Repair of Aerospace Composite Structures Using Liquid Thermoplastic Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Manufacturing of Composite Laminates

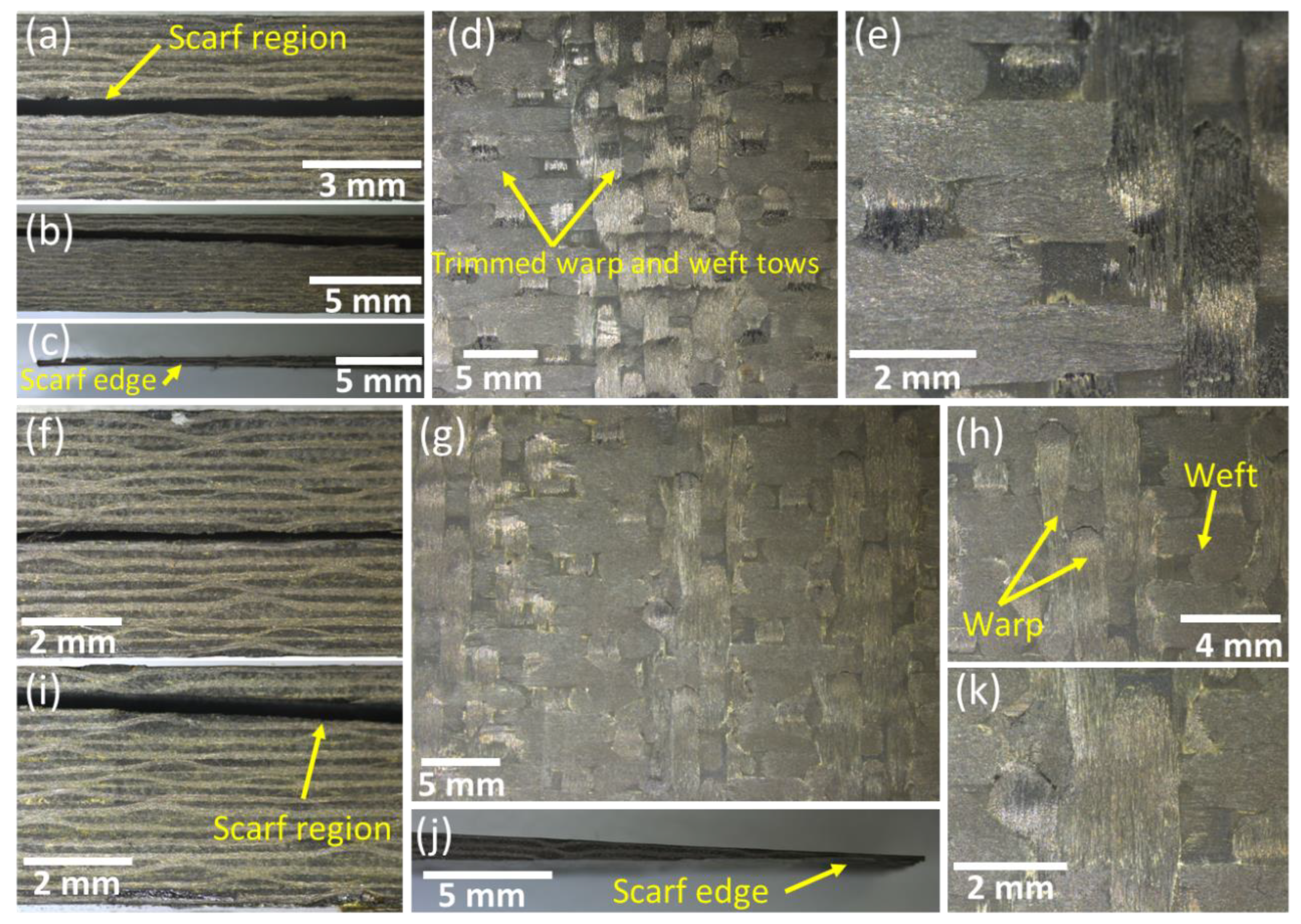

2.2.2. Machining of Composite Laminates

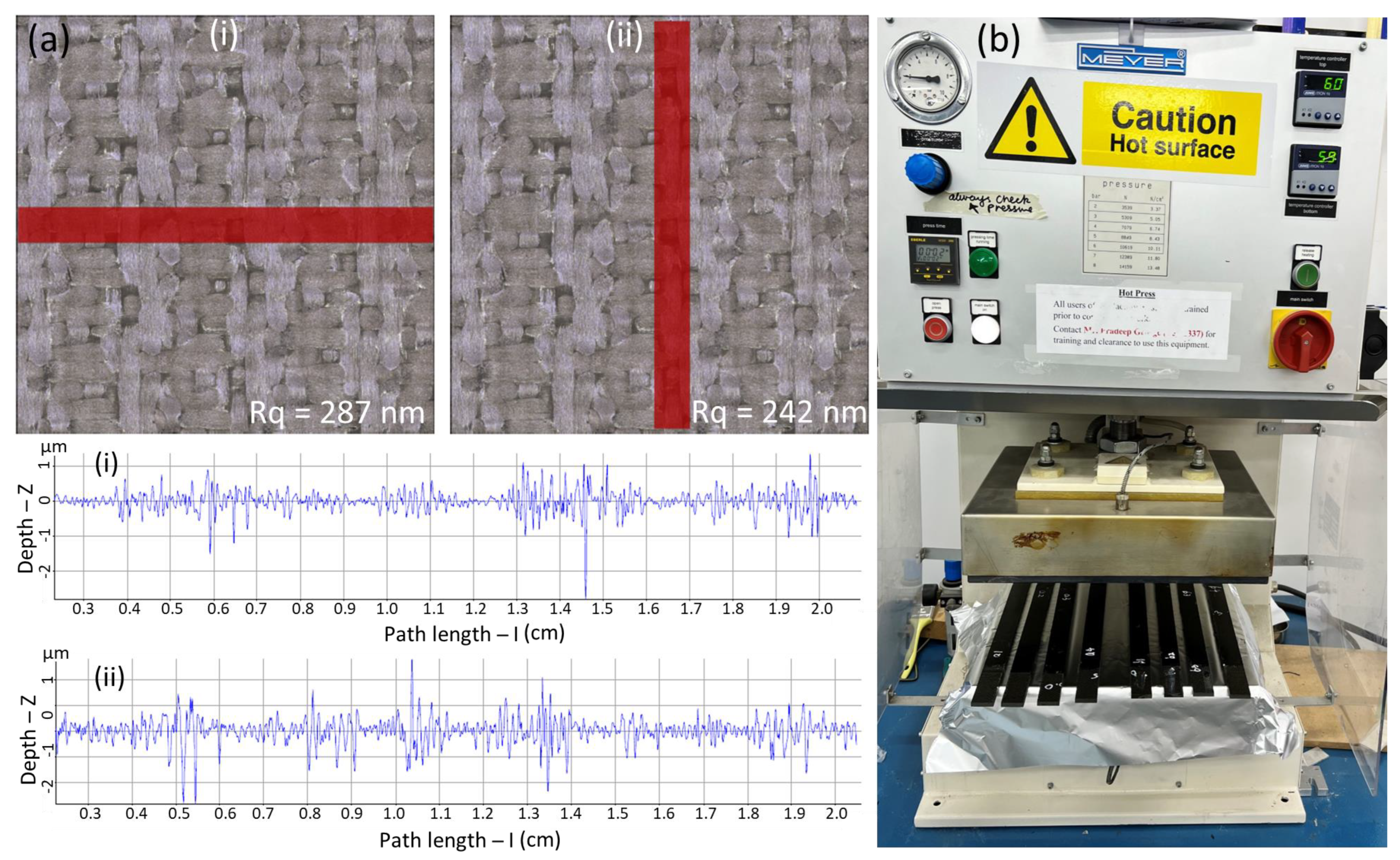

Surface Roughness

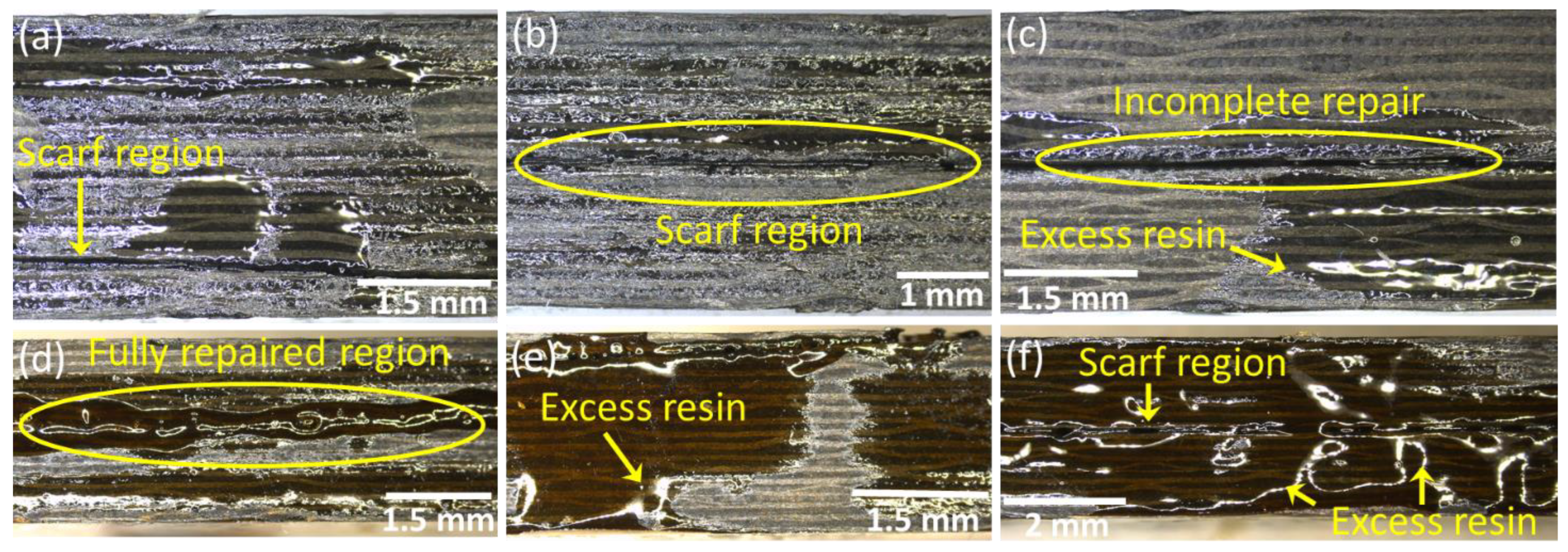

2.2.3. Repair of Scarf Joints

2.2.4. Optical Microscopy

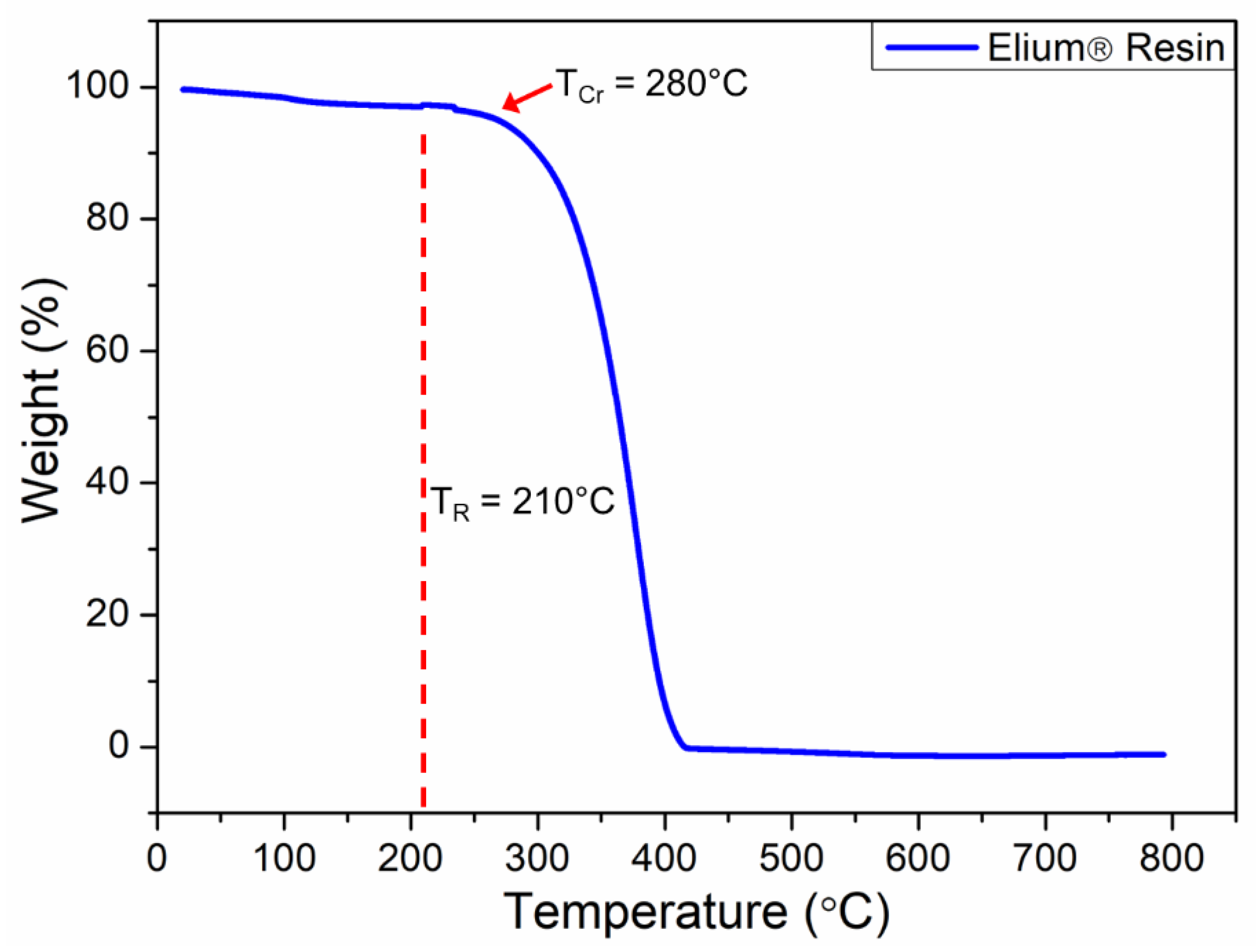

2.2.5. Thermogravimetric Analysis

2.2.6. Dynamic Mechanical Analysis (DMA)

2.2.7. Flexural Testing

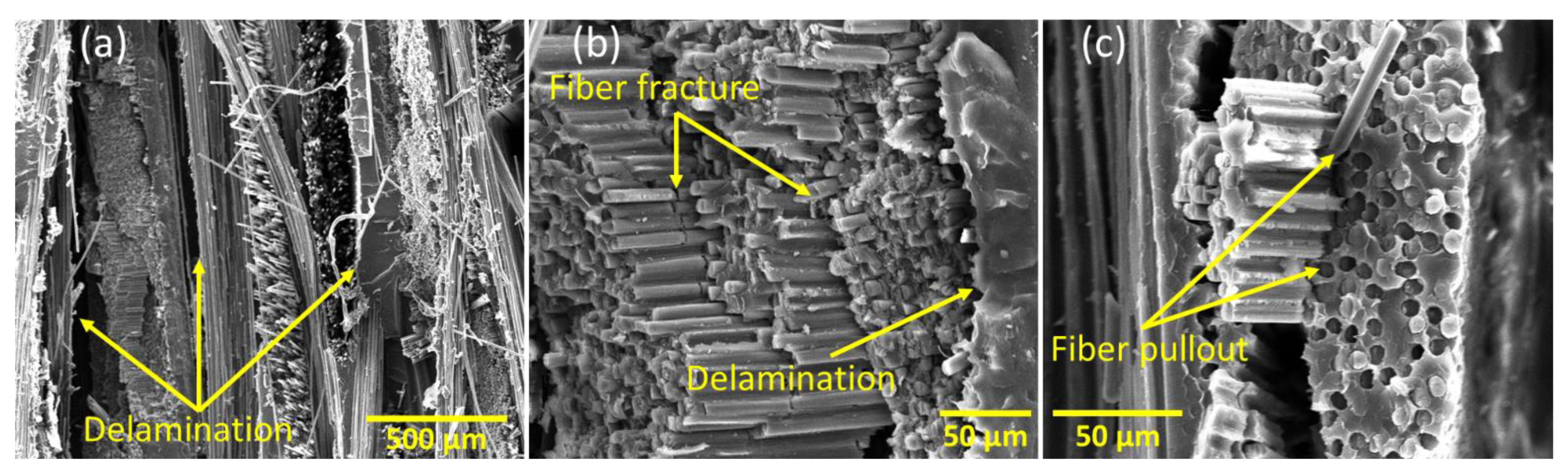

2.2.8. Fractographic Analysis

3. Results and Discussion

3.1. Optical Microscopy

3.2. Thermogravimetric Analysis

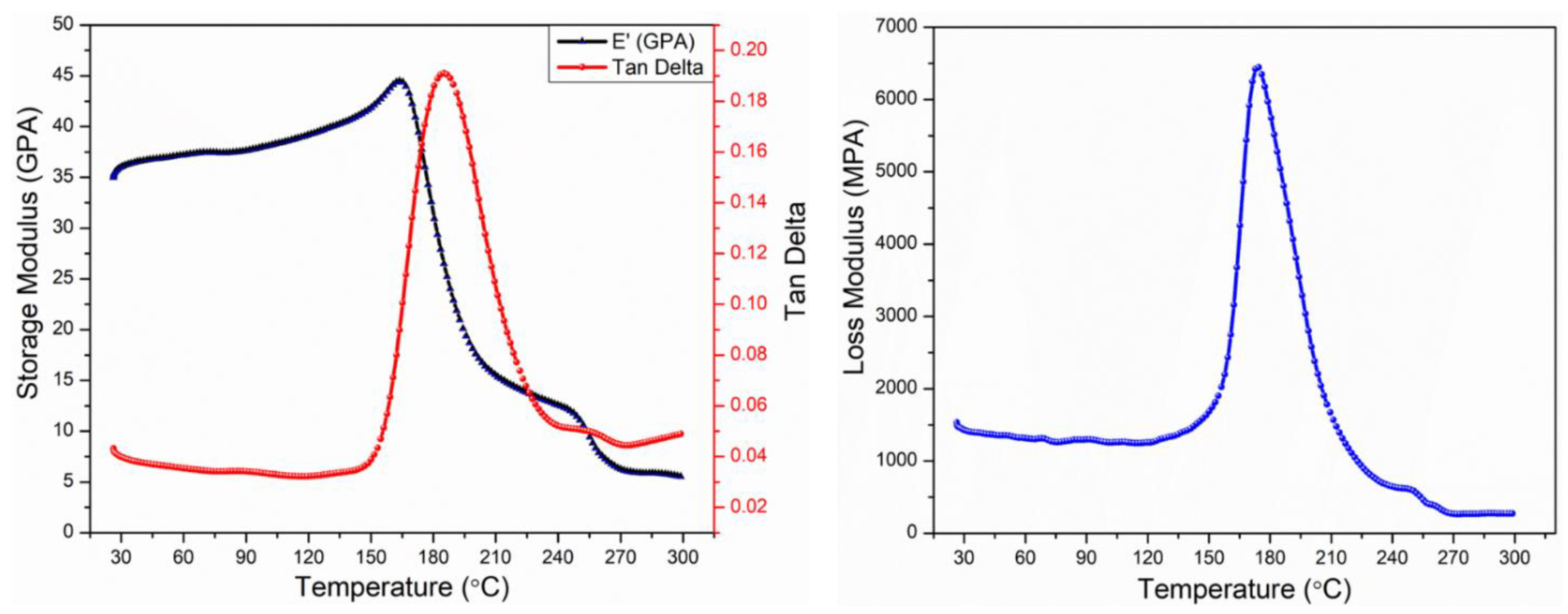

3.3. Dynamic Mechanical Analysis

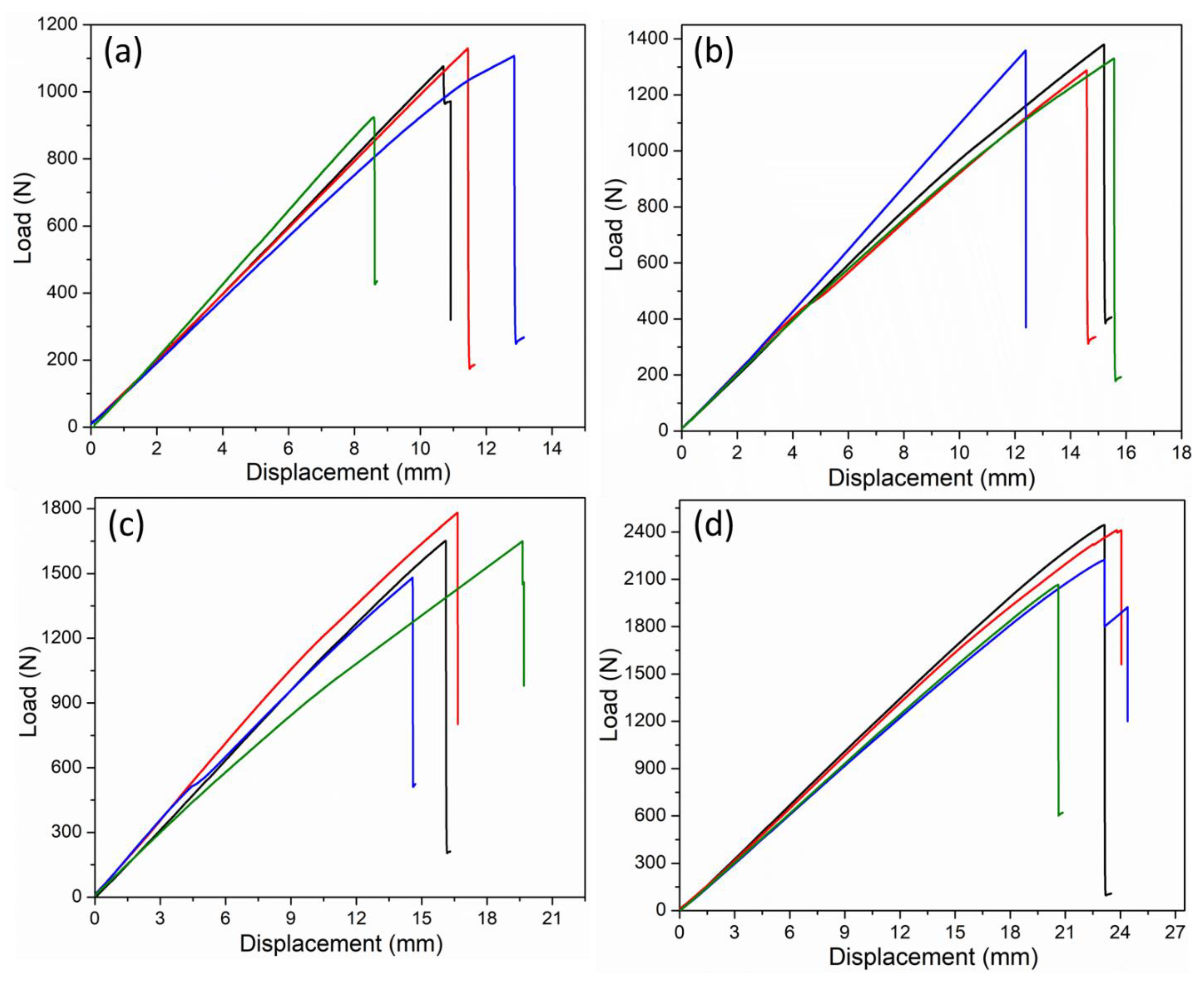

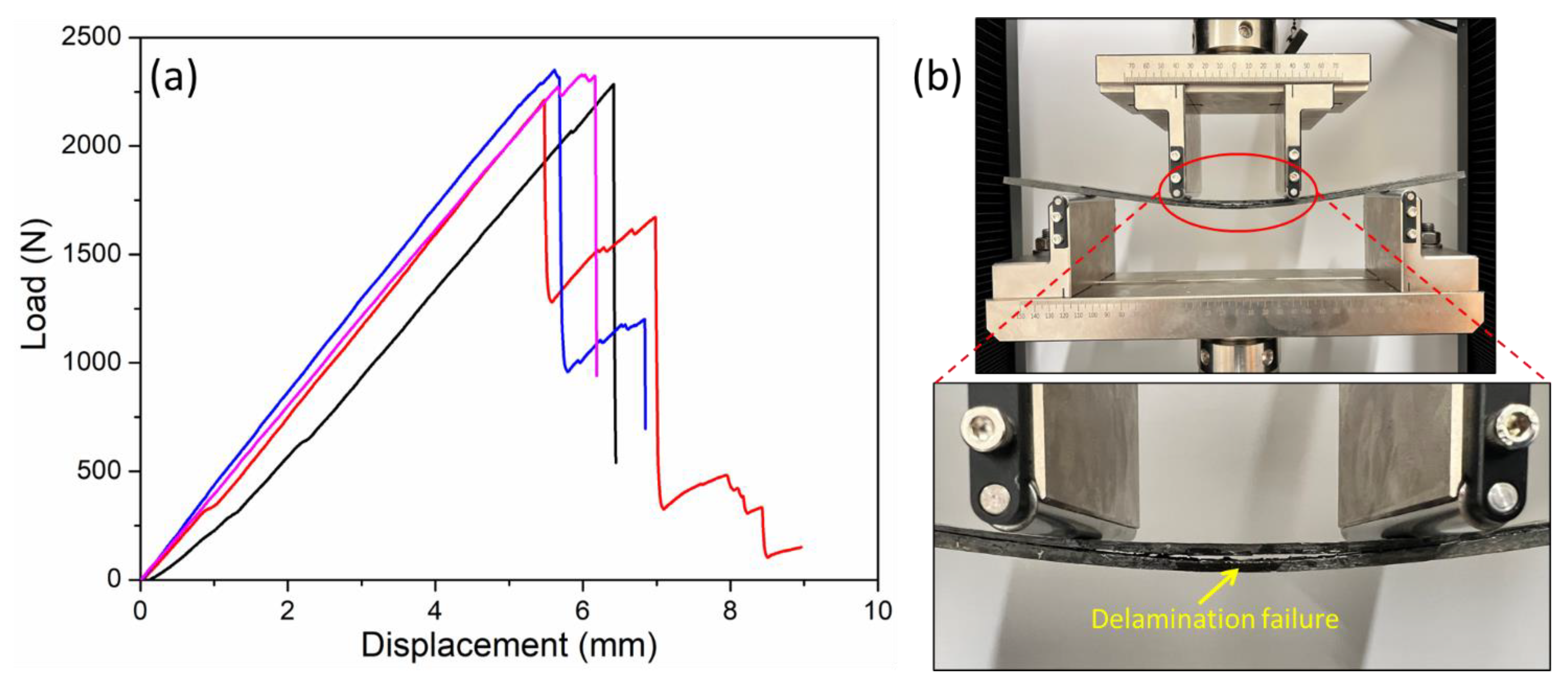

3.4. Flexural Properties

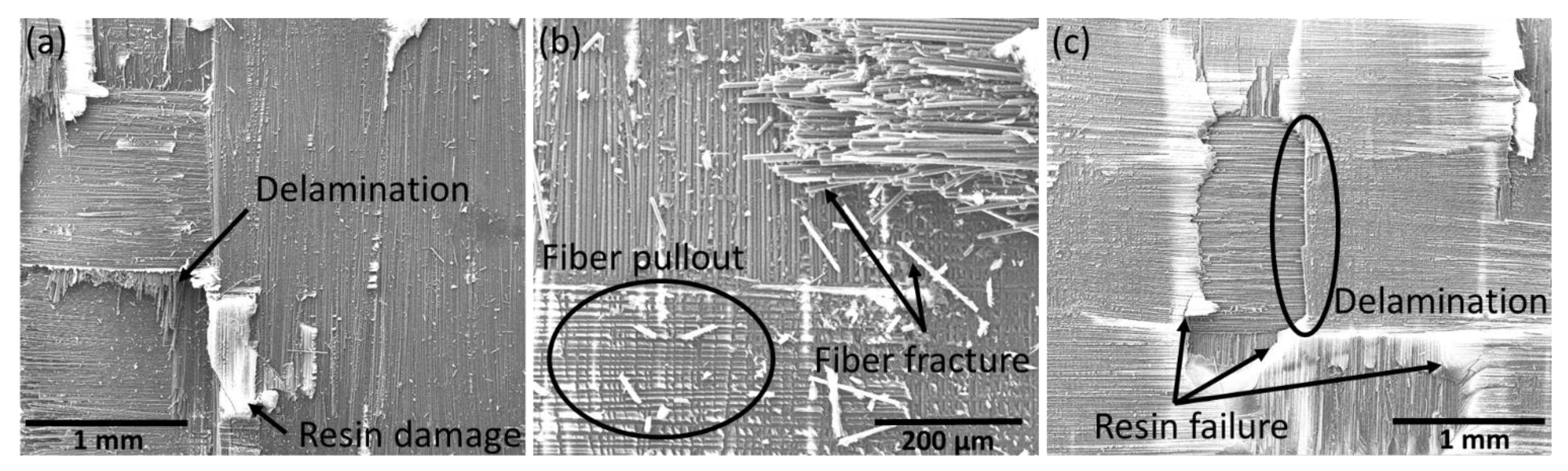

3.5. Fractographic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, T.; Irfan, M.S.; Cantwell, W.J.; Umer, R. Crack healing in infusible thermoplastic composite laminates. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106896. [Google Scholar] [CrossRef]

- Parmar, H.; Khan, T.; Tucci, F.; Umer, R.; Carlone, P. Advanced robotics and additive manufacturing of composites: Towards a new era in Industry 4.0. Mater. Manuf. Process. 2022, 37, 483–517. [Google Scholar] [CrossRef]

- Khan, T.; Fikri, A.; Irfan, M.S.; Gunister, E.; Umer, R. The effect of hybridization on microstructure and thermo-mechanical properties of composites reinforced with different weaves of glass and carbon fabrics. J. Compos. Mater. 2020, 55, 1635–1651. [Google Scholar] [CrossRef]

- Irfan, M.S.; Alia, R.A.; Khan, T.; Cantwell, W.J.; Umer, R. Time-temperature superposition of flexural creep response of carbon fiber PEKK composites manufactured using different prepreg stacking sequence. J. Thermoplast. Compos. Mater. 2023, 36, 1135–1153. [Google Scholar] [CrossRef]

- Irfan, M.S.; Khan, T.; Hussain, T.; Liao, K.; Umer, R. Carbon coated piezoresistive fiber sensors: From process monitoring to structural health monitoring of composites—A review. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106236. [Google Scholar] [CrossRef]

- Umer, R.; Waggy, E.M.; Haq, M.; Loos, A.C. Experimental and numerical characterizations of flexural behavior of VARTM-infused composite sandwich structures. J. Reinf. Plast. Compos. 2012, 31, 67–76. [Google Scholar] [CrossRef]

- Marsh, G. Airbus A350 XWB Update. Reinf. Plast. 2010, 54, 20–24. [Google Scholar] [CrossRef]

- Barroeta Robles, J.; Dubé, M.; Hubert, P.; Yousefpour, A. Repair of thermoplastic composites: An overview. Adv. Manuf. Polym. Compos. Sci. 2022, 8, 68–96. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Skuse, B. The Untapped Potential in Formula 1 Composite Manufacture|CompositesWorld. Available online: https://www.compositesworld.com/articles/the-untapped-potential-in-formula-1-composite-manufacture (accessed on 13 September 2022).

- Wagih, A.; Tao, R.; Lubineau, G. Bio-inspired adhesive joint with improved interlaminar fracture toughness. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106530. [Google Scholar] [CrossRef]

- Gardiner, G. Thermoplastic Composite Demonstrators—EU Roadmap for Future Airframes|CompositesWorld. Available online: https://www.compositesworld.com/articles/thermoplastic-composite-demonstrators-eu-roadmap-for-future-airframes- (accessed on 13 September 2022).

- Khan, T.; Aziz, A.R.; Irfan, M.S.; Cantwell, W.J.; Umer, R. Energy absorption in carbon fiber honeycomb structures manufactured using a liquid thermoplastic resin. J. Compos. Mater. 2022, 56, 1335–1348. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef]

- Vedernikov, A.; Minchenkov, K.; Gusev, S.; Sulimov, A.; Zhou, P.; Li, C.; Xian, G.; Akhatov, I.; Safonov, A. Effects of the Pre-Consolidated Materials Manufacturing Method on the Mechanical Properties of Pultruded Thermoplastic Composites. Polymers 2022, 14, 2246. [Google Scholar] [CrossRef] [PubMed]

- Ridha, M.; Tan, V.B.; Tay, T.E. Traction–separation laws for progressive failure of bonded scarf repair of composite panel. Compos. Struct. 2011, 93, 1239–1245. [Google Scholar] [CrossRef]

- Wang, C.H.; Gunnion, A.J. On the design methodology of scarf repairs to composite laminates. Compos. Sci. Technol. 2008, 68, 35–46. [Google Scholar] [CrossRef]

- Wang, C.H.; Duong, C.N. Design of scarf and doubler-scarf joints. Bond. Jt. Repairs Compos. Airframe Struct. 2016, 4, 83–112. [Google Scholar] [CrossRef]

- Jones, J.S.; Graves, S.R. Repair Techniques for Celion/LARC-160 Graphite/Polyimide Composite Structures. 1984. Available online: https://apps.dtic.mil/sti/citations/ADA305211 (accessed on 14 September 2022).

- Olajide, S.O.; Kandare, E.; Khatibi, A.A. Fatigue life uncertainty of adhesively bonded composite scarf joints—An airworthiness perspective. J. Adhes. 2016, 93, 515–530. [Google Scholar] [CrossRef]

- Darwish, F.H.; Shivakumar, K.N. Experimental and Analytical Modeling of Scarf Repaired Composite Panels. Mech. Adv. Mater. Struct. 2013, 21, 207–212. [Google Scholar] [CrossRef]

- CWang, H.; Gunnion, A.J. Optimum shapes for minimising bond stress in scarf repairs. Aust. J. Mech. Eng. 2015, 6, 153–158. [Google Scholar] [CrossRef]

- Jen, Y.M. Fatigue life evaluation of adhesively bonded scarf joints. Int. J. Fatigue 2012, 36, 30–39. [Google Scholar] [CrossRef]

- Li, J.; Yan, Y.; Zhang, T.; Liang, Z. Experimental study of adhesively bonded CFRP joints subjected to tensile loads. Int. J. Adhes. Adhes. 2015, 57, 95–104. [Google Scholar] [CrossRef]

- Ashcroft, I.A.; Wahab, M.A.; Crocombe, A.D.; Hughes, D.J.; Shaw, S.J. The effect of environment on the fatigue of bonded composite joints. Part 1: Testing and fractography. Compos. Part A Appl. Sci. Manuf. 2001, 32, 45–58. [Google Scholar] [CrossRef]

- Slattery, P.G.; McCarthy, C.T.; O’Higgins, R.M. Assessment of residual strength of repaired solid laminate composite materials through mechanical testing. Compos. Struct. 2016, 147, 122–130. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Khan, K.A.; Liao, K.; Umer, R. Resin infusion process monitoring using graphene coated glass fabric sensors and infusible thermoplastic and thermoset matrices. Polym. Compos. 2022, 43, 2924–2940. [Google Scholar] [CrossRef]

- Obande, W.; Brádaigh, C.M.; Ray, D. Continuous fibre-reinforced thermoplastic acrylic-matrix composites prepared by liquid resin infusion—A review. Compos. B Eng. 2021, 215, 108771. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Cantwell, W.J.; Umer, R. Visualization and investigation of healing mechanism in carbon fiber reinforced Elium® composites. J. Thermoplast. Compos. Mater. 2022. [Google Scholar] [CrossRef]

- CYCOM 937A|Solvay. Available online: https://www.solvay.com/en/product/cycom-937a (accessed on 30 January 2023).

- Sheikh-Ahmad, J.Y.; Almaskari, F.; Hafeez, F. Thermal aspects in machining CFRPs: Effect of cutter type and cutting parameters. Int. J. Adv. Manuf. Technol. 2019, 100–112, 2569–2582. [Google Scholar] [CrossRef]

- Irfan, M.S.; Ali, M.A.; Khan, T.; Anwer, S.; Liao, K.; Umer, R. MXene and graphene coated multifunctional fiber reinforced aerospace composites with sensing and EMI shielding abilities. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107351. [Google Scholar] [CrossRef]

- Standard Test Method for Plastics: Dynamic Mechanical Properties: In Flexure (Three-Point Bending). Available online: https://www.astm.org/d5023-15.html (accessed on 21 May 2022).

- Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending. Available online: https://www.astm.org/d6272-17e01.html (accessed on 21 May 2022).

- Khan, T.; Aydın, O.A.; Acar, V.; Aydın, M.R.; Hülagü, B.; Bayrakçeken, H.; Seydibeyoğlu, M.Ö.; Akbulut, H. Experimental investigation of mechanical and modal properties of Al2O3 nanoparticle reinforced polyurethane core sandwich structures. Mater. Today Commun. 2020, 24, 101233. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Othman, R.; Najjar, I.M. Impact and bending analysis of composite scarf adhesive joints modified with MWCNTs at room and hot temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2019, 610, 012007. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Aljinaidi, A.A.; Hamed, M.A. Fatigue and reliability analysis of nano-modified scarf adhesive joints in carbon fiber composites. Compos. B Eng. 2017, 120, 103–117. [Google Scholar] [CrossRef]

- Atas, C.; Akgun, Y.; Dagdelen, O.; Icten, B.M.; Sarikanat, M. An experimental investigation on the low velocity impact response of composite plates repaired by VARIM and hand lay-up processes. Compos. Struct. 2011, 93, 1178–1186. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Aljinaidi, A.A.; Hamed, M.A. Analysis of adhesively bonded CFRE composite scarf joints modified with MWCNTs. Compos. Part A Appl. Sci. Manuf. 2015, 71, 59–71. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Najjar, I.M. Adhesive layer analysis for scarf bonded joint in CFRE composites modified with MWCNTs under tensile and fatigue loads. Compos. Struct. 2018, 184, 411–427. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Cantwell, W.J.; Rehan, U. Visualizing pseudo-ductility in carbon/glass fiber hybrid composites manufactured using infusible thermoplastic Elium® resin. Polym. Compos. 2022. [Google Scholar] [CrossRef]

- Naresh, K.; Shankar, K.; Rao, B.S.; Velmurugan, R. Effect of high strain rate on glass/carbon/hybrid fiber reinforced epoxy laminated composites. Compos. B Eng. 2016, 100, 125–135. [Google Scholar] [CrossRef]

- Rathore, D.K.; Prusty, R.K.; Mohanty, S.C.; Singh, B.P.; Ray, B.C. In-situ elevated temperature flexural and creep response of inter-ply glass/carbon hybrid FRP composites. Mech. Mater. 2017, 105, 99–111. [Google Scholar] [CrossRef]

- Din, I.U.; Naresh, K.; Umer, R.; Khan, K.A.; Drzal, L.T.; Haq, M.; Cantwell, W.J. Processing and out-of-plane properties of composites with embedded graphene paper for EMI shielding applications. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105901. [Google Scholar] [CrossRef]

| Property | Description |

|---|---|

| Name | CYCOM® 937A |

| Fiber type | Carbon fiber |

| Weave type | Plain |

| Fiber count | 3 K |

| Fiber diameter (µm) | 7 |

| Density (g/cm3) | 1.76 |

| Areal weight (g/m2) | 230 |

| Resin type | Toughened epoxy |

| Resin density (g/cm3) | 1.27 |

| Glass transition (°C) | 190 |

| Nominal thickness (mm) | 0.36 |

| Sample | Viscoelastic Properties | |||

|---|---|---|---|---|

| Maximum Storage Modulus (GPa) | Maximum Loss Modulus (GPa) | Tan Delta Peak | Tg (°C) | |

| Pristine | 44.5 | 6.5 | 0.19 | 186.6 |

| Results | Pristine | Specimen Type | |||

|---|---|---|---|---|---|

| Repaired (25 °C) | Repaired (210 °C) | ||||

| Type A | Type B | Type A | Type B | ||

| Peak Load (N) | 2356 ± 96 | 1059 ± 22 | 1339 ± 34 | 1640 ± 106 | 2285 ± 152 |

| Flexural strength (MPa) | 901 ± 21 | 407 ± 31 | 514 ± 13 | 630 ± 41 | 877 ± 58 |

| Residual strength (%) | -- | 45 | 57 | 70 | 97 |

| Flexural modulus (GPa) | 65 ± 1.5 | 30 ± 1.9 | 36 ± 1.1 | 47 ± 2.3 | 64 ± 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, T.; Hafeez, F.; Umer, R. Repair of Aerospace Composite Structures Using Liquid Thermoplastic Resin. Polymers 2023, 15, 1377. https://doi.org/10.3390/polym15061377

Khan T, Hafeez F, Umer R. Repair of Aerospace Composite Structures Using Liquid Thermoplastic Resin. Polymers. 2023; 15(6):1377. https://doi.org/10.3390/polym15061377

Chicago/Turabian StyleKhan, Tayyab, Farrukh Hafeez, and Rehan Umer. 2023. "Repair of Aerospace Composite Structures Using Liquid Thermoplastic Resin" Polymers 15, no. 6: 1377. https://doi.org/10.3390/polym15061377

APA StyleKhan, T., Hafeez, F., & Umer, R. (2023). Repair of Aerospace Composite Structures Using Liquid Thermoplastic Resin. Polymers, 15(6), 1377. https://doi.org/10.3390/polym15061377