Investigation of Novel Solid Dielectric Material for Transformer Windings

Abstract

:1. Introduction

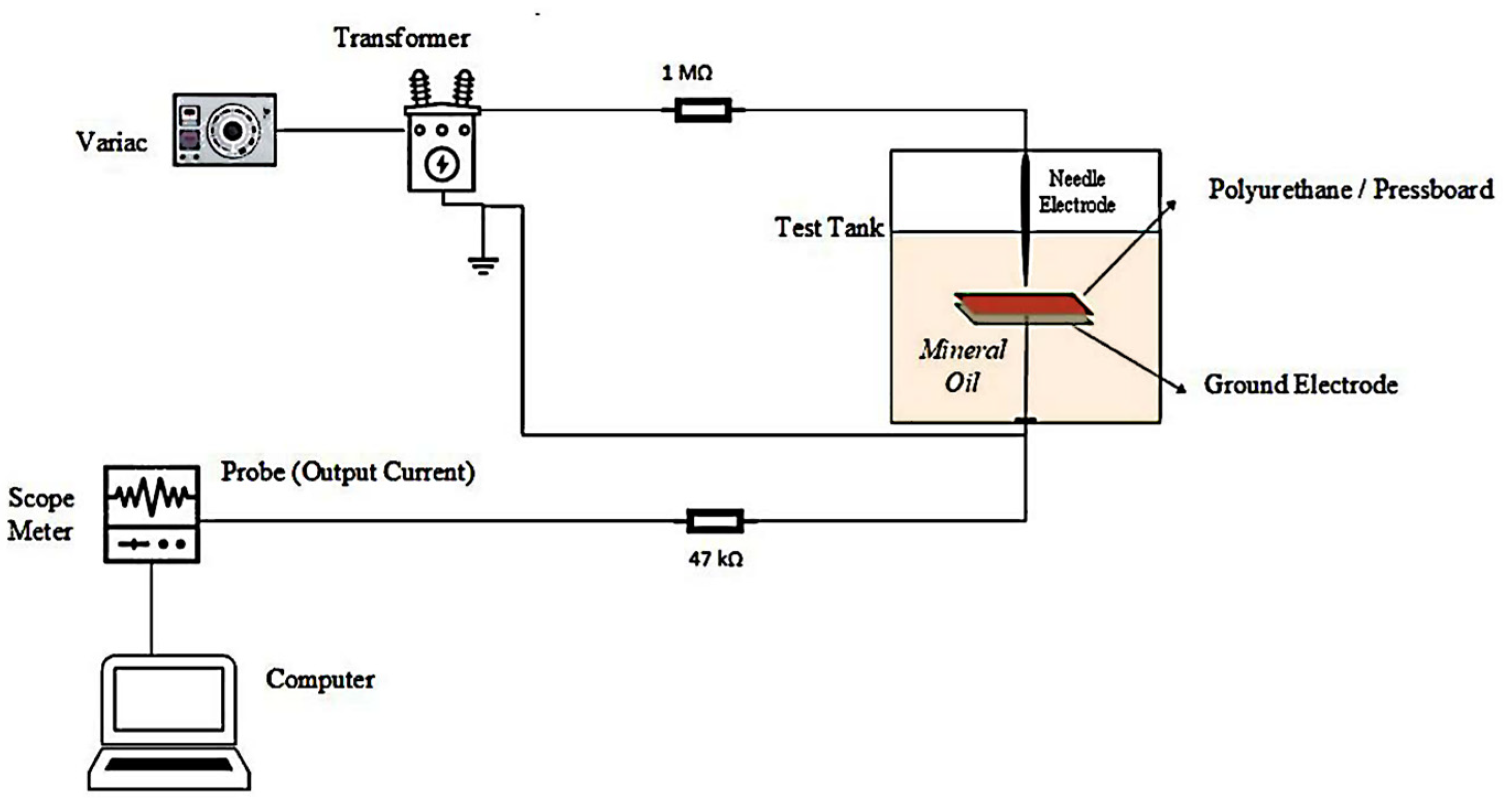

2. Measurement Methodology

3. Results and Discussion

3.1. Leakage Current and Harmonic Analysis

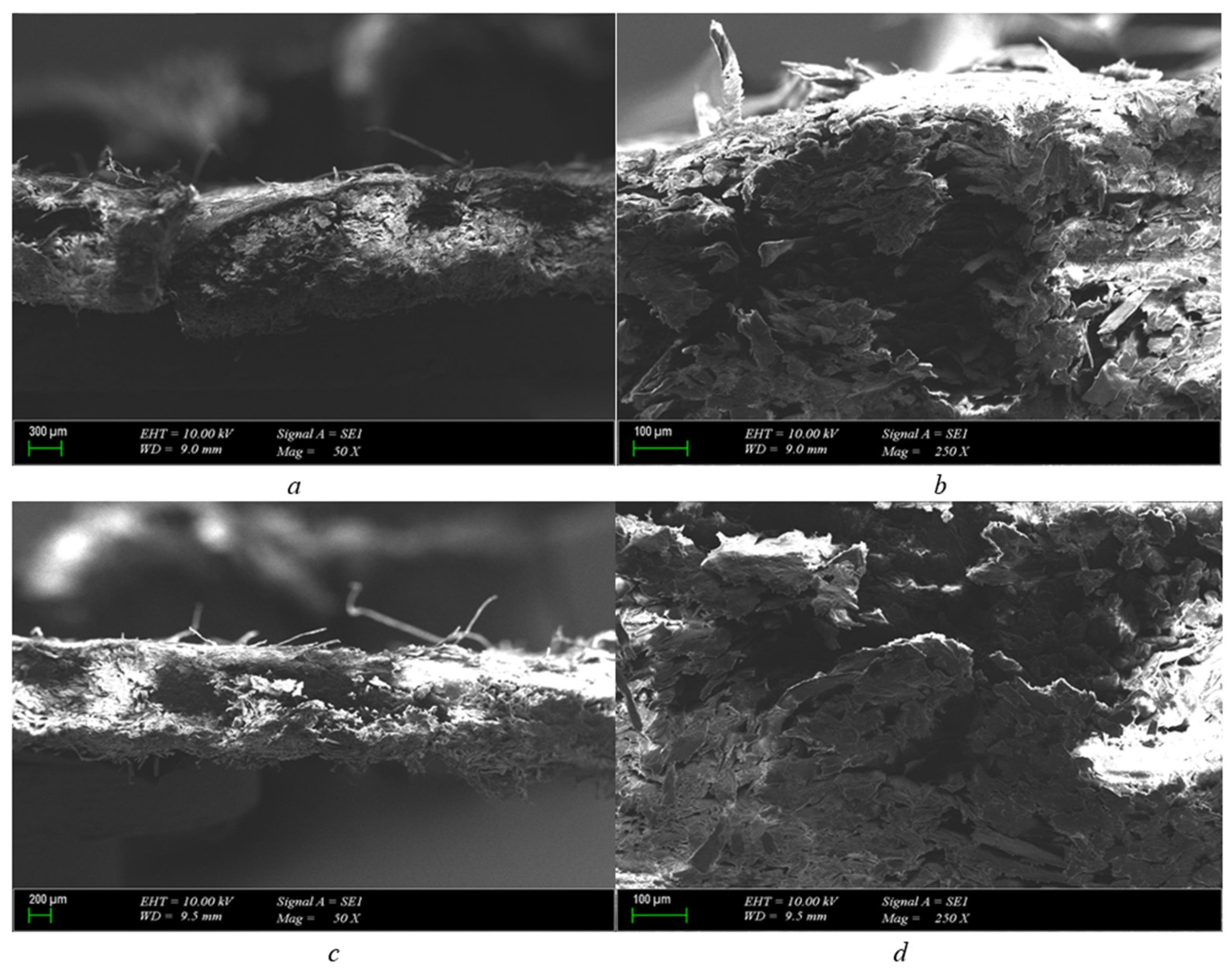

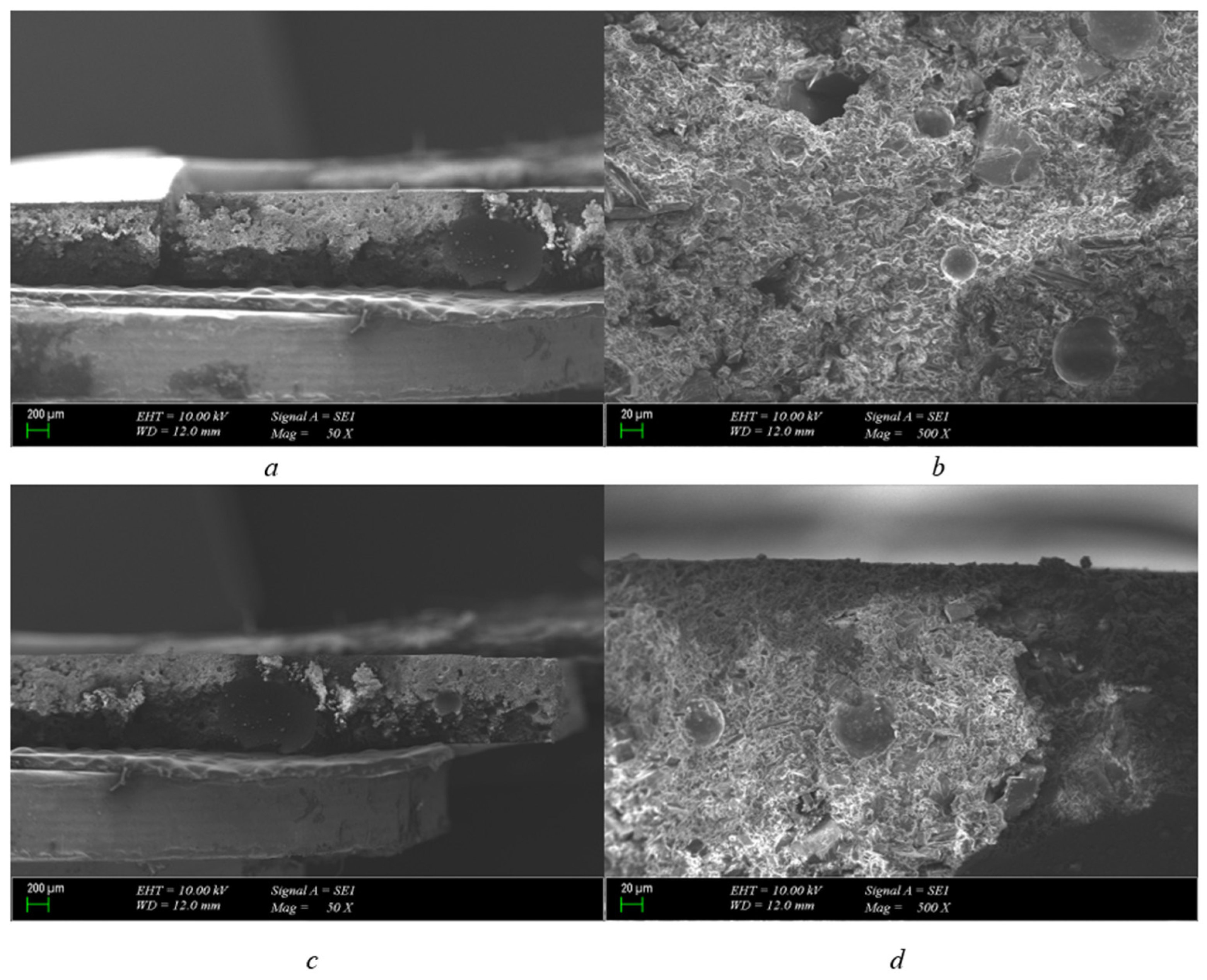

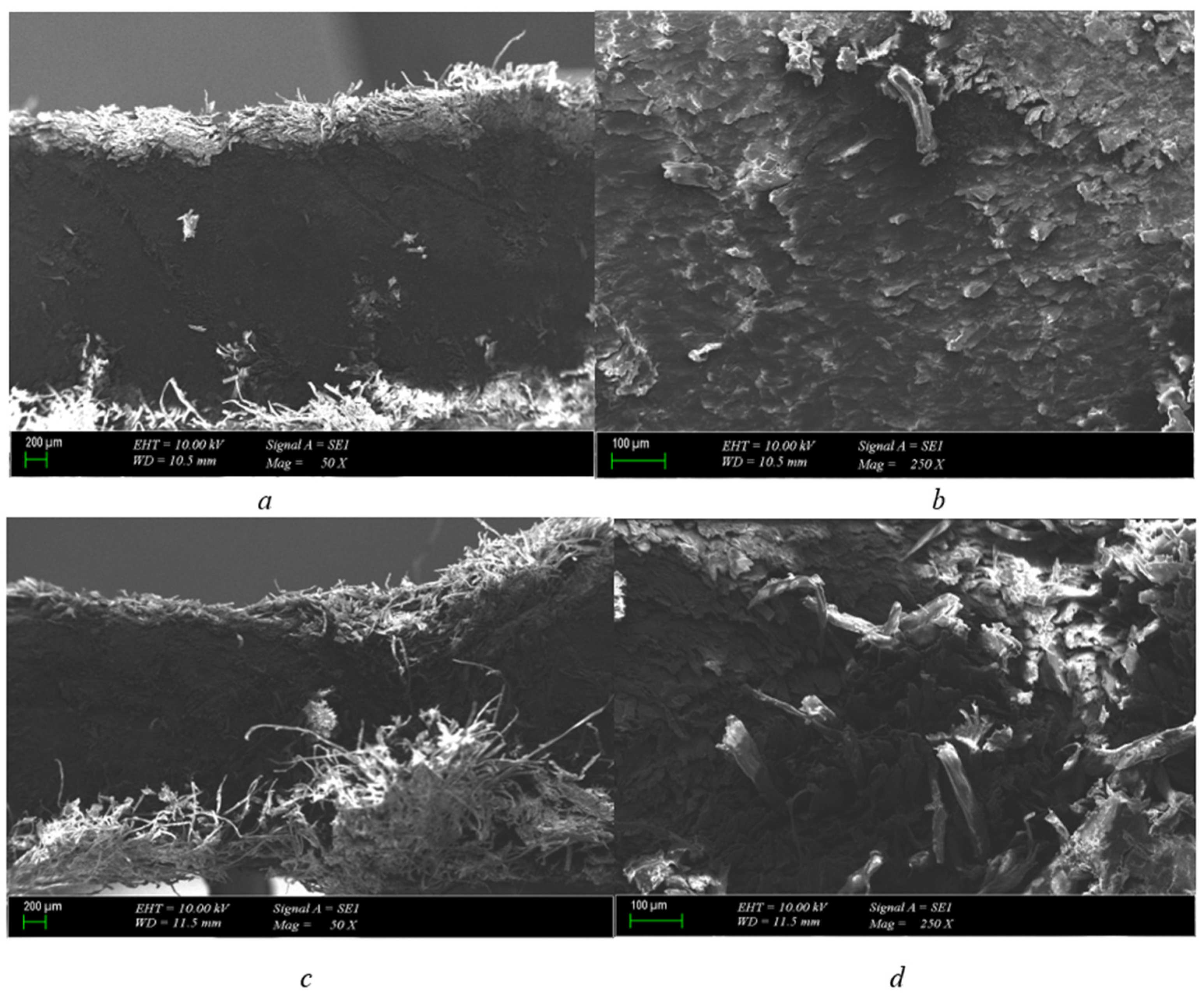

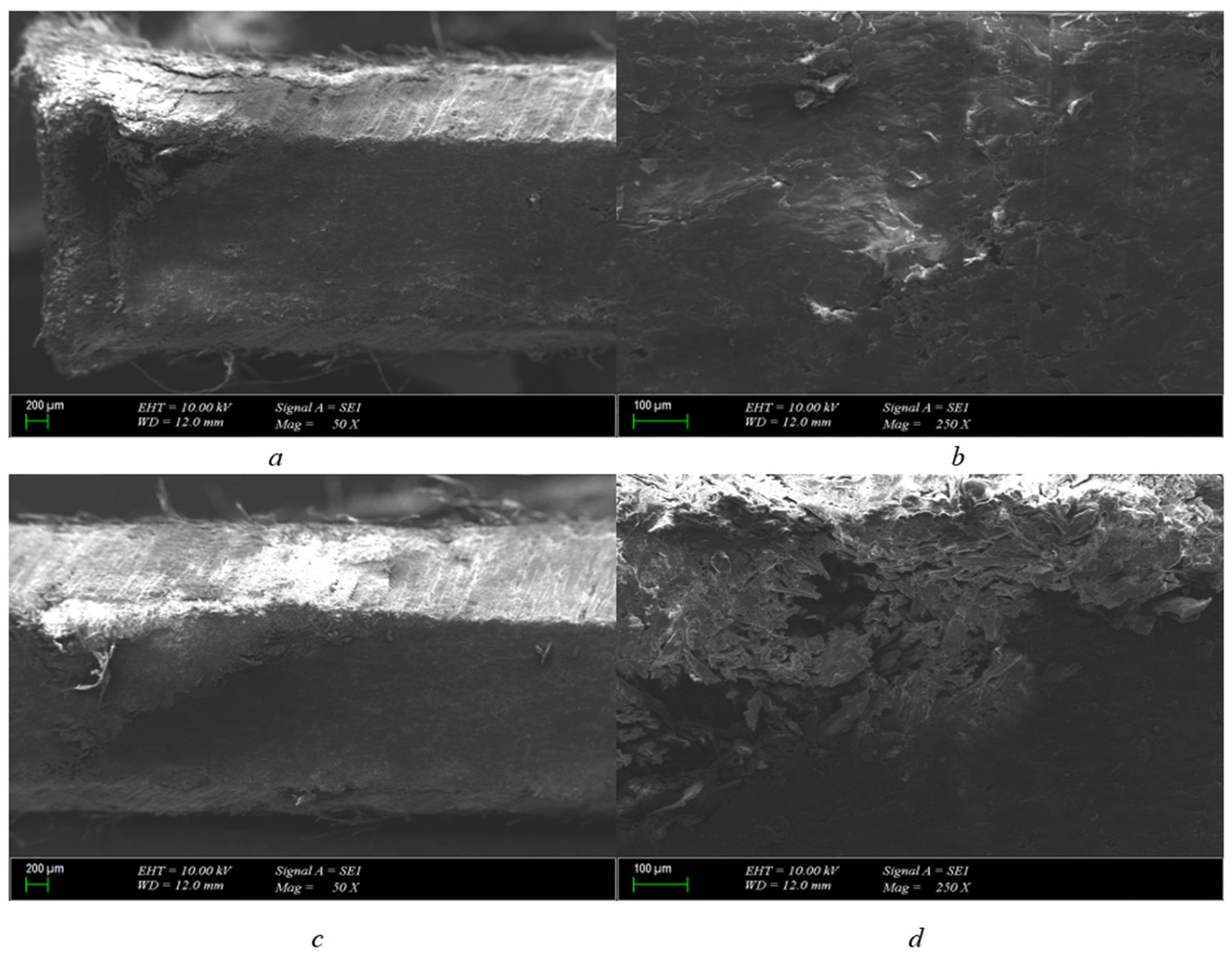

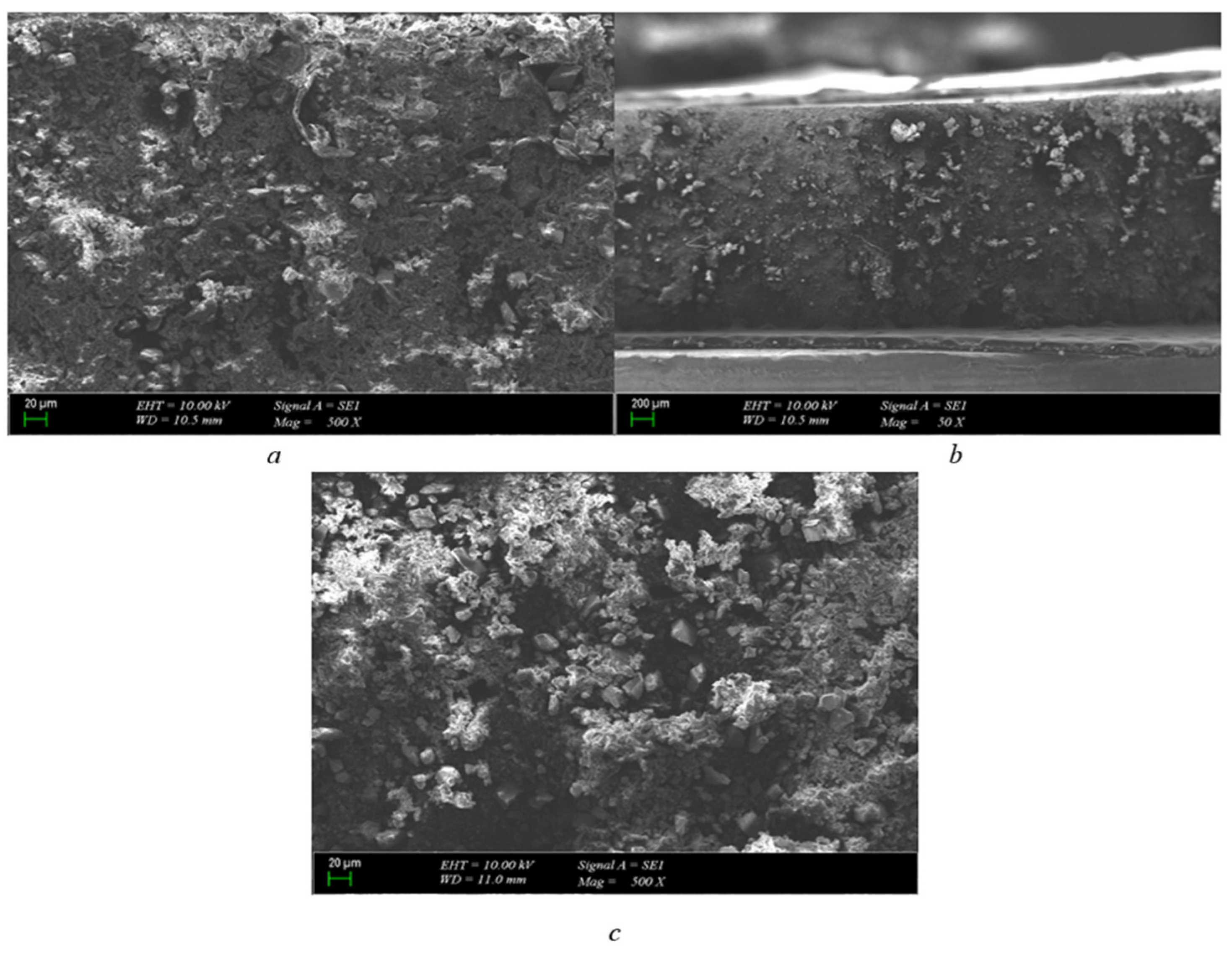

3.2. Scanning Electron Microscopy (SEM) Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alencar, R.J.N.; Bezerra, U.H. Power transformer differential protection through gradient of the differential current. J. Control. Autom. Electr. Syst. 2013, 24, 162–173. [Google Scholar] [CrossRef]

- Patel, D.; Chothani, N.G.; Mistry, K.D.; Raichura, M. Design and development of fault classification algorithm based on relevance vector machine for power transformer. IET Electric Power Appl. 2018, 12, 557–565. [Google Scholar] [CrossRef]

- Bourreau, D.; Péden, A. Solid and non-solid dielectric material characterization for millimeter and sub-millimeter wave applications. In Proceedings of the 50th European Microwave Conference (EuMC), Utrecht, The Netherlands, 12–14 January 2021; pp. 909–912. [Google Scholar] [CrossRef]

- Liu, J.; Cao, Z.; Fan, X.; Zhang, H.; Geng, C.; Zhang, Y. Influence of Oil–Pressboard Mass Ratio on the Equilibrium Characteristics of Furfural under Oil Replacement Conditions. Polymers 2020, 12, 2760. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Yu, R.; Hu, G.; Liu, C.; Zhuang, X.; Zhou, P. Development Processes of Surface Trucking and Partial Discharge of Pressboards Immersed in Mineral Oil: Effect of Tip Curvatures. Energies 2019, 12, 554. [Google Scholar] [CrossRef]

- Koziol, M.; Nagi, L. Comparative analysis of measurement methods for partial discharges generated on the surface of solid dielectrics in insulating oil. In Proceedings of the 20th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 15–17 May 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Aruna, M.; Pattanshetti, V.V.; Ravi, K.N.; Vasudev, N. Power transformer winding insulation: A review of material characteristics. Int. J. Mod. Eng. Res. (IJMER) 2011, 1, 312–318. [Google Scholar]

- Morooka, H.; Yamagishi, A.; Kawamura, K.; Kojima, H.; Hayakawa, N. Thermal-degradation mechanism of mineral-oil-immersed pressboards and influence of aging on pressboard properties. In Proceedings of the 2018 Condition Monitoring and Diagnosis (CMD), Perth, WA, Australia, 23–26 September 2018; pp. 1–4. [Google Scholar]

- Nedjar, M. Weibull statistics in dielectric strength of oil-impregnated pressboard under ramped AC and DC voltages. J. Energy Power Eng. 2013, 7, 2388. [Google Scholar]

- Florkowski, M.; Furgał, J.; Kuniewski, M.; Pająk, P. Investigations of transformer winding responses to standard full and chopped lightning impulses. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018; pp. 1–4. [Google Scholar]

- Chaw, E.E.; Tun, M.T.; Aung, H.W. Design comparison for rectangular and round winding distribution transformer (1000 kVA). Int. J. Sci. Eng. Appl. 2018, 7, 375–380. [Google Scholar]

- Malik, H.; Yadav, A.K.; Mishra, S.; Mehto, T. Application of neuro-fuzzy scheme to investigate the winding insulation paper deterioration in oil-immersed power transformer. Int. J. Electr. Power Energy Syst. 2013, 53, 256–271. [Google Scholar] [CrossRef]

- Pradhan, M.K.; Yew, K.J.H. Experimental investigation of insulation parameters affecting power transformer condition assessment using frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1851–1859. [Google Scholar] [CrossRef]

- Sun, L.; Fan, X.; Jiang, S.; Wang, B.; Liu, Y.; Gao, S.; Meng, L. Study on electrical aging characteristics of fiber sheath materials in power transformer oil. J. Electr. Eng. Technol. 2019, 14, 323–330. [Google Scholar] [CrossRef]

- Sun, W.; Yang, L.; Zare, F.; Xia, Y.; Cheng, L.; Zhou, K. 3D modeling of an HVDC converter transformer and its application on the electrical field of windings subject to voltage harmonics. Int. J. Electr. Power Energy Syst. 2020, 117, 105581. [Google Scholar] [CrossRef]

- Calcara, L.; Sangiovanni, S.; Pompili, M. Standardized methods for the determination of breakdown voltages of liquid dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 101–106. [Google Scholar] [CrossRef]

- Calcara, L.; Sangiovanni, S.; Pompili, M. Partial Discharge Inception Voltage in Insulating Liquids Dependence from the Definition Used. In Proceedings of the 2020 IEEE 3rd International Conference on Dielectrics (ICD), Valencia, Spain, 5–31 July 2020; pp. 736–739. [Google Scholar] [CrossRef]

- Atalar, F.; Uğur, E.; Bilgin, S.; Ersoy Yilmaz, A.; Uğur, M. Investigation of the oil/pressboard ratio effect on dielectric behaviour. In Proceedings of the International Scientific Conference (UNITECH), Gabrovo, Bulgaria, 15–16 November 2019; pp. 12–18. [Google Scholar]

- Schurch, R.; Munoz, O.; Ardila-Rey, J.; Donoso, P.; Peesapati, V. Identification of Electrical Tree Aging State in Epoxy Resin Using Partial Discharge Waveforms Compared to Traditional Analysis. Polymers 2023, 15, 2461. [Google Scholar] [CrossRef] [PubMed]

- Aydogan, A.; Atalar, F.; Ersoy Yilmaz, A.; Rozga, P. Using the method of harmonic distortion analysis in partial discharge assessment in mineral oil in a non-uniform electric field. Energies 2020, 13, 4830. [Google Scholar] [CrossRef]

- Atalar, F.; Ersoy, A.; Rozga, P. Investigation of effects of different high voltage types on dielectric strength of insulating liquids. Energies 2022, 15, 8116. [Google Scholar] [CrossRef]

- Ullah, I.; Ullah, R.; Amin, M.; Rahman, R.A.; Khan, A.; Ullah, N.; Alotaibi, S. Lifetime Estimation and Orientation Effect Based on Long-Term Degradation Analysis of Thermoset and Thermoplastic Insulators. Polymers 2022, 14, 3927. [Google Scholar] [CrossRef] [PubMed]

| Material | Voltage (kV) | Peak Value Positive (A) | Peak Count Positive | Threshold Value (A) |

|---|---|---|---|---|

| Pressboard | 14.4 | 0.44 | 55 | 0.42 |

| Polyurethane | 14.4 | 0.46 | 36 | 0.44 |

| Pressboard | 18 | 0.54 | 8 | 0.52 |

| Polyurethane | 18 | 0.56 | 8 | 0.54 |

| Pressboard | 21.6 | 0.68 | 0 | 0.68 |

| Polyurethane | 21.6 | 1.04 | 29 | 0.68 |

| Pressboard | 25.2 | 2.04 | 16 | 0.96 |

| Polyurethane | 25.2 | 1.44 | 70 | 1.2 |

| Material | Voltage (kV) | Peak Value Positive (A) | Peak Count Positive | Threshold Value (A) |

|---|---|---|---|---|

| Pressboard | 14.4 | 0.58 | 14 | 0.56 |

| Polyurethane | 14.4 | 0.64 | 15 | 0.62 |

| Pressboard | 18 | 0.54 | 0 | 0.54 |

| Polyurethane | 18 | 0.54 | 8 | 0.52 |

| Pressboard | 21.6 | 0.86 | 31 | 0.84 |

| Polyurethane | 21.6 | 1.08 | 14 | 0.96 |

| Pressboard | 25.2 | 1.76 | 40 | 0.96 |

| Polyurethane | 25.2 | 1.52 | 92 | 1.2 |

| Material | Voltage (kV) | Peak Value Positive (A) | Peak Count Positive | Threshold Value (A) |

|---|---|---|---|---|

| Pressboard | 14.4 | 0.44 | 7 | 0.42 |

| Polyurethane | 14.4 | 0.44 | 3 | 0.42 |

| Pressboard | 18 | 0.58 | 89 | 0.54 |

| Polyurethane | 18 | 0.54 | 76 | 0.52 |

| Pressboard | 21.6 | 0.72 | 25 | 0.68 |

| Polyurethane | 21.6 | 0.68 | 0 | 0.68 |

| Pressboard | 25.2 | 0.96 | 2 | 0.88 |

| Polyurethane | 25.2 | 0.88 | 0 | 0.88 |

| Harmonic Values (A) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Polyurethane | Pressboard | |||||||

| Frequency | 14.4 kV | 18 kV | 21.6 kV | 25.2 kV | 14.4 kV | 18 kV | 21.6 kV | 25.2 kV |

| (Hz) | ||||||||

| 50 | 0.0193 | 0.0049 | 0.0484 | 0.1654 | 0.0074 | 0.0040 | 0.0468 | 0.0429 |

| 100 | 0.1920 | 0.2385 | 0.2874 | 0.4649 | 0.1877 | 0.2324 | 0.2843 | 0.4316 |

| 150 | 0.0009 | 0.0015 | 0.0013 | 0.0216 | 0.0007 | 0.0010 | 0.0011 | 0.0226 |

| 200 | 0.0028 | 0.0031 | 0.0046 | 0.0081 | 0.0024 | 0.0026 | 0.0042 | 0.0059 |

| 250 | 0.0008 | 0.0012 | 0.0021 | 0.0019 | 0.0007 | 0.0011 | 0.0022 | 0.0049 |

| 300 | 0.0136 | 0.0181 | 0.0221 | 0.0308 | 0.0133 | 0.0175 | 0.0213 | 0.0316 |

| 350 | 0.0010 | 0.0016 | 0.0014 | 0.0029 | 0.0010 | 0.0012 | 0.0019 | 0.0039 |

| 400 | 0.0099 | 0.0130 | 0.0125 | 0.0229 | 0.0101 | 0.0116 | 0.0142 | 0.0186 |

| 450 | 0.0007 | 0.0008 | 0.0019 | 0.0028 | 0.0010 | 0.0008 | 0.0015 | 0.0020 |

| 500 | 0.0073 | 0.0107 | 0.0131 | 0.0216 | 0.0091 | 0.0107 | 0.0151 | 0.0198 |

| 550 | 0.0015 | 0.0017 | 0.0014 | 0.0038 | 0.0016 | 0.0011 | 0.0016 | 0.0022 |

| 600 | 0.0058 | 0.0059 | 0.0085 | 0.0124 | 0.0051 | 0.0058 | 0.0080 | 0.0108 |

| 650 | 0.0004 | 0.0008 | 0.0016 | 0.0035 | 0.0003 | 0.0011 | 0.0012 | 0.0023 |

| 700 | 0.0056 | 0.0060 | 0.0062 | 0.0178 | 0.0058 | 0.0051 | 0.0088 | 0.0102 |

| 750 | 0.0012 | 0.0011 | 0.0009 | 0.0035 | 0.0010 | 0.0008 | 0.0015 | 0.0028 |

| 800 | 0.0056 | 0.0071 | 0.0089 | 0.0128 | 0.0048 | 0.0060 | 0.0060 | 0.0121 |

| 850 | 0.0005 | 0.0009 | 0.0007 | 0.0037 | 0.0009 | 0.0007 | 0.0012 | 0.0038 |

| 900 | 0.0033 | 0.0048 | 0.0071 | 0.0096 | 0.0033 | 0.0044 | 0.0045 | 0.0108 |

| 950 | 0.0007 | 0.0011 | 0.0020 | 0.0024 | 0.0009 | 0.0010 | 0.0014 | 0.0026 |

| 1000 | 0.0014 | 0.0006 | 0.0028 | 0.0033 | 0.0003 | 0.0011 | 0.0019 | 0.0083 |

| Harmonic Values (A) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Polyurethane | Pressboard | |||||||

| Frequency | 14.4 kV | 18 kV | 21.6 kV | 25.2 kV | 14.4 kV | 18 kV | 21.6 kV | 25.2 kV |

| (Hz) | ||||||||

| 50 | 0.0392 | 0.0046 | 0.1137 | 0.1759 | 0.0151 | 0.0040 | 0.0329 | 0.0510 |

| 100 | 0.2707 | 0.2324 | 0.4049 | 0.4777 | 0.2548 | 0.2338 | 0.3791 | 0.4364 |

| 150 | 0.0038 | 0.0015 | 0.0125 | 0.0205 | 0.0043 | 0.0012 | 0.0182 | 0.0285 |

| 200 | 0.0034 | 0.0030 | 0.0069 | 0.0072 | 0.0015 | 0.0030 | 0.0057 | 0.0071 |

| 250 | 0.0018 | 0.0005 | 0.0034 | 0.0018 | 0.0017 | 0.0014 | 0.0048 | 0.0060 |

| 300 | 0.0188 | 0.0172 | 0.0262 | 0.0309 | 0.0198 | 0.0170 | 0.0286 | 0.0344 |

| 350 | 0.0026 | 0.0014 | 0.0042 | 0.0040 | 0.0035 | 0.0012 | 0.0046 | 0.0064 |

| 400 | 0.0123 | 0.0122 | 0.0193 | 0.0214 | 0.0112 | 0.0141 | 0.0160 | 0.0164 |

| 450 | 0.0016 | 0.0008 | 0.0018 | 0.0024 | 0.0005 | 0.0012 | 0.0035 | 0.0026 |

| 500 | 0.0125 | 0.0113 | 0.0168 | 0.0211 | 0.0106 | 0.0114 | 0.0149 | 0.0164 |

| 550 | 0.0032 | 0.0011 | 0.0048 | 0.0030 | 0.0021 | 0.0016 | 0.0028 | 0.0033 |

| 600 | 0.0062 | 0.0045 | 0.0099 | 0.0122 | 0.0059 | 0.0092 | 0.0057 | 0.0081 |

| 650 | 0.0019 | 0.0011 | 0.0018 | 0.0029 | 0.0003 | 0.0014 | 0.0011 | 0.0019 |

| 700 | 0.0085 | 0.0061 | 0.0095 | 0.0147 | 0.0066 | 0.0086 | 0.0084 | 0.0090 |

| 750 | 0.0024 | 0.0010 | 0.0024 | 0.0029 | 0.0008 | 0.0018 | 0.0014 | 0.0023 |

| 800 | 0.0071 | 0.0063 | 0.0108 | 0.0140 | 0.0068 | 0.0056 | 0.0089 | 0.0092 |

| 850 | 0.0015 | 0.0011 | 0.0032 | 0.0035 | 0.0019 | 0.0009 | 0.0024 | 0.0021 |

| 900 | 0.0064 | 0.0053 | 0.0107 | 0.0137 | 0.0068 | 0.0029 | 0.0113 | 0.0135 |

| 950 | 0.0012 | 0.0013 | 0.0017 | 0.0030 | 0.0008 | 0.0007 | 0.0021 | 0.0037 |

| 1000 | 0.0020 | 0.0003 | 0.0035 | 0.0034 | 0.0042 | 0.0007 | 0.0063 | 0.0051 |

| Harmonic Values (A) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Polyurethane | Pressboard | |||||||

| Frequency | 14.4 kV | 18 kV | 21.6 kV | 25.2 kV | 14.4 kV | 18 kV | 21.6 kV | 25.2 kV |

| (Hz) | ||||||||

| 50 | 0.1876 | 0.2322 | 0.281 | 0.3301 | 0.1871 | 0.233 | 0.2844 | 0.3304 |

| 100 | 0.001 | 0.001 | 0.0017 | 0.0025 | 0.0008 | 0.0009 | 0.0009 | 0.0022 |

| 150 | 0.0026 | 0.0031 | 0.005 | 0.0064 | 0.0023 | 0.003 | 0.0045 | 0.0072 |

| 200 | 0.0011 | 0.0008 | 0.002 | 0.0011 | 0.0011 | 0.0012 | 0.0021 | 0.0014 |

| 250 | 0.0139 | 0.0157 | 0.0214 | 0.0243 | 0.0132 | 0.0179 | 0.0218 | 0.023 |

| 300 | 0.001 | 0.0016 | 0.0014 | 0.0016 | 0.0009 | 0.0012 | 0.0014 | 0.002 |

| 350 | 0.0096 | 0.0114 | 0.0134 | 0.0153 | 0.0109 | 0.0136 | 0.016 | 0.0204 |

| 400 | 0.0008 | 0.0008 | 0.0016 | 0.0016 | 0.0008 | 0.0011 | 0.0015 | 0.0019 |

| 450 | 0.008 | 0.0113 | 0.0142 | 0.0154 | 0.0096 | 0.0118 | 0.0156 | 0.0161 |

| 500 | 0.0016 | 0.0014 | 0.0016 | 0.0011 | 0.0014 | 0.0013 | 0.0016 | 0.0025 |

| 550 | 0.0066 | 0.0087 | 0.008 | 0.0089 | 0.0067 | 0.0082 | 0.0093 | 0.0121 |

| 600 | 0.0008 | 0.001 | 0.0011 | 0.0013 | 0.0006 | 0.0014 | 0.0011 | 0.0008 |

| 650 | 0.0064 | 0.0036 | 0.0096 | 0.0106 | 0.0077 | 0.009 | 0.0114 | 0.0119 |

| 700 | 0.0012 | 0.0009 | 0.0025 | 0.0009 | 0.0013 | 0.0018 | 0.002 | 0.0012 |

| 750 | 0.005 | 0.0089 | 0.0063 | 0.0078 | 0.0037 | 0.005 | 0.0071 | 0.0099 |

| 800 | 0.0005 | 0.0014 | 0.0007 | 0.001 | 0.0005 | 0.0013 | 0.0017 | 0.0017 |

| 850 | 0.0033 | 0.0056 | 0.0046 | 0.0047 | 0.0021 | 0.0028 | 0.0036 | 0.0045 |

| 900 | 0.0005 | 0.001 | 0.001 | 0.0009 | 0.0005 | 0.0006 | 0.0012 | 0.0009 |

| 950 | 0.0013 | 0.0013 | 0.0024 | 0.0026 | 0.0009 | 0.0012 | 0.0007 | 0.0022 |

| 1000 | 0.0008 | 0.0004 | 0.0009 | 0.0018 | 0.0008 | 0.0008 | 0.0011 | 0.0008 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ersoy, A.; Atalar, F.; Aydoğan, A. Investigation of Novel Solid Dielectric Material for Transformer Windings. Polymers 2023, 15, 4671. https://doi.org/10.3390/polym15244671

Ersoy A, Atalar F, Aydoğan A. Investigation of Novel Solid Dielectric Material for Transformer Windings. Polymers. 2023; 15(24):4671. https://doi.org/10.3390/polym15244671

Chicago/Turabian StyleErsoy, Aysel, Fatih Atalar, and Alper Aydoğan. 2023. "Investigation of Novel Solid Dielectric Material for Transformer Windings" Polymers 15, no. 24: 4671. https://doi.org/10.3390/polym15244671

APA StyleErsoy, A., Atalar, F., & Aydoğan, A. (2023). Investigation of Novel Solid Dielectric Material for Transformer Windings. Polymers, 15(24), 4671. https://doi.org/10.3390/polym15244671