Three-Dimensional Printing of Recycled Polypropylene and Activated Carbon Coatings for Harmful Gas Adsorption and Antibacterial Properties

Abstract

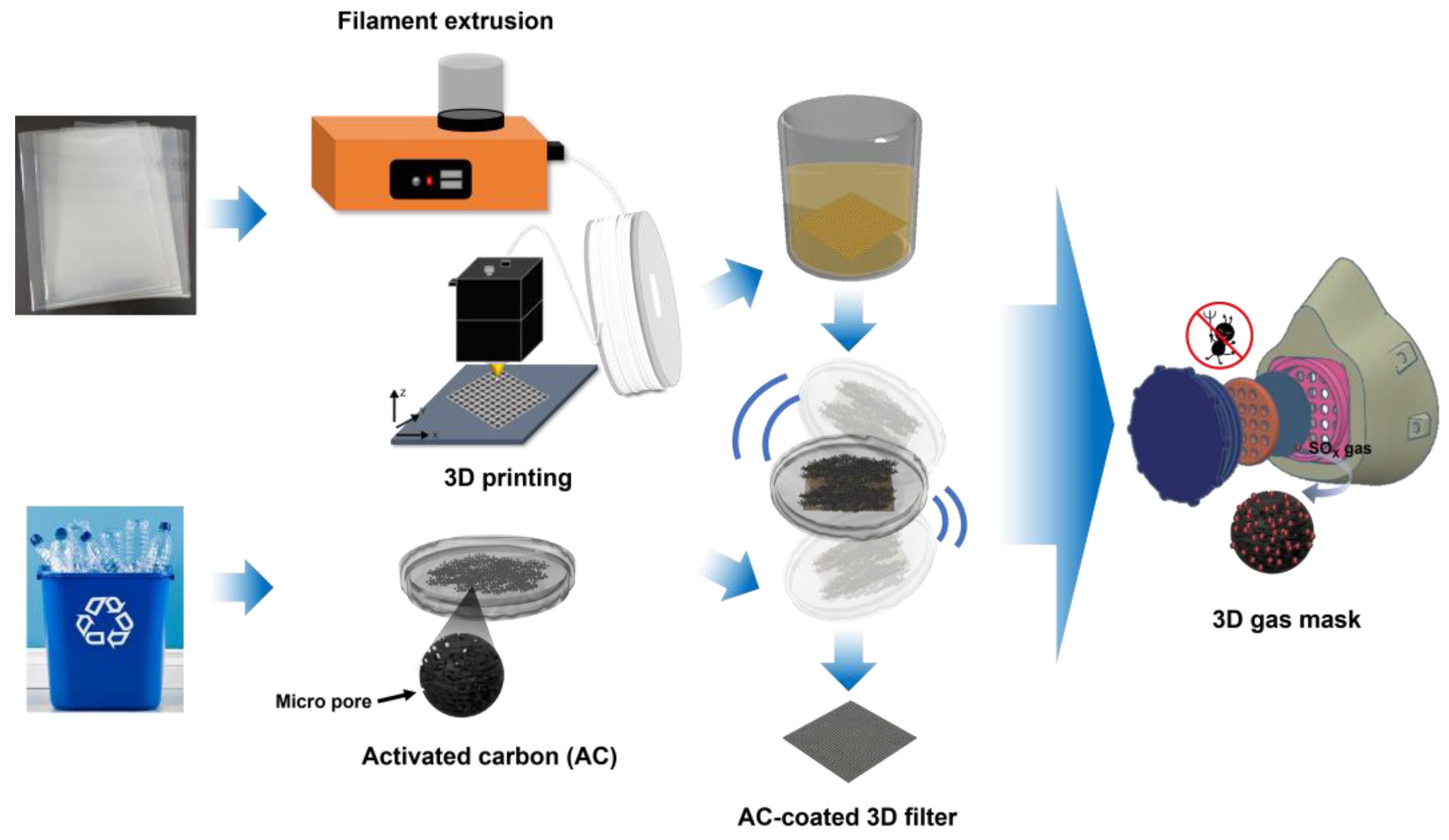

1. Introduction

2. Experimental section

2.1. Materials

2.2. Synthesis of Activated Carbon Based on Recycled Polymer

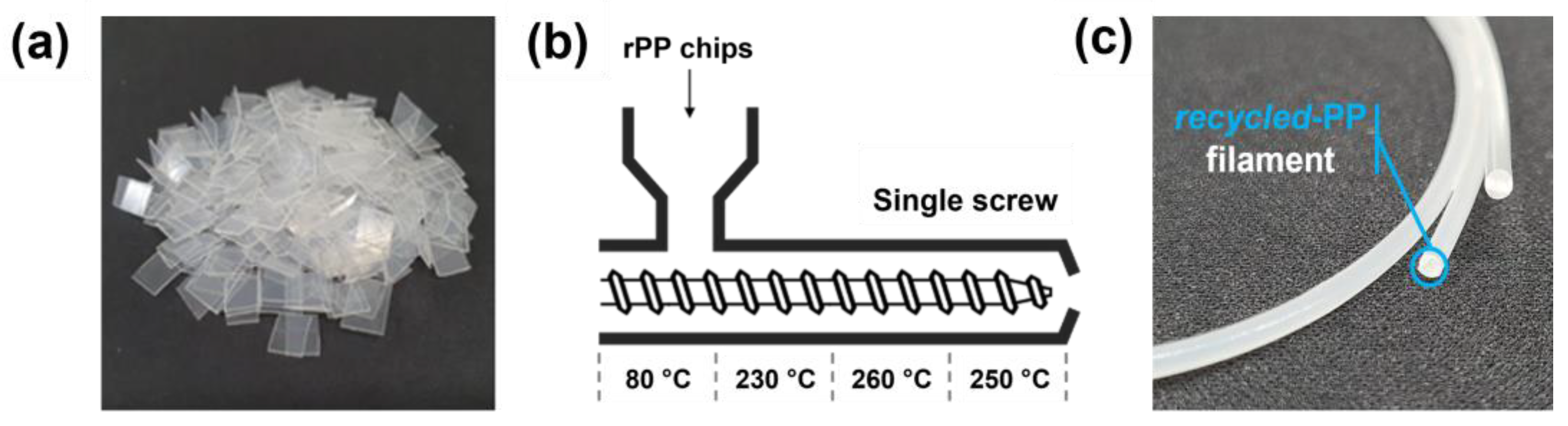

2.3. Filament Extrusion with Recycled Polymer

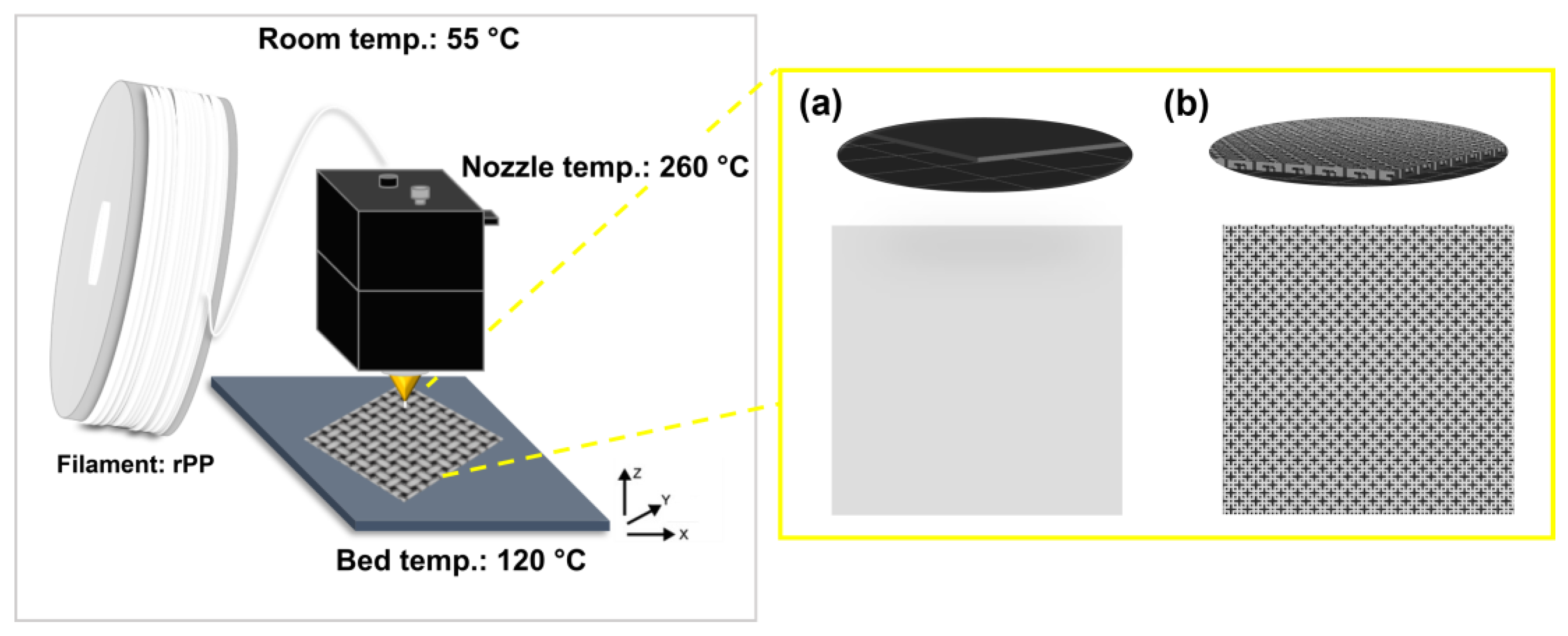

2.4. Three-Dimensional Printing with Recycled Polymer Filament

2.5. Coating with AC on 3D Printed Filter Template

2.6. Characterization

3. Results and Discussion

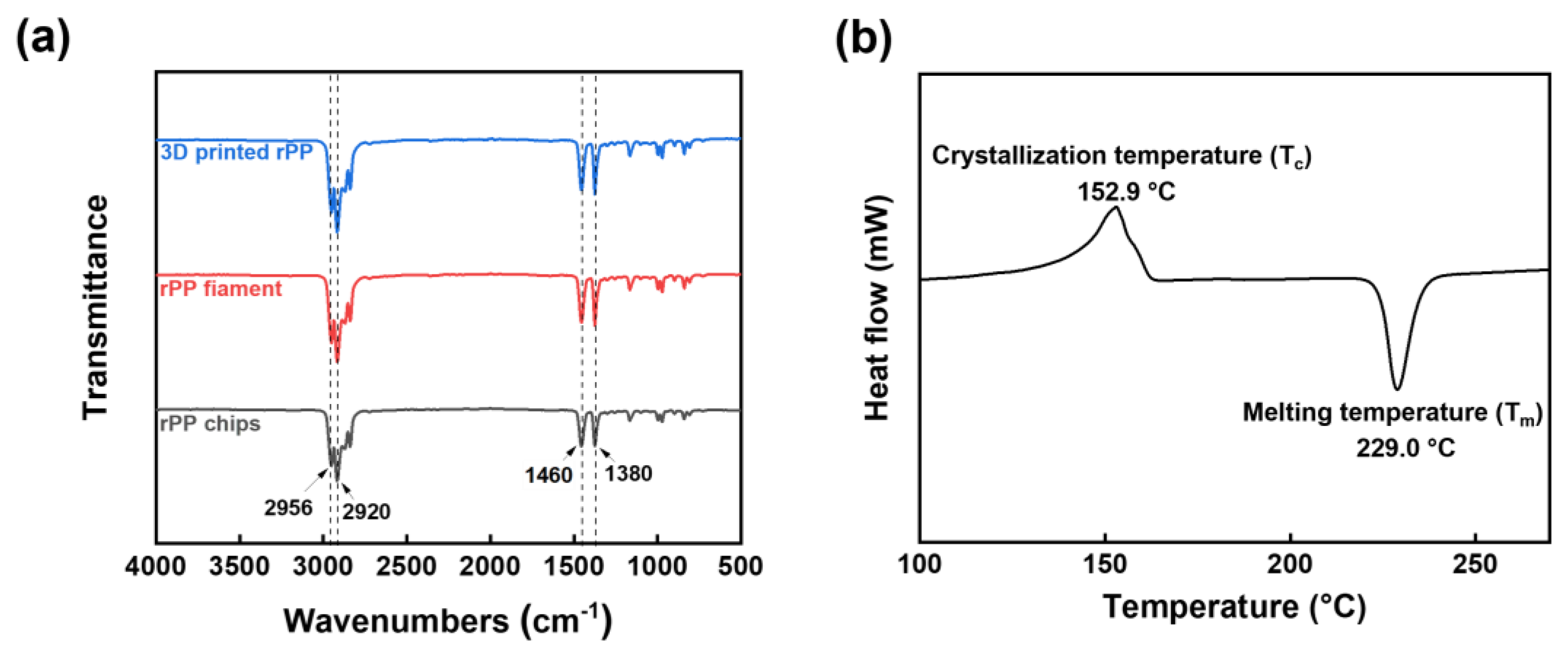

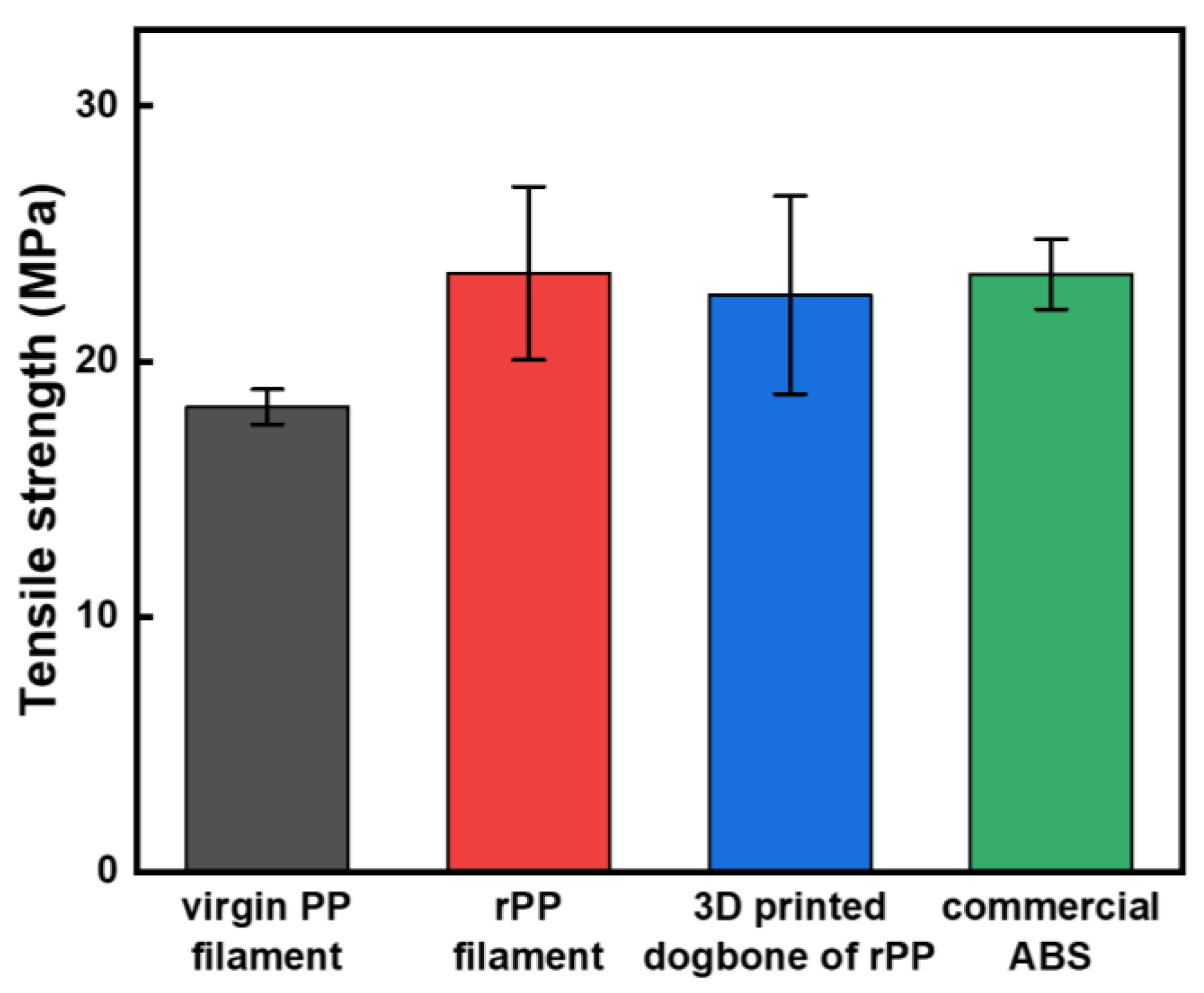

3.1. Characterization of Recycled Polymer

3.2. Characterization of Activated Carbon

3.3. Preparation and Characterization of AC-Coated 3D Filter

3.4. Harmful Gas Adsorption Abilities and Antibacterial Properties of AC-Coated 3D Filter

3.5. Application of AC-Coated 3D Filter to 3D Printed Gas Mask

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Syed, A.M.T.; Elias, P.K.; Amit, B.; Susmita, B.; Lisa, O.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2017, 1, 1–16. [Google Scholar]

- Holzmann, P.; Breitenecker, R.J.; Soomro, A.A.; Schwarz, E.J. User entrepreneur business models in 3D printing. J. Manuf. Technol. Manag. 2017, 28, 75–94. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical properties of specimens 3D printed with virgin and recycled polylactic acid. 3D Print Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Fu, J.; He, Y. A Review of 3D Printing Technologies for Soft Polymer Materials. Adv. Funct. Mater. 2020, 30, 2000187. [Google Scholar] [CrossRef]

- Tess. Indian Jewelry Brand Isharya Unveils ‘Infinite Petals’ 3D Printer Jewelry Collection 2017. 3D Printer and 3D Printing News, (accessed on 12 April 2017).

- Thomas. 3D Printed Jellyfish Robots Created to Monitor Fragile Coral Reefs. 3D Printer and 3D Printing News, (accessed on 3 October 2018).

- Thomas, G.E. Transportation to Produce Up to 2018, 250 3D Printed Locomotive Parts by 2025. 3D Printer and 3D Printing News, (accessed on 28 September 2018).

- Paul, G.T. Allen’s Stratolaunch Space Venture Uses 3D Printing to Develop PGA Rocket Engine 2018. 3D Printer and 3D Printing News. (accessed on 1 October 2018).

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Lambeth. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Seo, S.W.; Choi, Y.J.; Kim, J.H.; Cho, J.H.; Lee, Y.-S.; Im, J.S. Micropore-structured activated carbon prepared by waste PET/petroleum-based pitch. Carbon Lett. 2019, 29, 385–392. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Akkad, R.O.; Soliman, A.A.; Madkour, T.M. Characterisation of thermally treated and untreated polyeth-ylene–polypropylene blends using DSC, TGA and IR techniques. Plast. Rubber. Compos. 2009, 38, 265–278. [Google Scholar] [CrossRef]

- Nasir, A.; Yasin, T.; Islam, A. Thermo-oxidative degradation behavior of recycled polypropylene. J. Appl. Polym. Sci. 2011, 119, 3315–3320. [Google Scholar] [CrossRef]

- Camacho, W.; Karlsson, S. NIR, DSC, and FTIR as quantitative methods for compositional analysis of blends of polymers obtained from recycled mixed plastic waste. Polym. Eng. Sci. DSC NIR 2001, 41, 1626–1635. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical recycling of packaging plastics: A review. Macromol. Rapid. Commun. 2021, 42, e2000415. [Google Scholar] [CrossRef] [PubMed]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Strapasson, R. Valorização do Polipropileno Através de Sua Mistura e Reciclagem; Universidade Federal do Paraná: Curitiba, Brazil, 2004. [Google Scholar]

- Bahlouli, N.; Pessey, D.; Raveyre, C.; Guillet, J.; Ahzi, S.; Dahoun, A.; Hiver, J.M. Recycling effects on the rheological and thermomechanical properties of polypropylene-based composites. Mater. Des. 2012, 33, 451–458. [Google Scholar] [CrossRef]

- Perrin, D.; Mantaux, O.; Ienny, P.; Léger, R.; Dumon, M.; Lopez-Cuesta, J.M. Influence of impurities on the performances of HIPS recycled from waste electric and electronic equipment (WEEE). Waste Manag. J. M Lopez 2016, 56, 438–445. [Google Scholar] [CrossRef]

- Cruz, O.F.; Campello-Gómez, I.; Casco, M.E.; Serafin, J.; Silvestre-Albero, J.; Martínez-Escandell, M.; Hotza, D.; Rambo, C.R. Enhanced CO2 capture by cupuassu shell-derived activated carbon with high microporous volume. Carbon Lett. 2022; online published. [Google Scholar]

- Isinkaralar, K.; Turkyilmaz, A. Simultaneous adsorption of selected VOCs in the gas environment by low-cost adsorbent from Ricinus communis. Carbon Lett. 2022, 32, 1781–1789. [Google Scholar] [CrossRef]

- Lu, C.; Ma, W.; Ba, S.; Zhang, D. Resin content calculation of carbon fiber/poly (ether ether ketone) by thermogravimetric analysis. Polym. Test 2023, 117, 107861. [Google Scholar] [CrossRef]

- Burchacka, E.; Pstrowska, K.; Beran, E.; Fałtynowicz, H.; Chojnacka, K.; Kułażyński, M. Antibacterial agents adsorbed on active carbon: A new approach for S. aureus and E. coli pathogen elimination. Pathogens 2021, 10, 1066. [Google Scholar] [CrossRef]

- Bai, B.C.; Lee, H.; Lee, C.W.; Lee, Y.; Im, J.S. N2 plasma treatment on activated carbon fibers for toxic gas removal: Mechanism study by electrochemical investigation. Chem. Eng. J. 2016, 306, 260–268. [Google Scholar] [CrossRef]

- Burchacka, E.; Pstrowska, K.; Beran, E.; Fałtynowicz, H.; Chojnacka, K.; Kułażyński, M. Activated carbon surface modifications by adsorption of bacteria and their effect on aqueous lead adsorption. J. Chem. Technol. Biotechnol. 2001, 76, 120–1215. [Google Scholar] [CrossRef]

- Kianfar, E.; Sayadi, H. Recent advances in properties and applications of nanoporous materials and porous carbons. Carbon Lett. 2022, 32, 1645–1669. [Google Scholar] [CrossRef]

- Mojoudi, N.; Mirghaffari, N.; Soleimani, M.; Sayadi, H.; Shariatmadari, H.; Belver, C.; Bedia, J. Phenol adsorption on high microporous activated carbons prepared from oily sludge: Equilibrium, kinetic and thermodynamic studies. Sci. Rep. 2019, 9, 19352. [Google Scholar] [CrossRef]

| SBET (m2/g) | Vmic (cm3/g) | Vtotal (cm3/g) | Micropore Fraction (%) | |

|---|---|---|---|---|

| cAC | 1849 | 0.74 | 0.76 | 97.4 |

| rAC | 3298 | 1.42 | 1.55 | 91.6 |

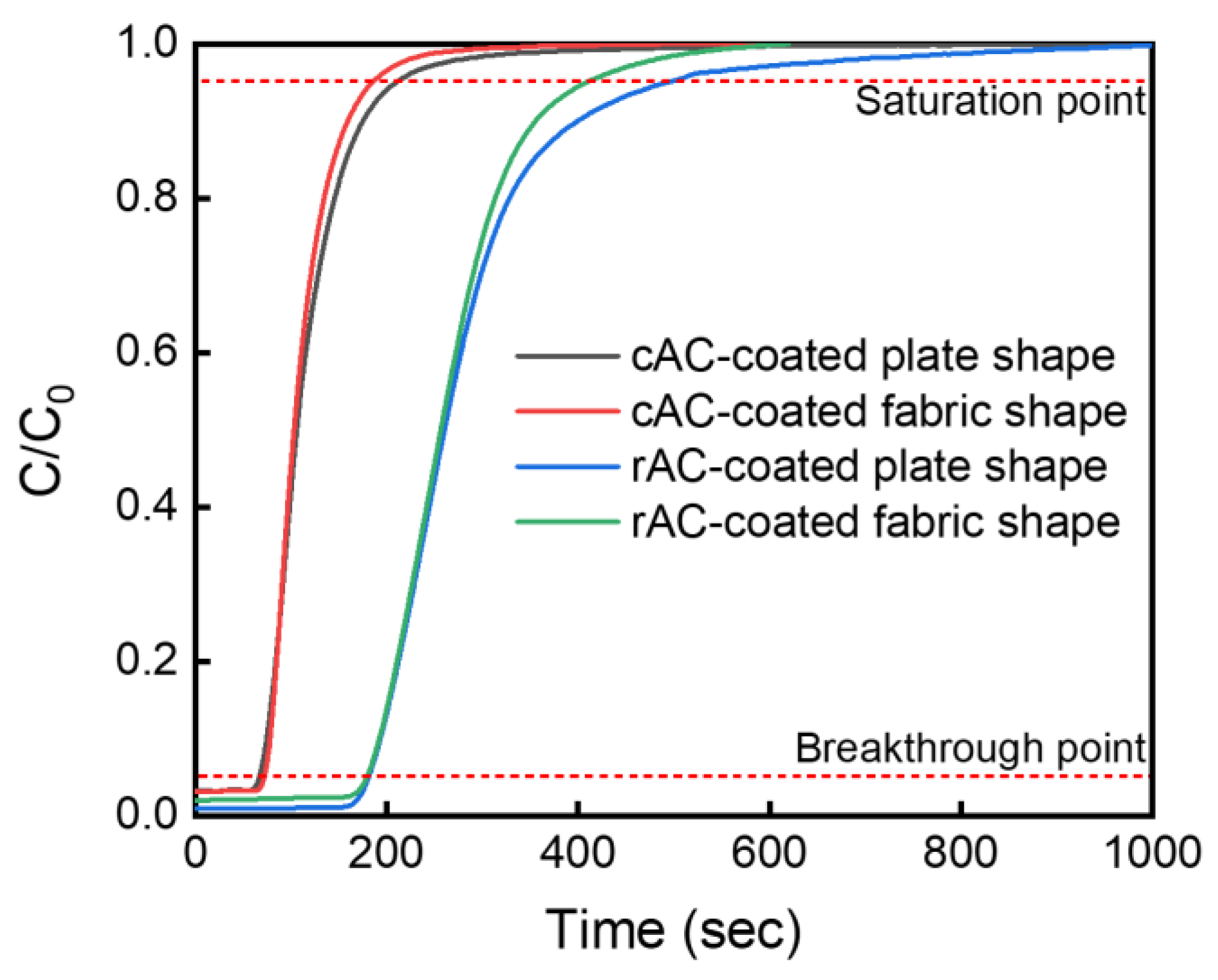

| Breakthrough Time | Saturation Time | Percentage of SO2 Removal | Adsorption Capacity | |

|---|---|---|---|---|

| t0.05 | t0.95 | RSO2 | qtotal | |

| (min) | (min) | (%) | (mg) | |

| cAC-coated plate shape | 67 | 185 | 0.95 | 572.52 |

| cAC-coated fabric shape | 73 | 210 | 1.02 | 611.88 |

| rAC-coated plate shape | 179 | 409 | 1.49 | 891.77 |

| rAC-coated fabric shape | 181 | 493 | 1.73 | 1038.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.B.; An, S.H.; Jung, J.W.; Lee, J.U. Three-Dimensional Printing of Recycled Polypropylene and Activated Carbon Coatings for Harmful Gas Adsorption and Antibacterial Properties. Polymers 2023, 15, 1173. https://doi.org/10.3390/polym15051173

Park JB, An SH, Jung JW, Lee JU. Three-Dimensional Printing of Recycled Polypropylene and Activated Carbon Coatings for Harmful Gas Adsorption and Antibacterial Properties. Polymers. 2023; 15(5):1173. https://doi.org/10.3390/polym15051173

Chicago/Turabian StylePark, Jung Bin, Seok Hwan An, Jae Woong Jung, and Jea Uk Lee. 2023. "Three-Dimensional Printing of Recycled Polypropylene and Activated Carbon Coatings for Harmful Gas Adsorption and Antibacterial Properties" Polymers 15, no. 5: 1173. https://doi.org/10.3390/polym15051173

APA StylePark, J. B., An, S. H., Jung, J. W., & Lee, J. U. (2023). Three-Dimensional Printing of Recycled Polypropylene and Activated Carbon Coatings for Harmful Gas Adsorption and Antibacterial Properties. Polymers, 15(5), 1173. https://doi.org/10.3390/polym15051173