Influence of Compounding Parameters on Color Space and Properties of Thermoplastics with Ultramarine Blue Pigment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compounding and Fabrication

2.3. Characterization

2.3.1. Morphology

2.3.2. Rheological Properties

2.3.3. Thermal Properties

2.3.4. Color Measurement

2.3.5. Flexural Properties

3. Results and Discussion

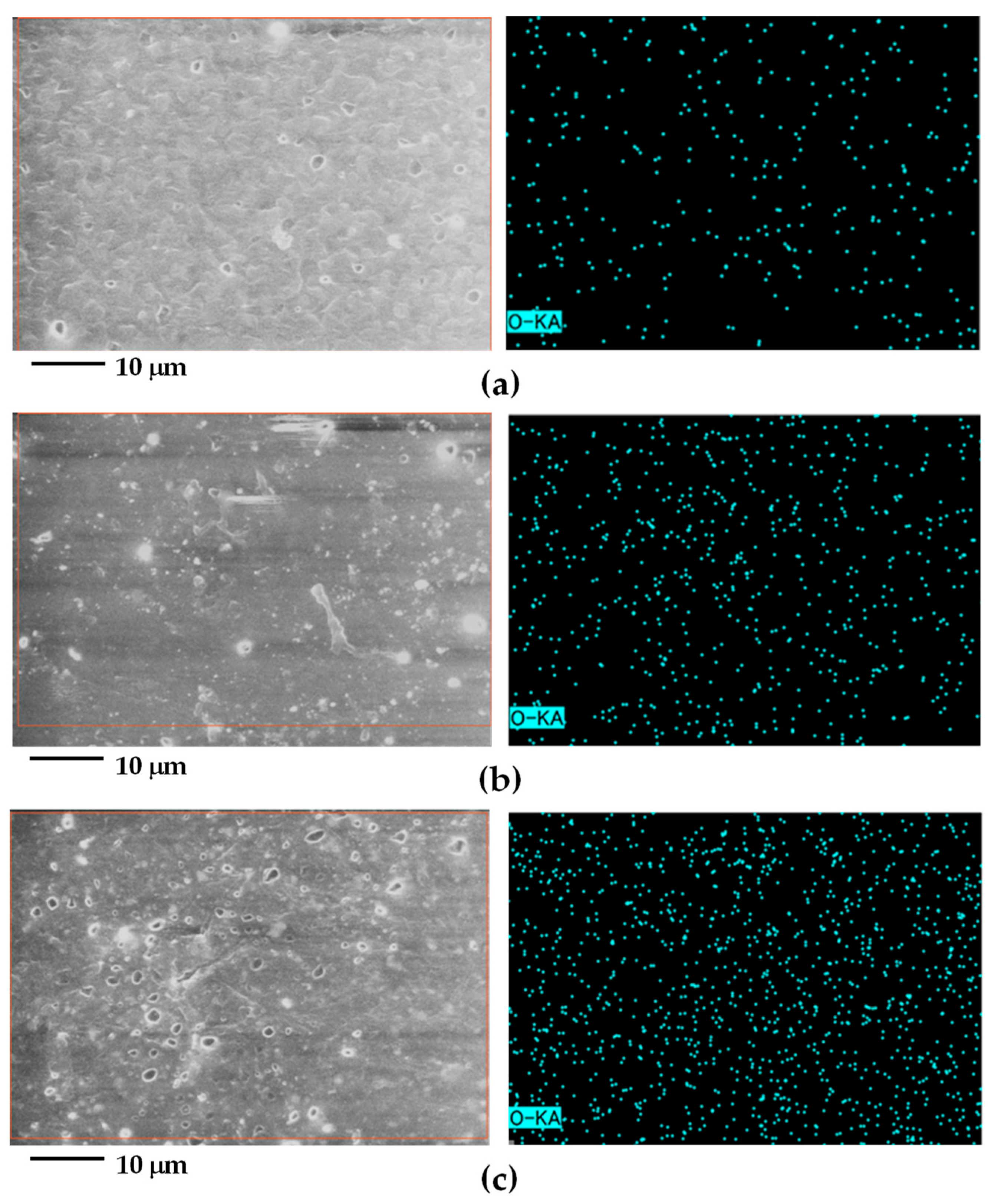

3.1. Observation of Ultramarine Blue Pigment

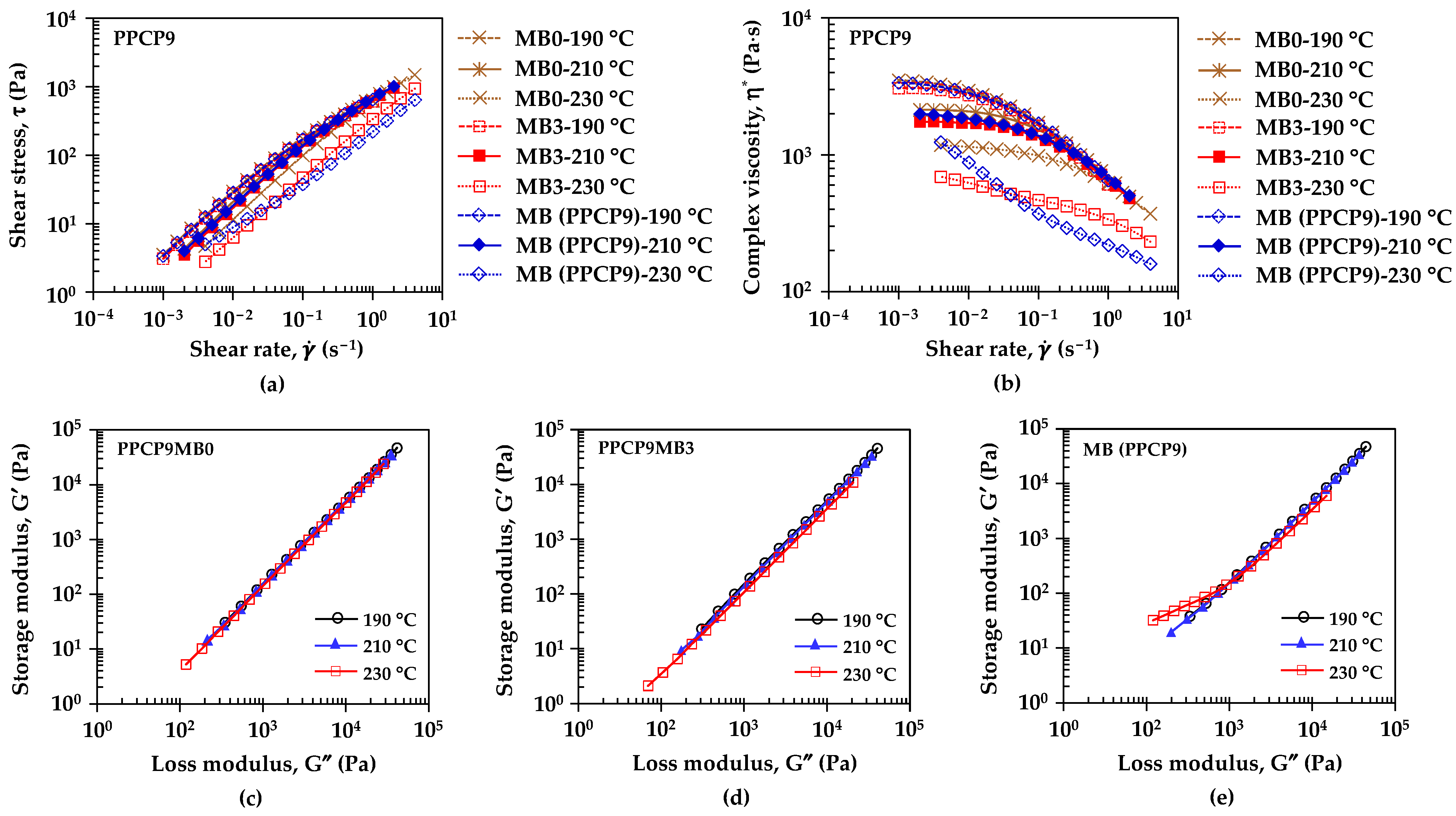

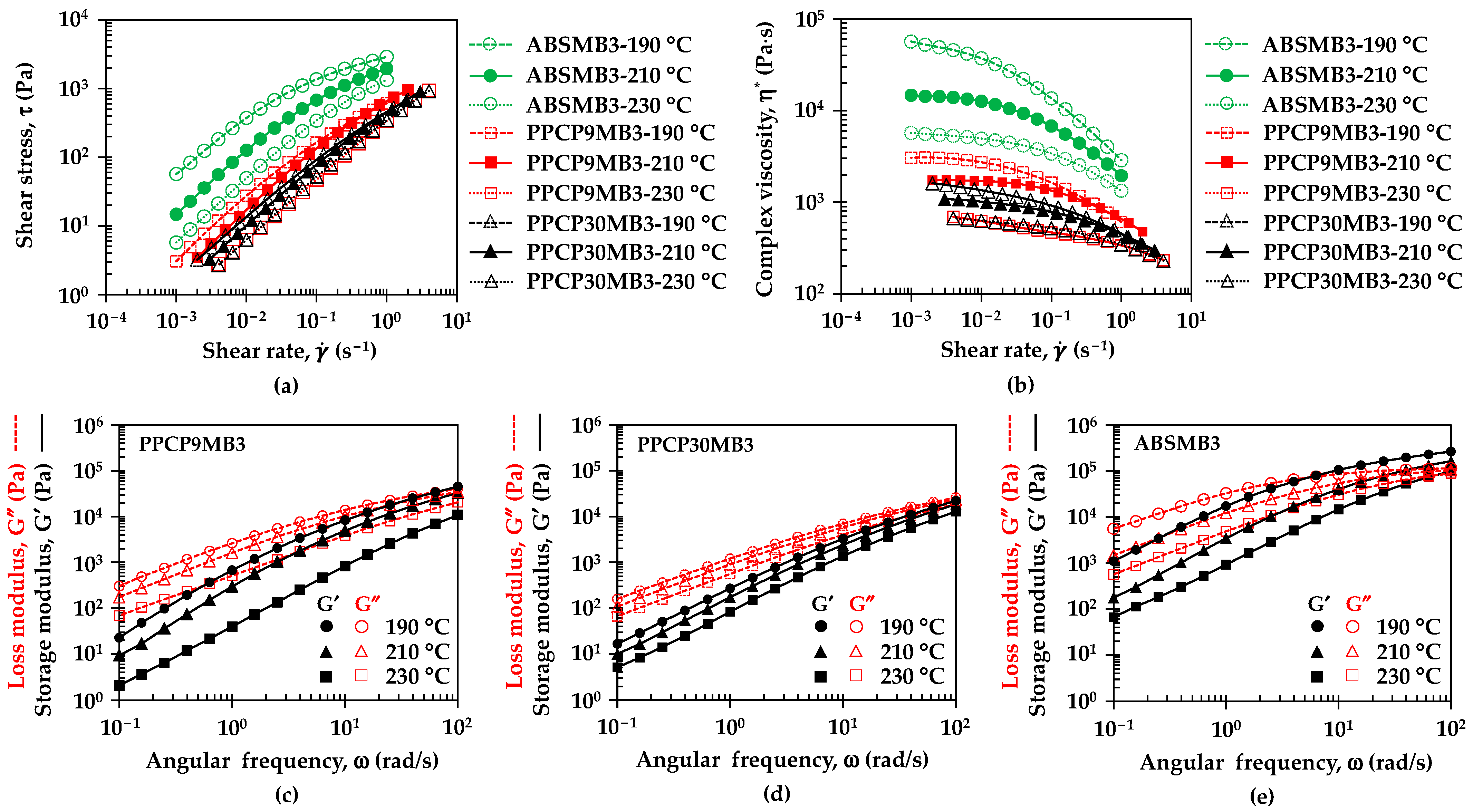

3.2. Rheological Behavior of Thermoplastics Incorporated with Masterbatch

3.3. Thermal Properties and Crystallization Behavior of Semicrystalline Polypropylene Copolymer

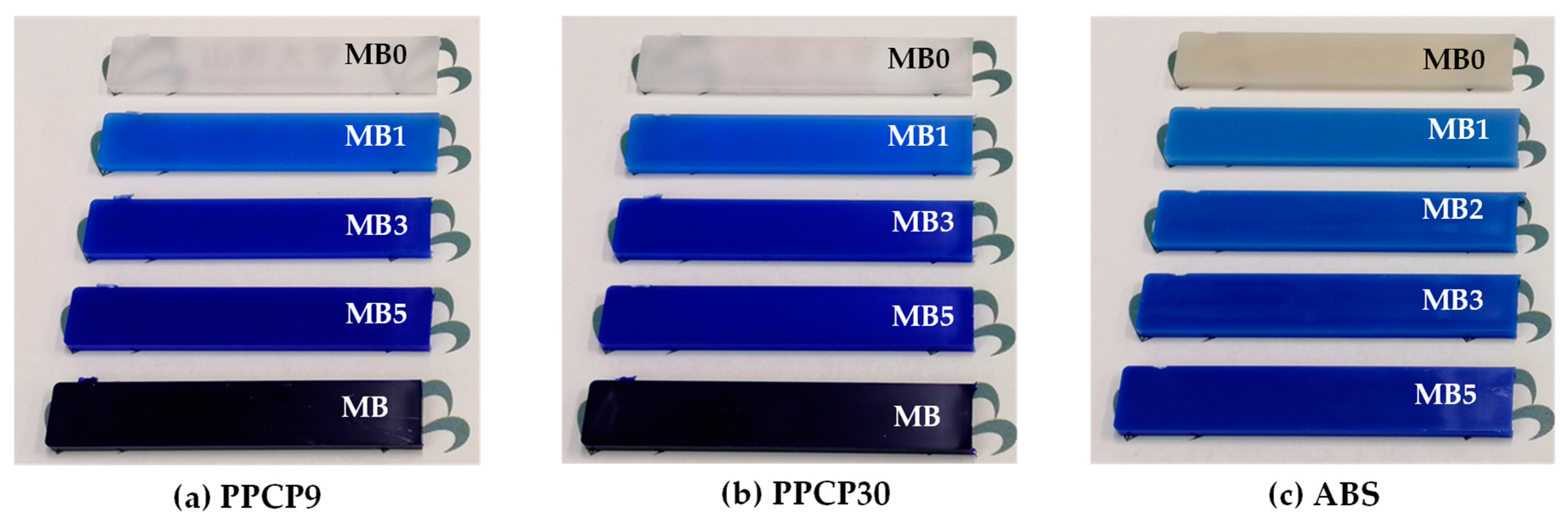

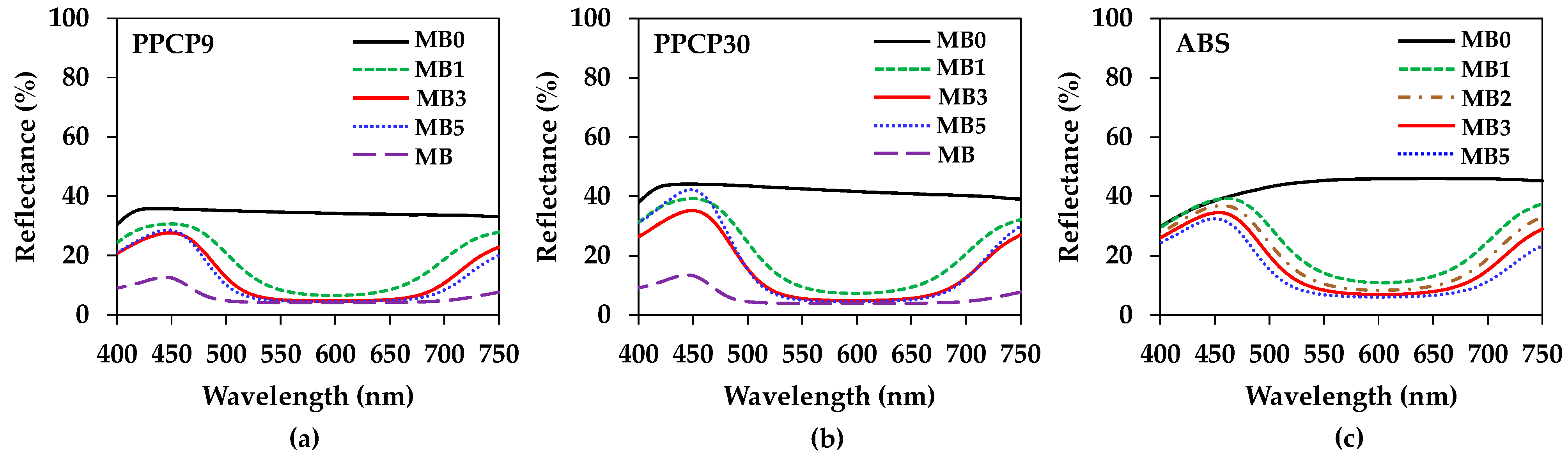

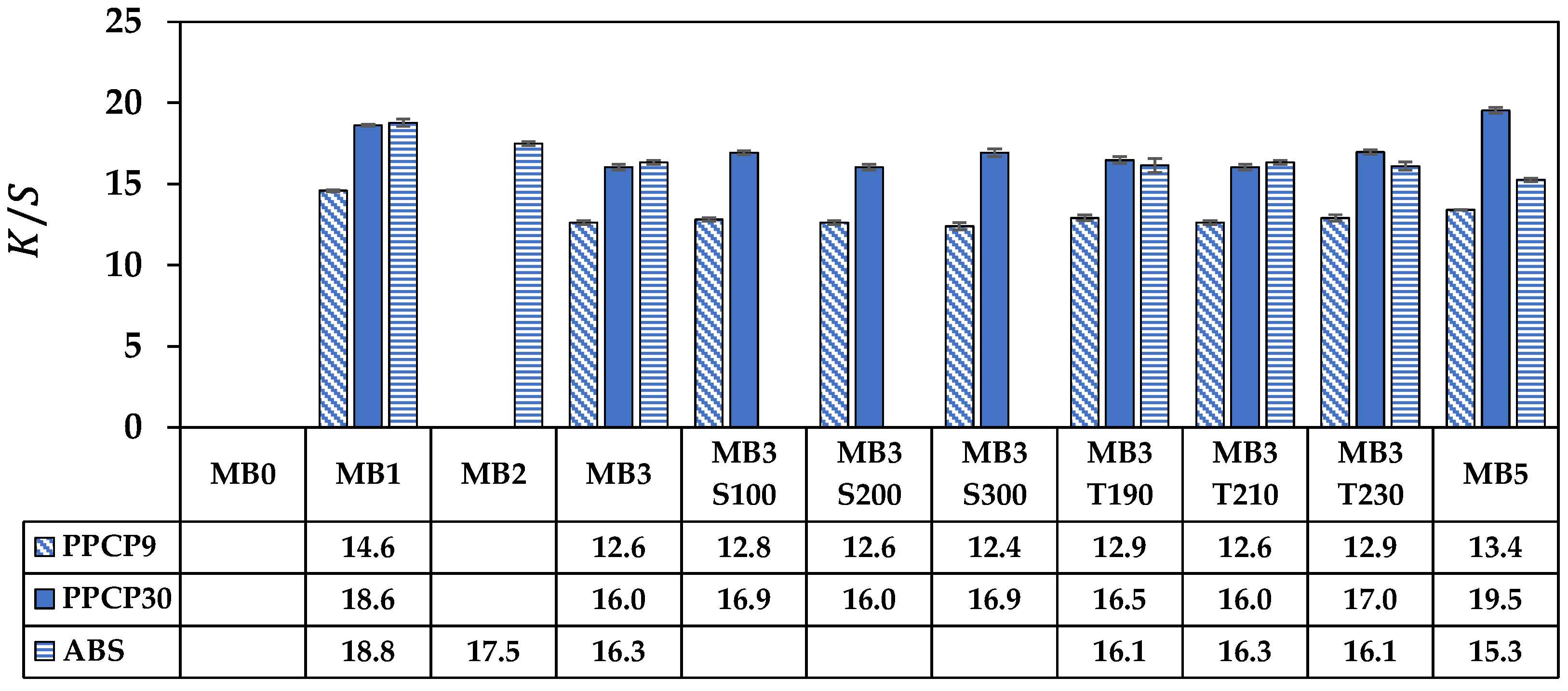

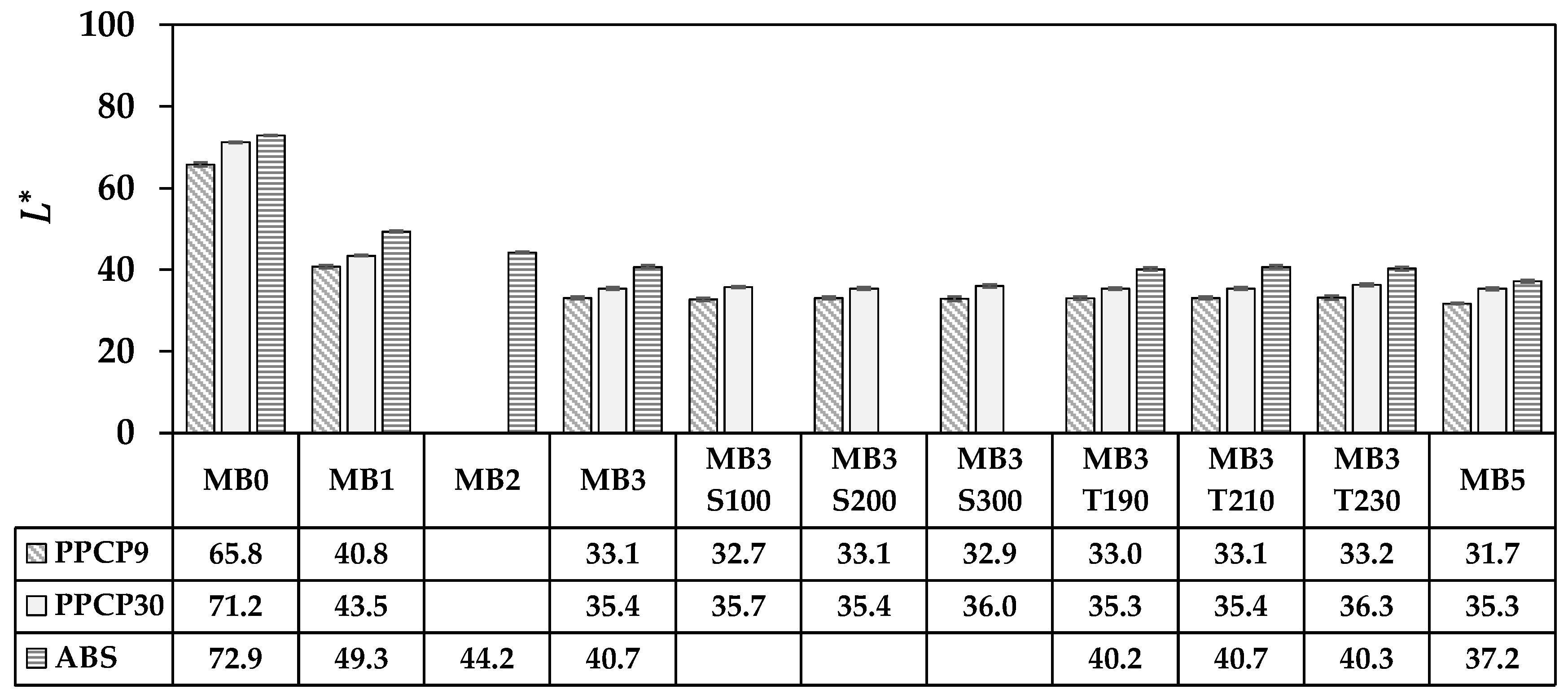

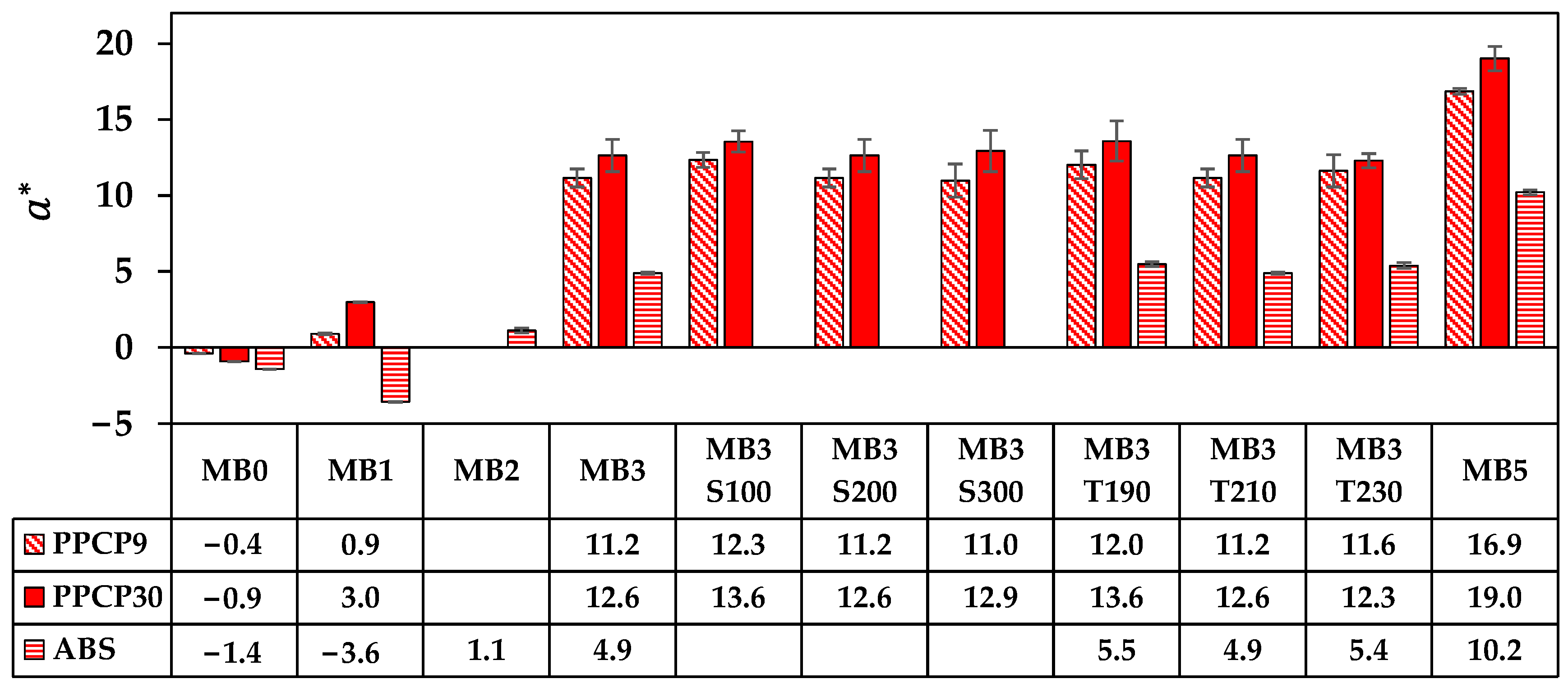

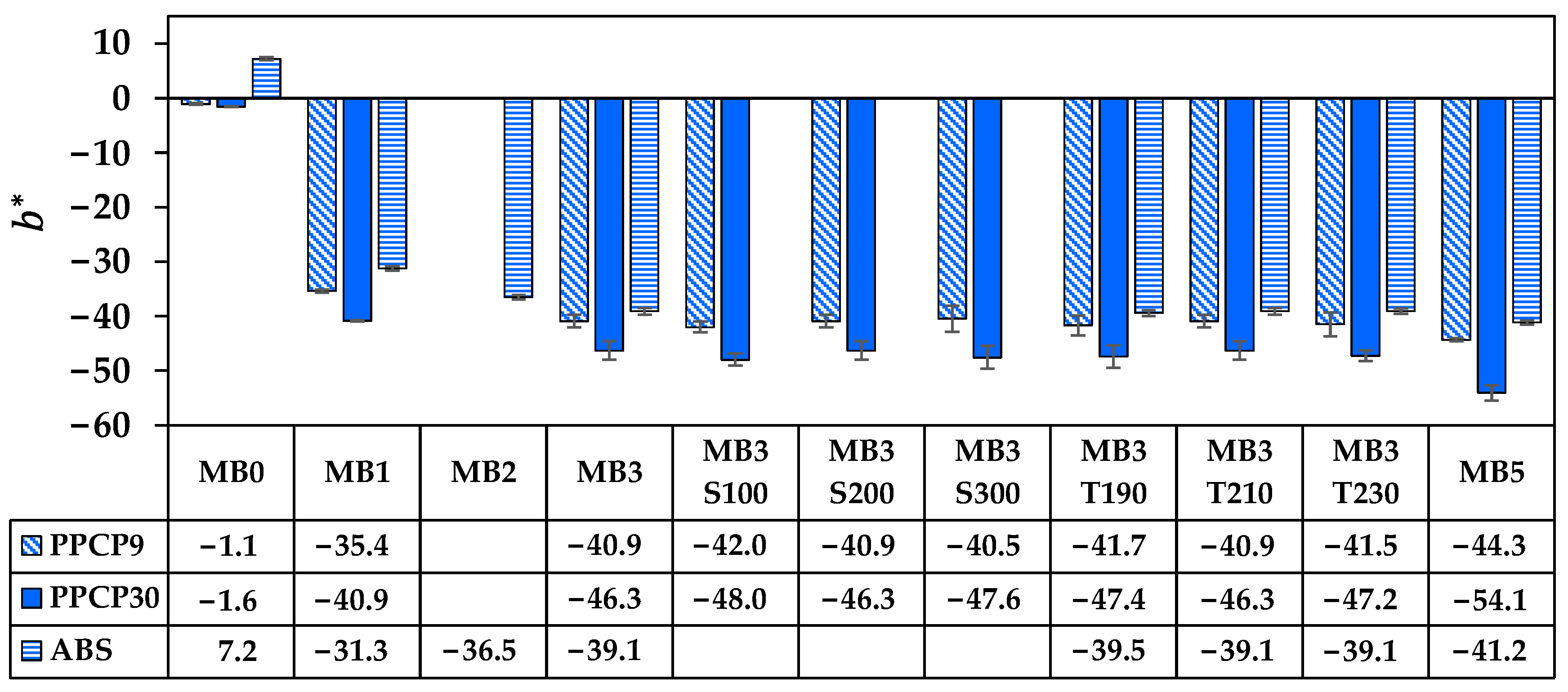

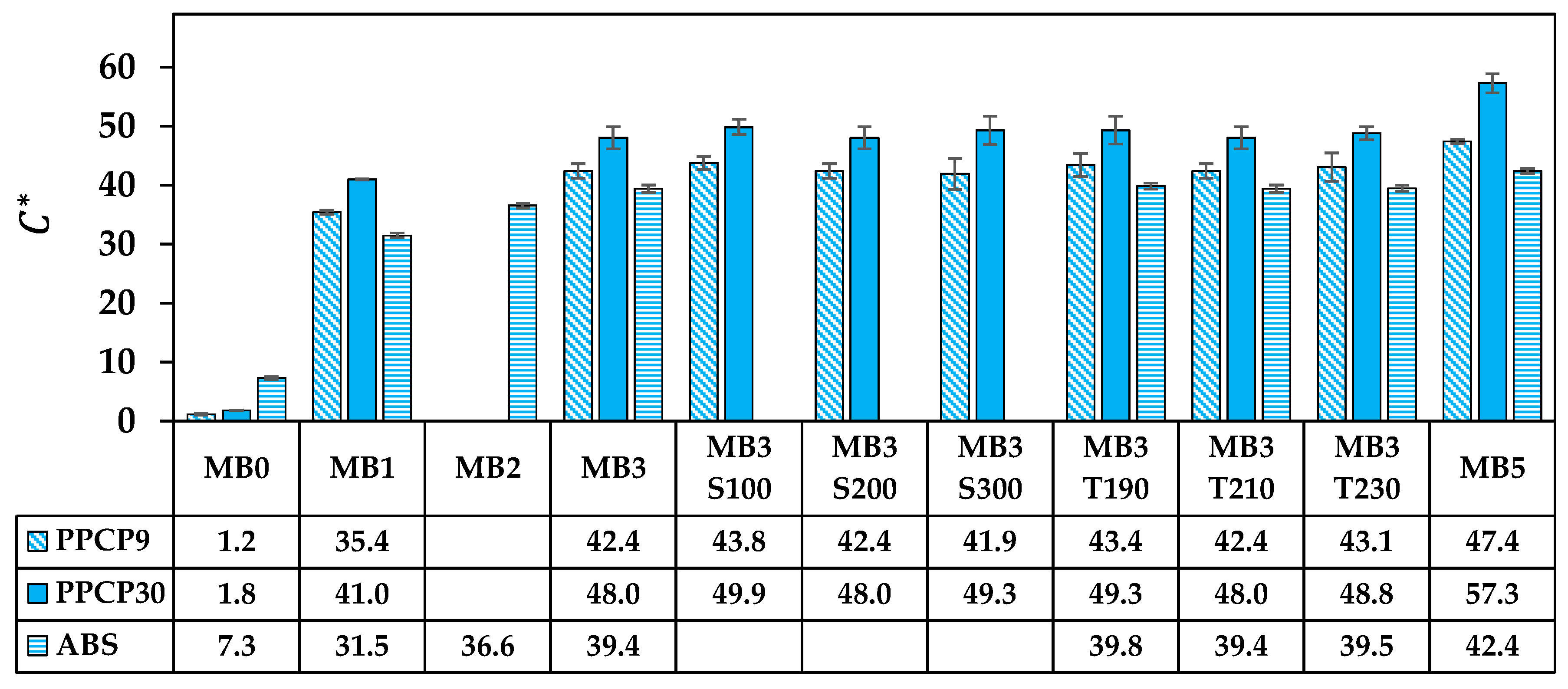

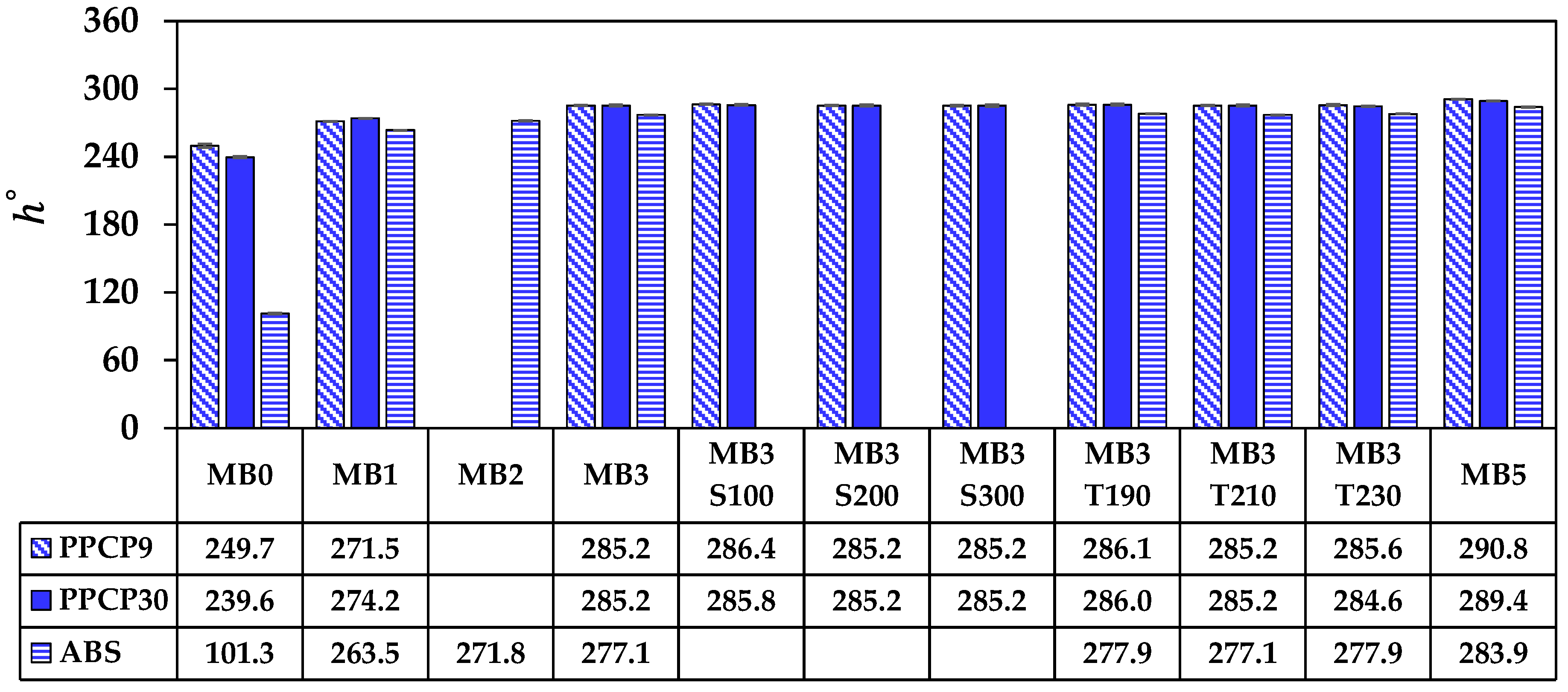

3.4. Color Spaces of Thermoplastics Incorporated with Masterbatch

3.4.1. Effects of Compounding Conditions on Color Space

3.4.2. Statistical Analysis of the Effects of Compounding Conditions on Color Space

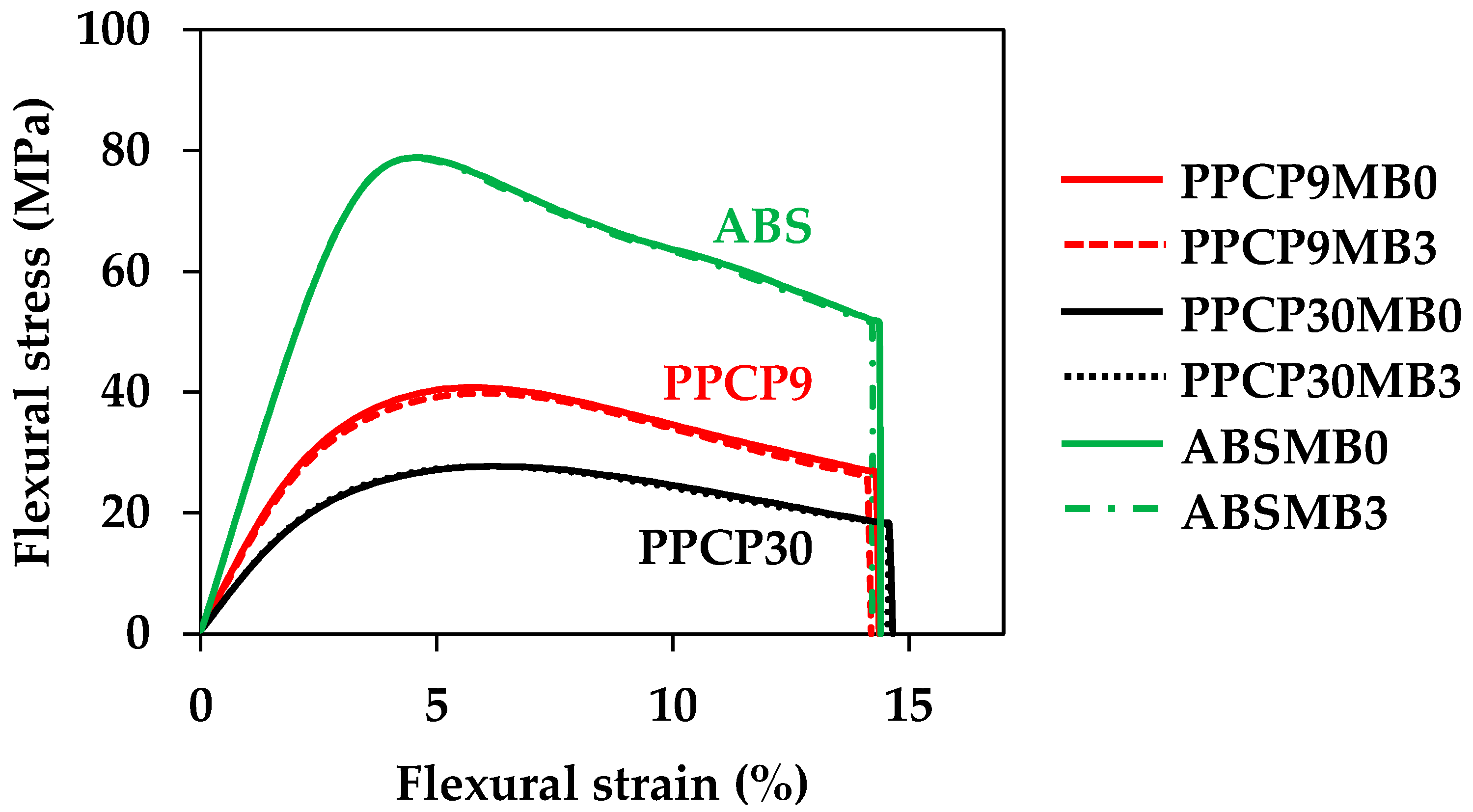

3.5. Flexural Properties of Injection Molded Colored Thermoplastics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | PPCP9 | PPCP30 | ABS | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 190 °C | 210 °C | 230 °C | 190 °C | 210 °C | 230 °C | 190 °C | 210 °C | 230 °C | ||||||||||

| 1 | 2 | |||||||||||||||||

| MB0 | 855 | 0.76 | 789 | 0.80 | 600 | 0.84 | 3836 | 0.57 | 2684 | 0.72 | 1553 | 0.81 | ||||||

| MB1 | 760 | 0.82 | 474 | 0.81 | 2838 | 0.73 | ||||||||||||

| MB3 | 837 | 0.77 | 744 | 0.82 | 325 | 0.85 | 494 | 0.78 | 457 | 0.82 | 339 | 0.85 | 4260 | 0.57 | 2929 | 0.72 | 1864 | 0.81 |

| MB5 | 754 | 0.83 | 472 | 0.82 | 2856 | 0.72 | ||||||||||||

| MB3S100 | 711 | 0.82 | 442 | 0.82 | ||||||||||||||

| MB3S300 | 704 | 0.84 | 434 | 0.83 | ||||||||||||||

| MB3T190 | 762 | 0.82 | 446 | 0.82 | ||||||||||||||

| MB3T230 | 712 | 0.82 | 461 | 0.82 | ||||||||||||||

| MB | 872 | 0.77 | 761 | 0.81 | 214 | 0.71 | ||||||||||||

| Sample | Residual 1 (%) | Opacity 2 | ||||

|---|---|---|---|---|---|---|

| PPCP9 | PPCP30 | ABS | PPCP9 | PPCP30 | ABS | |

| MB0 | 0.05 | 0 | 61 | 69 | 85 | |

| MB1 | 0.28 | 0.28 | 85 | 91 | 98 | |

| MB2 | 99 | |||||

| MB3 | 0.59 | 0.57 | 94 | 97 | 99 | |

| MB5 | 0.93 | 0.90 | 97 | 99 | 100 | |

| MB3S100 | 0.54 | 94 | 97 | |||

| MB3S300 | 0.60 | 95 | 97 | |||

| MB3T190 | 0.56 | 94 | 98 | 100 | ||

| MB3T230 | 0.61 | 94 | 98 | 99 | ||

Statistical Analysis Experimental Design

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP9MB0 | 3 | 65.750 | A |

| PPCP9MB1 | 3 | 40.757 | B |

| PPCP9MB3T230 | 3 | 33.153 | C |

| PPCP9MB3T210 | 3 | 33.077 | C |

| PPCP9MB3S200 | 3 | 33.077 | C |

| PPCP9MB3 | 3 | 33.077 | C |

| PPCP9MB3T190 | 3 | 33.030 | C |

| PPCP9MB3S300 | 3 | 32.920 | C |

| PPCP9MB3S100 | 3 | 32.720 | C |

| PPCP9MB5 | 3 | 31.7267 | D |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP9MB5 | 3 | 16.853 | A |

| PPCP9MB3S100 | 3 | 12.347 | B |

| PPCP9MB3T190 | 3 | 12.027 | B C |

| PPCP9MB3T230 | 3 | 11.623 | B C |

| PPCP9MB3T210 | 3 | 11.160 | C |

| PPCP9MB3S200 | 3 | 11.160 | C |

| PPCP9MB3 | 3 | 11.160 | C |

| PPCP9MB3S300 | 3 | 10.980 | C |

| PPCP9MB1 | 3 | 0.8967 | D |

| PPCP9MB0 | 3 | −0.3967 | E |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP9MB0 | 3 | −1.0800 | A |

| PPCP9MB1 | 3 | −35.410 | B |

| PPCP9MB3S300 | 3 | −40.47 | C |

| PPCP9MB3T210 | 3 | −40.923 | C |

| PPCP9MB3S200 | 3 | −40.923 | C |

| PPCP9MB3 | 3 | −40.923 | C |

| PPCP9MB3T230 | 3 | −41.50 | C |

| PPCP9MB3T190 | 3 | −41.73 | C |

| PPCP9MB3S100 | 3 | −42.013 | C D |

| PPCP9MB5 | 3 | −44.347 | D |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP9MB5 | 3 | 47.443 | A |

| PPCP9MB3S100 | 3 | 43.790 | B |

| PPCP9MB3T190 | 3 | 43.43 | B |

| PPCP9MB3T230 | 3 | 43.10 | B |

| PPCP9MB3T210 | 3 | 42.420 | B |

| PPCP9MB3S200 | 3 | 42.420 | B |

| PPCP9MB3 | 3 | 42.420 | B |

| PPCP9MB3S300 | 3 | 41.93 | B |

| PPCP9MB1 | 3 | 35.420 | C |

| PPCP9MB0 | 3 | 1.1500 | D |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP9MB5 | 3 | 290.807 | A |

| PPCP9MB3S100 | 3 | 286.373 | B |

| PPCP9MB3T190 | 3 | 286.057 | B C |

| PPCP9MB3T230 | 3 | 285.623 | B C |

| PPCP9MB3T210 | 3 | 285.247 | C |

| PPCP9MB3S200 | 3 | 285.247 | C |

| PPCP9MB3 | 3 | 285.247 | C |

| PPCP9MB3S300 | 3 | 285.157 | C |

| PPCP9MB1 | 3 | 271.453 | D |

| PPCP9MB0 | 3 | 249.683 | E |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP30MB0 | 3 | 71.2033 | A |

| PPCP30MB1 | 3 | 43.4533 | B |

| PPCP30MB3T230 | 3 | 36.293 | C |

| PPCP30MB3S300 | 3 | 36.013 | C D |

| PPCP30MB3S100 | 3 | 35.720 | D E |

| PPCP30MB3T210 | 3 | 35.397 | E |

| PPCP30MB3S200 | 3 | 35.397 | E |

| PPCP30MB3 | 3 | 35.397 | E |

| PPCP30MB5 | 3 | 35.347 | E |

| PPCP30MB3T190 | 3 | 35.347 | E |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP30MB5 | 3 | 19.023 | A |

| PPCP30MB3T190 | 3 | 13.580 | B |

| PPCP30MB3S100 | 3 | 13.550 | B |

| PPCP30MB3S300 | 3 | 12.933 | B |

| PPCP30MB3T210 | 3 | 12.630 | B |

| PPCP30MB3S200 | 3 | 12.630 | B |

| PPCP30MB3 | 3 | 12.630 | B |

| PPCP30MB3T230 | 3 | 12.297 | B |

| PPCP30MB1 | 3 | 2.9867 | C |

| PPCP30MB0 | 3 | −0.92667 | D |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP30MB0 | 3 | −1.5800 | A |

| PPCP30MB1 | 3 | −40.8867 | B |

| PPCP30MB3T210 | 3 | −46.343 | C |

| PPCP30MB3S200 | 3 | −46.343 | C |

| PPCP30MB3 | 3 | −46.343 | C |

| PPCP30MB3T230 | 3 | −47.247 | C |

| PPCP30MB3T190 | 3 | −47.40 | C |

| PPCP30MB3S300 | 3 | −47.59 | C |

| PPCP30MB3S100 | 3 | −47.987 | C |

| PPCP30MB5 | 3 | −54.060 | D |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP30MB5 | 3 | 57.313 | A |

| PPCP30MB3S100 | 3 | 49.863 | B |

| PPCP30MB3S300 | 3 | 49.32 | B |

| PPCP30MB3T190 | 3 | 49.32 | B |

| PPCP30MB3T230 | 3 | 48.820 | B |

| PPCP30MB3T210 | 3 | 48.04 | B |

| PPCP30MB3S200 | 3 | 48.04 | B |

| PPCP30MB3 | 3 | 48.04 | B |

| PPCP30MB1 | 3 | 40.9933 | C |

| PPCP30MB0 | 3 | 1.8333 | D |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| PPCP30MB5 | 3 | 289.380 | A |

| PPCP30MB3T190 | 3 | 285.957 | B |

| PPCP30MB3S100 | 3 | 285.763 | B |

| PPCP30MB3T210 | 3 | 285.230 | B C |

| PPCP30MB3S200 | 3 | 285.230 | B C |

| PPCP30MB3 | 3 | 285.230 | B C |

| PPCP30MB3S300 | 3 | 285.177 | B C |

| PPCP30MB3T230 | 3 | 284.590 | C |

| PPCP30MB1 | 3 | 274.180 | D |

| PPCP30MB0 | 3 | 239.560 | E |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| ABSMB0 | 3 | 72.8867 | A |

| ABSMB1 | 3 | 49.340 | B |

| ABSMB2 | 3 | 44.2233 | C |

| ABSMB3T210 | 3 | 40.703 | D |

| ABSMB3 | 3 | 40.703 | D |

| ABSMB3T230 | 3 | 40.263 | D E |

| ABSMB3T190 | 3 | 40.150 | E |

| ABSMB5 | 3 | 37.187 | F |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| ABSMB5 | 3 | 10.2067 | A |

| ABSMB3T190 | 3 | 5.4800 | B |

| ABSMB3T230 | 3 | 5.390 | B |

| ABSMB3T210 | 3 | 4.8767 | C |

| ABSMB3 | 3 | 4.8767 | C |

| ABSMB2 | 3 | 1.1200 | D |

| ABSMB0 | 3 | −1.43667 | E |

| ABSMB1 | 3 | −3.5867 | F |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| ABSMB0 | 3 | 7.193 | A |

| ABSMB1 | 3 | −31.293 | B |

| ABSMB2 | 3 | −36.547 | C |

| ABSMB3T210 | 3 | −39.097 | D |

| ABSMB3 | 3 | −39.097 | D |

| ABSMB3T230 | 3 | −39.107 | D |

| ABSMB3T190 | 3 | −39.463 | D |

| ABSMB5 | 3 | −41.170 | E |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| ABSMB5 | 3 | 42.417 | A |

| ABSMB3T190 | 3 | 39.840 | B |

| ABSMB3T230 | 3 | 39.480 | B |

| ABSMB3T210 | 3 | 39.403 | B |

| ABSMB3 | 3 | 39.403 | B |

| ABSMB2 | 3 | 36.563 | C |

| ABSMB1 | 3 | 31.500 | D |

| ABSMB0 | 3 | 7.333 | E |

| Fisher Pairwise Comparisons | |||

|---|---|---|---|

| Grouping Information Using the Fisher LSD Method and 95% Confidence | |||

| Material | N | Mean | Grouping |

| ABSMB5 | 3 | 283.927 | A |

| ABSMB3T190 | 3 | 277.907 | B |

| ABSMB3T230 | 3 | 277.853 | B |

| ABSMB3T210 | 3 | 277.110 | C |

| ABSMB3 | 3 | 277.110 | C |

| ABSMB2 | 3 | 271.760 | D |

| ABSMB1 | 3 | 263.467 | E |

| ABSMB0 | 3 | 101.303 | F |

References

- Zweifel, H.M.; Ralph, D.; Schiller, M. Plastics Additives Handbook, 6th ed.; Hanser: Munich, Germany, 2009. [Google Scholar]

- Yücetürk, M.; Seydibeyoğlu, M.Ö. Understanding dispersion of copper phthalocyanine alpha blue pigment in polyethylene masterbatch with the use of wax. Color. Technol. 2020, 136, 526–534. [Google Scholar] [CrossRef]

- Suzuki, S.; Mizuguchi, J. Pigment-induced crystallization in colored plastics based on partially crystalline polymers. Dye. Pigment. 2004, 61, 69–77. [Google Scholar] [CrossRef][Green Version]

- Lee Wo, D.; Tanner, R.I. The impact of blue organic and inorganic pigments on the crystallization and rheological properties of isotactic polypropylene. Rheol. Acta 2010, 49, 75–88. [Google Scholar] [CrossRef]

- Sahin, S.; Yayla, P. Effects of processing parameters on the mechanical properties of polypropylene random copolymer. Polym. Test. 2005, 24, 1012–1021. [Google Scholar] [CrossRef]

- Saravari, O.; Keeratichiraththitikan, K.; Kerddonfag, N.; Chinsirikul, W. Effects of Phthalocyanine Blue and Ultramarine Blue Pigments on Nucleation of Polypropylene. Adv. Mater. Res. 2012, 488–489, 473–477. [Google Scholar]

- Barczewski, M.; Matykiewicz, D.; Hoffmann, B. Effect of Quinacridone Pigments on Properties and Morphology of Injection Molded Isotactic Polypropylene. Int. J. Polym. Sci. 2017, 2017, 7043297. [Google Scholar] [CrossRef]

- Buccella, M.; Dorigato, A.; Rizzola, F.; Caldara, M.; Fambri, L. Influence of the Processing Parameters on the Dispersion and Coloration Behavior of a Halogenated Copper Phthalocyanine-Based Masterbatch. Adv. Polym. Technol. 2018, 37, 778–785. [Google Scholar] [CrossRef]

- Xia, T.; Ye, Y.; Qin, W.-L. Acrylonitrile–butadiene–styrene colored with a nanoclay-based filler: Mechanical, thermal and colorimetric properties. Polym. Bull. 2019, 76, 3769–3784. [Google Scholar] [CrossRef]

- Deshmukh, S.P.; Parmar, M.B.; Rao, A.C.; Wadhwa, V. Polymer- and wax-based monoconcentrate predispersed pigments in the colouring of plastics. Color. Technol. 2010, 126, 189–193. [Google Scholar] [CrossRef]

- Murphy, J. The compounders’ guide to colour: Pigments, dyes and special effects. Plast. Addit. Compd. 1999, 1, 10–17. [Google Scholar]

- Kozłowska, M.; Lipińska, M.; Okraska, M.; Pietrasik, J. Polypropylene Color Masterbatches Containing Layered Double Hydroxide Modified with Quinacridone and Phthalocyanine Pigments & Rheological, Thermal and Application Properties. Materials 2023, 16, 6243. [Google Scholar] [PubMed]

- Hudecová, A.; Hricová, M.; Petková, M.; Plavec, R.; Tomčíková, Z.; Ujhelyiová, A. Colour masterbatches and their use in polylactic acid fibres dyeing. Acta Chim. Slovaca 2023, 16, 62–72. [Google Scholar] [CrossRef]

- Ariño, I.; Kleist, U.; Rigdahl, M. Color of pigmented plastics—Measurements and predictions. Polym. Eng. Sci. 2004, 44, 141–152. [Google Scholar] [CrossRef]

- Janostik, V.; Senkerik, V.; Manas, L.; Stanek, M.; Cvek, M. Injection-Molded Isotactic Polypropylene Colored with Green Transparent and Opaque Pigments. Int. J. Mol. Sci. 2023, 24, 9924. [Google Scholar] [CrossRef] [PubMed]

- Alsadi, J.; Saeed, U.; Ahmad, S.; Rizvi, G.; Ross, D. Processing issues of color mismatch: Rheological characterization of polycarbonate blends. Polym. Eng. Sci. 2015, 55, 1994–2001. [Google Scholar] [CrossRef]

- Rungswang, W.; Saendee, P.; Thitisuk, B.; Pathaweeisariyakul, T.; Cheevasrirungruang, W. Role of crystalline ethylene-propylene copolymer on mechanical properties of impact polypropylene copolymer. J. Appl. Polym. Sci. 2013, 128, 3131–3140. [Google Scholar] [CrossRef]

- Manabe, N.; Yokota, Y.; Nakatani, H.; Suzuki, S.; Boping, L.; Terano, M. Study of local oxidative degradation in polypropylene impact copolymer by energy dispersive X-ray system. Polym. Bull. 2005, 54, 141–145. [Google Scholar] [CrossRef]

- Trzaskalska, M.; Palutkiewicz, P.; Bociąga, E. Mechanical properties of colored acrylonitrile-butadiene-styrene injection molded parts. Polimery 2021, 63, 791–798. [Google Scholar] [CrossRef]

- Costa, L.C.; Henry, F. The Impact of Blue Inorganic Pigments on the Microwave Electrical Properties of Polymer Composites. Int. J. Microw. Sci. Technol. 2012, 2012, 628237. [Google Scholar] [CrossRef]

- Botos, J.; Murail, N.; Heidemeyer, P.; Kretschmer, K.; Ulmer, B.; Zentgraf, T.; Bastian, M.; Hochrein, T. Color measurement of plastics—From compounding via pelletizing, up to injection molding and extrusion. AIP Conf. Proc. 2014, 1593, 16–19. [Google Scholar]

- X-rite Pantone. A Guide to Understanding Color; X-rite Pantone: Grand Rapids, MI, USA, 2016; pp. 1–40. [Google Scholar]

- Agate, S.; Williams, A.; Dougherty, J.; Velev, O.D.; Pal, L. Polymer Color Intelligence: Effect of Materials, Instruments, and Measurement Techniques—A Review. ACS Omega 2023, 8, 23257–23270. [Google Scholar] [CrossRef] [PubMed]

- TN045; Choosing Conditions in Modulated DSC. TA Instruments: New Castle, DE, USA; pp. 1–4. Available online: https://www.tainstruments.com/pdf/literature/TN45.pdf (accessed on 12 December 2023).

- Zhang, C.; Shangguan, Y.; Chen, R.; Zheng, Q. Study on thermal behavior of impact polypropylene copolymer and its fractions. J. Appl. Polym. Sci. 2011, 119, 1560–1566. [Google Scholar] [CrossRef]

- Aris-Brosou, M.; Vincent, M.; Agassant, J.F.; Billon, N. Viscoelastic rheology in the melting and crystallization domain: Application to polypropylene copolymers. J. Appl. Polym. Sci. 2017, 134, 44690. [Google Scholar] [CrossRef]

- Schmidt, C.M.; Walton, M.S.; Trentelman, K. Characterization of Lapis Lazuli Pigments Using a Multitechnique Analytical Approach: Implications for Identification and Geological Provenancing. Anal. Chem. 2009, 81, 8513–8518. [Google Scholar] [CrossRef] [PubMed]

- Elizabeth, J.L. Ultramarine Blue Pigment, Synthetic. Available online: https://www.mccrone.com/mm/ultramarine-blue-pigment-synthetic/ (accessed on 7 November 2023).

- Sayed, D.S. Scientific investigation of the materials and techniques used in a 19th century egyptian cemetry wall painting (Hawsh al-Basha). Int. J. Conserv. Sci. 2013, 4, 145–152. [Google Scholar]

- Buck, E.C. Electron Microscopy Characterization of Suspended Solids from Hanford Tank 241-AP-105 Direct Feed Waste; Pacific Northwest National Lab: Richland, WA, USA, 2017; p. 11.

- Polychronopoulos, N.D.; Vlachopoulos, J. Polymer Processing and Rheology. In Functional Polymers; Jafar Mazumder, M.A., Sheardown, H., Al-Ahmed, A., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–47. [Google Scholar]

- Cassagnau, P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer 2008, 49, 2183–2196. [Google Scholar] [CrossRef]

- Chafidz, A.; Kaavessina, M.; Al-Zahrani, S.; Al-Otaibi, M.N. Rheological and mechanical properties of polypropylene/calcium carbonate nanocomposites prepared from masterbatch. J. Thermoplast. Compos. Mater. 2016, 29, 593–622. [Google Scholar] [CrossRef]

- Malvern, A. Basic Introduction to Rheology; Malvern: Malvern, UK, 2016; pp. 1–20. [Google Scholar]

- Xu, X.; Gao, C.; Zheng, Q.; Jiang, X. Linear/Nonlinear Rheological Properties and Percolation Threshold of Polydimethylsiloxane Filled with Calcium Carbonate. Nihon Reoroji Gakkaishi 2007, 35, 283–291. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, X.; Li, H.; Yan, S. Orientation-induced crystallization of isotactic polypropylene. Polymer 2013, 54, 4404–4421. [Google Scholar] [CrossRef]

- Lee, H.; Kim, Y.S.; Choi, W.H.; Yun, D.W.; Lee, J.; Song, J.M.; Kim, S.; Kim, J.; Kim, S.Y. Processing temperature window design via controlling matrix composition for polypropylene-based self-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106301. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.; Wu, C. Crystallization Behavior of Polypropylene Filled with Modified Carbon Black. Polym. J. 2007, 39, 722–730. [Google Scholar] [CrossRef]

- Thomas, L.C. Modulated DSC Paper#6 Measurement of Initial Crystallinity in Semi-Cystalline Polymers; TA Instruments: New Castle, DE, USA, 2005. [Google Scholar]

- TA384; Thermal Analysis Investigation of a Poly(Lactic acid) Biodegradable Plastic. TA Instruments: New Castle, DE, USA, 2007.

- Somani, R.H.; Yang, L.; Hsiao, B.S.; Sun, T.; Pogodina, N.V.; Lustiger, A. Shear-Induced Molecular Orientation and Crystallization in Isotactic Polypropylene: Effects of the Deformation Rate and Strain. Macromolecules 2005, 38, 1244–1255. [Google Scholar] [CrossRef]

- Vuluga, Z.; Corobea, M.C.; Elizetxea, C.; Ordonez, M.; Ghiurea, M.; Raditoiu, V.; Nicolae, C.A.; Florea, D.; Iorga, M.; Somoghi, R.; et al. Morphological and Tribological Properties of PMMA/Halloysite Nanocomposites. Polymers 2018, 10, 816. [Google Scholar] [CrossRef] [PubMed]

- Rungswang, W.; Jarumaneeroj, C.; Jirasukho, P.; Juabrum, S.; Pakawanit, P.; Soontaranon, S.; Rugmai, S. Time-Resolved SAXS/WAXD under Tensile Deformation: Role of Segmental Ethylene–Propylene Copolymers in Impact-Resistant Polypropylene Copolymers. ACS Appl. Polym. Mater. 2021, 3, 6394–6406. [Google Scholar] [CrossRef]

- de la Rie, E.R.; Michelin, A.; Ngako, M.; Del Federico, E.; Del Grosso, C. Photo-catalytic degradation of binding media of ultramarine blue containing paint layers: A new perspective on the phenomenon of “ultramarine disease” in paintings. Polym. Degrad. Stab. 2017, 144, 43–52. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Gu, J.; Weng, Y.X.; Huang, Z.G.; Qiu, D.; Shao, S.X. Optimization of the preparation process of biodegradable masterbatches and characterization of their rheological and application properties. Polym. Test. 2018, 70, 526–532. [Google Scholar] [CrossRef]

- Pagnan, C.S.; Mottin, A.C.; Oréfice, R.L.; Ayres, E.; Câmara, J.J.D. Annatto-colored Poly(3-hydroxybutyrate): A Comprehensive Study on Photodegradation. J. Polym. Environ. 2018, 26, 1169–1178. [Google Scholar] [CrossRef]

- Zhang, W.; Su, H.; Hao, Z.; Mao, Z.; Feng, X.; Sui, X.; Wang, B. Preparation and application of cellulose-based colorants with high color strength. Cellulose 2023, 30, 9161–9174. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; Jonh Wiley & Sons, Inc.: New York, NY, USA, 2012. [Google Scholar]

- Pairwise Comparisons for One-Way ANOVA. Available online: https://support.minitab.com/en-us/minitab/21/help-and-how-to/statistical-modeling/anova/how-to/one-way-anova/interpret-the-results/all-statistics-and-graphs/pairwise-comparisons/ (accessed on 15 October 2023).

| Material | Symbol | MFR 1 (g/10 min) | Tg 2 (°C) | Tm 2 (°C) | Td 3 (°C) | Residual 3 (%) |

|---|---|---|---|---|---|---|

| PPCP (AW564) | PPCP9 | 9 | N/A 4 | 167.8 | 425.0 | 0.06 |

| PPCP (PP8285E1) | PPCP30 | 30 | N/A | 167.4 | 423.0 | 0.09 |

| ABS (100-322) | ABS | 15 | 104.6 | - | 408.0 | 1.29 |

| MB of PPCP9 | MB (PPCP9) | N/A | N/A | 144.0, 167.0 | 408.3 | 15.72 |

| MB of PPCP30 | MB (PPCP30) | N/A | N/A | 142.1, 165.5 | 398.1 | 16.80 |

| MB of ABS | MB (ABS) | N/A | 99.0, 105 | 142.3 | 395.6 | 18.71 |

| Parameter | Polymer (wt.%) | MB (wt.%) | Die Temperature (°C) | Screw Speed (rpm) | Designation |

|---|---|---|---|---|---|

| Masterbatch (MB) | 100 | 0 | 210 | 200 | MB0 |

| 99 | 1 | 210 | 200 | MB1 | |

| 97 | 3 | 210 | 200 | MB3 | |

| 95 | 5 | 210 | 200 | MB5 | |

| Screw speed (S) | 97 | 3 | 210 | 100 | MB3S100 |

| 97 | 3 | 210 | 200 | MB3S200 | |

| 97 | 3 | 210 | 300 | MB3S300 | |

| Temperature (T) | 97 | 3 | 190 | 200 | MB3T190 |

| 97 | 3 | 210 | 200 | MB3T210 | |

| 97 | 3 | 230 | 200 | MB3T230 |

| Material | Sample | Total Heat Flow | Reversible Heat Flow | Nonreversible Heat Flow | ||||

|---|---|---|---|---|---|---|---|---|

| ΔHm Total (J/g) | Tm Total (°C) | ΔHm Rev (J/g) | Tm Rev (°C) | ΔHm Nonrev (J/g) | Tm Nonrev (°C) | Tc Nonrev (°C) | ||

| PPCP9 | MB0 | 85.8 | 167.4 | 22.4 | 157.7, 169.1 | 66.5 | 167.4 | 137.0 |

| MB1 | 83.9 | 167.4 | 23.6 | 156.7, 170.1 | 62.2 | 167.3 | 133.0 | |

| MB3 | 82.0 | 167.1 | 21.3 | 157.3, 169.0 | 62.3 | 167.0 | 131.2 | |

| MB5 | 82.9 | 167.1 | 18.7 | 157.6, 169.1 | 63.6 | 167.0 | 132.7 | |

| MB3S100 | 85.8 | 166.9 | 16.5 | 155.8, 170.3 | 66.0 | 166.9 | 130.8 | |

| MB3S300 | 85.3 | 166.8 | 14.6 | 155.0, 169.8 | 66.7 | 166.7 | 130.8 | |

| MB3T190 | 89.4 | 167.4 | 34.3 | 160.0, 167.8 | 57.8 | 167.5 | 133.6 | |

| MB3T230 | 85.1 | 166.5 | 28.8 | 158.7, 168.9 | 56.7 | 166.5 | 131.7 | |

| Masterbatch | 70.4 | 104.6, 144.4, 167.0 | 23.2 | 145.3, 156.4, 169.7 | 47.9 | 104.1, 142.7, 166.9 | 124.6, 139.7 | |

| PPCP30 | MB0 | 72.4 | 165.9 | 27.5 | 158.2, 167.8 | 46.6 | 165.9 | 134.4 |

| MB1 | 68.9 | 166.2 | 11.5 | 155.0, 169.2 | 54.6 | 166.2 | 133.2 | |

| MB3 | 70.7 | 166.5 | 11.2 | 155.3, 169.9 | 55.4 | 166.4 | 129.2 | |

| MB5 | 68.6 | 166.2 | 15.3 | 156.1, 168.8 | 51.7 | 166.1 | 132.1 | |

| Masterbatch | 60.3 | 103.7, 142.6, 166.2 | 11.4 | 144.6, 153.1, 169.6 | 45.4 | 103.9, 142.2, 166.1 | 123.0, 137.5 | |

| Material | Degree of Freedom | Color Space | p-Value | R-sq (adj) | R-sq (pred) |

|---|---|---|---|---|---|

| 0.00 | 99.84 | 99.75 | |||

| 0.00 | 98.32 | 98.08 | |||

| PPCP9 | 9 | 0.00 | 98.76 | 98.08 | |

| 0.00 | 98.65 | 97.91 | |||

| 0.00 | 99.69 | 99.52 | |||

| 0.00 | 99.93 | 99.89 | |||

| 0.00 | 97.35 | 95.88 | |||

| PPCP30 | 9 | 0.00 | 98.95 | 98.37 | |

| 0.00 | 98.76 | 98.08 | |||

| 0.00 | 99.81 | 99.70 | |||

| 0.00 | 99.92 | 99.87 | |||

| 0.00 | 99.92 | 99.87 | |||

| ABS | 7 | 0.00 | 99.91 | 99.85 | |

| 0.00 | 99.81 | 99.70 | |||

| 0.00 | 100.00 | 100.00 |

| Material | Sample | Flexural Modulus (GPa) | Flexural Strength (MPa) | Flexural Strain (%) |

|---|---|---|---|---|

| PPCP9 | MB0 | 1.46 ± 0.043 | 40.8 ± 0.010 | 14.4 ± 0.017 |

| MB1 | 1.42 ± 0.001 | 40.0 ± 0.097 | 14.3 ± 0.008 | |

| MB3 | 1.42 ± 0.005 | 39.8 ± 0.063 | 14.2 ± 0.026 | |

| MB5 | 1.42 ± 0.013 | 39.6 ± 0.233 | 14.2 ± 0.008 | |

| MB3T190 | 1.47 ± 0.022 | 40.6 ± 0.366 | 14.3 ± 0.149 | |

| MB3T230 | 1.39 ± 0.001 | 39.5 ± 0.017 | 14.3 ± 0.051 | |

| PPCP30 | MB0 | 1.01 ± 0.013 | 27.7 ± 0.185 | 14.7 ± 0.066 |

| MB1 | 0.99 ± 0.005 | 27.8 ± 0.138 | 14.6 ± 0.037 | |

| MB3 | 1.02 ± 0.006 | 27.9 ± 0.138 | 14.6 ± 0.161 | |

| MB5 | 0.98 ± 0.007 | 27.3 ± 0.069 | 14.6 ± 0.098 | |

| ABS | MB0 | 2.55 ± 0.015 | 79.8 ± 0.427 | 14.4 ± 0.051 |

| MB1 | 2.56 ± 0.014 | 78.5 ± 0.478 | 14.1 ± 0.057 | |

| MB3 | 2.57 ± 0.009 | 78.6 ± 0.305 | 14.2 ± 0.059 | |

| MB5 | 2.57 ± 0.042 | 79.0 ± 1.192 | 14.3 ± 0.149 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neo, P.K.; Kitada, Y.; Deeying, J.; Thumsorn, S.; Soon, M.F.; Goh, Q.S.; Leong, Y.W.; Ito, H. Influence of Compounding Parameters on Color Space and Properties of Thermoplastics with Ultramarine Blue Pigment. Polymers 2023, 15, 4718. https://doi.org/10.3390/polym15244718

Neo PK, Kitada Y, Deeying J, Thumsorn S, Soon MF, Goh QS, Leong YW, Ito H. Influence of Compounding Parameters on Color Space and Properties of Thermoplastics with Ultramarine Blue Pigment. Polymers. 2023; 15(24):4718. https://doi.org/10.3390/polym15244718

Chicago/Turabian StyleNeo, Puay Keong, Yuki Kitada, Jakawat Deeying, Supaphorn Thumsorn, Moi Fuai Soon, Qing Sheng Goh, Yew Wei Leong, and Hiroshi Ito. 2023. "Influence of Compounding Parameters on Color Space and Properties of Thermoplastics with Ultramarine Blue Pigment" Polymers 15, no. 24: 4718. https://doi.org/10.3390/polym15244718

APA StyleNeo, P. K., Kitada, Y., Deeying, J., Thumsorn, S., Soon, M. F., Goh, Q. S., Leong, Y. W., & Ito, H. (2023). Influence of Compounding Parameters on Color Space and Properties of Thermoplastics with Ultramarine Blue Pigment. Polymers, 15(24), 4718. https://doi.org/10.3390/polym15244718