Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Proportions and Specimen Preparation

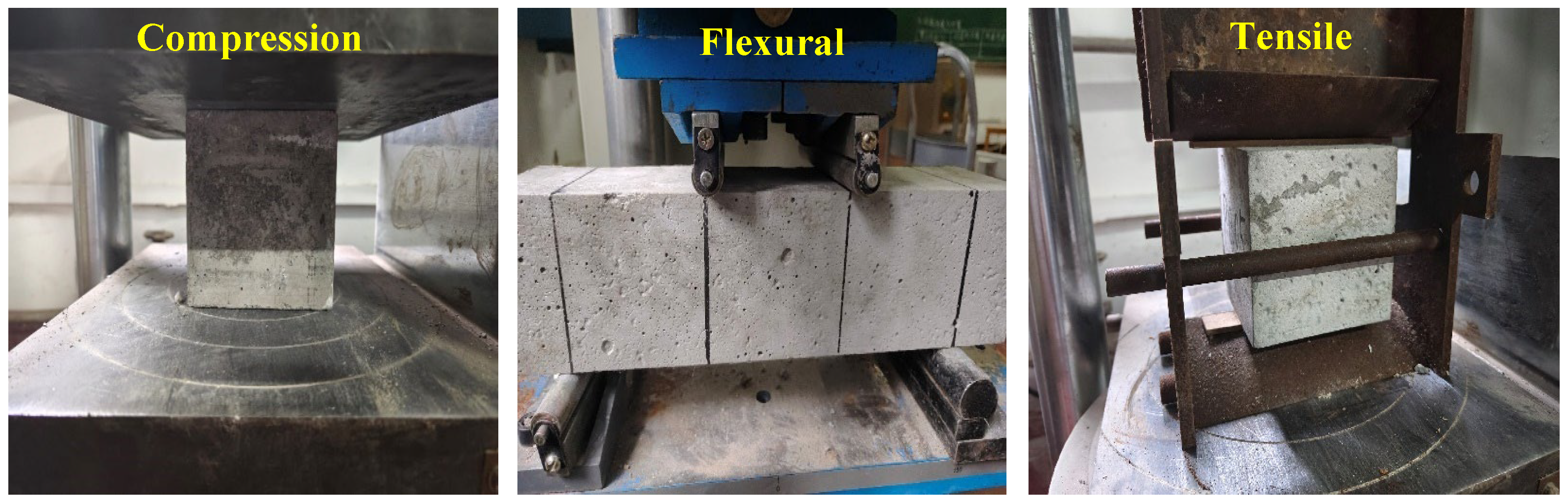

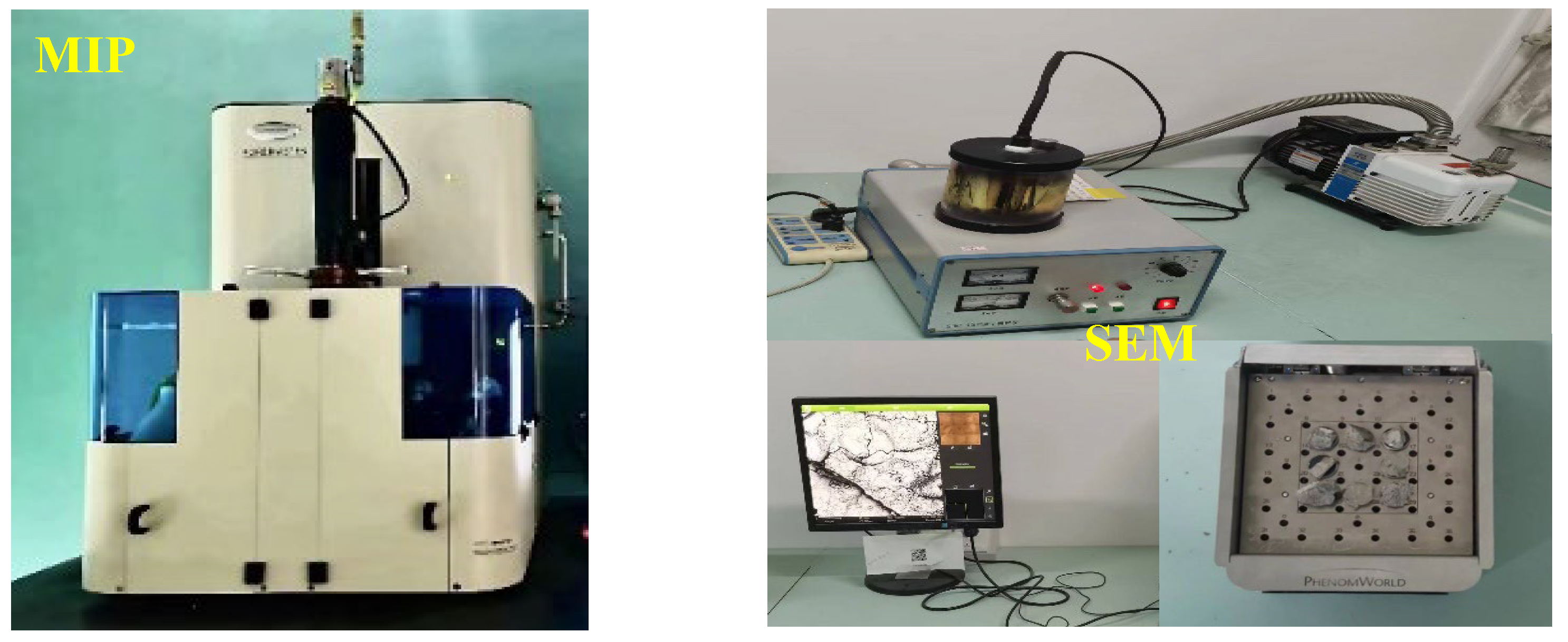

2.3. Test Methods

3. Results and Discussion

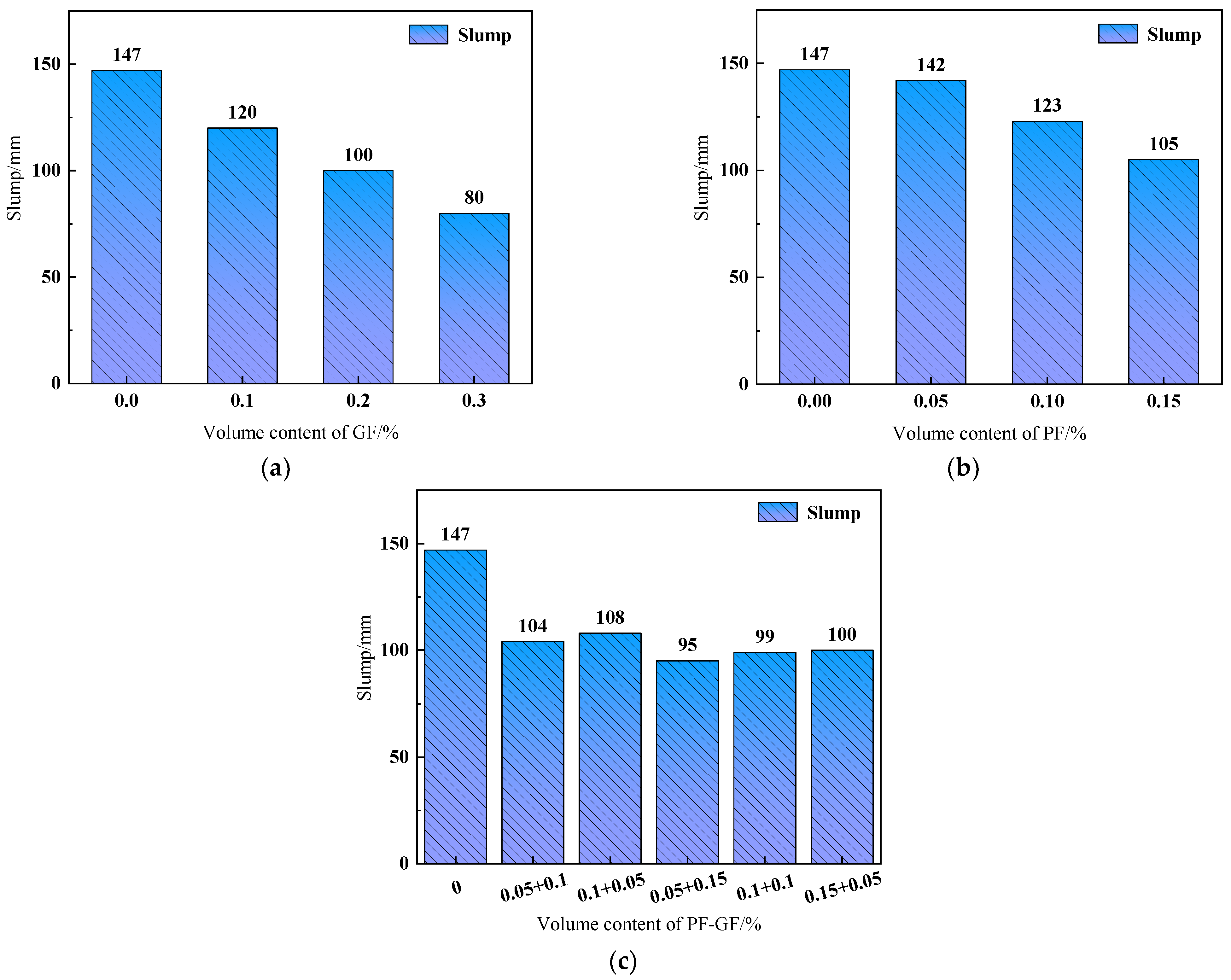

3.1. Workability

3.2. Failure Process

3.3. Strength Analysis

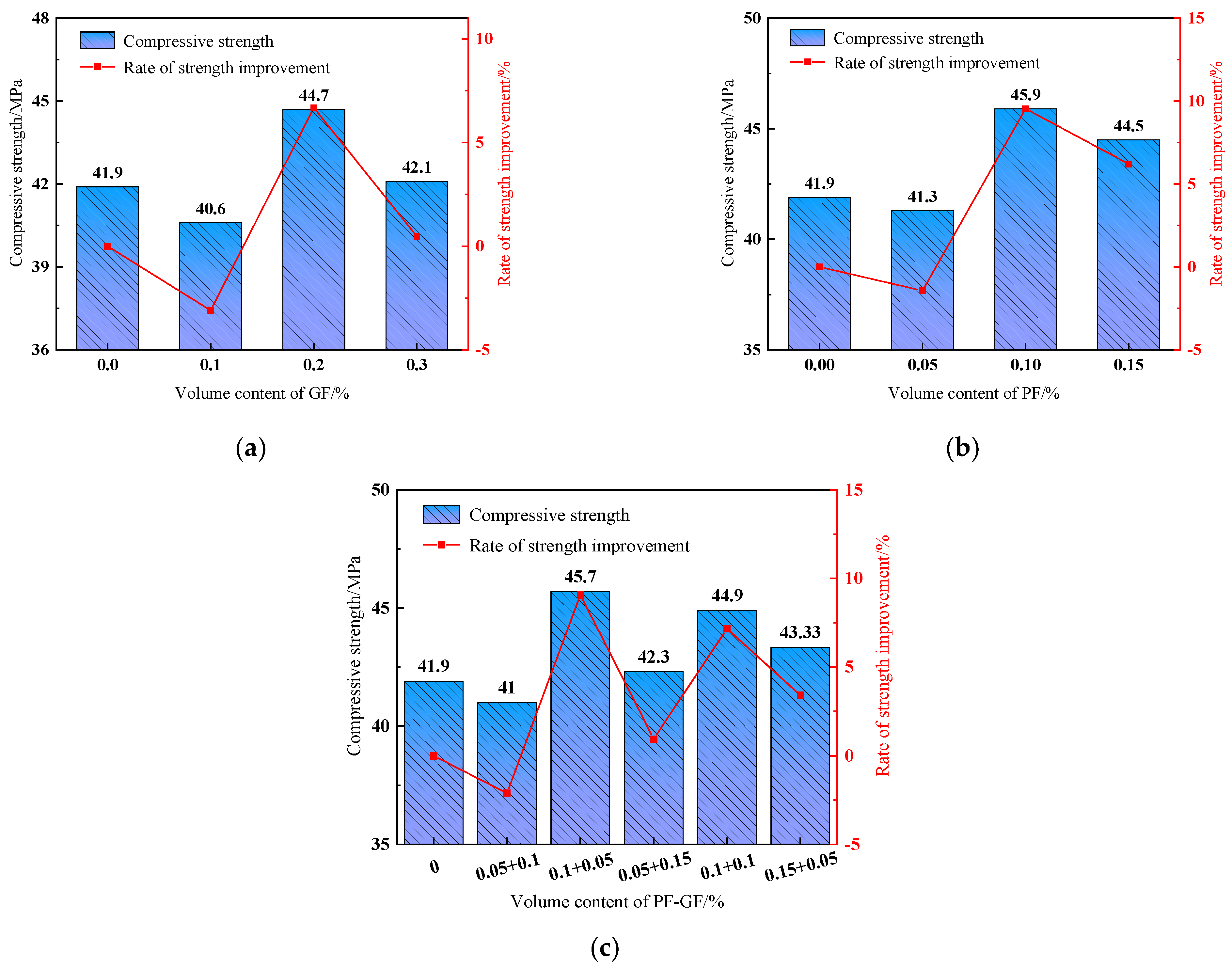

3.3.1. Compressive Strength

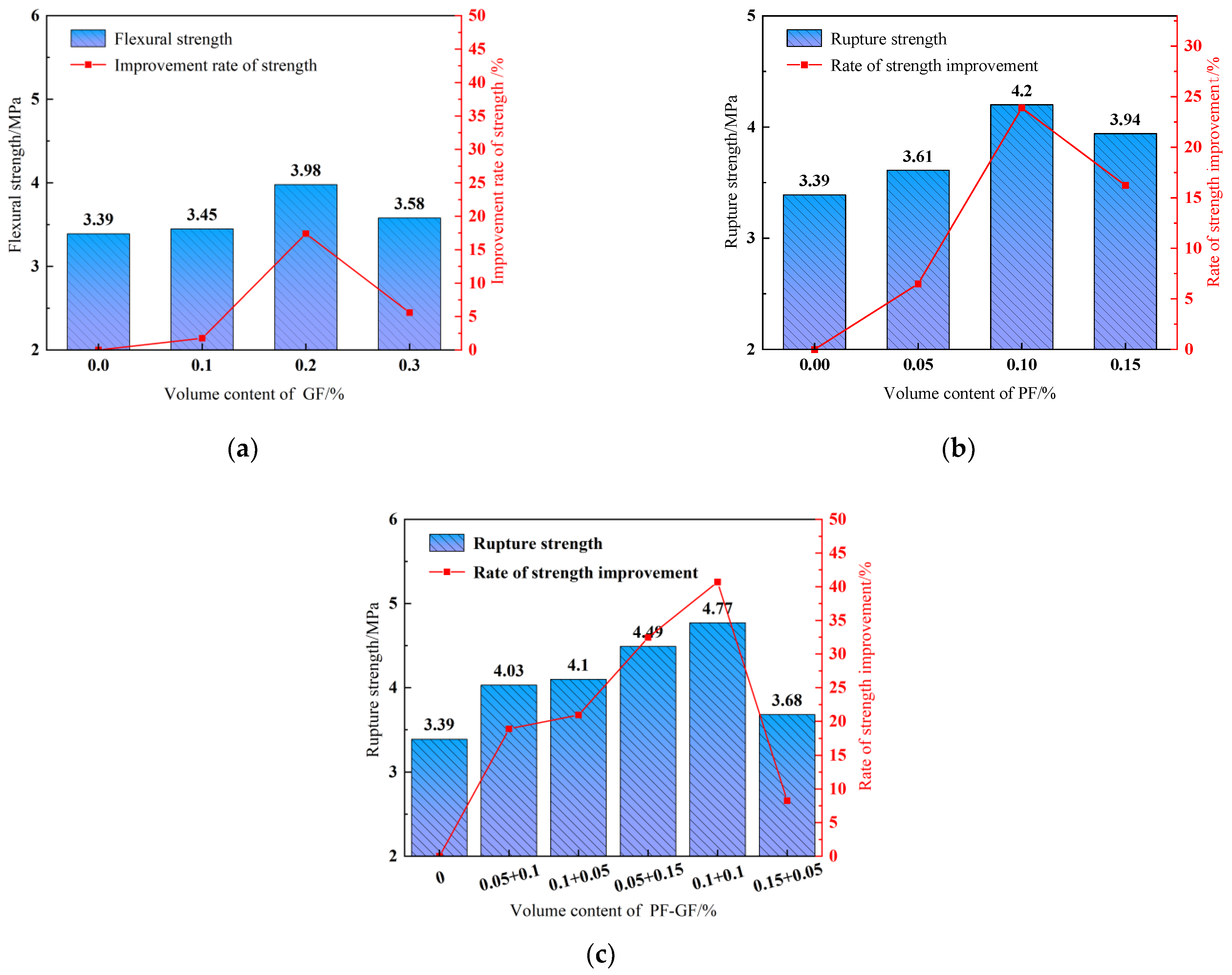

3.3.2. Flexural Strength

3.3.3. Splitting Tensile Strength

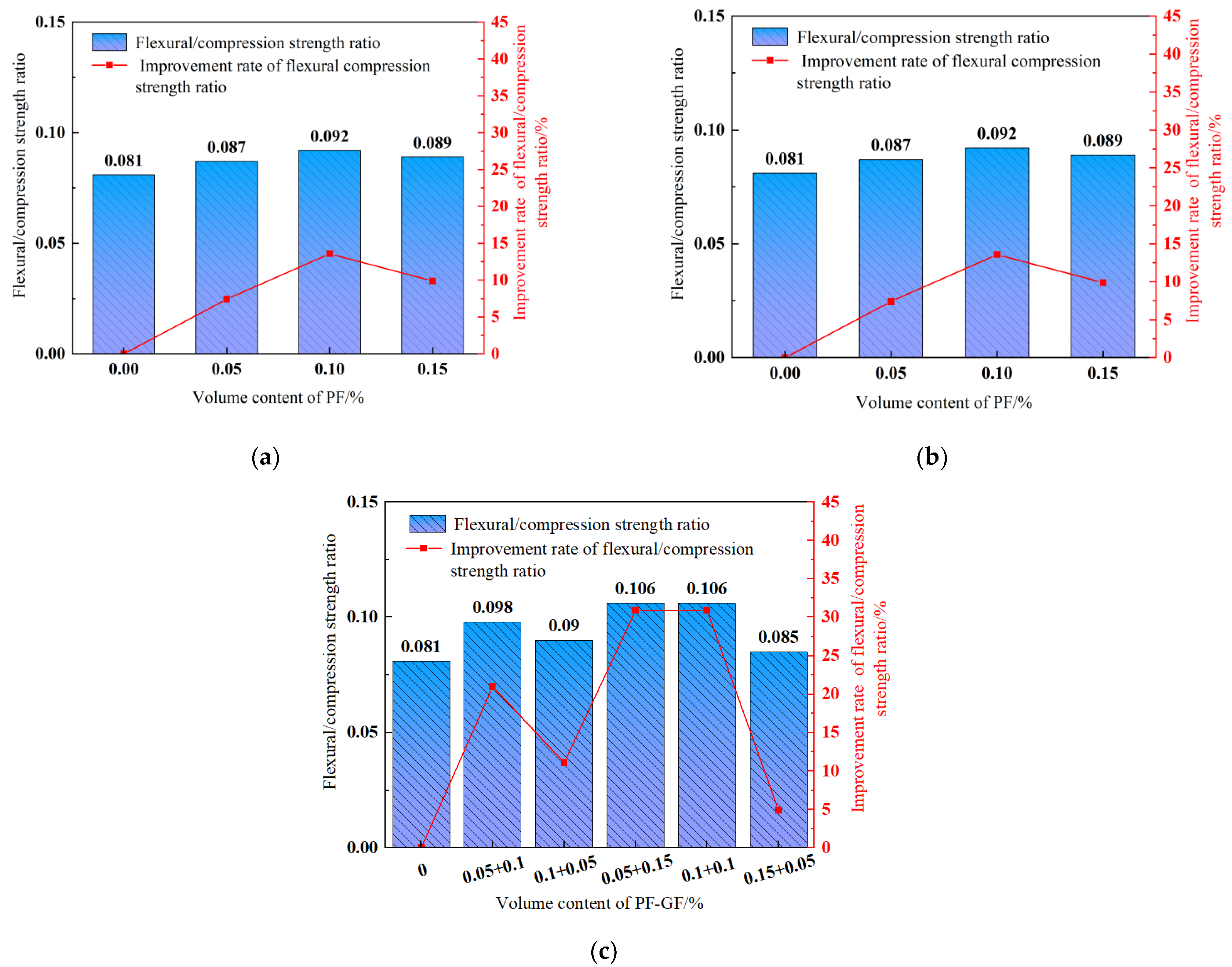

3.3.4. Flexural/Compressive and Tensile/Compressive Strength Ratios

- Flexural/compressive strength ratio.

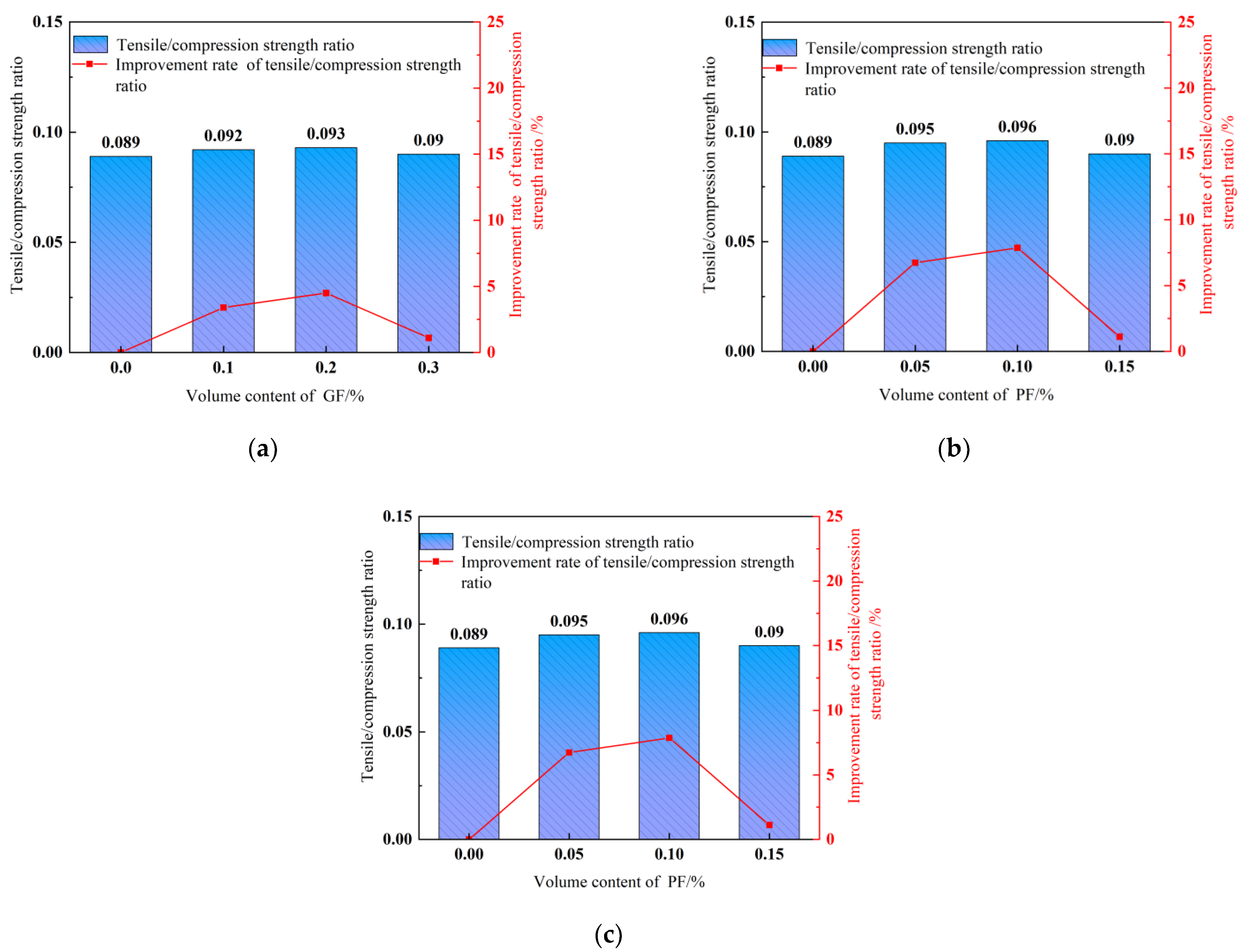

- Tensile/compressive strength ratio.

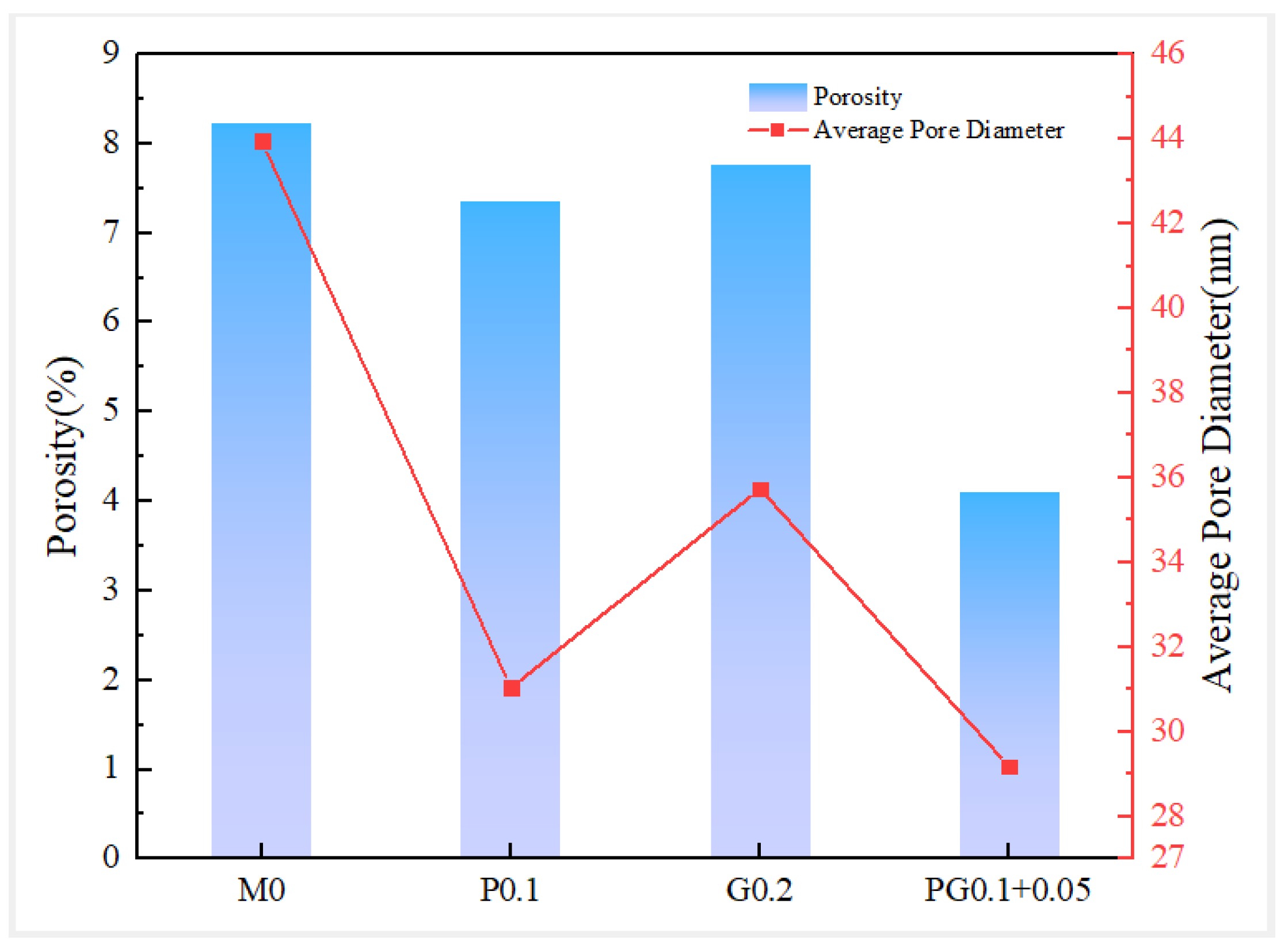

3.4. Pore Structure

3.5. Micromorphological Analysis

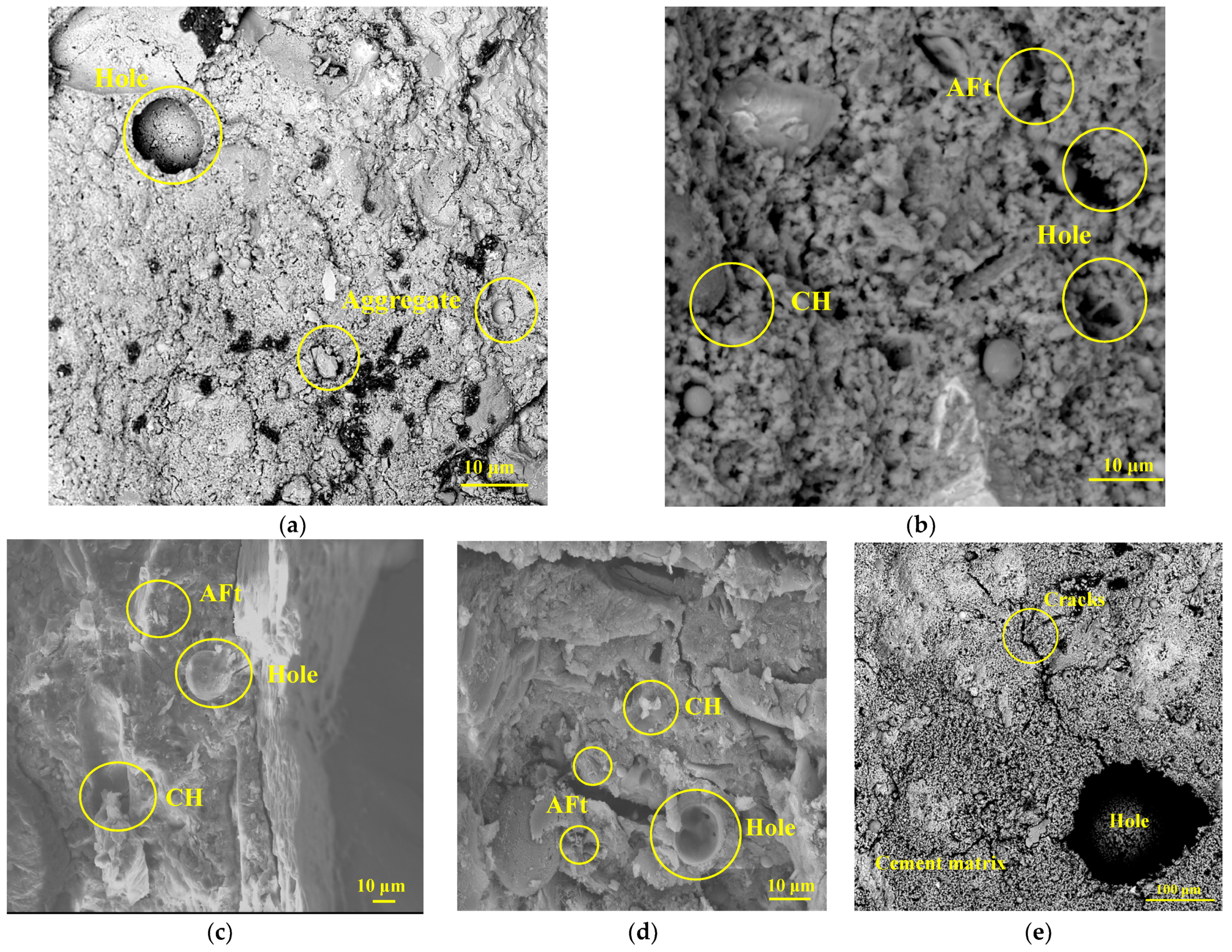

3.5.1. Cement Slurry Microstructure

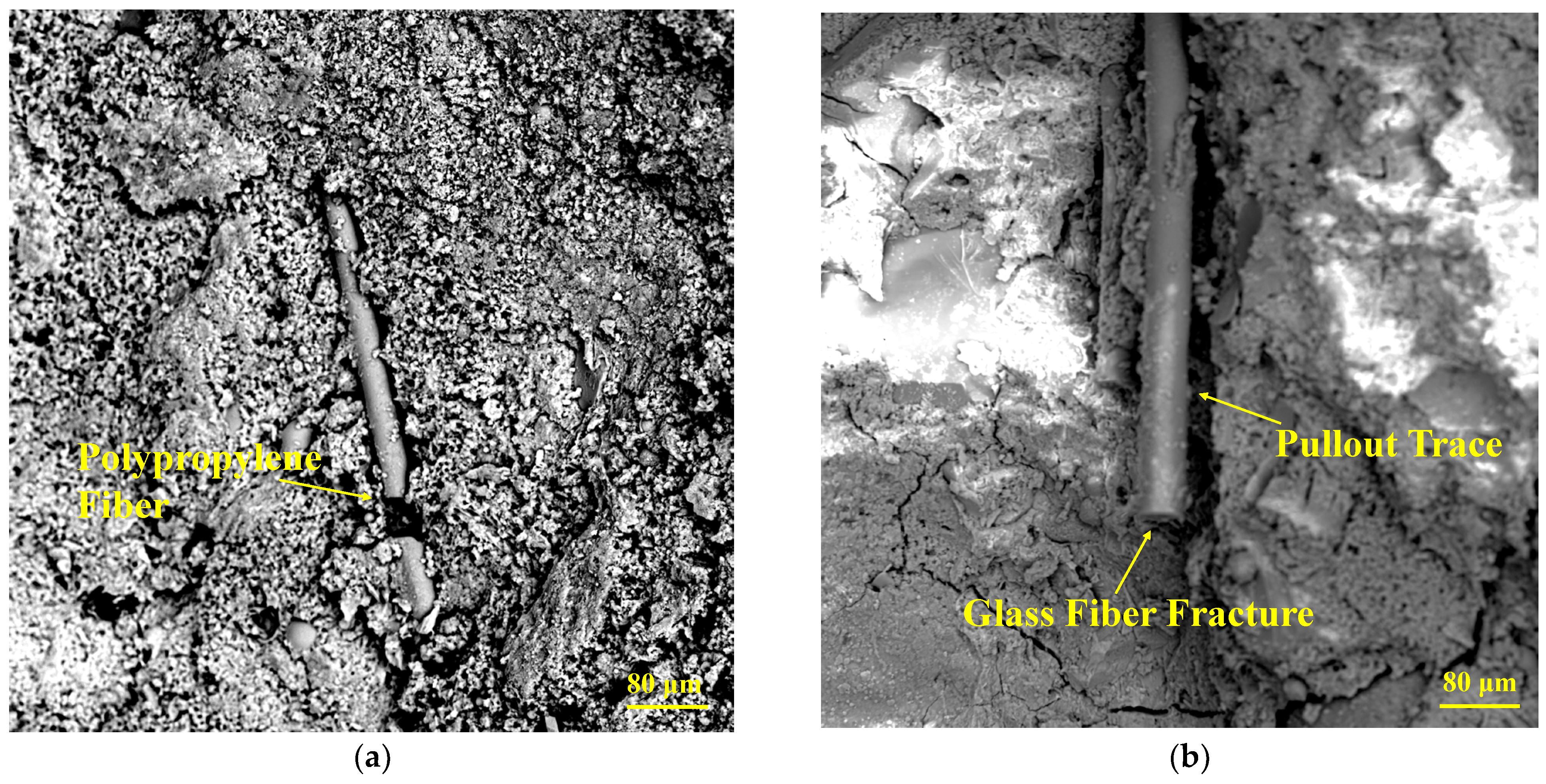

3.5.2. Fiber Microstructure and Toughening Mechanism

4. Conclusions

- (1)

- The slump of FRDSC with different fibers decreases with the increasing fiber content. The slump of HyRDSC decreases with the increase in GF volume. When the mixture amount is 0.2% and the mixture ratio of PF to GF is 1:3, the slump of HyFRDSC decreases by 35.4%.

- (2)

- FRDSC shows obvious plastic characteristics upon compressive, flexural and splitting tensile fractures. The strength improvements from fiber reinforcement rank as flexural strength > splitting tensile strength > cube compressive strength. The optimum PF and GF contents are 0.1% and 0.2%, respectively. The effect of PFs on the DSC compressive and tensile strengths is better than that of GFs. In the case of the hybrid fiber of 0.1% PF + 0.1% GF, the DSC flexural strength is increased by 40.7%. For 0.1% PF + 0.05% GF content, the compressive strength and splitting tensile strength are enhanced by 9.1% and 17.11%, respectively.

- (3)

- Compared with the reference DSC, the flexural/compressive strength ratios of GFRDSC, PFRDSC and HyFRDSC are increased by 9.88%, 13.58% and 30.86%, respectively; their tensile/compressive strength ratios are increased by 4.5%, 5% and 18%, respectively. Fibers enhance DSC toughness, and the improvement effect of the hybrid fiber is relatively significant.

- (4)

- The effect of hybrid fibers on the internal pores of DSC is more significant than that of single fibers. The porosity and average pore size of HyDSC decrease by 50.01% and 33.61%, respectively. In addition, the pore volume ratio below 20 nm increases to 22.46% and that above 200 nm decreases to 22.77%.

- (5)

- HyFRDSC has the most dense and homogeneous microstructure among the mixtures. PFs alleviate the stresses in a “bridging” manner until yielding, and the damage form is dominated by fracture. For GFs, at the initial stress stage, the internal stress is greater than the interface force between the fiber and DSC and less than the yield load of the fiber, so the fiber has obvious drawing marks. When the internal stress is greater than the yield load of the fiber, the fiber will also eventually have fracture damage.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time is running out for sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef]

- Macfarlane, M.; Mitchell, P. Scoping and assessment of the environmental and social impacts of river mining in Jamaica. Chemistry 2003, 8, 4980–4991. [Google Scholar]

- Krause, J.C.; Diesing, M.; Arlt, G. The physical and biological impact of sand extraction: A case study of the Western Baltic Sea. J. Coast. Res. 2010, SI 51, 215–226. [Google Scholar]

- Sreebha, S.; Padmalal, D. Environmental impact assessment of sand mining from the small catchment rivers in the southwestern coast of India: A Case Study. Environ. Manag. 2011, 47, 130–140. [Google Scholar] [CrossRef]

- Brito, J.D.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Kaufmann, J. Evaluation of the combination of desert sand and calcium sulfoaluminate cement for the production of concrete. Constr. Build. Mater. 2020, 243, 118281. [Google Scholar] [CrossRef]

- Benabed, B.; Azzouz, L.; Kadri, E.-H.; Kenai, S.; Belaidi, A.S.E. Effect of fine aggregate replacement with desert dune sand on fresh properties and strength of self-compacting mortars. J. Adhes. Sci. Technol. 2014, 28, 2182–2195. [Google Scholar] [CrossRef]

- Abu Seif, E.S. Assessing the engineering properties of concrete made with fine dune sands: An experimental study. Arab. J. Geosci. 2013, 6, 857–863. [Google Scholar] [CrossRef]

- Li, Y.G.; Zhang, H.M.; Liu, G.X.; Hu, D.W.; Ma, X.R. Multi-scale study on mechanical property and strength prediction of aeolian sand concrete. Constr. Build. Mater. 2020, 247, 118538. [Google Scholar] [CrossRef]

- Bai, J.W.; Zhao, Y.R.; Shi, J.N.; He, X.Y. Cross-scale Study on the Mechanical Properties and Frost Resistance Durability of Aeolian Sand Concrete. Ksce J. Civ. Eng. 2021, 25, 4386–4402. [Google Scholar] [CrossRef]

- Zhang, G.; Song, J.; Yang, J.; Liu, X. Performance of mortar and concrete made with a fine aggregate of desert sand. Build. Environ. 2006, 41, 1478–1481. [Google Scholar] [CrossRef]

- Shi, Z. Green manufacturing of silicate materials using desert sand as a raw-material resource. Constr. Build. Mater. 2022, 338, 127539. [Google Scholar] [CrossRef]

- Yan, W.; Wu, G.; Dong, Z. Optimization of the mix proportion for desert sand concrete based on a statistical model. Constr. Build. Mater. 2019, 226, 469–482. [Google Scholar] [CrossRef]

- Anandamurthy, A.; Guna, V.; Ilangovan, M.; Reddy, N. A review of fibrous reinforcements of concrete. J. Reinf. Plast. Compos. 2017, 36, 519–552. [Google Scholar] [CrossRef]

- Lee, J.-H.; Cho, B.; Choi, E. Flexural capacity of fiber reinforced concrete with a consideration of concrete strength and fiber content. Constr. Build. Mater. 2017, 138, 222–231. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Deng, D.; Wang, K.; Duan, W.H. Reinforcement effects of polyvinyl alcohol and polypropylene fibers on the fracture behaviors of sulfoaluminate cement composites. Cem. Concr. Compos. 2018, 88, 139–149. [Google Scholar] [CrossRef]

- He, W.; Kong, X.; Fu, Y.; Zhou, C.; Zheng, Z. Experimental investigation on the mechanical properties and microstructure of hybrid fiber reinforced recycled aggregate concrete. Constr. Build. Mater. 2020, 261, 120488. [Google Scholar] [CrossRef]

- Kanagavel, R.; Arunachalam, K. Experimental investigation on mechanical properties of hybrid fiber reinforced quaternary cement concrete. J. Eng. Fibers Fabr. 2016, 10, 155892501501000407. [Google Scholar] [CrossRef]

- Junwei, Z.; Shijie, L.; Hongjian, P. Experimental investigation of multiscale hybrid fibres on the mechanical properties of high-performance concrete. Constr. Build. Mater. 2021, 299, 123895. [Google Scholar] [CrossRef]

- Song, W.; Yin, J. Hybrid effect evaluation of steel fiber and carbon fiber on the performance of the fiber reinforced concrete. Materials 2016, 9, 704. [Google Scholar] [CrossRef] [PubMed]

- Jiayue, L.; Zongcai, D. Tensile behavior of ultra-high performance concrete reinforced with different hybrid fibers. Struct. Concr. 2022, 24, 1415–1435. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Cracking behaviour and constitutive modelling of hybrid fibre reinforced concrete. J. Build. Eng. 2020, 30, 101272. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. Experimental investigation on the tensile behavior of hybrid steel-PVA fiber reinforced concrete containing fly ash and slag powder. Constr. Build. Mater. 2020, 241, 118000. [Google Scholar] [CrossRef]

- Lin, J.-X.; Song, Y.; Xie, Z.-H.; Guo, Y.-C.; Yuan, B.; Zeng, J.-J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Experimental study on the mechanical properties and the microstructure of hybrid-fiber-reinforced concrete under an early stage. Struct. Concr. 2020, 21, 1106–1122. [Google Scholar] [CrossRef]

- Ahmad, H.; Lagoudas, D.C. Effective elastic properties of fiberreinforced concrete with random fibers. J. Eng. Mech. 1991, 117, 2931–2938. [Google Scholar] [CrossRef]

- Bijo, M.; Unnikrishnan, S. Mechanical strength and impact resistance of hybrid fiber reinforced concrete with coconut and polypropylene fibers. Mater. Today Proc. 2022, 65, 1873–1880. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, W.; Bu, M.; Guo, B.; Niu, D. Effect and action mechanism of fibers on mechanical behavior of hybrid basalt-polypropylene fiber-reinforced concrete. Structures 2021, 34, 3596–3610. [Google Scholar] [CrossRef]

- Resan, S.a.F.; Chassib, S.M.; Zemam, S.K.; Madhi, M.J. New Approach of Concrete Tensile Strength Test. Case Stud. Constr. Mater. 2020, 12, e00347. [Google Scholar] [CrossRef]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Akça, K.R.; Çakır, Ö.; İpek, M. Properties of polypropylene fiber reinforced concrete using recycled aggregates. Constr. Build. Mater. 2015, 98, 620–630. [Google Scholar] [CrossRef]

- Suiffi, H.; El Maliki, A.; Cherkaoui, O.; Dalal, M. Study of the durability of concrete mixed with polypropylene fibers. Procedia Struct. Integr. 2021, 33, 229–236. [Google Scholar] [CrossRef]

- Topcu, I.B.; Canbaz, M. Effect of different fibers on the mechanical properties of concrete containing fly ash. Constr. Build. Mater. 2007, 21, 1486–1491. [Google Scholar] [CrossRef]

- Najm, H.; Balaguru, P. Effect of large-diameter polymeric fibers on shrinkage cracking of cement composites. ACI Mater. 2002, 99, 345–351. [Google Scholar] [CrossRef]

- Hilles, M.M.; Ziara, M.M. Mechanical behavior of high strength concrete reinforced with glass fiber. Eng. Sci. Technol. Int. J. 2019, 22, 920–928. [Google Scholar] [CrossRef]

- Kasagani, H.; Rao, C. Effect of graded fibers on stress strain behaviour of Glass Fiber Reinforced Concrete in tension. Constr. Build. Mater. 2018, 183, 592–604. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Jia, Y. Effect of using hybrid polypropylene and glass fibre on the mechanical properties and permeability of concrete. Materials 2019, 12, 3786. [Google Scholar] [CrossRef]

- Liu, J.; Jia, Y.; Wang, J. Experimental study on mechanical and durability properties of glass and polypropylene fiber reinforced concrete. Fibers Polym. 2019, 20, 1900–1908. [Google Scholar] [CrossRef]

- Qu, C.; Qin, Y.; Luo, L.; Zhang, L. Mechanical properties and acoustic emission analysis of desert sand concrete reinforced with steel fiber. Sci. Rep. 2022, 12, 20488. [Google Scholar] [CrossRef] [PubMed]

- El-Hassan, H.; Medljy, J.; El-Maaddawy, T. Properties of steel fiber-reinforced alkali-activated slag concrete made with recycled concrete aggregates and dune sand. Sustainability 2021, 13, 8017. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Effect of steel fibers on the performance of concrete made with recycled concrete aggregates and dune sand. Constr. Build. Mater. 2019, 213, 348–359. [Google Scholar] [CrossRef]

- Che, J.; Guo, Z.; Li, Q.; Liu, H. Mechanical Properties of Desert-Sand-Based Steel-PVA Hybrid Fiber Reinforced Engineered Cementitious Composites (H-DSECC). KSCE J. Civ. Eng. 2022, 26, 5160–5172. [Google Scholar] [CrossRef]

- GB/T175-2020; Common Portland Cement. Chinese Standards Institute: Beijing, China, 2020.

- GBT 14684-2011; Sand for Construction. Chinese Standards Institute: Beijing, China, 2022.

- JGJ 55-2011; Specification for Mix Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- GB/T50008-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- GB/T50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Architecture & Building Press: Beijing, China, 2016.

- Zhang, Z.; Yang, F.; Liu, J.-C.; Wang, S. Eco-friendly high strength, high ductility engineered cementitious composites (ECC) with substitution of fly ash by rice husk ash. Cem. Concr. Res. 2020, 137, 106200. [Google Scholar] [CrossRef]

- Antiohos, S.; Papadakis, V.; Tsimas, S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem. Concr. Res. 2014, 61, 20–27. [Google Scholar] [CrossRef]

- Singh, M.; Saini, B.; Chalak, H. Performance and composition analysis of engineered cementitious composite (ECC)—A review. J. Build. Eng. 2019, 26, 100851. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Shi, J.; Wu, Z.; Zhuang, J.; Chen, R.; Zhu, T.; Yuan, C.; Li, H. The Effect of Superabsorbent Polymer on Fair-Faced Concrete Performance Based on White Cement. Adv. Civ. Eng. 2023, 2023, 6615183. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Fiber type effect on strength, toughness and microstructure of early age cemented tailings backfill. Constr. Build. Mater. 2019, 223, 44–54. [Google Scholar] [CrossRef]

| Ignition Loss/% | Specific Surface Area m2/kg | Initial Setting Duration/min | Final Setting Duration/min | Stability | Flexural Strength /MPa | Compressive Strength /MPa | Cl−/% | SO3/% | MgO/% |

|---|---|---|---|---|---|---|---|---|---|

| 3.49 | 349 | 187 | 246 | Qualified | 5.8 | 30.7 | 0.032 | 2.41 | 3.32 |

| Fine Aggregate | Bulk Density | Apparent Density | Fineness Modulus | Mud Content | Superplasticizer |

|---|---|---|---|---|---|

| Unit | kg/m3 | kg/m3 | % | % | |

| River sand | 1558 | 2578 | 2.3 | 2.5 | 0.8 |

| Desert sand | 1542 | 2602 | 1.1 | 1.2 | 2.1 |

| Ignition Loss/% | Moisture Content/% | Density g/cm3 | Bulk Density g/cm3 | AI2O3/% | AIO2/% | Cl−/% | SO3/% | CaO/% | Fe/% | Free CaO/% |

|---|---|---|---|---|---|---|---|---|---|---|

| 2.8 | 0.85 | 2.55 | 1.12 | 24.2 | 45.1 | 0.015 | 2.1 | 5.6 | 0.85/ | 0.85 |

| Fiber Type | Density/g·cm−3 | Diameter/μm | Length/mm | Tensile Strength/MPa | Elastic Modulus/GPa | Elongation after Fracture/% |

|---|---|---|---|---|---|---|

| PFs | 0.9 | 31.86 | 12 | 567 | 5.2 | 39 |

| GFs | 2.4 | 18 | 2500 | 70 | 3.6 |

| Desert Sand | Water | Cement | Fly Ash | Sand | Stone | Water-Reducing Agent |

|---|---|---|---|---|---|---|

| 225 | 181 | 362 | 40 | 524 | 1333 | 3.2 |

| Specimen No. | PF/(kg·m−3) | GF/(kg·m−3) |

|---|---|---|

| M0 | 0 | 0 |

| P0.05 | 0.45 | 0 |

| P0.1 | 0.9 | 0 |

| P0.15 | 1.35 | 0 |

| G0.1 | 0 | 2.4 |

| G0.2 | 0 | 4.8 |

| G0.3 | 0 | 7.2 |

| PG0.05 + 0.1 | 0.45 | 2.4 |

| PG0.1 + 0.05 | 0.9 | 1.2 |

| PG0.05 + 0.15 | 0.45 | 3.6 |

| PG0.1 + 0.1 | 0.9 | 2.4 |

| PG0.15 + 0.05 | 1.35 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, L.; Wen, B.; Huang, W.; Zhang, X.; Zhang, X. Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete. Polymers 2023, 15, 4675. https://doi.org/10.3390/polym15244675

Hou L, Wen B, Huang W, Zhang X, Zhang X. Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete. Polymers. 2023; 15(24):4675. https://doi.org/10.3390/polym15244675

Chicago/Turabian StyleHou, Lina, Baojun Wen, Wei Huang, Xue Zhang, and Xinyu Zhang. 2023. "Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete" Polymers 15, no. 24: 4675. https://doi.org/10.3390/polym15244675

APA StyleHou, L., Wen, B., Huang, W., Zhang, X., & Zhang, X. (2023). Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete. Polymers, 15(24), 4675. https://doi.org/10.3390/polym15244675