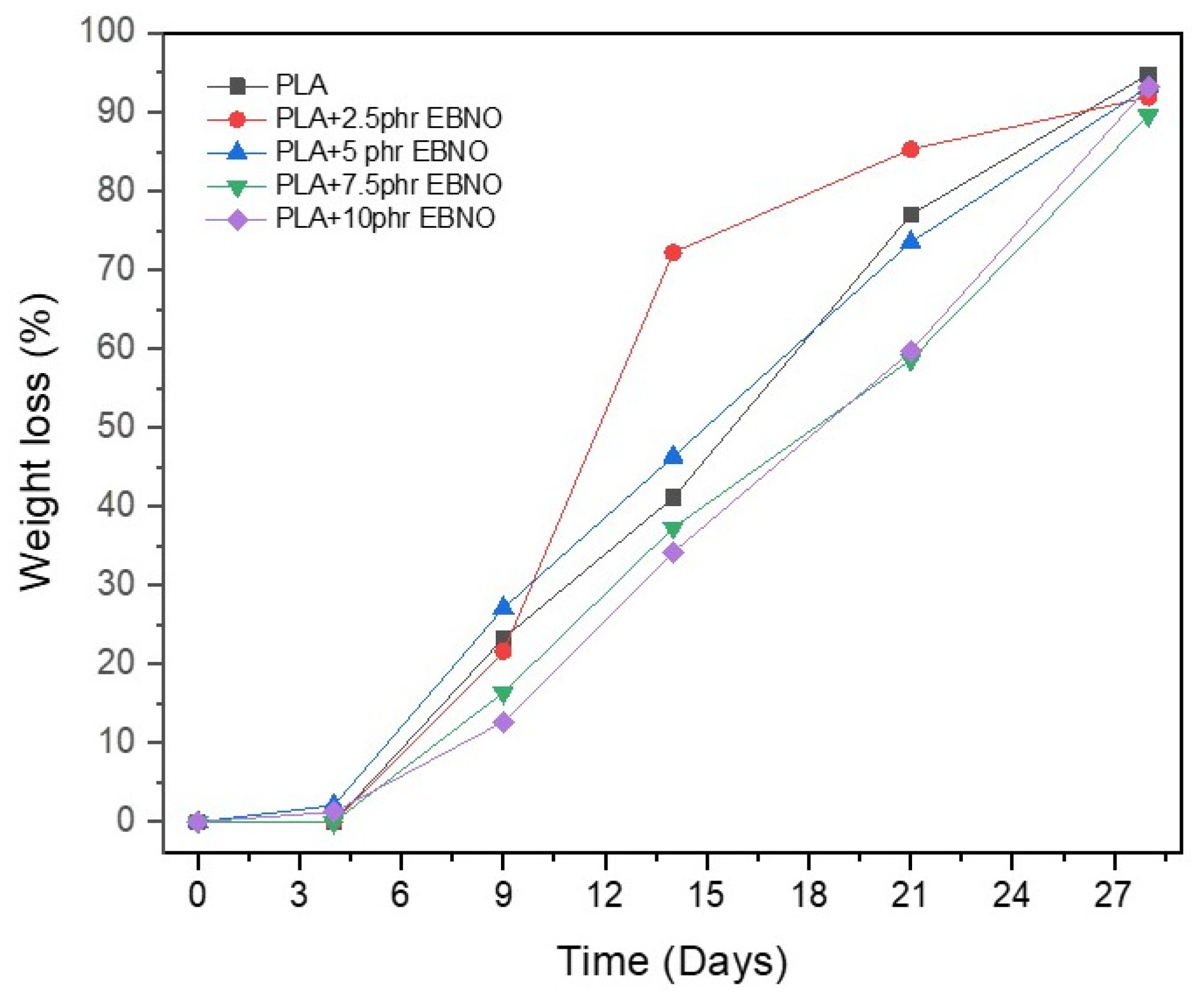

3.6. Disintegration under Composting Conditions of PLA Formulations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, S.X.; Andriyana, A.; Ong, H.C.; Lim, S.; Pang, Y.L.; Ngoh, G.C. A Comprehensive Review on the Emerging Roles of Nanofillers and Plasticizers towards Sustainable Starch-Based Bioplastic Fabrication. Polymers 2022, 14, 664. [Google Scholar] [CrossRef]

- Plastics Europe. An Analysis of European Plasticcs Production, Demand and Waste Data; Plastics Europe: London, UK, 2021; p. 34. [Google Scholar]

- Ioakeimidis, C.; Fotopoulou, K.; Karapanagioti, H.; Geraga, M.; Zeri, C.; Papathanassiou, E.; Galgani, F.; Papatheodorou, G. The degradation potential of PET bottles in the marine environment: An ATR-FTIR based approach. Sci. Rep. 2016, 6, 23501. [Google Scholar] [CrossRef]

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the gap for bioplastic use in food packaging: An update. Environ. Sci. Technol. 2020, 54, 4712–4732. [Google Scholar] [CrossRef]

- Delacuvellerie, A.; Cyriaque, V.; Gobert, S.; Benali, S.; Wattiez, R. The plastisphere in marine ecosystem hosts potential specific microbial degraders including Alcanivorax borkumensis as a key player for the low-density polyethylene degradation. J. Hazard. Mater. 2019, 380, 120899. [Google Scholar] [CrossRef] [PubMed]

- Scheper, T.; Faurie, R.; Thommel, J. Advances in Biochemical Engineering/Biotechnology: Food Biotechnology; Springer: Berlin/Heidelberg, Germany, 2008; p. 109. [Google Scholar] [CrossRef]

- Jiménez, L.; Mena, M.; Prendiz, J.; Salas, L.; Vega-Baudrit, J. Polylactic acid (PLA) as a bioplastic and its possible applications in the food industry. J. Food Sci. Nutr. 2019, 5, 2–6. [Google Scholar] [CrossRef]

- Jeremic, S.; Milovanovic, J.; Mojicevic, M.; Bogojevic, S.S.; Nikodinovic-Runic, J. Understanding bioplastic materials–Current state and trends. J. Serb. Chem. Soc. 2020, 85, 1507–1538. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics. Facts and Figures; European Bioplastics: Berlin, Germany, 2021; p. 16. [Google Scholar]

- Jadhav, E.B.; Sankhla, M.S.; Bhat, R.A.; Bhagat, D. Microplastics from food packaging: An overview of human consumption, health threats, and alternative solutions. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100608. [Google Scholar] [CrossRef]

- Morão, A.; De Bie, F. Life cycle impact assessment of polylactic acid (PLA) produced from sugarcane in Thailand. J. Polym. Environ. 2019, 27, 2523–2539. [Google Scholar] [CrossRef]

- Leja, K.; Lewandowicz, G. Polymer biodegradation and biodegradable polymers—A review. Pol. J. Environ. Stud. 2010, 19, 255–266. [Google Scholar]

- Carbonell-Verdu, A.; Samper, M.D.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Plasticization effect of epoxidized cottonseed oil (ECSO) on poly (lactic acid). Ind. Crops Prod. 2017, 104, 278–286. [Google Scholar] [CrossRef]

- Murariu, M.; Ferreira, A.D.S.; Pluta, M.; Bonnaud, L.; Alexandre, M.; Dubois, P. Polylactide (PLA)–CaSO4 composites toughened with low molecular weight and polymeric ester-like plasticizers and related performances. Eur. Polym. J. 2008, 44, 3842–3852. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, S.; Chen, H.; Wang, S.; Nie, K.; Li, Z. Effects of poly (ethylene glycol) grafted silica nanoparticles on crystallization behavior of poly (d-lactide). Polym. Int. 2015, 64, 1066–1071. [Google Scholar] [CrossRef]

- Hassouna, F.; Raquez, J.-M.; Addiego, F.; Dubois, P.; Toniazzo, V.; Ruch, D. New approach on the development of plasticized polylactide (PLA): Grafting of poly (ethylene glycol)(PEG) via reactive extrusion. Eur. Polym. J. 2011, 47, 2134–2144. [Google Scholar] [CrossRef]

- Teixeira, E.d.M.; Curvelo, A.A.; Corrêa, A.C.; Marconcini, J.M.; Glenn, G.M.; Mattoso, L.H. Properties of thermoplastic starch from cassava bagasse and cassava starch and their blends with poly (lactic acid). Ind. Crops Prod. 2012, 37, 61–68. [Google Scholar] [CrossRef]

- Müller, P.; Bere, J.; Fekete, E.; Móczó, J.; Nagy, B.; Kállay, M.; Gyarmati, B.; Pukánszky, B. Interactions, structure and properties in PLA/plasticized starch blends. Polymer 2016, 103, 9–18. [Google Scholar] [CrossRef]

- Nofar, M.; Tabatabaei, A.; Sojoudiasli, H.; Park, C.; Carreau, P.; Heuzey, M.-C.; Kamal, M. Mechanical and bead foaming behavior of PLA-PBAT and PLA-PBSA blends with different morphologies. Eur. Polym. J. 2017, 90, 231–244. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Ferri, J.; Dominici, F.; Boronat, T.; Sanchez-Nacher, L.; Balart, R.; Torre, L. Manufacturing and compatibilization of PLA/PBAT binary blends by cottonseed oil-based derivatives. Express Polym. Lett. 2018, 12, 808–823. [Google Scholar] [CrossRef]

- Gonzalez, L.; Agüero, A.; Quiles-Carrillo, L.; Lascano, D.; Montanes, N. Optimization of the loading of an environmentally friendly compatibilizer derived from linseed oil in poly (lactic acid)/diatomaceous earth composites. Materials 2019, 12, 1627. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Candela, I.; Gomez-Caturla, J.; Cardona, S.; Lora-García, J.; Fombuena, V. Novel compatibilizers and plasticizers developed from epoxidized and maleinized chia oil in composites based on PLA and chia seed flour. Eur. Polym. J. 2022, 173, 111289. [Google Scholar] [CrossRef]

- Meier, M.A.; Metzger, J.O.; Schubert, U.S. Plant oil renewable resources as green alternatives in polymer science. Chem. Soc. Rev. 2007, 36, 1788–1802. [Google Scholar] [CrossRef]

- Maisonneuve, L.; Lebarbé, T.; Grau, E.; Cramail, H. Structure–properties relationship of fatty acid-based thermoplastics as synthetic polymer mimics. Polym. Chem. 2013, 4, 5472–5517. [Google Scholar] [CrossRef]

- Louis, G.M.B.; Sundaram, R.; Sweeney, A.M.; Schisterman, E.F.; Maisog, J.; Kannan, K. Urinary bisphenol A, phthalates, and couple fecundity: The Longitudinal Investigation of Fertility and the Environment (LIFE) Study. Fertil. Steril. 2014, 101, 1359–1366. [Google Scholar] [CrossRef]

- Liao, C.; Liu, F.; Alomirah, H.; Loi, V.D.; Mohd, M.A.; Moon, H.-B.; Nakata, H.; Kannan, K. Bisphenol S in urine from the United States and seven Asian countries: Occurrence and human exposures. Environ. Sci. Technol. 2012, 46, 6860–6866. [Google Scholar] [CrossRef]

- Dominguez-Candela, I.; Ferri, J.M.; Cardona, S.C.; Lora, J.; Fombuena, V. Dual plasticizer/thermal stabilizer effect of epoxidized chia seed oil (Salvia hispanica l.) to improve ductility and thermal properties of poly (lactic acid). Polymers 2021, 13, 1283. [Google Scholar] [CrossRef]

- Janković, M.R.; Govedarica, O.M.; Sinadinović-Fišer, S.V. The epoxidation of linseed oil with in situ formed peracetic acid: A model with included influence of the oil fatty acid composition. Ind. Crops Prod. 2020, 143, 111881. [Google Scholar] [CrossRef]

- Danov, S.; Kazantsev, O.; Esipovich, A.; Belousov, A.; Rogozhin, A.; Kanakov, E. Recent advances in the field of selective epoxidation of vegetable oils and their derivatives: A review and perspective. Catal. Sci. Technol. 2017, 7, 3659–3675. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Xiong, Z.; Yang, Y.; Feng, J.; Zhang, X.; Zhang, C.; Tang, Z.; Zhu, J. Preparation and characterization of poly (lactic acid)/starch composites toughened with epoxidized soybean oil. Carbohydr. Polym. 2013, 92, 810–816. [Google Scholar] [CrossRef]

- Balart, J.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Qu, J.P. Mechanical and rheological properties of epoxidized soybean oil plasticized poly (lactic acid). J. Appl. Polym. Sci. 2009, 112, 3185–3191. [Google Scholar] [CrossRef]

- Torres, F.G.; Gonzales, K.N.; Troncoso, O.P.; Chávez, J.; De-la-Torre, G.E. Sustainable applications of lignocellulosic residues from the production of Brazil nut in the Peruvian Amazon. Environ. Qual. Manag. 2022, 31, 291–300. [Google Scholar] [CrossRef]

- Lima, C.R.R.d.C.; López-García, P.; Tavares, V.F.; Almeida, M.M.d.; Zanolini, C.; Aurora-Prado, M.S.; Santoro, M.I.R.M.; Kedor-Hackamnn, E. Separation and identification of fatty acids in cosmetic formulations containing Brazil nut oil by capillary electrophoresis. Rev. Ciências Farm. Básica Apl. 2011, 32, 341–348. [Google Scholar]

- Cornelio-Santiago, H.P.; Bodini, R.B.; de Oliveira, A.L. Potential of oilseeds native to Amazon and Brazilian Cerrado Biomes: Benefits, chemical and functional properties, and extraction methods. J. Am. Oil Chem. Soc. 2021, 98, 3–20. [Google Scholar] [CrossRef]

- Chunhieng, T.; Hafidi, A.; Pioch, D.; Brochier, J.; Didier, M. Detailed study of Brazil nut (Bertholletia excelsa) oil micro-compounds: Phospholipids, tocopherols and sterols. J. Braz. Chem. Soc. 2008, 19, 1374–1380. [Google Scholar] [CrossRef]

- Stoian, D. Cosechando lo que cae: La economía de la castaña (Bertholletia excelsa HBK) en la Amazonía boliviana. Prod. For. Medios Subsist. Y Conserv. 2004, 3, 102. [Google Scholar]

- Coslovsky, S. Economic development without pre-requisites: How Bolivian producers met strict food safety standards and dominated the global Brazil-nut market. World Dev. 2014, 54, 32–45. [Google Scholar] [CrossRef]

- Guariguata, M.R.; Cronkleton, P.; Duchelle, A.E.; Zuidema, P.A. Revisiting the ‘cornerstone of Amazonian conservation’: A socioecological assessment of Brazil nut exploitation. Biodivers. Conserv. 2017, 26, 2007–2027. [Google Scholar] [CrossRef]

- Vink, E.T.; Rabago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to NatureWorks™ polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Muniz, M.A.P.; Dos Santos, M.N.F.; da Costa, C.E.F.; Morais, L.; Lamarão, M.L.N.; Ribeiro-Costa, R.M.; Silva-Júnior, J.O.C. Physicochemical characterization, fatty acid composition, and thermal analysis of Bertholletia excelsa HBK oil. Pharmacogn. Mag. 2015, 11, 147. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Bernardi, L.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Development of environmentally friendly composite matrices from epoxidized cottonseed oil. Eur. Polym. J. 2015, 63, 1–10. [Google Scholar] [CrossRef]

- Sempere-Torregrosa, J.; Ferri, J.M.; de la Rosa-Ramírez, H.; Pavon, C.; Samper, M.D. Effect of Epoxidized and Maleinized Corn Oil on Properties of Polylactic Acid (PLA) and Polyhydroxybutyrate (PHB) Blend. Polymers 2022, 14, 4205. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Arrieta, M.; López-Martínez, J.; Samper, M. Improvement of PLA film ductility by plasticization with epoxidized karanja oil. Polym. Degrad. Stab. 2020, 179, 109259. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized Jatropha Oil as a Sustainable Plasticizer to Poly(lactic Acid). Polymers 2017, 9, 204. [Google Scholar] [CrossRef] [PubMed]

- Awale, R.J.; Ali, F.B.; Azmi, A.S.; Puad, N.I.M.; Anuar, H.; Hassan, A. Enhanced flexibility of biodegradable polylactic acid/starch blends using epoxidized palm oil as plasticizer. Polymers 2018, 10, 977. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Campo, M.J.; Quiles-Carrillo, L.; Masia, J.; Reig-Pérez, M.J.; Montanes, N.; Balart, R. Environmentally friendly compatibilizers from soybean oil for ternary blends of poly (lactic acid)-PLA, poly (ε-caprolactone)-PCL and poly (3-hydroxybutyrate)-PHB. Materials 2017, 10, 1339. [Google Scholar] [CrossRef]

- Yong, A.X.; Sims, G.D.; Gnaniah, S.J.; Ogin, S.L.; Smith, P.A. Heating rate effects on thermal analysis measurement of T g in composite materials. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 43–51. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized vegetable oils plasticized poly (lactic acid) biocomposites: Mechanical, thermal and morphology properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Montanes, N.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil as biobased plasticizer in poly (lactic acid)-based formulations. Polym. Int. 2017, 66, 882–891. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly (lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef]

- Gil-Castell, O.; Badia, J.; Kittikorn, T.; Strömberg, E.; Martínez-Felipe, A.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Hydrothermal ageing of polylactide/sisal biocomposites. Studies of water absorption behaviour and Physico-Chemical performance. Polym. Degrad. Stab. 2014, 108, 212–222. [Google Scholar] [CrossRef]

- Ray, S.S.; Yamada, K.; Ogami, A.; Okamoto, M.; Ueda, K. New polylactide/layered silicate nanocomposite: Nanoscale control over multiple properties. Macromol. Rapid Commun. 2002, 23, 943–947. [Google Scholar] [CrossRef]

- Lerma-Canto, A.; Gomez-Caturla, J.; Herrero-Herrero, M.; Garcia-Garcia, D.; Fombuena, V. Development of polylactic acid thermoplastic starch formulations using maleinized hemp oil as biobased plasticizer. Polymers 2021, 13, 1392. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, D.; Fenollar, O.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of Mechanical Ductile Properties of Poly (3-hydroxybutyrate) by Using Vegetable Oil Derivatives. Macromol. Mater. Eng. 2017, 302, 1600330. [Google Scholar] [CrossRef]

- Balart, J.; Montanes, N.; Fombuena, V.; Boronat, T.; Sánchez-Nacher, L. Disintegration in compost conditions and water uptake of green composites from poly (lactic acid) and hazelnut shell flour. J. Polym. Environ. 2018, 26, 701–715. [Google Scholar] [CrossRef]

| Parts Per Hundred Resin (phr) | ||

|---|---|---|

| Reference | PLA | Epoxidized Brazil Nut Oil (EBNO) |

| PLA | 100 | 0 |

| PLA + 2.5 phr EBNO | 100 | 2.5 |

| PLA + 5 phr EBNO | 100 | 5 |

| PLA + 7.5 phr EBNO | 100 | 7.5 |

| PLA + 10 phr EBNO | 100 | 10 |

| Samples | TGA Parameters | DSC Parameters (2nd Heating) | ||||||

|---|---|---|---|---|---|---|---|---|

| T5% (°C) | Tmax (°C) | Tg (°C) | Tcc (°C) | ΔHc (J g−1) | Tm (°C) | ΔHm (J g−1) | XPLA (%) | |

| PLA | 329.9 | 375.3 | 61.6 | 124.8 | 10.1 | 166.8 | 15.0 | 5.3 |

| PLA + 2.5 phr EBNO | 320.6 | 370.7 | 59.6 | 108.1 | 32.2 | 169.1 | 38.2 | 6.6 |

| PLA + 5 phr EBNO | 311.3 | 368.3 | 58.9 | 104.4 | 30.3 | 167.9 | 40.9 | 12.0 |

| PLA + 7.5 phr EBNO | 325.3 | 366.0 | 57.9 | 98.9 | 21.5 | 166.8 | 44.9 | 27.1 |

| PLA + 10 phr EBNO | 315.9 | 368.3 | 59.8 | 101.9 | 22.3 | 167.3 | 45.1 | 26.7 |

| Samples | HDT (°C) |

|---|---|

| PLA | 59.2 ± 0.5 |

| PLA + 2.5 phr EBNO | 58.8 ± 0.4 |

| PLA + 5 phr EBNO | 58 ± 0.6 |

| PLA + 7.5 phr EBNO | 57.8 ± 0.5 |

| PLA + 10 phr EBNO | 57 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perez-Nakai, A.; Lerma-Canto, A.; Dominguez-Candela, I.; Ferri, J.M.; Fombuena, V. Novel Epoxidized Brazil Nut Oil as a Promising Plasticizing Agent for PLA. Polymers 2023, 15, 1997. https://doi.org/10.3390/polym15091997

Perez-Nakai A, Lerma-Canto A, Dominguez-Candela I, Ferri JM, Fombuena V. Novel Epoxidized Brazil Nut Oil as a Promising Plasticizing Agent for PLA. Polymers. 2023; 15(9):1997. https://doi.org/10.3390/polym15091997

Chicago/Turabian StylePerez-Nakai, Aina, Alejandro Lerma-Canto, Ivan Dominguez-Candela, Jose Miguel Ferri, and Vicent Fombuena. 2023. "Novel Epoxidized Brazil Nut Oil as a Promising Plasticizing Agent for PLA" Polymers 15, no. 9: 1997. https://doi.org/10.3390/polym15091997

APA StylePerez-Nakai, A., Lerma-Canto, A., Dominguez-Candela, I., Ferri, J. M., & Fombuena, V. (2023). Novel Epoxidized Brazil Nut Oil as a Promising Plasticizing Agent for PLA. Polymers, 15(9), 1997. https://doi.org/10.3390/polym15091997