Synthesis, Properties, and Applications of Nanocomposite Materials Based on Bacterial Cellulose and MXene

Abstract

:1. Introduction

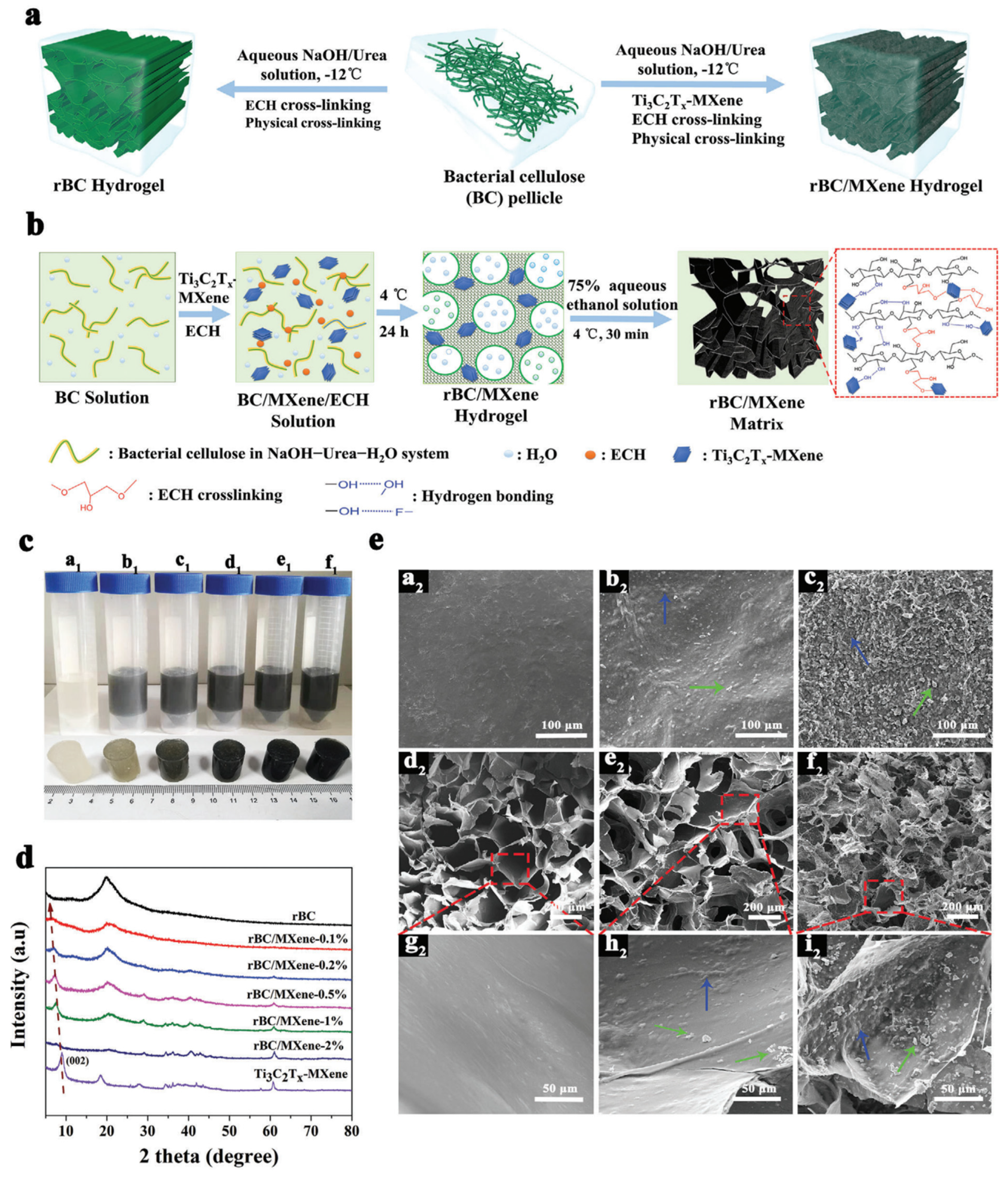

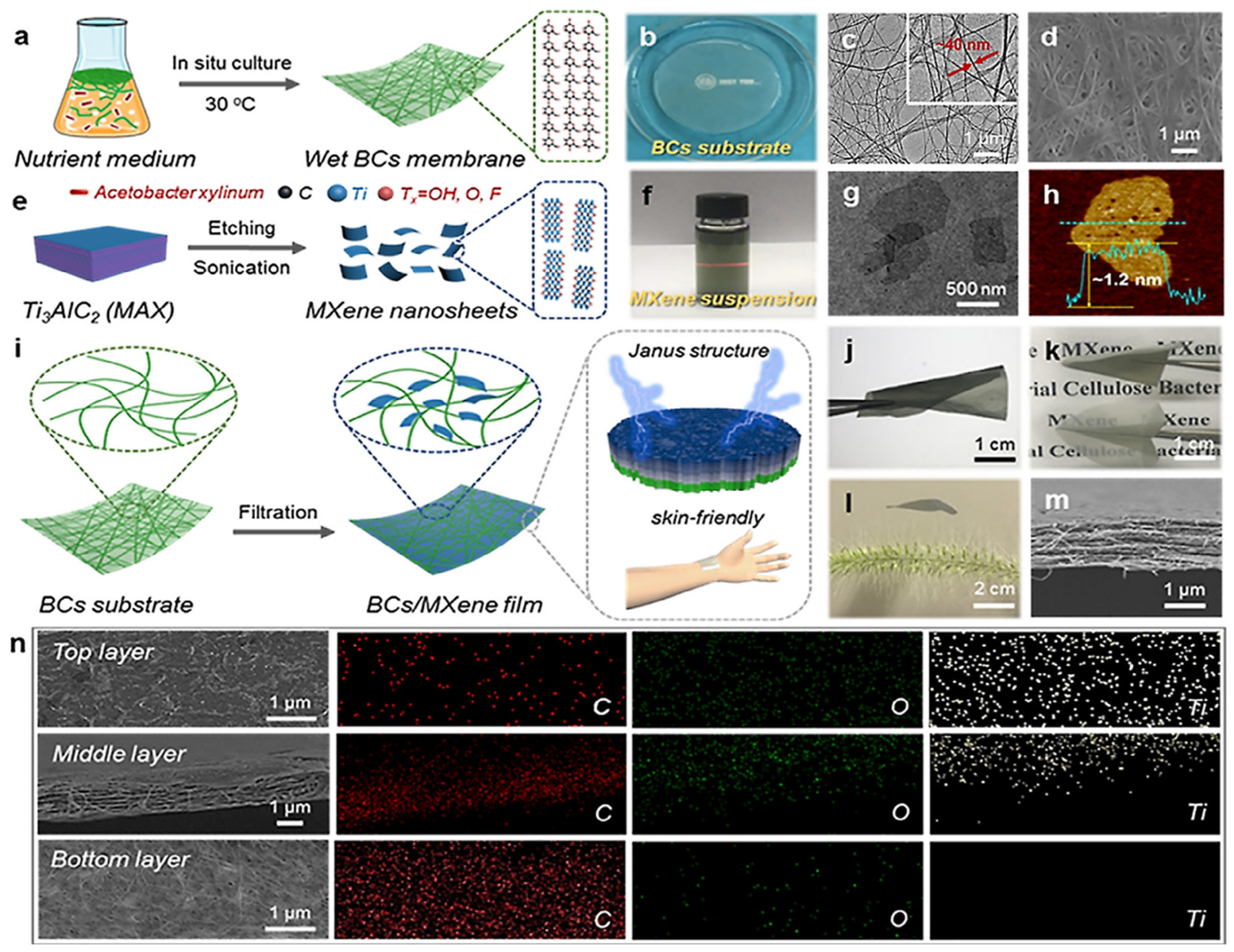

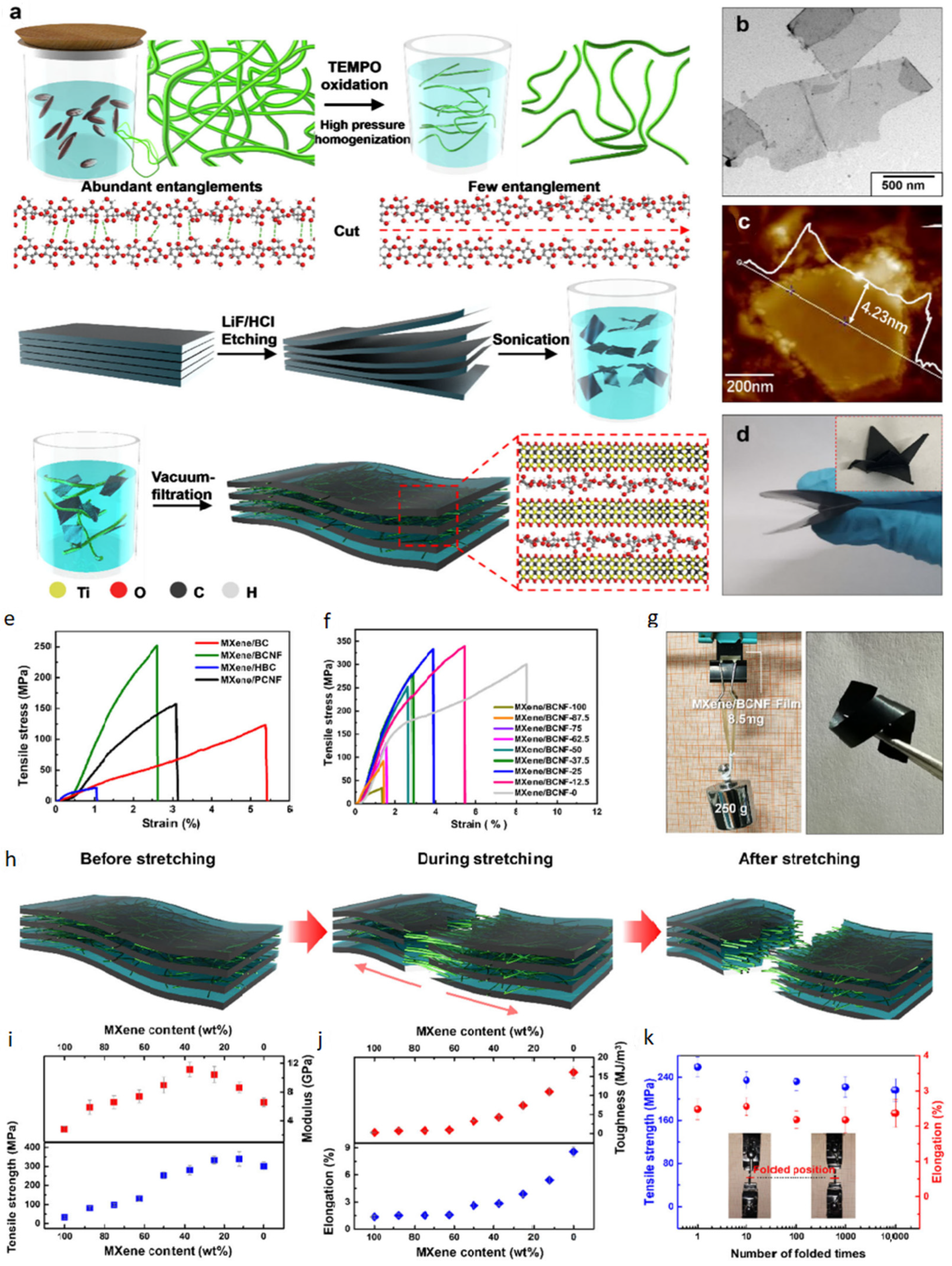

2. Synthesis of MXene/BC-Based Composites

2.1. Fabrication of Multilayer Ti3C2Tx-MXene

2.2. Fabrication of Bacterial Cellulose (BC)

2.3. Fabrication of the BC/MXene Based Composite Films

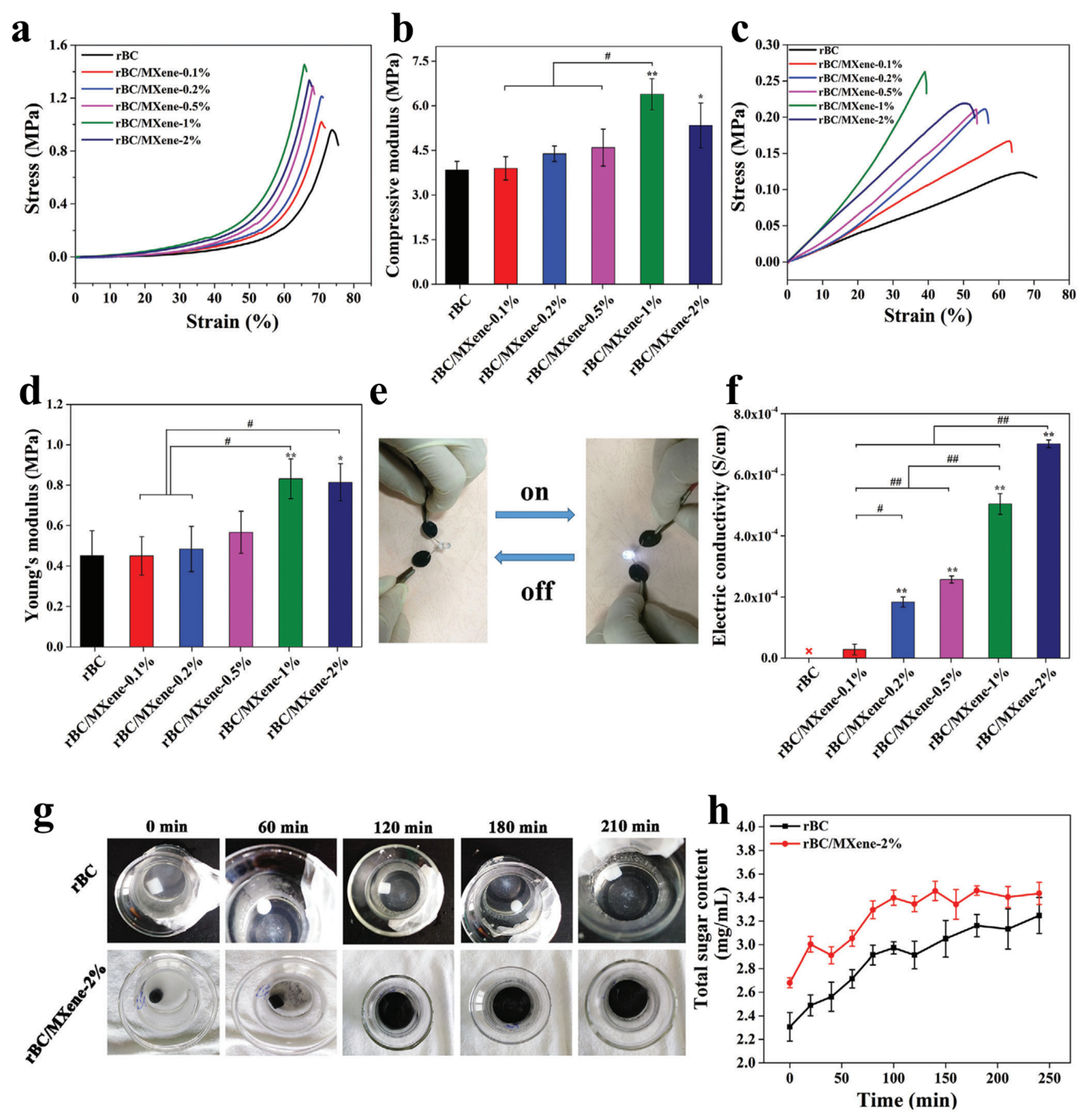

3. Physical–Chemical Properties of Composite BC/MXene Films

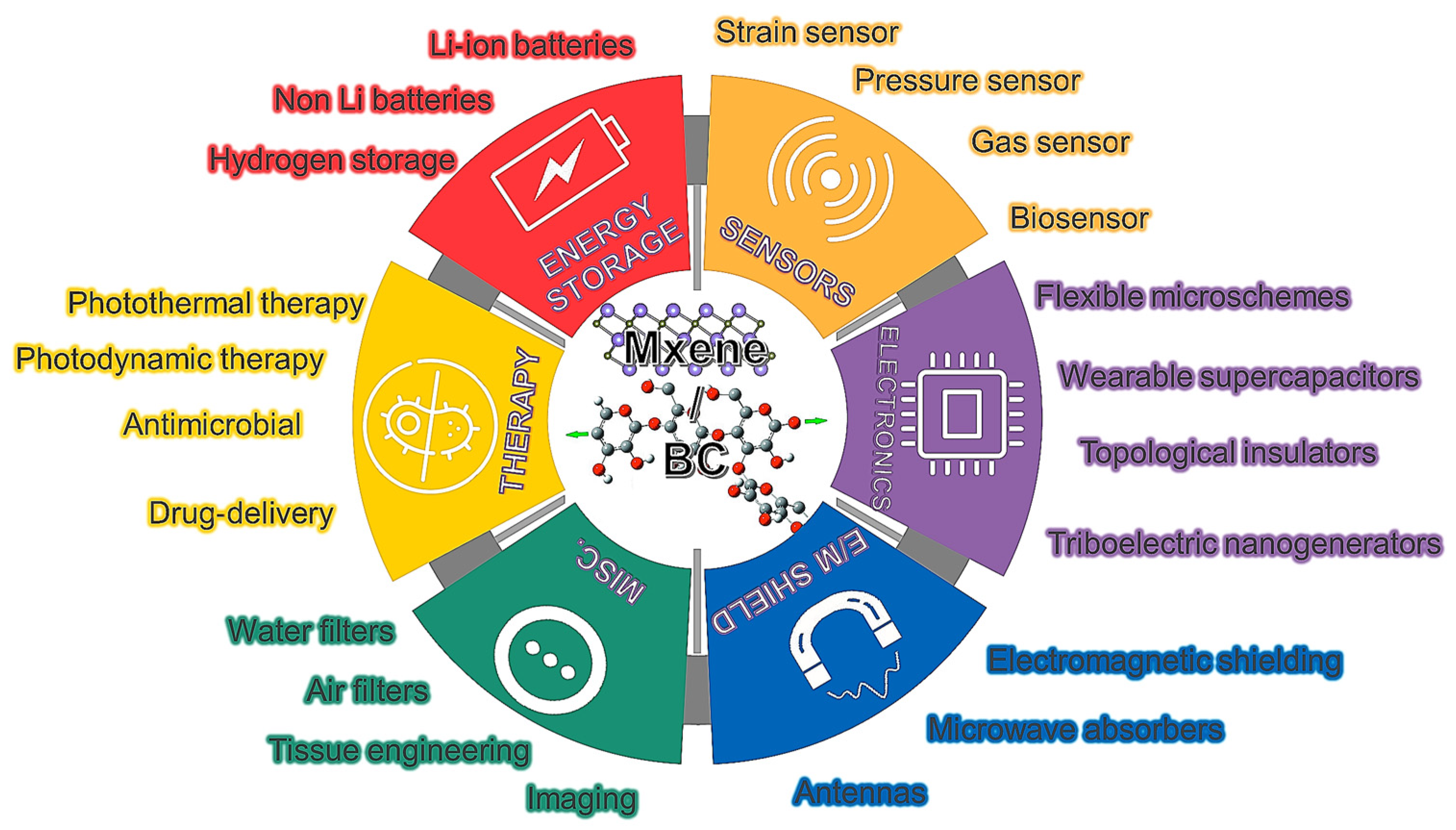

4. Application of BC/MXene-Based Composites

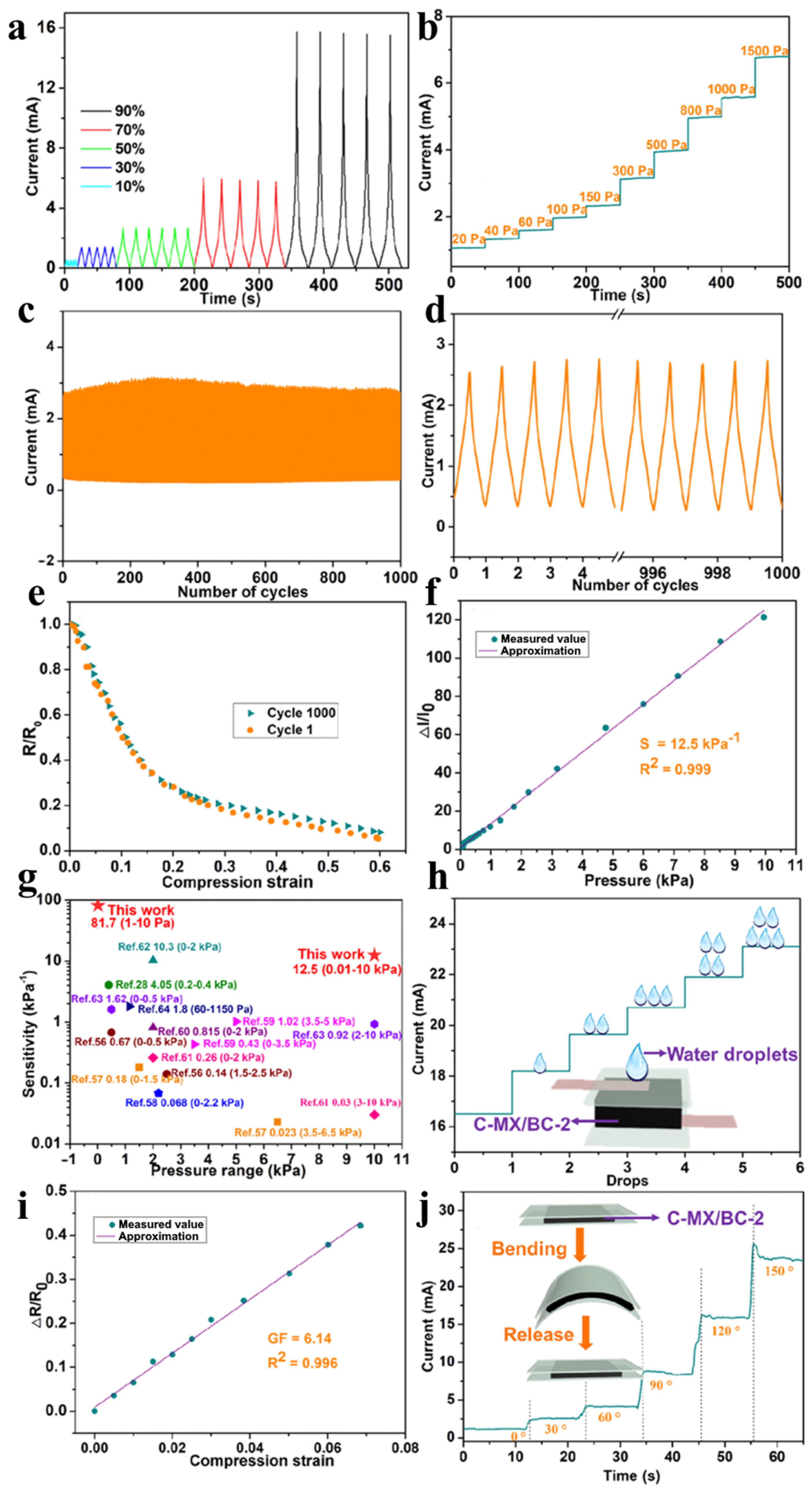

4.1. Sensor Electronics

4.2. Tissue Engineering

4.3. Supercapacitors

4.4. Electromagnetic Interference Shielding

4.5. Honorable Mention

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, G.-H.; Moon, H.; Kim, H.; Lee, G.H.; Kwon, W.; Yoo, S.; Myung, D.; Yun, S.H.; Bao, Z.; Hahn, S.K. Multifunctional Materials for Implantable and Wearable Photonic Healthcare Devices. Nat. Rev. Mater. 2020, 5, 149–165. [Google Scholar] [CrossRef] [PubMed]

- Anasori, B.; Lukatskaya, M.R.; Gogotsi, Y. 2D Metal Carbides and Nitrides (MXenes) for Energy Storage. Nat. Rev. Mater. 2017, 2, 16098. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [PubMed]

- Pogorielov, M.; Smyrnova, K.; Kyrylenko, S.; Gogotsi, O.; Zahorodna, V.; Pogrebnjak, A. MXenes—A New Class of Two-Dimensional Materials: Structure, Properties and Potential Applications. Nanomaterials 2021, 11, 3412. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, N.; Li, L.; Hu, X.; Zou, Z.; Wang, J.; Luo, S.; Gao, Y. A Highly Flexible and Sensitive Piezoresistive Sensor Based on MXene with Greatly Changed Interlayer Distances. Nat. Commun. 2017, 8, 1207. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Li, X.; Bai, Y.; Xiao, H.; Liu, Y.; Liu, R.; Yuan, G. Engineering 3D Ion Transport Channels for Flexible MXene Films with Superior Capacitive Performance. Adv. Funct. Mater. 2019, 29, 1900326. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Wan, F.; Tie, Z.; Niu, Z. Scalable 3D Self-Assembly of MXene Films for Flexible Sandwich and Microsized Supercapacitors. Adv. Funct. Mater. 2021, 31, 2101302. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, X.; Yan, R.; Yang, J.; Liu, Y.; Dong, S. Ion-Assisted Self-Assembly of Macroporous MXene Films as Supercapacitor Electrodes. J. Mater. Chem. C 2020, 8, 2008–2013. [Google Scholar] [CrossRef]

- Sikdar, A.; Dutta, P.; Deb, S.K.; Majumdar, A.; Padma, N.; Ghosh, S.; Maiti, U.N. Spontaneous Three-Dimensional Self-Assembly of MXene and Graphene for Impressive Energy and Rate Performance Pseudocapacitors. Electrochim. Acta 2021, 391, 138959. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.; Zhu, C.; Lin, S.; Wen, J.; Jin, Q.; Zhang, X. In Situ Polymerized Ti3C2Tx/PDA Electrode with Superior Areal Capacitance for Supercapacitors. J. Alloys Compd. 2019, 778, 858–865. [Google Scholar] [CrossRef]

- Huang, H.; He, J.; Wang, Z.; Zhang, H.; Jin, L.; Chen, N.; Xie, Y.; Chu, X.; Gu, B.; Deng, W.; et al. Scalable, and Low-Cost Treating-Cutting-Coating Manufacture Platform for MXene-Based On-Chip Micro-Supercapacitors. Nano Energy 2020, 69, 104431. [Google Scholar] [CrossRef]

- Tang, X.; Guo, X.; Wu, W.; Wang, G. 2D Metal Carbides and Nitrides (MXenes) as High-Performance Electrode Materials for Lithium-Based Batteries. Adv. Energy Mater. 2018, 8, 1801897. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, R.; Wang, A.; Guo, W.; Liu, X.; Luo, J. MXene Aerogel Scaffolds for High-Rate Lithium Metal Anodes. Angew. Chemie Int. Ed. 2018, 57, 15028–15033. [Google Scholar] [CrossRef]

- Kyrylenko, S.; Kornienko, V.; Gogotsi, O.; Oleshko, O.; Kolesnyk, M.; Mishchenko, O.; Zahorodna, V.; Buranich, V.; Pogrebnjak, A.; Zozulia, Y.; et al. Bio-Functionalization of Electrospun Polymeric Nanofibers by Ti3C2Tx MXene. In Proceedings of the 2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP), Sumy, Ukraine, 9–13 November 2020; IEEE: New York, NY, USA; pp. 02BA10-1–02BA10-5. [Google Scholar]

- Diedkova, K.; Pogrebnjak, A.D.; Kyrylenko, S.; Smyrnova, K.; Buranich, V.V.; Horodek, P.; Zukowski, P.; Koltunowicz, T.N.; Galaszkiewicz, P.; Makashina, K.; et al. Polycaprolactone–MXene Nanofibrous Scaffolds for Tissue Engineering. ACS Appl. Mater. Interfaces 2023, 15, 14033–14047. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Li, H.; Cheng, J.; He, T.; Li, J.; Wang, B. Nanocellulose Intercalation to Boost the Performance of MXene Pressure Sensor for Human Interactive Monitoring. J. Mater. Sci. 2021, 56, 13859–13873. [Google Scholar] [CrossRef]

- Cheng, Y.; Xie, Y.; Cao, H.; Li, L.; Liu, Z.; Yan, S.; Ma, Y.; Liu, W.; Yue, Y.; Wang, J.; et al. High-Strength MXene Sheets through Interlayer Hydrogen Bonding for Self-Healing Flexible Pressure Sensor. Chem. Eng. J. 2023, 453, 139823. [Google Scholar] [CrossRef]

- Xu, B.; Ye, F.; Chen, R.; Luo, X.; Xue, Z.; Li, R.; Chang, G. A Supersensitive Wearable Sensor Constructed with PDMS Porous Foam and Multi-Integrated Conductive Pathways Structure. Ceram. Int. 2023, 49, 4641–4649. [Google Scholar] [CrossRef]

- Moreira, S.; Silva, N.B.; Almeida-Lima, J.; Rocha, H.A.O.; Medeiros, S.R.B.; Alves, C.; Gama, F.M. BC Nanofibres: In Vitro Study of Genotoxicity and Cell Proliferation. Toxicol. Lett. 2009, 189, 235–241. [Google Scholar] [CrossRef]

- Pértile, R.A.N.; Moreira, S.; Gil da Costa, R.M.; Correia, A.; Guãrdao, L.; Gartner, F.; Vilanova, M.; Gama, M. Bacterial Cellulose: Long-Term Biocompatibility Studies. J. Biomater. Sci. Polym. Ed. 2012, 23, 1339–1354. [Google Scholar] [CrossRef]

- Koehler, J.; Brandl, F.P.; Goepferich, A.M. Hydrogel Wound Dressings for Bioactive Treatment of Acute and Chronic Wounds. Eur. Polym. J. 2018, 100, 1–11. [Google Scholar] [CrossRef]

- Dutta, S.D.; Patel, D.K.; Lim, K.-T. Functional Cellulose-Based Hydrogels as Extracellular Matrices for Tissue Engineering. J. Biol. Eng. 2019, 13, 55. [Google Scholar] [CrossRef] [PubMed]

- Song, B.; Gu, Y.; Pu, J.; Reid, B.; Zhao, Z.; Zhao, M. Application of Direct Current Electric Fields to Cells and Tissues In Vitro and Modulation of Wound Electric Field in Vivo. Nat. Protoc. 2007, 2, 1479–1489. [Google Scholar] [CrossRef] [PubMed]

- Nuccitelli, R. A Role for Endogenous Electric Fields in Wound Healing. Curr. Top. Dev. Biol. 2003, 58, 1–26. [Google Scholar]

- Jabbari, F.; Babaeipour, V.; Bakhtiari, S. Bacterial Cellulose-Based Composites for Nerve Tissue Engineering. Int. J. Biol. Macromol. 2022, 217, 120–130. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Cao, W.-T.; Zhang, W.; Ma, M.-G.; Sun, W.-M.; Zhang, J.; Chen, F. Wearable, Ultrathin and Transparent Bacterial Celluloses/MXene Film with Janus Structure and Excellent Mechanical Property for Electromagnetic Interference Shielding. Chem. Eng. J. 2021, 403, 126438. [Google Scholar] [CrossRef]

- Wan, Y.; Xiong, P.; Liu, J.; Feng, F.; Xun, X.; Gama, F.M.; Zhang, Q.; Yao, F.; Yang, Z.; Luo, H.; et al. Ultrathin, Strong, and Highly Flexible Ti3C2Tx MXene/Bacterial Cellulose Composite Films for High-Performance Electromagnetic Interference Shielding. ACS Nano 2021, 15, 8439–8449. [Google Scholar] [CrossRef]

- Xu, X.; Wu, S.; Cui, J.; Yang, L.; Liu, D.; Zhang, Y.; Chen, X.; Wu, K.; Sun, D. Insights into the Microstructures and Reinforcement Mechanism of Nano-Fibrillated Cellulose/MXene Based Electromagnetic Interference Shielding Film. Cellulose 2021, 28, 3311–3325. [Google Scholar] [CrossRef]

- Khan, U.; Luo, Y.; Kong, L.B.; Que, W. Synthesis of Fluorine Free MXene through Lewis Acidic Etching for Application as Electrode of Proton Supercapacitors. J. Alloys Compd. 2022, 926, 166903. [Google Scholar] [CrossRef]

- Aslam, M.K.; Niu, Y.; Xu, M. MXenes for Non-Lithium-Ion (Na, K, Ca, Mg, and Al) Batteries and Supercapacitors. Adv. Energy Mater. 2021, 11, 2000681. [Google Scholar] [CrossRef]

- Salim, O.; Mahmoud, K.A.; Pant, K.K.; Joshi, R.K. Introduction to MXenes: Synthesis and Characteristics. Mater. Today Chem. 2019, 14, 100191. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Thakur, A.; Chandran, B.S.N.; Davidson, K.; Bedford, A.; Fang, H.; Im, Y.; Kanduri, V.; Wyatt, B.C.; Nemani, S.K.; Poliukhova, V.; et al. Step-by-Step Guide for Synthesis and Delamination of Ti3C2Tx MXene. Small Methods 2023, 7, 2300030. [Google Scholar] [CrossRef] [PubMed]

- Lim, K.R.G.; Shekhirev, M.; Wyatt, B.C.; Anasori, B.; Gogotsi, Y.; Seh, Z.W. Fundamentals of MXene Synthesis. Nat. Synth. 2022, 1, 601–614. [Google Scholar] [CrossRef]

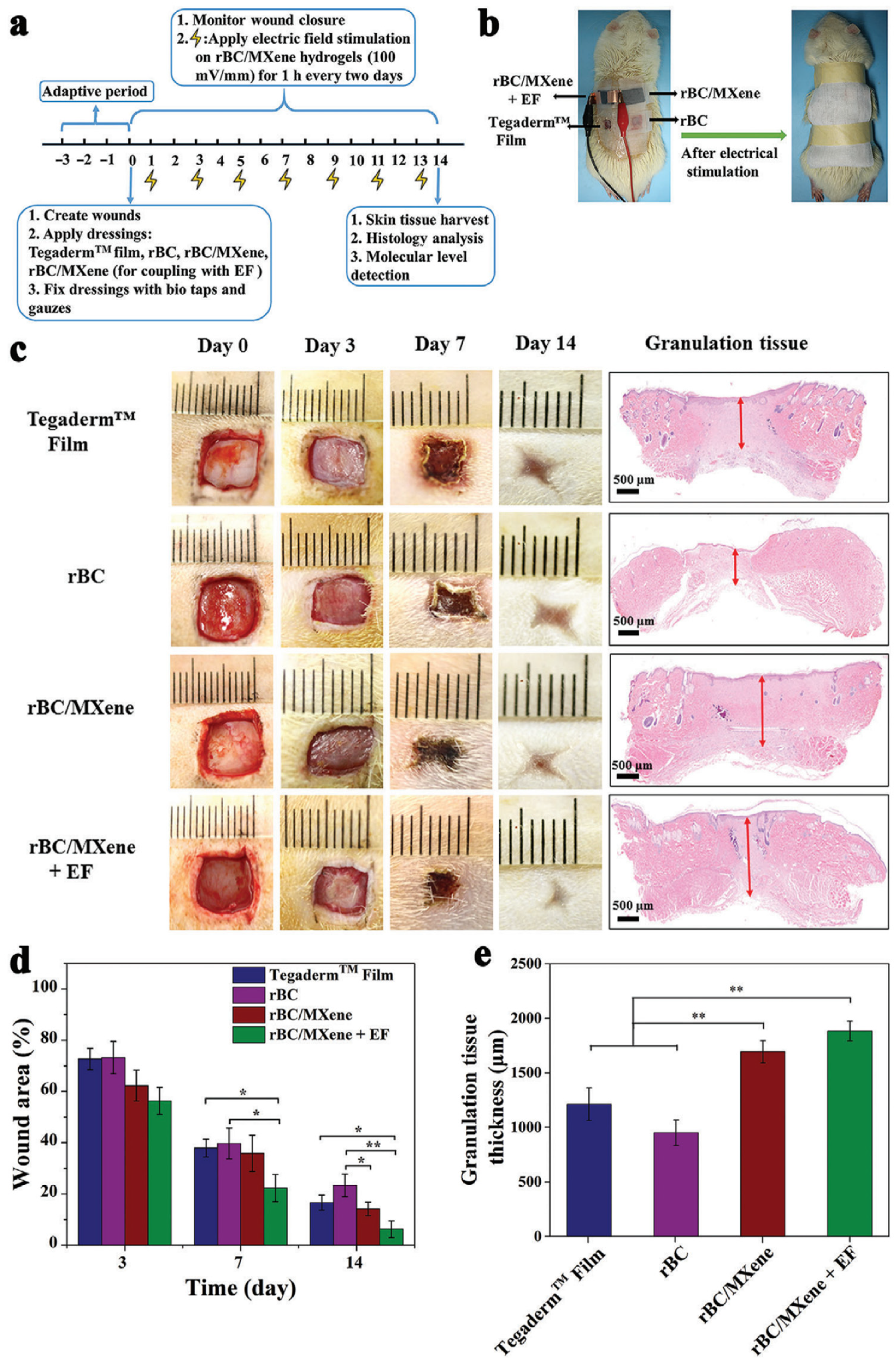

- Mao, L.; Hu, S.; Gao, Y.; Wang, L.; Zhao, W.; Fu, L.; Cheng, H.; Xia, L.; Xie, S.; Ye, W.; et al. Biodegradable and Electroactive Regenerated Bacterial Cellulose/MXene (Ti3C2Tx) Composite Hydrogel as Wound Dressing for Accelerating Skin Wound Healing under Electrical Stimulation. Adv. Healthc. Mater. 2020, 9, 2000872. [Google Scholar] [CrossRef] [PubMed]

- Costa, A.F.S.; Almeida, F.C.G.; Vinhas, G.M.; Sarubbo, L.A. Production of Bacterial Cellulose by Gluconacetobacter Hansenii Using Corn Steep Liquor as Nutrient Sources. Front. Microbiol. 2017, 8, 2027. [Google Scholar] [CrossRef]

- Wang, S.; Li, T.; Chen, C.; Kong, W.; Zhu, S.; Dai, J.; Diaz, A.J.; Hitz, E.; Solares, S.D.; Li, T.; et al. Transparent, Anisotropic Biofilm with Aligned Bacterial Cellulose Nanofibers. Adv. Funct. Mater. 2018, 28, 1707491. [Google Scholar] [CrossRef]

- Xie, H.; Yang, C.; Fu, K.K.; Yao, Y.; Jiang, F.; Hitz, E.; Liu, B.; Wang, S.; Hu, L. Flexible, Scalable, and Highly Conductive Garnet-Polymer Solid Electrolyte Templated by Bacterial Cellulose. Adv. Energy Mater. 2018, 8, 1703474. [Google Scholar] [CrossRef]

- Li, H.; Cheng, Z.; Zhang, Q.; Natan, A.; Yang, Y.; Cao, D.; Zhu, H. Bacterial-Derived, Compressible, and Hierarchical Porous Carbon for High-Performance Potassium-Ion Batteries. Nano Lett. 2018, 18, 7407–7413. [Google Scholar] [CrossRef]

- Lahiri, D.; Nag, M.; Dutta, B.; Dey, A.; Sarkar, T.; Pati, S.; Edinur, H.A.; Abdul Kari, Z.; Mohd Noor, N.H.; Ray, R.R. Bacterial Cellulose: Production, Characterization, and Application as Antimicrobial Agent. Int. J. Mol. Sci. 2021, 22, 12984. [Google Scholar] [CrossRef]

- Gromovykh, T.I.; Feldman, N.B.; Tikhonova, O.A.; Lutsenko, S.V.; Timashev, P.S.; Bardakova, K.N.; Churbanov, S.N.; Kiselyova, O.I.; Kraeva, M.N.; Grinevich, A.S. Elaboration of a Bacterial Cellulose Matrix for the Immobilisation of Escherichia Coli Cells. Int. J. Nanotechnol. 2018, 15, 288. [Google Scholar] [CrossRef]

- Gromovykh, T.I.; Vasil’kov, A.Y.; Kov, N.A.; Sadykova, V.S.; Feldman, N.B.; Demchenko, A.G.; Lyundup, A.V.; Butenko, I.E.; Lutsenko, S.V. Creation of Composites of Bacterial Cellulose and Silver Nanoparticles: Evaluation of Antimicrobial Activity and Cytotoxicity. Int. J. Nanotechnol. 2019, 16, 408. [Google Scholar] [CrossRef]

- Savitskaya, I.; Kistaubayeva, A.; Digel, I.; Shokatayeva, D. Physicochemical and Antibacterial Properties of Composite Films Based on Bacterial Cellulose and Chitosan for Wound Dressing Materials. Eurasian Chem. J. 2017, 19, 255. [Google Scholar] [CrossRef]

- Zhantlessova, S.; Savitskaya, I.; Kistaubayeva, A.; Ignatova, L.; Talipova, A.; Pogrebnjak, A.; Digel, I. Advanced “Green” Prebiotic Composite of Bacterial Cellulose/Pullulan Based on Synthetic Biology-Powered Microbial Coculture Strategy. Polymers 2022, 14, 3224. [Google Scholar] [CrossRef] [PubMed]

- Peng, R.; Yu, B.; Hu, H. MXene Interlayer Space Expansion: Alleviating Coulomb Attraction and Steric Resistance on Multivalent Charge Carriers toward Micro-Supercapacitors with Enhanced Areal Energy Density. J. Electroanal. Chem. 2022, 922, 116716. [Google Scholar] [CrossRef]

- Jin, X.; Wang, S.; Sang, C.; Yue, Y.; Xu, X.; Mei, C.; Xiao, H.; Lou, Z.; Han, J. Patternable Nanocellulose/Ti3C2Tx Flexible Films with Tunable Photoresponsive and Electromagnetic Interference Shielding Performances. ACS Appl. Mater. Interfaces 2022, 14, 35040–35052. [Google Scholar] [CrossRef] [PubMed]

- Acharya, S.; Liyanage, S.; Parajuli, P.; Rumi, S.S.; Shamshina, J.L.; Abidi, N. Utilization of Cellulose to Its Full Potential: A Review on Cellulose Dissolution, Regeneration, and Applications. Polymers 2021, 13, 4344. [Google Scholar] [CrossRef] [PubMed]

- Minnick, D.L.; Flores, R.A.; DeStefano, M.R.; Scurto, A.M. Cellulose Solubility in Ionic Liquid Mixtures: Temperature, Cosolvent, and Antisolvent Effects. J. Phys. Chem. B 2016, 120, 7906–7919. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Fang, Y.; Xiang, J.; Ma, Y.; Lu, A.; Kang, H.; Huang, Y.; Guo, H.; Liu, R.; Zhang, L. Intermolecular Interactions and 3D Structure in Cellulose–NaOH–Urea Aqueous System. J. Phys. Chem. B 2014, 118, 10250–10257. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Huang, J.; Zhong, Y.; Li, K.; Zhang, L.; Cai, J. High-Strength and High-Toughness Double-Cross-Linked Cellulose Hydrogels: A New Strategy Using Sequential Chemical and Physical Cross-Linking. Adv. Funct. Mater. 2016, 26, 6279–6287. [Google Scholar] [CrossRef]

- Cai, J.; Kimura, S.; Wada, M.; Kuga, S.; Zhang, L. Cellulose Aerogels from Aqueous Alkali Hydroxide–Urea Solution. ChemSusChem 2008, 1, 149–154. [Google Scholar] [CrossRef]

- Chang, C.; Zhang, L.; Zhou, J.; Zhang, L.; Kennedy, J.F. Structure and Properties of Hydrogels Prepared from Cellulose in NaOH/Urea Aqueous Solutions. Carbohydr. Polym. 2010, 82, 122–127. [Google Scholar] [CrossRef]

- Cao, W.-T.; Chen, F.-F.; Zhu, Y.-J.; Zhang, Y.-G.; Jiang, Y.-Y.; Ma, M.-G.; Chen, F. Binary Strengthening and Toughening of MXene/Cellulose Nanofiber Composite Paper with Nacre-Inspired Structure and Superior Electromagnetic Interference Shielding Properties. ACS Nano 2018, 12, 4583–4593. [Google Scholar] [CrossRef]

- Savitskaya, I.S.; Shokatayeva, D.H.; Kistaubayeva, A.S.; Ignatova, L.V.; Digel, I.E. Antimicrobial and Wound Healing Properties of a Bacterial Cellulose Based Material Containing B. Subtilis Cells. Heliyon 2019, 5, e02592. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Zhu, M.; Zhang, W.; Zhen, X.; Pei, Z.; Xue, Q.; Zhi, C.; Shi, P. Ultrathin MXene-Micropattern-Based Field-Effect Transistor for Probing Neural Activity. Adv. Mater. 2016, 28, 3333–3339. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Chen, Q.; Li, P.; Zhou, A.; Cao, X.; Hu, Q. Preparation, Mechanical and Anti-Friction Performance of MXene/Polymer Composites. Mater. Des. 2016, 92, 682–689. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, Y.; Zhuo, H.; Liu, L.; Jing, S.; Zhong, L.; Peng, X.; Sun, R. Compressible, Elastic, and Pressure-Sensitive Carbon Aerogels Derived from 2D Titanium Carbide Nanosheets and Bacterial Cellulose for Wearable Sensors. Chem. Mater. 2019, 31, 3301–3312. [Google Scholar] [CrossRef]

- Xiao, J.; Tan, Y.; Song, Y.; Zheng, Q. A Flyweight and Superelastic Graphene Aerogel as a High-Capacity Adsorbent and Highly Sensitive Pressure Sensor. J. Mater. Chem. A 2018, 6, 9074–9080. [Google Scholar] [CrossRef]

- Qin, Y.; Peng, Q.; Ding, Y.; Lin, Z.; Wang, C.; Li, Y.; Xu, F.; Li, J.; Yuan, Y.; He, X.; et al. Lightweight, Superelastic, and Mechanically Flexible Graphene/Polyimide Nanocomposite Foam for Strain Sensor Application. ACS Nano 2015, 9, 8933–8941. [Google Scholar] [CrossRef]

- Wu, X.; Han, Y.; Zhang, X.; Zhou, Z.; Lu, C. Large-Area Compliant, Low-Cost, and Versatile Pressure-Sensing Platform Based on Microcrack-Designed Carbon Black@Polyurethane Sponge for Human-Machine Interfacing. Adv. Funct. Mater. 2016, 26, 6246–6256. [Google Scholar] [CrossRef]

- Si, Y.; Wang, X.; Yan, C.; Yang, L.; Yu, J.; Ding, B. Pressure Sensors: Ultralight Biomass-Derived Carbonaceous Nanofibrous Aerogels with Superelasticity and High Pressure-Sensitivity (Adv. Mater. 43/2016). Adv. Mater. 2016, 28, 9655. [Google Scholar] [CrossRef]

- Iqbal, A.; Sambyal, P.; Koo, C.M. 2D MXenes for Electromagnetic Shielding: A Review. Adv. Funct. Mater. 2020, 30, 2000883. [Google Scholar] [CrossRef]

- Han, M.; Shuck, C.E.; Rakhmanov, R.; Parchment, D.; Anasori, B.; Koo, C.M.; Friedman, G.; Gogotsi, Y. Beyond Ti3C2Tx: MXenes for Electromagnetic Interference Shielding. ACS Nano 2020, 14, 5008–5016. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic Interference Shielding with 2D Transition Metal Carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Liu, J.; Zhang, X.; Tian, D.; Zhan, Z.; Lu, C. Ultrathin MXene/Calcium Alginate Aerogel Film for High-Performance Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2019, 6, 1802040. [Google Scholar] [CrossRef]

- Liu, R.; Miao, M.; Li, Y.; Zhang, J.; Cao, S.; Feng, X. Ultrathin Biomimetic Polymeric Ti3C2Tx MXene Composite Films for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 44787–44795. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; Dai, L.; Liu, X.; Li, L.; Yang, Y.; Cao, Y.; Wang, W.; Wu, H.; Guo, S. Flame-Retardant Poly(Vinyl Alcohol)/MXene Multilayered Films with Outstanding Electromagnetic Interference Shielding and Thermal Conductive Performances. Chem. Eng. J. 2020, 380, 122475. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, Z.; Li, Y.; Han, G.; Feng, Y.; Wang, B.; Zhang, D.; Ma, J.; Liu, C. Flexible, Robust, and Multifunctional Electromagnetic Interference Shielding Film with Alternating Cellulose Nanofiber and MXene Layers. ACS Appl. Mater. Interfaces 2020, 12, 4895–4905. [Google Scholar] [CrossRef]

- Zhan, Z.; Song, Q.; Zhou, Z.; Lu, C. Ultrastrong and Conductive MXene/Cellulose Nanofiber Films Enhanced by Hierarchical Nano-Architecture and Interfacial Interaction for Flexible Electromagnetic Interference Shielding. J. Mater. Chem. C 2019, 7, 9820–9829. [Google Scholar] [CrossRef]

- Wei, H.; Wang, M.; Zheng, W.; Jiang, Z.; Huang, Y. 2D Ti3C2Tx MXene/Aramid Nanofibers Composite Films Prepared via a Simple Filtration Method with Excellent Mechanical and Electromagnetic Interference Shielding Properties. Ceram. Int. 2020, 46, 6199–6204. [Google Scholar] [CrossRef]

- Cao, W.; Ma, C.; Tan, S.; Ma, M.; Wan, P.; Chen, F. Ultrathin and Flexible CNTs/MXene/Cellulose Nanofibrils Composite Paper for Electromagnetic Interference Shielding. Nano-Micro Lett. 2019, 11, 72. [Google Scholar] [CrossRef]

- Xu, H.; Yin, X.; Li, X.; Li, M.; Liang, S.; Zhang, L.; Cheng, L. Lightweight Ti2CTx MXene/Poly(Vinyl Alcohol) Composite Foams for Electromagnetic Wave Shielding with Absorption-Dominated Feature. ACS Appl. Mater. Interfaces 2019, 11, 10198–10207. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Zhang, L.; Shi, L.; Wang, P. MXene Ti3C2: An Effective 2D Light-to-Heat Conversion Material. ACS Nano 2017, 11, 3752–3759. [Google Scholar] [CrossRef] [PubMed]

- Krasteva, P.V.; Bernal-Bayard, J.; Travier, L.; Martin, F.A.; Kaminski, P.-A.; Karimova, G.; Fronzes, R.; Ghigo, J.-M. Insights into the Structure and Assembly of a Bacterial Cellulose Secretion System. Nat. Commun. 2017, 8, 2065. [Google Scholar] [CrossRef] [PubMed]

- Tian, W.; VahidMohammadi, A.; Reid, M.S.; Wang, Z.; Ouyang, L.; Erlandsson, J.; Pettersson, T.; Wågberg, L.; Beidaghi, M.; Hamedi, M.M. Multifunctional Nanocomposites with High Strength and Capacitance Using 2D MXene and 1D Nanocellulose. Adv. Mater. 2019, 31, 1902977. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Cao, C.; Liu, J.; Sun, D.; Song, W. N-Doped Carbon Nanofibers Derived from Bacterial Cellulose as an Excellent Metal-Free Catalyst for Selective Oxidation of Arylalkanes. Chem. Commun. 2019, 55, 1935–1938. [Google Scholar] [CrossRef]

- Jiao, S.; Zhou, A.; Wu, M.; Hu, H. Kirigami Patterning of MXene/Bacterial Cellulose Composite Paper for All-Solid-State Stretchable Micro-Supercapacitor Arrays. Adv. Sci. 2019, 6, 1900529. [Google Scholar] [CrossRef]

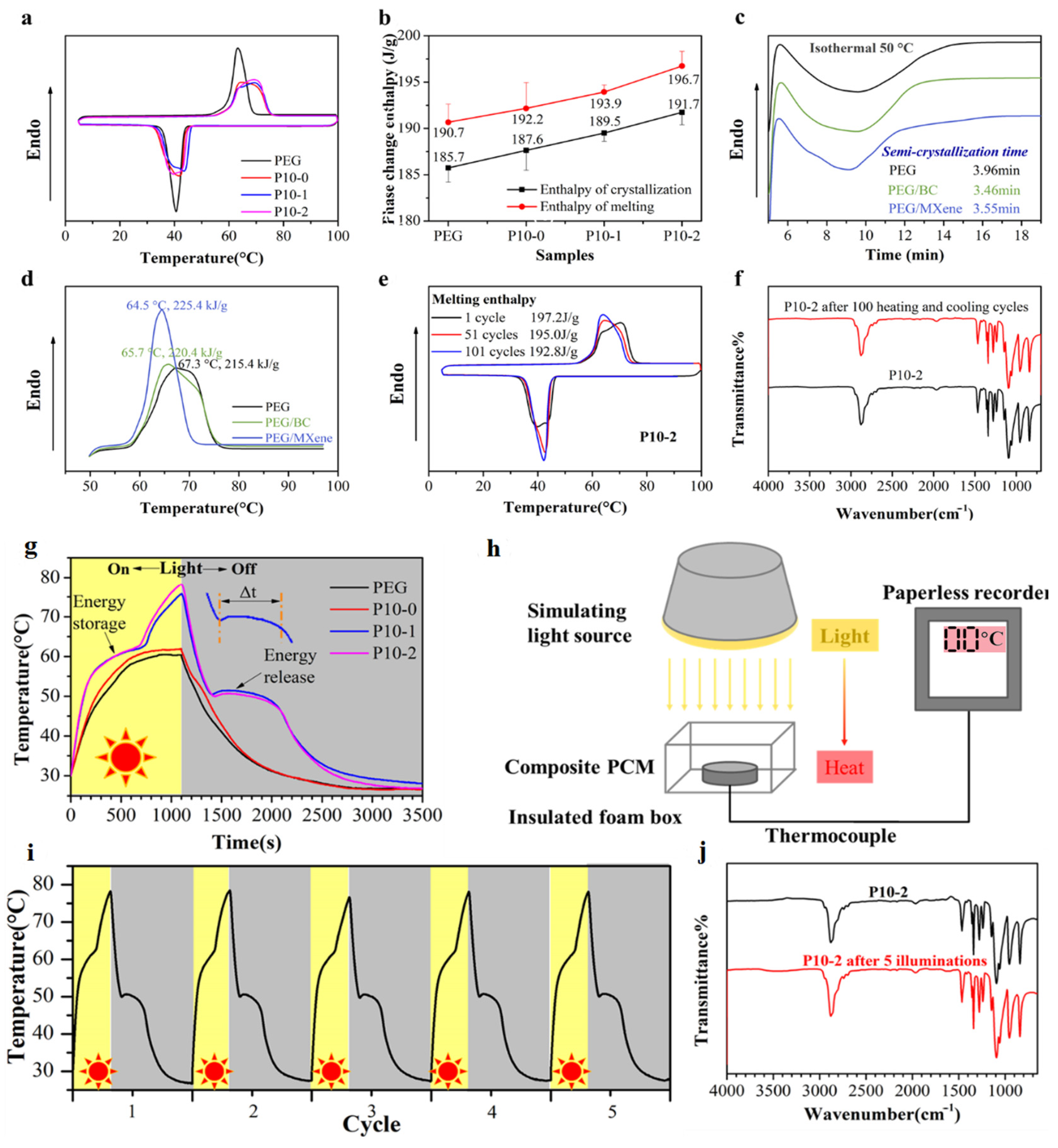

- Tang, L.; Zhao, X.; Feng, C.; Bai, L.; Yang, J.; Bao, R.; Liu, Z.; Yang, M.; Yang, W. Bacterial Cellulose/MXene Hybrid Aerogels for Photodriven Shape-Stabilized Composite Phase Change Materials. Sol. Energy Mater. Sol. Cells 2019, 203, 110174. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Qiu, J.; Jin, X.; Umair, M.M.; Lu, R.; Zhang, S.; Tang, B. Ag-Graphene/PEG Composite Phase Change Materials for Enhancing Solar-Thermal Energy Conversion and Storage Capacity. Appl. Energy 2019, 237, 83–90. [Google Scholar] [CrossRef]

- Silakhori, M.; Metselaar, H.S.C.; Mahlia, T.M.I.; Fauzi, H.; Baradaran, S.; Naghavi, M.S. Palmitic Acid/Polypyrrole Composites as Form-Stable Phase Change Materials for Thermal Energy Storage. Energy Convers. Manag. 2014, 80, 491–497. [Google Scholar] [CrossRef]

- Gurtner, G.C.; Werner, S.; Barrandon, Y.; Longaker, M.T. Wound Repair and Regeneration. Nature 2008, 453, 314–321. [Google Scholar] [CrossRef]

- Guo, Y.; Zhong, M.; Fang, Z.; Wan, P.; Yu, G. A Wearable Transient Pressure Sensor Made with MXene Nanosheets for Sensitive Broad-Range Human–Machine Interfacing. Nano Lett. 2019, 19, 1143–1150. [Google Scholar] [CrossRef] [PubMed]

- Qiu, A.; Li, P.; Yang, Z.; Yao, Y.; Lee, I.; Ma, J. A Path Beyond Metal and Silicon:Polymer/Nanomaterial Composites for Stretchable Strain Sensors. Adv. Funct. Mater. 2019, 29, 1806306. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Liu, Q.; Cheng, W.; Wang, X.; Pan, L.; Xu, B.; Xu, H. A Self-Healable, Highly Stretchable, and Solution Processable Conductive Polymer Composite for Ultrasensitive Strain and Pressure Sensing. Adv. Funct. Mater. 2018, 28, 1705551. [Google Scholar] [CrossRef]

- Ha, M.; Lim, S.; Ko, H. Wearable and Flexible Sensors for User-Interactive Health-Monitoring Devices. J. Mater. Chem. B 2018, 6, 4043–4064. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, A.F.; Fernandes, A.J.S.; Leitão, C.; Deuermeier, J.; Marques, A.C.; Martins, R.; Fortunato, E.; Costa, F.M. Laser-Induced Graphene Strain Sensors Produced by Ultraviolet Irradiation of Polyimide. Adv. Funct. Mater. 2018, 28, 1805271. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis Microstructure Inspired Graphene Pressure Sensor with Random Distributed Spinosum for High Sensitivity and Large Linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef]

- Tao, L.-Q.; Zhang, K.-N.; Tian, H.; Liu, Y.; Wang, D.-Y.; Chen, Y.-Q.; Yang, Y.; Ren, T.-L. Graphene-Paper Pressure Sensor for Detecting Human Motions. ACS Nano 2017, 11, 8790–8795. [Google Scholar] [CrossRef]

- D’Elia, E.; Barg, S.; Ni, N.; Rocha, V.G.; Saiz, E. Self-Healing Graphene-Based Composites with Sensing Capabilities. Adv. Mater. 2015, 27, 4788–4794. [Google Scholar] [CrossRef]

- Gao, L.; Zhu, C.; Li, L.; Zhang, C.; Liu, J.; Yu, H.-D.; Huang, W. All Paper-Based Flexible and Wearable Piezoresistive Pressure Sensor. ACS Appl. Mater. Interfaces 2019, 11, 25034–25042. [Google Scholar] [CrossRef]

- Yan, T.; Wang, Z.; Pan, Z.-J. Flexible Strain Sensors Fabricated Using Carbon-Based Nanomaterials: A Review. Curr. Opin. Solid State Mater. Sci. 2018, 22, 213–228. [Google Scholar] [CrossRef]

- Yao, S.; Ren, P.; Song, R.; Liu, Y.; Huang, Q.; Dong, J.; O’Connor, B.T.; Zhu, Y. Nanomaterial-Enabled Flexible and Stretchable Sensing Systems: Processing, Integration, and Applications. Adv. Mater. 2020, 32, 1902343. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Jian, M.; Wang, C.; Zhang, Y. Carbonized Silk Nanofiber Membrane for Transparent and Sensitive Electronic Skin. Adv. Funct. Mater. 2017, 27, 1605657. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, X.; Huang, H.; Wang, H.; Lin, W.; Peng, Z. Full 3D Printing of Stretchable Piezoresistive Sensor with Hierarchical Porosity and Multimodulus Architecture. Adv. Funct. Mater. 2019, 29, 1807569. [Google Scholar] [CrossRef]

- Chen, S.; Song, Y.; Xu, F. Flexible and Highly Sensitive Resistive Pressure Sensor Based on Carbonized Crepe Paper with Corrugated Structure. ACS Appl. Mater. Interfaces 2018, 10, 34646–34654. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Yuan, X.; Zeng, G.; Zhou, J.; Wang, X.; Chew, J.W. Clay-Inspired MXene-Based Electrochemical Devices and Photo-Electrocatalyst: State-of-the-Art Progresses and Challenges. Adv. Mater. 2018, 30, 1704561. [Google Scholar] [CrossRef]

- Gao, Y.; Yan, C.; Huang, H.; Yang, T.; Tian, G.; Xiong, D.; Chen, N.; Chu, X.; Zhong, S.; Deng, W.; et al. Microchannel-Confined MXene Based Flexible Piezoresistive Multifunctional Micro-Force Sensor. Adv. Funct. Mater. 2020, 30, 1909603. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Cao, Y.; Wang, G. Functional MXene Materials: Progress of Their Applications. Chem. Asian J. 2018, 13, 2742–2757. [Google Scholar] [CrossRef]

- Wang, K.; Lou, Z.; Wang, L.; Zhao, L.; Zhao, S.; Wang, D.; Han, W.; Jiang, K.; Shen, G. Bioinspired Interlocked Structure-Induced High Deformability for Two-Dimensional Titanium Carbide (MXene)/Natural Microcapsule-Based Flexible Pressure Sensors. ACS Nano 2019, 13, 9139–9147. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chang, T.-H.; Jing, L.; Li, K.; Yang, H.; Chen, P.-Y. Heterogeneous, 3D Architecturing of 2D Titanium Carbide (MXene) for Microdroplet Manipulation and Voice Recognition. ACS Appl. Mater. Interfaces 2020, 12, 8392–8402. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Reliable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X. Highly Compressible, Thermally Stable, Light-Weight, and Robust Aramid Nanofibers/Ti3AlC2 MXene Composite Aerogel for Sensitive Pressure Sensor. ACS Nano 2020, 14, 10633–10647. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, H.; Kokabi, M.; Mousavi, S.M. Conductive Bacterial Cellulose/Multiwall Carbon Nanotubes Nanocomposite Aerogel as a Potentially Flexible Lightweight Strain Sensor. Carbohydr. Polym. 2018, 201, 228–235. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Wan, Y.; He, F.; Liang, H.; Luo, H.; Han, J. Mechanical, Moisture Absorption, and Photodegradation Behaviors of Bacterial Cellulose Nanofiber- Reinforced Unsaturated Polyester Composites. Adv. Polym. Technol. 2011, 30, 249–256. [Google Scholar] [CrossRef]

- Andrade, F.K.; Moreira, S.M.G.; Domingues, L.; Gama, F.M.P. Improving the Affinity of Fibroblasts for Bacterial Cellulose Using Carbohydrate-Binding Modules Fused to RGD. J. Biomed. Mater. Res. Part A 2010, 92A, 9–17. [Google Scholar] [CrossRef]

- Fan, Z.; Liu, B.; Wang, J.; Zhang, S.; Lin, Q.; Gong, P.; Ma, L.; Yang, S. A Novel Wound Dressing Based on Ag/Graphene Polymer Hydrogel: Effectively Kill Bacteria and Accelerate Wound Healing. Adv. Funct. Mater. 2014, 24, 3933–3943. [Google Scholar] [CrossRef]

- Anumolu, S.S.; Menjoge, A.R.; Deshmukh, M.; Gerecke, D.; Stein, S.; Laskin, J.; Sinko, P.J. Doxycycline Hydrogels with Reversible Disulfide Crosslinks for Dermal Wound Healing of Mustard Injuries. Biomaterials 2011, 32, 1204–1217. [Google Scholar] [CrossRef]

- Murphy, P.S.; Evans, G.R.D. Advances in Wound Healing: A Review of Current Wound Healing Products. Plast. Surg. Int. 2012, 2012, 190436. [Google Scholar] [CrossRef]

- Bhang, S.H.; Jang, W.S.; Han, J.; Yoon, J.-K.; La, W.-G.; Lee, E.; Kim, Y.S.; Shin, J.-Y.; Lee, T.-J.; Baik, H.K.; et al. Zinc Oxide Nanorod-Based Piezoelectric Dermal Patch for Wound Healing. Adv. Funct. Mater. 2017, 27, 1603497. [Google Scholar] [CrossRef]

- Reid, B.; Zhao, M. The Electrical Response to Injury: Molecular Mechanisms and Wound Healing. Adv. Wound Care 2014, 3, 184–201. [Google Scholar] [CrossRef]

- Petrofsky, J.; Schwab, E.; Lo, T.; Cuneo, M.; Lawson, D. The Thermal Effect on the Blood Flow Response to Electrical Stimulation. Med. Sci. Monit. 2007, 13, CR498-504. [Google Scholar]

- Ud-Din, S.; Sebastian, A.; Giddings, P.; Colthurst, J.; Whiteside, S.; Morris, J.; Nuccitelli, R.; Pullar, C.; Baguneid, M.; Bayat, A. Angiogenesis Is Induced and Wound Size Is Reduced by Electrical Stimulation in an Acute Wound Healing Model in Human Skin. PLoS ONE 2015, 10, e0124502. [Google Scholar] [CrossRef] [PubMed]

- Snyder, A.R.; Perotti, A.L.; Lam, K.C.; Bay, R.C. The Influence of High-Voltage Electrical Stimulation on Edema Formation after Acute Injury: A Systematic Review. J. Sport Rehabil. 2010, 19, 436–451. [Google Scholar] [CrossRef] [PubMed]

- Gentzkow, G.D. Electrical Stimulation to Heal Dermal Wounds. J. Dermatol. Surg. Oncol. 1993, 19, 753–758. [Google Scholar] [CrossRef] [PubMed]

- Sebastian, A.; Syed, F.; Perry, D.; Balamurugan, V.; Colthurst, J.; Chaudhry, I.H.; Bayat, A. Acceleration of Cutaneous Healing by Electrical Stimulation: Degenerate Electrical Waveform down-Regulates Inflammation, up-Regulates Angiogenesis and Advances Remodeling in Temporal Punch Biopsies in a Human Volunteer Study. Wound Repair Regen. 2011, 19, 693–708. [Google Scholar] [CrossRef]

- Song, B.; Zhao, M.; Forrester, J.V.; McCaig, C.D. Electrical Cues Regulate the Orientation and Frequency of Cell Division and the Rate of Wound Healing In Vivo. Proc. Natl. Acad. Sci. USA 2002, 99, 13577–13582. [Google Scholar] [CrossRef]

- Zhao, M.; Song, B.; Pu, J.; Wada, T.; Reid, B.; Tai, G.; Wang, F.; Guo, A.; Walczysko, P.; Gu, Y.; et al. Electrical Signals Control Wound Healing through Phosphatidylinositol-3-OH Kinase-γ and PTEN. Nature 2006, 442, 457–460. [Google Scholar] [CrossRef]

- Guo, A.; Song, B.; Reid, B.; Gu, Y.; Forrester, J.V.; Jahoda, C.A.B.; Zhao, M. Effects of Physiological Electric Fields on Migration of Human Dermal Fibroblasts. J. Investig. Dermatol. 2010, 130, 2320–2327. [Google Scholar] [CrossRef]

- Chiang, M.; Cragoe, E.J.; Vanable, J.W. Intrinsic Electric Fields Promote Epithelization of Wounds in the Newt, Notophthalmus Viridescens. Dev. Biol. 1991, 146, 377–385. [Google Scholar] [CrossRef]

- Peters, M.J.; Stinstra, G.; Hendriks, M. Estimation of the Electrical Conductivity of Human Tissue. Electromagnetics 2001, 21, 545–557. [Google Scholar] [CrossRef]

- Zhao, X.; Wu, H.; Guo, B.; Dong, R.; Qiu, Y.; Ma, P.X. Antibacterial Anti-Oxidant Electroactive Injectable Hydrogel as Self-Healing Wound Dressing with Hemostasis and Adhesiveness for Cutaneous Wound Healing. Biomaterials 2017, 122, 34–47. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Huang, R.; Huang, Z.; Hu, B.; Zheng, W.; Yang, G.; Jiang, X. Evaluation of the Effect of the Structure of Bacterial Cellulose on Full Thickness Skin Wound Repair on a Microfluidic Chip. Biomacromolecules 2015, 16, 780–789. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Tian, Y.; Zheng, W.; Feng, Y.; Huang, R.; Shao, J.; Tang, R.; Wang, P.; Jia, Y.; Zhang, J.; et al. Composites of Bacterial Cellulose and Small Molecule-Decorated Gold Nanoparticles for Treating Gram-Negative Bacteria-Infected Wounds. Small 2017, 13, 1700130. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Liu, W.; Zhang, M.; Si, C.; Zhang, X.; Li, B. Cellulose Nanocrystals and Cellulose Nanofibrils Based Hydrogels for Biomedical Applications. Carbohydr. Polym. 2019, 209, 130–144. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Du, H.; Zhang, M.; Liu, K.; Liu, H.; Xie, H.; Zhang, X.; Si, C. Bacterial Cellulose-Based Composite Scaffolds for Biomedical Applications: A Review. ACS Sustain. Chem. Eng. 2020, 8, 7536–7562. [Google Scholar] [CrossRef]

- Walker, B.W.; Portillo Lara, R.; Mogadam, E.; Hsiang Yu, C.; Kimball, W.; Annabi, N. Rational Design of Microfabricated Electroconductive Hydrogels for Biomedical Applications. Prog. Polym. Sci. 2019, 92, 135–157. [Google Scholar] [CrossRef]

- Huang, K.; Li, Z.; Lin, J.; Han, G.; Huang, P. Two-Dimensional Transition Metal Carbides and Nitrides (MXenes) for Biomedical Applications. Chem. Soc. Rev. 2018, 47, 5109–5124. [Google Scholar] [CrossRef]

- Li, X.; Gu, T.; Wei, B. Dynamic and Galvanic Stability of Stretchable Supercapacitors. Nano Lett. 2012, 12, 6366–6371. [Google Scholar] [CrossRef]

- Hu, M.; Wang, J.; Liu, J.; Zhang, J.; Ma, X.; Huang, Y. An Intrinsically Compressible and Stretchable All-in-One Configured Supercapacitor. Chem. Commun. 2018, 54, 6200–6203. [Google Scholar] [CrossRef]

- Qi, D.; Liu, Z.; Liu, Y.; Leow, W.R.; Zhu, B.; Yang, H.; Yu, J.; Wang, W.; Wang, H.; Yin, S.; et al. Suspended Wavy Graphene Microribbons for Highly Stretchable Microsupercapacitors. Adv. Mater. 2015, 27, 5559–5566. [Google Scholar] [CrossRef]

- Chen, C.; Cao, J.; Wang, X.; Lu, Q.; Han, M.; Wang, Q.; Dai, H.; Niu, Z.; Chen, J.; Xie, S. Highly Stretchable Integrated System for Micro-Supercapacitor with AC Line Filtering and UV Detector. Nano Energy 2017, 42, 187–194. [Google Scholar] [CrossRef]

- Yun, J.; Song, C.; Lee, H.; Park, H.; Jeong, Y.R.; Kim, J.W.; Jin, S.W.; Oh, S.Y.; Sun, L.; Zi, G.; et al. Stretchable Array of High-Performance Micro-Supercapacitors Charged with Solar Cells for Wireless Powering of an Integrated Strain Sensor. Nano Energy 2018, 49, 644–654. [Google Scholar] [CrossRef]

- Lee, G.; Kim, D.; Kim, D.; Oh, S.; Yun, J.; Kim, J.; Lee, S.-S.; Ha, J.S. Fabrication of a Stretchable and Patchable Array of High Performance Micro-Supercapacitors Using a Non-Aqueous Solvent Based Gel Electrolyte. Energy Environ. Sci. 2015, 8, 1764–1774. [Google Scholar] [CrossRef]

- Kim, H.; Yoon, J.; Lee, G.; Paik, S.; Choi, G.; Kim, D.; Kim, B.-M.; Zi, G.; Ha, J.S. Encapsulated, High-Performance, Stretchable Array of Stacked Planar Micro-Supercapacitors as Waterproof Wearable Energy Storage Devices. ACS Appl. Mater. Interfaces 2016, 8, 16016–16025. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.Y.; Yoon, J.; Jin, S.W.; Lim, Y.; Lee, S.-J.; Zi, G.; Ha, J.S. High-Density, Stretchable, All-Solid-State Microsupercapacitor Arrays. ACS Nano 2014, 8, 8844–8855. [Google Scholar] [CrossRef] [PubMed]

- Lim, Y.; Yoon, J.; Yun, J.; Kim, D.; Hong, S.Y.; Lee, S.-J.; Zi, G.; Ha, J.S. Biaxially Stretchable, Integrated Array of High Performance Microsupercapacitors. ACS Nano 2014, 8, 11639–11650. [Google Scholar] [CrossRef] [PubMed]

- Qi, D.; Liu, Y.; Liu, Z.; Zhang, L.; Chen, X. Design of Architectures and Materials in In-Plane Micro-Supercapacitors: Current Status and Future Challenges. Adv. Mater. 2017, 29, 1602802. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Pei, Z.; Ye, C. Recent Advances in Designing and Fabrication of Planar Micro-Supercapacitors for On-Chip Energy Storage. Energy Storage Mater. 2015, 1, 82–102. [Google Scholar] [CrossRef]

- Naguib, M.; Mochalin, V.N.; Barsoum, M.W.; Gogotsi, Y. 25th Anniversary Article: MXenes: A New Family of Two-Dimensional Materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef]

- Mashtalir, O.; Naguib, M.; Mochalin, V.N.; Dall’Agnese, Y.; Heon, M.; Barsoum, M.W.; Gogotsi, Y. Intercalation and Delamination of Layered Carbides and Carbonitrides. Nat. Commun. 2013, 4, 1716. [Google Scholar] [CrossRef]

- Xu, M.; Lei, S.; Qi, J.; Dou, Q.; Liu, L.; Lu, Y.; Huang, Q.; Shi, S.; Yan, X. Opening Magnesium Storage Capability of Two-Dimensional MXene by Intercalation of Cationic Surfactant. ACS Nano 2018, 12, 3733–3740. [Google Scholar] [CrossRef]

- Hu, H.; Bai, Z.; Niu, B.; Wu, M.; Hua, T. Binder-Free Bonding of Modularized MXene Thin Films into Thick Film Electrodes for On-Chip Micro-Supercapacitors with Enhanced Areal Performance Metrics. J. Mater. Chem. A 2018, 6, 14876–14884. [Google Scholar] [CrossRef]

- Zhao, M.-Q.; Ren, C.E.; Ling, Z.; Lukatskaya, M.R.; Zhang, C.; Van Aken, K.L.; Barsoum, M.W.; Gogotsi, Y. Flexible MXene/Carbon Nanotube Composite Paper with High Volumetric Capacitance. Adv. Mater. 2015, 27, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Kyrylenko, S.; Gogotsi, O.; Baginskiy, I.; Balitskyi, V.; Zahorodna, V.; Husak, Y.; Yanko, I.; Pernakov, M.; Roshchupkin, A.; Lyndin, M.; et al. MXene-Assisted Ablation of Cells with a Pulsed Near-Infrared Laser. ACS Appl. Mater. Interfaces 2022, 14, 28683–28696. [Google Scholar] [CrossRef] [PubMed]

- Kołtunowicz, T.N.; Gałaszkiewicz, P.; Kierczyński, K.; Rogalski, P.; Okal, P.; Pogrebnjak, A.D.; Buranich, V.; Pogorielov, M.; Diedkova, K.; Zahorodna, V.; et al. Investigation of AC Electrical Properties of MXene-PCL Nanocomposites for Application in Small and Medium Power Generation. Energies 2021, 14, 7123. [Google Scholar] [CrossRef]

- Bao, W.; Liu, L.; Wang, C.; Choi, S.; Wang, D.; Wang, G. Facile Synthesis of Crumpled Nitrogen-Doped MXene Nanosheets as a New Sulfur Host for Lithium-Sulfur Batteries. Adv. Energy Mater. 2018, 8, 1702485. [Google Scholar] [CrossRef]

- Su, D.; Cortie, M.; Fan, H.; Wang, G. Prussian Blue Nanocubes with an Open Framework Structure Coated with PEDOT as High-Capacity Cathodes for Lithium–Sulfur Batteries. Adv. Mater. 2017, 29, 1700587. [Google Scholar] [CrossRef]

- Hu, H.; Hua, T. An Easily Manipulated Protocol for Patterning of MXenes on Paper for Planar Micro-Supercapacitors. J. Mater. Chem. A 2017, 5, 19639–19648. [Google Scholar] [CrossRef]

- Kurra, N.; Ahmed, B.; Gogotsi, Y.; Alshareef, H.N. MXene-on-Paper Coplanar Microsupercapacitors. Adv. Energy Mater. 2016, 6, 1601372. [Google Scholar] [CrossRef]

- Peng, Y.-Y.; Akuzum, B.; Kurra, N.; Zhao, M.-Q.; Alhabeb, M.; Anasori, B.; Kumbur, E.C.; Alshareef, H.N.; Ger, M.-D.; Gogotsi, Y. All-MXene (2D Titanium Carbide) Solid-State Microsupercapacitors for on-Chip Energy Storage. Energy Environ. Sci. 2016, 9, 2847–2854. [Google Scholar] [CrossRef]

- Shen, B.-S.; Wang, H.; Wu, L.-J.; Guo, R.-S.; Huang, Q.; Yan, X.-B. All-Solid-State Flexible Microsupercapacitor Based on Two-Dimensional Titanium Carbide. Chin. Chem. Lett. 2016, 27, 1586–1591. [Google Scholar] [CrossRef]

- Weng, G.; Li, J.; Alhabeb, M.; Karpovich, C.; Wang, H.; Lipton, J.; Maleski, K.; Kong, J.; Shaulsky, E.; Elimelech, M.; et al. Layer-by-Layer Assembly of Cross-Functional Semi-transparent MXene-Carbon Nanotubes Composite Films for Next-Generation Electromagnetic Interference Shielding. Adv. Funct. Mater. 2018, 28, 1803360. [Google Scholar] [CrossRef]

- Liang, X.; Rangom, Y.; Kwok, C.Y.; Pang, Q.; Nazar, L.F. Interwoven MXene Nanosheet/Carbon-Nanotube Composites as Li-S Cathode Hosts. Adv. Mater. 2017, 29, 1603040. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Gong, Y.; Chen, R.; Zhang, M.; Zhou, J.; An, J.; Lv, F.; Guo, S.; Sun, G. A Solid-State Fibriform Supercapacitor Boosted by Host-Guest Hybridization between the Carbon Nanotube Scaffold and MXene Nanosheets. Small 2018, 14, 1801203. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Shen, J.; Ge, G.; Zhang, Y.; Jin, W.; Huang, W.; Shao, J.; Yang, J.; Dong, X. Stretchable Ti3C2Tx MXene/Carbon Nanotube Composite Based Strain Sensor with Ultrahigh Sensitivity and Tunable Sensing Range. ACS Nano 2018, 12, 56–62. [Google Scholar] [CrossRef]

- Zhou, Z.; Panatdasirisuk, W.; Mathis, T.S.; Anasori, B.; Lu, C.; Zhang, X.; Liao, Z.; Gogotsi, Y.; Yang, S. Layer-by-Layer Assembly of MXene and Carbon Nanotubes on Electrospun Polymer Films for Flexible Energy Storage. Nanoscale 2018, 10, 6005–6013. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, L.; Yan, X.; Ding, X. Recent Advances of Cellulose-Based Materials and Their Promising Application in Sodium-Ion Batteries and Capacitors. Small 2018, 14, 1802444. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent Advances in Carbon-Based Polymer Nanocomposites for Electromagnetic Interference Shielding. Prog. Mater. Sci. 2019, 103, 319–373. [Google Scholar] [CrossRef]

- Jiang, D.; Murugadoss, V.; Wang, Y.; Lin, J.; Ding, T.; Wang, Z.; Shao, Q.; Wang, C.; Liu, H.; Lu, N.; et al. Electromagnetic Interference Shielding Polymers and Nanocomposites—A Review. Polym. Rev. 2019, 59, 280–337. [Google Scholar] [CrossRef]

- Yun, J.; Lim, Y.; Jang, G.N.; Kim, D.; Lee, S.-J.; Park, H.; Hong, S.Y.; Lee, G.; Zi, G.; Ha, J.S. Stretchable Patterned Graphene Gas Sensor Driven by Integrated Micro-Supercapacitor Array. Nano Energy 2016, 19, 401–414. [Google Scholar] [CrossRef]

- Gupta, S.; Tai, N.-H. Carbon Materials and Their Composites for Electromagnetic Interference Shielding Effectiveness in X-Band. Carbon N. Y. 2019, 152, 159–187. [Google Scholar] [CrossRef]

- Li, N.; Huang, Y.; Du, F.; He, X.; Lin, X.; Gao, H.; Ma, Y.; Li, F.; Chen, Y.; Eklund, P.C. Electromagnetic Interference (EMI) Shielding of Single-Walled Carbon Nanotube Epoxy Composites. Nano Lett. 2006, 6, 1141–1145. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.-B.; Yang, Y.; Wang, M.; Cao, A.; Yu, Z.-Z. High-Performance Epoxy Nanocomposites Reinforced with Three-Dimensional Carbon Nanotube Sponge for Electromagnetic Interference Shielding. Adv. Funct. Mater. 2016, 26, 447–455. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Zhang, Z. Lightweight and Anisotropic Porous MWCNT/WPU Composites for Ultrahigh Performance Electromagnetic Interference Shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, C.; Ma, C.; Ren, W.; Cheng, H.-M. Lightweight and Flexible Graphene Foam Composites for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, N.; Sun, X.; Lin, X.; Shen, X.; Jia, J.; Zhang, B.; Tang, B.; Chan, M.; Kim, J.-K. Highly Aligned Graphene/Polymer Nanocomposites with Excellent Dielectric Properties for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.; Pei, S.; Qian, X.; Liu, H.; Liu, Z.; Zhang, W.; Zhou, T.; Zhang, Z.; Zhang, X.; Cheng, H.; et al. Superhigh Electromagnetic Interference Shielding of Ultrathin Aligned Pristine Graphene Nanosheets Film. Adv. Mater. 2020, 32, 1907411. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Wang, N.; Legut, D.; Si, C.; Zhang, Q.; Du, S.; Germann, T.C.; Francisco, J.S.; Zhang, R. Rational Design of Flexible Two-Dimensional MXenes with Multiple Functionalities. Chem. Rev. 2019, 119, 11980–12031. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.-B.; Sun, R.; Liu, Y.; Liu, Z.; Zhou, A.; Yu, Z.-Z. Hydrophobic, Flexible, and Lightweight MXene Foams for High-Performance Electromagnetic-Interference Shielding. Adv. Mater. 2017, 29, 1702367. [Google Scholar] [CrossRef]

- Li, X.; Yin, X.; Song, C.; Han, M.; Xu, H.; Duan, W.; Cheng, L.; Zhang, L. Self-Assembly Core-Shell Graphene-Bridged Hollow MXenes Spheres 3D Foam with Ultrahigh Specific EM Absorption Performance. Adv. Funct. Mater. 2018, 28, 1803938. [Google Scholar] [CrossRef]

- Vural, M.; Pena-Francesch, A.; Bars-Pomes, J.; Jung, H.; Gudapati, H.; Hatter, C.B.; Allen, B.D.; Anasori, B.; Ozbolat, I.T.; Gogotsi, Y.; et al. Inkjet Printing of Self-Assembled 2D Titanium Carbide and Protein Electrodes for Stimuli-Responsive Electromagnetic Shielding. Adv. Funct. Mater. 2018, 28, 1801972. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, J.; Peng, W.; Zhu, Y.; Zhao, Y.; Jiang, K.; Peng, M.; Tan, Y. Highly Stable 3D Ti3C2Tx MXene-Based Foam Architectures toward High-Performance Terahertz Radiation Shielding. ACS Nano 2020, 14, 2109–2117. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.-H.; Zhang, T.; Yang, H.; Li, K.; Tian, Y.; Lee, J.Y.; Chen, P.-Y. Controlled Crumpling of Two-Dimensional Titanium Carbide (MXene) for Highly Stretchable, Bendable, Efficient Supercapacitors. ACS Nano 2018, 12, 8048–8059. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.-W.; Zhang, H.-B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.-Z. Multifunctional and Water-Resistant MXene-Decorated Polyester Textiles with Outstanding Electromagnetic Interference Shielding and Joule Heating Performances. Adv. Funct. Mater. 2019, 29, 1806819. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Lee, S.-Y.; Wei, T.; Li, J.; Fan, Z. Nanocellulose: A Promising Nanomaterial for Advanced Electrochemical Energy Storage. Chem. Soc. Rev. 2018, 47, 2837–2872. [Google Scholar] [CrossRef]

- Ma, L.; Bi, Z.; Xue, Y.; Zhang, W.; Huang, Q.; Zhang, L.; Huang, Y. Bacterial Cellulose: An Encouraging Eco-Friendly Nano-Candidate for Energy Storage and Energy Conversion. J. Mater. Chem. A 2020, 8, 5812–5842. [Google Scholar] [CrossRef]

- Wang, B.; Li, J.; Wu, Z.; Sheng, N.; Zhang, M.; Han, Z.; Jin, M.; Li, J.; Lv, X.; Ou, K.; et al. Salinity Power Generation Based Biocompatible Bacterial Cellulose/MXene Membrane for Biological Power Source. Nano Energy 2022, 102, 107702. [Google Scholar] [CrossRef]

- Shypylenko, A.; Pshyk, A.V.; Grześkowiak, B.; Medjanik, K.; Peplinska, B.; Oyoshi, K.; Pogrebnjak, A.; Jurga, S.; Coy, E. Effect of Ion Implantation on the Physical and Mechanical Properties of Ti-Si-N Multifunctional Coatings for Biomedical Applications. Mater. Des. 2016, 110, 821–829. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Kong, C.-H.; Webster, R.F.; Tilley, R.D.; Takeda, Y.; Oyoshi, K.; Bondar, O.V.; Buranich, V.V.; Konstantinov, S.V.; Baimoldanova, L.S.; et al. Antibacterial Effect of Au Implantation in Ductile Nanocomposite Multilayer (TiAlSiY)N/CrN Coatings. ACS Appl. Mater. Interfaces 2019, 11, 48540–48550. [Google Scholar] [CrossRef]

- Turlybekuly, A.; Pogrebnjak, A.D.; Sukhodub, L.F.; Sukhodub, L.B.; Kistaubayeva, A.S.; Savitskaya, I.S.; Shokatayeva, D.H.; Bondar, O.V.; Shaimardanov, Z.K.; Plotnikov, S.V.; et al. Synthesis, Characterization, in Vitro Biocompatibility and Antibacterial Properties Study of Nanocomposite Materials Based on Hydroxyapatite-Biphasic ZnO Micro- and Nanoparticles Embedded in Alginate Matrix. Mater. Sci. Eng. C 2019, 104, 109965. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Sukhodub, L.; Sukhodub, L.; Bondar, O.; Kumeda, M.; Shaimardanova, B.; Shaimardanov, Z.; Turlybekuly, A. Composite Material with Nanoscale Architecture Based on Bioapatite, Sodium Alginate and ZnO Microparticles. Ceram. Int. 2019, 45, 7504–7514. [Google Scholar] [CrossRef]

- Sukhodub, L.F.; Sukhodub, L.B.; Pogrebnjak, A.D.; Turlybekuly, A.; Kistaubayeva, A.; Savitskaya, I.; Shokatayeva, D. Effect of Magnetic Particles Adding into Nanostructured Hydroxyapatite–Alginate Composites for Orthopedics. J. Korean Ceram. Soc. 2020, 57, 557–569. [Google Scholar] [CrossRef]

- Sukhodub, L.F.; Pogrebnjak, A.D.; Sukhodub, L.B.; Sagidugumar, A.; Kistaubayeva, A.S.; Savitskaya, I.S.; Talipova, A.; Sadibekov, A.; Kantay, N.; Akatan, K.; et al. Antibacterial and Physical Characteristics of Silver-Loaded Hydroxyapatite/Alginate Composites. Funct. Compos. Struct. 2021, 3, 045010. [Google Scholar] [CrossRef]

- Kravchenko, Y.O.; Coy, E.; Załęski, K.; Iatsunskyi, I.; Pogorielov, M.; Korniienko, V.; Pshyk, A.V.; Pogrebnjak, A.D.; Beresnev, V.M. Biocompatibility and Electron Microscopy Studies of Epitaxial Nanolaminate (Al0·5Ti0.5)N/ZrN Coatings Deposited by Arc-PVD Technique. Ceram. Int. 2021, 47, 34648–34656. [Google Scholar] [CrossRef]

- Zhi, H.; Zhang, X.; Wang, F.; Wan, P.; Feng, L. Flexible Ti3C2Tx MXene/PANI/Bacterial Cellulose Aerogel for e-Skins and Gas Sensing. ACS Appl. Mater. Interfaces 2021, 13, 45987–45994. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Cui, J.; Zhang, L.; Xu, X.; Chen, X.; Sun, D. A Moisture-Driven Actuator Based on Polydopamine-Modified MXene/Bacterial Cellulose Nanofiber Composite Film. Adv. Funct. Mater. 2021, 31, 2101378. [Google Scholar] [CrossRef]

| Sample | Tensile Strength (MPa) | Deformation at Break (%) | Viscosity (MJ/m3) | Young’s Modulus (GPa) | Number of Folding (Time) |

|---|---|---|---|---|---|

| BC | 389.7 ± 5.3 | 10.1 ± 0.3 | 23.6 ± 1.4 | 6.6 ± 0.9 | 5055 ± 45 |

| BX-1 | 407.3 ± 11.8 | 9.6 ± 0.2 | 24.3 ± 0.6 | 7.3 ± 0.3 | 5265 ± 87 |

| BX-2 | 451.0 ± 19.2 | 9.6 ± 0.4 | 25.9 ± 4.4 | 7.6 ± 0.1 | 5560 ± 44 |

| BX-3 | 469.4 ± 11.9 | 10.3 ± 0.4 | 28.3 ± 2.5 | 7.8 ± 0.7 | 5828 ± 65 |

| BX-4 | 481.5 ± 7.3 | 10.8 ± 0.3 | 29.4 ± 0.2 | 8.0 ± 0.6 | 5944 ± 50 |

| BX-5 | 532.9 ± 22.4 | 11.0 ± 0.9 | 31.1 ± 2.7 | 8.3 ± 1.3 | 6152 ± 51 |

| Sample | TM (°C) | ΔHM (J/g) | TC (°C) | ΔHC (J/g) |

|---|---|---|---|---|

| PEG | 63.5 ± 0.3 | 190.7 ± 2.0 | 41.1 ± 0.4 | 185.7 ± 1.5 |

| P10-0 | 67.5 ± 2.5 | 192.2 ± 2.8 | 39.7 ± 1.7 | 187.6 ± 2.1 |

| P10-1 | 67.9 ± 2.7 | 193.9 ± 0.8 | 42.7 ± 0.8 | 189.5 ± 0.9 |

| P10-2 | 67.0 ± 2.1 | 196.7 ± 1.6 | 41.5 ± 1.7 | 191.7 ± 1.3 |

| Type of Composite | The Composite Form | Synthesis Method | Specific Properties | Application | References |

|---|---|---|---|---|---|

| Ti3C2Tx/BC | Film | Vacuum filtration | High mechanical strength (225 MPa), low detective limit (0.4 Pa), outperformed repeatability (25,000 cycles) | Pressure sensor | [16] |

| BCs/MXene film | Film | Vacuum filtration | Flexibility, transparency, conductivity | Wearable electronics, electromagnetic interference (EMI) shielding | [26] |

| rBC/MXene Hydrogel | Hydrogels | Chemical precipitation | Flexibility, electrical conductivity | Wound dressing | [35] |

| C-MX/BC-x carbon aerogel | Carbon aerogel | Directional freezing, freeze-drying, carbonization | Super compressibility, elasticity, high sensitivity (0–10 kPa) | Electronics and electronic skins | [57] |

| Ti3C2Tx/BC | Film | In situ biosynthesis | Ultrathin films, electrically conductive, mechanically strong | Electromagnetic interference (EMI) shielding | [27] |

| BC/MXene hybrid aerogels | Hybrid aerogels | Freeze-drying | Ultralight, excellent shape stability, high energy storage capacity | Solar thermal energy storage | [78] |

| MXene/BCNF | Film | Vacuum filtration | High tensile strength (252.2 MPa), excellent folding endurance (10,000 times), high electrical conductivity (443.5 S cm−1). | Electromagnetic interference (EMI) shielding | [28] |

| MXene/BC | Paper | Vacuum filtration | Flexibility, mechanical strength | Micro-supercapacitor | [77] |

| MXene/BC derived | Carbon aerogel | Thermal annealing/carbonization | High sensitivity (95.2 kPa−1, 50 Pa) | Pressure sensor | [81] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talipova, A.B.; Buranych, V.V.; Savitskaya, I.S.; Bondar, O.V.; Turlybekuly, A.; Pogrebnjak, A.D. Synthesis, Properties, and Applications of Nanocomposite Materials Based on Bacterial Cellulose and MXene. Polymers 2023, 15, 4067. https://doi.org/10.3390/polym15204067

Talipova AB, Buranych VV, Savitskaya IS, Bondar OV, Turlybekuly A, Pogrebnjak AD. Synthesis, Properties, and Applications of Nanocomposite Materials Based on Bacterial Cellulose and MXene. Polymers. 2023; 15(20):4067. https://doi.org/10.3390/polym15204067

Chicago/Turabian StyleTalipova, Aizhan B., Volodymyr V. Buranych, Irina S. Savitskaya, Oleksandr V. Bondar, Amanzhol Turlybekuly, and Alexander D. Pogrebnjak. 2023. "Synthesis, Properties, and Applications of Nanocomposite Materials Based on Bacterial Cellulose and MXene" Polymers 15, no. 20: 4067. https://doi.org/10.3390/polym15204067

APA StyleTalipova, A. B., Buranych, V. V., Savitskaya, I. S., Bondar, O. V., Turlybekuly, A., & Pogrebnjak, A. D. (2023). Synthesis, Properties, and Applications of Nanocomposite Materials Based on Bacterial Cellulose and MXene. Polymers, 15(20), 4067. https://doi.org/10.3390/polym15204067