Coating of Felt Fibers with Carbon Nanotubes and PEDOT with Different Counterions: Temperature and Electrical Field Effects

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

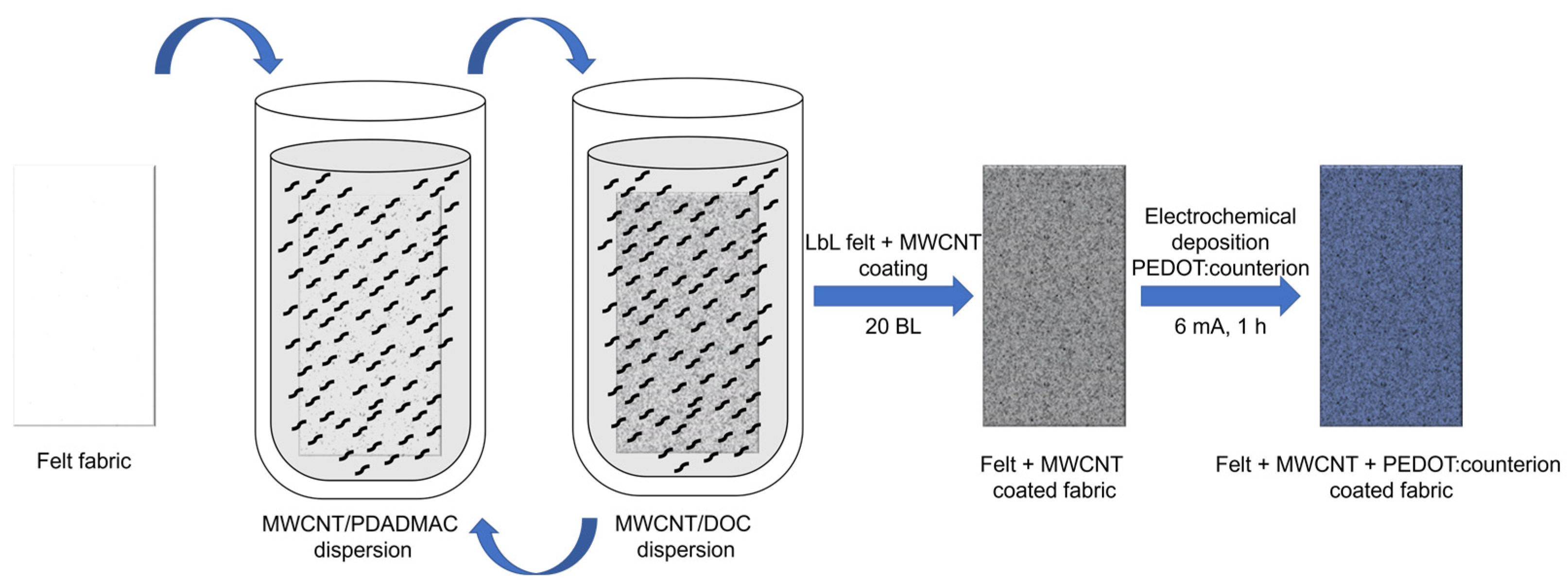

2.2. Sample Preparation

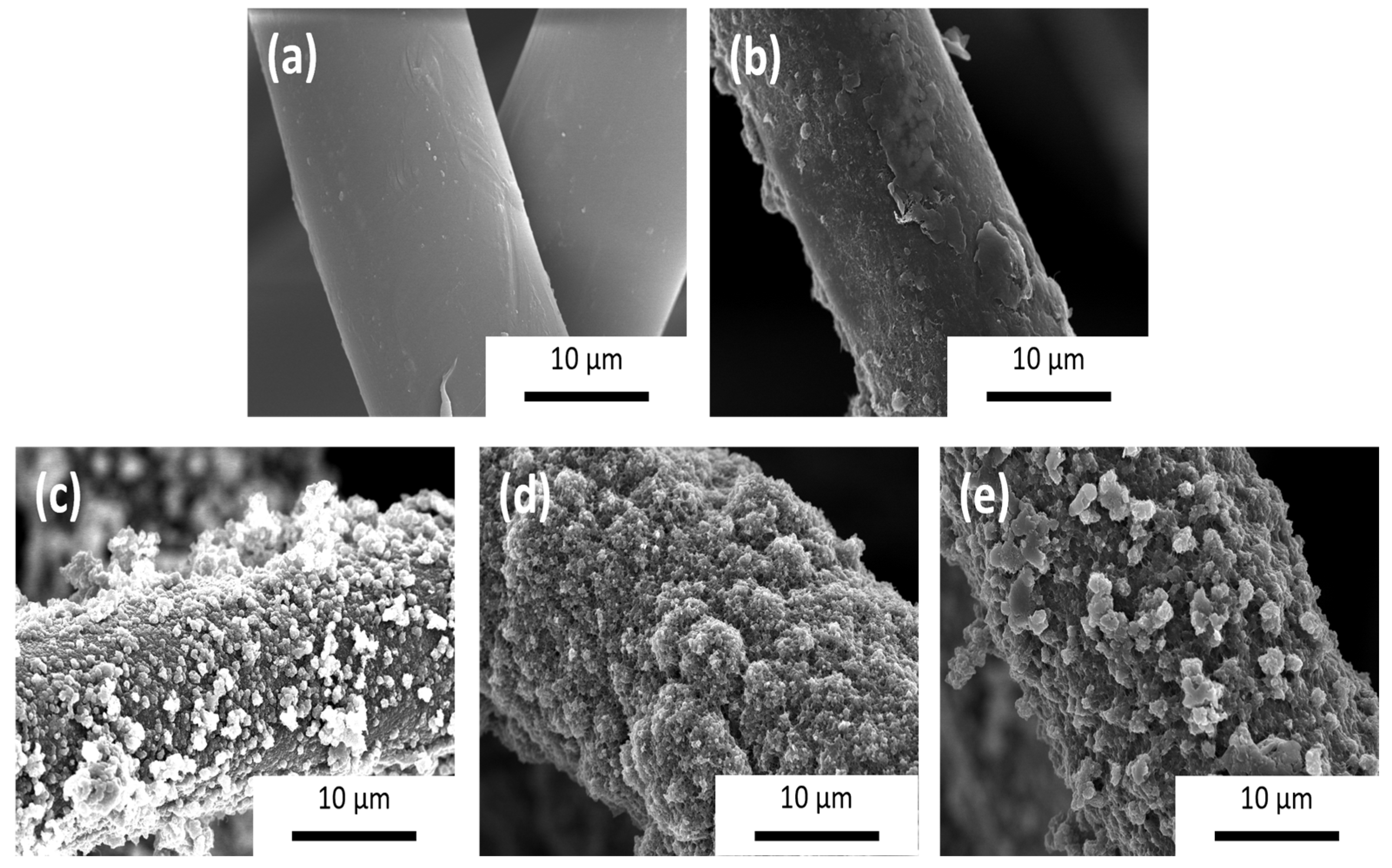

2.3. Morphological Characterization (SEM)

2.4. Thermogravimetric Analysis (TGA)

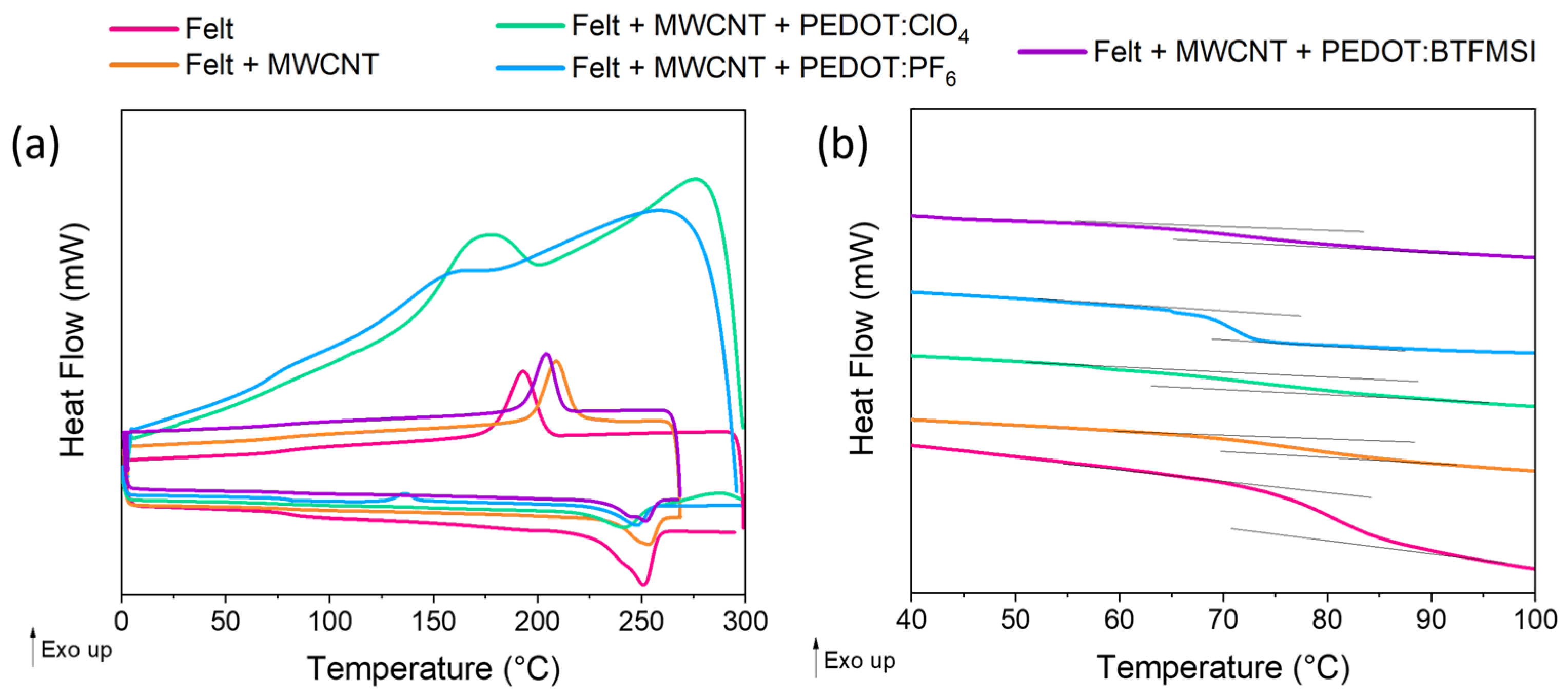

2.5. Differential Scanning Calorimetry (DSC)

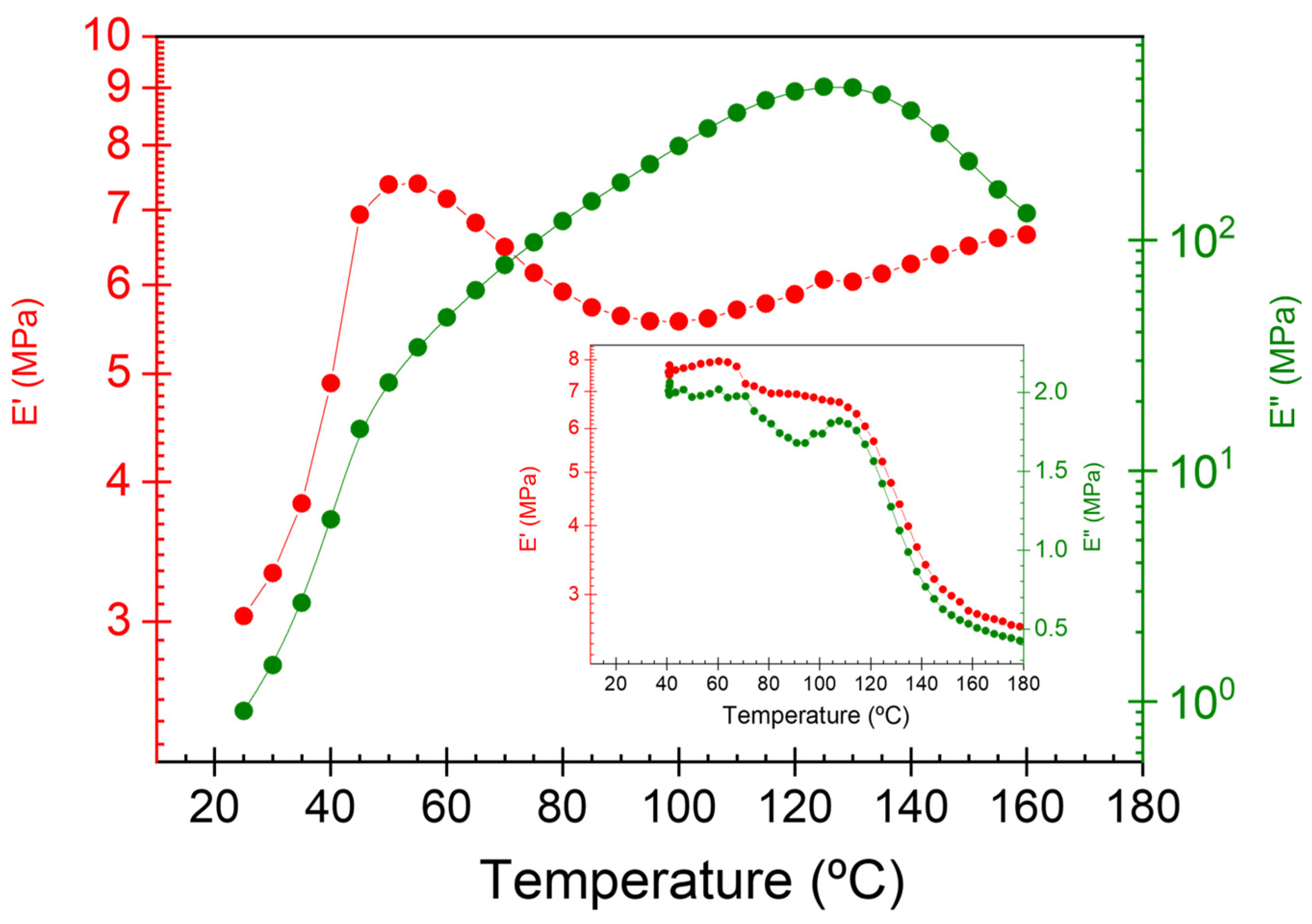

2.6. Dynamo-Mechanical Analysis (DMA)

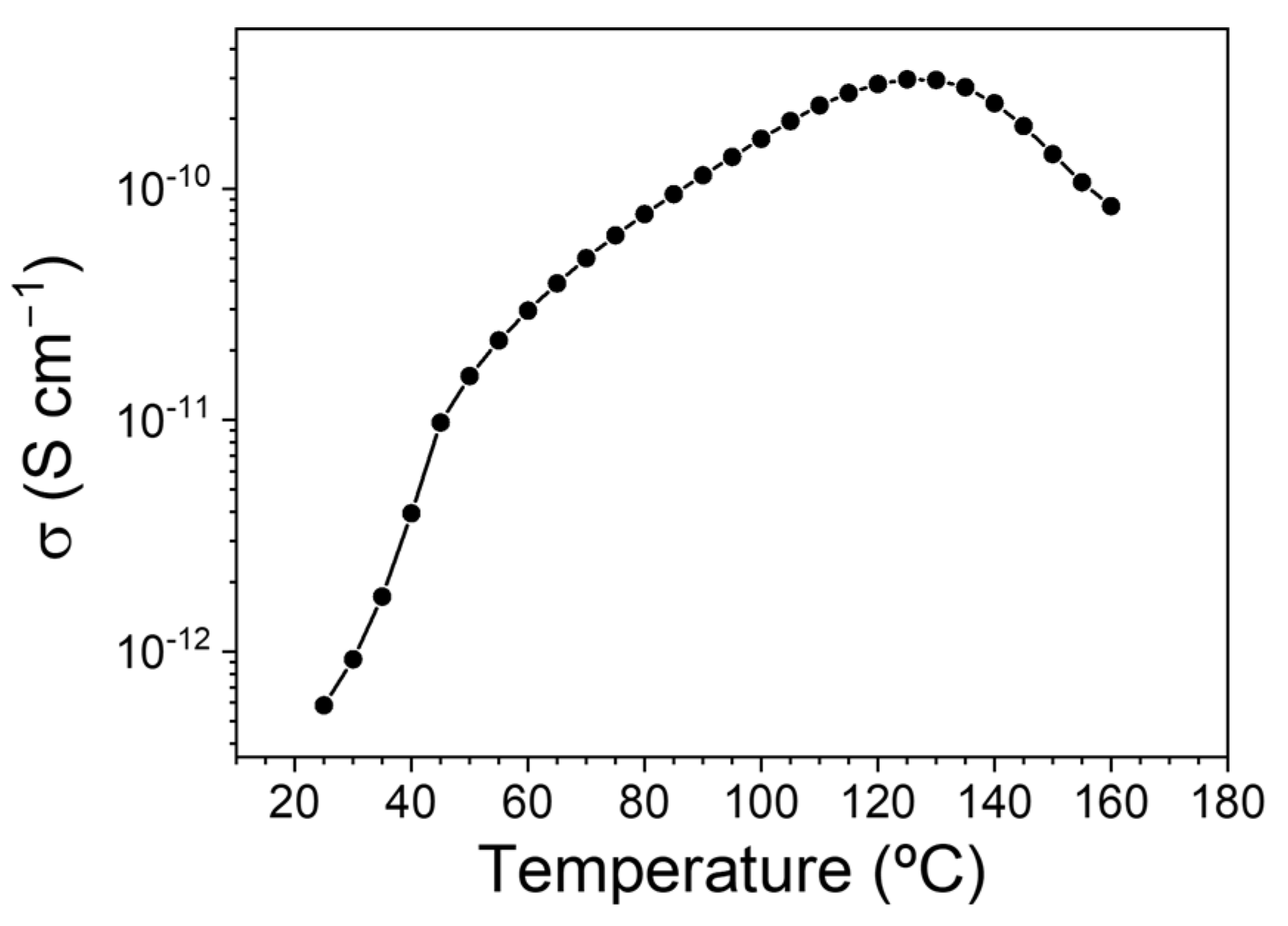

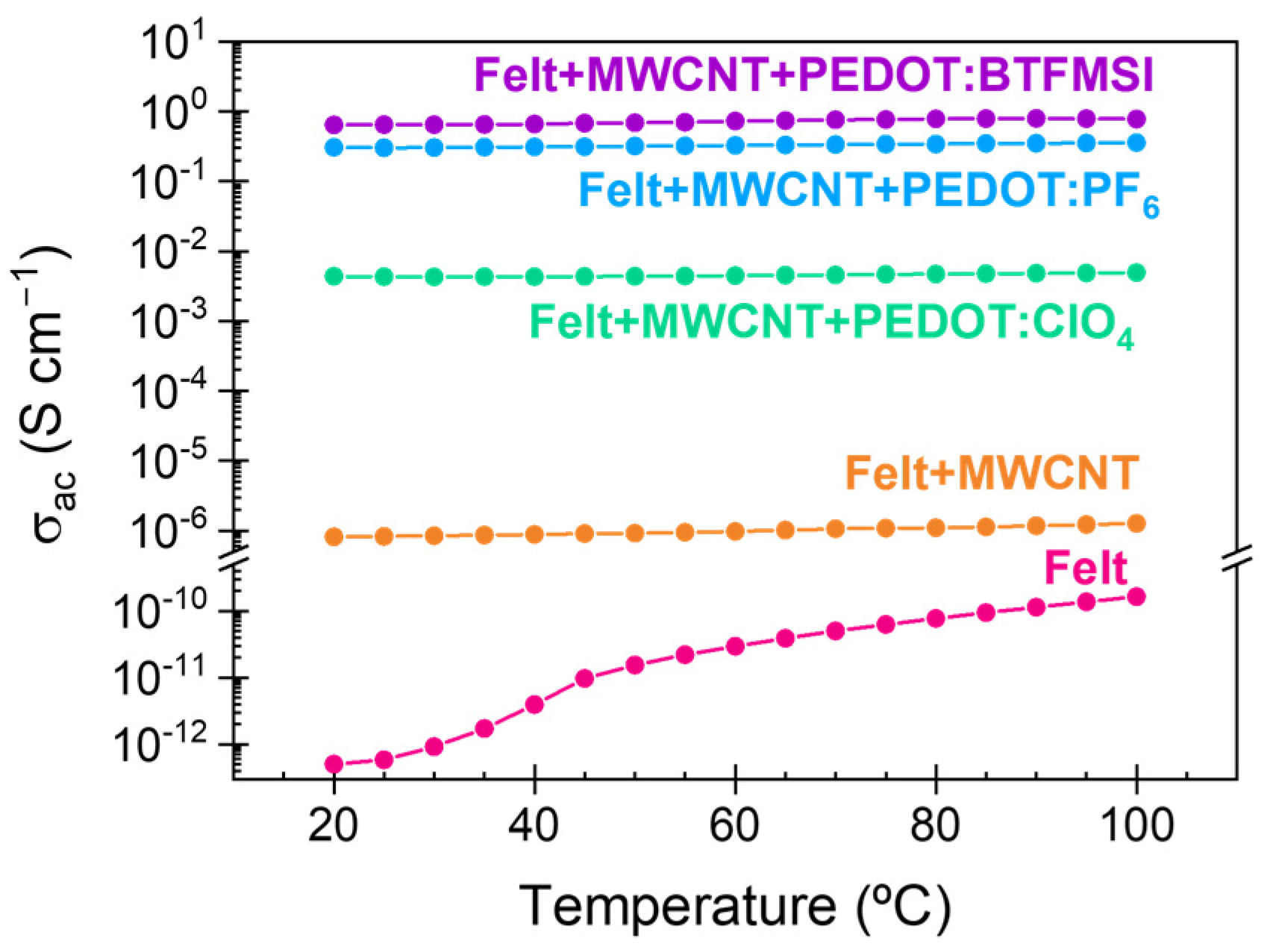

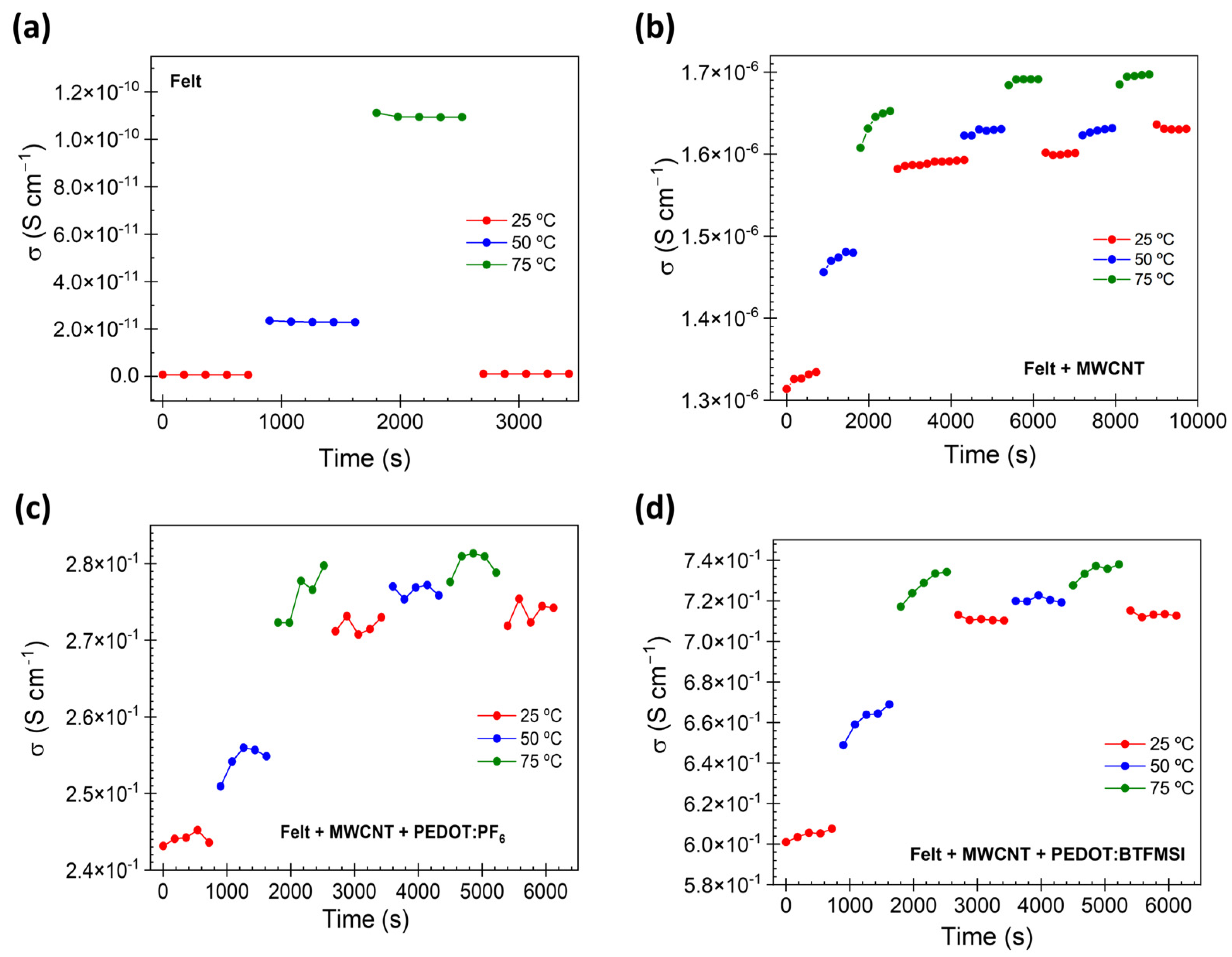

2.7. Analysis by Dielectric Relaxation Spectroscopy (DRS)

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garimella, S.V.; Persoons, T.; Weibel, J.A.; Gektin, V. Electronics Thermal Management in Information and Communications Technologies: Challenges and Future Directions. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 1191–1205. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef]

- Park, S.; Jayaraman, S. Smart Textiles: Wearable Electronic Systems. MRS Bull. 2003, 28, 585–591. [Google Scholar] [CrossRef]

- Wei, J. How Wearables Intersect with the Cloud and the Internet of Things: Considerations for the Developers of Wearables. IEEE Consum. Electron. Mag. 2014, 3, 53–56. [Google Scholar] [CrossRef]

- Hu, L.; Pasta, M.; La Mantia, F.; Cui, L.; Jeong, S.; Deshazer, H.D.; Choi, J.W.; Han, S.M.; Cui, Y. Stretchable, Porous, and Conductive Energy Textiles. Nano Lett. 2010, 10, 708–714. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.; Jia, L.; Mathewson, K.E.; Jang, K.-I.; Kim, J.; Fu, H.; Huang, X.; Chava, P.; Wang, R.; et al. Soft Microfluidic Assemblies of Sensors, Circuits, and Radios for the Skin. Science 2014, 344, 70–74. [Google Scholar] [CrossRef]

- Wang, X.; Lu, X.; Liu, B.; Chen, D.; Tong, Y.; Shen, G. Flexible Energy-Storage Devices: Design Consideration and Recent Progress. Adv. Mater. 2014, 26, 4763–4782. [Google Scholar] [CrossRef] [PubMed]

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive Polymers for Smart Textile Applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Yin, Z.; Lu, H.; Gan, L.; Zhang, Y. Electronic Fibers/Textiles for Health-Monitoring: Fabrication and Application. Adv. Mater. Technol. 2023, 8, 2200654. [Google Scholar] [CrossRef]

- Shao, Y.; Song, Q.; Chen, W.; Ifra, M.; Jiang, J.; Liu, Y. Characteristics of Electrical Heating and Sensing Properties for CNTs/GNs Polyester-Knitted Fabrics Based on Network Structure. Fibers Polym. 2023, 24, 1139–1148. [Google Scholar] [CrossRef]

- Cui, N.; Song, Y.; Tan, C.-H.; Zhang, K.; Yang, X.; Dong, S.; Xie, B.; Huang, F. Stretchable Transparent Electrodes for Conformable Wearable Organic Photovoltaic Devices. NPJ Flex. Electron. 2021, 5, 31. [Google Scholar] [CrossRef]

- Candadai, A.A.; Nadler, E.J.; Burke, J.S.; Weibel, J.A.; Marconnet, A.M. Thermal and Mechanical Characterization of High Performance Polymer Fabrics for Applications in Wearable Devices. Sci. Rep. 2021, 11, 8705. [Google Scholar] [CrossRef] [PubMed]

- Berhe, M.K. Ergonomic Temperature Limits for Handheld Electronic Devices. In Proceedings of the ASME 2007 InterPACK Conference, Vancouver, BC, Canada, 8–12 July 2007; ASMEDC: New York, NY, USA, 2007; Volume 2, pp. 1041–1047. [Google Scholar]

- Kuzum, D.; Takano, H.; Shim, E.; Reed, J.C.; Juul, H.; Richardson, A.G.; de Vries, J.; Bink, H.; Dichter, M.A.; Lucas, T.H.; et al. Transparent and Flexible Low Noise Graphene Electrodes for Simultaneous Electrophysiology and Neuroimaging. Nat. Commun. 2014, 5, 5259. [Google Scholar] [CrossRef]

- Wang, X.; Tian, H.; Mohammad, M.A.; Li, C.; Wu, C.; Yang, Y.; Ren, T.-L. A Spectrally Tunable All-Graphene-Based Flexible Field-Effect Light-Emitting Device. Nat. Commun. 2015, 6, 7767. [Google Scholar] [CrossRef] [PubMed]

- Serrano-Claumarchirant, J.F.; Brotons-Alcázar, I.; Culebras, M.; Sanchis, M.J.; Cantarero, A.; Muñoz-Espí, R.; Gómez, C.M. Electrochemical Synthesis of an Organic Thermoelectric Power Generator. ACS Appl. Mater. Interfaces 2020, 12, 46348–46356. [Google Scholar] [CrossRef]

- Serrano-Claumarchirant, J.F.; Muñoz-Espí, R.; Cantarero, A.; Culebras, M.; Gómez, C.M. Electrochemical Deposition of Conductive Polymers on Fabrics. Coatings 2023, 13, 383. [Google Scholar] [CrossRef]

- Serrano-Claumarchirant, J.F.; Nasiri, M.A.; Cho, C.; Cantarero, A.; Culebras, M.; Gómez, C.M. Textile-based Thermoelectric Generator Produced Via Electrochemical Polymerization. Adv. Mater. Interfaces 2023, 10, 2202105. [Google Scholar] [CrossRef]

- Jose, F. Serrano-Claumarchirant Hybrid Materials Based on Conductive Polymers for Energy Harvesting; University of Valencia: Valencia, Spain, 2022. [Google Scholar]

- Castagnola, V.; Bayon, C.; Descamps, E.; Bergaud, C. Morphology and Conductivity of PEDOT Layers Produced by Different Electrochemical Routes. Synth. Met. 2014, 189, 7–16. [Google Scholar] [CrossRef]

- Vlamidis, Y.; Lanzi, M.; Salatelli, E.; Gualandi, I.; Fraboni, B.; Setti, L.; Tonelli, D. Electrodeposition of PEDOT Perchlorate as an Alternative Route to PEDOT:PSS for the Development of Bulk Heterojunction Solar Cells. J. Solid State Electrochem. 2015, 19, 1685–1693. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal Degradation Study of Waste Polyethylene Terephthalate (PET) under Inert and Oxidative Environments. Thermochim. Acta 2019, 679, 178340. [Google Scholar] [CrossRef]

- Lee, C.J.; Tsai, I.S. Effect of Different Dielectric Constant Solvents Addition on PEDOT-PSS Conductive Polymer and Its Application. Mater. Sci. Forum 2011, 687, 625–633. [Google Scholar] [CrossRef]

- Panowicz, R.; Konarzewski, M.; Durejko, T.; Szala, M.; Łazińska, M.; Czerwińska, M.; Prasuła, P. Properties of Polyethylene Terephthalate (PET) after Thermo-Oxidative Aging. Materials 2021, 14, 3833. [Google Scholar] [CrossRef] [PubMed]

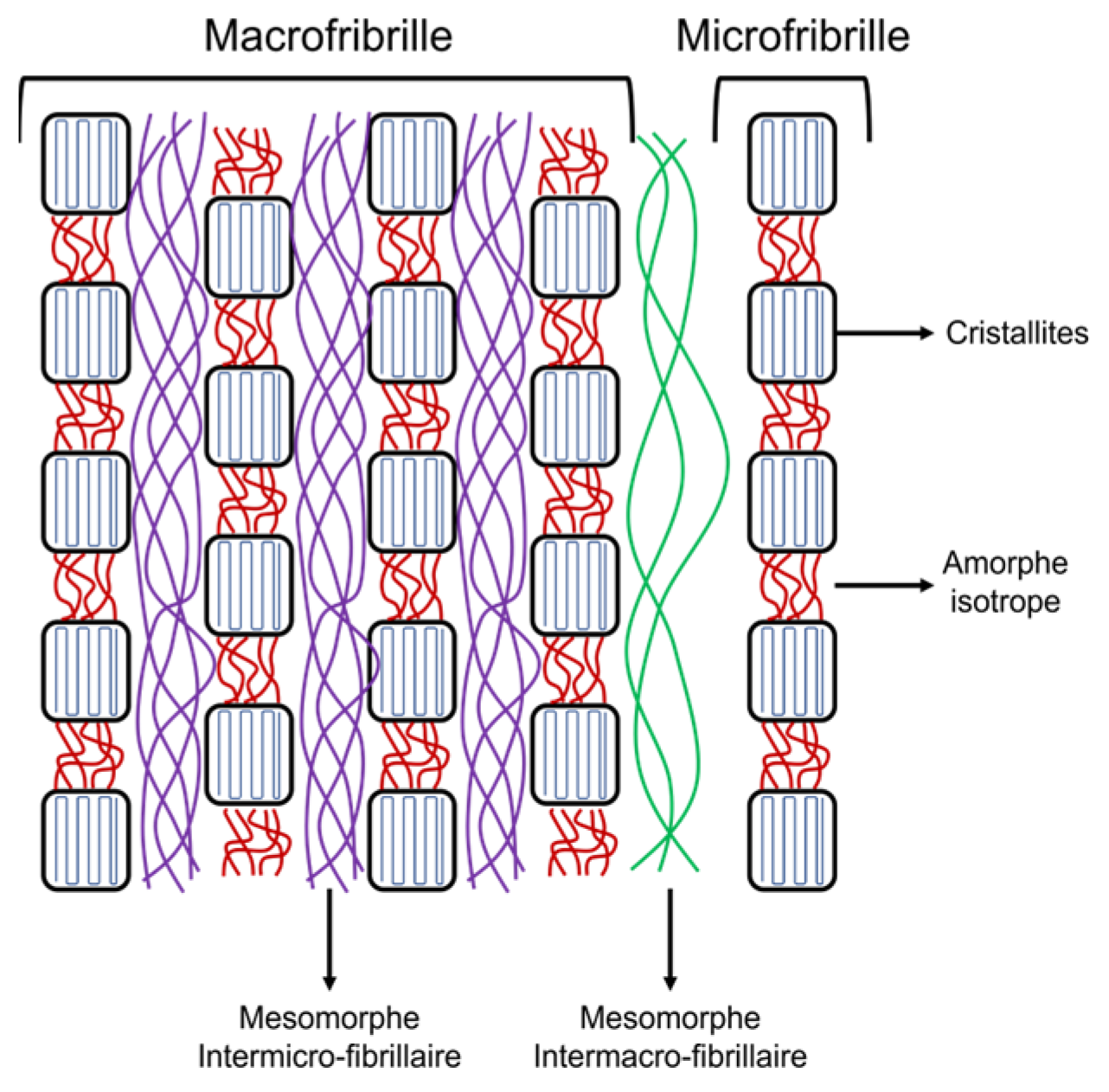

- Wunderlich, B. Thermal Analysis of Polymeric Materials; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 3-540-23629-5. [Google Scholar]

- Moraes, M.R.; Alves, A.C.; Toptan, F.; Martins, M.S.; Vieira, E.M.F.; Paleo, A.J.; Souto, A.P.; Santos, W.L.F.; Esteves, M.F.; Zille, A. Glycerol/PEDOT:PSS Coated Woven Fabric as a Flexible Heating Element on Textiles. J. Mater. Chem. C Mater. 2017, 5, 3807–3822. [Google Scholar] [CrossRef]

- Rodrigues, A.; Figueiredo, L.; Diogo, H.; Bordado, J. Mechanical Behavior of PET Fibers and Textiles for Stent-Grafts Using Video Extensometry and Image Analysis. Sci. Technol. Mater. 2018, 30, 23–33. [Google Scholar] [CrossRef]

- Rahimi, M.H.; Parvinzadeh, M.; Navid, M.Y.; Ahmadi, S. Thermal Characterization and Flammability of Polyester Fiber Coated with Nonionic and Cationic Softeners. J. Surfactants Deterg. 2011, 14, 595–603. [Google Scholar] [CrossRef]

- Gudayu, A.D.; Steuernagel, L.; Meiners, D.; Gideon, R. Characterization of the Dynamic Mechanical Properties of Sisal Fiber Reinforced PET Composites; Effect of Fiber Loading and Fiber Surface Modification. Polym. Polym. Compos. 2021, 29, S719–S728. [Google Scholar] [CrossRef]

- Corradini, E.; Imam, S.H.; Agnelli, J.A.M.; Mattoso, L.H.C. Effect of Coconut, Sisal and Jute Fibers on the Properties of Starch/Gluten/Glycerol Matrix. J. Polym. Environ. 2009, 17, 1–9. [Google Scholar] [CrossRef]

- Mccrum, N.G.; Read, B.E.; Williams, G. Anelastic and Dielectric Effects in Polymeric Solids; Dove Publications: New York, NY, USA, 1991. [Google Scholar]

- Gao, J.; He, Y.; Gong, X. Effect of Electric Field Induced Alignment and Dispersion of Functionalized Carbon Nanotubes on Properties of Natural Rubber. Results Phys. 2018, 9, 493–499. [Google Scholar] [CrossRef]

- Gupta, P.; Rajput, M.; Singla, N.; Kumar, V.; Lahiri, D. Electric Field and Current Assisted Alignment of CNT inside Polymer Matrix and Its Effects on Electrical and Mechanical Properties. Polymer 2016, 89, 119–127. [Google Scholar] [CrossRef]

- Yang, Z.; Tong, Y.; Xu, W.; Yin, X.; Zhang, G.; Qu, J. Electric Field-Induced Alignment of MWCNTs during the Processing of PP/MWCNT Composites: Effects on Electrical, Dielectric, and Rheological Properties. J. Polym. Eng. 2018, 38, 881–889. [Google Scholar] [CrossRef]

- Soccio, M.; Nogales, A.; Martín-Fabiani, I.; Lotti, N.; Munari, A.; Ezquerra, T.A. Relaxation Dynamics and Cold Crystallization of Poly(Pentamethylene Terephthalate) as Revealed by Dielectric Spectroscopy. Polymer 2014, 55, 1552–1559. [Google Scholar] [CrossRef]

- Lechat, C.; Bunsell, A.R.; Davies, P.; Piant, A. Mechanical Behaviour of Polyethylene Terephthalate & Polyethylene Naphthalate Fibres under Cyclic Loading. J. Mater. Sci. 2006, 41, 1745–1756. [Google Scholar] [CrossRef]

- Kremer, F.; Schönhals, A. (Eds.) Broadband Dielectric Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 978-3-642-62809-2. [Google Scholar]

| Felt | Felt + MWCNT | Felt + MWCNT + PEDOT:ClO4 | Felt + MWCNT + PEDOT:PF6 | Felt + MWCNT + PEDOT:BTFMSI | |

|---|---|---|---|---|---|

| T5% (°C) | 367.65 | 376.85 | 262.22 | 316.87 | 328.10 |

| T10% (°C) | 387.51 | 393.02 | 334.41 | 341.50 | 354.88 |

| T20% (°C) | 402.33 | 406.45 | 389.81 | 371.16 | 379.62 |

| T30% (°C) | 411.02 | 414.41 | 404.90 | 393.11 | 391.97 |

| T40% (°C) | 417.45 | 420.40 | 413.88 | 406.97 | 401.68 |

| T50% (°C) | 422.87 | 425.65 | 420.59 | 416.94 | 410.81 |

| T60% (°C) | 427.91 | 430.68 | 426.71 | 425.74 | 417.80 |

| T70% (°C) | 433.93 | 436.84 | 434.19 | 433.91 | 429.01 |

| T80% (°C) | 452.84 | 453.28 | 457.64 | 454.26 | 454.06 |

| T90% (°C) | 479.08 | 486.04 | 480.68 | 522.32 | 478.32 |

| T95% (°C) | 487.97 | 530.56 | 488.68 | 543.47 | 482.07 |

| Residue % (700 °C) | 0 | 0 | 0.56 | 0.615 | 0.199 |

| Sample | Tg (°C) | Tm (°C) | (J g−1) | |

|---|---|---|---|---|

| Felt | 78.64 | 252.96 | 45.493 | 32.5 |

| Felt + MWCNT | 76.03 | 246.58 | 43.581 | 31.1 |

| Felt + MWCNT + PEDOT:ClO4 | 73.34 | 242.90 | 51.004 | 36.4 |

| Felt + MWCNT + PEDOT:PF6 | 68.09 | 242.09 | 46.695 | 33.3 |

| Felt + MWCNT + PEDOT:BTFMSI | 68.85 | 240.28 | 45.990 | 32.8 |

| σ (S cm−1) | |||

|---|---|---|---|

| Sample | 25 °C | 50 °C | 75 °C |

| Felt | 6.8714 × 10−13 | 2.3347 × 10−11 | 1.0412 × 10−10 |

| Felt + MWCNT | 8.2385 × 10−7 | 9.1966 × 10−7 | 1.0794 × 10−6 |

| Felt + MWCNT + PEDOT:ClO4 | 4.3024 × 10−3 | 4.3714 × 10−3 | 4.6916 × 10−3 |

| Felt + MWCNT + PEDOT:PF6 | 2.4313 × 10−1 | 3.1838 × 10−1 | 3.4121 × 10−1 |

| Felt + MWCNT + PEDOT:BTFMSI | 6.4476 × 10−1 | 6.8881 × 10−1 | 7.6804 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carsí, M.; Sanchis, M.J.; Serrano-Claumarchirant, J.F.; Culebras, M.; Gómez, C.M. Coating of Felt Fibers with Carbon Nanotubes and PEDOT with Different Counterions: Temperature and Electrical Field Effects. Polymers 2023, 15, 4075. https://doi.org/10.3390/polym15204075

Carsí M, Sanchis MJ, Serrano-Claumarchirant JF, Culebras M, Gómez CM. Coating of Felt Fibers with Carbon Nanotubes and PEDOT with Different Counterions: Temperature and Electrical Field Effects. Polymers. 2023; 15(20):4075. https://doi.org/10.3390/polym15204075

Chicago/Turabian StyleCarsí, Marta, María J. Sanchis, José F. Serrano-Claumarchirant, Mario Culebras, and Clara M. Gómez. 2023. "Coating of Felt Fibers with Carbon Nanotubes and PEDOT with Different Counterions: Temperature and Electrical Field Effects" Polymers 15, no. 20: 4075. https://doi.org/10.3390/polym15204075

APA StyleCarsí, M., Sanchis, M. J., Serrano-Claumarchirant, J. F., Culebras, M., & Gómez, C. M. (2023). Coating of Felt Fibers with Carbon Nanotubes and PEDOT with Different Counterions: Temperature and Electrical Field Effects. Polymers, 15(20), 4075. https://doi.org/10.3390/polym15204075