Flexible Piezoresistive Polystyrene Composite Sensors Filled with Hollow 3D Graphitic Shells

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of 3D Graphitic Shells

2.2. Composite Preparation Procedure

2.3. Characterization and Instruments

3. Results

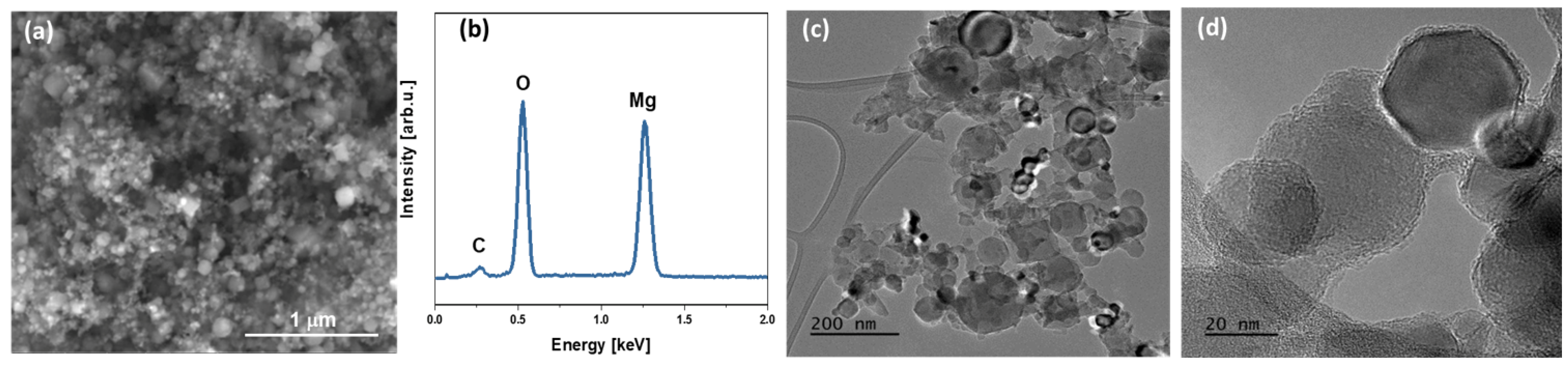

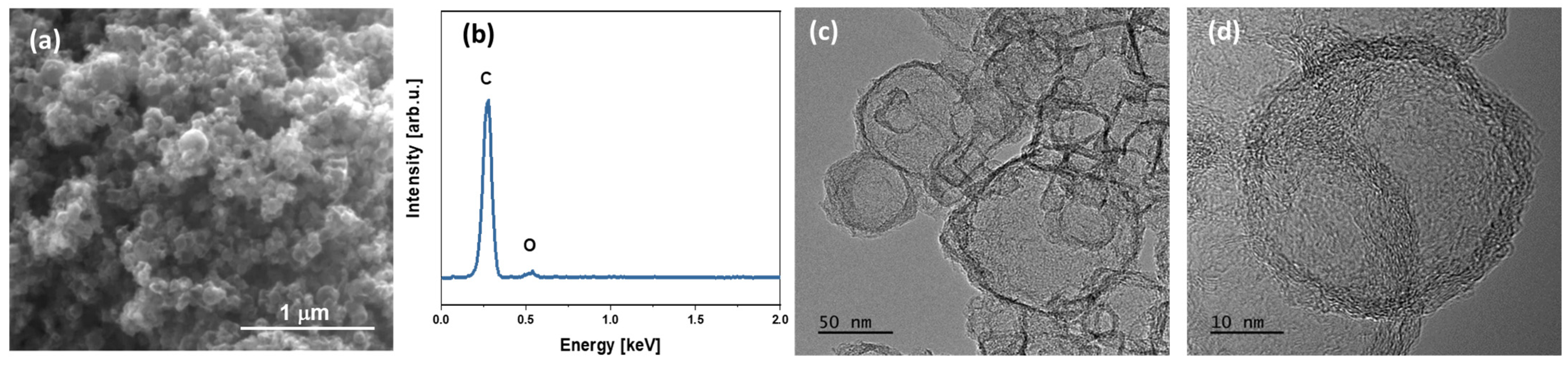

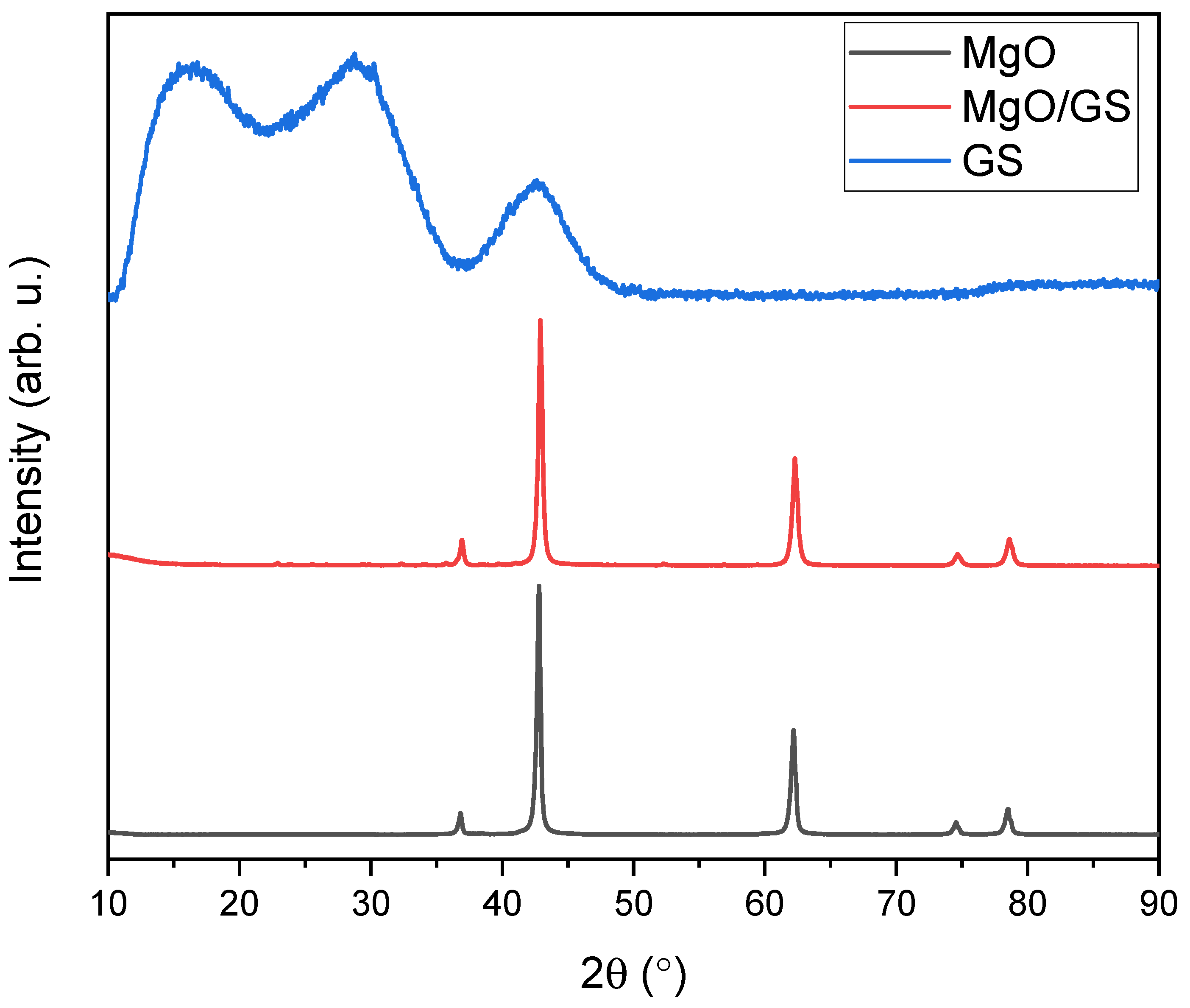

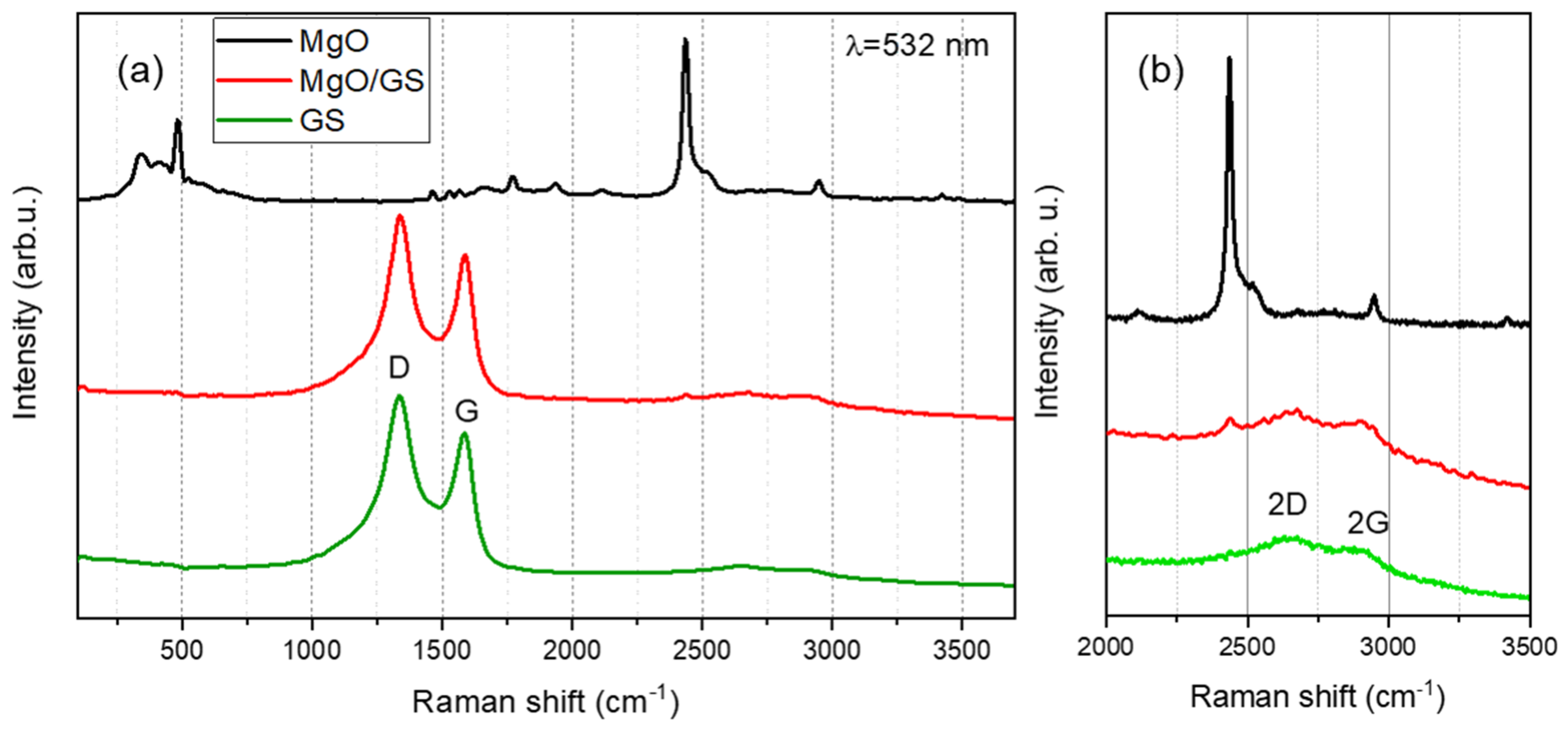

3.1. Characterization of Graphitic Shells

3.2. Characterization of PS Nanocomposites

4. Conclusions

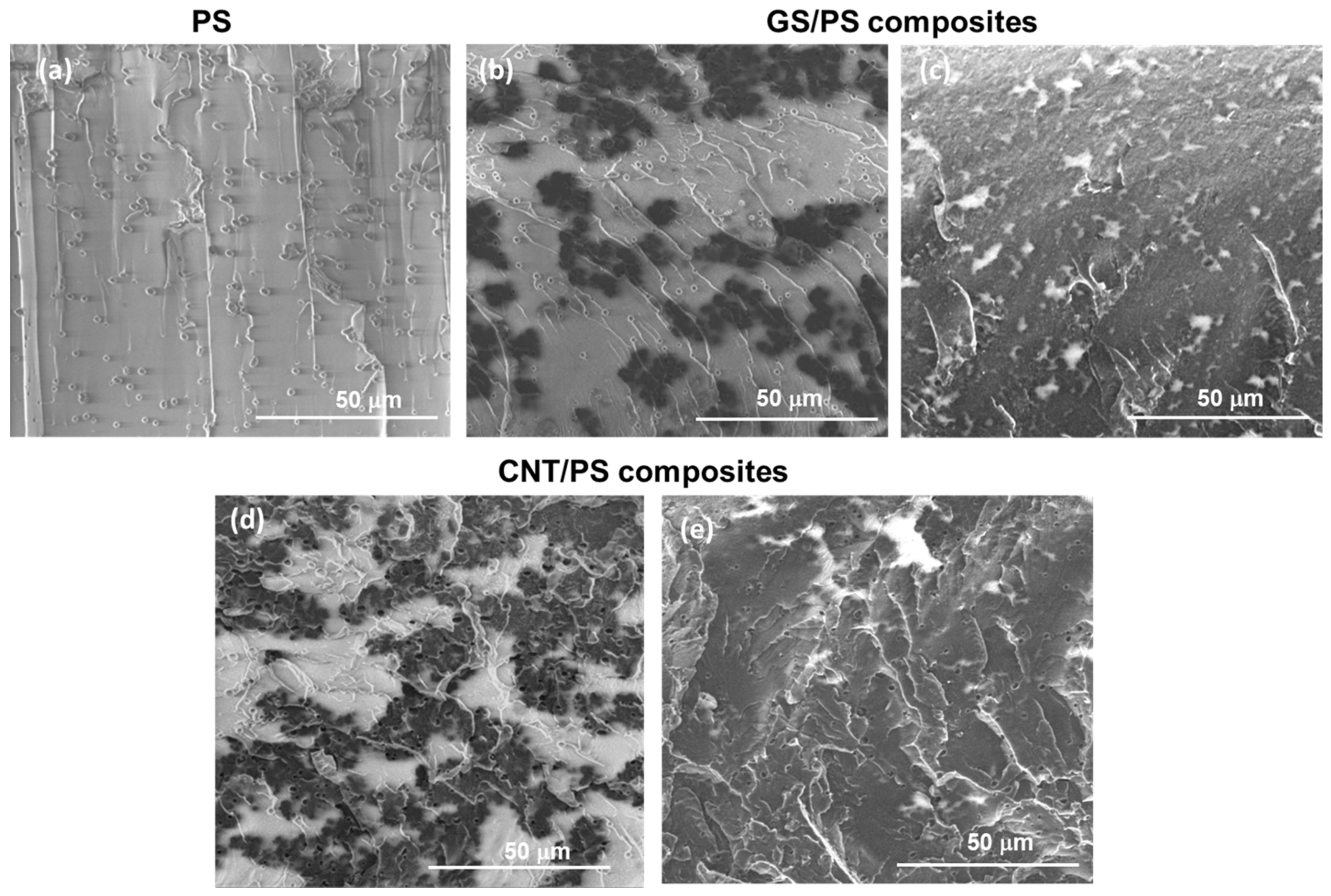

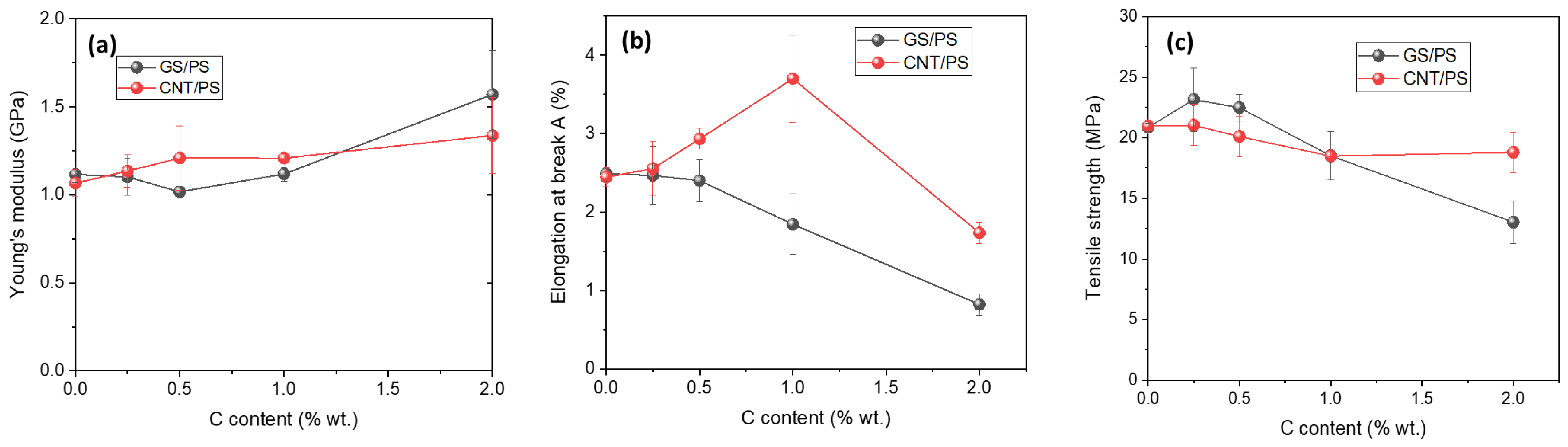

- The addition of carbon nanotubes (CNTs) to PS improved the storage modulus of all CNT/PS composites, except for the composite with the highest CNT content (2 wt.%), due to the increased stiffness associated with dispersed carbon structures having a relatively high aspect ratio in the matrix. However, the use of spherical graphitic shells (GS) as a nanofiller in a PS matrix did not show an enhancing effect on the storage modulus. On the contrary, noticeable decreases in the storage modulus values of GS/PS composites were observed compared to pure PS and composites with CNTs. This decrease can be attributed to the local agglomeration of GS nanoparticles in the PS phase, as confirmed by scanning electron microscopy (SEM) observations. The results of Young’s modulus under tensile deformation for the studied composites were consistent with the dynamic mechanical analysis (DMA) results. The elongation at break values showed improvement for all composites with CNTs, except for the composite with 2 wt.% of CNTs, while a reduction in this parameter was observed for all composites with GS.

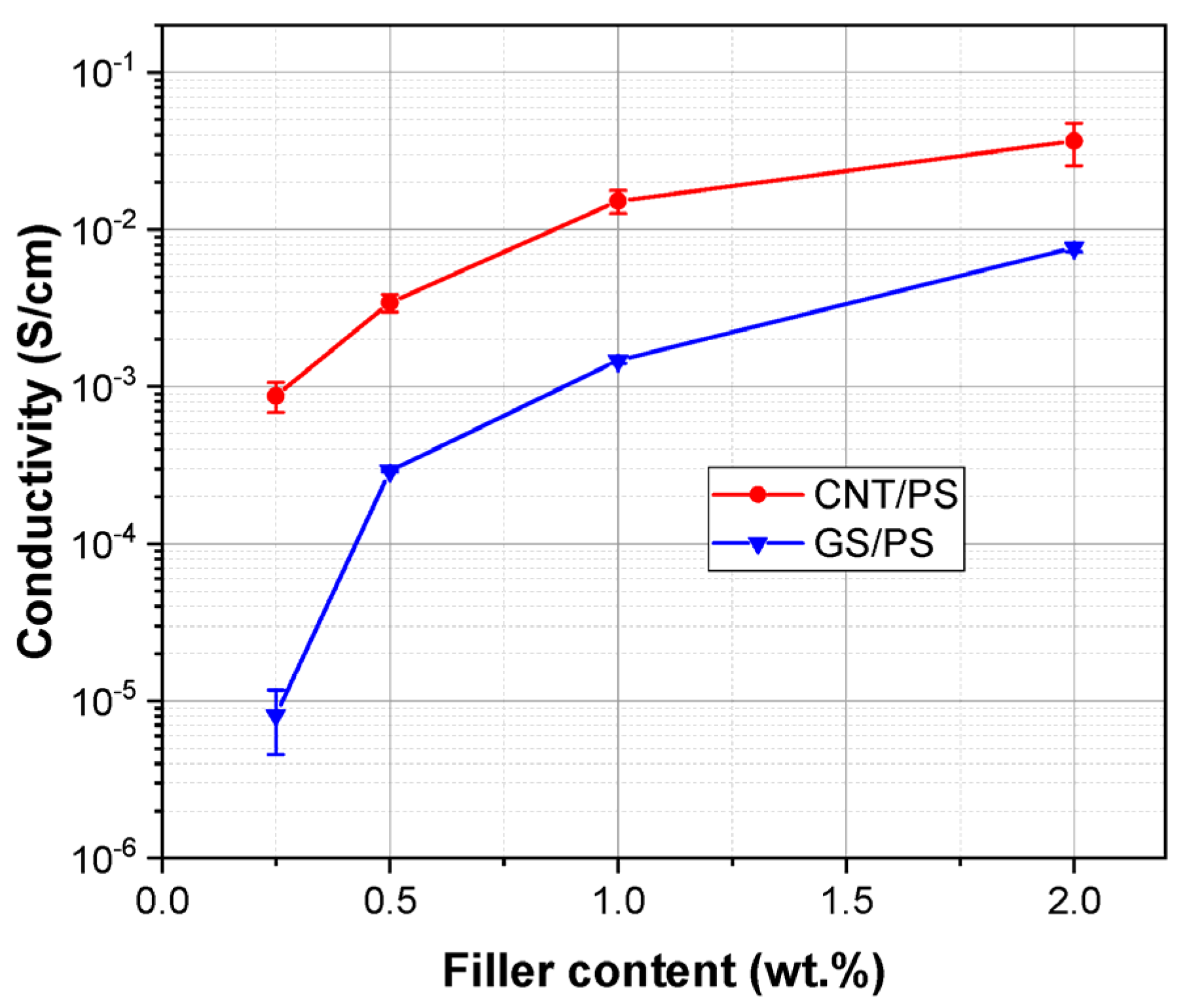

- SEM observations revealed that a concentration of 0.25 wt.% of graphitic shells was insufficient to achieve a uniform distribution of the filler in the PS matrix and to create a conductive path of GS nanoparticles, unlike carbon nanotubes, which formed effective connections in the matrix at a concentration of 0.25 wt.%. The application of 0.5 wt.% of both graphitic shells and carbon nanotubes resulted in composites with conductivity similar to semiconductors, which is highly desirable for piezoresistive strain sensors.

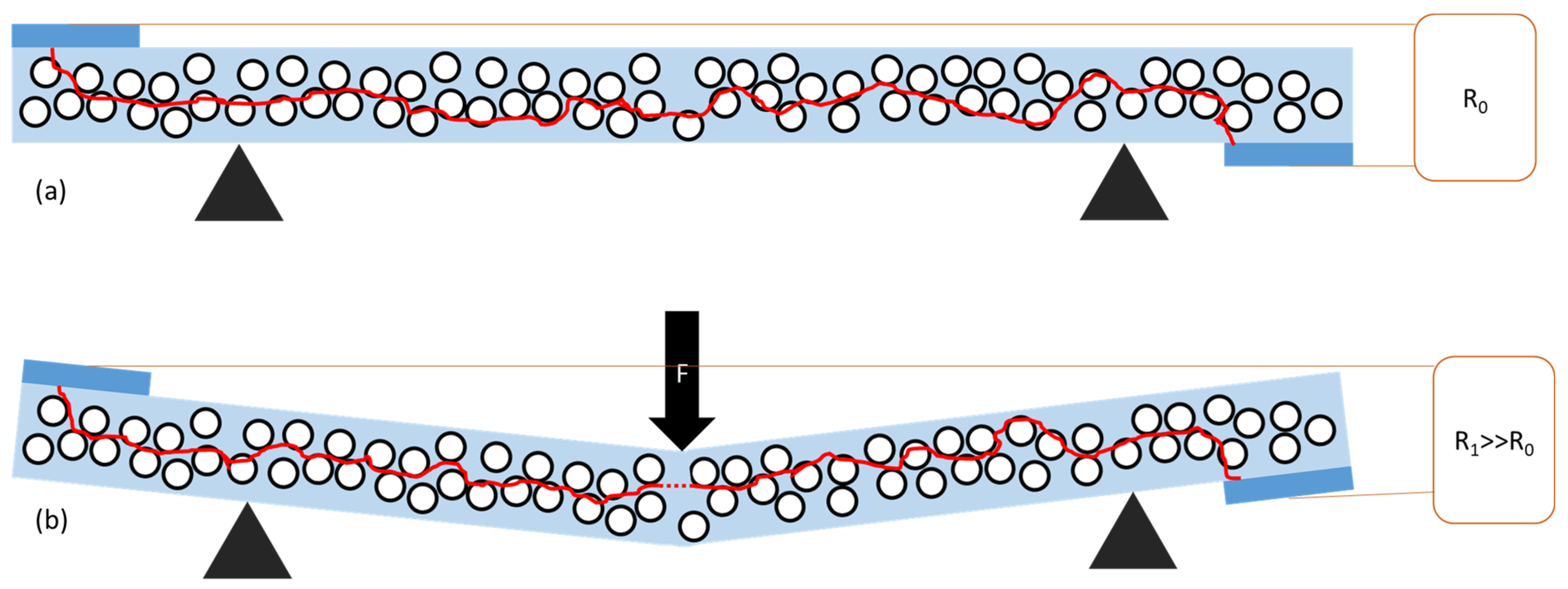

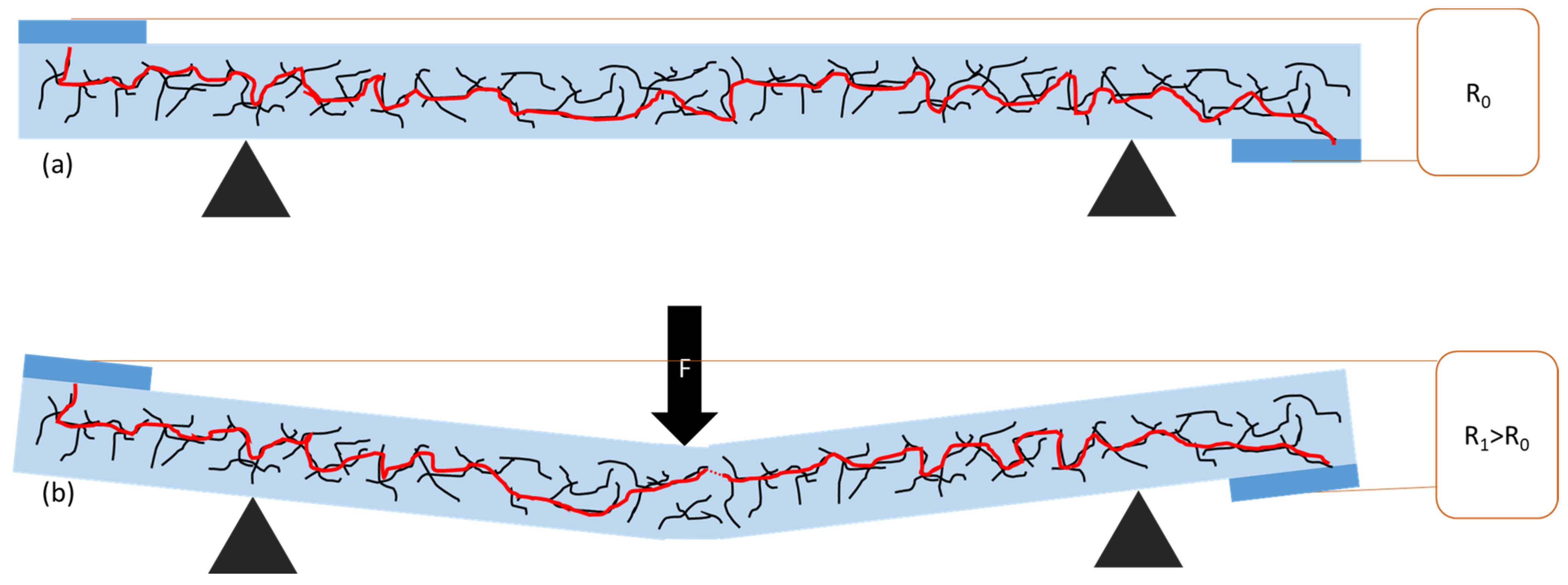

- Piezoresistive tests under bending and tensile stress showed that composites with graphitic shells exhibited higher stability of response compared to those with carbon nanotubes, which can be attributed to the unique morphology of graphitic shells. The use of hollow spheres allowed for good composite conductivity in the initial state and high sensitivity under deformation, which cannot be achieved using multi-walled carbon nanotubes.

- The polystyrene-based composites filled with graphitic hollow spheres exhibit exceptional piezoresistive characteristics during bending, making them suitable for use as an active element of flow sensors dedicated to both gaseous and liquid media. Another promising application is the detection of bending in various construction and building structures, including, for example, bridges, pillars, etc.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferreira, A.; Silva, J.P.; Rodrigues, R.; Martin, N.; Lanceros-Méndez, S.; Vaz, F. High performance piezoresistive response of nanostructured ZnO/Ag thin films for pressure sensing applications. Thin Solid Films 2019, 691, 137587. [Google Scholar] [CrossRef]

- Ferreira, A.; Correia, V.; Mendes, E.; Lopes, C.; Vaz, J.F.V.; Lanceros-Mendez, S. Piezoresistive Polymer-Based Materials for Real-Time Assessment of the Stump/Socket Interface Pressure in Lower Limb Amputees. IEEE Sens. J. 2017, 17, 2182–2190. [Google Scholar] [CrossRef]

- Lee, D.C.; Lee, J.J.; Yun, S.J. The mechanical characteristics of smart composite structures with embedded optical fiber sensors. Compos. Struct. 1995, 32, 39–50. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Vertuccio, L.; Guadagno, L. Experimental and theoretical study on piezoresistive properties of a structural resin reinforced with carbon nanotubes for strain sensing and damage monitoring. Compos. Part B Eng. 2018, 145, 90–99. [Google Scholar] [CrossRef]

- Wang, X.D.; Wang, J.C.; Biswas, S.; Kim, H.; Nam, I.W. Mechanical, electrical, and piezoresistive sensing characteristics of epoxy-based composites incorporating hybridized networks of carbon nanotubes, graphene, carbon nanofibers, or graphite nanoplatelets. Sensors 2020, 20, 2094. [Google Scholar] [CrossRef]

- Nasouri, K.; Shoushtari, A.M. Designing, modeling and manufacturing of lightweight carbon nanotubes/polymer composite nanofibers for electromagnetic interference shielding application. Compos. Sci. Technol. 2017, 145, 46–54. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Alcock, B.; Cabrera, N.O.; Peijs, T. Flame-Retardancy Properties of Intumescent Ammonium Poly(Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene. Polym. Polym. Compos. 2008, 16, 101–113. [Google Scholar] [CrossRef]

- Li, D.; Chen, Q.; Yang, Y.; Chen, Y.; Xiao, C. Effects of flake graphite on property optimisation in thermal conductive composites based on polyamide 66. Plast. Rubber Compos. 2017, 46, 266–276. [Google Scholar] [CrossRef]

- Obitayo, W.; Liu, T. A review: Carbon nanotube-based piezoresistive strain sensors. J. Sens. 2012, 2012, 652438. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Chen, D.; Miao, J.; Lin, S.; Cui, D. Highly Sensitive and Flexible Piezoresistive Pressure Sensors Based on 3D Reduced Graphene Oxide Aerogel. IEEE Electron. Device Lett. 2021, 42, 589–592. [Google Scholar] [CrossRef]

- Phiri, J.; Gane, P.; Maloney, T.C. General overview of graphene: Production, properties and application in polymer composites. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2017, 215, 9–28. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Szeluga, U.; Pusz, S.; Kumanek, B.; Olszowska, K.; Kobyliukh, A.; Trzebicka, B. Effect of graphene filler structure on electrical, thermal, mechanical, and fire retardant properties of epoxy-graphene nanocomposites—A review. Crit. Rev. Solid State Mater. Sci. 2021, 46, 152–187. [Google Scholar] [CrossRef]

- Yasmin, A.; Luo, J.J.; Daniel, I.M. Processing of expanded graphite reinforced polymer nanocomposites. Compos. Sci. Technol. 2006, 66, 1182–1189. [Google Scholar] [CrossRef]

- Qiu, S.; Hu, W.; Yu, B.; Yuan, B.; Zhu, Y.; Jiang, S.; Wang, B.; Song, L.; Hu, Y. Effect of functionalized graphene oxide with organophosphorus oligomer on the thermal and mechanical properties and fire safety of polystyrene. Ind. Eng. Chem. Res. 2015, 54, 3309–3319. [Google Scholar] [CrossRef]

- Johnson, D.W.; Dobson, B.P.; Coleman, K.S. A manufacturing perspective on graphene dispersions. Curr. Opin. Colloid Interface Sci. 2015, 20, 367–382. [Google Scholar] [CrossRef]

- Mamunya, Y.P. Morphology and percolation conductivity of polymer blends containing carbon black Morphology and Percolation Conductivity of Polymer Blends Containing Carbon Black. J. Macromol. Sci. Part B Phys. 1999, B38, 615–622. [Google Scholar] [CrossRef]

- Mamunya, Y.; Boudenne, A.; Lebovka, N.; Ibos, L.; Candau, Y.; Lisunova, M. Electrical and thermophysical behaviour of PVC-MWCNT nanocomposites. Compos. Sci. Technol. 2008, 68, 1981–1988. [Google Scholar] [CrossRef]

- Lisunova, M.O.; Mamunya, Y.P.; Lebovka, N.I.; Melezhyk, A.V. Percolation behaviour of ultrahigh molecular weight polyethylene/multi-walled carbon nanotubes composites. Eur. Polym. J. 2007, 43, 949–958. [Google Scholar] [CrossRef]

- Mamunya, Y.; Matzui, L.; Vovchenko, L.; Maruzhenko, O.; Oliynyk, V.; Pusz, S.; Kumanek, B.; Szeluga, U. Influence of conductive nano- and microfiller distribution on electrical conductivity and EMI shielding properties of polymer/carbon composites. Compos. Sci. Technol. 2019, 170, 51–59. [Google Scholar] [CrossRef]

- Kolisnyk, R.; Korab, M.; Iurzhenko, M.; Masiuchok, O.; Mamunya, Y. Development of heating elements based on conductive polymer composites for electrofusion welding of plastics. J. Appl. Polym. Sci. 2021, 138, 50418. [Google Scholar] [CrossRef]

- Masiuchok, O.; Iurzhenko, M.; Kolisnyk, R.; Mamunya, Y.; Godzierz, M.; Demchenko, V.; Yermolenko, D.; Shadrin, A. Polylactide/Carbon Black Segregated Composites for 3D Printing of Conductive Products. Polymers 2022, 14, 4022. [Google Scholar] [CrossRef] [PubMed]

- Maruzhenko, O.; Mamunya, Y.; Boiteux, G.; Pusz, S.; Szeluga, U.; Pruvost, S. Improving the thermal and electrical properties of polymer composites by ordered distribution of carbon micro- and nanofillers. Int. J. Heat Mass Transf. 2019, 138, 75–84. [Google Scholar] [CrossRef]

- Hu, H.; Wang, X.; Wang, J.; Wan, L.; Liu, F.; Zheng, H.; Chen, R.; Xu, C. Preparation and properties of graphene nanosheets-polystyrene nanocomposites via in situ emulsion polymerization. Chem. Phys. Lett. 2010, 484, 247–253. [Google Scholar] [CrossRef]

- Chen, W.; Wang, B.; Zhu, Q.; Yan, X. Flexible pressure sensors with a wide detection range based on self-assembled polystyrene microspheres. Sensors 2019, 19, 5194. [Google Scholar] [CrossRef] [PubMed]

- Gong, T.; Zhang, H.; Huang, W.; Mao, L.; Ke, Y.; Gao, M.; Yu, B. Highly responsive flexible strain sensor using polystyrene nanoparticle doped reduced graphene oxide for human health monitoring. Carbon 2018, 140, 286–295. [Google Scholar] [CrossRef]

- Bachmatiuk, A.; Mendes, R.G.; Hirsch, C.; Jähne, C.; Lohe, M.R.; Grothe, J.; Kaskel, S.; Fu, L.; Klingeler, R.; Eckert, J.; et al. Few-layer graphene shells and nonmagnetic encapsulates: A versatile and nontoxic carbon nanomaterial. ACS Nano 2013, 7, 10552–10562. [Google Scholar] [CrossRef]

- Rümmeli, M.H.; Kramberger, C.; Grüneis, A.; Ayala, P.; Gemming, T.; Büchner, B.; Pichler, T. On the graphitization nature of oxides for the formation of carbon nanostructures. Chem. Mater. 2007, 19, 4105–4107. [Google Scholar] [CrossRef]

- Weibel, A.; Mesguich, D.; Chevallier, G.; Flahaut, E.; Laurent, C. Fast and easy preparation of few-layered-graphene/magnesia powders for strong, hard and electrically conducting composites. Carbon 2018, 136, 270–279. [Google Scholar] [CrossRef]

- Yang, Z.; Chabi, S.; Xia, Y.; Zhu, Y. Preparation of 3D graphene-based architectures and their applications in supercapacitors. Prog. Nat. Sci. Mater. Int. 2015, 25, 554–562. [Google Scholar] [CrossRef]

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Rietveld, H. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Karolus, M.; Łagiewka, E. Crystallite size and lattice strain in nanocrystalline Ni-Mo alloys studied by Rietveld refinement. J. Alloys Compd. 2004, 367, 235–238. [Google Scholar] [CrossRef]

- Toby, B.H. R factors in Rietveld analysis: How good is good enough? Powder Diffr. 2006, 21, 67–70. [Google Scholar] [CrossRef]

- Visweswaran, S.; Venkatachalapathy, R.; Haris, M.; Murugesan, R. Characterization of MgO thin film prepared by spray pyrolysis technique using perfume atomizer. J. Mater. Sci. Mater. Electron. 2020, 31, 14838–14850. [Google Scholar] [CrossRef]

- Debelak, B.; Lafdi, K. Use of exfoliated graphite filler to enhance polymer physical properties. Carbon 2007, 45, 1727–1734. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Song, S.; Zhang, S.; Cha, J.; Kim, K.; Yoon, H.; Jung, Y.; Paik, K.-W.; Jeon, S. Strength dependence of epoxy composites on the average filler size of non-oxidized graphene flake. Carbon 2017, 113, 379–386. [Google Scholar] [CrossRef]

- Smoleń, P.; Czujko, T.; Komorek, Z.; Grochala, D.; Rutkowska, A.; Osiewicz-Powęzka, M. Mechanical and electrical properties of epoxy composites modified by functionalized multiwalled carbon nanotubes. Materials 2021, 14, 3325. [Google Scholar] [CrossRef]

- Zacharia, R.; Ulbricht, H.; Hertel, T. Interlayer cohesive energy of graphite from thermal desorption of polyaromatic hydrocarbons. Phys. Rev. B 2004, 69, 155406. [Google Scholar] [CrossRef]

- Lu, H.; Nutt, S. Restricted relaxation in polymer nanocomposites near the glass transition. Macromolecules 2003, 36, 4010–4016. [Google Scholar] [CrossRef]

- Shen, L.; Liu, L.; Wang, W.; Zhou, Y. In situ self-sensing of delamination initiation and growth in multi-directional laminates using carbon nanotube interleaves. Compos. Sci. Technol. 2018, 167, 141–147. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Zhang, P.; Zhai, Y.; Luo, Y.; Li, L.; Luo, S. Structure dependent properties of carbon nanomaterials enabled fiber sensors for in situ monitoring of composites. Compos. Struct. 2018, 195, 36–44. [Google Scholar] [CrossRef]

- Alamusi; Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar] [CrossRef]

- Daňová, R.; Olejnik, R.; Slobodian, P.; Matyas, J. The piezoresistive highly elastic sensor based on carbon nanotubes for the detection of breath. Polymers 2020, 12, 713. [Google Scholar] [CrossRef]

- Huang, W.; Dai, K.; Zhai, Y.; Liu, H.; Zhan, P.; Gao, J.; Zheng, G.; Liu, C.; Shen, C. Flexible and Lightweight Pressure Sensor Based on Carbon Nanotube/Thermoplastic Polyurethane-Aligned Conductive Foam with Superior Compressibility and Stability. ACS Appl. Mater. Interfaces 2017, 9, 42266–42277. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Wang, T.; Niu, X.; Wang, Y.; Xu, S.; Jiang, Y.; Chen, L.; Liu, H. Flexible and high-performance piezoresistive strain sensors based on multi-walled carbon nanotubes@polyurethane foam. RSC Adv. 2022, 12, 14190–14196. [Google Scholar] [CrossRef]

| Polymer System | DSC | DMA | ||||||

|---|---|---|---|---|---|---|---|---|

| Tg [°C] | E’g [MPa] | E’r [MPa] | TinfE’ [°C] | E”max [MPa] | TE” [°C] | tan δ | S1/2 (tan δ) | |

| PS | 81.4 | 3082 | 1.258 | 78.9 | 278 | 87.1 | 3.152 | 13.2 |

| +GS | ||||||||

| 0.25%GS/PS | 92.6 | 2229 | 0.385 | 76.9 | 231 | 80.9 | 2.601 | 14.1 |

| 0.5%GS/PS | 91.1 | 2980 | 0.541 | 87.1 | 322 | 90.1 | 2.036 | 23.2 |

| 1%GS/PS | 92.4 | 3487 | 0.489 | 86.5 | 291 | 87.6 | 1.812 | 21.0 |

| 2%GS/PS | 93.7 | 2941 | 1.507 | 86.0 | 347 | 87.9 | 1.771 | 19.6 |

| +CNTs | ||||||||

| 0.25%CNTs/PS | 92.6 | 3632 | 0.487 | 90.1 | 442 | 90.5 | 2.351 | 18.8 |

| 0.5%CNTs/PS | 93.6 | 3628 | 0.477 | 80.8 | 451 | 86.7 | 1.961 | 22.5 |

| 1%CNTs/PS | 91.4 | 3588 | 0.466 | 87.4 | 465 | 87.4 | 1.761 | 25.3 |

| 2%CNTs/PS | 93.2 | 2640 | 0.796 | 92.2 | 394 | 90.5 | 2.177 | 17.2 |

| Polymer System | Thickness [mm] | Young’s Modulus E [GPa] | Tensile Strength Rm [MPa] | Elongation at Break A [%] |

|---|---|---|---|---|

| PS | 0.22 ± 0.03 | 1.12 ± 0.05 | 20.85 ± 0.36 | 2.49 ± 0.10 |

| +GS | ||||

| 0.25GS%/PS | 0.26 ± 0.05 | 1.10 ± 0.11 | 23.14 ± 2.62 | 2.47 ± 0.37 |

| 0.5GS%/PS | 0.27 ± 0.06 | 1.02 ± 0.03 | 22.47 ± 1.11 | 2.40 ± 0.37 |

| 1GS%/PS | 0.26 ± 0.01 | 1.12 ± 0.04 | 18.50 ± 1.99 | 1.85 ± 0.38 |

| 2GS%/PS | 0.28 ± 0.04 | 1.57 ± 0.25 | 13.04 ± 1.78 | 0.82 ± 0.14 |

| +CNTs | ||||

| 0.25CNTs%/PS | 0.34 ± 0.07 | 1.14 ± 0.09 | 21.03 ± 1.71 | 2.56 ± 0.34 |

| 0.5CNTs%/PS | 0.29 ± 0.02 | 1.21 ± 0.18 | 20.09 ± 1.69 | 2.93 ± 0.13 |

| 1CNTs%/PS | 0.27 ± 0.05 | 1.21 ± 0.03 | 18.46 ± 0.03 | 3.70 ± 1.56 |

| 2CNTs%/PS | 0.24 ± 0.02 | 1.34 ± 0.22 | 18.78 ± 1.66 | 1.73 ± 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzenko, N.; Godzierz, M.; Kurtyka, K.; Hercog, A.; Nocoń-Szmajda, K.; Gawron, A.; Szeluga, U.; Trzebicka, B.; Yang, R.; Rümmeli, M.H. Flexible Piezoresistive Polystyrene Composite Sensors Filled with Hollow 3D Graphitic Shells. Polymers 2023, 15, 4674. https://doi.org/10.3390/polym15244674

Guzenko N, Godzierz M, Kurtyka K, Hercog A, Nocoń-Szmajda K, Gawron A, Szeluga U, Trzebicka B, Yang R, Rümmeli MH. Flexible Piezoresistive Polystyrene Composite Sensors Filled with Hollow 3D Graphitic Shells. Polymers. 2023; 15(24):4674. https://doi.org/10.3390/polym15244674

Chicago/Turabian StyleGuzenko, Nataliia, Marcin Godzierz, Klaudia Kurtyka, Anna Hercog, Klaudia Nocoń-Szmajda, Anna Gawron, Urszula Szeluga, Barbara Trzebicka, Ruizhi Yang, and Mark H. Rümmeli. 2023. "Flexible Piezoresistive Polystyrene Composite Sensors Filled with Hollow 3D Graphitic Shells" Polymers 15, no. 24: 4674. https://doi.org/10.3390/polym15244674

APA StyleGuzenko, N., Godzierz, M., Kurtyka, K., Hercog, A., Nocoń-Szmajda, K., Gawron, A., Szeluga, U., Trzebicka, B., Yang, R., & Rümmeli, M. H. (2023). Flexible Piezoresistive Polystyrene Composite Sensors Filled with Hollow 3D Graphitic Shells. Polymers, 15(24), 4674. https://doi.org/10.3390/polym15244674