Research Advances in Wood Composites in Applications of Industrial Wastewater Purification and Solar-Driven Seawater Desalination

Abstract

:1. Introduction

2. Application of Wood Composites in Water Purification

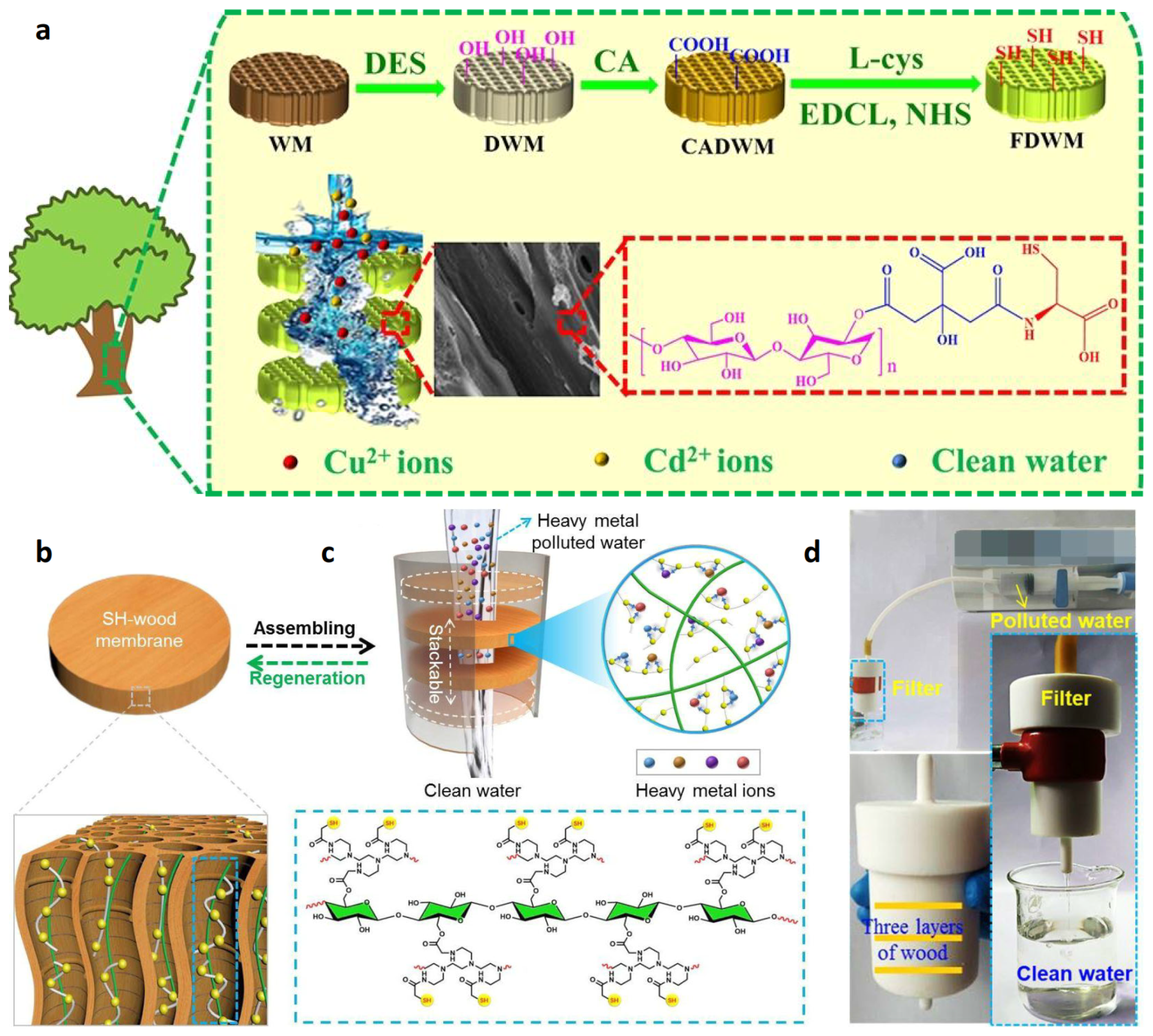

2.1. Adsorption of Heavy Metal Ions

2.2. Disinfection and Sterilization

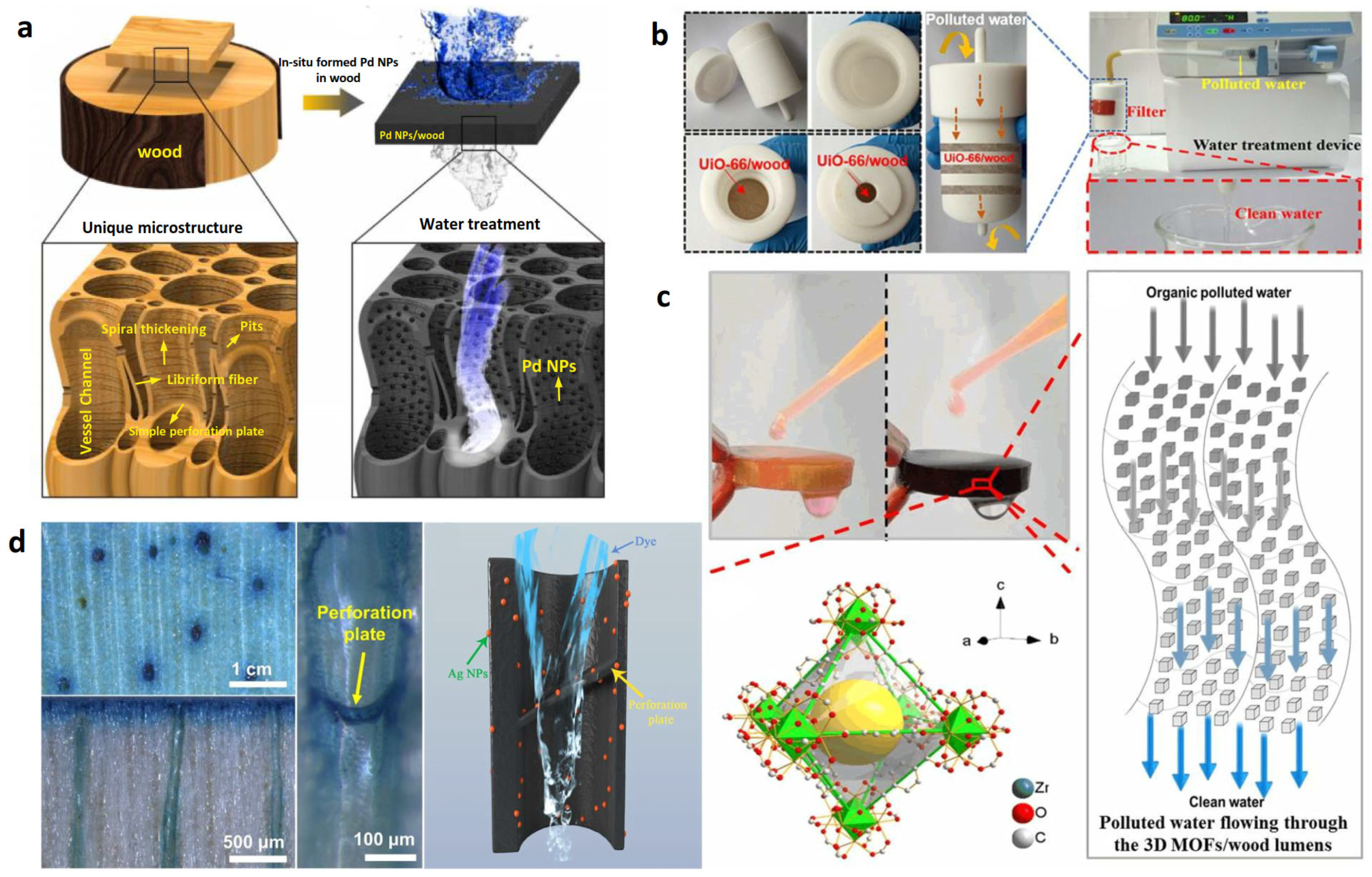

2.3. Removal of Aromatic Dyes

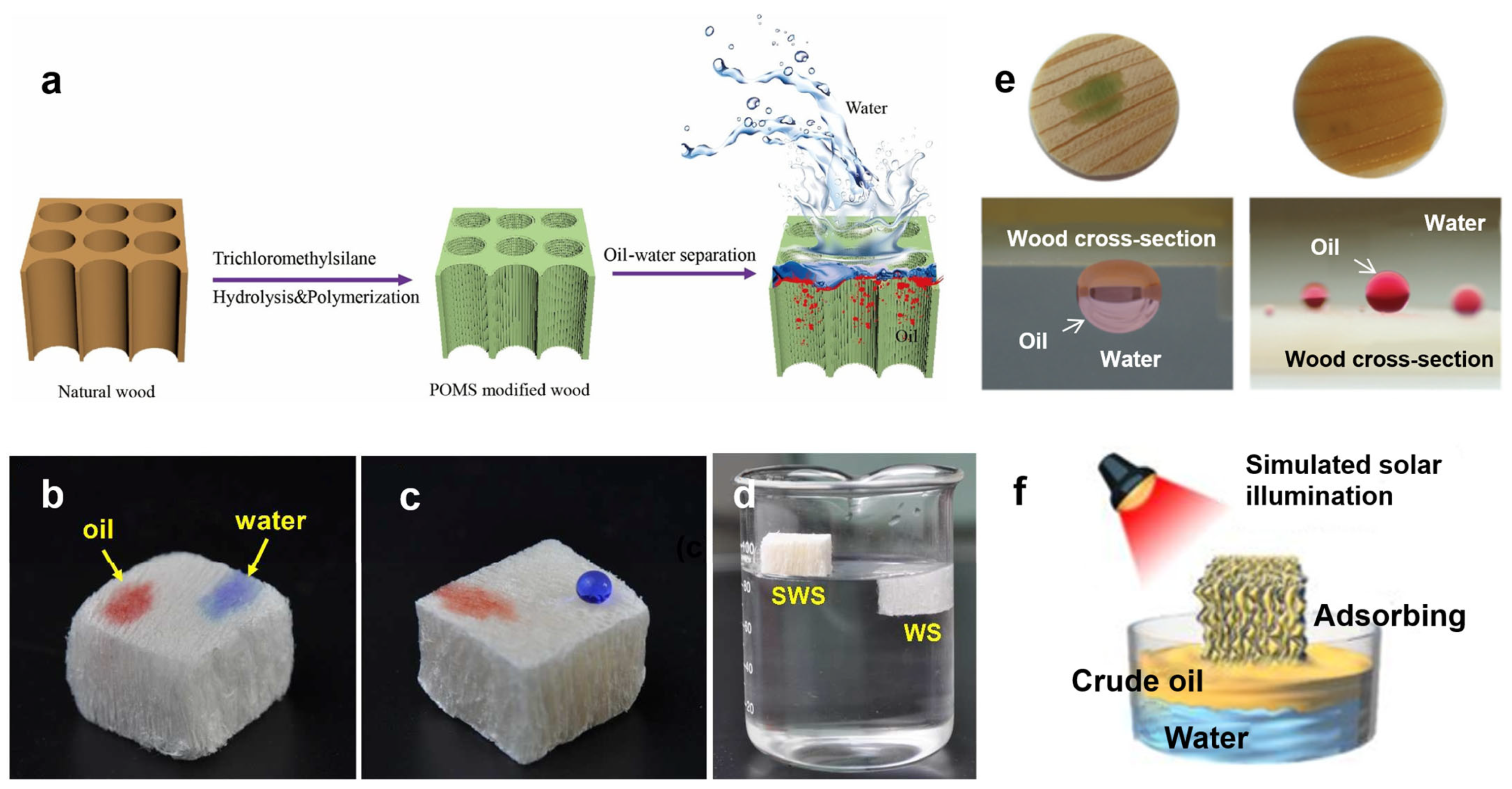

2.4. Oil–Water Separation

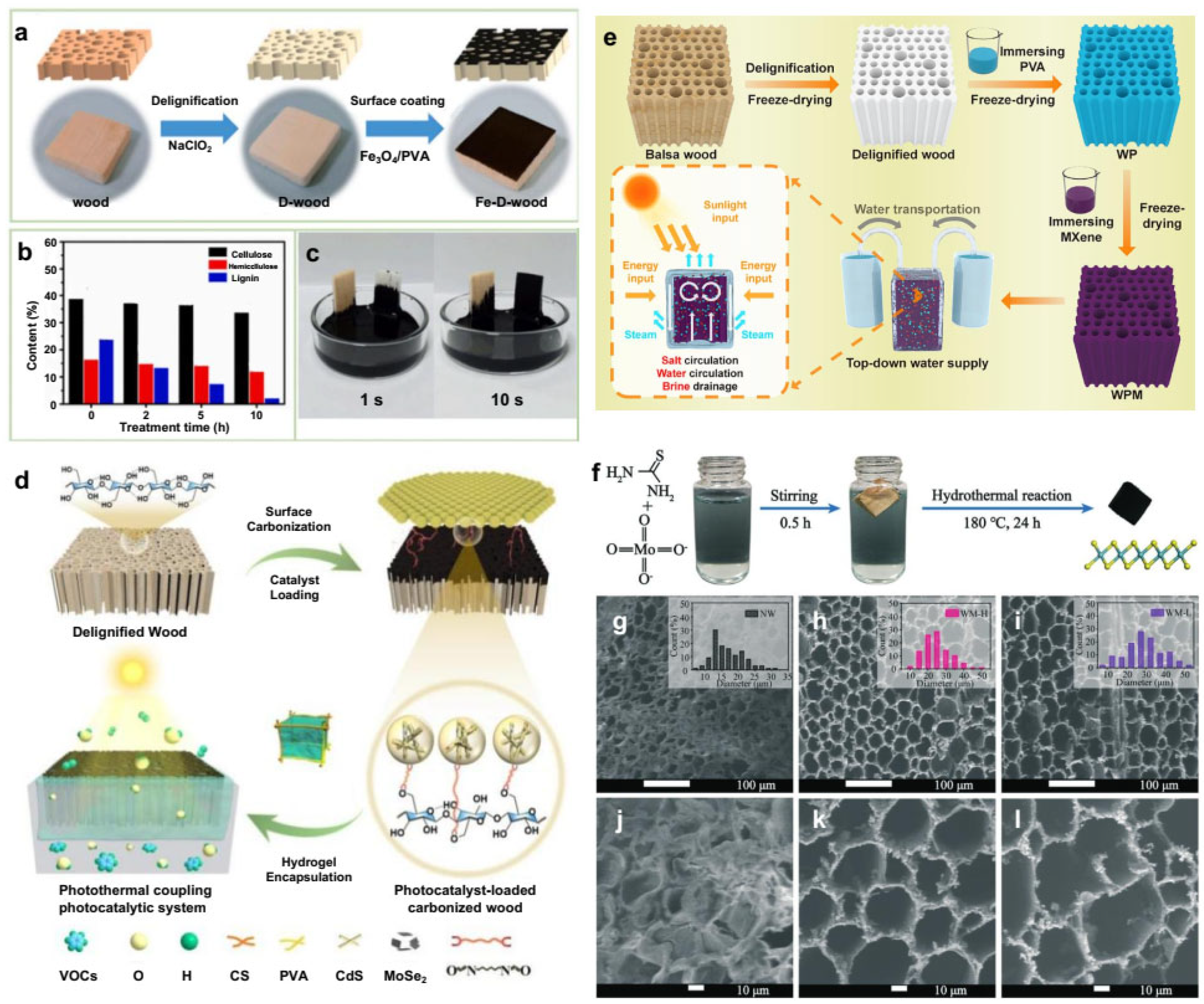

3. Application of Wood Composites in Solar Desalination

3.1. Directly Carbonized Wood

3.2. Wood/Carbon Nanomaterial Composites

3.3. Wood/Semiconductor Material Composites

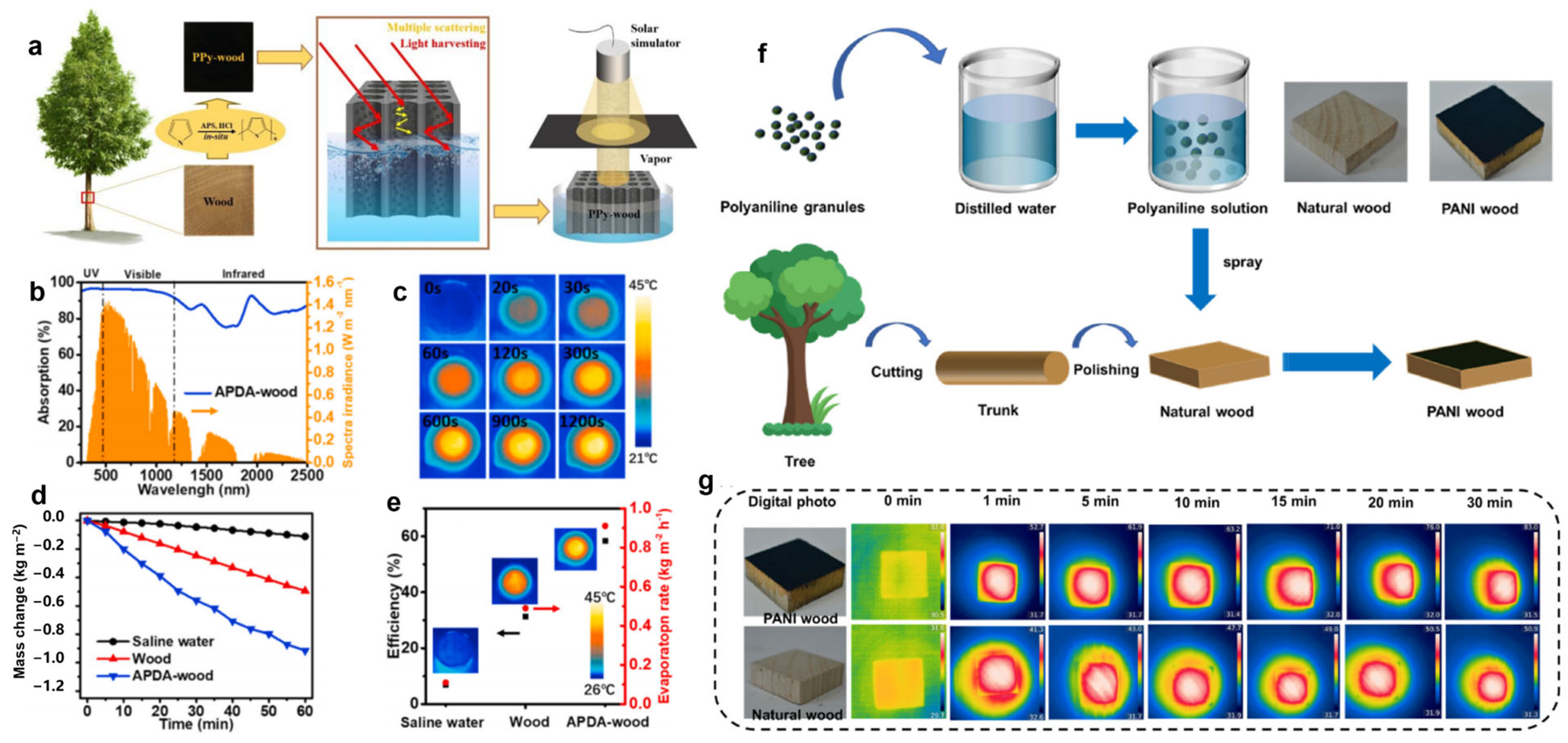

3.4. Wood/Polymer Composites

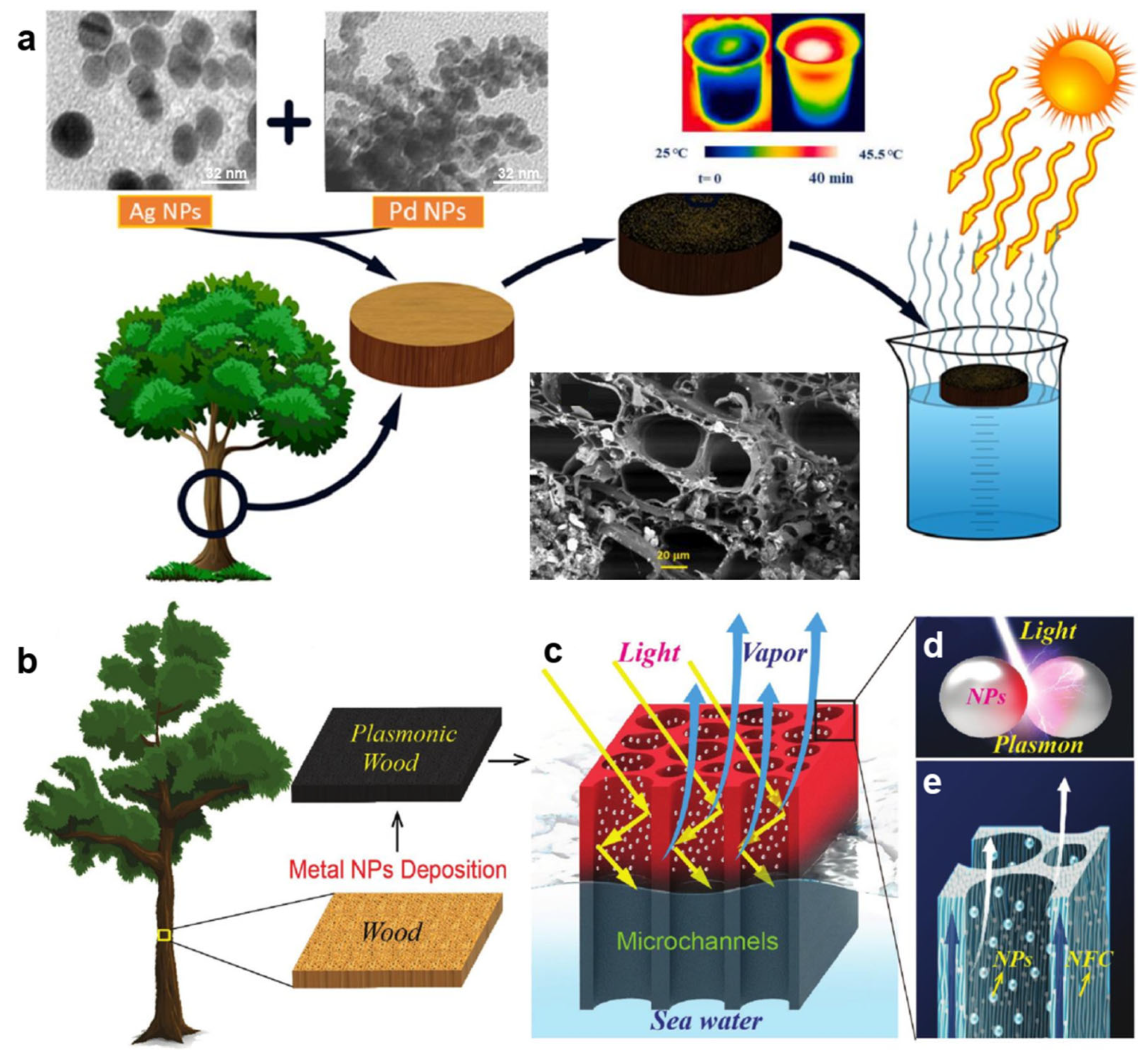

3.5. Wood/Precious Metal Composites

4. Summary and Prospects

4.1. Existing Issues

4.2. Further Research

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.J.; Kuang, Y.D.; Zhu, S.Z.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.; Hu, L. Structure-property-function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Boutilier, M.; Lee, J.; Chambers, V. Water filtration using plant xylem. PLoS ONE 2014, 9, e89934. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.Z.; Fang, Y.; Li, Q.; Bai, L.; Liu, S.; Li, J.; Chen, W. Nanostructures of plant cell walls and individualization methodology of nanofibrillated cellulose. Acta Polym. Sin. 2020, 51, 586–597. [Google Scholar]

- Zhang, M.; Zhou, N.; Shi, Y.; Ma, Y.; An, C.; Li, J.; Jiang, W.; Wang, C.; Shi, J. Construction of antibacterial, superwetting, catalytic, and porous lignocellulosic nanofibril composites for wastewater purification. Adv. Mater. Interfaces 2022, 9, 2201388. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, M. Progress in the Preparation of Stimulus-Responsive Cellulose Hydrogels and Their Application in Slow-Release Fertilizers. Polymers 2023, 15, 3643. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, L.; Wei, X. Removal of lead ions from aqueous solution by the dried aquatic plant, Lemna perpusilla Torr. J. Hazard. Mater. 2013, 244–245, 603–612. [Google Scholar] [CrossRef]

- Liu, C.; Luan, P.C.; Li, Q.; Cheng, Z.; Xiang, P.; Liu, D.; Hou, Y.; Yang, Y.; Zhu, H. Biopolymers derived from trees as sustainable multifunctional materials: A review. Adv. Mater. 2020, 33, 1654. [Google Scholar] [CrossRef]

- Lars, A.B.I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 2018, 30, 1–15. [Google Scholar]

- Li, J.; Sun, Q.F. Inspirations from nature preliminary discussion of wood bionics. China Eng. Sci. 2014, 16, 4–12. [Google Scholar]

- Yi, J.Y.; Huo, Z.; Asiri, A.M.; Alamry, K.A.; Li, J. Application of agroforestry waste biomass adsorption materials in water pollution treatment. Chem. Prog. 2019, 31, 760–772. [Google Scholar]

- Roccaro, P.; Sgroi, M.; Vagliasind, F.G.A. Removal of xenobiotic compounds from wastewater for environment protection: Treatment processes and costs. Chem. Eng. Trans. 2013, 32, 505–510. [Google Scholar]

- Burakov, A.E.; Galunin, E.V.; Burakova, I.V.; Kucherova, A.E.; Agarwal, S.; Tkachev, A.G.; Gupta, V.K. Adsorption of heavy metals on conventional and nanostructured materials for wastewater treatment purposes: A review. Ecotoxicol. Environ. Saf. 2018, 148, 702–712. [Google Scholar] [CrossRef] [PubMed]

- Santhosh, C.; Velmurugan, V.; Jacob, G.; Jeong, S.K.; Grace, N.A.; Bhatnagar, A. Role of nanomaterials in water treatment applications: A review. Chem. Eng. J. 2016, 306, 1116–1137. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, C.; Ma, Y.; Du, X.; Shi, Y.; Li, J.; Shi, J. Fabrication of superwetting, antimicrobial and conductive fibrous membranes for removing/collecting oil contaminants. RSC Adv. 2020, 10, 21636–21642. [Google Scholar] [CrossRef] [PubMed]

- Jiao, M.L.; Yao, Y.G.; Chen, C.J.; Jiang, B.; Pastel, G.; Lin, Z.; Wu, Q.; Cui, M.; He, S.; Hu, L. Highly efficient water treatment via a wood-based and reusable filter. ACS Mater. Lett. 2020, 2, 430–437. [Google Scholar] [CrossRef]

- Chen, F.J.; Gong, A.S.; Zhu, M.W.; Chen, G.; Lacey, S.D.; Jiang, F.; Li, Y.; Wang, Y.; Dai, J.; Yao, Y.; et al. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment. ACS Nano 2017, 11, 4275–4282. [Google Scholar] [CrossRef] [PubMed]

- An, C.C.; Zhang, M.; Xiao, Z.H.; Yang, Q.; Feng, L.; Li, S.; Shi, M. Lignocellulose/chitosan hybrid aerogel composited with fluorescence molecular probe for simultaneous adsorption and detection of heavy metal pollutants. J. Environ. Chem. Eng. 2023, 11, 111205. [Google Scholar] [CrossRef]

- Tripathi, A.; Ranjanm, R. Heavy metal removal from wastewater using low cost adsorbents. J. Bioremediat. Biodegrad. 2015, 6, 315. [Google Scholar] [CrossRef]

- Zhu, M.W.; Li, Y.J.; Chen, G.; Jiang, F.; Yang, Z.; Luo, X.; Wang, Y.; Lacey, S.D.; Dai, J.; Wang, C.; et al. Tree-inspired design for high-efficiency water extraction. Adv. Mater. 2017, 29, 1704107. [Google Scholar] [CrossRef]

- Ahmad, A.; Rafatullah, M.; Sulaiman, O.; Ibrahim, M.H.; Chii, Y.Y.; Siddique, B.M. Removal of Cu (II) and Pb (II) ions from aqueous solutions by adsorption on sawdust of meranti wood. Desalination 2009, 247, 636–646. [Google Scholar] [CrossRef]

- He, L.; Zhao, L.; Sun, W.; Fang, J.; Liu, X.; Qi, J.; Qian, Y.; Li, H. 3D Wood Microfilter for Fast and Efficient Removal of Heavy Metal Ions from Water. Langmuir 2023, 39, 15319–15327. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Liu, H.; Li, J.; Yang, K.; Zhang, Z.; Chen, F.; Wang, B. High-throughput metal trap: Sulfhydryl-functionalized wood membrane stacks for rapid and highly efficient heavy metal ion removal. ACS Appl. Mater. Interfaces 2020, 12, 15002–15011. [Google Scholar] [CrossRef] [PubMed]

- Pei, L.F.; Jiang, L.L.; Hou, X.G. Applicaton of nanoadsorbent in wastewater treatment of heavy metals and organic matter. China Metall. 2018, 28, 1–5. [Google Scholar]

- Cai, X.H.; Liu, H.W.; Zhi, L.H.; Wen, H.; Yu, A.; Li, L.; Chen, F.; Wang, B. Ag-C3N4/rGO nanocomposite as a highly efficient metal-free photocatalyst for direct C-H arylation under visible light irradiation. RSC Adv. 2017, 7, 46132–46138. [Google Scholar] [CrossRef]

- Wang, R.R.; Li, Q.R.; Xiao, H.Y.; Xie, D.; Lu, H. Synthesis of NiO using pine as template and adsorption performance for Pb(II) from aqueous solution. Appl. Surf. Sci. 2013, 279, 129–136. [Google Scholar] [CrossRef]

- Vitas, S.; Keplinger, T.; Reichholf, N.; Figi, R.; Cabane, E. Functional lignocellulosic material for the remediation of copper (II) ions from water: Towards the design of a wood filter. J. Hazard. Mater. 2018, 355, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Lu, Q.; Yu, W. The improvement of heavy metals removal by wood membrane in drinking water treatment: Comparison with polymer membrane and associated mechanism. Chemosphere 2023, 324, 138297. [Google Scholar] [CrossRef]

- Gu, Y.; Ye, M.X.; Wang, Y.C.; Li, H.M.; Zhang, H.M.; Wang, G.Z.; Zhang, Y.X.; Zhao, H.J. Lignosulfonate functionalized g-C3N4/carbonized wood sponge for highly efficient heavy metal ion scavenging. J. Mater. Chem. A 2020, 8, 12687–12698. [Google Scholar] [CrossRef]

- Guo, Q.; Qiu, Y.Q. Research progress in application of nano-silver in water treatment. Synth. Mater. Aging Appl. 2019, 48, 125–129. [Google Scholar]

- Zhang, M.; Shi, Y.; Wang, R.; Chen, K.; Zhou, N.; Yang, Q.; Shi, J. Triple-functional lignocellulose/chitosan/Ag@TiO2 nanocomposite membrane for simultaneous sterilization, oil/water emulsion separation, and organic pollutant removal. J. Environ. Chem. Eng. 2021, 9, 106728. [Google Scholar] [CrossRef]

- Macior, A.; Zaborniak, I.; Chmielarz, P.; Smenda, J.; Wolski, K.; Ciszkowicz, E.; Lecka-Szlachta, K. A New Protocol for Ash Wood Modification: Synthesis of Hydrophobic and Antibacterial Brushes from the Wood Surface. Molecules 2022, 27, 890. [Google Scholar] [CrossRef]

- Dai, X.; Qi, Y.; Luo, H.; He, Z.; Wei, L.; Dong, X.; Ma, X.; Yang, D.; Li, Y. Leachability and Anti-Mold Efficiency of Nanosilver on Poplar Wood Surface. Polymers 2022, 14, 884. [Google Scholar] [CrossRef]

- Che, W.; Xiao, Z.; Wang, Z.; Li, J.; Wang, H.; Wang, Y.; Xie, Y. Wood-based mesoporous filter decorated with silver nanoparticles for water purification. ACS Sustain. Chem. Eng. 2019, 7, 5134–5141. [Google Scholar] [CrossRef]

- Wen, J.J.; Tan, X.J.; Hu, Y.Y.; Guo, Q.; Hong, X. Filtration and electrochemical disinfection performance of PAN/PANI/AgNWs-CC composite nanofiber membrane. Environ. Sci. Technol. 2017, 51, 6395–6403. [Google Scholar] [CrossRef]

- Huo, Z.Y.; Luo, Y.F.; Xie, X.; Feng, C.; Jiang, K.; Wang, J.; Hu, H. Carbon-nanotube sponges enabling high-efficiency and reliable cell inactivation by low-voltage electroporation. Environ. Sci. Nano 2017, 4, 2010–2017. [Google Scholar] [CrossRef]

- Yang, Z.; Ni, H.; Liu, P.; Liu, H.; Yang, K.; Zhang, Z.; Wang, B.; Li, X.; Chen, F. Nanofibrils in 3D aligned channel arrays with synergistic effect of Ag/NPs for rapid and highly efficient electric field disinfection. Chin. Chem. Lett. 2021, 32, 3143–3148. [Google Scholar] [CrossRef]

- Du, X.; Shi, L.; Pang, J.; Zheng, H.; Shi, J.; Zhang, M. Fabrication of superwetting and antimicrobial wood-based mesoporous composite decorated with silver nanoparticles for purifying the polluted-water with oils, dyes and bacteria. J. Environ. Chem. Eng. 2022, 10, 107152. [Google Scholar] [CrossRef]

- Cheng, Z.; Guan, H.; Meng, J.; Wang, X. Dual-functional porous wood filter for simultaneous oil/water separation and organic pollutant removal. ACS Omega 2020, 5, 14096–14103. [Google Scholar] [CrossRef]

- Adam, A.M.A.; Saad, H.A.; Atta, A.A.; Alsawat, M.; Hegab, M.S.; Refatm, M.S.; Altalhim, T.A.; Alosaimi, E.H.; Younes, A. Preparation and characterization of new CrFeO3-carbon composite using environmentally friendly methods to remove organic dye pollutants from aqueous solutions. Crystals 2021, 11, 960. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Guo, R.X.; Cai, X.H.; Liu, H.W.; Yang, Z.; Meng, Y.; Chen, F.; Li, Y.; Wang, B. In situ growth of metal-organic frameworks in three-dimensional aligned lumen arrays of wood for rapid and highly efficient organic pollutant removal. Environ. Sci. Technol. 2019, 53, 2705–2712. [Google Scholar] [CrossRef]

- Liu, G.; Chen, D.; Liu, R.; Yu, Z.; Jiang, J.; Liu, Y.; Hu, J.; Chang, S. Antifouling wood matrix with natural water transfer and microreaction channels for water treatment. ACS Sustain. Chem. Eng. 2019, 7, 6782–6791. [Google Scholar] [CrossRef]

- Goodman, S.M.; Bura, R.; Dichiara, A.B. Facile impregnation of graphene into porous wood filters for the dynamic removal and recovery of dyes from aqueous solutions. ACS Appl. Nano Mater. 2018, 1, 5682–5690. [Google Scholar] [CrossRef]

- Sens, M.L.; Emmendoerfer, M.L.; Mueller, L.C. Water filtration through wood with helical cross-flow. Desalination Water Treat. 2015, 53, 15–26. [Google Scholar] [CrossRef]

- Cui, Z.; Wu, J.; Xu, Y.; Wu, T.; Li, H.; Li, J.; Kang, L.; Cai, Y.; Li, J.; Tian, D. In-situ growth of polyoxometalate-based metal-organic frameworks on wood as a promising dual-function filter for effective hazardous dye and iodine capture. Chem. Eng. J. 2023, 451, 138371. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, T. The Wood/MoS2 Composites with Good Adsorption and Photocatalytic Ability for Highly Efficient Removal of Organic Dye Molecules. Chem. Sel. 2023, 8, e202300119. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, L.; Du, X.; Li, Z.; Shi, Y.; An, C.; Li, J.; Wang, C.; Shi, J. Janus mesoporous wood-based membrane for simultaneous oil/water separation, aromatic dyes removal, and seawater desalination. Ind. Crops Prod. 2022, 188, 115643. [Google Scholar] [CrossRef]

- Li, J.; Zhang, M.; Qiang, T. Research progress in modified PVDF membrane with inorganic particles for oil bearing wastewater treatment in oilfields. J. For. Environ. 2016, 36, 257–265. [Google Scholar]

- Wang, C.Y.; Wang, X.; Yu, Q. New research progress of functional wood. J. For. Eng. 2019, 4, 10–18. [Google Scholar]

- Zhao, M.; Tao, Y.; Wang, J.; He, Y. Facile preparation of superhydrophobic porous wood for continuous oil-water separation. J. Water Process Eng. 2020, 36, 101279. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.H.; Wu, P.C.; Chen, S.; Guo, X.; Meng, G.; Peng, B.; Wu, J.; Liu, Z. Environmentally benign chitosan as reductant and supporter for synthesis of Ag/AgCl/chitosan composites by one-step and their photocatalytic degradation performance under visible-light irradiation. Front. Mater. Sci. 2017, 11, 130–138. [Google Scholar] [CrossRef]

- Guan, H.; Cheng, Z.; Wang, X. Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano 2018, 12, 10365–10373. [Google Scholar] [CrossRef]

- Song, J.W.; Chen, C.J.; Wang, C.W.; Kuang, Y.; Li, Y.; Jiang, F.; Li, Y.; Hitz, E.; Zhang, Y.; Liu, B.; et al. Super flexible wood. ACS Appl. Mater. Interfaces 2017, 9, 23520–23527. [Google Scholar] [CrossRef]

- Chao, W.; Sun, X.; Li, Y.; Cao, G.; Wang, R.; Wang, C.; Ho, S. Enhanced directional seawater desalination using a structure-guided wood aerogel. ACS Appl. Mater. Interfaces 2020, 12, 22387–22397. [Google Scholar] [CrossRef]

- Fu, Q.L.; Ansari, F.; Zhou, Q.; Berglund, L.A. Wood nanotechnology for strong, mesoporous, and hydrophobic biocomposites for selective separation of oil/water mixtures. ACS Nano 2018, 12, 2222–2230. [Google Scholar] [CrossRef]

- Wang, K.; Liu, X.; Tan, Y.; Zhang, W.; Zhang, S.; Li, J.; Huang, A. Highly fluorinated and hierarchical HNTs/SiO2 Chemical hybrid particles for substrate-independent superamphiphobic coatings. Chem. Eng. J. 2019, 359, 626–640. [Google Scholar] [CrossRef]

- Blanco, M.V.D.; Fscher, E.J.; Cabane, E. Underwater superoleophobic wood cross sections for efficient oil/water separation. Adv. Mater. Interfaces 2017, 4, 1700584. [Google Scholar] [CrossRef]

- Chao, W.X.; Wang, S.B.; Li, Y.D.; Cao, G.; Zhao, Y.; Sun, X.; Wang, C.; Ho, S. Natural sponge-like wood-derived aerogel for solar-assisted adsorption and recovery of high-viscous crude oil. Chem. Eng. J. 2020, 400, 125865. [Google Scholar] [CrossRef]

- Zhu, Y.R.; Li, H.Q.; Huang, W.; Lai, X.; Zeng, X. Facile fabrication of superhydrophobic wood aerogel by vapor deposition method for oil-water separation. Surf. Interfaces 2023, 37, 102746. [Google Scholar] [CrossRef]

- Chen, Z.H.; Su, X.J.; Li, K.Q.; Chen, R.; Lai, Z.; Li, X.; Chen, S.; Wu, W. Superhydrophobic PDMS/PEI-cCNTs wood with Joule heat and demulsification capability for oil-water emulsio70n separation. Prog. Org. Coat. 2023, 185, 107960. [Google Scholar] [CrossRef]

- Wu, J.W.; Tian, J.; Qian, Z.H.; Huang, J.; Sun, D. Highly robust separation for aqueous oils enabled by balsa wood-based cellulose aerogel with intrinsic superior hydrophilicity. Sep. Purif. Technol. 2023, 315, 123688. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, M.; Du, X.; Liu, B.; Li, S.; An, C. In-situ polymerization of pyrrole on elastic wood for high efficiency seawater desalination and oily water purification. J. Mater. Sci. 2022, 57, 16317–16332. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly anisotropic, highly transparent wood composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef]

- Grassi, G.; Magnani, F. Stomatal, mesophyll conductance and biochemical limitations to photosynthesis as affected by drought and leaf ontogeny in ash and oak trees. Plant Cell Environ. 2005, 28, 834–849. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, H.; Kong, F.; Zhang, Y.; Wang, S.; Liu, S.; Lucia, L.A.; Fatehi, P.; Pang, H. Fabrication, characteristics and applications of carbon materials with different morphologies and porous structures produced from wood liquefaction: A review. Chem. Eng. J. 2019, 364, 226–243. [Google Scholar] [CrossRef]

- Xue, G.; Liu, K.; Chen, Q.; Yang, P.; Li, J.; Ding, T.; Duan, J.; Qi, B.; Zhou, J. Robust and low-cost flame-treated wood for high-performance solar steam generation. ACS Appl. Mater. Interfaces 2017, 9, 15052–15057. [Google Scholar] [CrossRef]

- Kuang, Y.; Chen, C.; He, S.; Hitz, E.; Wang, Y.; Gan, W.; Mi, R.; Hu, L. A high-performance self-regenerating solar evaporator for continuous water desalination. Adv. Mater. 2019, 31, 1900498. [Google Scholar] [CrossRef]

- Chen, J.; Jian, M.; Yang, X. Highly Effective Multifunctional Solar Evaporator with Scaffolding Structured Carbonized Wood and Biohydrogel. ACS Appl. Mater. Interfaces 2022, 14, 46491–46501. [Google Scholar] [CrossRef]

- Ghafurian, M.M.; Niazmand, H.; Ebrahimnia-Bajestan, E.; Taylor, R.A. Wood surface treatment techniques for enhanced solar steam generation. Renew. Energy 2020, 146, 2308–2315. [Google Scholar] [CrossRef]

- Vélez-Cordero, J.R.; Hernandez-Cordero, J. Heat generation and conduction in PDMS-carbon nanoparticle membranes irradiated with optical fibers. Int. J. Therm. Sci. 2015, 96, 12–22. [Google Scholar] [CrossRef]

- Gao, T.; Li, Y.; Chen, C.; Yang, Z.; Kuang, Y.; Jia, C.; Song, J.; Hitz, E.M.; Liu, B.; Huang, H.; et al. Architecting a floatable, durable, and scalable steam generator: Hydrophobic/hydrophilic bifunctional structure for solar evaporation enhancement. Small Methods 2019, 3, 1800176. [Google Scholar] [CrossRef]

- Zhao, D.L.; Chung, T.S. Applications of carbon quantum dots (CQDs) in membrane technologies: A review. Water Res. 2018, 147, 43–49. [Google Scholar] [CrossRef]

- Ito, Y.; Tanabe, Y.; Han, J.; Fujita, T.; Tanigaki, K.; Chen, M. Multifunctional porous graphene for high-efficiency steam generation by heat localization. Adv. Mater. 2015, 27, 4302–4307. [Google Scholar] [CrossRef]

- Liu, K.K.; Jiang, Q.; Tadepalli, S.; Raliya, R.; Biswas, P.; Naik, R.R.; Singamaneni, S. Wood–graphene oxide composite for highly efficient solar steam generation and desalination. ACS Appl. Mater. Interfaces 2017, 9, 7675–7681. [Google Scholar] [CrossRef]

- Jiang, Q.; Tian, L.; Liu, K.K.; Tadepalli, S.; Raliya, R.; Biswas, P.; Naik, R.R.; Singamaneni, S. Bilayered biofoam for highly efficient solar steam generation. Adv. Mater. 2016, 28, 9400–9407. [Google Scholar] [CrossRef]

- Chao, W.; Li, Y.; Sun, X.; Cao, G.; Wang, C.; Ho, S. Enhanced wood-derived photothermal evaporation system by in-situ incorporated lignin carbon quantum dots. Chem. Eng. J. 2021, 405, 126703. [Google Scholar] [CrossRef]

- Hu, Z.; Hao, L.; Liu, N.; He, P.P.; Bai, H.Y.; Niu, R.; Gong, J. High-performance bilayer solar evaporators constructed by candle-derived carbon nanoparticle/wood hybrid. Mater. Today Commun. 2021, 28, 102636. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Li, W.; Li, C.; Jiao, F.; Yu, Z.; Li, X. Three-dimensional disposable wooden chopsticks-derived solar-thermal evaporators for environmental energy-enhanced water evaporation and purification. Compos. Commun. 2023, 44, 101746. [Google Scholar] [CrossRef]

- Song, L.; Zhang, X.F.; Wang, Z.; Zheng, T.; Yao, J. Fe3O4/polyvinyl alcohol decorated delignified wood evaporator for continuous solar steam generation. Desalination 2021, 507, 115024. [Google Scholar] [CrossRef]

- Fan, D.Q.; Lu, Y.; Xu, X.L.; Tang, Y.; Zhang, H.; Mi, Y.; Yang, X. Multifunctional wood-based hydrogels for wastewater treatment and interfacial solar steam generation. Chem. Eng. J. 2023, 471, 144421. [Google Scholar] [CrossRef]

- He, F.; Han, M.; Zhang, J.; Wang, Z.; Wu, X.; Zhou, Y.; Jiang, L.; Peng, S.; Li, Y. A simple, mild and versatile method for preparation of photothermal woods toward highly efficient solar steam generation. Nano Energy 2020, 71, 104650. [Google Scholar] [CrossRef]

- Yan, C.; Huang, J.; Liang, Z.; Yang, D.; Li, Z. Fabrication of a Highly Efficient Wood-Based Solar Interfacial Evaporator with Self-Desalting and Sterilization Performance. Langmuir 2022, 38, 12813–12821. [Google Scholar] [CrossRef]

- Hu, C.; Li, W.; Zhao, H.Y.; Li, C.; Ma, Z.; Hao, L.; Pang, Y.; Yu, Z.; Li, X. Salt-resistant wood-based solar steam generator with top-down water supply for high-yield and long-term desalination of seawater and brine water. Chem. Eng. J. 2023, 460, 141622. [Google Scholar] [CrossRef]

- He, X.; Zhang, L.; Hu, X.; Zhou, Q. Formation of S defects in MoS2-coated wood for high-efficiency seawater desalination. Environ. Sci. Nano 2021, 8, 2069–2080. [Google Scholar] [CrossRef]

- Okamoto, T.; Kumagai, S.; Fukuzaki, E.; Ishii, H.; Watanabe, G.; Niitsu, N.; Annaka, Y.; Yamagishi, M.; Tani, Y.; Sugiura, H.; et al. Robust, high-performance n-type organic semiconductors. Sci. Adv. 2020, 6, eaaz0632. [Google Scholar] [CrossRef]

- Long, R.; Li, Y.; Song, L.; Xiong, Y. Coupling solar energy into reactions: Materials design for surface plasmon-mediated catalysis. Small 2015, 11, 3873–3889. [Google Scholar] [CrossRef]

- Brongersma, M.L.; Halas, N.J.; Nordlander, P. Plasmon-induced hot carrier science and technology. Nat. Nanotechnol. 2015, 10, 25–34. [Google Scholar] [CrossRef]

- Zha, Z.; Yue, X.; Ren, Q.; Dai, Z. Uniform polypyrrole nanoparticles with high photothermal conversion efficiency for photothermal ablation of cancer cells. Adv. Mater. 2013, 25, 777–782. [Google Scholar] [CrossRef]

- Zhang, L.; Tang, B.; Wu, J.; Li, R.; Wang, P. Hydrophobic light-to-heat conversion membranes with self-healing ability for interfacial solar heating. Adv. Mater. 2015, 27, 4889–4894. [Google Scholar] [CrossRef]

- Zou, Y.; Yang, P.; Yang, L. Boosting solar steam generation by photothermal enhanced polydopamine/wood composites. Polymer 2021, 217, 123464. [Google Scholar] [CrossRef]

- Huang, W.; Hu, G.; Tian, C.; Wang, X.; Tu, J.; Cao, Y.; Zhang, K. Nature-inspired salt resistant polypyrrole–wood for highly efficient solar steam generation. Sustain. Energy Fuels 2019, 3, 3000–3008. [Google Scholar] [CrossRef]

- Wang, Z.; Yan, Y.; Shen, X.; Jin, C.; Sun, Q.; Li, H. A wood–polypyrrole composite as a photothermal conversion device for solar evaporation enhancement. J. Mater. Chem. A 2019, 7, 20706–20712. [Google Scholar] [CrossRef]

- Qu, M.; Yan, J.; Ge, J.; Zhao, Y.; Xue, Y.; Liu, X.; Liu, H.; Yan, M.; He, J. Nature-inspired wood-based solar evaporation system for efficient desalination and water purification. J. Mater. Sci. 2023, 58, 6220–6236. [Google Scholar] [CrossRef]

- Lin, Z.X.; Wu, T.T.; Jia, B.X.; Shi, J.; Zhou, B.; Zhu, C.; Wang, Y.; Liang, R.; Mizuno, M. Nature-inspired poly (N-phenylglycine)/wood solar evaporation system for high-efficiency desalination and water purification. Colloids Surf. A Physicochem. Eng. Asp. 2022, 637, 128272. [Google Scholar] [CrossRef]

- Li, L.; He, N.; Yang, S.; Zhang, Q.; Zhang, H.; Wang, B.; Dong, T.; Wang, H.; Jiang, B.; Tang, D. Strong tough hydrogel solar evaporator with wood skeleton construction enabling ultra-durable brine desalination. EcoMat 2023, 5, e12282. [Google Scholar] [CrossRef]

- Sheng, K.; Tian, M.; Zhu, J. When Coordination Polymers Meet Wood: From Molecular Design toward Sustainable Solar Desalination. ACS Nano 2023, 17, 15482–15491. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Tang, M.; Guan, B.; Wang, K.; Yang, J.; Wang, F.; Wang, M.; Shan, J.; Chen, Z.; Wei, D.; et al. Hierarchical graphene foam for efficient omnidirectional solar–thermal energy conversion. Adv. Mater. 2017, 29, 1702590. [Google Scholar] [CrossRef]

- Gao, M.; Connor, P.K.N.; Ho, G.W. Plasmonic photothermic directed broadband sunlight harnessing for seawater catalysis and desalination. Energy Environ. Sci. 2016, 9, 3151–3160. [Google Scholar] [CrossRef]

- Linic, S.; Aslam, U.; Boerigter, C.; Morabito, M. Photochemical transformations on plasmonic metal nanoparticles. Nat. Mater. 2015, 14, 567–576. [Google Scholar] [CrossRef]

- Gao, M.; Zhu, L.; Peh, C.K.; Ho, G.W. Solar absorber material and system designs for photothermal water vaporization towards clean water and energy production. Energy Environ. Sci. 2019, 12, 841–864. [Google Scholar] [CrossRef]

- Webb, J.A.; Bardhan, R. Emerging advances in nanomedicine with engineered gold nanostructures. Nanoscale 2014, 6, 2502–2530. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Gao, M.; Peh, C.K.N.; Ho, G.W. Solar-driven photothermal nanostructured materials designs and prerequisites for evaporation and catalysis applications. Mater. Horiz. 2018, 5, 323–343. [Google Scholar] [CrossRef]

- Zhou, L.; Tan, Y.; Ji, D.; Zhu, B.; Zhang, P.; Xu, J.; Gan, Q.; Yu, Z.; Zhu, J. Self-assembly of highly efficient, broadband plasmonic absorbers for solar steam generation. Sci. Adv. 2016, 2, e1501227. [Google Scholar] [CrossRef] [PubMed]

- Goharshadi, K.; Sajjadi, S.A.; Goharshadi, E.K.; Mehrkhah, R. Highly efficient plasmonic wood/Ag/Pd photoabsorber in interfacial solar steam generation. Mater. Res. Bull. 2022, 154, 111916. [Google Scholar] [CrossRef]

- Zhu, M.; Li, Y.; Chen, F.; Zhu, X.; Dai, Y.; Li, Y.; Yang, Z.; Yan, X.; Song, J.; Wang, Y.; et al. Plasmonic wood for high-efficiency solar steam generation. Adv. Energy Mater. 2018, 8, 1701028. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, D.; Zheng, D.; Li, Z.; Wang, C.; Li, J.; Zhang, M. Research Advances in Wood Composites in Applications of Industrial Wastewater Purification and Solar-Driven Seawater Desalination. Polymers 2023, 15, 4712. https://doi.org/10.3390/polym15244712

Song D, Zheng D, Li Z, Wang C, Li J, Zhang M. Research Advances in Wood Composites in Applications of Industrial Wastewater Purification and Solar-Driven Seawater Desalination. Polymers. 2023; 15(24):4712. https://doi.org/10.3390/polym15244712

Chicago/Turabian StyleSong, Dongsheng, Dingqiang Zheng, Zhenghui Li, Chengyu Wang, Jian Li, and Ming Zhang. 2023. "Research Advances in Wood Composites in Applications of Industrial Wastewater Purification and Solar-Driven Seawater Desalination" Polymers 15, no. 24: 4712. https://doi.org/10.3390/polym15244712

APA StyleSong, D., Zheng, D., Li, Z., Wang, C., Li, J., & Zhang, M. (2023). Research Advances in Wood Composites in Applications of Industrial Wastewater Purification and Solar-Driven Seawater Desalination. Polymers, 15(24), 4712. https://doi.org/10.3390/polym15244712