Characterization of Photocurable IP-PDMS for Soft Micro Systems Fabricated by Two-Photon Polymerization 3D Printing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. The 2PP Printing Parameters

2.3. Wettability Tests

2.4. FTIR

2.5. Nanoindentation

2.6. Friction Test

2.7. Dielectric Properties Tests

3. IP-PDMS Characterization

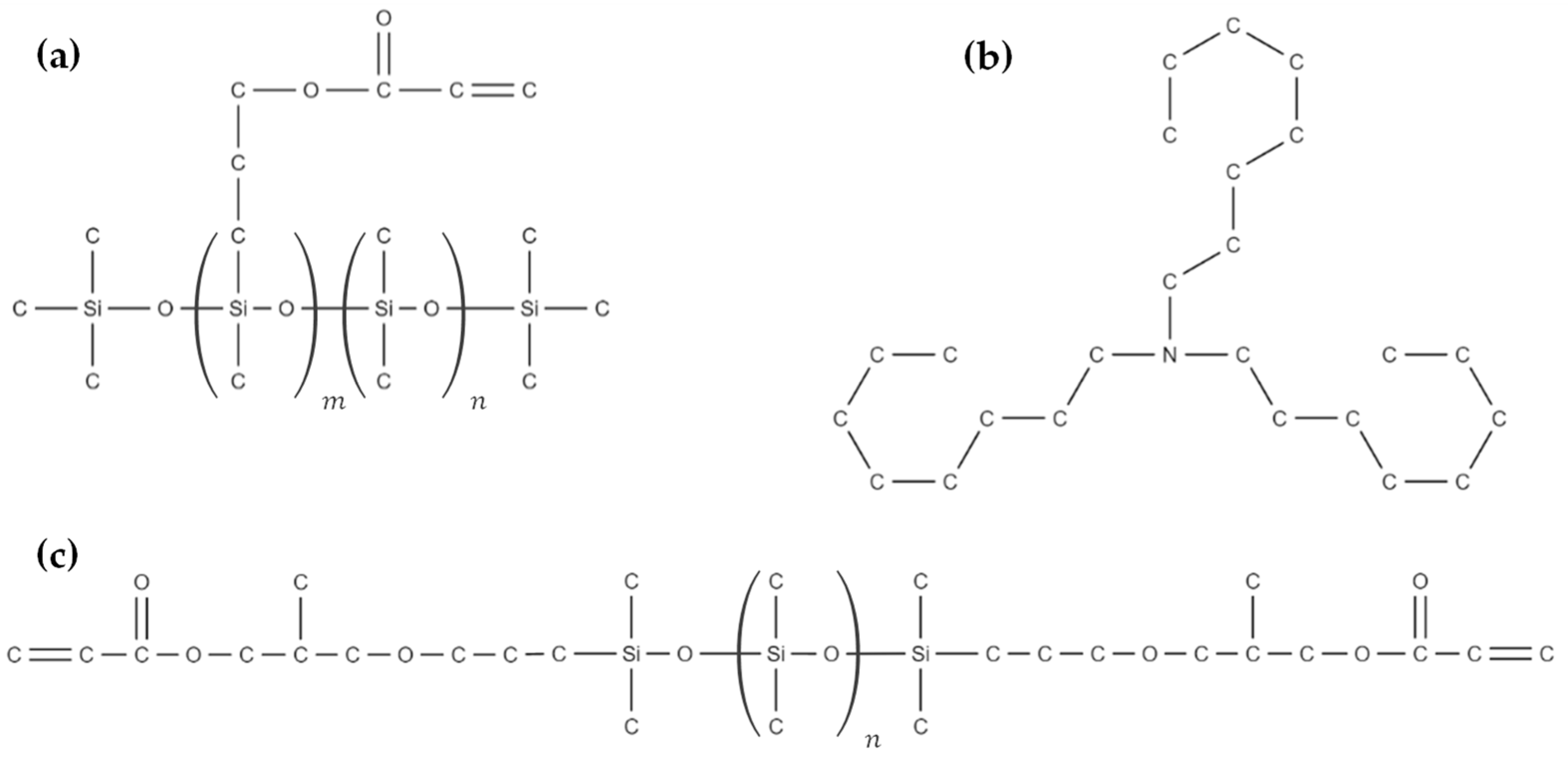

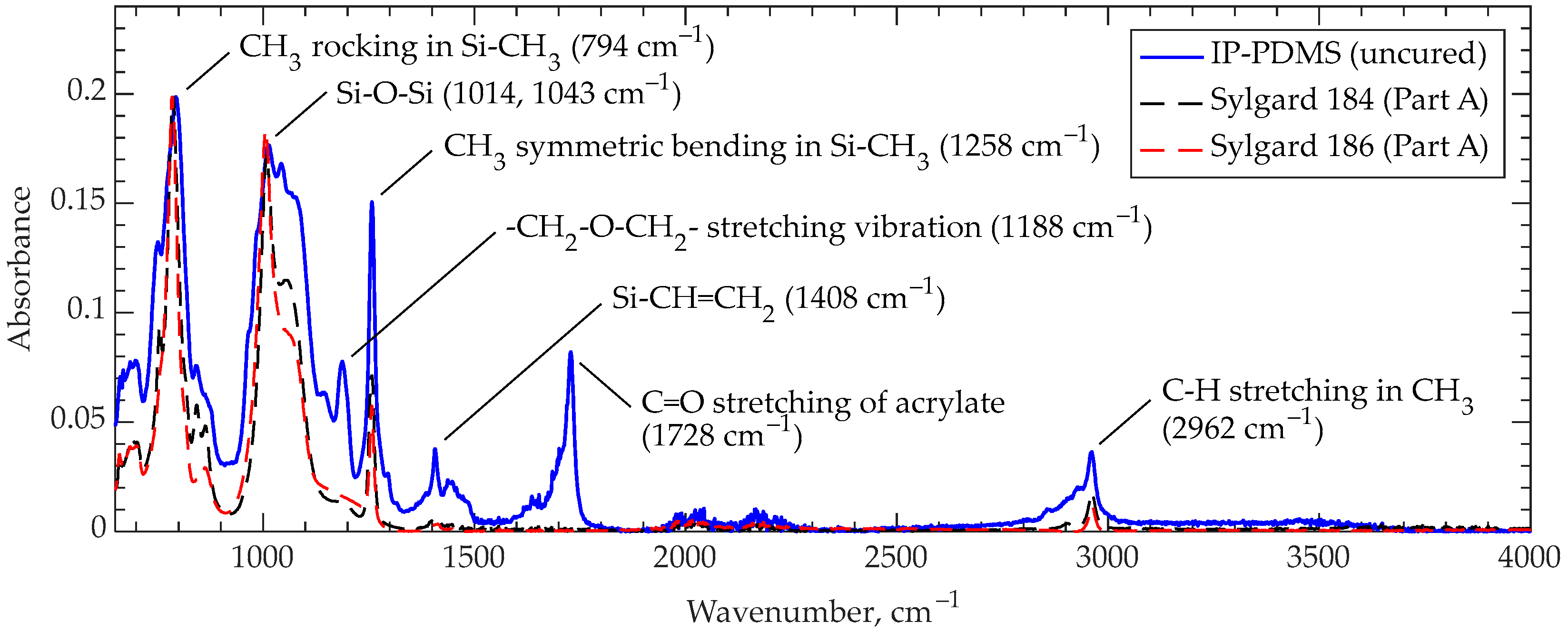

3.1. Composition Characterization of Uncured IP-PDMS through FTIR

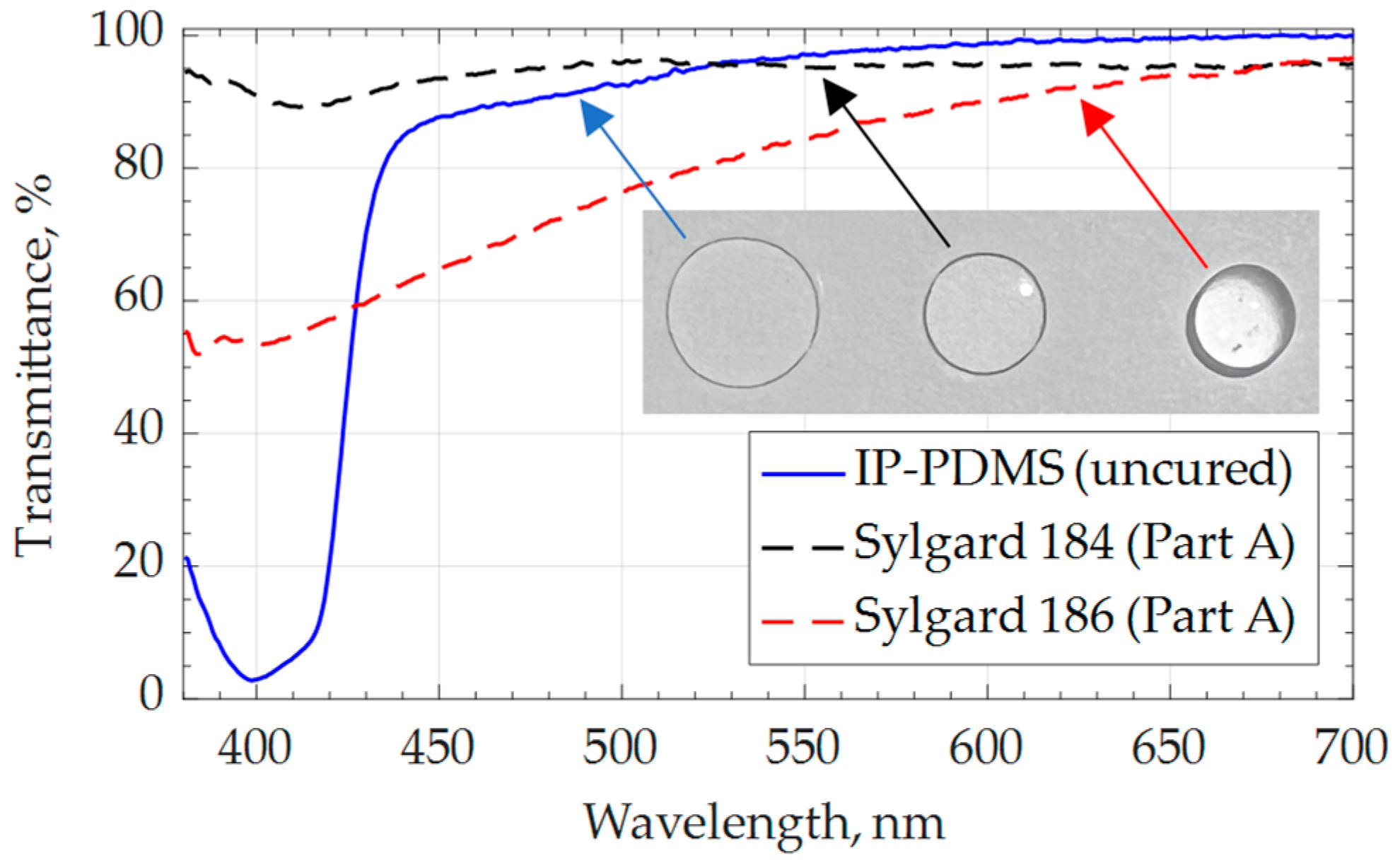

3.2. Transmittance of Uncured IP-PDMS

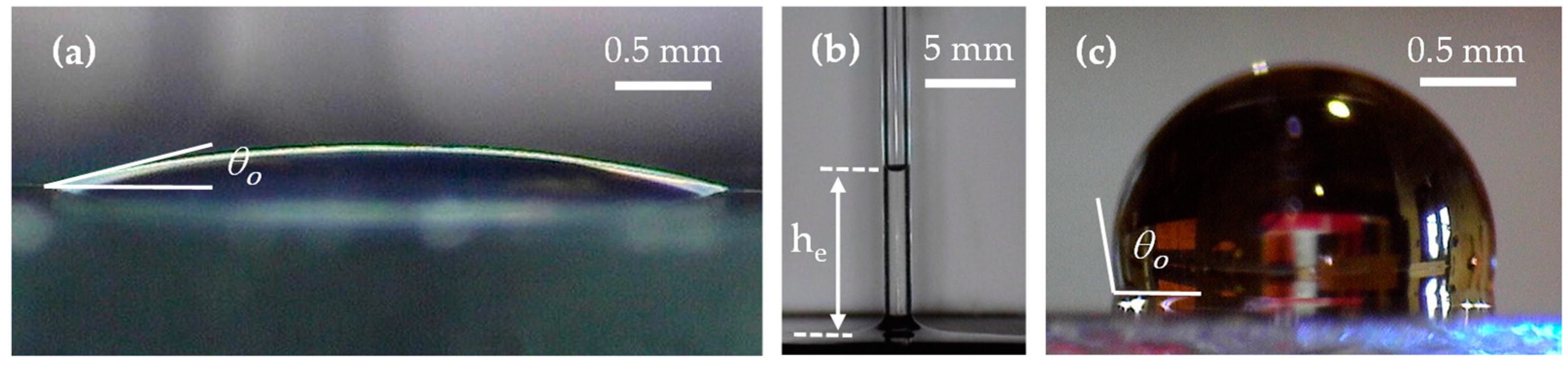

3.3. Wettability Properties of Uncured IP-PDMS

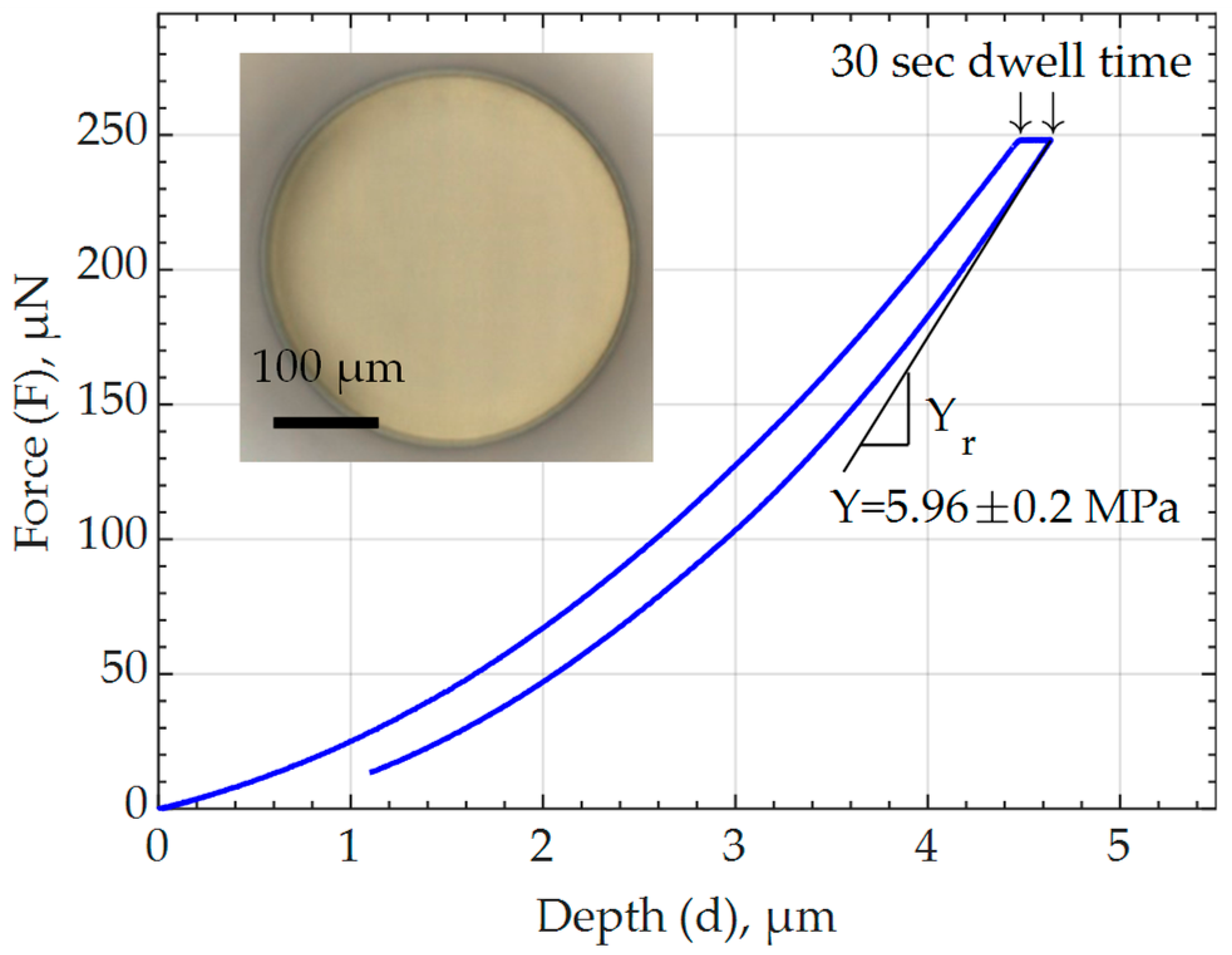

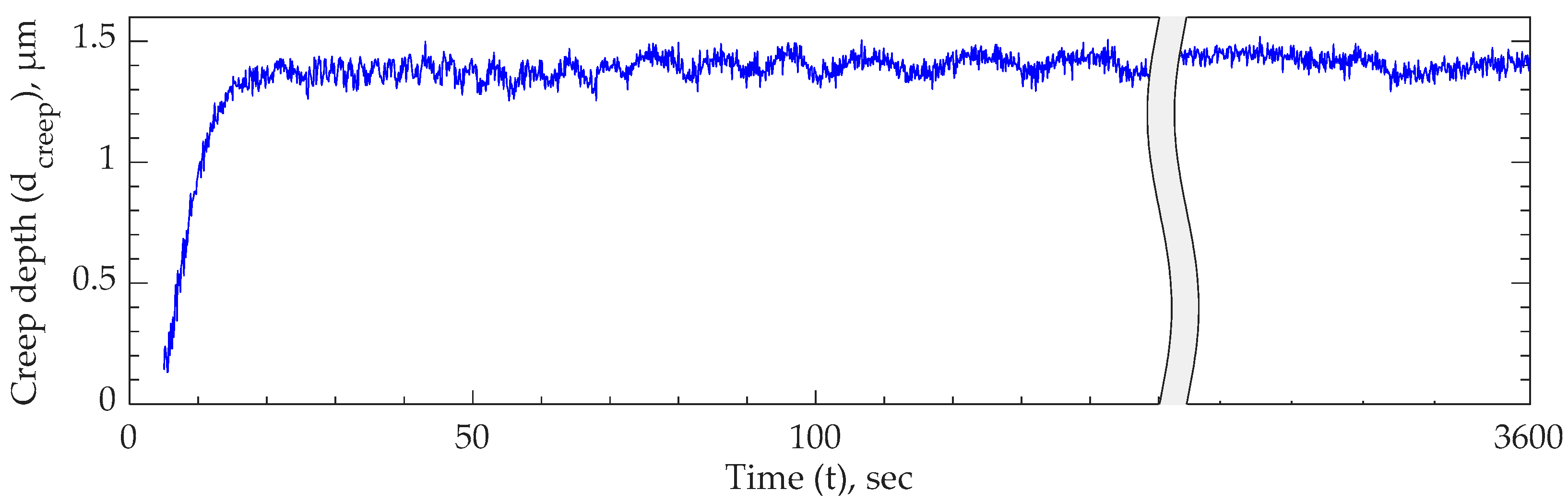

3.4. Mechanical Properties of Cured IP-PDMS through Nanoindentation

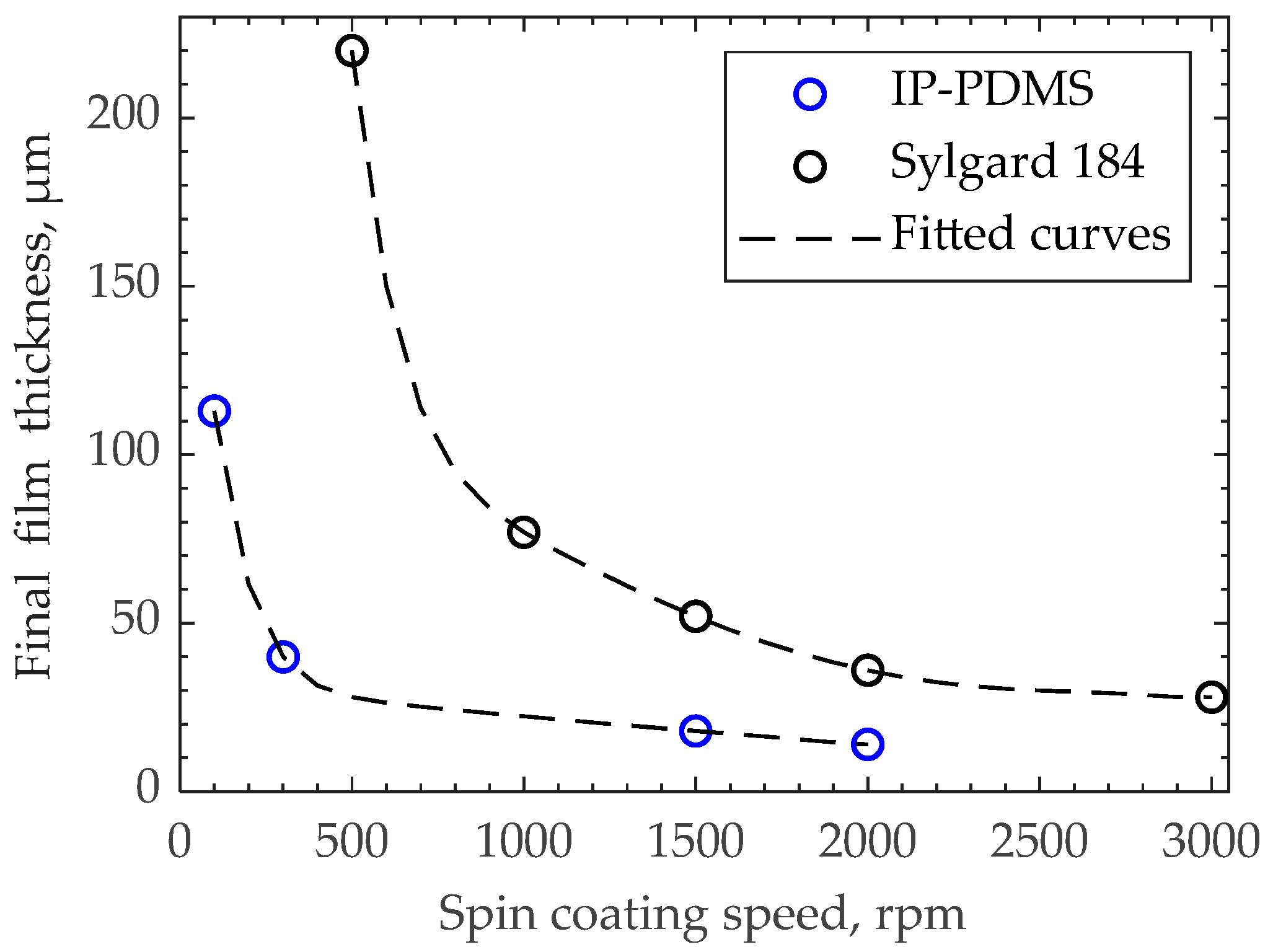

3.5. Spin Coating of Uncured IP-PDMS

3.6. Friction Coefficients of Cured IP-PDMS

3.7. Dielectric Properties of Cured IP-PDMS

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rogkas, N.; Vakouftsis, C.; Spitas, V.; Lagaros, N.D.; Georgantzinos, S.K. Design Aspects of Additive Manufacturing at Microscale: A Review. Micromachines 2022, 13, 775. [Google Scholar] [CrossRef] [PubMed]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2012, 67, 1721–1754. [Google Scholar] [CrossRef]

- Regis, J.E.; Renteria, A.; Hall, S.E.; Hassan, M.S.; Marquez, C.; Lin, Y. Recent Trends and Innovation in Additive Manufacturing of Soft Functional Materials. Materials 2021, 14, 4521. [Google Scholar] [CrossRef] [PubMed]

- Verma, R.; Adhikary, R.R.; Banerjee, R. Smart material platforms for miniaturized devices: Implications in disease models and diagnostics. Lab A Chip 2016, 16, 1978–1992. [Google Scholar] [CrossRef]

- Li, S.; Bai, H.; Shepherd, R.F.; Zhao, H. Bio-inspired Design and Additive Manufacturing of Soft Materials, Machines, Robots, and Haptic Interfaces. Angew. Chem. Int. Ed. 2019, 58, 11182–11204. [Google Scholar] [CrossRef]

- Bunea, A.-I.; del Castillo Iniesta, N.; Droumpali, A.; Wetzel, A.E.; Engay, E.; Taboryski, R. Micro 3D Printing by Two-Photon Polymerization: Configurations and Parameters for the Nanoscribe System. Micro 2021, 1, 164–180. [Google Scholar] [CrossRef]

- Tony, A.; Badea, I.; Yang, C.; Liu, Y.; Wells, G.; Wang, K.; Yin, R.; Zhang, H.; Zhang, W. The Additive Manufacturing Approach to Polydimethylsiloxane (PDMS) Microfluidic Devices: Review and Future Directions. Polymers 2023, 15, 1926. [Google Scholar] [CrossRef]

- Busche, J.F.; Starke, G.; Knickmeier, S.; Dietzel, A. Controllable dry adhesion based on two-photon polymerization and replication molding for space debris removal. Micro Nano Eng. 2020, 7, 100052–100057. [Google Scholar] [CrossRef]

- Nanoscribe GmbH & Co. KG. IP-PDMS Photoresin. Elastic Biocompatible Printing Material for Various Applications. Available online: https://www.nanoscribe.com/en/products/ip-photoresins/ip-pdms/ (accessed on 8 August 2023).

- van Altena, P.F.J.; Accardo, A. Micro 3D Printing Elastomeric IP-PDMS Using Two-Photon Polymerisation: A Comparative Analysis of Mechanical and Feature Resolution Properties. Polymers 2023, 15, 1816. [Google Scholar] [CrossRef]

- Sharaf, A.; Frimat, J.P.; Kremers, G.J.; Accardo, A. Suppression of auto-fluorescence from high-resolution 3D polymeric architectures fabricated via two-photon polymerization for cell biology applications. Micro Nano Eng. 2023, 19, 100188–100197. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Dong, X.; Ren, Z.; Hu, W.; Sitti, M. Creating three-dimensional magnetic functional microdevices via molding-integrated direct laser writing. Nat. Commun. 2022, 13, 2016–2026. [Google Scholar] [CrossRef] [PubMed]

- Lüken, A.; Stüwe, L.; Rauer, S.B.; Oelker, J.; Linkhorst, J.; Wessling, M. Fabrication, Flow Assembly, and Permeation of Microscopic Any-Shape Particles. Small 2022, 18, 2107508–2107519. [Google Scholar] [CrossRef] [PubMed]

- Bunea, A.-I.; Szczotka, N.; Navne, J.; Taboryski, R. Single-step fabrication of superhydrophobic surfaces by two-photon polymerization micro 3D printing. Micro Nano Eng. 2023, 19, 100192–100198. [Google Scholar] [CrossRef]

- van Kesteren, S.; Shen, X.; Aldeghi, M.; Isa, L. Printing on particles: Combining two-photon nanolithography and capillary assembly to fabricate multi-material microstructures. Adv. Mater. 2022, 35, 2207101–2207110. [Google Scholar] [CrossRef]

- Adam, G.; Ulliac, G.; Clevy, C.; Cappelleri, D.J. 3D printed vision-based micro-force sensors for microrobotic applications. J. Micro-Bio Robot. 2022, 18, 15–24. [Google Scholar] [CrossRef]

- Munding, N.; Fladung, M.; Chen, Y.; Hippler, M.; Ho, A.D.; Wegener, M.; Bastmeyer, M.; Tanaka, M. Bio-Metamaterials for Mechano-Regulation of Mesenchymal Stem Cells. Adv. Funct. Mater. 2023, 2301133. [Google Scholar] [CrossRef]

- Nanoscribe GmbH & Co. KG. IP-PDMS; MSDS No. IP-PDMS; Nanoscribe: Eggenstein-Leopoldshafen, Germany, 2021. [Google Scholar]

- Arkles, B. Reactive Silicones: Forging New Polymer Links; Gelest, Inc.: Frankfurt am Main, Germany, 2013. [Google Scholar]

- Carpi, F.; Anderson, I.; Bauer, S.; Frediani, G.; Gallone, G.; Gei, M.; Graaf, C.; Jean-Mistral, C.; Kaal, W.; Kofod, G.; et al. Standards for dielectric elastomer transducers. Smart Mater. Struct. 2015, 24, 105025–105049. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Kim, H.; Bae, Y.M.; Lee, K.-H.; Cho, H.J. Effect of thermal treatment on the chemical resistance of polydimethylsiloxane for microfluidic devices. J. Micromechanics Microengineering 2013, 23, 035007–035013. [Google Scholar] [CrossRef]

- Johnson, L.M.; Gao, L.; Shields Iv, C.W.; Smith, M.; Efimenko, K.; Cushing, K.; Genzer, J.; López, G.P. Elastomeric microparticles for acoustic mediated bioseparations. J. Nanobiotechnology 2013, 11, 22:21–22:28. [Google Scholar] [CrossRef]

- Stafie, N.; Stamatialis, D.F.; Wessling, M. Effect of PDMS cross-linking degree on the permeation performance of PAN/PDMS composite nanofiltration membranes. Sep. Purif. Technol. 2005, 45, 220–231. [Google Scholar] [CrossRef]

- Saha, S.K.; Divin, C.; Cuadra, J.A.; Panas, R.M. Effect of Proximity of Features on the Damage Threshold During Submicron Additive Manufacturing Via Two-Photon Polymerization. J. Micro Nano-Manuf. 2017, 5, 031002–031011. [Google Scholar] [CrossRef]

- Hamraoui, A.; Nylander, T. Analytical Approach for the Lucas–Washburn Equation. J. Colloid Interface Sci. 2002, 250, 415–421. [Google Scholar] [CrossRef]

- Madsen, F.B.; Daugaard, A.E.; Hvilsted, S.; Skov, A.L. The Current State of Silicone-Based Dielectric Elastomer Transducers. Macromol. Rapid Commun. 2016, 37, 378–413. [Google Scholar] [CrossRef]

- Vaicekauskaite, J.; Mazurek, P.; Vudayagiri, S.; Ladegaard Skov, A. Silicone elastomer map: Design the ideal elastomer. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Denver, CO, USA, 4–5 March 2019. [Google Scholar] [CrossRef]

- Sikulskyi, S.; Ren, Z.; Mekonnen, D.T.; Holyoak, A.; Srinivasaraghavan Govindarajan, R.; Kim, D. Additively manufactured unimorph dielectric elastomer actuators: Design, materials, and fabrication. Front. Robot. AI 2022, 9, 1034914–1034932. [Google Scholar] [CrossRef] [PubMed]

- Moučka, R.; Sedlačík, M.; Osička, J.; Pata, V. Mechanical properties of bulk Sylgard 184 and its extension with silicone oil. Sci. Rep. 2021, 11, 19090–19098. [Google Scholar] [CrossRef] [PubMed]

- Kadooka, K.; Imamura, H.; Taya, M. Experimentally verified model of viscoelastic behavior of multilayer unimorph dielectric elastomer actuators. Smart Mater. Struct. 2016, 25, 105028–105041. [Google Scholar] [CrossRef]

- Chen, Y.; Agostini, L.; Moretti, G.; Fontana, M.; Vertechy, R. Dielectric elastomer materials for large-strain actuation and energy harvesting: A comparison between styrenic rubber, natural rubber and acrylic elastomer. Smart Mater. Struct. 2019, 28, 114001–114019. [Google Scholar] [CrossRef]

- Li, Z.; Yu, H.; Wang, Q.J. Contact Creep Behavior of Polydimethylsiloxane and Influence of Load, Tip Size, and Crosslink Density. Tribol. Lett. 2013, 49, 291–299. [Google Scholar] [CrossRef]

- Wang, Z.; Schmitt, D.R.; Wang, R. Modeling of viscoelastic properties of nonpermeable porous rocks saturated with highly viscous fluid at seismic frequencies at the core scale. J. Geophys. Res. Solid Earth 2017, 122, 6067–6086. [Google Scholar] [CrossRef]

- Epaarachchi, J.A. The effect of viscoelasticity on fatigue behaviour of polymer matrix composites. In Creep and Fatigue in Polymer Matrix Composites, Guedes, R.M., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 492–513. [Google Scholar] [CrossRef]

- Mata, A.; Fleischman, A.J.; Roy, S. Characterization of Polydimethylsiloxane (PDMS) Properties for Biomedical Micro/Nanosystems. Biomed. Microdevices 2005, 7, 281–293. [Google Scholar] [CrossRef]

- Placet, V.; Delobelle, P. Mechanical properties of bulk polydimethylsiloxane for microfluidics over a large range of frequencies and aging times. J. Micromechanics Microengineering 2015, 25, 035009–035016. [Google Scholar] [CrossRef]

- Lee, H.K.; Chang, S.I.; Yoon, E. A Flexible Polymer Tactile Sensor: Fabrication and Modular Expandability for Large Area Deployment. J. Microelectromechanical Syst. 2006, 15, 1681–1686. [Google Scholar] [CrossRef]

- Bistac, S.; Schmitt, M.; Ghorbal, A. Sliding Friction of Polymers: The Complex Role of Interface. World Tribol. Congr. 2007, 42010, 647–658. [Google Scholar] [CrossRef]

- Lee, S.-J.; Sohn, Y.-C.; Kim, C.-L. Friction and Wear Characteristics of Polydimethylsiloxane under Water-Based Lubrication Conditions. Materials 2022, 15, 3262. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Vudayagiri, S.; Jensen, L.A.; Skov, A.L. Temperature dependence of dielectric breakdown of silicone-based dielectric elastomers. Int. J. Smart Nano Mater. 2020, 11, 129–146. [Google Scholar] [CrossRef]

- Albuquerque, F.B.; Shea, H. Influence of humidity, temperature and prestretch on the dielectric breakdown strength of silicone elastomer membranes for DEAs. Smart Mater. Struct. 2020, 29, 105024–105032. [Google Scholar] [CrossRef]

- Foerster-Zuegel, F.; Solano-Arana, S.; Klug, F.; Schlaak, H. Dielectric breakdown strength measurements with silicone-based single-layer dielectric elastomer transducers. Smart Mater. Struct. 2019, 28, 075042–075049. [Google Scholar] [CrossRef]

- Kim, D.; Sikulskyi, S. 4D-printed dielectric elastomer soft robots: Modeling and fabrications. In Smart Materials in Additive Manufacturing, Volume 1: 4D Printing Principles and Fabrication; Bodaghi, M., Zolfagharian, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 19–54. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Hatching Distance | 0.3 µm |

| Slicing Distance | 0.3 µm |

| Contour Distance | 0.2 µm |

| Core Laser Power | 80%/40 mW |

| Shell Laser Power | 60%/30 mW |

| Core Scan Speed | 100,000 µm/s |

| Shell Scan Speed | 20,000 µm/s |

| Property | Value | Figure | |||

|---|---|---|---|---|---|

| Transmittance (uncured IP-PDMS resin) | >90% for wavelengths above 440 nm <20% for wavelengths below 420 nm | Figure 3 | |||

| Contact angle | 11.5 ± 0.6° (uncured IP-PDMS resin on glass) 103.7 ± 0.5° (water on cured spin coated IP-PDMS) | Figure 4a Figure 4c | |||

| Surface tension (uncured IP-PDMS resin) | 26.7 ± 4.2 mN/m | Figure 4b | |||

| Young’s modulus * | 5.96 ± 0.2 MPa | Figure 5 | |||

| Creep * | no secondary creep observed at room temperature | Figure 6 | |||

| Storage modulus * | 8.5–10 MPa @ 10–160 Hz | ~15 MPa @ ≥170 Hz | Figure 7 | ||

| Loss factor * | 0.05–0.15 @ 10–160 Hz | 0.4 @ 170 Hz | |||

| Friction coefficient with glass (spin coated cured IP-PDMS) | @ 10 µm/s | @ 33 µm/s | @ 100 µm/s | Figure 9 | |

| Static | 0.103 | 0.167 | 0.462 | ||

| Dynamic | 0.103 | 0.129 | 0.385 | ||

| Relative dielectric permittivity (spin coated cured IP-PDMS) | 2.63 ± 0.02 @ 101–104 Hz | - | |||

| Breakdown strength | first BD *† | selected BDs *† | spin-coated (cured) IP-PDMS | Figure 10 | |

| 59.4 ± 7.5 V/µm | 73.3 ± 13.3 V/µm | 85.7 ± 12.4 V/µm | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srinivasaraghavan Govindarajan, R.; Sikulskyi, S.; Ren, Z.; Stark, T.; Kim, D. Characterization of Photocurable IP-PDMS for Soft Micro Systems Fabricated by Two-Photon Polymerization 3D Printing. Polymers 2023, 15, 4377. https://doi.org/10.3390/polym15224377

Srinivasaraghavan Govindarajan R, Sikulskyi S, Ren Z, Stark T, Kim D. Characterization of Photocurable IP-PDMS for Soft Micro Systems Fabricated by Two-Photon Polymerization 3D Printing. Polymers. 2023; 15(22):4377. https://doi.org/10.3390/polym15224377

Chicago/Turabian StyleSrinivasaraghavan Govindarajan, Rishikesh, Stanislav Sikulskyi, Zefu Ren, Taylor Stark, and Daewon Kim. 2023. "Characterization of Photocurable IP-PDMS for Soft Micro Systems Fabricated by Two-Photon Polymerization 3D Printing" Polymers 15, no. 22: 4377. https://doi.org/10.3390/polym15224377

APA StyleSrinivasaraghavan Govindarajan, R., Sikulskyi, S., Ren, Z., Stark, T., & Kim, D. (2023). Characterization of Photocurable IP-PDMS for Soft Micro Systems Fabricated by Two-Photon Polymerization 3D Printing. Polymers, 15(22), 4377. https://doi.org/10.3390/polym15224377