Mechanically Tunable Flexible Photonic Device for Strain Sensing Applications

Abstract

1. Introduction

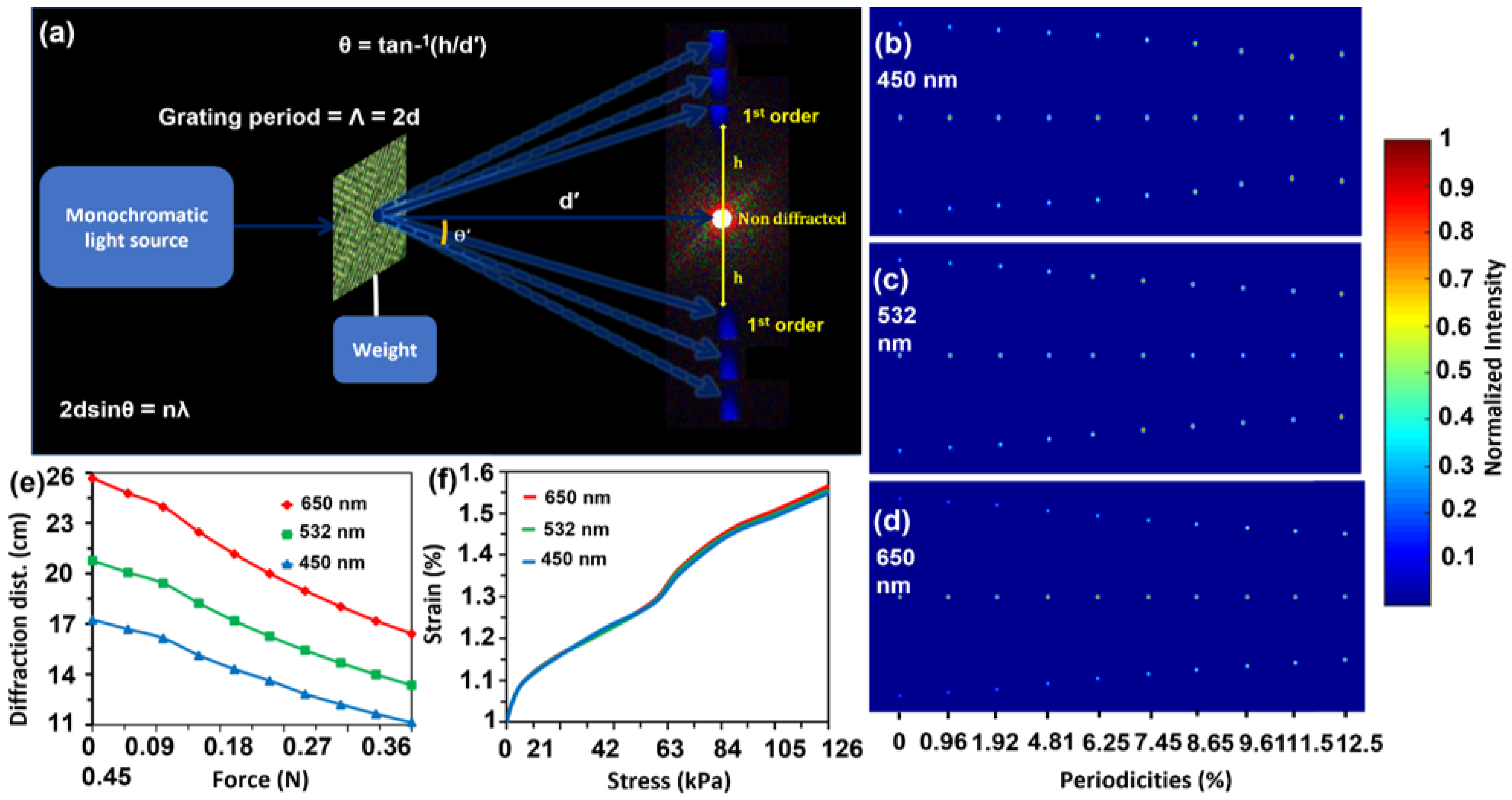

The Diffraction-Based Optical Sensing Scheme

2. Materials and Methods

2.1. Materials and Equipment

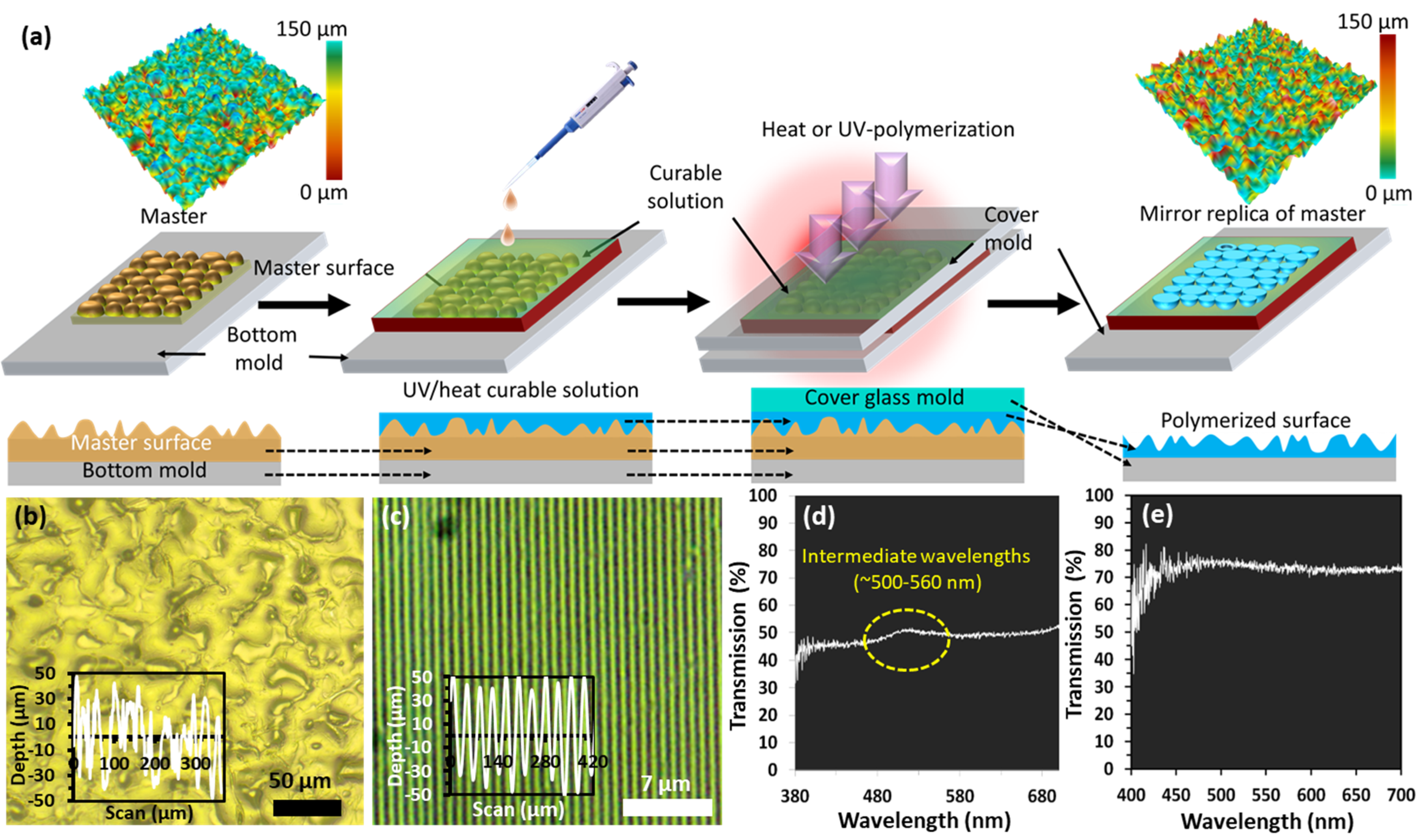

2.2. Fabrication of Flexible Nano/Microstructures

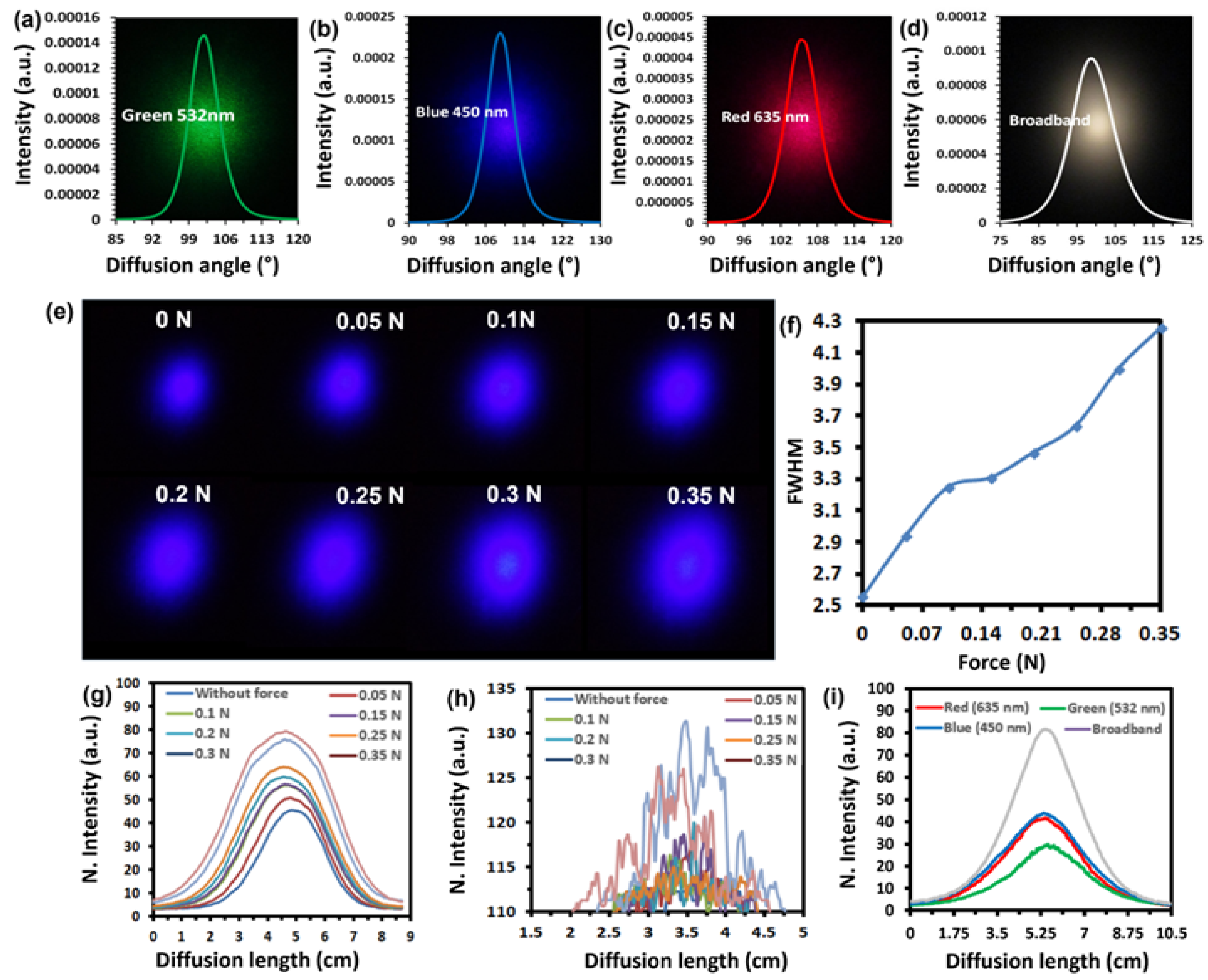

2.3. Optical Characterization and Simulation

3. Results and Discussion

4. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Do, T.N.; Visell, Y. Stretchable, Twisted Conductive Microtubules for Wearable Computing, Robotics, Electronics, and Healthcare. Sci. Rep. 2017, 7, 1753. [Google Scholar] [CrossRef] [PubMed]

- Ahuja, D.; Parande, D. Optical Sensors and Their Applications. In Opto-Mechatronic Systems Handbook; CRC Press: Boca Raton, FL, USA, 2002; pp. 123–148. [Google Scholar]

- Kenry; Yeo, J.C.; Lim, C.T. Emerging Flexible and Wearable Physical Sensing Platforms for Healthcare and Biomedical Applications. Microsyst. Nanoeng. 2016, 2, 16043. [Google Scholar] [CrossRef] [PubMed]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwödiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An Ultra-Lightweight Design for Imperceptible Plastic Electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A Wearable and Highly Sensitive Pressure Sensor with Ultrathin Gold Nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.; Jia, L.; Mathewson, K.E.; Jang, K.-I.; Kim, J.; Fu, H.; Huang, X.; Chava, P.; Wang, R.; et al. Soft Microfluidic Assemblies of Sensors, Circuits, and Radios for the Skin. Science 2014, 344, 70–74. [Google Scholar] [CrossRef]

- Morin, S.A.; Shepherd, R.F.; Kwok, S.W.; Stokes, A.A.; Nemiroski, A.; Whitesides, G.M. Camouflage and Display for Soft Machines. Science 2012, 337, 828–832. [Google Scholar] [CrossRef]

- Araci, I.E.; Su, B.; Quake, S.R.; Mandel, Y. An Implantable Microfluidic Device for Self-Monitoring of Intraocular Pressure. Nat. Med. 2014, 20, 1074–1078. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.N.; Chen, W.P. Crescent Shaped Fabry-Perot Fiber Cavity for Ultra-Sensitive Strain Measurement. Sci. Rep. 2016, 6, 38390. [Google Scholar] [CrossRef]

- Liu, S.; Yang, K.; Wang, Y.; Qu, J.; Liao, C.; He, J.; Li, Z.; Yin, G.; Sun, B.; Zhou, J.; et al. High-Sensitivity Strain Sensor Based on in-Fiber Rectangular Air Bubble. Sci. Rep. 2015, 5, 7624. [Google Scholar] [CrossRef]

- Ding, W.; Jiang, Y.; Gao, R.; Liu, Y. High-Temperature Fiber-Optic Fabry-Perot Interferometric Sensors. Rev. Sci. Instrum. 2015, 86, 055001. [Google Scholar] [CrossRef]

- Sherlock, T.; Nasrullah, A.; Litvinov, J.; Cacao, E.; Knoop, J.; Kemper, S.; Kourentzi, K.; Kar, A.; Ruchhoeft, P.; Willson, R. Suspended, Micron-Scale Corner Cube Retroreflectors as Ultra-Bright Optical Labels. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2011, 29, 06FA01. [Google Scholar] [CrossRef]

- Lou, Y.; Wang, H.; Liu, Q.; Shi, Y.; He, S. Analysis and Fabrication of Corner Cube Array Based on Laser Direct Writing Technology. Appl. Opt. 2010, 49, 5567. [Google Scholar] [CrossRef]

- Shaar, N.S.; Barbastathis, G.; Livermore, C. Integrated Folding, Alignment, and Latching for Reconfigurable Origami Microelectromechanical Systems. J. Microelectromech. Syst. 2015, 24, 1043–1051. [Google Scholar] [CrossRef]

- Khalid, M.W.; Ahmed, R.; Yetisen, A.K.; AlQattan, B.; Butt, H. Holographic Writing of Ink-Based Phase Conjugate Nanostructures via Laser Ablation. Sci. Rep. 2017, 7, 10603. [Google Scholar] [CrossRef]

- Jolic, K.I.; Ghantasala, M.K.; Harvey, E.C. Excimer Laser Machining of Corner Cube Structures. J. Micromech. Microeng. 2004, 14, 388–397. [Google Scholar] [CrossRef]

- Yuan, J.; Chang, S.; Li, S.; Zhang, Y. Design and Fabrication of Micro-Cube-Corner Array Retro-Reflectors. Opt. Commun. 2002, 209, 75–83. [Google Scholar] [CrossRef]

- Ahmed, R.; Rifat, A.A.; Hassan, M.U.; Yetisen, A.K.; Butt, H. Phase-Conjugated Directional Diffraction from a Retroreflector Array Hologram. RSC Adv. 2017, 7, 25657–25664. [Google Scholar] [CrossRef]

- Ahmed, R.; Yetisen, A.K.; Yun, S.H.; Butt, H. Color-Selective Holographic Retroreflector Array for Sensing Applications. Light Sci. Appl. 2017, 6, e16214. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, R.; Yetisen, A.K.; El Khoury, A.; Butt, H. Printable Ink Lenses, Diffusers, and 2D Gratings. Nanoscale 2017, 9, 266–276. [Google Scholar] [CrossRef]

- Ahmad, Z.; Rahman, A.M.N.A.A. Plastics in Waveguide Application. In Encyclopedia of Materials: Plastics and Polymers; Elsevier: Amsterdam, The Netherlands, 2022; pp. 295–315. [Google Scholar]

- Nur, O.; Willander, M. Conventional Nanofabrication Methods. In Low Temperature Chemical Nanofabrication; Elsevier: Amsterdam, The Netherlands, 2020; pp. 49–86. ISBN 978-0-12-813345-3. [Google Scholar]

- Zhao, Q.; Yetisen, A.K.; Sabouri, A.; Yun, S.H.; Butt, H. Printable Nanophotonic Devices via Holographic Laser Ablation. ACS Nano 2015, 9, 9062–9069. [Google Scholar] [CrossRef]

- Yu, Z.; Raman, A.; Fan, S. Fundamental Limit of Light Trapping in Grating Structures. Opt. Express 2010, 18, A366. [Google Scholar] [CrossRef] [PubMed]

- Rößler, F.; Kunze, T.; Lasagni, A.F. Fabrication of Diffraction Based Security Elements Using Direct Laser Interference Patterning. Opt. Express 2017, 25, 22959. [Google Scholar] [CrossRef] [PubMed]

- Tay, S.; Blanche, P.-A.; Voorakaranam, R.; Tunç, A.V.; Lin, W.; Rokutanda, S.; Gu, T.; Flores, D.; Wang, P.; Li, G.; et al. An Updatable Holographic Three-Dimensional Display. Nature 2008, 451, 694–698. [Google Scholar] [CrossRef] [PubMed]

- Blanche, P.-A.; Bablumian, A.; Voorakaranam, R.; Christenson, C.; Lin, W.; Gu, T.; Flores, D.; Wang, P.; Hsieh, W.-Y.; Kathaperumal, M.; et al. Holographic Three-Dimensional Telepresence Using Large-Area Photorefractive Polymer. Nature 2010, 468, 80–83. [Google Scholar] [CrossRef]

- Ge, D.; Shi, J.; Rezk, A.; Ma, C.; Zhang, L.; Yang, P.; Zhu, S. Two-Dimensional Hole-Array Grating-Coupling-Based Excitation of Bloch Surface Waves for Highly Sensitive Biosensing. Nanoscale Res. Lett. 2019, 14, 1–9. [Google Scholar] [CrossRef]

- Esposito, F.; Sansone, L.; Srivastava, A.; Baldini, F.; Campopiano, S.; Chiavaioli, F.; Giordano, M.; Giannetti, A.; Iadicicco, A. Long Period Grating in Double Cladding Fiber Coated with Graphene Oxide as High-Performance Optical Platform for Biosensing. Biosens. Bioelectron. 2021, 172, 112747. [Google Scholar] [CrossRef]

- Alqurashi, T.; Penchev, P.; Yetisen, A.K.; Sabouri, A.; Ameen, R.M.; Dimov, S.; Butt, H. Femtosecond Laser Directed Fabrication of Optical Diffusers. RSC Adv. 2017, 7, 18019–18023. [Google Scholar] [CrossRef]

- AlQattan, B.; Doocey, J.; Ali, M.; Ahmed, I.; Salih, A.E.; Alam, F.; Bajgrowicz-Cieslak, M.; Yetisen, A.K.; Elsherif, M.; Butt, H. Direct Printing of Nanostructured Holograms on Consumable Substrates. ACS Nano 2021, 15, 2340–2349. [Google Scholar] [CrossRef]

- Ahmed, I.; Elsherif, M.; Park, S.; Yetisen, A.K.; Butt, H. Nanostructured Photonic Hydrogels for Real-Time Alcohol Detection. ACS Appl. Nano Mater. 2022, 5, 7744–7753. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Alqattan, B.; Benton, D.; Yetisen, A.K.; Butt, H. Conformable Holographic Photonic Ink Sensors Based on Adhesive Tapes for Strain Measurements. ACS Appl. Mater. Interfaces 2019, 11, 29147–29157. [Google Scholar] [CrossRef]

- Butt, H.; AlQattan, B. Printing Nanostructure Holograms on Contact Lenses via Direct Laser Ablation. Procedia CIRP 2022, 113, 594–598. [Google Scholar] [CrossRef]

- Tang, H.; Alqattan, B.; Jackson, T.; Pikramenou, Z.; Sun, X.W.; Wang, K.; Butt, H. Cost-Efficient Printing of Graphene Nanostructures on Smart Contact Lenses. ACS Appl. Mater. Interfaces 2020, 12, 10820–10828. [Google Scholar] [CrossRef]

- Godwin, E.W. Tension. In Mechanical Testing of Advanced Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2000; pp. 43–74. [Google Scholar]

- Hodgkinson, J.M. Testing the Strength and Stiffness of Polymer Matrix Composites. In Failure Mechanisms in Polymer Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2012; pp. 129–182. [Google Scholar]

- Chen, X.; Xiang, D.; Li, J.; Zhang, X.; Harkin-Jones, E.; Wu, Y.; Zhao, C.; Li, H.; Li, Z.; Wang, P.; et al. Flexible Strain Sensors with Enhanced Sensing Performance Prepared from Biaxially Stretched Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. ACS Appl. Electron. Mater. 2022, 4, 3071–3079. [Google Scholar] [CrossRef]

- Han, F.; Li, M.; Ye, H.; Zhang, G. Materials, Electrical Performance, Mechanisms, Applications, and Manufacturing Approaches for Flexible Strain Sensors. Nanomaterials 2021, 11, 1220. [Google Scholar] [CrossRef]

- Johnston, I.D.; Tracey, M.C.; Davis, J.B.; Tan, C.K.L. Micro Throttle Pump Employing Displacement Amplification in an Elastomeric Substrate. J. Micromech. Microeng. 2005, 15, 1831–1839. [Google Scholar] [CrossRef]

- Dardouri, M.; Bettencourt, A.; Martin, V.; Carvalho, F.A.; Santos, C.; Monge, N.; Santos, N.C.; Fernandes, M.H.; Gomes, P.S.; Ribeiro, I.A.C. Using Plasma-Mediated Covalent Functionalization of Rhamnolipids on Polydimethylsiloxane towards the Antimicrobial Improvement of Catheter Surfaces. Biomater. Adv. 2022, 134, 112563. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar Sahani, A. Role of Superhydrophobic Coatings in Biomedical Applications. Mater. Today Proc. 2021, 45, 5655–5659. [Google Scholar] [CrossRef]

- Wu, X.; Kim, S.-H.; Ji, C.-H.; Allen, M.G. A Solid Hydraulically Amplified Piezoelectric Microvalve. J. Micromech. Microeng. 2011, 21, 095003. [Google Scholar] [CrossRef]

- Bozukova, D.; Pagnoulle, C.; Jérôme, R.; Jérôme, C. Polymers in Modern Ophthalmic Implants—Historical Background and Recent Advances. Mater. Sci. Eng. R Rep. 2010, 69, 63–83. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A.; Camino, G. Organosilicon Compounds as Polymer Fire Retardants. In Polymer Green Flame Retardants; Elsevier: Amsterdam, The Netherlands, 2014; pp. 389–418. ISBN 9780444538093. [Google Scholar]

- Mata, A.; Fleischman, A.J.; Roy, S. Characterization of Polydimethylsiloxane (PDMS) Properties for Biomedical Micro/Nanosystems. Biomed. Microdevices 2005, 7, 281–293. [Google Scholar] [CrossRef] [PubMed]

- Johnston, I.D.; McCluskey, D.K.; Tan, C.K.L.; Tracey, M.C. Mechanical Characterization of Bulk Sylgard 184 for Microfluidics and Microengineering. J. Micromech. Microeng. 2014, 24, 035017. [Google Scholar] [CrossRef]

- Kamal, I.; Razak, H.R.A.; Abdul Karim, M.K.; Mashohor, S.; Liew, J.Y.C.; Low, Y.J.; Zaaba, N.A.; Norkhairunnisa, M.; Rafi, N.A.S.M. Mechanical and Imaging Properties of a Clinical-Grade Kidney Phantom Based on Polydimethylsiloxane and Elastomer. Polymers 2022, 14, 535. [Google Scholar] [CrossRef]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent Compatibility of Poly(Dimethylsiloxane)-Based Microfluidic Devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef] [PubMed]

- Greegor, R.B.; Parazzoli, C.G.; Li, K.; Tanielian, M.H. Origin of Dissipative Losses in Negative Index of Refraction Materials. Appl. Phys. Lett. 2003, 82, 2356–2358. [Google Scholar] [CrossRef]

- Khodasevych, I.E.; Shah, C.M.; Sriram, S.; Bhaskaran, M.; Withayachumnankul, W.; Ung, B.S.Y.; Lin, H.; Rowe, W.S.T.; Abbott, D.; Mitchell, A. Elastomeric Silicone Substrates for Terahertz Fishnet Metamaterials. Appl. Phys. Lett. 2012, 100, 061101. [Google Scholar] [CrossRef]

- Chen, D.; Timperman, A.T. Analyte Enrichment via Ion Concentration Polarization with Hydrogel Plugs Polymerized in PDMS Microchannels by a Facile and Comprehensive Method for Improved Polymerization. Anal. Chem. 2022, 94, 15586–15594. [Google Scholar] [CrossRef]

- Chen, W.; Lam, R.H.W.; Fu, J. Photolithographic Surface Micromachining of Polydimethylsiloxane (PDMS). Lab Chip 2012, 12, 391–395. [Google Scholar] [CrossRef]

- Liu, M.; Sun, J.; Sun, Y.; Bock, C.; Chen, Q. Thickness-Dependent Mechanical Properties of Polydimethylsiloxane Membranes. J. Micromech. Microeng. 2009, 19, 035028. [Google Scholar] [CrossRef]

- Pan, C.T.; Chen, Y.C.; Lin, P.-H.; Hsieh, C.C.; Hsu, F.T.; Lin, P.-H.; Chang, C.M.; Hsu, J.H.; Huang, J.C. Lens of Controllable Optical Field with Thin Film Metallic Glasses for UV-LEDs. Opt. Express 2014, 22, 14411. [Google Scholar] [CrossRef]

- Khalid, M.W.; Ahmed, R.; Yetisen, A.K.; Butt, H. Flexible Corner Cube Retroreflector Array for Temperature and Strain Sensing. RSC Adv. 2018, 8, 7588–7598. [Google Scholar] [CrossRef]

- Erdogan, T. Fiber Grating Spectra. J. Light. Technol. 1997, 15, 1277–1294. [Google Scholar] [CrossRef]

- Stover, J.C. Optical Scattering: Measurement and Analysis; SPIE: Bellingham, WA, USA, 1995; ISBN 9780819477767. [Google Scholar]

- van de Hulst, H.C. Light Scattering by Small Particles. Q. J. R. Meteorol. Soc. 1958, 84, 198–199. [Google Scholar] [CrossRef]

- Yetisen, A.K.; Butt, H.; da Cruz Vasconcellos, F.; Montelongo, Y.; Davidson, C.A.B.; Blyth, J.; Chan, L.; Carmody, J.B.; Vignolini, S.; Steiner, U.; et al. Light-Directed Writing of Chemically Tunable Narrow-Band Holographic Sensors. Adv. Opt. Mater. 2014, 2, 250–254. [Google Scholar] [CrossRef]

- Jin, C.; Ma, C.; Yang, Z.; Lin, H. A Force Measurement Method Based on Flexible PDMS Grating. Appl. Sci. 2020, 10, 2296. [Google Scholar] [CrossRef]

- Kim, Y.J.; Yoo, Y.J.; Kang, M.H.; Ko, J.H.; Park, M.R.; Yoo, D.E.; Lee, D.W.; Kim, K.; Kang, I.S.; Song, Y.M. Mechanotunable Optical Filters Based on Stretchable Silicon Nanowire Arrays. Nanophotonics 2020, 9, 3287–3293. [Google Scholar] [CrossRef]

- Wiącek, A.E.; Gozdecka, A.; Jurak, M. Physicochemical Characteristics of Chitosan–TiO 2 Biomaterial. 1. Stability and Swelling Properties. Ind. Eng. Chem. Res. 2018, 57, 1859–1870. [Google Scholar] [CrossRef]

- Gu, R.; Ji, M.; Xuan, Y.; Cui, Y.; Yuan, C.; Li, W.D.; Ge, H.; Chen, Y. Stretching-Tunable Metal Gratings Fabricated on an Elastomeric Substrate Using a Water-Soluble Sacrificial Layer. Appl. Phys. A Mater. Sci. Process. 2015, 121, 335–341. [Google Scholar] [CrossRef]

- Lim, J.-G.; Kwak, K.; Song, J.-K. Computation of Refractive Index and Optical Retardation in Stretched Polymer Films. Opt. Express 2017, 25, 16409. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.; Khalid, M.W.; Butt, H. Mechanically Tunable Flexible Photonic Device for Strain Sensing Applications. Polymers 2023, 15, 1814. https://doi.org/10.3390/polym15081814

Ali M, Khalid MW, Butt H. Mechanically Tunable Flexible Photonic Device for Strain Sensing Applications. Polymers. 2023; 15(8):1814. https://doi.org/10.3390/polym15081814

Chicago/Turabian StyleAli, Murad, Muhammad Waqas Khalid, and Haider Butt. 2023. "Mechanically Tunable Flexible Photonic Device for Strain Sensing Applications" Polymers 15, no. 8: 1814. https://doi.org/10.3390/polym15081814

APA StyleAli, M., Khalid, M. W., & Butt, H. (2023). Mechanically Tunable Flexible Photonic Device for Strain Sensing Applications. Polymers, 15(8), 1814. https://doi.org/10.3390/polym15081814