Development of Multiwalled Carbon Nanotubes/Halloysite Nanotubes Reinforced Thermal Responsive Shape Memory Polymer Nanocomposites for Enhanced Mechanical and Shape Recovery Characteristics in 4D Printing Applications

Abstract

1. Introduction

2. Materials and Characterization

2.1. Details of Shape-Memory Polymer and Specifications of Reinforcements

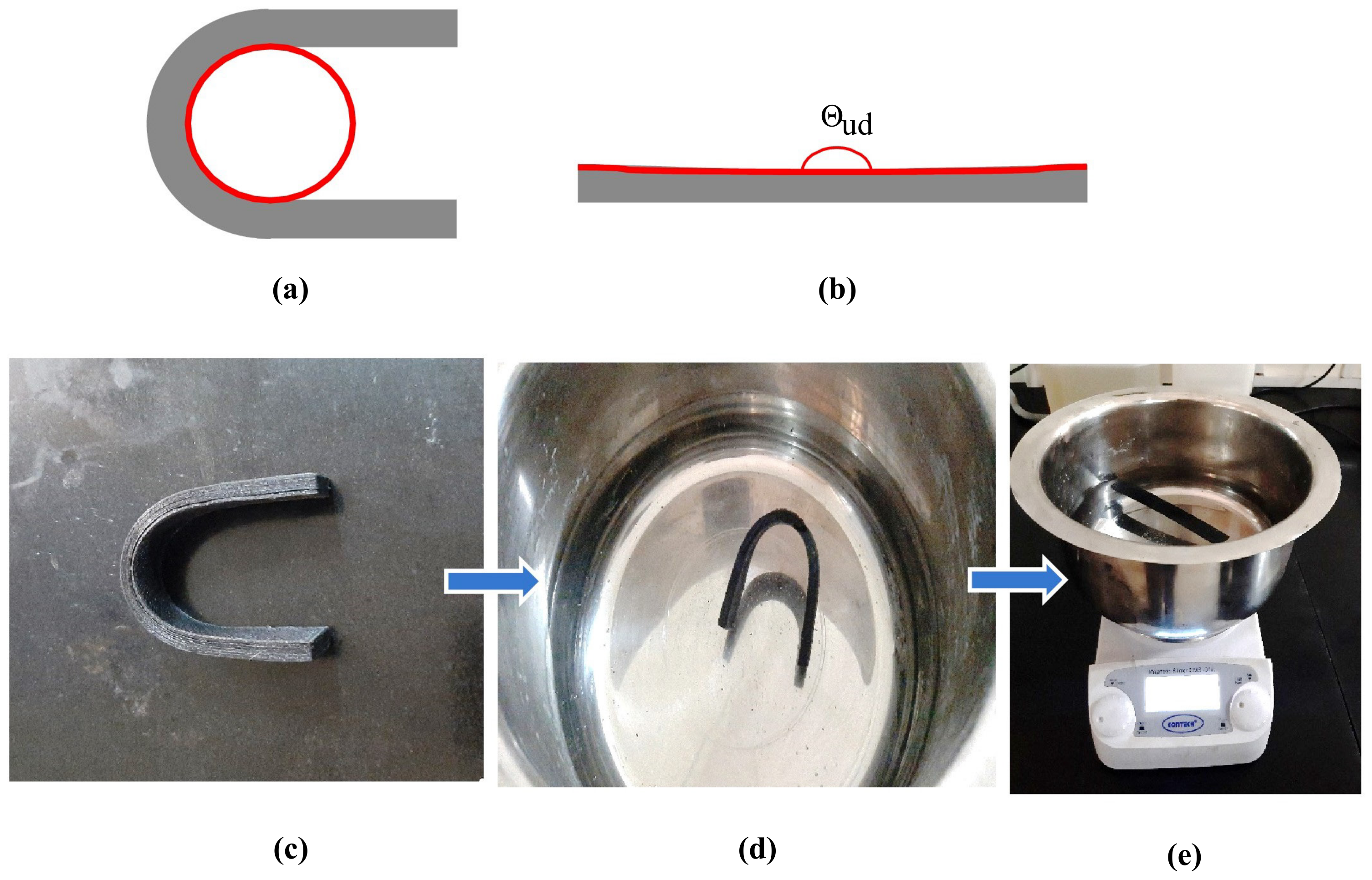

2.2. Processing of Shape-Memory Polymer Nanocomposites and 4D Printing

2.3. Differential Scanning Calorimetry (DSC) Test

2.4. Tensile Test

2.5. Flexural Test

2.6. Flexural Tests for Multiple Cycles

2.7. Shape-Recovery Test

2.8. Impact Test

3. Results and Discussion

3.1. Differential Scanning Calorimetry Results

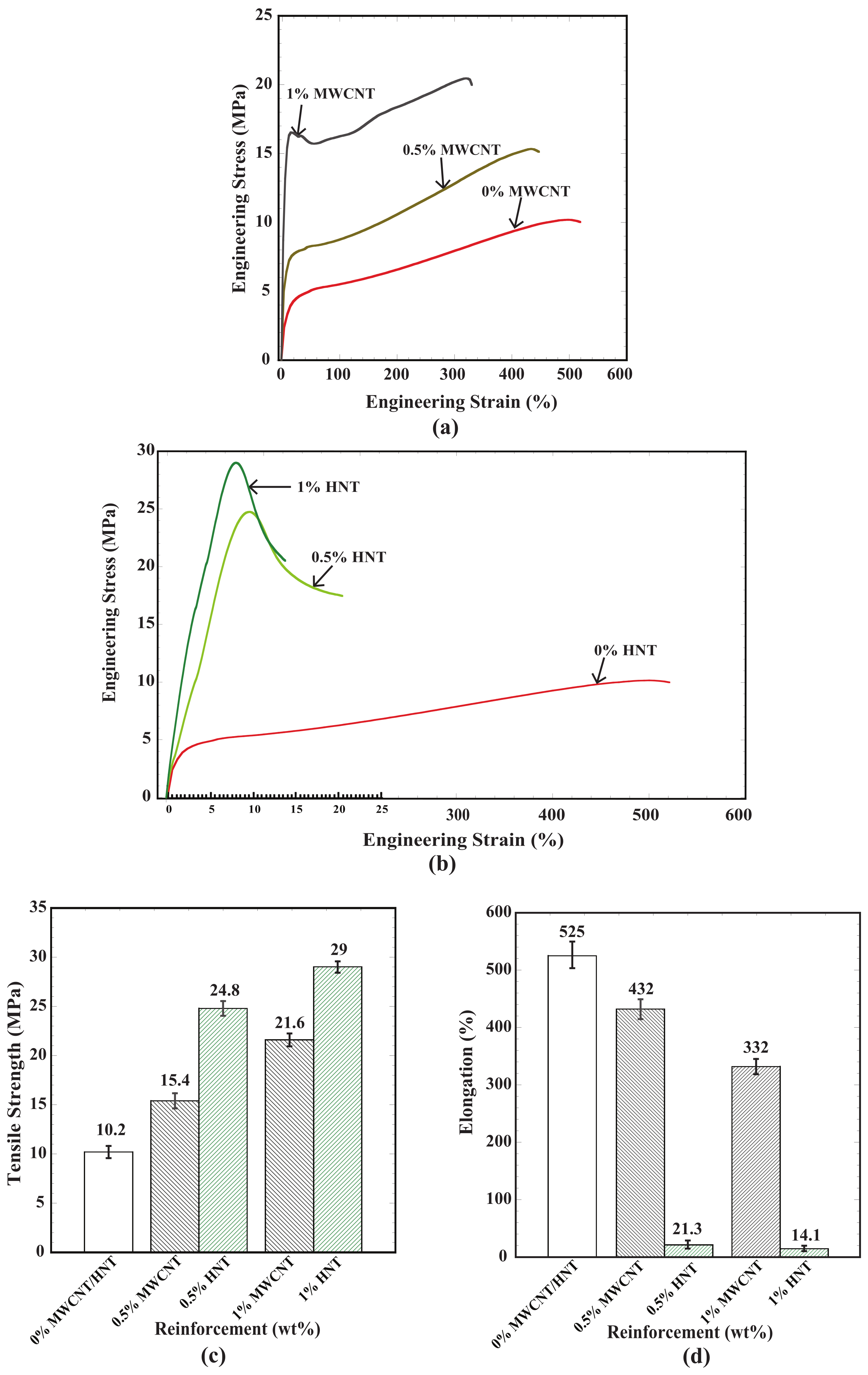

3.2. Results of the Uni-Axial Tensile Test

3.3. Flexural Test Results

3.4. Flexural Test Results for Repeated Cycles

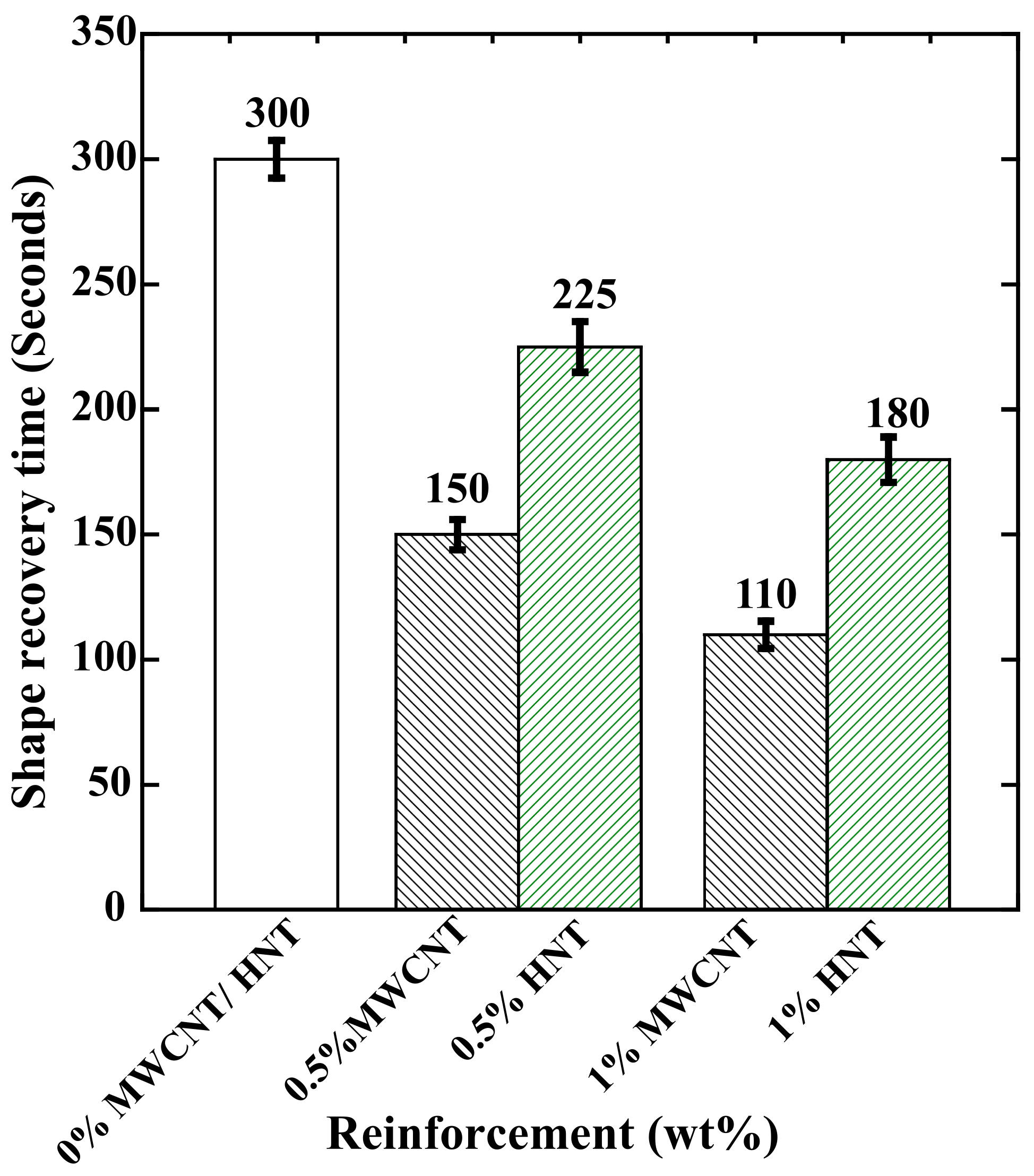

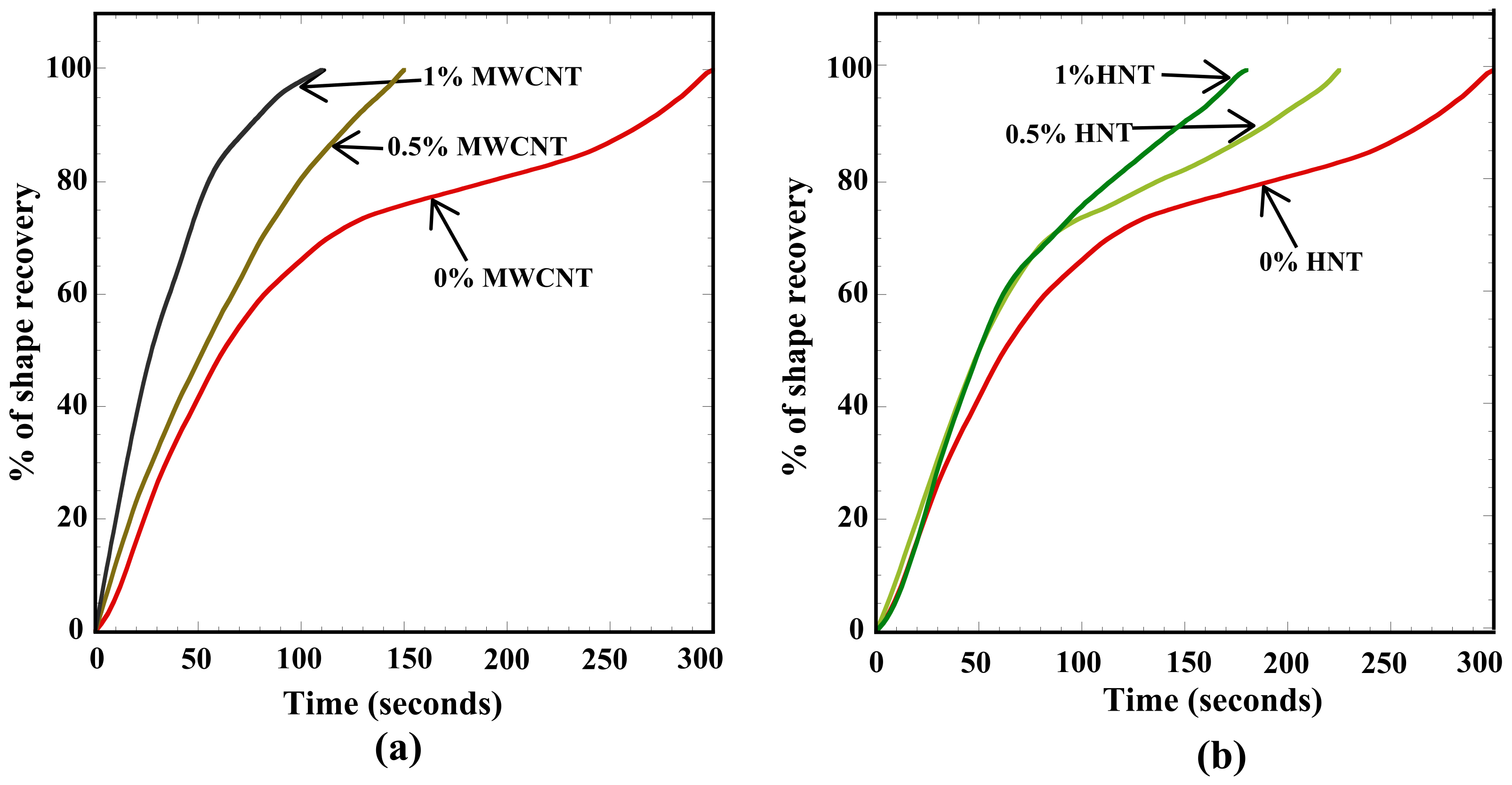

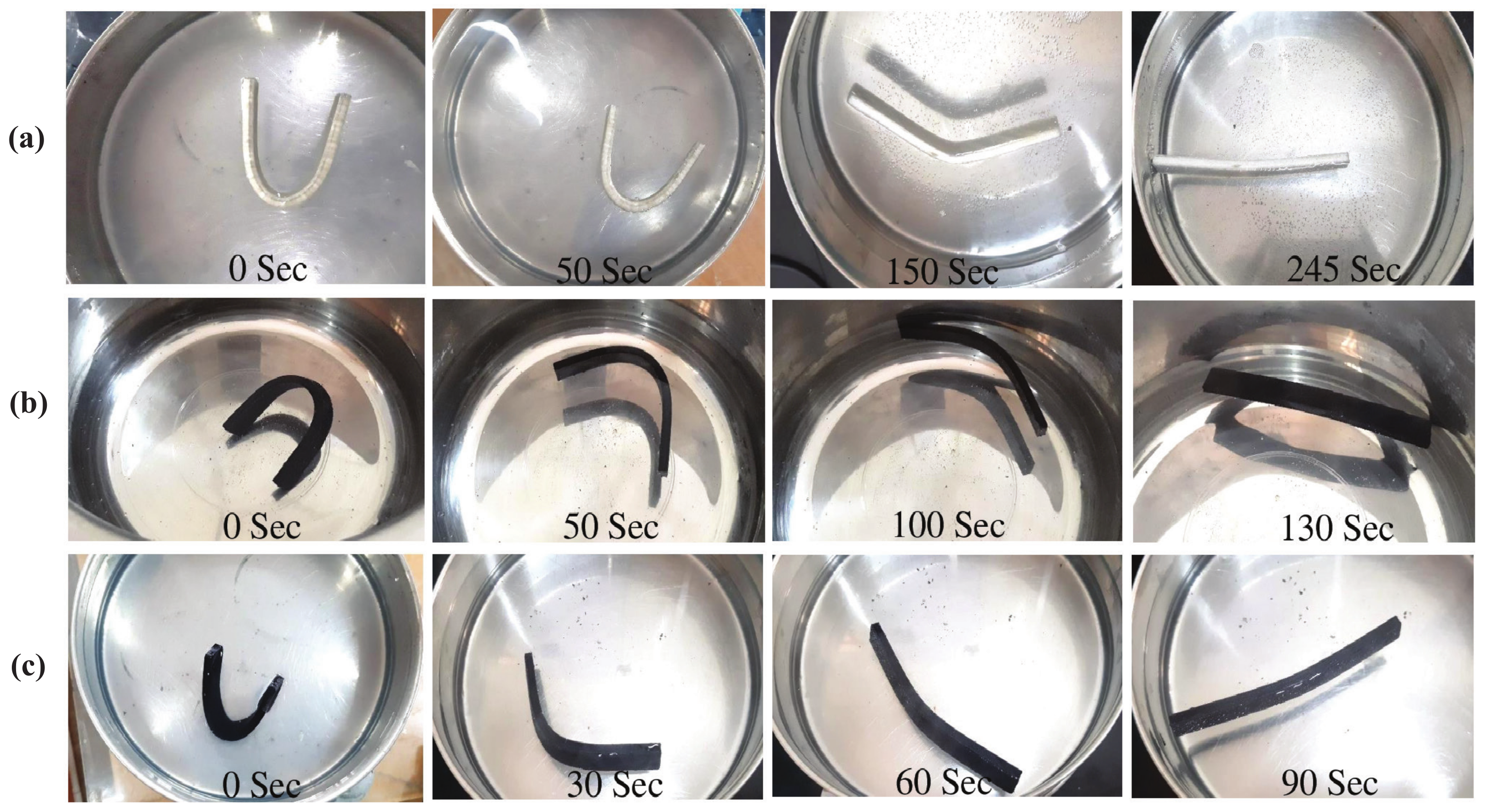

3.5. Shape-Recovery Test Results

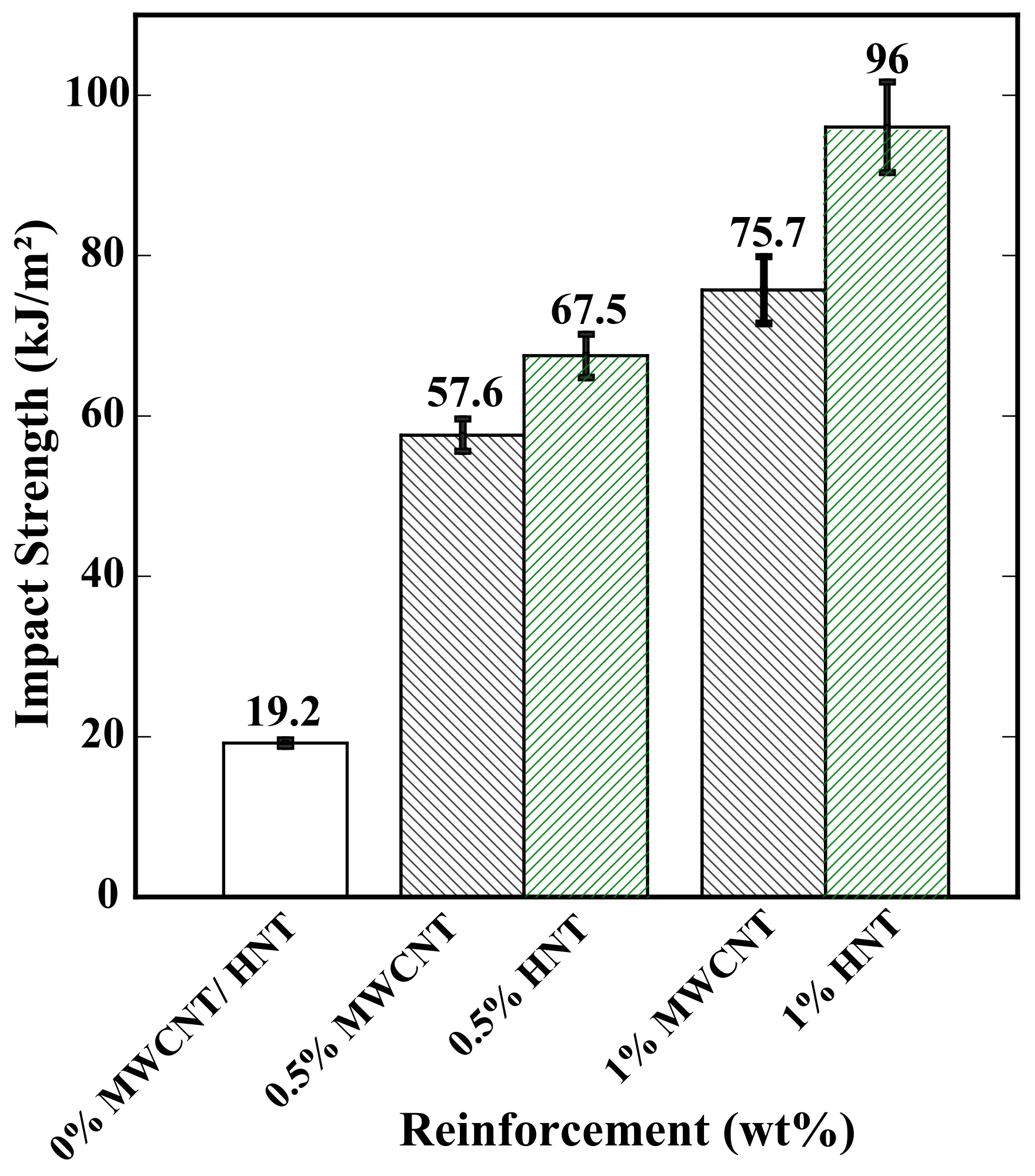

3.6. Impact Test Results

4. Conclusions

- The addition of reinforcements in the SMP matrix significantly affected the tensile strength and percentage of elongation. The HNT-reinforced specimens exhibited higher tensile than the MWCNT-reinforced specimens. At 1 wt%, the HNT-reinforced specimens showed 34% higher tensile strength than the MWCNT-reinforced specimens. At the same time, HNT-reinforced samples exhibited higher brittleness than that MWCNT-reinforced specimens.

- At all the weight percentages considered, HNT-reinforced specimens exhibited greater flexural strength when compared with MWCNT-reinforced specimens. The highest observed flexural strength was at 1 wt% of HNTs, which was about 57% higher than that of 1 wt% MWCNT-reinforced specimens.

- Flexural tests were repeated for three cycles for all the composites. A reduction in flexural strength can be observed after each cycle. Further, the % of this reduction was more in the case of MWCNT-reinforced specimens than that of HNT-reinforced specimens. This indicates better reusability with HNT-reinforced specimens even after a large bending deformation.

- Both reinforcements significantly reduced the shape-recovery time. For all the considered cases, 1 wt% MWCNT-reinforced specimens exhibited a quicker shape-recovery response, which was 38% faster than 1 wt% HNT-reinforced specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SMPU | Shape-memory polyurethane |

| MWCNTs | Multiwalled carbon nanotubes |

| HNTs | Halloysite nanotubes |

| SMPs | Shape-memory polymers |

| SMPPs | Shape-memory polymer pellets |

| Angle of the sample in undeformed/permanent shape | |

| Angle of the sample in deformed/temporary shape |

References

- Bi, H.; Ye, G.; Sun, H.; Ren, Z.; Gu, T.; Xu, M. Mechanically robust, shape memory, self-healing and 3D printable thermoreversible cross-linked polymer composites toward conductive and biomimetic skin devices applications. Addit. Manuf. 2022, 49, 102487. [Google Scholar] [CrossRef]

- Akbar, I.; Hadrouz, M.E.; Mansori, M.E.; Lagoudas, D. Continuum and subcontinuum simulation of FDM process for 4D printed shape memory polymers. J. Manuf. Process. 2022, 76, 335–348. [Google Scholar] [CrossRef]

- Tezerjani, S.M.D.; Yazdi, M.S.; Hosseinzadeh, M.H. The effect of 3D printing parameters on the shape memory properties of 4D printed polylactic acid circular disks: An experimental investigation and parameters optimization. Mater. Today Commun. 2022, 33, 104262. [Google Scholar] [CrossRef]

- Soleyman, E.; Aberoumand, M.; Soltanmohammadi, K.; Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 4D printing of PET-G via FDM including tailormade excess third shape. Manuf. Lett. 2022, 33, 1–4. [Google Scholar] [CrossRef]

- Song, M.; Liu, X.; Yue, H.; Li, S.; Guo, J. 4D printing of PLA/PCL-based bio-polyurethane via moderate cross-linking to adjust the microphase separation. Polymer 2022, 256, 125190. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y. Co-extrusion 4D printing of shape memory polymers with continuous metallic fibers for selective deformation. Compos. Sci. Technol. 2022, 227, 109603. [Google Scholar] [CrossRef]

- Hu, X.; Ge, Z.; Wang, X.; Jiao, N.; Tung, S.; Liu, L. Multifunctional thermo-magnetically actuated hybrid soft millirobot based on 4D printing. Compos. Part B 2022, 228, 109451. [Google Scholar] [CrossRef]

- Lin, C.; Liu, L.; Liu, Y.; Leng, J. 4D printing of shape memory polybutylene succinate/polylactic acid (PBS/PLA) and its potential applications. Compos. Struct. 2022, 279, 114729. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, F.; Wang, L.; Liu, Y.; Leng, J. 4D printing of electroactive shape-changing composite structures and their programmable behaviors. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106925. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Wu, W.; Dong, X.; Sang, L. 4D printing of mechanically robust PLA/TPU/Fe3O4 magneto-responsive shape memory polymers for smart structures. Compos. B 2023, 248, 110382. [Google Scholar] [CrossRef]

- Wan, X.; He, Y.; Liu, Y.; Leng, J. 4D printing of multiple shape memory polymer and nanocomposites with biocompatible, programmable and selectively actuated properties. Addit. Manuf. 2022, 53, 102689. [Google Scholar] [CrossRef]

- Tang, Z.; Gong, J.; Cao, P.; Tao, L.; Pei, X.; Wang, T.; Zhang, Y.; Wang, Q.; Zhang, J. 3D printing of a versatile applicability shape memory polymer with high strength and high transition temperature. Chem. Eng. J. 2022, 431, 134211. [Google Scholar] [CrossRef]

- Yue, C.; Li, M.; Liu, Y.; Fang, Y.; Song, Y.; Xu, M.; Li, J. Three-dimensional printing of cellulose nanofibers reinforced PHB/PCL/ Fe3O4 magneto-responsive shape memory polymer composites with excellent mechanical properties. Addit. Manuf. 2021, 46, 102146. [Google Scholar] [CrossRef]

- Barletta, M.; Gisario, A.; Mehrpouya, M. 4D printing of shape memory polylactic acid (PLA) components: Investigating the role of the operational parameters in fused deposition modelling (FDM). J. Manuf. Process. 2021, 61, 473–480. [Google Scholar] [CrossRef]

- Cersoli, T.; Cresanto, A.; Herberger, C.; MacDonald, E.; Cortes, P. 3D Printed Shape Memory Polymers Produced via Direct Pellet Extrusion. Micromachines 2021, 12, 87. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Wang, F.; Qi, B.; Ding, Z.; Rosen, D.W.; Ge, Q. 3D printing of multi-material composites with tunable shape memory behaviour. Mater. Design. 2020, 193, 108785. [Google Scholar] [CrossRef]

- Koualiarella, A.; Arvanitidis, A.; Argyros, A.; Kousiatza, C.; Karakalas, A.; Lagoudas, D.; Michailidis, N. Tuning of shape memory polymer properties by controlling 3D printing strategy. CIRP Ann.-Manuf. Technol. 2020, 1, 213–216. [Google Scholar] [CrossRef]

- Pandini, S.; Inverardi, N.; Scalet, G.; Battini, D.; Bignotti, F.; Marconi, S.; Auricchio, F. Shape memory response and hierarchical motion capabilities of 4D printed auxetic structures. Mech. Res. Commun. 2020, 103, 103463. [Google Scholar] [CrossRef]

- Patel, K.K.; Purohit, R. Improved shape memory and mechanical properties of microwave-induced shape memory polymer/MWCNTs composites. Mater. Today Commun. 2019, 20, 100579. [Google Scholar] [CrossRef]

- Kang, M.; Pyo, Y.; Jang, J.; Park, Y.; Son, Y.; Choi, M.C.; Ha, J.; Chang, Y.; Lee, C.S. Design of a shape memory composite(SMC) using 4D printing technology. Sens. Actuators 2018, A283, 187–195. [Google Scholar] [CrossRef]

- Hu, G.F.; Damanpack, A.R.; Bodaghi, M.; Liao, W.H. Increasing Dimension of Structures by 4D Printing Shape Memory Polymers via Fused Deposition Modeling. Smart Mater. Struct. 2017, 26, 125023. [Google Scholar] [CrossRef]

- Ly, S.T.; Kim, J.Y. 4D printing—Fused deposition modeling printing with thermal-responsive shape memory polymers. Int. J. Precis. Eng. Manuf.-Green Tech. 2017, 4, 267–272. [Google Scholar] [CrossRef]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef] [PubMed]

- Namathoti, S.; Vakkalagadda, M.R.K. Mechanical and Shape Recovery Characterization of MWCNTs/HNTs Reinforced Thermal Responsive Shape Memory Polymer Nanocomposites. Polymers 2023, 15, 710. [Google Scholar] [CrossRef]

- Namathoti, S.; Ravindra Kumar, V.M.; Rama Sreekanth, P.S. A review on progress in magnetic, microwave, ultrasonic responsive Shape-memory polymer composites. Mater. Today Proc. 2022, 56, 1182–1191. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Zolfagharian, A.; Bodaghi, M.; Baghani, M. A New Strategy for Achieving Shape Memory Effects in 4D Printed Two-Layer Composite Structures. Polymers 2022, 14, 5446. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing-Encapsulated Polycaprolactone–ThermoplasticPolyurethane with High Shape Memory Performances. Adv. Eng. Mater. 2022, 2022, 2201309. [Google Scholar] [CrossRef]

- Soleyman, E.; Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Ghasemi, I.; Abrinia, K.; Baniassadi, M.; Wang, K.; Baghani, M. Shape memory performance of PETG 4D printed parts under compression in cold, warm, and hot programming. Smart Mater. Struct. 2022, 31, 085002. [Google Scholar] [CrossRef]

- Deka, H.; Karak, N.; Kalita, R.D.; Buragohain, A.K. Biocompatible hyperbranched polyurethane/multi-walled carbon nanotube composites as shape memory materials. Carbon 2010, 48, 2013–2022. [Google Scholar] [CrossRef]

- Sahakaro, K. Mechanism of reinforcement using nanofillers in rubber nanocomposites. In Progress in Rubber Nanocomposites; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2017; pp. 81–113. [Google Scholar]

- Rana, S.; Karak, N.; Cho, J.W.; Kim, Y.H. Enhanced dispersion of carbon nanotubes in hyperbranched polyurethane and properties of nanocomposites. Nanotechnology 2008, 19, 495707. [Google Scholar] [CrossRef] [PubMed]

- Kalakonda, P.; Banne, S.; Kalakonda, P. Enhanced mechanical properties of multiwalled carbon nanotubes/thermoplastic polyurethane nanocomposites. Nanomater. Nanotechnol. 2019, 9, 1847980419840858. [Google Scholar] [CrossRef]

- Yetgin, S.H. Effect of multi walled carbon nanotube on mechanical, thermal and rheological properties of polypropylene. J. Mater. Res. Technol. 2019, 8, 4725–4735. [Google Scholar] [CrossRef]

- Szczygielska, A.; Kijeñski, J. Studies of properties of polypropylene/halloysite composites. Pol. J. Chem. Technol. 2011, 13, 61–65. [Google Scholar] [CrossRef]

- Kumar, D.; Jindal, P. Effect of multi-walled carbon nanotubes on thermal stability of polyurethane nanocomposites. Mater. Res. Express 2019, 6, 105336. [Google Scholar] [CrossRef]

- Fonseca, M.A.; Abreu, B.; Gonçalves, F.A.M.M.; Ferreira, A.G.M.; Moreira, R.A.S.; Oliveira, M.S.A. Shape memory polyurethanes reinforced with carbon nanotubes. Compos. Struct. 2013, 99, 105–111. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, J. Self-organizing alignment of carbon nanotube in shape memory segmented fiber prepared by in situ polymerization and melt spinning. Compos. Part A Appl. Sci. Manuf. 2008, 39, 314–321. [Google Scholar] [CrossRef]

- Arun, D.I.; Chakravarthy, P.; Arockiakumar, R.; Santhosh, B. Shape Memory Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

| Reinforcement | MWCNTs | HNTs |

|---|---|---|

| Purity (%) | 99 | 99.9 |

| Diameter (nm) | 5–20 | 15–50 |

| Length (µm) | 10 | 1–15 |

| Thermal conductivity (W/mK) | 0.35 | 0.092 |

| Density (Kg/m3) | 2100 | 2540 |

| Specific heat capacity (J/kgK) | 550 | 920 |

| Thermal diffusivity (mm2/s) | 0.303 | 0.039 |

| Printing Parameter | Value |

|---|---|

| Layer height (mm) | 0.2 |

| Print speed | 30 mm/s |

| Nozzle temperature | 220 °C |

| Print-bed temperature | 60 °C |

| Printing Pattern | 45° and 135° |

| Type of Reinforcement | % of Reinforcement | Tg (°C) | Tm (°C) |

|---|---|---|---|

| Pure SMPU | 0 | 56.5 | 163 |

| MWCNTs | 0.5 | 63 | 171 |

| 1 | 69 | 182 | |

| HNTs | 0.5 | 62 | 168 |

| 1 | 66 | 177 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Namathoti, S.; Vakkalagadda, M.R.K. Development of Multiwalled Carbon Nanotubes/Halloysite Nanotubes Reinforced Thermal Responsive Shape Memory Polymer Nanocomposites for Enhanced Mechanical and Shape Recovery Characteristics in 4D Printing Applications. Polymers 2023, 15, 1371. https://doi.org/10.3390/polym15061371

Namathoti S, Vakkalagadda MRK. Development of Multiwalled Carbon Nanotubes/Halloysite Nanotubes Reinforced Thermal Responsive Shape Memory Polymer Nanocomposites for Enhanced Mechanical and Shape Recovery Characteristics in 4D Printing Applications. Polymers. 2023; 15(6):1371. https://doi.org/10.3390/polym15061371

Chicago/Turabian StyleNamathoti, Sivanagaraju, and Manikanta Ravindra Kumar Vakkalagadda. 2023. "Development of Multiwalled Carbon Nanotubes/Halloysite Nanotubes Reinforced Thermal Responsive Shape Memory Polymer Nanocomposites for Enhanced Mechanical and Shape Recovery Characteristics in 4D Printing Applications" Polymers 15, no. 6: 1371. https://doi.org/10.3390/polym15061371

APA StyleNamathoti, S., & Vakkalagadda, M. R. K. (2023). Development of Multiwalled Carbon Nanotubes/Halloysite Nanotubes Reinforced Thermal Responsive Shape Memory Polymer Nanocomposites for Enhanced Mechanical and Shape Recovery Characteristics in 4D Printing Applications. Polymers, 15(6), 1371. https://doi.org/10.3390/polym15061371