Poly(3-hydroxybutyrate) Production from Lignocellulosic Wastes Using Bacillus megaterium ATCC 14581

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Strains

2.2. Microwave Irradiation of Biomass Using Response Surface Methodology (RSM)

2.3. Delignification of the Pretreated Biomass with Ammonia

2.4. Enzymatic Hydrolysis of the Delignified Biomass

2.5. PHA Production via Fermentation with Bacillus Megaterium ATCC 14581

2.5.1. Preparation of Stock Culture and Cultivation Conditions

2.5.2. PHB Production from Lignocellulosic Biomass

2.5.3. PHB Isolation and Purification

2.6. Chemical Characterization

2.6.1. Chemical Characterization of the Raw and Pretreated Biomass

2.6.2. Reducing Sugar Analysis

2.6.3. PHB Analysis via Gas Chromatography (GC)

2.7. Structural Characterization of the Obtained PHB

2.7.1. Electrospray Ionization High Resolution Mass Spectrometry (ESI-HRMS), Proton Nuclear Magnetic Resonance (1H-NMR), Carbon Nuclear Magnetic Resonance (13C-NMR)

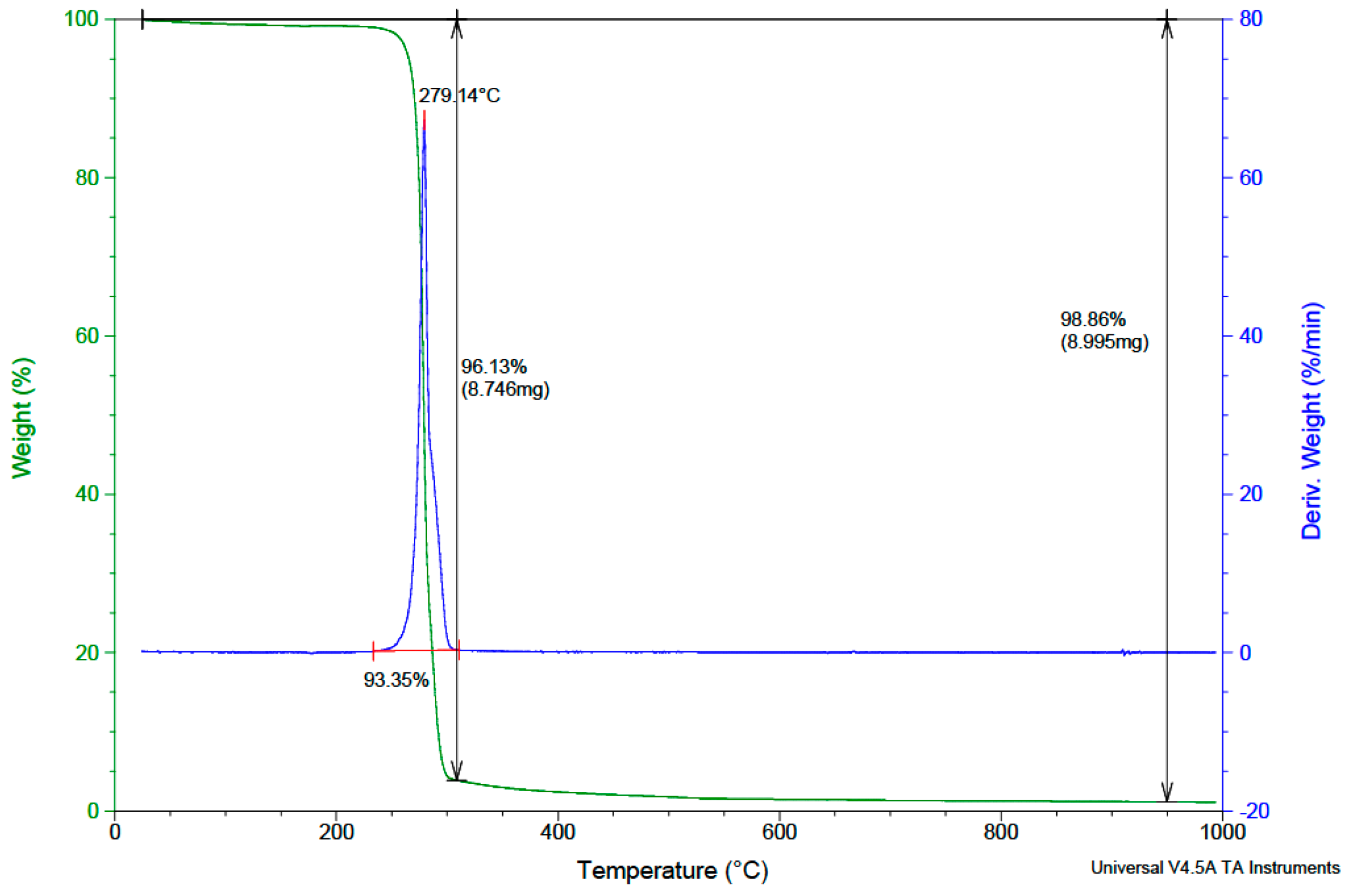

2.7.2. TGA/DTG Analysis

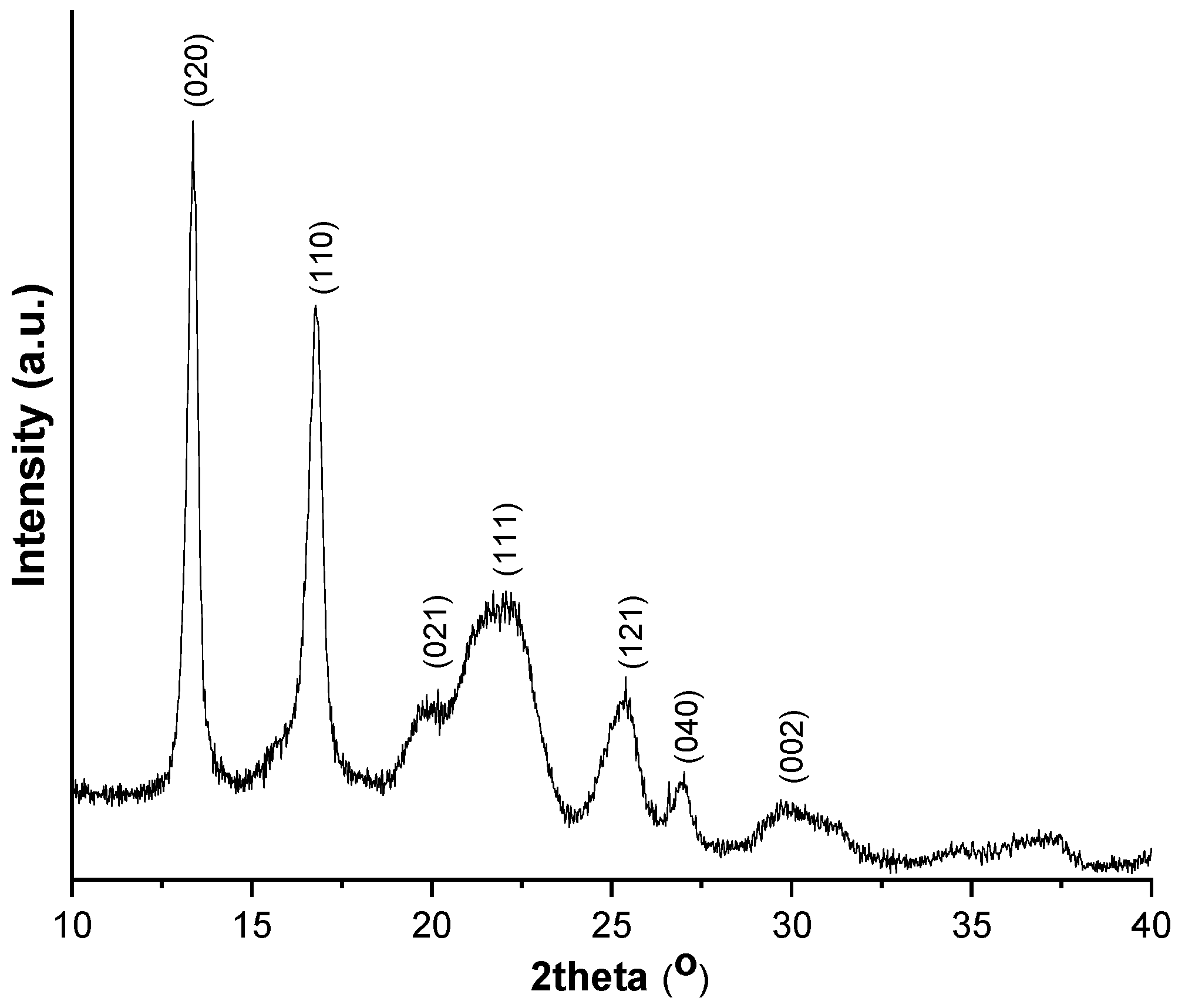

2.7.3. X-ray Diffraction (XRD)

2.7.4. FT-IR Spectroscopy

3. Results

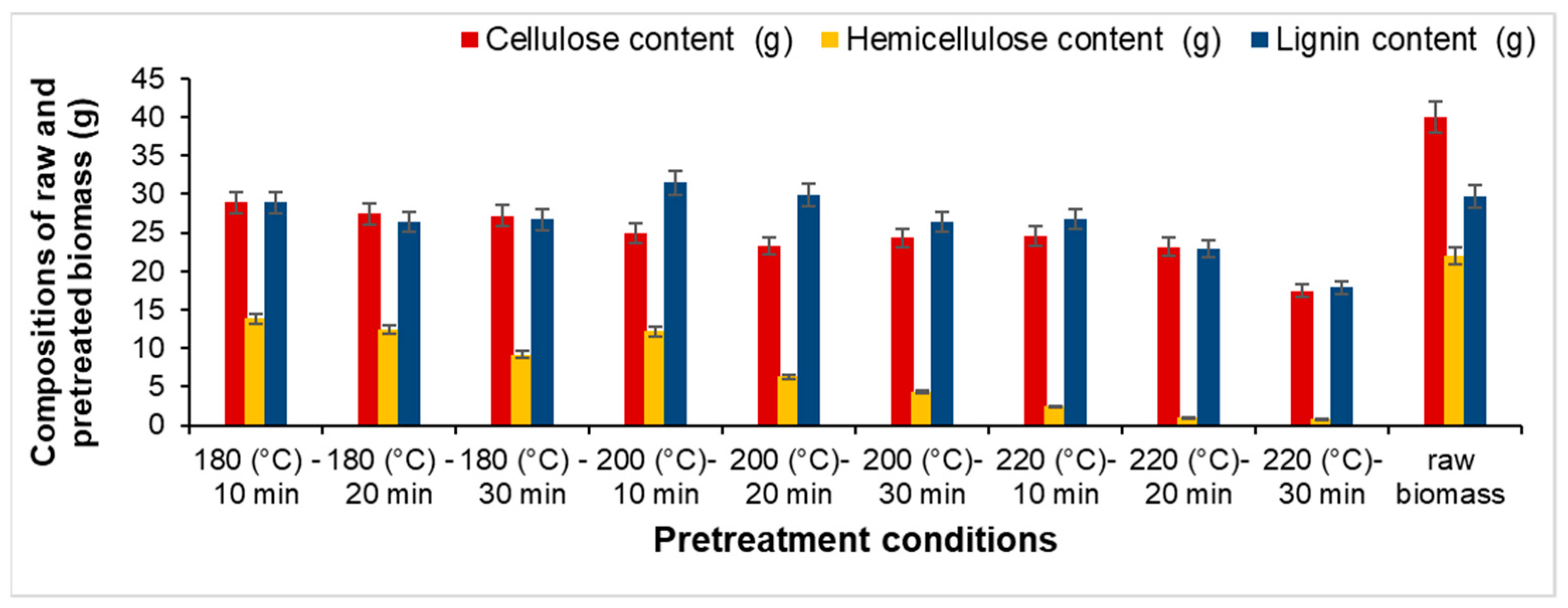

3.1. Chemical Compositions of the Raw Biomass

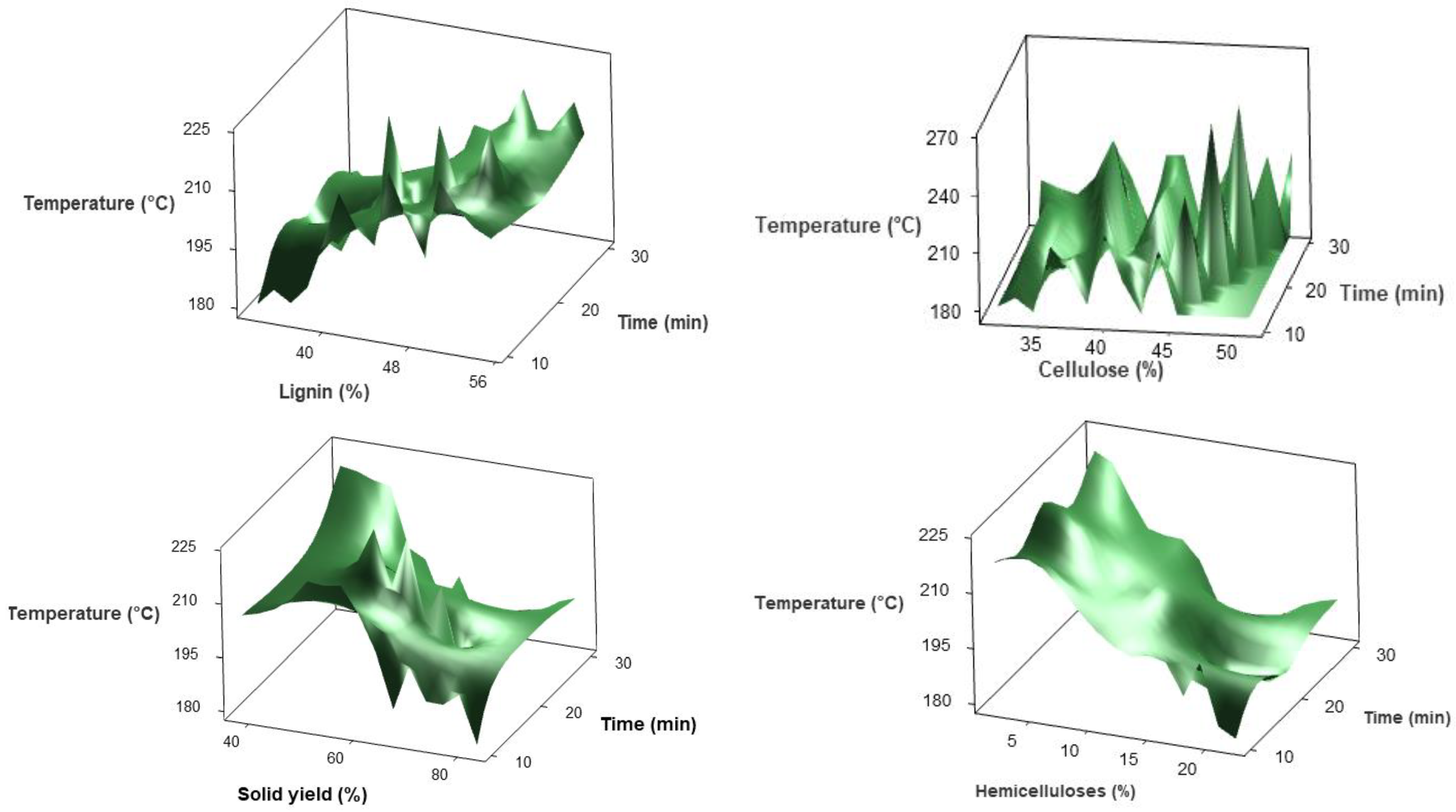

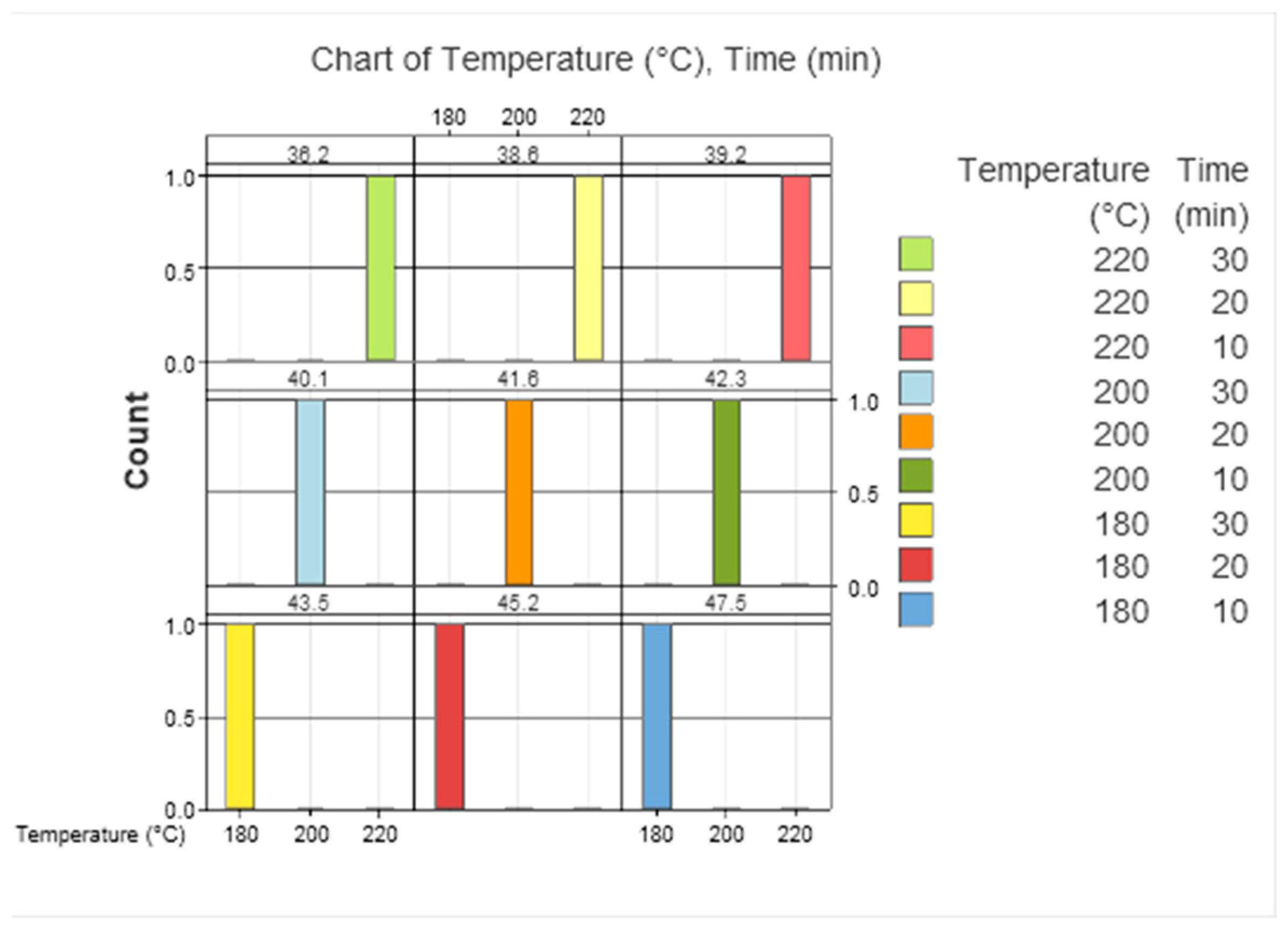

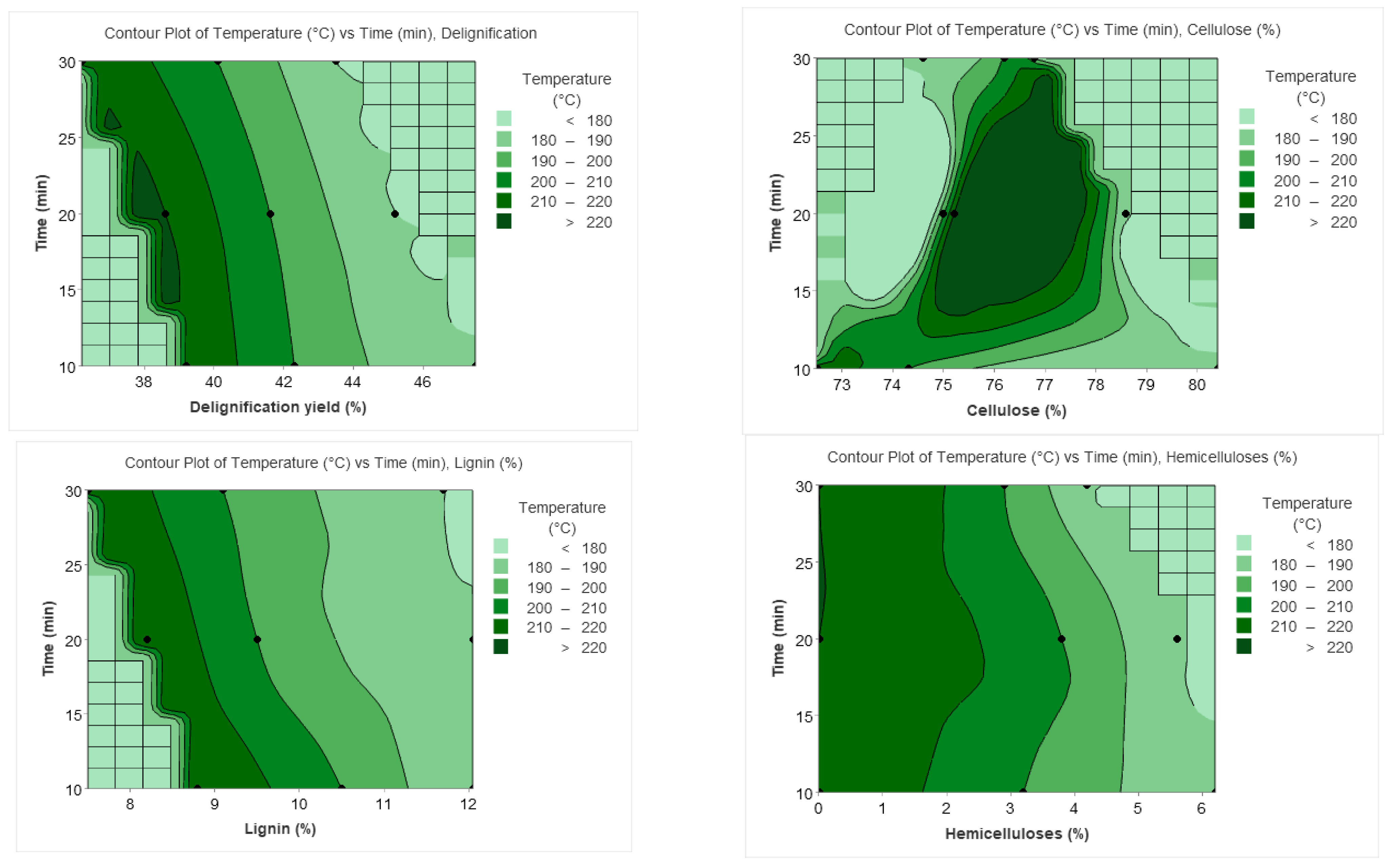

3.2. Chemical Compositions of the Pretreated Biomass Using Response Surface Methodology

3.3. Composition of Delignified Biomass

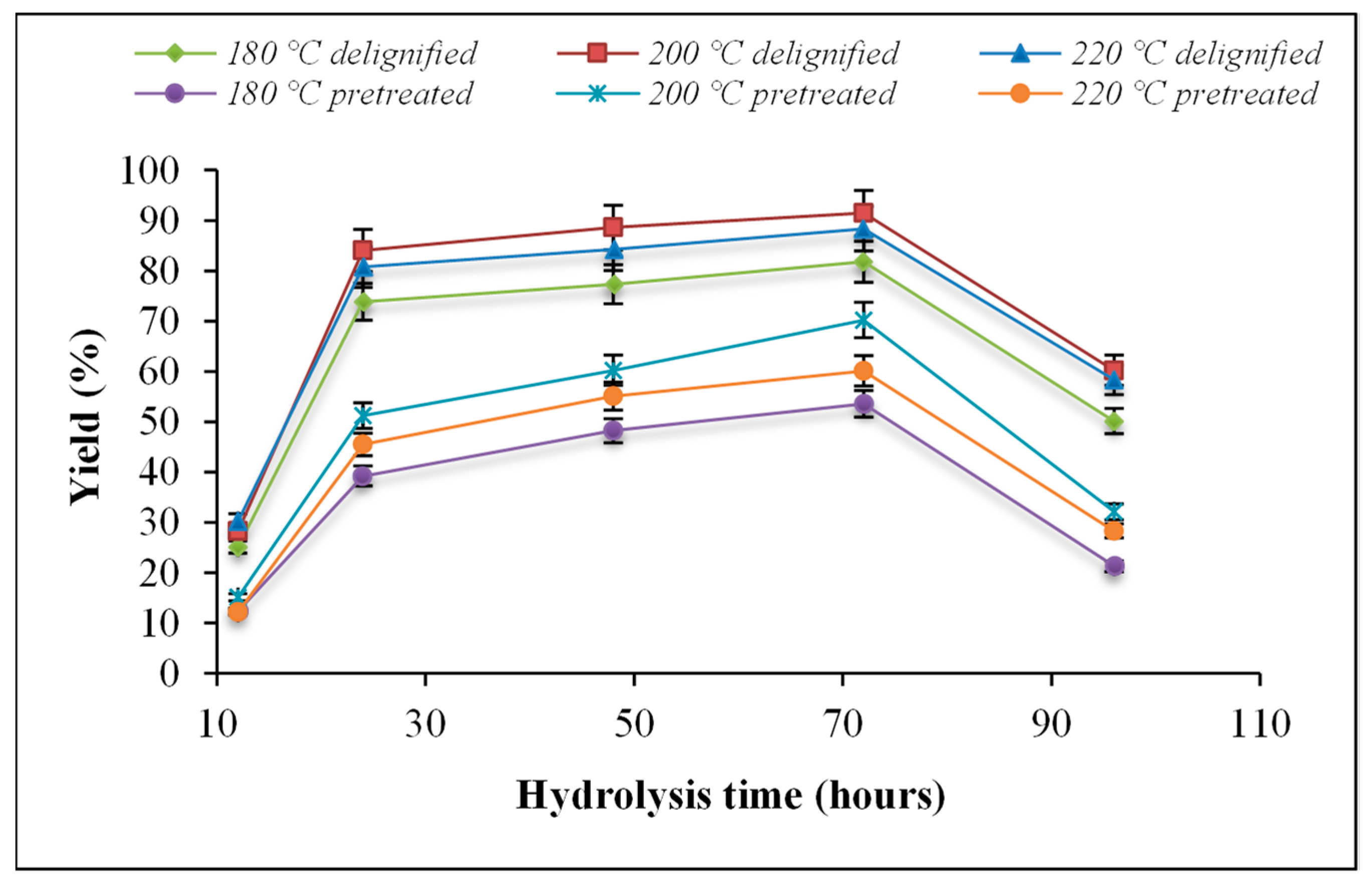

3.4. Enzymatic Hydrolysis of Pretreated and Delignified Biomass

3.5. PHB Production by Bacillus Megaterium ATCC 14581

3.6. Structural and Termal Characterization of PHB

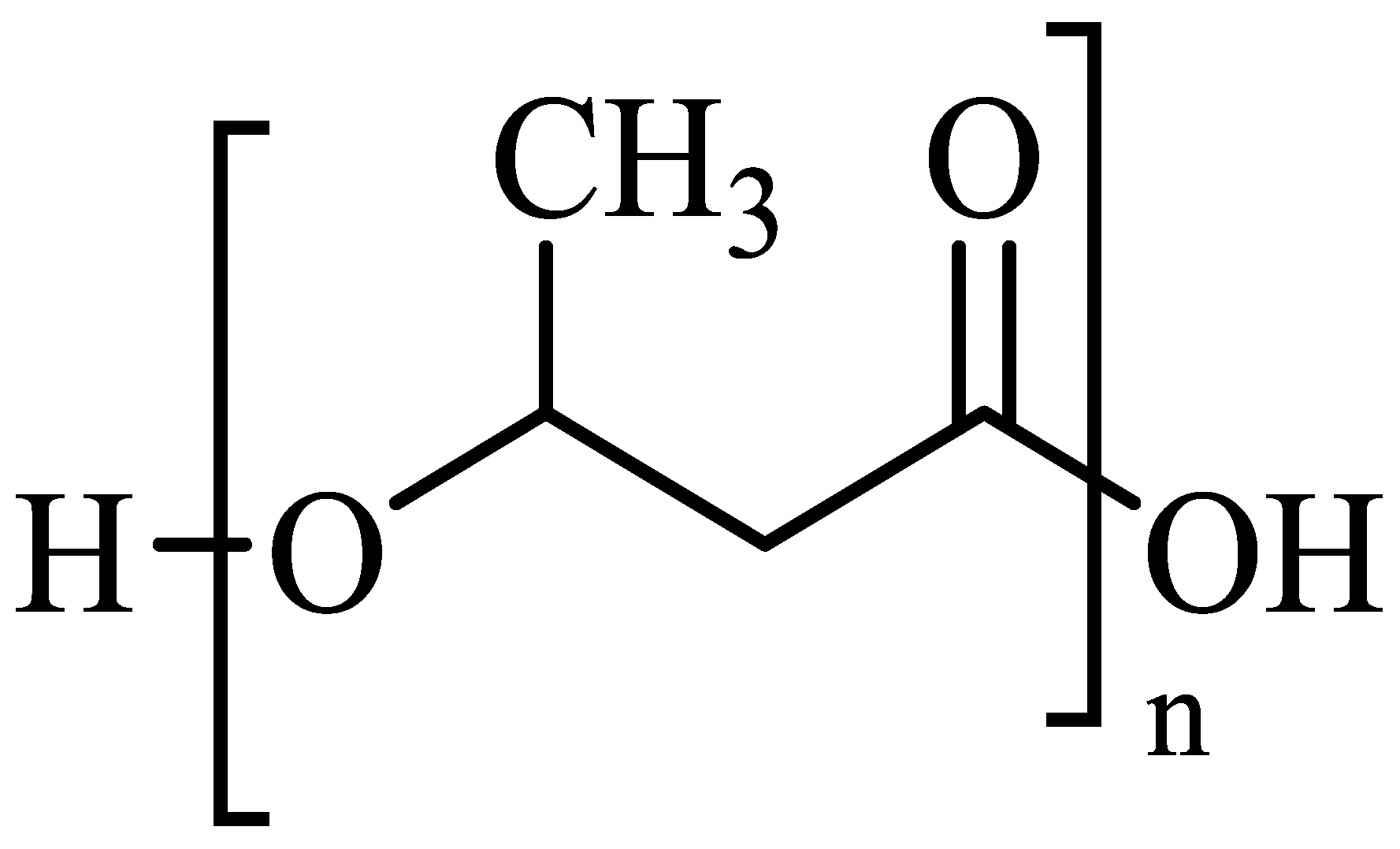

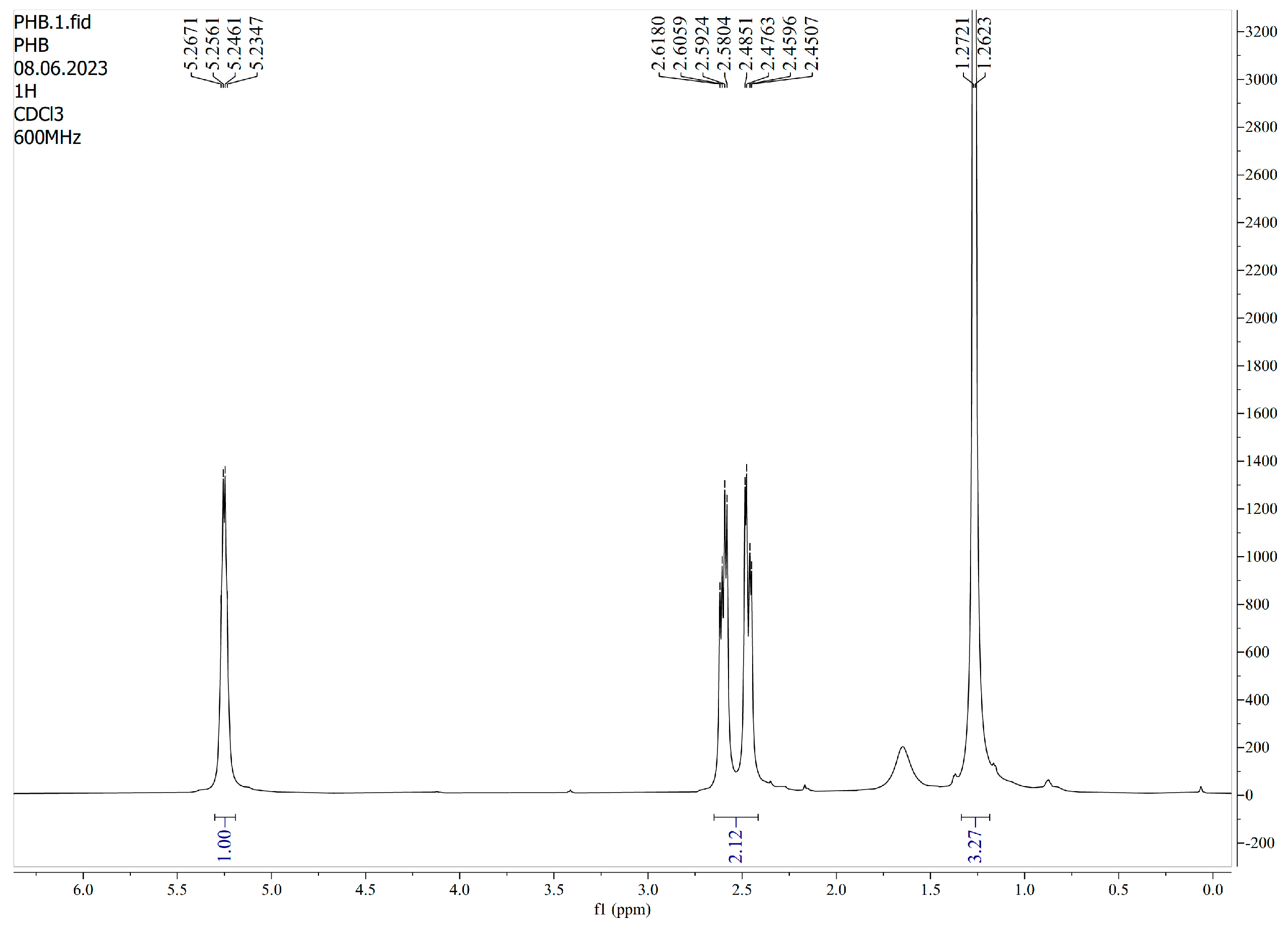

3.6.1. Proton Nuclear Magnetic Resonance (1H-NMR)

3.6.2. ESI-HRMS Spectra

3.6.3. Carbon Nuclear Magnetic Resonance (13C-NMR)

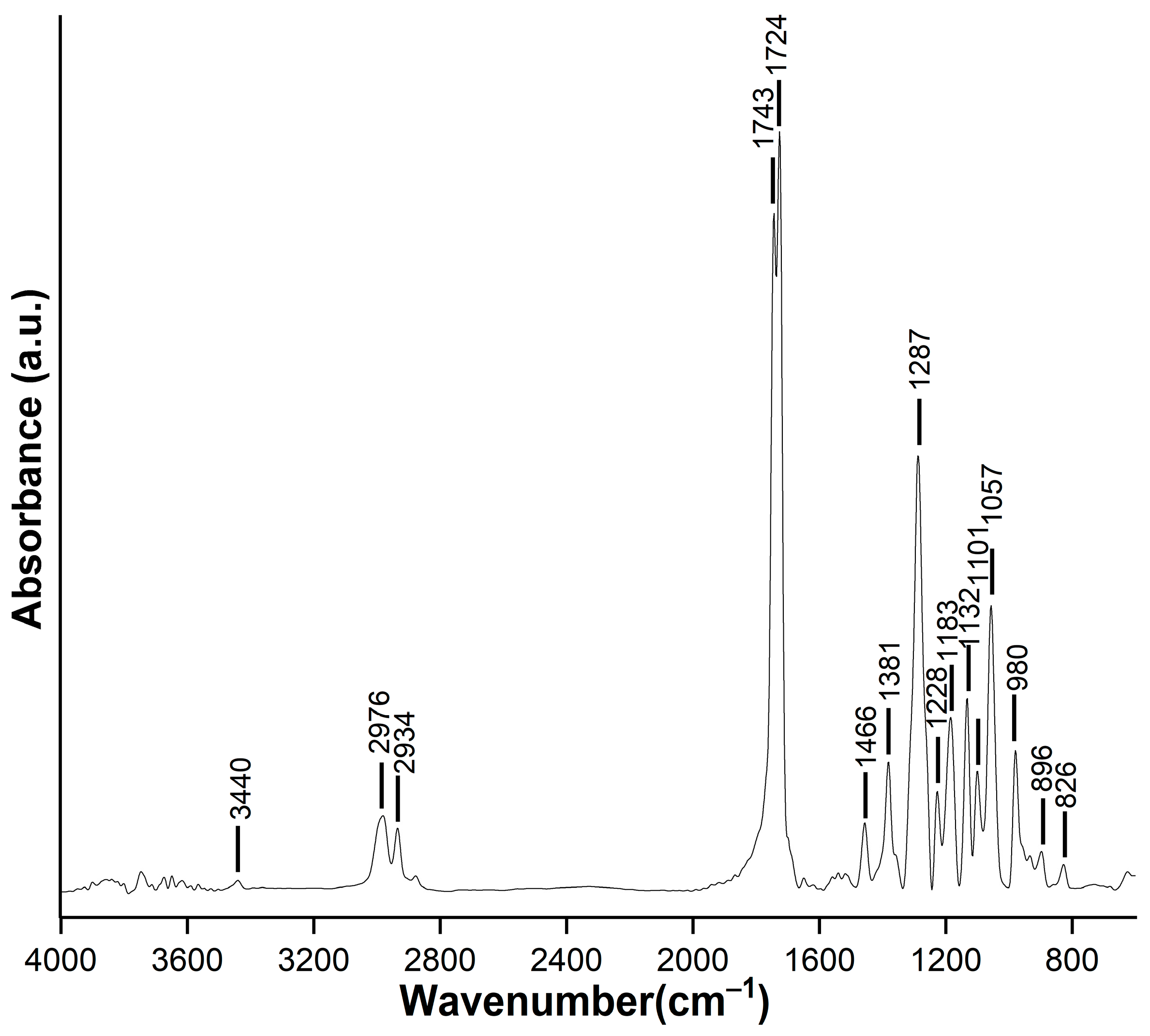

3.6.4. FT-IR Spectrum

3.6.5. TGA/DTG Analysis

3.6.6. XRD Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Thomas, A.P.; Kasa, V.P.; Dubey, B.K.; Sen, R.; Sarmah, A.K. Synthesis and commercialization of bioplastics: Organic waste as a sustainable feedstock. Sci. Total Environ. 2023, 904, 167243. [Google Scholar] [CrossRef]

- Stančin, H.; Strezov, V.; Mikulčić, H. Life cycle assessment of alternative fuel production by co-pyrolysis of waste biomass and plastics. J. Clean. Prod. 2023, 414, 137676. [Google Scholar] [CrossRef]

- Zhou, W.; Bergsma, S.; Colpa, D.I.; Euverink, G.-J.W.; Krooneman, J. Polyhydroxyalkanoates (PHAs) synthesis and degradation by microbes and applications towards a circular economy. J. Environ. Manag. 2023, 341, 118033. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Barletta, M.; Laheurte, P.; Langlois, V. Additive manufacturing of polyhydroxyalkanoates (PHAs) biopolymers: Materials, printing techniques, and applications. Mater. Sci. Eng. 2021, C127, 112216. [Google Scholar] [CrossRef]

- Noveli, L.D.D.; Cayavedra, S.M.; Rene, E.R. Polyhydroxyalkanoate (PHA) production via resource recovery from industrial waste streams: A review of techniques and perspectives. Bioresour. Technol. 2021, 331, 124985. [Google Scholar]

- Westlie, A.H.; Quinn, E.C.; Parker, C.R.; Chen, E.Y.-X. Synthetic biodegradable polyhydroxyalkanoates (PHAs): Recent advances and future challenges. Prog. Polym. Sci. 2022, 134, 101608. [Google Scholar]

- Muiruri, J.K.; Yeo, J.C.C.; Soo, X.Y.D.; Wang, S.; Liu, H.; Kong, J.; Cao, J.; Tan, B.H.; Suwardi, A.; Li, Z.; et al. Recent advances of sustainable Short-chain length polyhydroxyalkanoates (Scl-PHAs)—Plant biomass composites. Eur. Polym. J. 2023, 187, 111882. [Google Scholar] [CrossRef]

- Sohn, Y.J.; Son, J.; Lim, H.J.; Lim, S.H.; Park, S.J. Valorization of lignocellulosic biomass for polyhydroxyalkanoate production: Status and perspectives. Bioresour. Technol. 2022, 360, 127575. [Google Scholar] [CrossRef]

- González-Rojo, S.; Díez-Antolínez, R. Production of polyhydroxyalkanoates as a feasible alternative for an integrated multiproduct lignocellulosic biorefinery. Bioresour. Technol. 2023, 386, 129496. [Google Scholar] [CrossRef]

- Steinbüchel, A.; Valentin, H.E. Diversity of bacterial polyhydroxyalkanoic acids. FEMS Microbiol. Lett. 1995, 128, 219–228. [Google Scholar] [CrossRef]

- Yan, X.; Li, D.; Ma, X.; Li, J. Bioconversion of renewable lignocellulosic biomass into multicomponent substrate via pressurized hot water pretreatment for bioplastic polyhydroxyalkanoates accumulation. Bioresour. Technol. 2021, 339, 125667. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.F.; Taciro, M.K.; Ramos, M.E.M.; Carter, J.M.; Pradella, J.G.C.; Gomez, J.G.C. Poly-3-hydroxybutyrate (P3HB) production by bacteria from xylose, glucose and sugarcane bagasse hydrolysate. J. Ind. Microbiol. Biotechnol. 2004, 31, 245–254. [Google Scholar] [CrossRef] [PubMed]

- Bondar, M.; Pedro, F.; Oliveira, M.C.; da Fonseca, M.M.R.; Cesário, M.T. Red algae industrial residues as a sustainable carbon platform for the co-production of poly-3-hydroxybutyrate and gluconic acid by Halomonas boliviensis. Front. Bioeng. Biotechnol. 2022, 10, 934432. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Herrera, R.E.; Alemán-Huerta, M.E.; Rutiaga-Quiñones, O.M.; de Luna-Santillana, E.J.; Elufisan, T.O. A comprehensive view of Bacillus cereus as a polyhydroxyalkanoate (PHA) producer: A promising alternative to Petroplastics. Process Biochem. 2023, 129, 281–292. [Google Scholar] [CrossRef]

- Khomlaem, C.; Aloui, H.; Singhvi, M.; Kim, B.S. Production of polyhydroxyalkanoates and astaxanthin from lignocellulosic biomass in high cell density membrane bioreactor. Chem. Eng. J. 2023, 451, 138641. [Google Scholar] [CrossRef]

- Nygaard, D.; Yashchuk, O.; Noseda, D.G.; Araoz, B.; Hermida, E.B. Improved fermentation strategies in a bioreactor for enhancing poly(3-hydroxybutyrate) (PHB) production by wild type Cupriavidus necator from fructose. Helion 2021, 7, e05979. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, B.; Wang, F.; Ji, Y.; Gu, P.; Fan, X.; Li, Q. Response surface optimization of poly-β-hydroxybutyrate synthesized by Bacillus cereus L17 using acetic acid as carbon source. Int. J. Biol. Macromol. 2023, 247, 125628. [Google Scholar] [CrossRef]

- Kim, B.; Oh, S.J.; Hwang, J.H.; Kim, H.J.; Shin, N.; Bhatia, S.K.; Jeon, J.-M.; Yoon, J.-J.; Yoo, J.; Ahn, J.; et al. Polyhydroxybutyrate production from crude glycerol using a highly robust bacterial strain Halomonas sp. YLGW01. Int. J. Biol. Macromol. 2023, 236, 123997. [Google Scholar] [CrossRef]

- Cristea, A.; Baricz, A.; Leopold, N.; Floare, C.G.; Borodi, G.; Tripon, S.; Bulzu, P.A.; Andrei, A.-S.; Cadar, O.; Levei, E.A.; et al. Polyhydroxybutyrate production by an extremely halotolerant Halomonas elongate strain isolated from the hypersaline meromictic Fara Fund Lake. J. Appl. Microbiol. 2018, 125, 1343–1357. [Google Scholar] [CrossRef]

- Chiou, C.-Y.; Wang, H.-H.; Shaw, G.-C. Identification and characterization of the non-PTS fru locus of Bacillus megaterium ATCC 14581. Mol. Genet. Genom. 2002, 268, 240–248. [Google Scholar] [CrossRef]

- Cal, A.J.; Kibblewhite, R.E.; Sikkema, W.D.; Torres, L.F.; Hart-Cooper, W.M.; Orts, W.J.; Lee, C.C. Production of polyhydroxyalkanoate copolymers containing 4-hydroxybutyrate in engineered Bacillus megaterium. Int. J. Biol. Macromol. 2021, 168, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Israni, N.; Venkatachalam, P.; Gajaraj, B.; Nadumane, K.; Varalakshmi, K.N.; Shivakumar, S. Whey valorization for sustainable polyhydroxyalkanoate production by Bacillus megaterium: Production, characterization and in vitro biocompatibility evaluation. J. Environ. Manag. 2020, 255, 109884. [Google Scholar] [CrossRef] [PubMed]

- Senila, L.; Cadar, O.; Kovacs, E.; Gal, E.; Dan, M.; Stupar, Z.; Simedru, D.; Senila, M.; Roman, C. L-Poly(Lactic Acid) Production by Microwave Irradiation of Lactic Acid Obtained from Lignocellulosic Wastes. Int. J. Mol. Sci. 2023, 24, 9817. [Google Scholar] [CrossRef] [PubMed]

- Gunalan, S.; Thangaiag, A.; Rathnasamy, V.K.; Janaki, J.G.; Thiyagarajan, A.; Kuppusamy, S.; Arunachalam, L. Microwave-assisted extraction of biomolecules from moringa (Moringa oleifera Lam.) leaves var. PKM 1: A optimization study by response surface methodology (RSM). Kuwait J. Sci. 2023, 50, 339–344. [Google Scholar] [CrossRef]

- Sharma, L.; Alam, N.M.; Roy, S.; Satya, P.; Kar, G.; Ghosh, S.; Goswami, T.; Majumadar, B. Optimization of alkali pretreatment and enzymatic saccharification of jute (Corchorus olitorius L.) biomass using response surface methodology. Bioresour. Technol. 2023, 368, 128318. [Google Scholar] [CrossRef]

- Thuoc, D.V.; Chung, N.T.; Hatti-Kaul, R. Polyhydroxyalkanoate production from rice straw hydrolysate obtained by alkaline pretreatment and enzymatic hydrolysis using Bacillus strains isolated from decomposing straw. Bioresour. Bioprocess. 2021, 8, 98. [Google Scholar]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Dietrich, K.; Oliveira-Filho, E.R.; Dumont, M.-J.; Gomez, J.G.C.; Taciro, M.K.; da Silva, L.F.; Orsat, V.; Rio, L.F.D. Increasing PHB production with an industrially scalable hardwood hydrolysate as a carbon source. Ind. Crops Prod. 2020, 154, 112703. [Google Scholar] [CrossRef]

- Kucera, D.; Pernicová, I.; Kovalcik, A.; Mullerova, L.; Sedlacek, P.; Mravec, F.; Nebesarova, J.; Kalina, M.; Marova, I.; Krzyzanek, V.; et al. Characterization of the promising poly(3-hydroxybutyrate) producing halophilic bacterium Halomonas halophila. Bioresour. Technol. 2018, 256, 552–556. [Google Scholar] [CrossRef]

- Hathi, Z.J.; Haque, M.A.; Priya, A.; Qin, Z.-H.; Huang, S.; Lam, C.H.; Ladakis, D.; Pateraki, C.; Mettu, S.; Koutinas, A.; et al. Fermentative bioconversion of food waste into biopolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate) using Cupriavidus necator. Environ. Res. 2022, 215, 114323. [Google Scholar] [CrossRef]

- Senila, L.; Kovacs, E.; Scurtu, D.A.; Cadra, O.; Becze, A.; Senila, m.; Levei, E.A.; Dumitras, D.A.; Tenu, I.; Roman, C. Bioethanol Production from Vineyard Waste by Autohydrolysis Pretreatment and Chlorite Delignification via Simultaneous Saccharification and Fermentation. Molecules 2020, 25, 2606. [Google Scholar] [CrossRef] [PubMed]

- Bhati, R.; Samantaray, S.; Sharma, L.; Mallick, N. Poly-β-hydroxybutyrate accumulation in cyanobacteria under photoautotrophy. Biotechnool. J. 2010, 5, 1181–1185. [Google Scholar] [CrossRef] [PubMed]

- Rabiej, M. Application of the genetic algorithms and multi-objective optimization to the resolution of X-ray diffraction curves of semicrystalline polymers. Fibers Text. East. Eur. 2003, 11, 83. [Google Scholar]

- Shangdiar, S.; Cheng, P.-C.; Chen, S.-C.; Amesho, K.T.T.; Ponnusamy, V.K.; Lin, Y.-C. Enhancing sugar yield for bioconversion of rice straw: Optimization of Microwave-assisted Pretreatment using dilute acid hydrolysis. Environ. Technol. Innov. 2023, 32, 103313. [Google Scholar] [CrossRef]

- Sipponen, M.H.; Osterberg, M. Aqueous Ammonia Pre-treatment of Wheat Straw: Process Optimization and Broad Spectrum Dye Adsorption on Nitrogen-Containing Lignin. Front. Chem. 2019, 7, 545. [Google Scholar] [CrossRef]

- Tsafrakidou, P.; Moutsoglou, A.; Prodromidis, P.; Moschakis, T.; Goula, A.; Biliaderis, C.G.; Michaelidou, A.-M. Aqueous ammonia soaking pretreatment of spent coffee grounds for enhanced enzymatic hydrolysis: A bacterial cellulose production application. Sustain. Chem. Pharm. 2023, 33, 101121. [Google Scholar] [CrossRef]

- Park, Y.C.; Kim, J.S. Comparison of various alkaline pretreatment methods of lignocellulosic biomass. Energy 2012, 47, 31–35. [Google Scholar] [CrossRef]

- Kristensen, J.B.; Felby, C.; Jørgensen, H. Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol. Biofuels 2009, 2, 11. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.-K.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Varjani, S.; Nair, S.; Kim, D.-S.; Shin, H.-S.; et al. Developing Microbial Co-Culture System for Enhanced Polyhydroxyalkanoates (PHA) Production Using Acid Pretreated Lignocellulosic Biomass. Polymers 2022, 14, 726. [Google Scholar] [CrossRef]

- Yamane, T. Yield of Poly-3-Hydroxybutyrate from Various Carbon Sources: A Theoretical Study. Biotechnol. Bioeng. 1992, 41, 165–170. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Zhang, K.; Liu, M.; Liu, D.; Yan, X.; Si, M.; Shi, Y. Valorizing waste liquor from dilute acid pretreatment of lignocellulosic biomass by Bacillus megaterium B-10. Ind. Crops Prod. 2021, 161, 113160. [Google Scholar] [CrossRef]

- Saratale, G.D.; Oh, M.-K. Characterization of poly-3-hydroxybutyrate (PHB) produced from Ralstonia eutropha using an alkali-pretreated biomass feedstock. Int. J. Biol. Macromol. 2015, 80, 627–635. [Google Scholar] [CrossRef] [PubMed]

- Tadi, S.R.R.; Ravindran, S.D.; Balakrishnan, R.; Sivaprakasam, S. Recombinant production of poly-(3-hydroxybutyrate) by Bacillus megaterium utilizing millet bran and rapeseed meal hydrolysates. Bioresour. Technol. 2021, 326, 124800. [Google Scholar]

- De Sousa, L.; Manasa, Y.; Shivakumar, S. Bioconversion of lignocellulosic substrates for the production of polyhydroxyalkanoates. Biocatal. Agric. Biotechnol. 2020, 28, 101754. [Google Scholar] [CrossRef]

- Mohanrasu, K.; Rao, R.G.R.; Dinesh, G.H.; Zhang, K.; Prakash, G.S.; Song, D.-P.; Muniyasamy, S.; Pugazhendhi, A.; Jeyakanthan, J.; Arun, A. Optimization of media components and culture conditions for polyhydroxyalkanoates production by Bacillus megaterium. Fuel 2020, 271, 117522. [Google Scholar] [CrossRef]

- Schmid, M.T.; Song, H.; Raschbauer, M.; Emerstorfer, F.; Omann, M.; Stelzer, F.; Neureiter, M. Utilization of desugarized sugar beet molasses for the production of poly(3-hydroxybutyrate) by halophilic Bacillus megaterium uyuni S29. Process Biochem. 2019, 86, 9–15. [Google Scholar] [CrossRef]

- Nishida, M.; Tanaka, T.; Hayakawa, Y.; Nishida, M. Solid-State Nuclear Magnetic Resonance (NMR) and Nuclear Magnetic Relaxation Time Analyses of Molecular Mobility and Compatibility of Plasticized Polyhydroxyalkanoates (PHA) Copolymers. Polymers 2018, 10, 506. [Google Scholar] [CrossRef]

- Thammasittirong, A.; Saechow, S.; Thammasittirong, S.N. Efficient polyhydroxy butyrate production from Bacillus thuringiensis using sugarcane juice substrate. Turk. J. Biol. 2017, 41, 992–1002. [Google Scholar] [CrossRef]

- Rizzarelli, P.; Rapisarda, M. Matrix-Assisted Laser Desorption and Electrospray Ionization Tandem Mass Spectrometry of Microbial and Synthetic Biodegradable Polymers. Polymers 2023, 15, 2356. [Google Scholar] [CrossRef]

- Ekere, I.; Johnston, B.; Tchuenbou-Magaia, F.; Townrow, D.; Wojciechowski, S.; Marek, A.; Zawadiak, J.; Zieba, M.; Sikorska, W.; Adamus, G.; et al. Bioconversion Process of Polyethylene from Waste Tetra Pak® Packaging to Polyhydroxyalkanoates. Polymers 2022, 14, 2840. [Google Scholar] [CrossRef]

- Shaw, G.L.; Melby, M.K.; Horowitz, D.M.; Keeler, J.; Sanders, J.K.M. Nuclear magnetic resonance relaxation studies of poly(hydroxybutyrate) in whole cells and in artificial granules. Int. J. Biol. Macromol. 1994, 16, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Heitmann, A.P.; Patrício, P.S.O.; Coura, I.R.; Pedroso, E.F.; Souza, P.P.; Mansur, H.S.; Mansur, A.; Oliveira, L.C.A. Nanostructured niobium oxyhydroxide dispersed Poly(3-hydroxybutyrate) (PHB) films: Highly efficient photocatalysts for degradation methylene blue dye. Appl. Catal. B Environ. 2016, 189, 141–150. [Google Scholar] [CrossRef]

- Selvaraj, K.; Vishvanathan, N.; Dhandapani, R. Screening, optimization and characterization of poly hydroxy butyrate from fresh water microalgal isolates. Int. J. Biobased Plast. 2021, 3, 139–162. [Google Scholar] [CrossRef]

- Mottin, A.C.; Ayres, E.; Oréfice, R.L.; Câmara, J.J.D. What changes in poly (3-hydroxybutyrate) (PHB) when processed as electrospun nanofibers or thermo-compression molded film? Mater. Res. 2016, 19, 57–66. [Google Scholar] [CrossRef]

- Pradhan, S.; Dikshit, P.K.; Moholkar, V.S. Production, ultrasonic extraction, and characterization of poly (3-hydroxybutyrate) (PHB) using Bacillus megaterium and Cupriavidus necator. Polym. Advan. Technol. 2018, 29, 2392–2400. [Google Scholar] [CrossRef]

- Skrbić, Z.; Divjaković, V. Temperature influence on changes of parameters of the unit cell of biopolymer PHB. Polymer 1996, 37, 505–507. [Google Scholar] [CrossRef]

- Siracusa, V.; Karpova, S.; Olkhov, A.; Zhulkina, A.; Kosenko, R.; Iordanskii, A. Gas Transport Phenomena and Polymer Dynamics in PHB/PLA Blend Films as Potential Packaging Materials. Polymer 2020, 12, 647. [Google Scholar] [CrossRef] [PubMed]

| Input Variables | Symbols | Levels | ||

|---|---|---|---|---|

| Low Factorial (−1) | Center Point (0) | High Factorial (+1) | ||

| Temperature (°C) | X1 | 180 | 200 | 220 |

| Time (min) | X2 | 10 | 20 | 30 |

| Temperature (°C) | 180 | 180 | 180 | 200 | 200 | 200 | 220 | 220 | 220 |

|---|---|---|---|---|---|---|---|---|---|

| Time (min) | 10 | 20 | 30 | 10 | 20 | 30 | 10 | 20 | 30 |

| Solid yield (% of raw material, dry biomass) | 75.2 ± 2.1 | 68.3 ± 1.8 | 64.2 ± 1.5 | 70.5 ± 2.3 | 62.1 ± 3.2 | 56.3 ± 2.1 | 58.2 ± 2.6 | 50.1 ± 2.1 | 42.3 ± 1.8 |

| Cellulose (% of autohydrolyzed biomass, dry biomass) | 38.4 ± 1.1 | 40.2 ± 1.5 | 42.3 ± 1.4 | 35.4 ± 1.6 | 37.5 ± 1.8 | 43.2 ± 2.0 | 42.2 ± 2.1 | 46.2 ± 1.5 | 41.2 ± 1.6 |

| Hemicelluloses (% of autohydrolyzed biomass, dry biomass) | 20.1 ± 1.1 | 18.2 ± 1.1 | 14.3 ± 1.2 | 17.3 ± 0.9 | 10.1 ± 0.8 | 7.6 ± 0.06 | 4.2 ± 0.02 | 2.1 ± 0.01 | 1.8 ± 0.02 |

| Lignin (% of autohydrolyzed biomass, dry biomass) | 37.2 ± 1.3 | 38.6 ± 1.2 | 41.6 ± 1.6 | 44.6 ± 1.4 | 48.2 ± 1.2 | 46.8 ± 1.5 | 46 ± 1.8 | 45.6 ± 2.1 | 42.2 ± 1.7 |

| Solid compositions (% of autohydrolyzed biomass, dry biomass) | 95.7 ± 2.1 | 97 ± 3.2 | 98.2 ± 3.1 | 97.3 ± 2.5 | 95.8 ± 2.4 | 97.6 ± 2.8 | 90.4 ± 1.7 | 91.8 ± 1.9 | 97.6 ± 2.4 |

| s | R2 (%) | R2 (adj) (%) | R2 (Predicted) (%) | |

|---|---|---|---|---|

| Solid yield | 1.31 | 99.20 | 98.40 | 95.95 |

| Cellulose | 1.09 | 94.68 | 93.50 | 91.29 |

| Hemicelluloses | 1.84 | 95.30 | 92.94 | 90.68 |

| Lignin | 1.34 | 95.71 | 91.41 | 91.25 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 5 | 1980.73 | 396.15 | 10.40 | <0.0001 |

| Linear | 2 | 1917.99 | 959.00 | 25.18 | <0.0001 |

| X1 | 1 | 1073.39 | 1073.39 | 28.18 | <0.0001 |

| X2 | 1 | 844.61 | 844.61 | 22.17 | <0.0001 |

| Square | 2 | 44.73 | 22.37 | 0.59 | 0.565 |

| X1 X1 | 1 | 17.57 | 17.57 | 0.46 | 0.504 |

| X2 X2 | 1 | 27.16 | 27.16 | 0.71 | 0.408 |

| Two-Way Interaction | 1 | 18.01 | 18.01 | 0.47 | 0.499 |

| X1 X2 | 1 | 18.01 | 18.01 | 0.47 | 0.499 |

| Error | 21 | 799.93 | 38.09 | ||

| Lack-of-Fit | 3 | 180.21 | 60.07 | 1.74 | 0.194 |

| Pure Error | 18 | 619.72 | 34.43 | ||

| Total | 26 | 2780.66 |

| Carbon Source | Pretreatment Used | Microorganism | PHB | Reference |

|---|---|---|---|---|

| C (g/L) | ||||

| Rice straw | Sulfuric acid pretreatment | Bacillus megaterium B-10 | 1.496 | [41] |

| Lignocellulosic biomass (soybean husk, sunflower husk, wood straw) | Alkaline pretreatment | Ralstonia eutropha ATCC 17699 | 11.42 g/L PHB accumulation 74.45% | [42] |

| Rapeseed meal hydrolysates | Acid hydrolysis | Bacillus megaterium DSM 319 | 15.0 g/L | [43] |

| Lignocellulosic substrates (rice straw, corn husk, sugarcane bagasse, newspaper, wheat bran) | Biological pretreatment (Pleurotus ostreatus MTCC 142) | Bacillus megaterium Ti3 | 1 g/L (57.8% after 48 h) | [44] |

| Marine environment | - | Bacillus megaterium | 5.61 g/L | [45] |

| Sugar beet molasses | Bacillus megateriumuyuni S29 | 60 g P(3HB)/100 g cell dry biomass | [46] | |

| Cherry orchard waste | Microwave irradiation and ammonia delignification | Bacillus megaterium ATCC 14581 | 3.02 g/L | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senila, L.; Gál, E.; Kovacs, E.; Cadar, O.; Dan, M.; Senila, M.; Roman, C. Poly(3-hydroxybutyrate) Production from Lignocellulosic Wastes Using Bacillus megaterium ATCC 14581. Polymers 2023, 15, 4488. https://doi.org/10.3390/polym15234488

Senila L, Gál E, Kovacs E, Cadar O, Dan M, Senila M, Roman C. Poly(3-hydroxybutyrate) Production from Lignocellulosic Wastes Using Bacillus megaterium ATCC 14581. Polymers. 2023; 15(23):4488. https://doi.org/10.3390/polym15234488

Chicago/Turabian StyleSenila, Lacrimioara, Emese Gál, Eniko Kovacs, Oana Cadar, Monica Dan, Marin Senila, and Cecilia Roman. 2023. "Poly(3-hydroxybutyrate) Production from Lignocellulosic Wastes Using Bacillus megaterium ATCC 14581" Polymers 15, no. 23: 4488. https://doi.org/10.3390/polym15234488

APA StyleSenila, L., Gál, E., Kovacs, E., Cadar, O., Dan, M., Senila, M., & Roman, C. (2023). Poly(3-hydroxybutyrate) Production from Lignocellulosic Wastes Using Bacillus megaterium ATCC 14581. Polymers, 15(23), 4488. https://doi.org/10.3390/polym15234488