In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Foam Fabrication

2.3. Characterisation

3. Results and Discussion

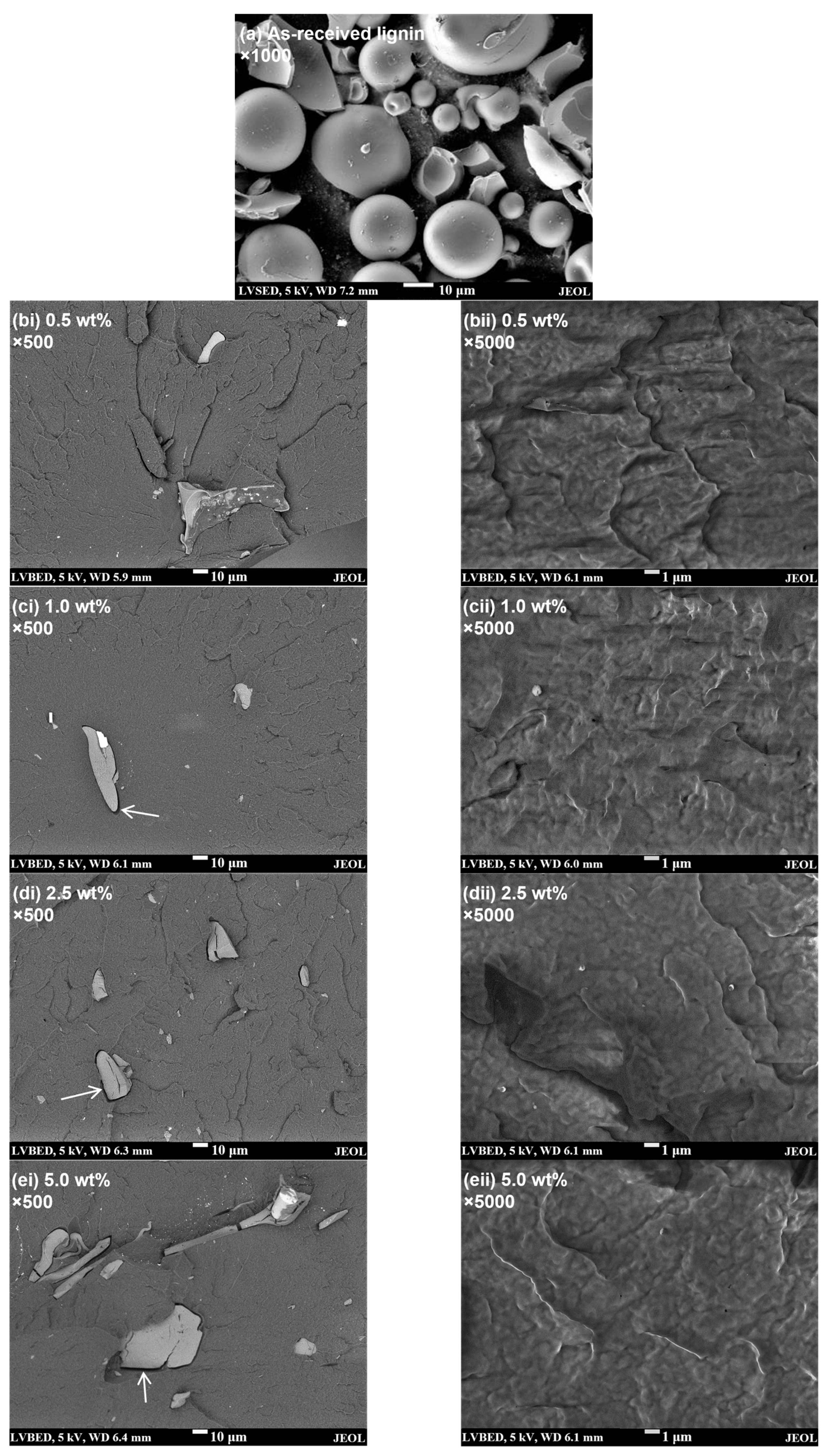

3.1. In Situ Dispersion of Lignin in PP via scCO2 Extrusion Foaming of PP/Lignin

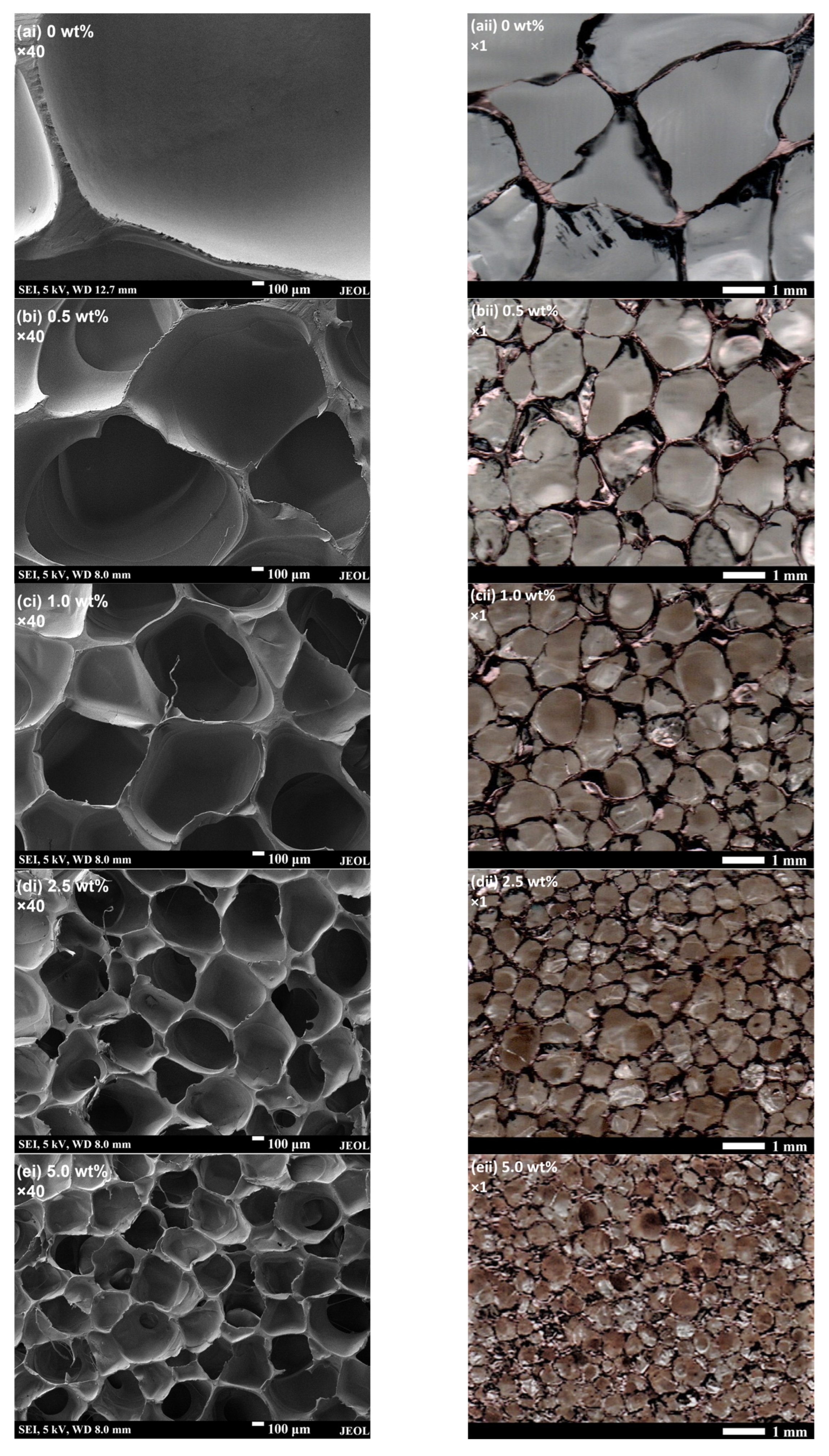

3.2. Nucleating Effect of Lignin in scCO2 Foaming of PP

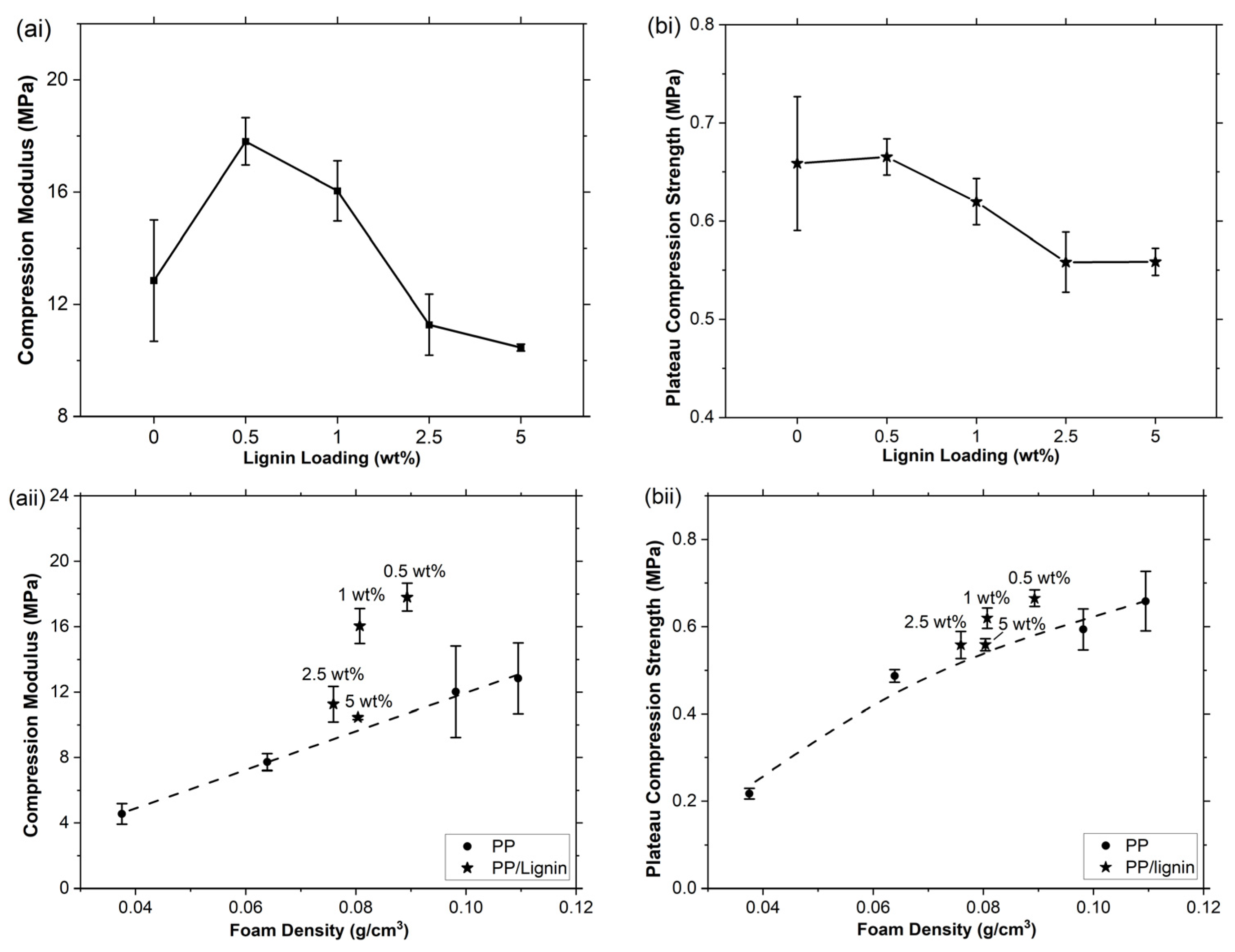

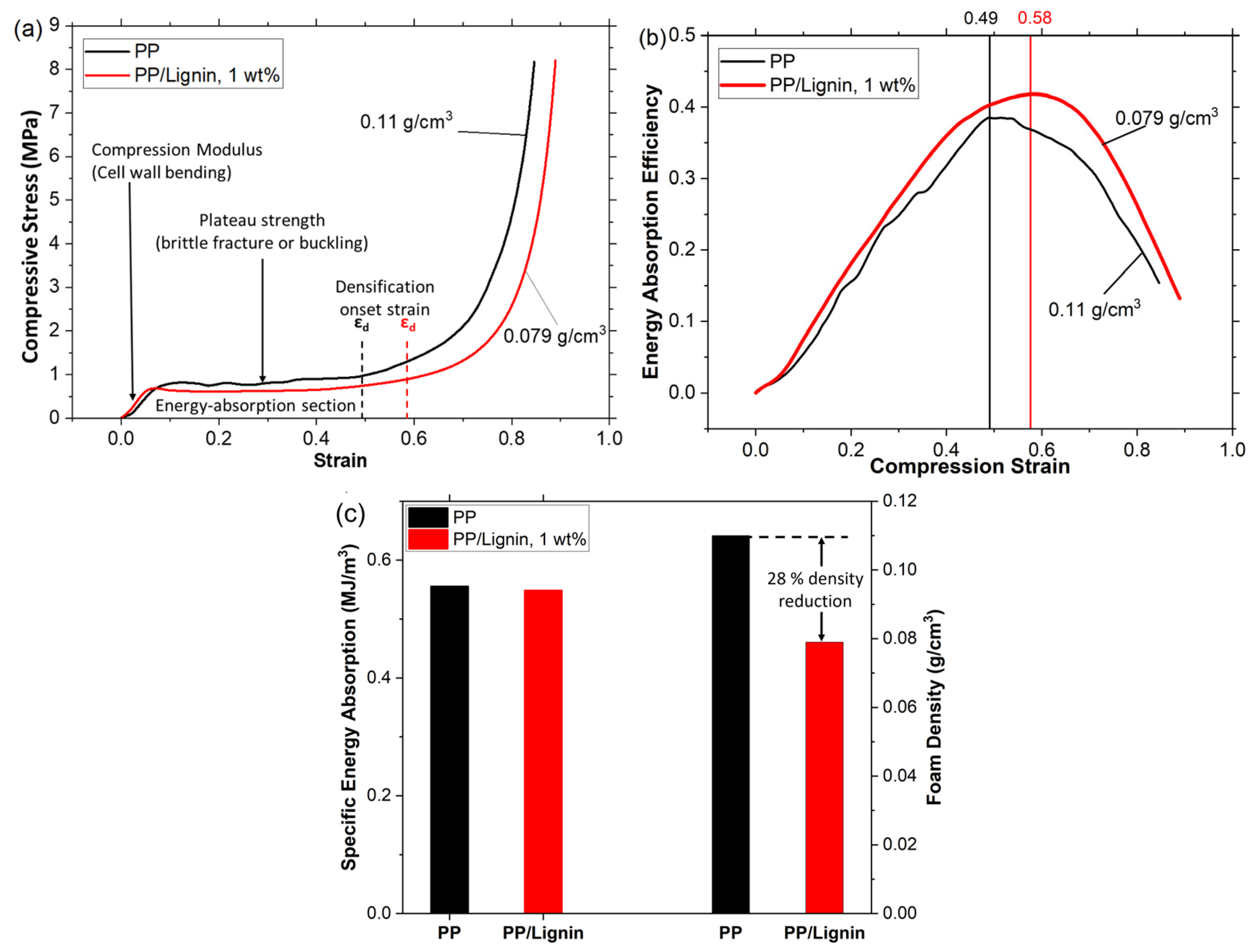

3.3. Compression and Energy Cushioning Properties of the PP/Lignin Foams

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Franco, P.; De Marco, I. Nanoparticles and Nanocrystals by Supercritical CO2-Assisted Techniques for Pharmaceutical Applications: A Review. Appl. Sci. 2021, 11, 1476. [Google Scholar] [CrossRef]

- Luz, S.M.; Caldeira-Pires, A.; Ferrão, P.M.C. Environmental benefits of substituting talc by sugarcane bagasse fibers as reinforcement in polypropylene composites: Ecodesign and LCA as strategy for automotive components. Resour. Conserv. Recycl. 2010, 54, 1135–1144. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, T.; Li, B.; Li, H.; Cao, Z.; Jin, G.; Zhao, L.; Xin, Z. Anti-Shrinking Foaming of Polyethylene with CO2 as Blowing Agent. J. Supercrit. Fluids 2020, 163, 104883. [Google Scholar] [CrossRef]

- Ramachandran, J.P.; Kottammal, A.P.; Antony, A.; Ramakrishnan, R.M.; Wallen, S.L.; Raveendran, P. Green processing: CO2-induced glassification of sucrose octaacetate and its implications in the spontaneous release of drug from drug-excipient composites. J. CO2 Util. 2021, 47, 101472. [Google Scholar] [CrossRef]

- Weingart, N.; Raps, D.; Lu, M.; Endner, L.; Altstädt, V. Comparison of the Foamability of Linear and Long-Chain Branched Polypropylene—The Legend of Strain-Hardening as a Requirement for Good Foamability. Polymers 2020, 12, 725. [Google Scholar] [CrossRef]

- Sauceau, M.; Fages, J.; Common, A.; Nikitine, C.; Rodier, E. New challenges in polymer foaming: A review of extrusion processes assisted by supercritical carbon dioxide. Prog. Polym. Sci. 2011, 36, 749–766. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. High thermal insulation and compressive strength polypropylene foams fabricated by high-pressure foam injection molding and mold opening of nano-fibrillar composites. Mater. Des. 2017, 131, 1–11. [Google Scholar] [CrossRef]

- Leung, S.; Wong, A.; Wang, L.; Park, C. Mechanism of Extensional Stress-Induced Cell Formation in Polymeric Foaming Processes with the Presence of Nucleating Agents. J. Supercrit. Fluids 2012, 63, 187–198. [Google Scholar] [CrossRef]

- Glogic, E.; Claverie, M.; Jubayed; Musumeci, V.; Carême, C.; Martin, F.; Sonnemann, G.; Aymonier, C. Greening Pathways for Synthetic Talc Production Based on the Supercritical Hydrothermal Flow Process. ACS Sustain. Chem. Eng. 2021, 9, 16597–16605. [Google Scholar] [CrossRef]

- Tran, T.; Steffen, J.E.; Clancy, K.M.; Bird, T.; Egilman, D.S. Talc, Asbestos, and Epidemiology: Corporate Influence and Scientific Incognizance. Epidemiology 2019, 30, 783–788. [Google Scholar] [CrossRef]

- Tadele, D.; Roy, P.; Defersha, F.; Misra, M.; Mohanty, A.K. A comparative life-cycle assessment of talc- and biochar-reinforced composites for lightweight automotive parts. Clean Technol. Environ. Policy 2020, 22, 639–649. [Google Scholar] [CrossRef]

- Yang, C.; Wang, M.; Xing, Z.; Zhao, Q.; Wang, M.; Wu, G. A new promising nucleating agent for polymer foaming: Effects of hollow molecular-sieve particles on polypropylene supercritical CO2 microcellular foaming. RSC Adv. 2018, 8, 20061–20067. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B. Lightweight and strong microcellular injection molded PP/talc nanocomposite. Compos. Sci. Technol. 2018, 168, 38–46. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Zhu, W.; Zhou, H.; Weng, Y.; Zhang, A.; Dong, G.; Zhao, G. Lightweight and strong polypropylene/talc/polytetrafluoroethylene foams with enhanced flame-retardant performance fabricated by microcellular foam injection foaming. Mater. Des. 2022, 215, 110539. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, L.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. Development of high thermal insulation and compressive strength BPP foams using mold-opening foam injection molding with in-situ fibrillated PTFE fibers. Eur. Polym. J. 2018, 98, 1–10. [Google Scholar] [CrossRef]

- Qiang, W.; Zhao, L.; Gao, X.; Liu, T.; Liu, Z.; Yuan, W.-K.; Hu, D. Dual role of PDMS on improving supercritical CO2 foaming of polypropylene: CO2-philic additive and crystallization nucleating agent. J. Supercrit. Fluids 2020, 163, 104888. [Google Scholar] [CrossRef]

- Liu, S.; Yin, S.; Duvigneau, J.; Vancso, G.J. Bubble seeding nanocavities: Multiple polymer foam cell nucleation by polydimethylsiloxane-grafted designer silica nanoparticles. ACS Nano. 2020, 14, 1623–1634. [Google Scholar] [CrossRef] [PubMed]

- Dias, O.A.T.; Sain, M.; Cesarino, I.; Leão, A.L. Development of high bio-content polypropylene composites with different industrial lignins. Polym. Adv. Technol. 2018, 30, 70–78. [Google Scholar] [CrossRef]

- Wypych, A. Lignin. In Databook of Adhesion Promoters; ChemTec Publishing: Toronto, ON, Canada, 2018; p. 161. [Google Scholar] [CrossRef]

- Sugiarto, S.; Leow, Y.; Tan, C.L.; Wang, G.; Kai, D. How far is Lignin from being a biomedical material? Bioact. Mater. 2021, 8, 71–94. [Google Scholar] [CrossRef]

- Ibrahim, M.N.M.; Iqbal, A.; Shen, C.C.; Bhawani, S.A.; Adam, F. Synthesis of lignin based composites of TiO2 for potential application as radical scavengers in sunscreen formulation. BMC Chem. 2019, 13, 17. [Google Scholar] [CrossRef]

- Ridho, M.R.; Agustiany, E.A.; Dn, M.R.; Madyaratri, E.W.; Ghozali, M.; Restu, W.K.; Falah, F.; Lubis, M.A.R.; Syamani, F.A.; Nurhamiyah, Y.; et al. Lignin as Green Filler in Polymer Composites: Development Methods, Characteristics, and Potential Applications. Adv. Mater. Sci. Eng. 2022, 2022, 1363481. [Google Scholar] [CrossRef]

- Yeo, J.-S.; Seong, D.-W.; Hwang, S.-H. Chemical surface modification of lignin particle and its application as filler in the polypropylene composites. J. Ind. Eng. Chem. 2015, 31, 80–85. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, M. Maleic anhydride-modified polyolefins as compatibilizer for lignin-reinforced polypropylene composites. Polym. Compos. 2018, 40, 2594–2601. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, W.; Xin, Z.; Zhao, S.; Shi, Y. Relationship between molecular structure, crystallization behavior, and mechanical properties of long chain branching polypropylene. J. Mater. Sci. 2016, 51, 5598–5608. [Google Scholar] [CrossRef]

- Azdast, T.; Hasanzadeh, R. Increasing cell density/decreasing cell size to produce microcellular and nanocellular thermoplastic foams: A review. J. Cell. Plast. 2020, 57, 769–797. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Zheng, W.; Park, C.B. A comprehensive review of cell structure variation and general rules for polymer microcellular foams. Chem. Eng. J. 2022, 430, 132662. [Google Scholar] [CrossRef]

- Liu, Q.X.; Zhu, Y.J.; Yang, G.W.; Yang, Q.B. Nucleation Thermodynamics inside Micro/nanocavity. J. Mater. Sci. Technol. 2008, 24, 183–186. [Google Scholar]

- Park, C.B.; Behravesh, A.; Venter, R.D. Low density microcellular foam processing in extrusion using CO2. Polym. Eng. Sci. 1998, 38, 1812–1823. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, W.; Scarpa, F.; Barton, D.; Rankin, K.; Zhu, Y.; Lang, Z.-Q.; Peng, H.-X. Topological characteristics and mechanical properties of uniaxially thermoformed auxetic foam. Mater. Des. 2021, 211, 110139. [Google Scholar] [CrossRef]

- Chen, L.; Rende, D.; Schadler, L.S.; Ozisik, R. Polymer nanocomposite foams. J. Mater. Chem. A 2013, 1, 3837–3850. [Google Scholar] [CrossRef]

- Zhu, Y.; Luo, G.; Zhang, R.; Cao, P.; Liu, Q.; Zhang, J.; Sun, Y.; Li, J.; Shen, Q.; Zhang, L. Numerical simulation of static mechanical properties of PMMA microcellular foams. Compos. Sci. Technol. 2020, 192, 108110. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, J.; Ling, Y.; Yao, S.; Jiang, X.; Hu, D.; Wang, H.; Zhao, L. Comprehensive analysis of mechanical properties of microcellular polypropylene: Experiment and simulation. Polym. Test. 2022, 116, 107812. [Google Scholar] [CrossRef]

- Chen, Y.; Das, R.; Battley, M. Effects of cell size and cell wall thickness variations on the stiffness of closed-cell foams. Int. J. Solids Struct. 2015, 52, 150–164. [Google Scholar] [CrossRef]

- Li, P.; Guo, Y.B.; Zhou, M.W.; Shim, V.P.W. Response of anisotropic polyurethane foam to compression at different loading angles and strain rates. Int. J. Impact Eng. 2019, 127, 154–168. [Google Scholar] [CrossRef]

- Xiao, Y.; Yin, J.; Zhang, X.; An, X.; Xiong, Y.; Sun, Y. Mechanical Performance and Cushioning Energy Absorption Characteristics of Rigid Polyurethane Foam at Low and High Strain Rates. Polym. Test. 2022, 109, 107531. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, K.H.; Lu, X.; Lau, S.K. In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties. Polymers 2023, 15, 1813. https://doi.org/10.3390/polym15081813

Ho KH, Lu X, Lau SK. In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties. Polymers. 2023; 15(8):1813. https://doi.org/10.3390/polym15081813

Chicago/Turabian StyleHo, Keen Hoe, Xuehong Lu, and Soo Khim Lau. 2023. "In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties" Polymers 15, no. 8: 1813. https://doi.org/10.3390/polym15081813

APA StyleHo, K. H., Lu, X., & Lau, S. K. (2023). In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties. Polymers, 15(8), 1813. https://doi.org/10.3390/polym15081813