Changes in Mechanical Properties of Fabrics Made of Standard and Recycled Polyester Yarns Due to Aging

Abstract

:1. Introduction

2. Methods and Materials

2.1. Material

2.2. Aging Protocol

- -

- Definition of the target group;

- -

- Determination of the training conditions of the target group;

- -

- Selection of materials;

- -

- Determination of the aging factors;

- -

- Determination of the aging processes;

- -

- Determination of the test methods.

2.3. Characterization Methods

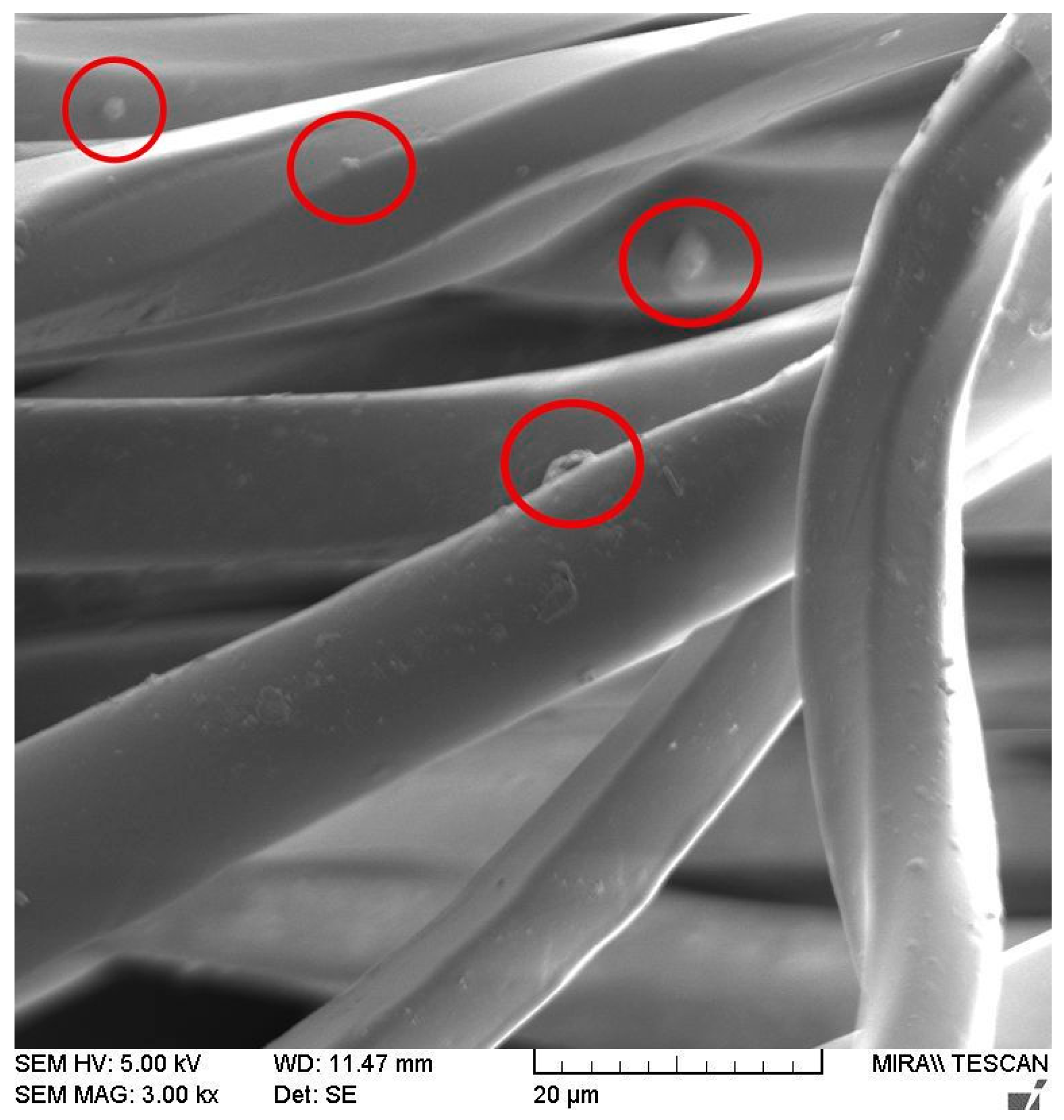

2.3.1. Surface Morphology Characterization

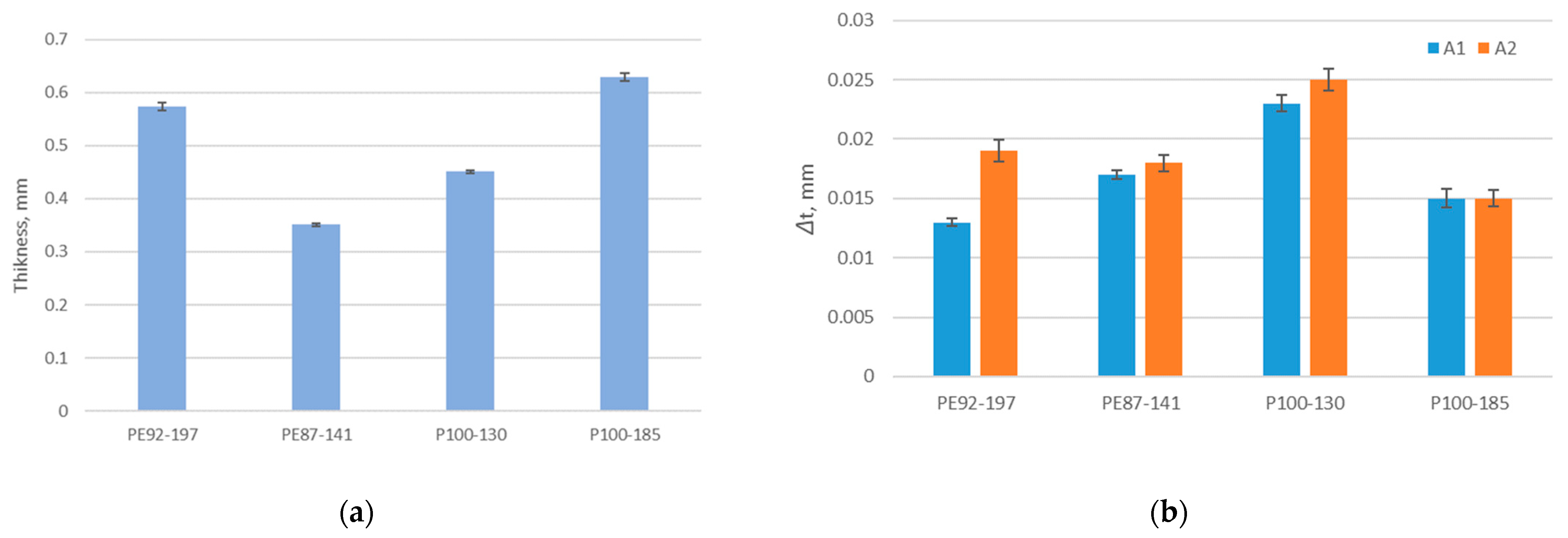

2.3.2. Thickness

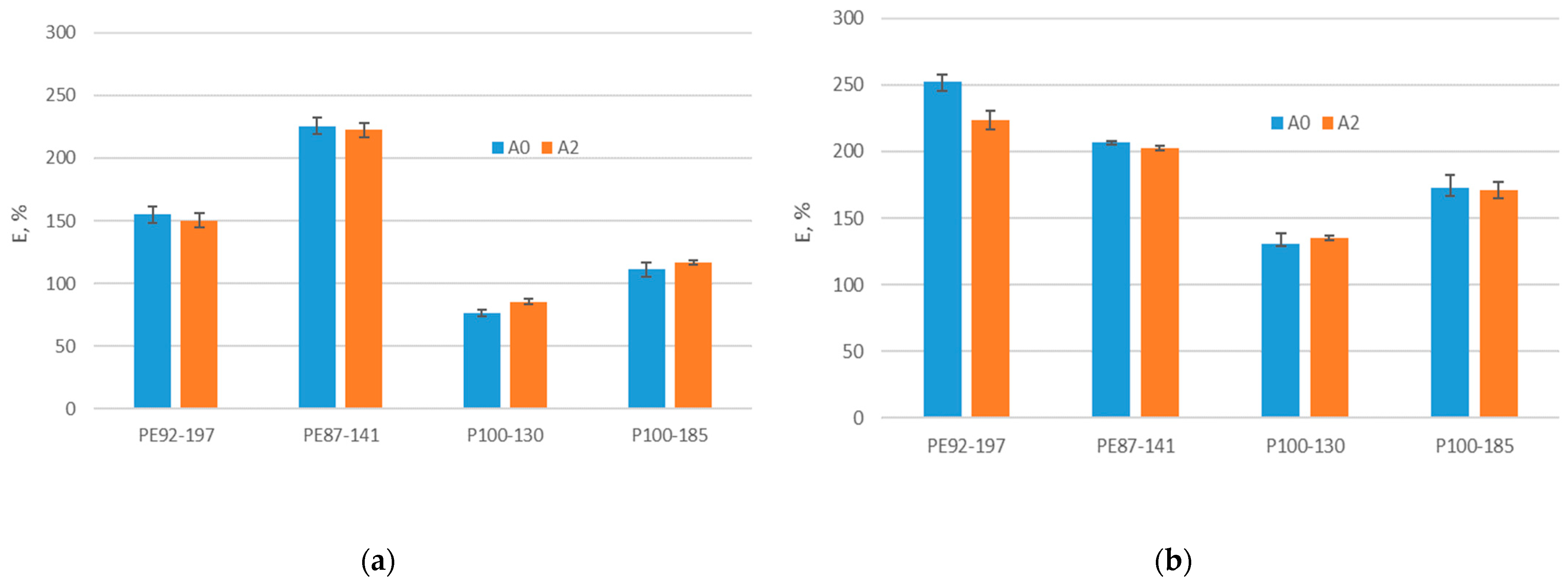

2.3.3. Elongation at Break and Force at Break

2.3.4. Bursting Force

2.3.5. Moisture Management

2.3.6. Abrasion

2.3.7. Fourier Transform Infrared Analysis

3. Results and Discussion

3.1. Results of the Surface Morphology Characterization

3.2. Results of Thickness Testing

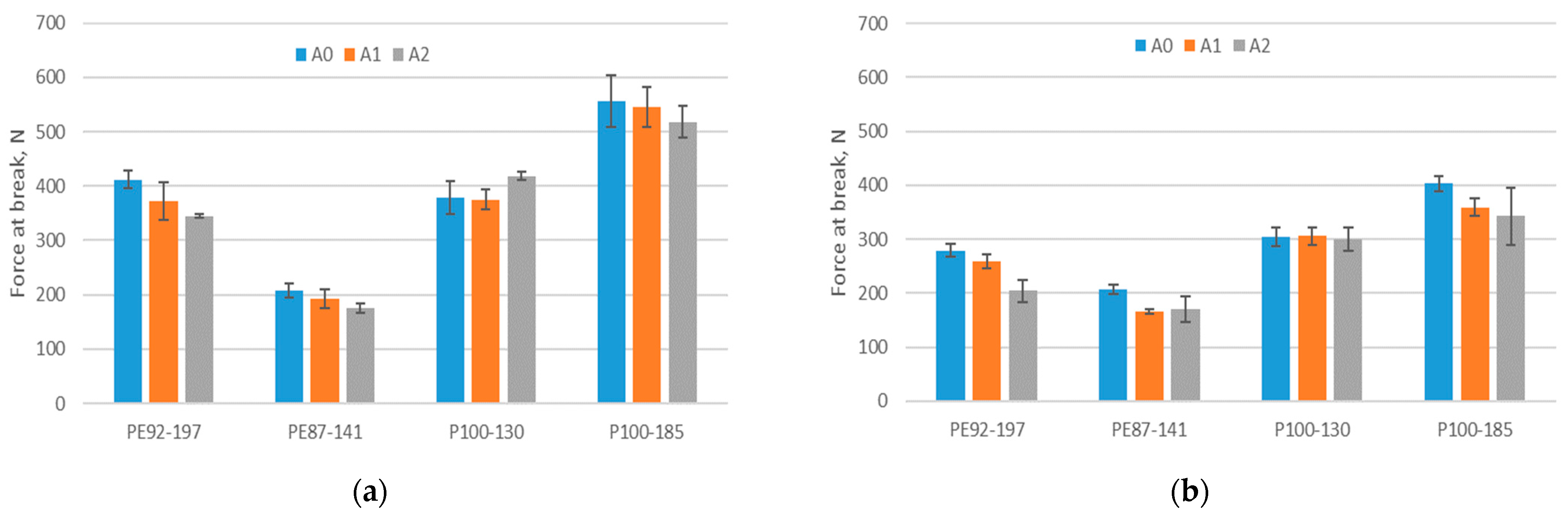

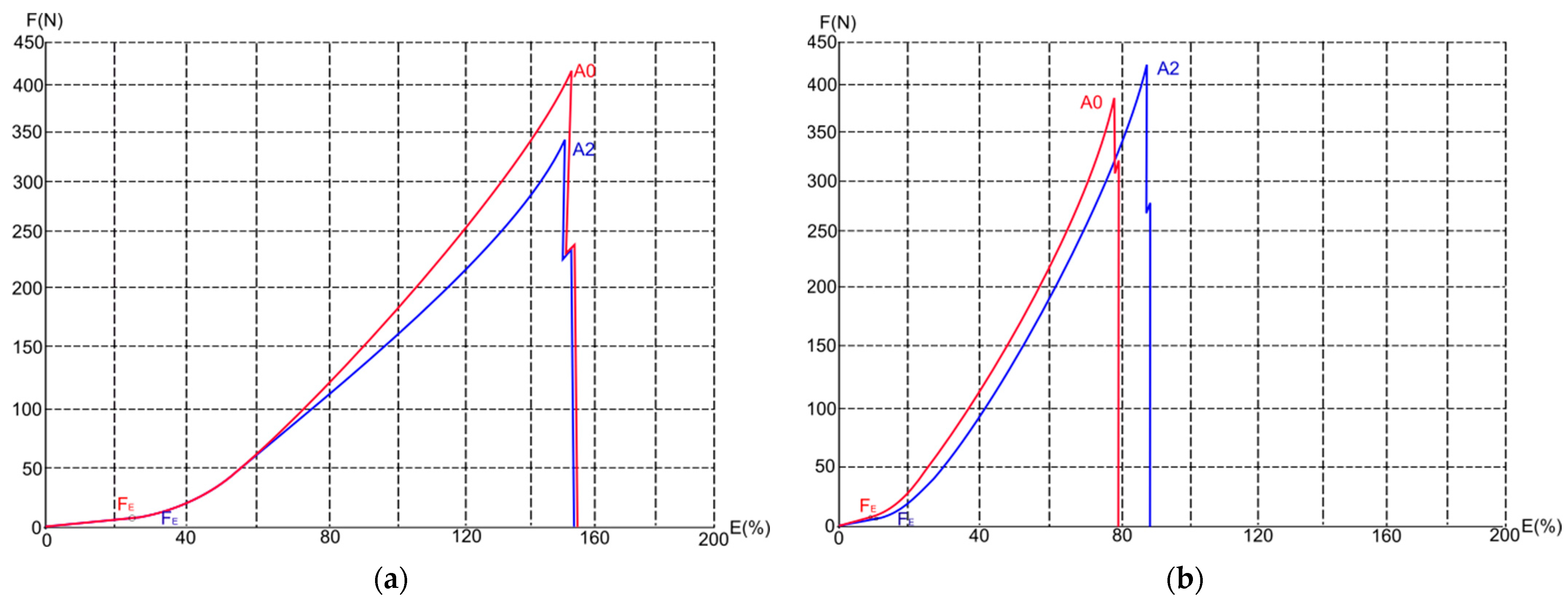

3.3. Results of Elongation and Force at Break Testing

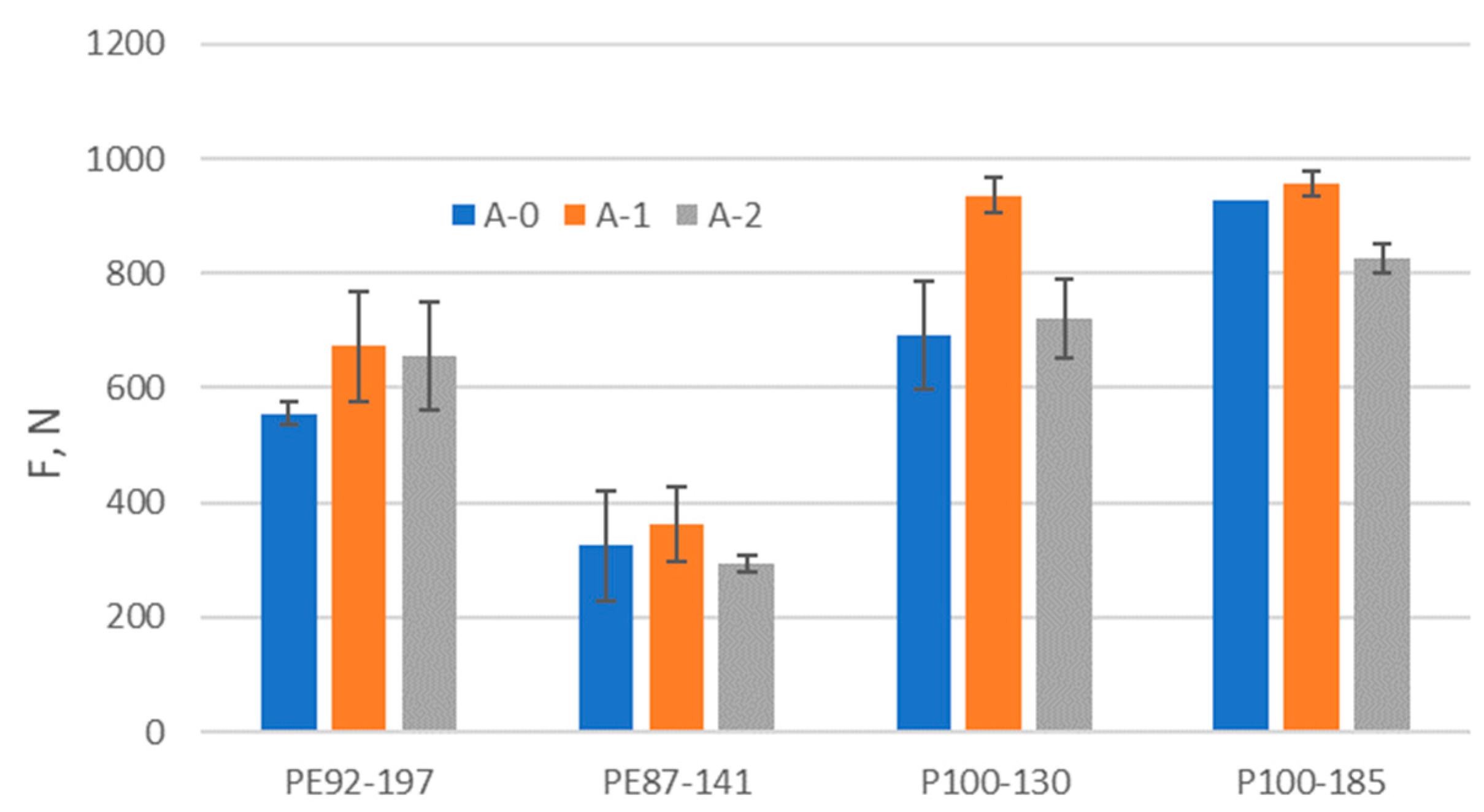

3.4. Results of Bursting Force Testing

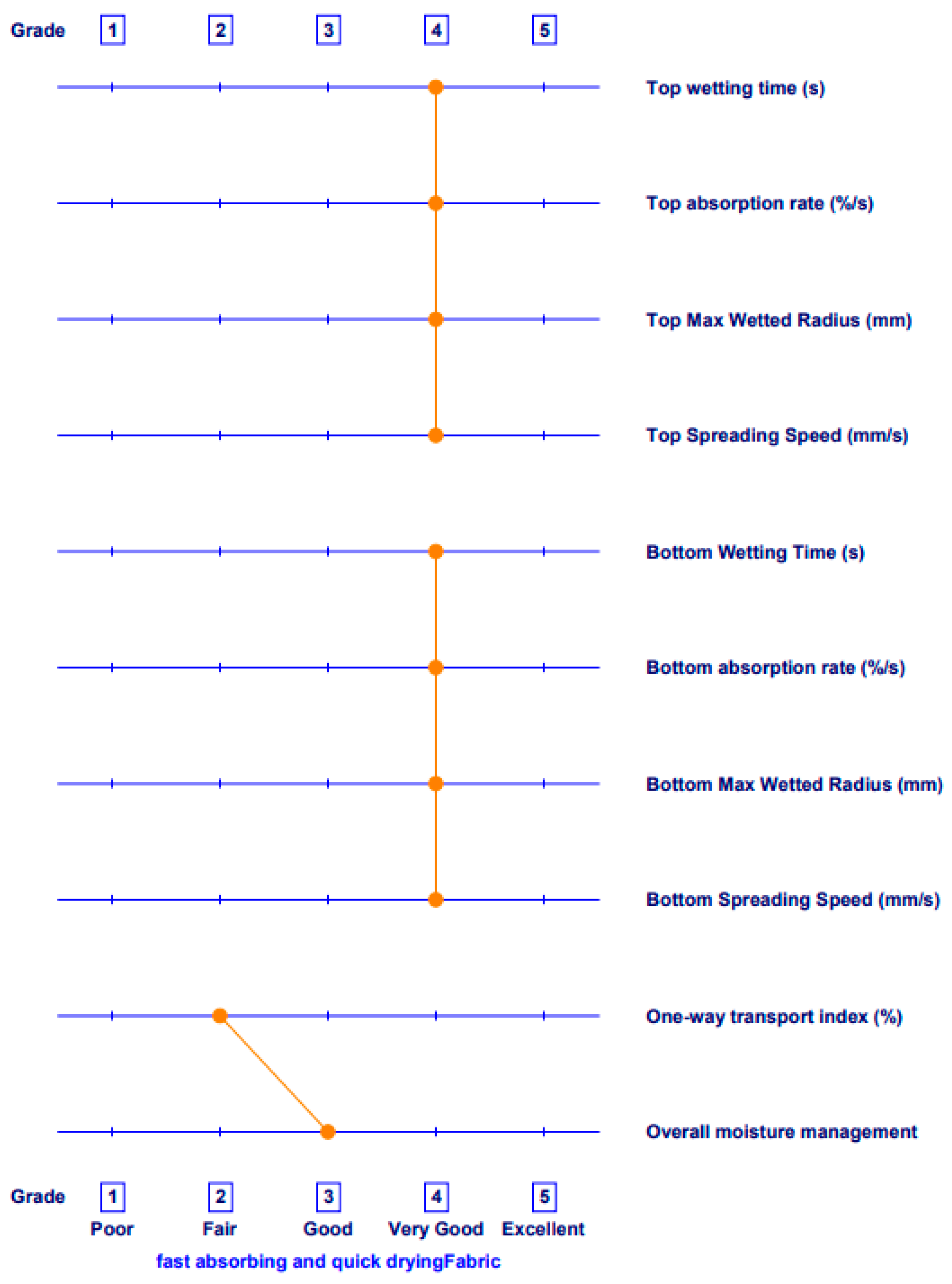

3.5. Moisture Management Test Results

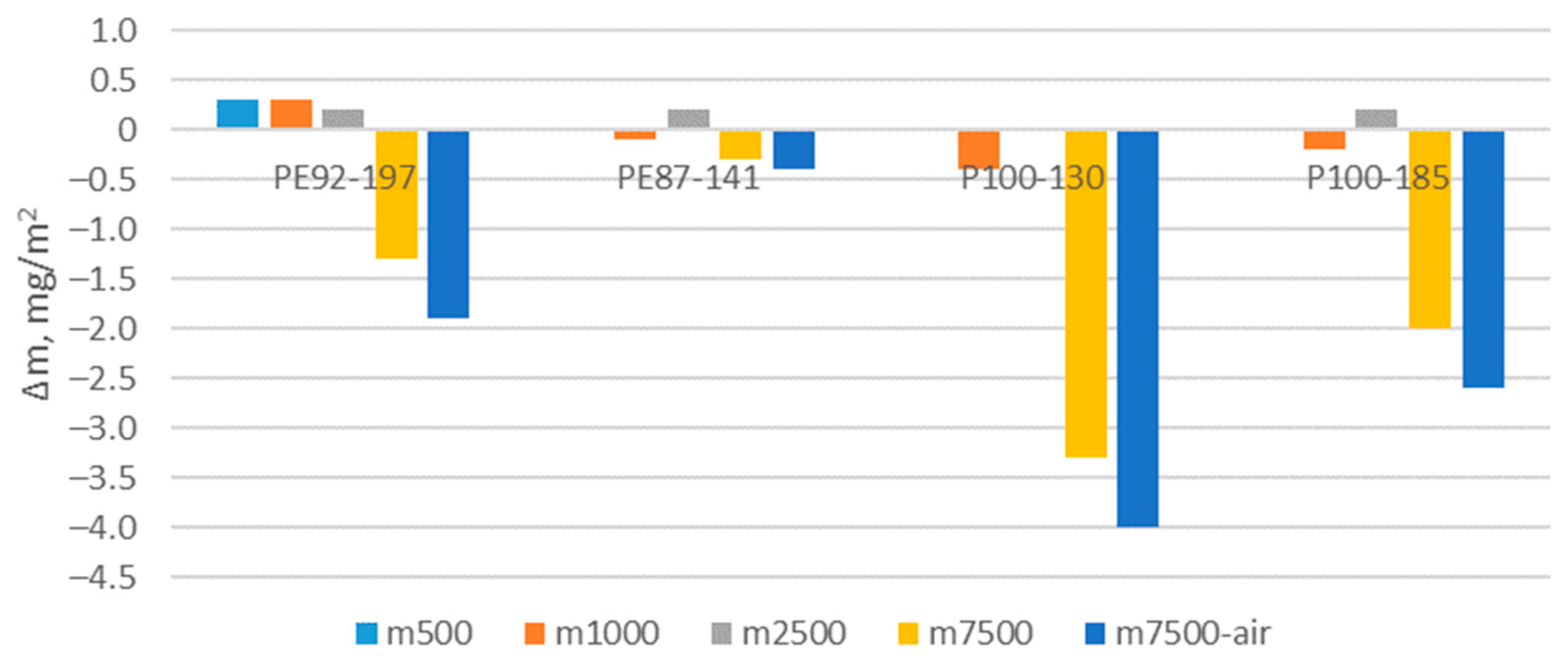

3.6. Results of Abrasion Testing

3.7. Results of Fourier Transform Infrared Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Venkatraman, P.; Hayes, S.G. Materials and Technology for Sportswear and Performance Apparel; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781482220513. [Google Scholar]

- Shishoo, R. Textiles for Sportswear; Elsevier Science: Amsterdam, The Netherlands, 2015; ISBN 9781782422365. [Google Scholar]

- McKeen, L.W. The Effect of UV Light and Weather on Plastics and Elastomers; Elsevier: Oxford, UK, 2013; ISBN 978-1-4557-2851-0. [Google Scholar]

- McKeen, L.W. Effect of Temperature and other Factors on Plastics and Elastomers, 2nd ed.; Elsevier: Oxford, UK, 2007; ISBN 9780815515685. [Google Scholar]

- ASTM G151-10; Standard Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources. ASTM International: West Conshohocken, PA, USA.

- Wypych, G. Handbook of Material Weathering; ChemTec Publishing: Toronto, ON, Canada, 2013; ISBN 978-1-895198-62-1. [Google Scholar]

- Lemmi, T.S.; Barburski, M.; Kabziński, A.; Frukacz, K. Effect of Thermal Aging on the Mechanical Properties of High Tenacity Polyester Yarn. Materials 2021, 14, 1666. [Google Scholar] [CrossRef] [PubMed]

- Azmami, O.; Sajid, L.; Boukhriss, A.; Majid, S.; El Ahmadi, Z.; Benayada, A.; Gmouh, S. Mechanical and aging performances of Palm/Wool and Palm/Polyester nonwovens coated by waterborne polyurethane for automotive interiors. Ind. Crop. Prod. 2021, 170, 113681. [Google Scholar] [CrossRef]

- Kharazmi, P.; Björk, F. Durability study of reinforced polyester composite used as pipe lining under artificial aging conditions. Cogent Eng. 2019, 6, 1693719. [Google Scholar] [CrossRef]

- Mijas, G.; Riba-Moliner, M.; Cayuela, D. The Effect of Accelerated Aging on the Molecular Weight and Thermal and Mechanical Properties of Polyester Yarns Containing Ceramic Particles. Polymers 2023, 15, 1348. [Google Scholar] [CrossRef] [PubMed]

- Salopek Čubrić, I.; Potočić Matković, V.M.; Skenderi, Z.; Tarbuk, A. Impact of substrate on water vapor resistance of naturally weathered coated fabrics. Text. Res. J. 2017, 87, 1541–1553. [Google Scholar] [CrossRef]

- Salopek Čubrić, I.; Čubrić, G.; Potočić Matković, V.M. Behavior of Polymer Materials Exposed to Aging in the Swimming Pool: Focus on Properties That Assure Comfort and Durability. Polymers 2021, 13, 2414. [Google Scholar] [CrossRef] [PubMed]

- La Mantia, F.P.; Scaffaro, R.; Baiamonte, M.; Ceraulo, M.; Mistretta, M.C. Comparison of the Recycling Behavior of a Polypropylene Sample Aged in Air and in Marine Water. Polymers 2023, 15, 2173. [Google Scholar] [CrossRef] [PubMed]

- Iñiguez, M.E.; Conesa, J.A.; Fullana, A. Recyclability of four types of plastics exposed to UV irradiation in a marine environment. Waste Manag. 2018, 79, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Marjo, C.E.; Gatenby, S.; Rich, A.M.; Gong, B.; Chee, S. ATR-FTIR as a tool for assessing potential for chemical ageing in Spandex/Lycra®/elastane-based fabric collections. Stud. Conserv. 2016, 62, 343–353. [Google Scholar] [CrossRef]

- Yin, Y.; Yao, D.; Wang, C.; Wang, Y. Removal of spandex from nylon/spandex blended fabrics by selective polymer degradation. Text. Res. J. 2014, 84, 16–27. [Google Scholar] [CrossRef]

- Čubrić, I.S.; Čubrić, G.; Križmančić, I.K.; Kovačević, M. Evaluation of Changes in Polymer Material Properties Due to Aging in Different Environments. Polymers 2022, 14, 1682. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.T.; Chan, W.S.; Chow, D.H. Systematic review of selecting comfortable sportswear: Predicting wearing comfort based on physiological responses and materials properties. Text. Res. J. 2023, 93, 3926–3941. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Sampath, M.B.; Ramachandran, T. Moisture Management in an Active Sportswear: Techniques and Evaluation—A Review Article. J. Inst. Eng. Ser. E 2013, 93, 61–68. [Google Scholar] [CrossRef]

- ECMWF. Available online: https://www.ecmwf.int/en/forecasts/datasets/set-i (accessed on 25 March 2023).

- ISO 105-E04:2013; Textiles: Tests for Colour Fastness. Part E04: Colour Fastness to Perspiration. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 6330:2021; Textiles—Domestic Washing and Drying Procedures for Textile Testing. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 139:2005; Textiles—Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 2005.

- ISO 5084:1996; Textiles—Determination of Thickness of Textiles and Textile Products. ISO: Geneva, Switzerland, 1996.

- ISO 13934-1:2013; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. ISO: Geneva, Switzerland, 2013.

- ASTM D3787; Textile Ball Burst Testing. ADMET, Inc.: Norwood, MA, USA, 2020.

- AATCC TM 195-2021; Liquid Moisture Management Properties of Textile Fabrics. AATCC: Durham, NC, USA, 2021.

- ISO 12947-3:1998; Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method—Part 3: Determination of Mass Loss. ISO: Geneva, Switzerland, 1998.

- Choi, Y.J.; Kim, I.; Kim, S.H. Effect of heat-setting on the physical properties of chemically recycled polyester nonwoven fabrics. Text. Res. J. 2019, 89, 498–509. [Google Scholar] [CrossRef]

- Yaping, C.; Mitrano, D.M.; Hufenus, R.; Nowack, B. Formation of Fiber Fragments during Abrasion of Polyester Textiles Environmental. Sci. Technol. 2021, 55, 8001–8009. [Google Scholar] [CrossRef]

| Fabric ID | PE92-197 | PE87-141 | P100-130 | P100-185 |

|---|---|---|---|---|

| Main raw material | 92% PES standard | 87% PES standard | 100% PES recycled | 100% PES recycled |

| Additional raw material | 8% Elastane | 13% Elastane | - | - |

| Mass per unit area | 197 g/m2 | 141 g/m2 | 130 g/m2 | 185 g/m2 |

| Designation | Su Exposure | Duration, min | AS Exposure | Duration, min | Number of Wcyc | Duration, min |

|---|---|---|---|---|---|---|

| A0 | - | - | - | - | - | - |

| A1 | + | 1440 | + | 1260 | 12 | 444 |

| A2 | + | 4320 | + | 3780 | 36 | 1332 |

| WTT | WTB | TAR | BAR | TSS | BSS | |

|---|---|---|---|---|---|---|

| WTT | 1.00000 | |||||

| WTB | 0.99285 | 1.00000 | ||||

| TAR | −0.47946 | −0.48508 | 1.00000 | |||

| BAR | −0.49266 | −0.49469 | 0.98765 | 1.00000 | ||

| TSS | −0.86727 | −0.88493 | 0.44280 | 0.48298 | 1.00000 | |

| BSS | −0.85289 | −0.87779 | 0.48066 | 0.51955 | 0.99401 | 1.00000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katić Križmančić, I.; Salopek Čubrić, I.; Potočić Matković, V.M.; Čubrić, G. Changes in Mechanical Properties of Fabrics Made of Standard and Recycled Polyester Yarns Due to Aging. Polymers 2023, 15, 4511. https://doi.org/10.3390/polym15234511

Katić Križmančić I, Salopek Čubrić I, Potočić Matković VM, Čubrić G. Changes in Mechanical Properties of Fabrics Made of Standard and Recycled Polyester Yarns Due to Aging. Polymers. 2023; 15(23):4511. https://doi.org/10.3390/polym15234511

Chicago/Turabian StyleKatić Križmančić, Ines, Ivana Salopek Čubrić, Vesna Marija Potočić Matković, and Goran Čubrić. 2023. "Changes in Mechanical Properties of Fabrics Made of Standard and Recycled Polyester Yarns Due to Aging" Polymers 15, no. 23: 4511. https://doi.org/10.3390/polym15234511

APA StyleKatić Križmančić, I., Salopek Čubrić, I., Potočić Matković, V. M., & Čubrić, G. (2023). Changes in Mechanical Properties of Fabrics Made of Standard and Recycled Polyester Yarns Due to Aging. Polymers, 15(23), 4511. https://doi.org/10.3390/polym15234511