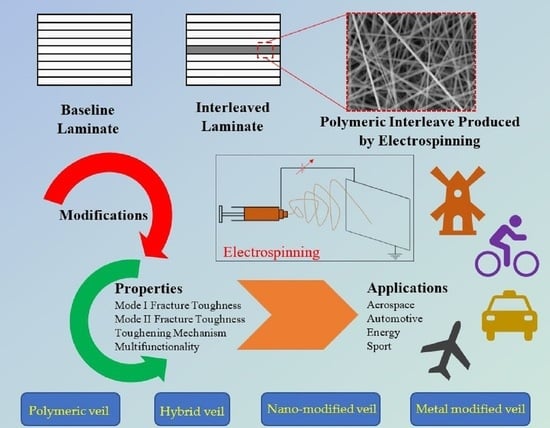

A Review of Electrospun Nanofiber Interleaves for Interlaminar Toughening of Composite Laminates

Abstract

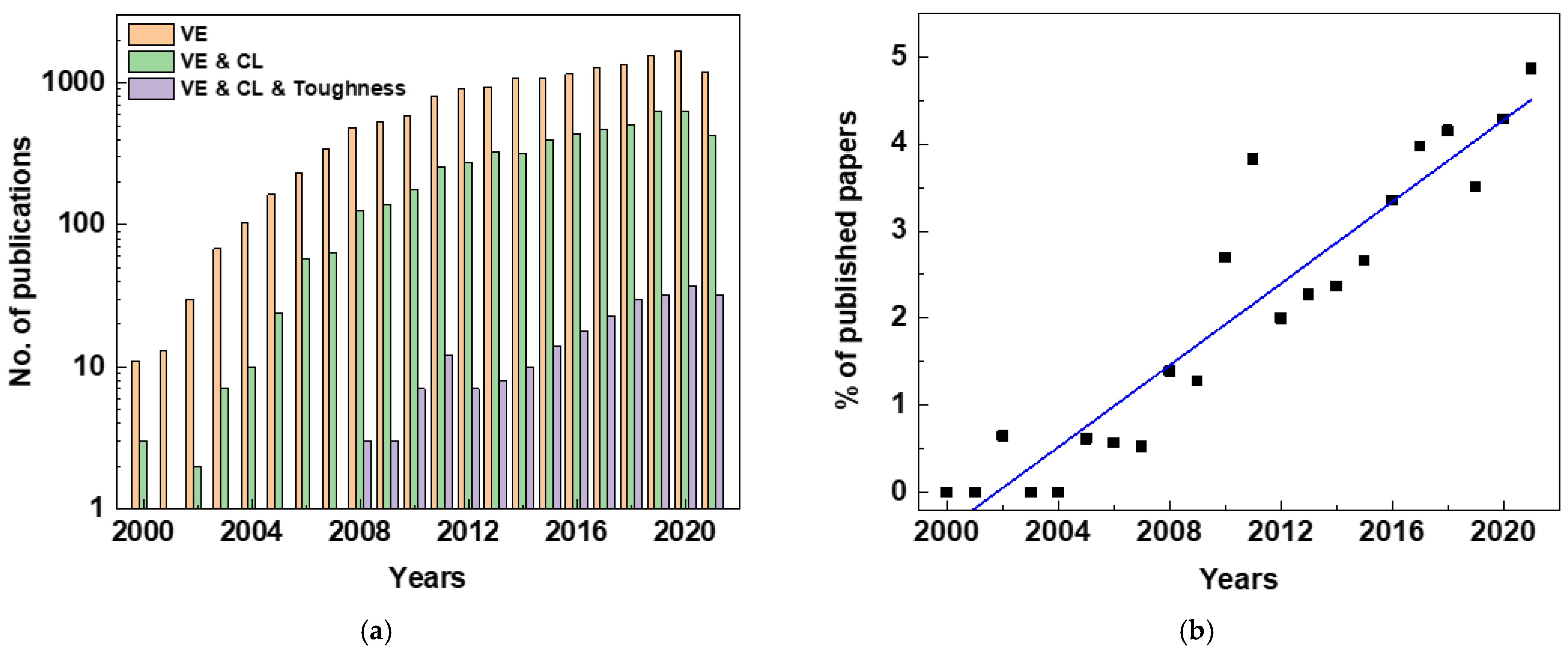

1. Introduction

2. Methodology

3. Production of Veil

4. Comparative Analysis of the Toughening Effect

4.1. Polyethylene Terephthalate

4.1.1. Neat PET Veil

4.1.2. PET-CF Hybrid Veil

4.1.3. Nano-Modified PET Veil

4.2. Polyphenylene Sulfide

4.2.1. Neat PPS Veil

4.2.2. Nano-Modified PPS Veil

4.3. Polyamide

4.3.1. Neat PA Veil

4.3.2. Metal-Modified PA Veil

4.4. Polyacrylonitrile

4.4.1. Neat PAN Veil

4.4.2. Nano-Modified PAN Veil

4.5. Polycaprolactone

5. Toughening Mechanism

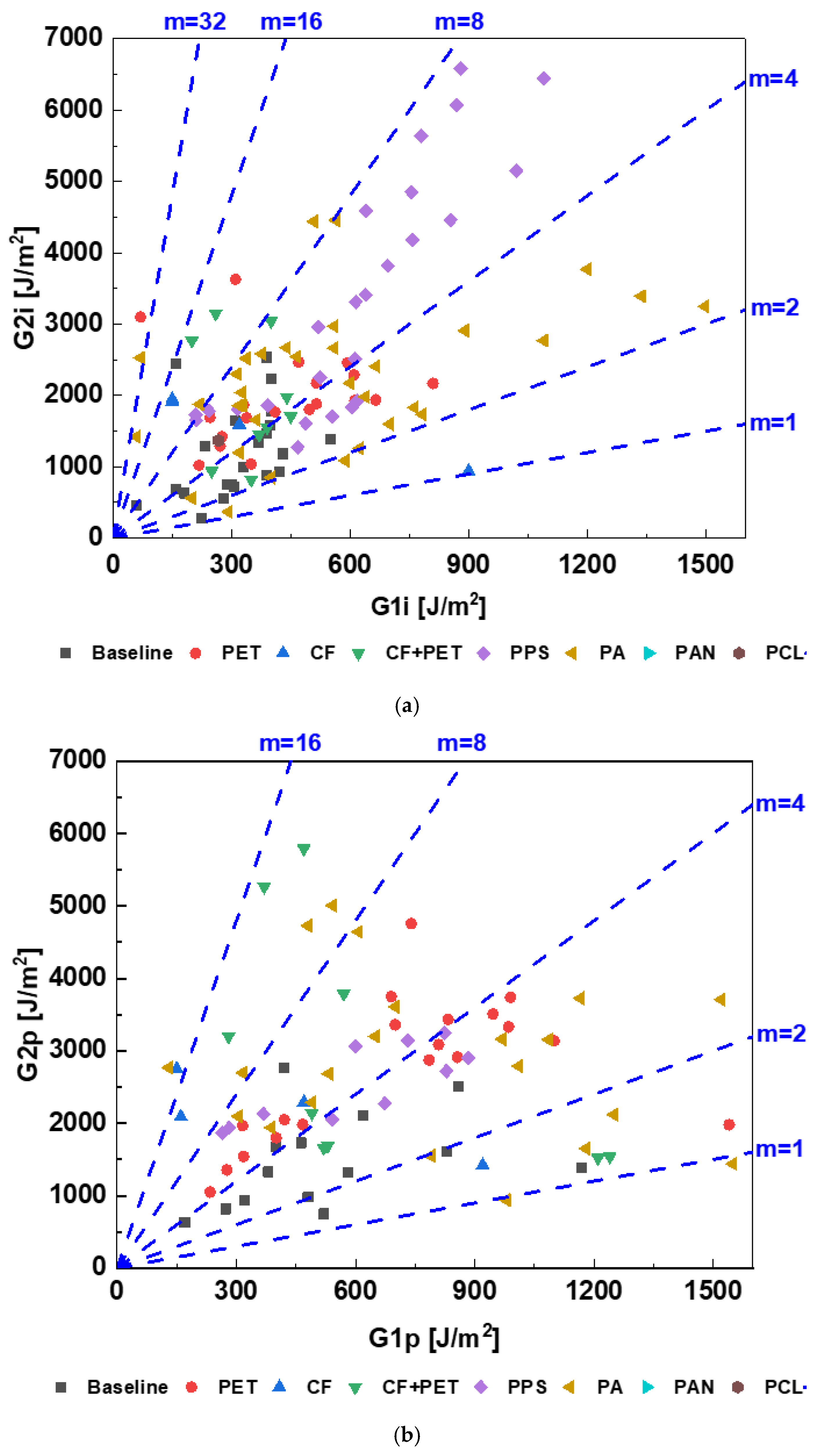

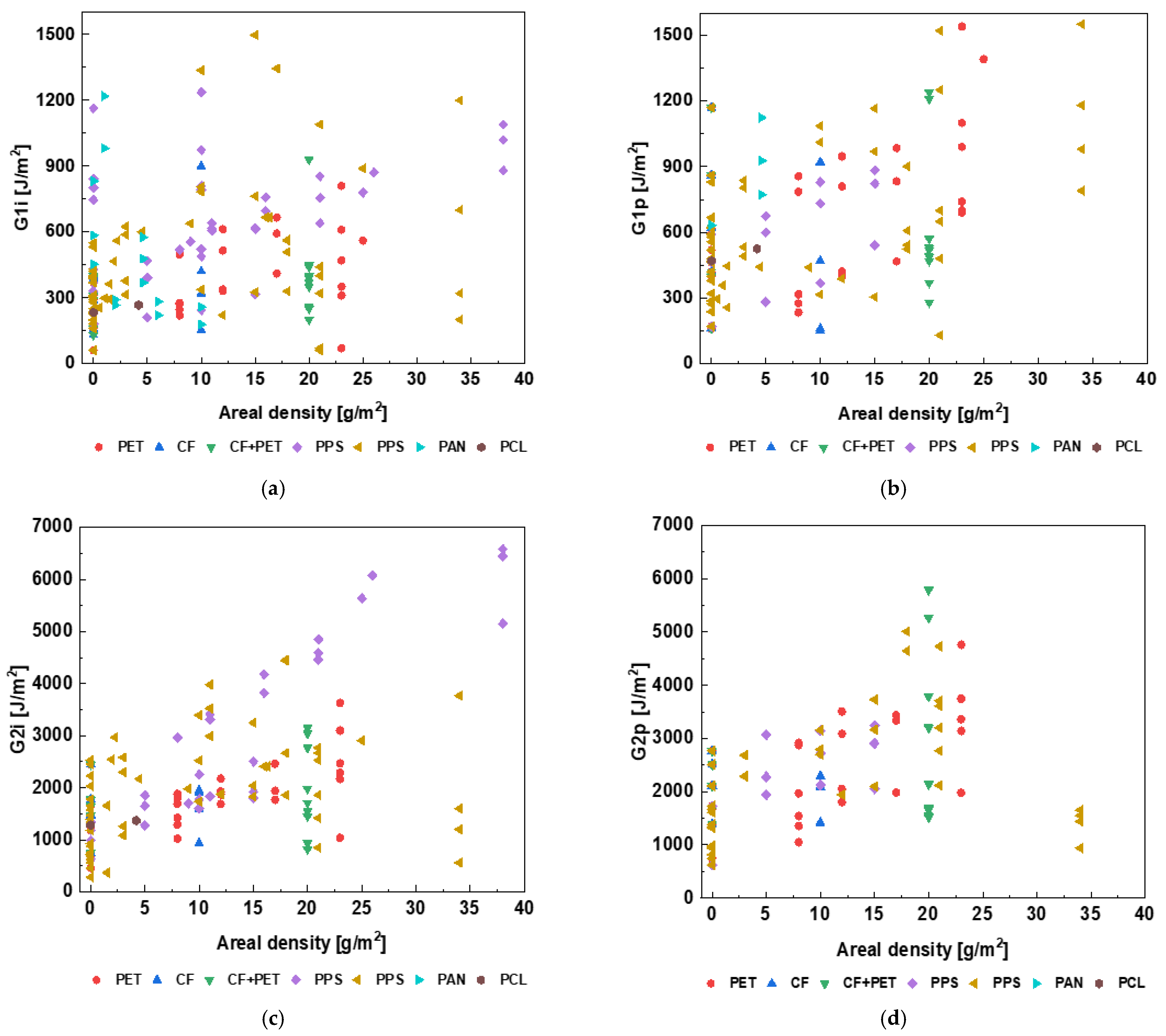

6. Statistical Analysis

6.1. Mode Ratio

6.2. Areal Density

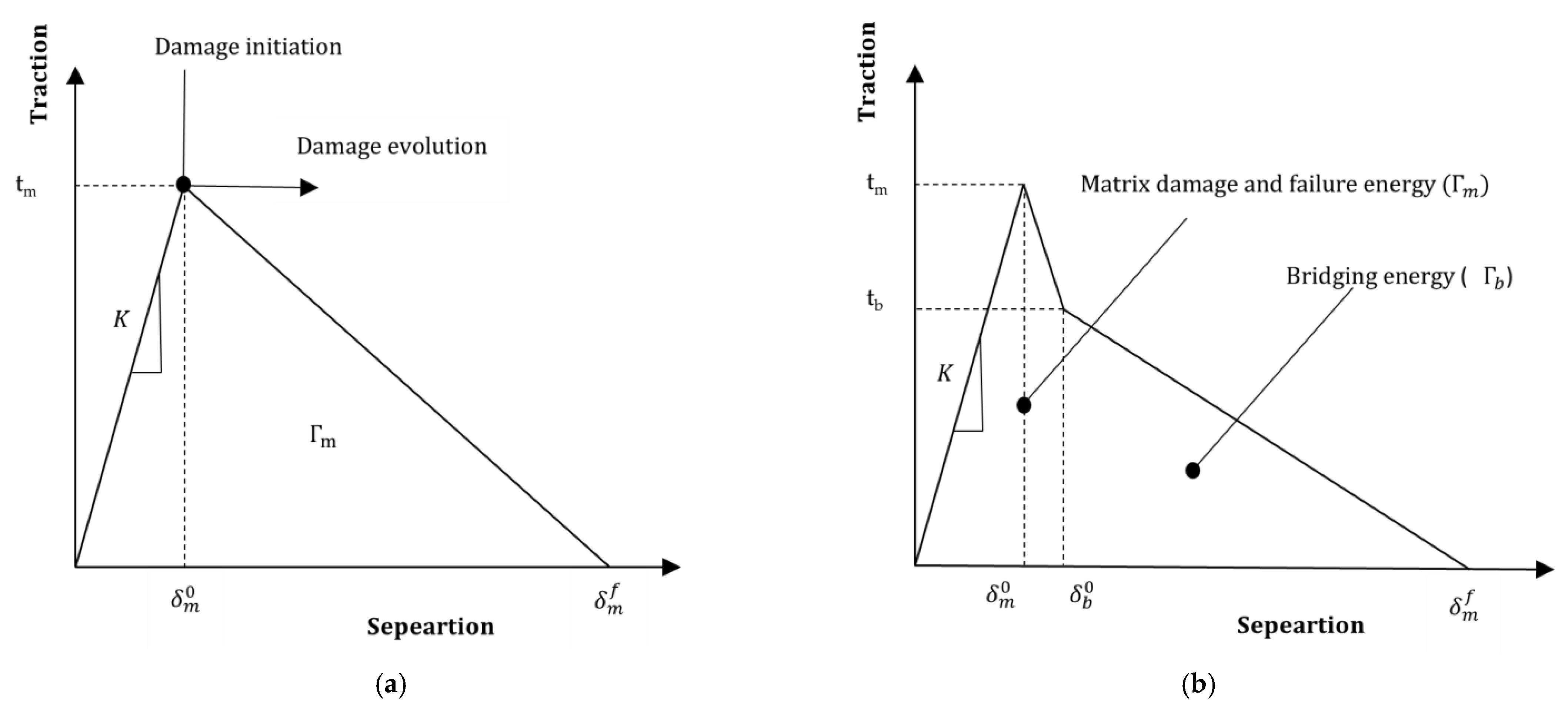

7. Numerical Modeling of Delamination

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 2D | Two-dimensional |

| 3D | Three-dimensional |

| 5H | 5-harness |

| AgNO3 | Silver nitrate |

| AgNW | Silver nanowire |

| ASTM | American Society for Testing and Materials |

| CF | Carbon fiber |

| CFRP | Carbon fiber-reinforced polymer |

| CNT | Carbon nanotubes |

| COH2D4 | Four-node two-dimensional cohesive |

| CPE4R | Plane-strain quadrilateral with reduced integration |

| DCB | Double-cantilever beam |

| ENF | End notch flexure |

| FRP | Fiber-reinforced polymer |

| FT | Fracture toughness |

| G/CFRP | Glass/carbon fiber-reinforced polymer |

| G1i | Mode I initiation [J/m2] |

| G1p | Mode I propagation [J/m2] |

| G2i | Mode II initiation [J/m2] |

| G2p | Mode II propagation [J/m2] |

| GF | Glass fiber |

| GNP | Graphene nanoparticles |

| K | Penalty stiffness |

| La | Size of tougher zone |

| m | Mode ratio |

| MWCNT | Multi-walled carbon nanotube |

| NCF | Non-crimp fabric |

| PA | Polyamide |

| PAN | Polyacrylonitrile |

| PAI | Polyamide-imide |

| PCL | Polycaprolactone |

| PES | Polyethersulfone |

| PET | Polyethylene terephthalate |

| PPS | Polyphenylene sulfide |

| PVB | Polyvinyl butyral |

| PVDF | Polyvinylidene fluoride |

| r | Correlation coefficient |

| tb | Bridging strength |

| tm | Cohesive strength |

| TiO2 | Titanium dioxide |

| UD | Unidirectional |

| VARTM | Vacuum-assisted resin transfer molding |

| VI | Vacuum infusion |

| Cohesive energy |

Appendix A. Collection of Parameters to Model Delamination of FRP Laminates

| Materials | Test | Cohesive Parameters | Ref. | |||||

| K [MPa/mm] | tm [MPa] | [N/mm] | tb [MPa] | [N/mm] | La [mm] | |||

| -/CF/Epoxy prepreg | DCB | 80,000 | 60 | 0.8 | - | - | - | Moroni 2013, [65] |

| Nylon 66/” | 64,000 | 48 | 1 | 0.8 | 0.6 | - | ||

| -/CF/Epoxy prepreg | ENF | 40,000 | 30 | 3 | 30 | 2.2 | 10 | |

| Nylon 66/” | “ | 35 | 3.5 | 35 | 3 | 15 | ||

| -/Woven CF/Epoxy | DCB | 55,000 | 60 | 0.75 | - | - | - | Giuliese 2015, [66] |

| 150 nm/25 µm thick/random Nylon 66/” | “ | 48 | 1 | 1 | 0.45 | - | ||

| 150 nm/50 µm thick/random Nylon 66/” | “ | 38 | 0.3 | - | - | - | ||

| 500 nm/25 µm thick/random Nylon 66/” | “ | 25 | 0.33 | - | - | - | ||

| 500 nm/50 µm thick/random Nylon 66/” | “ | 40 | 0.17 | - | - | - | ||

| 150 nm/25 µm thick/oriented Nylon 66/” | “ | 23 | 0.28 | 1 | 0.22 | - | ||

| 150 nm/50 µm thick/oriented Nylon 66/” | “ | 20 | 0.25 | 1 | 0.22 | - | ||

| 500 nm/25 µm thick/oriented Nylon 66/” | “ | 30 | 0.22 | - | - | - | ||

| 500 nm/50 µm thick/oriented Nylon 66/” | “ | 8 | 0.2 | - | - | - | ||

| -/Woven CF/Epoxy | ENF | 55,000 | 30 | 3 | 30 | 2.2 | 10 | |

| 150 nm/25 µm thick/random Nylon 66/” | “ | 40 | 3.3 | 51 | 4.6 | 20 | ||

| 150 nm/50 µm thick/random Nylon 66/” | “ | 17.5 | 1 | 35 | 2 | 25 | ||

| 500 nm/25 µm thick/random Nylon 66/” | “ | 30 | 1.1 | 30 | 1.45 | 25 | ||

| 500 nm/50 µm thick/random Nylon 66/” | “ | 30 | 1.65 | - | - | - | ||

| 150 nm/25 µm thick/oriented Nylon 66/” | “ | 35 | 1.8 | 48 | 3 | 25 | ||

| 150 nm/50 µm thick/oriented Nylon 66/” | “ | 45 | 3.1 | 48 | 3.45 | 10 | ||

| 500 nm/25 µm thick/oriented Nylon 66/” | “ | 14 | 0.7 | 7 | 0.28 | 10 | ||

| 500 nm/50 µm thick/oriented Nylon 66/” | “ | 17 | 1.25 | 8 | 0.35 | 20 | ||

| -/2 twill CF/Epoxy prepreg | DCB | 80,000 | 50 | 0.25 | - | - | - | Saghafi 2016, [67] |

| Thin PVDF/” | “ | 50 | 0.36 | - | - | - | ||

| Thick PVDF/” | “ | 50 | 0.47 | - | - | - | ||

| -/2 twill CF/Epoxy prepreg | ENF | 50,000 | 70 | 0.18 | - | - | - | Saghafi 2019, [68] |

| Thin PVDF/” | “ | 73 | 0.29 | - | - | - | ||

| Thick PVDF/” | “ | 85 | 0.38 | - | - | - | ||

| -/E-GF/Phenolic resin | ENF | 40,000 | 15 | 0.581 | - | - | - | Barzoki 2019, [69] |

| 100 nm-PVB/” | “ | 50 | 0.143 | - | - | - | ||

| 165 nm-PVB/” | “ | 12.5 | 0.749 | - | - | - | ||

| 314 nm-PVB/” | “ | 10 | 0.44 | - | - | - | ||

| 500 nm-PVB/” | 100,000 | 9 | 0.423 | - | - | - | ||

| 165 nm (aligned)-PVB/” | “ | 8 | 0.393 | - | - | - | ||

| “: Same as in the row above; -: not available. | ||||||||

References

- Lu, Z.; Li, Y.; Xie, J. Durability of BFRP Bars Wrapped in Seawater Sea Sand Concrete. Compos. Struct. 2021, 255, 112935. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.; Xian, G. Water Absorption and Long-Term Thermal and Mechanical Properties of Carbon/Glass Hybrid Rod for Bridge Cable. Eng. Struct. 2023, 274, 115176. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Wang, Y. Mechanical Performance Evolution and Life Prediction of Prestressed CFRP Plate Exposed to Hygrothermal and Freeze-Thaw Environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Quaresimin, M.; Schulte, K.; Zappalorto, M.; Chandrasekaran, S. Toughening Mechanisms in Polymer Nanocomposites: From Experiments to Modelling. Compos. Sci. Technol. 2016, 123, 187–204. [Google Scholar] [CrossRef]

- Islam, A.B.M.I.; Kelkar, A.D. Prospects and Challenges of Nanomaterial Engineered Prepregs for Improving Interlaminar Properties of Laminated Composites––a Review. MRS Commun. 2017, 7, 102–108. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Cox, B.N. A Mechanistic Interpretation of the Comparative In-Plane Mechanical Properties of 3D Woven, Stitched and Pinned Composites. Compos. Part A 2010, 41, 709–728. [Google Scholar] [CrossRef]

- Mouritz, A.P. Review of Z-Pinned Composite Laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2383–2397. [Google Scholar] [CrossRef]

- Guzman de Villoria, R.; Hallander, P.; Ydrefors, L.; Nordin, P.; Wardle, B.L. In-Plane Strength Enhancement of Laminated Composites via Aligned Carbon Nanotube Interlaminar Reinforcement. Compos. Sci. Technol. 2016, 133, 33–39. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre Hybridisation in Polymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Lomov, S.V.; Molnár, K. Compressibility of Carbon Fabrics with Needleless Electrospun PAN Nanofibrous Interleaves. Express Polym. Lett. 2016, 10, 25–35. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Mode I and Mode II Interlaminar Fracture Toughness of Composite Laminates Interleaved with Electrospun Nanofibre Veils. Compos. Part A Appl. Sci. Manuf. 2015, 72, 11–21. [Google Scholar] [CrossRef]

- Meireman, T.; Daelemans, L.; Rijckaert, S.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Delamination Resistant Composites by Interleaving Bio-Based Long-Chain Polyamide Nanofibers through Optimal Control of Fiber Diameter and Fiber Morphology. Compos. Sci. Technol. 2020, 193, 108126. [Google Scholar] [CrossRef]

- García-Rodríguez, S.M.; Costa, J.; Rankin, K.E.; Boardman, R.P.; Singery, V.; Mayugo, J.A. Interleaving Light Veils to Minimise the Trade-off between Mode-I Interlaminar Fracture Toughness and in-Plane Properties. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105659. [Google Scholar] [CrossRef]

- Quan, D.; Bologna, F.; Scarselli, G.; Ivankovic, A.; Murphy, N. Interlaminar Fracture Toughness of Aerospace-Grade Carbon Fibre Reinforced Plastics Interleaved with Thermoplastic Veils. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105642. [Google Scholar] [CrossRef]

- Sela, N.; Ishai, O. Interlaminar Fracture Toughness and Toughening of Laminated Composite Materials: A Review. Composites 1989, 20, 423–435. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun Nanofiber: Emerging Reinforcing Filler in Polymer Matrix Composite Materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Palazzetti, R.; Zucchelli, A. Electrospun Nanofibers as Reinforcement for Composite Laminates Materials—A Review. Compos. Struct. 2017, 182, 711–727. [Google Scholar] [CrossRef]

- Mitchell, G.R. Electrospinning: Principles, Practice and Possibilities; Edited; Tang, B.Z., Abd-El-Aziz, A.S., Craig, S., Dong, J., Masuda, T., Weder, C., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2015; ISBN 978-1849735568. [Google Scholar]

- Yuris, A.; Dzenis, D.H.R. Delamination Resistant Composites Prepared by Small Diameter Fiber Reinforcement at Ply Interfaces. US Patent No. 6,265,333 B1, July 2001. [Google Scholar]

- Molnar, K.; Nagy, Z.K. Corona-Electrospinning: Needleless Method for High-Throughput Continuous Nanofiber Production. Eur. Polym. J. 2016, 74, 279–286. [Google Scholar] [CrossRef]

- Molnár, K.; Vas, L.M. Electrospun Composite Nanofibers and Polymer Composites. In Synthetic Polymer-Polymer Composites; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2012; pp. 301–349. [Google Scholar]

- ASTM D5528-01; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D7905; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM: West Conshohocken, PA, USA, 2014.

- Tzetzis, D.; Hogg, P.J.; Jogia, M. Double Cantilever Beam Mode-I Testing for Vacuum Infused Repairs of GFRP. J. Adhes. Sci. Technol. 2003, 17, 309–328. [Google Scholar] [CrossRef]

- Tzetzis, D.; Hogg, P.J. Bondline Toughening of Vacuum Infused Composite Repairs. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1239–1251. [Google Scholar] [CrossRef]

- Kuwata, M.; Hogg, P.J. Interlaminar Toughness of Interleaved CFRP Using Non-Woven Veils: Part 2. Mode-II Testing. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1560–1570. [Google Scholar] [CrossRef]

- Kuwata, M.; Hogg, P.J. Interlaminar Toughness of Interleaved CFRP Using Non-Woven Veils: Part 1. Mode-I Testing. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1551–1559. [Google Scholar] [CrossRef]

- Quan, D.; Mischo, C.; Li, X.; Scarselli, G.; Ivanković, A.; Murphy, N. Improving the Electrical Conductivity and Fracture Toughness of Carbon Fibre/Epoxy Composites by Interleaving MWCNT-Doped Thermoplastic Veils. Compos. Sci. Technol. 2019, 182, 107775. [Google Scholar] [CrossRef]

- Quan, D.; Bologna, F.; Scarselli, G.; Ivanković, A.; Murphy, N. Mode-II Fracture Behaviour of Aerospace-Grade Carbon Fibre/Epoxy Composites Interleaved with Thermoplastic Veils. Compos. Sci. Technol. 2020, 191, 108065. [Google Scholar] [CrossRef]

- Fitzmaurice, K.; Ray, D.; McCarthy, M.A. PET Interleaving Veils for Improved Fracture Toughness of Glass Fibre/Low-Styrene-Emission Unsaturated Polyester Resin Composites. J. Appl. Polym. Sci. 2016, 133, 42877. [Google Scholar] [CrossRef]

- Del Saz-Orozco, B.; Ray, D.; Stanley, W.F. Effect of Thermoplastic Veils on Interlaminar Fracture Toughness of a Glass Fiber/Vinyl Ester Composite. Polym. Compos. 2017, 38, 2501–2508. [Google Scholar] [CrossRef]

- Quan, D.; Mischo, C.; Binsfeld, L.; Ivankovic, A.; Murphy, N. Fracture Behaviour of Carbon Fibre/Epoxy Composites Interleaved by MWCNT- and Graphene Nanoplatelet-Doped Thermoplastic Veils. Compos. Struct. 2020, 235, 111767. [Google Scholar] [CrossRef]

- Ramirez, V.A.; Hogg, P.J.; Sampson, W.W. The Influence of the Nonwoven Veil Architectures on Interlaminar Fracture Toughness of Interleaved Composites. Compos. Sci. Technol. 2015, 110, 103–110. [Google Scholar] [CrossRef]

- Ramji, A.; Xu, Y.; Yasaee, M.; Grasso, M.; Webb, P. Delamination Migration in CFRP Laminates under Mode I Loading. Compos. Sci. Technol. 2020, 190, 108067. [Google Scholar] [CrossRef]

- Saghafi, H.; Zucchelli, A.; Palazzetti, R.; Minak, G. The Effect of Interleaved Composite Nanofibrous Mats on Delamination Behavior of Polymeric Composite Materials. Compos. Struct. 2014, 109, 41–47. [Google Scholar] [CrossRef]

- Saghafi, H.; Palazzetti, R.; Zucchelli, A.; Minak, G. Influence of Electrospun Nanofibers on the Interlaminar Properties of Unidirectional Epoxy Resin/Glass Fiber Composite Laminates. J. Reinf. Plast. Compos. 2015, 34, 907–914. [Google Scholar] [CrossRef]

- Nash, N.H.; Ray, D.; Young, T.M.; Stanley, W.F. The Influence of Hydrothermal Conditioning on the Mode-I, Thermal and Flexural Properties of Carbon/Benzoxazine Composites with a Thermoplastic Toughening Interlayer. Compos. Part A Appl. Sci. Manuf. 2015, 76, 135–144. [Google Scholar] [CrossRef]

- Nash, N.H.; Young, T.M.; Stanley, W.F. The Influence of a Thermoplastic Toughening Interlayer and Hydrothermal Conditioning on the Mode-II Interlaminar Fracture Toughness of Carbon/Benzoxazine Composites. Compos. Part A Appl. Sci. Manuf. 2016, 81, 111–120. [Google Scholar] [CrossRef]

- Guo, M.; Yi, X.; Liu, G.; Liu, L. Simultaneously Increasing the Electrical Conductivity and Fracture Toughness of Carbon-Fiber Composites by Using Silver Nanowires-Loaded Interleaves. Compos. Sci. Technol. 2014, 97, 27–33. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, J.; Liu, G.; Chen, P.; Guo, M. Controlling the Crack Propagation Path of the Veil Interleaved Composite by Fusion-Bonded Dots. Polymers 2019, 11, 1260. [Google Scholar] [CrossRef]

- Ognibene, G.; Latteri, A.; Mannino, S.; Saitta, L.; Recca, G.; Scarpa, F.; Cicala, G. Interlaminar Toughening of Epoxy Carbon Fiber Reinforced Laminates: Soluble Versus Non-Soluble Veils. Polymers 2019, 11, 1029. [Google Scholar] [CrossRef]

- Pozegic, T.R.; King, S.G.; Fotouhi, M.; Stolojan, V.; Silva, S.R.P.; Hamerton, I. Delivering Interlaminar Reinforcement in Composites through Electrospun Nanofibres. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 155–171. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Experimental and Statistical Analysis of Carbon Fiber/Epoxy Composites Interleaved with Nylon 6,6 Nonwoven Fabric Interlayers. J. Compos. Mater. 2020, 54, 4173–4184. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Effect of Polyamide-6,6 (PA 66) Nonwoven Veils on the Mechanical Performance of Carbon Fiber/Epoxy Composites. Compos. Struct. 2018, 194, 21–35. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Enhancement of Interlaminar Fracture Toughness of Carbon Fiber-Epoxy Composites Using Polyamide-6,6 Electrospun Nanofibers. J. Appl. Polym. Sci. 2017, 134, 45244. [Google Scholar] [CrossRef]

- Alessi, S.; Di Filippo, M.; Dispenza, C.; Focarete, M.L.; Gualandi, C.; Palazzetti, R.; Pitarresi, G.; Zucchelli, A. Effects of Nylon 6,6 Nanofibrous Mats on Thermal Properties and Delamination Behavior of High Performance CFRP Laminates. Polym. Compos. 2015, 36, 1303–1313. [Google Scholar] [CrossRef]

- Barjasteh, E.; Sutanto, C.; Reddy, T.; Vinh, J. A Graphene/Graphite-Based Conductive Polyamide 12 Interlayer for Increasing the Fracture Toughness and Conductivity of Carbon-Fiber Composites. J. Compos. Mater. 2017, 51, 2879–2887. [Google Scholar] [CrossRef]

- Monteserín, C.; Blanco, M.; Murillo, N.; Pérez-Márquez, A.; Maudes, J.; Gayoso, J.; Laza, J.M.; Hernáez, E.; Aranzabe, E.; Vilas, J.L. Novel Antibacterial and Toughened Carbon-Fibre/Epoxy Composites by the Incorporation of TiO2 Nanoparticles Modified Electrospun Nanofibre Veils. Polymers 2019, 11, 1524. [Google Scholar] [CrossRef]

- Monteserín, C.; Blanco, M.; Murillo, N.; Pérez-Márquez, A.; Maudes, J.; Gayoso, J.; Laza, J.; Aranzabe, E.; Vilas, J. Effect of Different Types of Electrospun Polyamide 6 Nanofibres on the Mechanical Properties of Carbon Fibre/Epoxy Composites. Polymers 2018, 10, 1190. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Nanofibre Bridging as a Toughening Mechanism in Carbon/Epoxy Composite Laminates Interleaved with Electrospun Polyamide Nanofibrous Veils. Compos. Sci. Technol. 2015, 117, 244–256. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Using Aligned Nanofibres for Identifying the Toughening Micromechanisms in Nanofibre Interleaved Laminates. Compos. Sci. Technol. 2016, 124, 17–26. [Google Scholar] [CrossRef]

- Daelemans, L.; Van Der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Damage-Resistant Composites Using Electrospun Nanofibers: A Multiscale Analysis of the Toughening Mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef]

- De Schoenmaker, B.; Van der Heijden, S.; De Baere, I.; Van Paepegem, W.; De Clerck, K. Effect of Electrospun Polyamide 6 Nanofibres on the Mechanical Properties of a Glass Fibre/Epoxy Composite. Polym. Test. 2013, 32, 1495–1501. [Google Scholar] [CrossRef]

- O’Donovan, K.; Ray, D.; McCarthy, M.A. Toughening Effects of Interleaved Nylon Veils on Glass Fabric/Low-Styrene-Emission Unsaturated Polyester Resin Composites. J. Appl. Polym. Sci. 2015, 132, 41462. [Google Scholar] [CrossRef]

- Hamer, S.; Leibovich, H.; Green, A.; Intrater, R.; Avrahami, R.; Zussman, E.; Siegmann, A.; Sherman, D. Mode I Interlaminar Fracture Toughness of Nylon 66 Nanofibrilmat Interleaved Carbon/Epoxy Laminates. Polym. Compos. 2011, 32, 1781–1789. [Google Scholar] [CrossRef]

- Guo, M.; Yi, X.; Rudd, C.; Liu, X. Preparation of Highly Electrically Conductive Carbon-Fiber Composites with High Interlaminar Fracture Toughness by Using Silver-Plated Interleaves. Compos. Sci. Technol. 2019, 176, 29–36. [Google Scholar] [CrossRef]

- VanderVennet, J.A.; Duenas, T.; Dzenis, Y.; Peterson, C.T.; Bakis, C.E.; Carter, D.; Roberts, J.K. Fracture Toughness Characterization of Nanoreinforced Carbon-Fiber Composite Materials for Damage Mitigation. In Proceedings of the Behavior and Mechanics of Multifunctional Materials and Composites 2011, San Diego, CA, USA, 7–9 March 2011; Ounaies, Z., Seelecke, S.S., Eds.; SPIE: Bellingham, WA, USA, 2011; Volume 7978, p. 797823. [Google Scholar]

- Zhang, J.; Yang, T.; Lin, T.; Wang, C.H. Phase Morphology of Nanofibre Interlayers: Critical Factor for Toughening Carbon/Epoxy Composites. Compos. Sci. Technol. 2012, 72, 256–262. [Google Scholar] [CrossRef]

- Chiu, K.R.; Duenas, T.; Dzenis, Y.; Kaser, J.; Bakis, C.E.; Roberts, J.K.; Carter, D. Comparative Study of Nanomaterials for Interlaminar Reinforcement of Fiber-Composite Panels. In Proceedings of the Behavior and Mechanics of Multifunctional Materials and Composites 2013, San Diego, CA, USA, 10–14 March 2013; Goulbourne, N.C., Naguib, H.E., Eds.; 2013; Volume 8689, p. 86891D. [Google Scholar]

- Razavi, S.M.J.; Neisiany, R.E.; Khorasani, S.N.; Ramakrishna, S.; Berto, F. Effect of Neat and Reinforced Polyacrylonitrile Nanofibers Incorporation on Interlaminar Fracture Toughness of Carbon/Epoxy Composite. Theor. Appl. Mech. Lett. 2018, 8, 126–131. [Google Scholar] [CrossRef]

- Molnár, K.; Szebényi, G.; Szolnoki, B.; Marosi, G.; Vas, L.M.; Toldy, A. Enhanced Conductivity Composites for Aircraft Applications: Carbon Nanotube Inclusion Both in Epoxy Matrix and in Carbonized Electrospun Nanofibers. Polym. Adv. Technol. 2014, 25, 981–988. [Google Scholar] [CrossRef]

- Eskizeybek, V.; Yar, A.; Avcı, A. CNT-PAN Hybrid Nanofibrous Mat Interleaved Carbon/Epoxy Laminates with Improved Mode I Interlaminar Fracture Toughness. Compos. Sci. Technol. 2018, 157, 30–39. [Google Scholar] [CrossRef]

- Cohades, A.; Daelemans, L.; Ward, C.; Meireman, T.; Van Paepegem, W.; De Clerck, K.; Michaud, V. Size Limitations on Achieving Tough and Healable Fibre Reinforced Composites through the Use of Thermoplastic Nanofibres. Compos. Part A Appl. Sci. Manuf. 2018, 112, 485–495. [Google Scholar] [CrossRef]

- Van der Heijden, S.; Daelemans, L.; De Schoenmaker, B.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Interlaminar Toughening of Resin Transfer Moulded Glass Fibre Epoxy Laminates by Polycaprolactone Electrospun Nanofibres. Compos. Sci. Technol. 2014, 104, 66–73. [Google Scholar] [CrossRef]

- Moroni, F.; Palazzetti, R.; Zucchelli, A.; Pirondi, A. A Numerical Investigation on the Interlaminar Strength of Nanomodified Composite Interfaces. Compos. Part B Eng. 2013, 55, 635–641. [Google Scholar] [CrossRef]

- Giuliese, G.; Palazzetti, R.; Moroni, F.; Zucchelli, A.; Pirondi, A. Cohesive Zone Modelling of Delamination Response of a Composite Laminate with Interleaved Nylon 6,6 Nanofibres. Compos. Part B Eng. 2015, 78, 384–392. [Google Scholar] [CrossRef]

- Saghafi, H.; Ghaffarian, S.R.; Brugo, T.M.; Minak, G.; Zucchelli, A.; Saghafi, H.A. The Effect of Nanofibrous Membrane Thickness on Fracture Behaviour of Modified Composite Laminates—A Numerical and Experimental Study. Compos. Part B Eng. 2016, 101, 116–123. [Google Scholar] [CrossRef]

- Saghafi, H.; Moallemzadeh, A.R.; Zucchelli, A.; Brugo, T.M.; Minak, G. Shear Mode of Fracture in Composite Laminates Toughened by Polyvinylidene Fluoride Nanofibers. Compos. Struct. 2019, 227, 111327. [Google Scholar] [CrossRef]

- Barzoki, P.K.; Rezadoust, A.M.; Latifi, M.; Saghafi, H.; Minak, G. Effect of Nanofiber Diameter and Arrangement on Fracture Toughness of out of Autoclave Glass/Phenolic Composites—Experimental and Numerical Study. Thin Walled Struct. 2019, 143, 106251. [Google Scholar] [CrossRef]

| G1i | G1p | G2i | G2p | |

|---|---|---|---|---|

| Correlation coefficient (r) | 0.44 | 0.34 | 0.59 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahato, B.; Lomov, S.V.; Shiverskii, A.; Owais, M.; Abaimov, S.G. A Review of Electrospun Nanofiber Interleaves for Interlaminar Toughening of Composite Laminates. Polymers 2023, 15, 1380. https://doi.org/10.3390/polym15061380

Mahato B, Lomov SV, Shiverskii A, Owais M, Abaimov SG. A Review of Electrospun Nanofiber Interleaves for Interlaminar Toughening of Composite Laminates. Polymers. 2023; 15(6):1380. https://doi.org/10.3390/polym15061380

Chicago/Turabian StyleMahato, Biltu, Stepan V. Lomov, Aleksei Shiverskii, Mohammad Owais, and Sergey G. Abaimov. 2023. "A Review of Electrospun Nanofiber Interleaves for Interlaminar Toughening of Composite Laminates" Polymers 15, no. 6: 1380. https://doi.org/10.3390/polym15061380

APA StyleMahato, B., Lomov, S. V., Shiverskii, A., Owais, M., & Abaimov, S. G. (2023). A Review of Electrospun Nanofiber Interleaves for Interlaminar Toughening of Composite Laminates. Polymers, 15(6), 1380. https://doi.org/10.3390/polym15061380