1. Introduction

Thin-walled structures have found extensive applications across various domains, including the automotive sector, aerospace, civil engineering, biomedicine, and more. This popularity stems from their remarkable attributes, such as extremely low weight, cost-effective manufacturing, and exceptional energy absorption efficiency [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12]. Over the past few decades, conventional thin-walled tubes like circular tubes [

13,

14], triangular tubes [

5,

15], square tubes [

16], and polygonal tubes [

17,

18] have been the subject of extensive research and investigation. However, simple tubes suffer from their limited design space, which makes it difficult to further improve their performance. Improving the mechanical properties of thin-walled structures has become a prominent research area within the field of lightweight energy absorption. Several novel thin-walled design strategies have been proposed and investigated, including various cross-sectional configurations [

19,

20,

21,

22], structural hierarchies [

1,

23], multi-cell tubes [

7,

24], gradient thicknesses [

25,

26,

27,

28,

29,

30,

31], composite tubes [

6,

32], and form filling [

4,

8,

33,

34].

The utilization of multi-cell tubes has gained considerable attention in the pursuit of enhancing the crashworthiness of thin-walled structures, owing to their exceptional energy absorption characteristics [

35,

36]. Wierzbicki and Abramowicz delved into the folding mechanism of thin-walled structures and the crushing behavior of multi-corner columns. They established that the energy absorption performance of these structures was heavily influenced by the number of corner elements, and they successfully predicted the mean crushing force of multi-corner columns subjected to axial compression [

37,

38]. Kim introduced innovative multi-cell profiles featuring four square elements at the corners, resulting in significant improvements in crash energy absorption and weight efficiency when compared to conventional square box columns [

39]. Chen and Wierzbicki introduced single-layer and double-layer partitions into hollow columns [

40]. Through numerical simulations, it was found that the multi-cell tube could significantly enhance the compressive strength of the structure. The concept of hierarchy was incorporated into thin-walled circular tubes by Zhang et al. [

41]. Their findings demonstrated that the crushing performance of these tubes could be significantly enhanced by substituting the original single-cell circular tube wall with a series of smaller tubes. Recently, the multi-cell approach has been demonstrated to improve the crashworthiness of structures. However, multi-cell tubes still have a broad design space.

More recently, the exploration of hierarchical structures found in biological tissues has sparked innovative approaches to designing high-performance energy absorbers [

1,

42,

43]. Wu et al. introduced triangular, square, and pentagonal tree-like fractal structures, which exhibited significant potential for enhancing energy absorption properties when compared to single-walled structures [

44]. Ha et al. took inspiration from nature and constructed a novel bio-inspired hierarchical multi-cell square (BHMS) tube, mimicking the gradient distribution of cell sizes found in biological structures like bones and bamboo. Compression simulations of different-order BHMS structures revealed that high-order BHMS tubes possessed substantially higher

SEA capabilities compared to their low-order counterparts [

45]. Drawing inspiration from the growth patterns and microstructures of plant stems, Gong et al. introduced a series of tubes with m parts and n layers (PmLnBTs). Their theoretical predictions and numerical analyses indicated that PmLnBTs exhibited superior crashworthiness performance when compared to traditional bi-tubular circular tubes [

46]. Wang et al. [

47] introduced an innovative thin-walled multi-cell tubular structure featuring a modified face-centered cubic (MFCS) cross-section, drawing inspiration from the unique characteristics of the glass sponge’s skeletal structure. When compared to conventional multi-cell tubes, the MCFS structure displayed micro-folding lobes with shorter wavelengths, leading to significantly improved energy absorption efficiency. Moreover, the mean crushing force of this MCFS structure approached that of an ideal energy absorber. Besides the above-mentioned tube structures, sandwich structures with thin-walled cores have also been heavily used for energy absorption. Thin-walled sandwich structures typically consist of stiff skin layers and corrugated core sheets, resulting in superior bending stiffness, strength, and

SEA properties compared to solid monolithic construction [

48,

49]. Dayyani et al. categorized sandwich panels into three distinct groups: curved corrugated core sandwich panels, bi-directional corrugated core sandwich panels, and hierarchical corrugated core sandwich panels [

50]. Notably, the use of curved corrugated sheets, including triangular and trapezoidal shapes, as cores for sandwich panels has been the subject of extensive research and investigation [

51,

52,

53]. Li et al. [

54] employed 3D printing technology to fabricate Grid-shaped, V-shaped, and U-shaped corrugated sandwich structures, allowing for a comparison of the mechanical properties of various shapes and layers. Their findings showed that the deformation modes of these sandwich structures were influenced by the load-carrying path and the relative mechanical properties between interlayers and cores. Yang et al. introduced an innovative lightweight bi-directionally sinusoidal corrugated core sandwich panel inspired by mantis shrimp structures [

55]. Their research demonstrated that bi-directional corrugated core sandwich panels exhibited significantly enhanced crashworthiness compared to conventional triangular and sinusoidal corrugated sandwich panels. In order to enhance the energy absorption capacity of thin-walled core sandwich panels, Kooistra et al. [

56] introduced the concept of hierarchical corrugated core sandwich panels in their study [

56]. They conducted a comparative analysis examining the transverse compression and shear collapse mechanisms of first-order and second-order corrugated truss structures. Their research findings revealed that the strength of second-order trusses was approximately ten times greater than that of first-order trusses with the same relative density. This substantial increase in strength contributed significantly to boosting the

SEA of the hierarchical corrugated core sandwich panel.

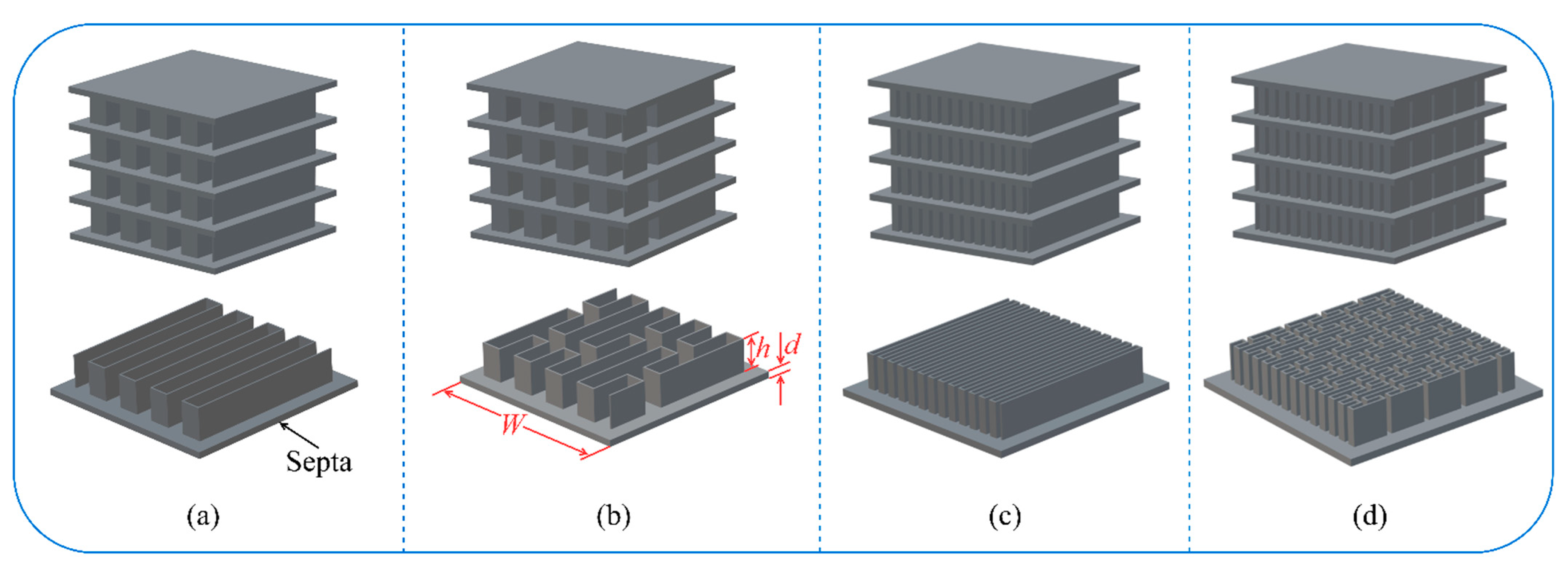

In order to improve energy absorption capabilities, many researchers have also proposed multilayer thin-walled sandwich structures. Energy absorption in these sandwich panels demonstrates an increase when the number of layers increases. Notably, there has been substantial interest in the field of crashworthiness research in structural design methods that draw inspiration from biological multilayer structures. This is due to their ability to generate unique geometric shapes and enhance energy absorption efficiency. For instance, the cuttlebone has a complex porous structure and mechanics with an asymmetric S-shaped wall structure connecting laminar septa, which helps it to withstand significant hydrostatic pressure in deep-sea environments. Polymers are frequently employed as raw materials for the 3D printing of high-precision structures, owing to their inherent plasticity and resilience. Consequently, numerous researchers have utilized 3D-printed polymer specimens to simulate and analyze the mechanical properties of complex structures [

57,

58]. Mao et al. [

59] employed polymeric materials to manufacture structures resembling cuttlebones that exhibited superior strength and energy absorption capabilities compared to octet-truss lattices, as well as traditional polymer and metal foams. In addition, Wu et al. [

60] optimized and designed a new elliptical corrugated cuttlebone-like multilayer structure based on the sinusoidally corrugated cuttlebone-like multilayer structure and subsequently utilized 3D printing technology with a C-UV9400E photosensitive resin to manufacture specimens for mechanical analysis, which significantly improved the compressive and shear capacities. The multilayer structure of the cuttlebone, interconnected by thin-walled structures, greatly enhances the cuttlefish’s survival ability in the deep sea and also provides inspiration for the design of new multilayer sandwich structures.

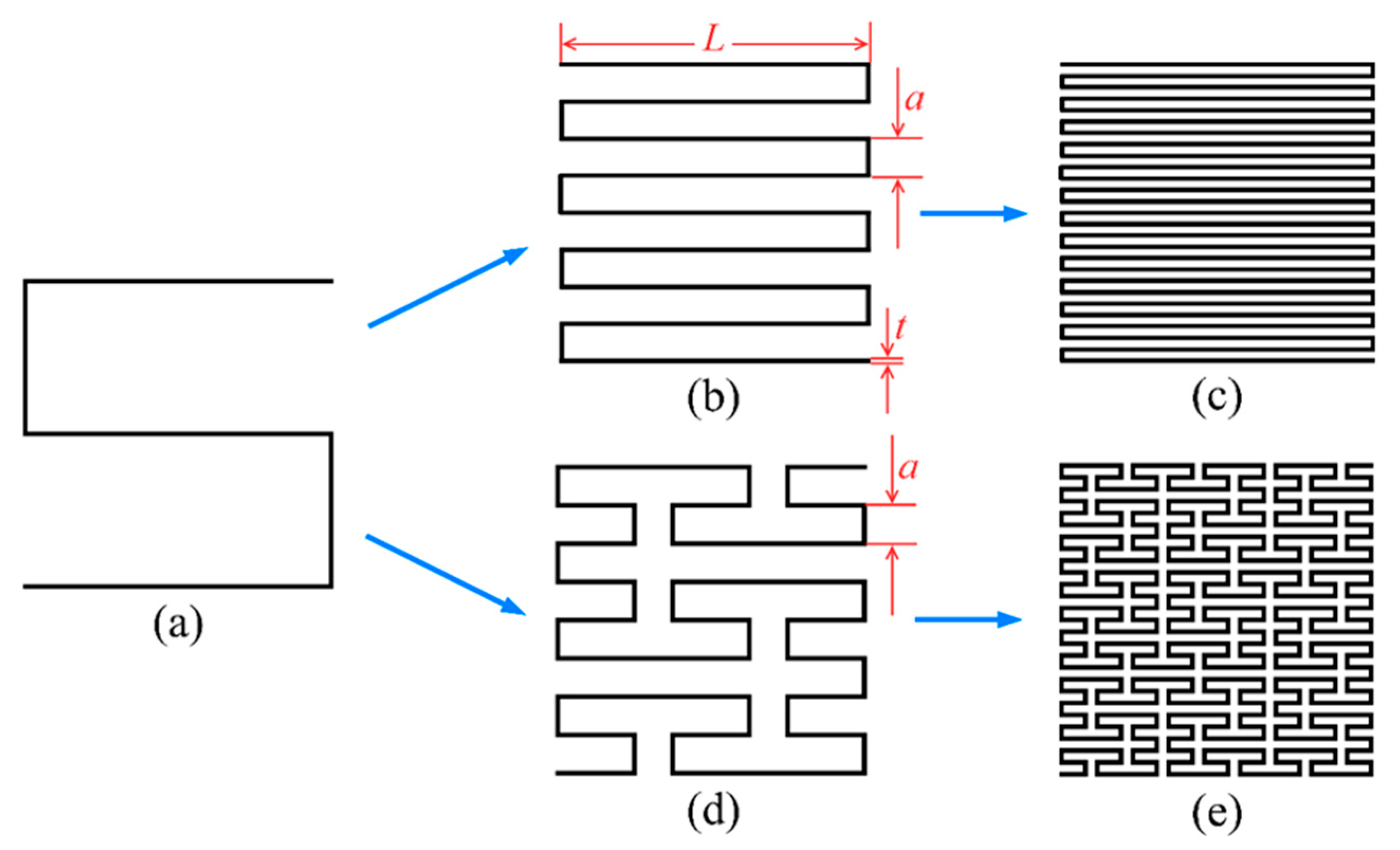

As already mentioned, well-designed structures with complex geometries, such as hierarchical multi-cell tubes, hierarchical corrugated core sandwich panels, and cuttlebone-like multilayer sandwiches, have better crashworthiness performance than conventional thin-walled structures according to all evaluation criteria. From a geometric perspective, the absorbing energy of a thin-walled sandwich structure can be regulated by changing the filling materials in the core space. Theoretically, space-filling curves (SFCs) are characterized by a unique property: that is, a specific space can be completely filled with a continuous curve of infinite length after an infinite number of iterations. Peano space-filling curves, as the most well-known SFCs, have the capability to fill a defined design space with an infinite length of curves. In the context of thin-walled sandwich structures inspired by Peano space-filling curves and with a specified relative density, it is possible to fill the cross-sections of their cores with infinite space-filling curves by progressively increasing the level of fractal hierarchy. Therefore, thin-walled sandwich structures with cross-sectional configurations of Peano space-filling curves could have great potential for offering excellent energy absorption capacity in the axial loading direction. In addition, the linear continuity and highly fractal characteristics of Peano space-filling curves could give thin-walled sandwich structures many multifunctional advantages, which could meet the crashworthiness requirements of equipment such as supercapacitors, jet engine inlets, and heat exchangers [

61,

62,

63]. However, Peano space-filling curves have rarely been used as the design topic for thin-walled sandwich structures.

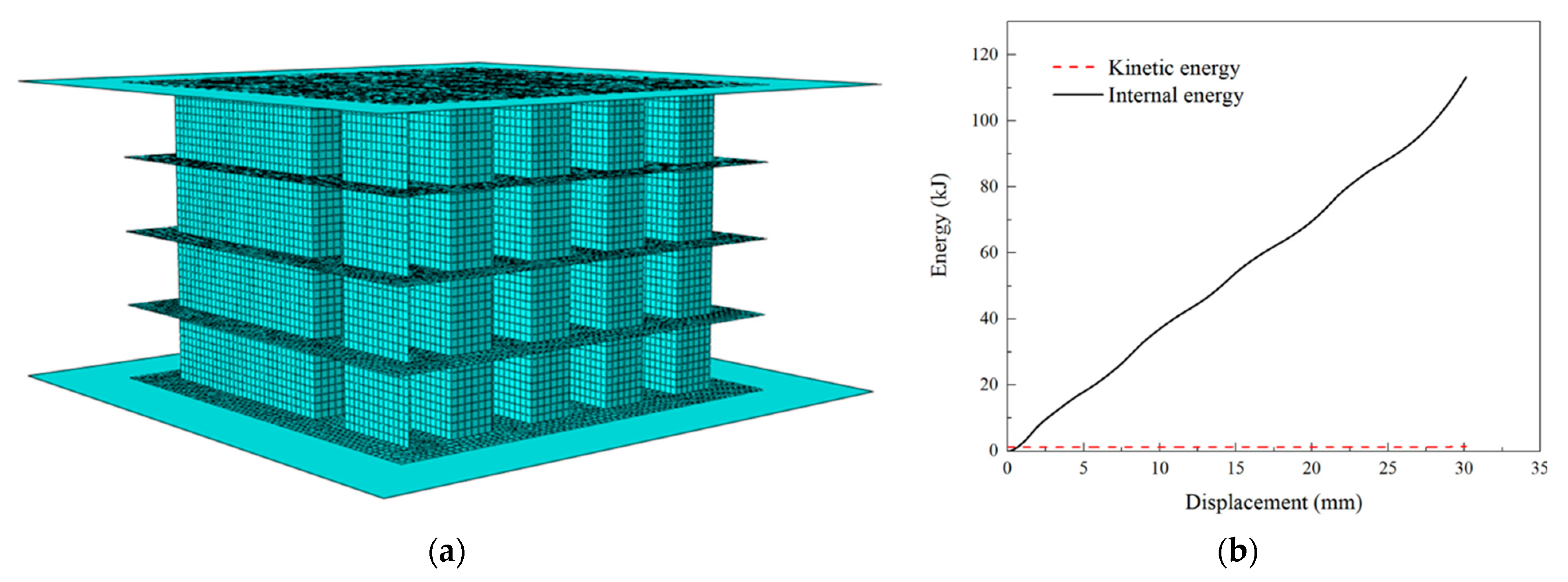

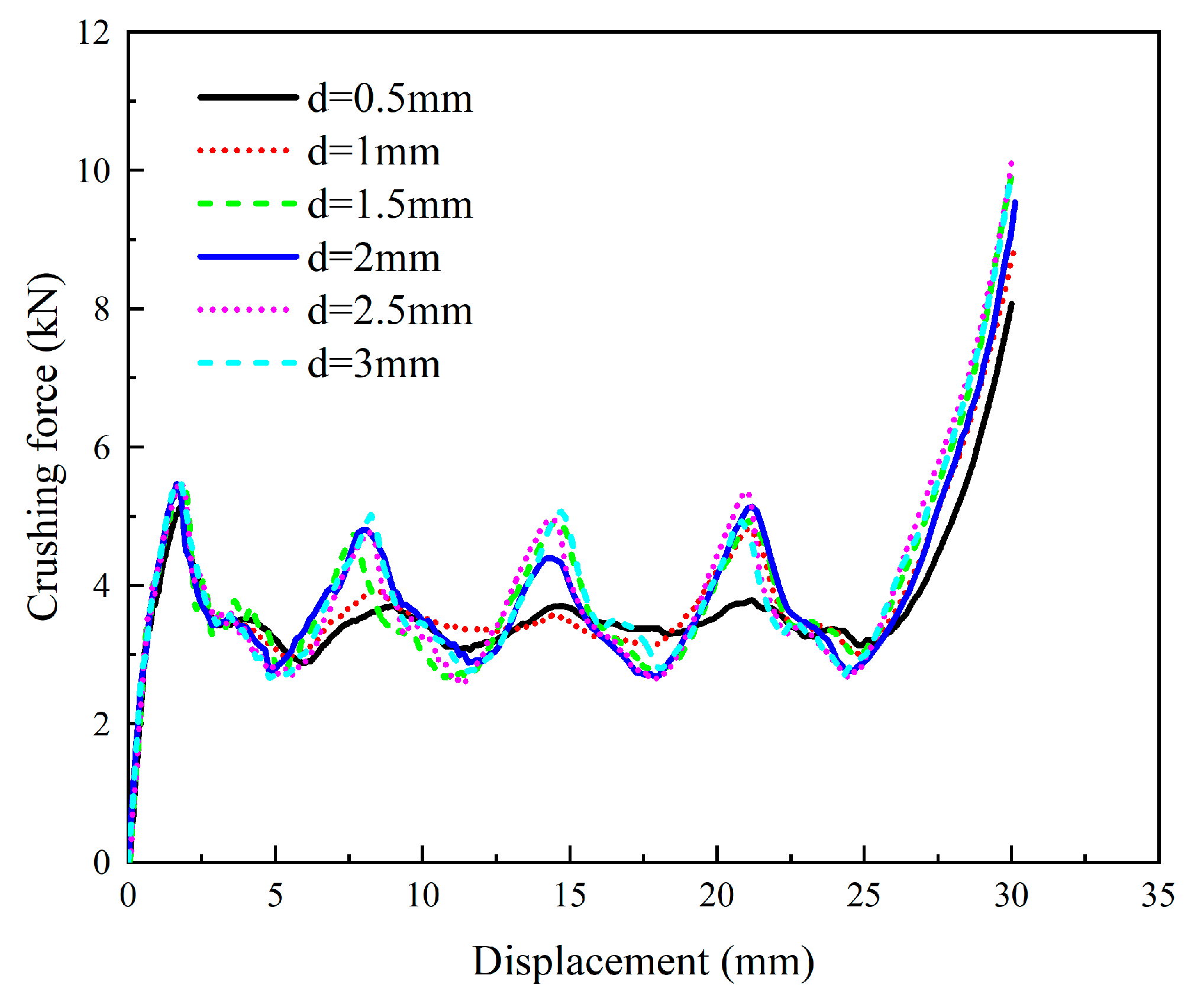

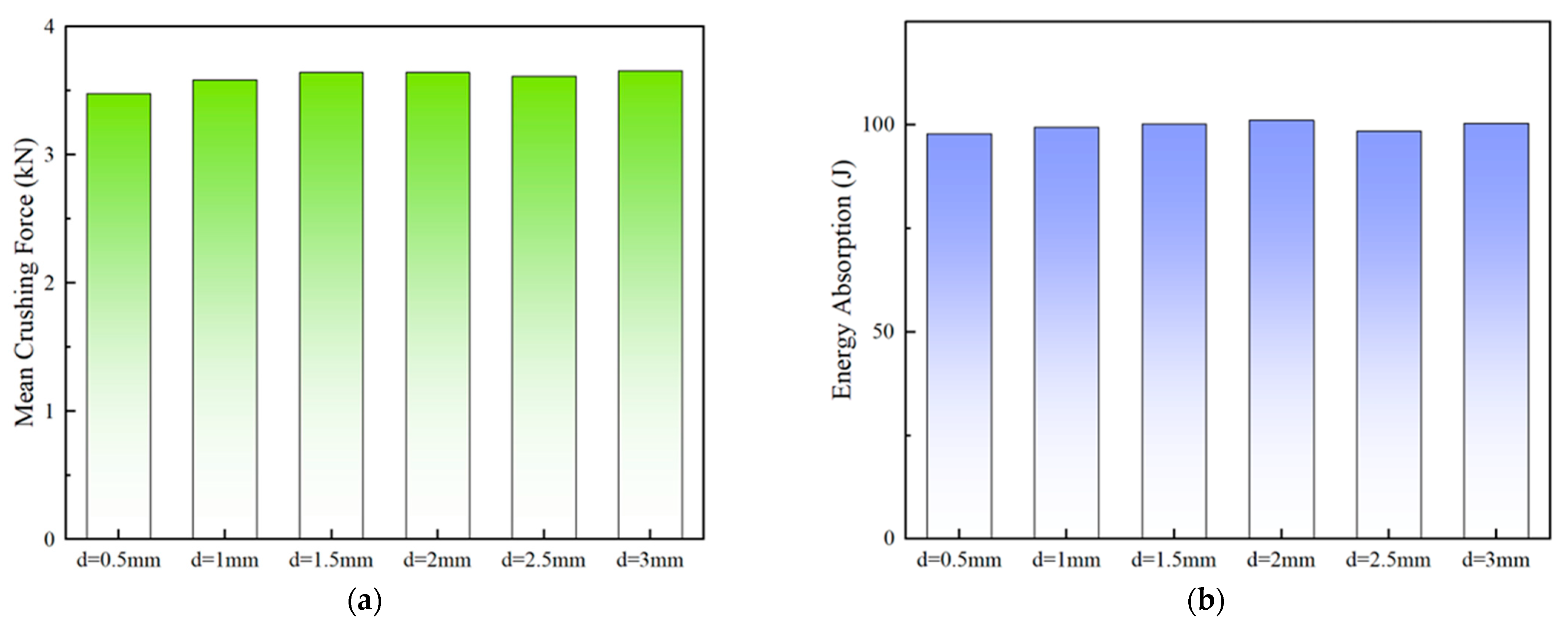

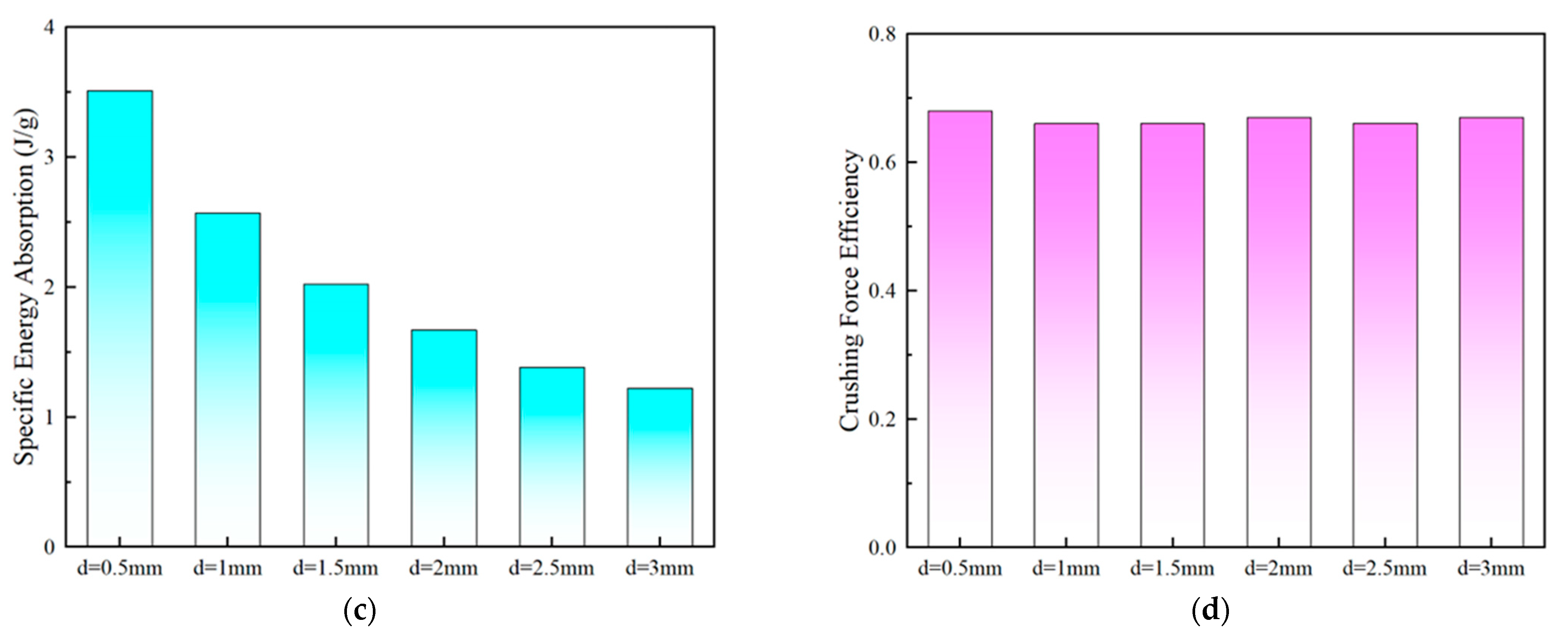

To fill the above gap, inspired by Peano space-filling curves, novel multilayer thin-walled sandwich structures were proposed and fabricated in this study. The paper is organized as follows:

Section 2 presents the evolution process of SFCs and the fabrication of structures.

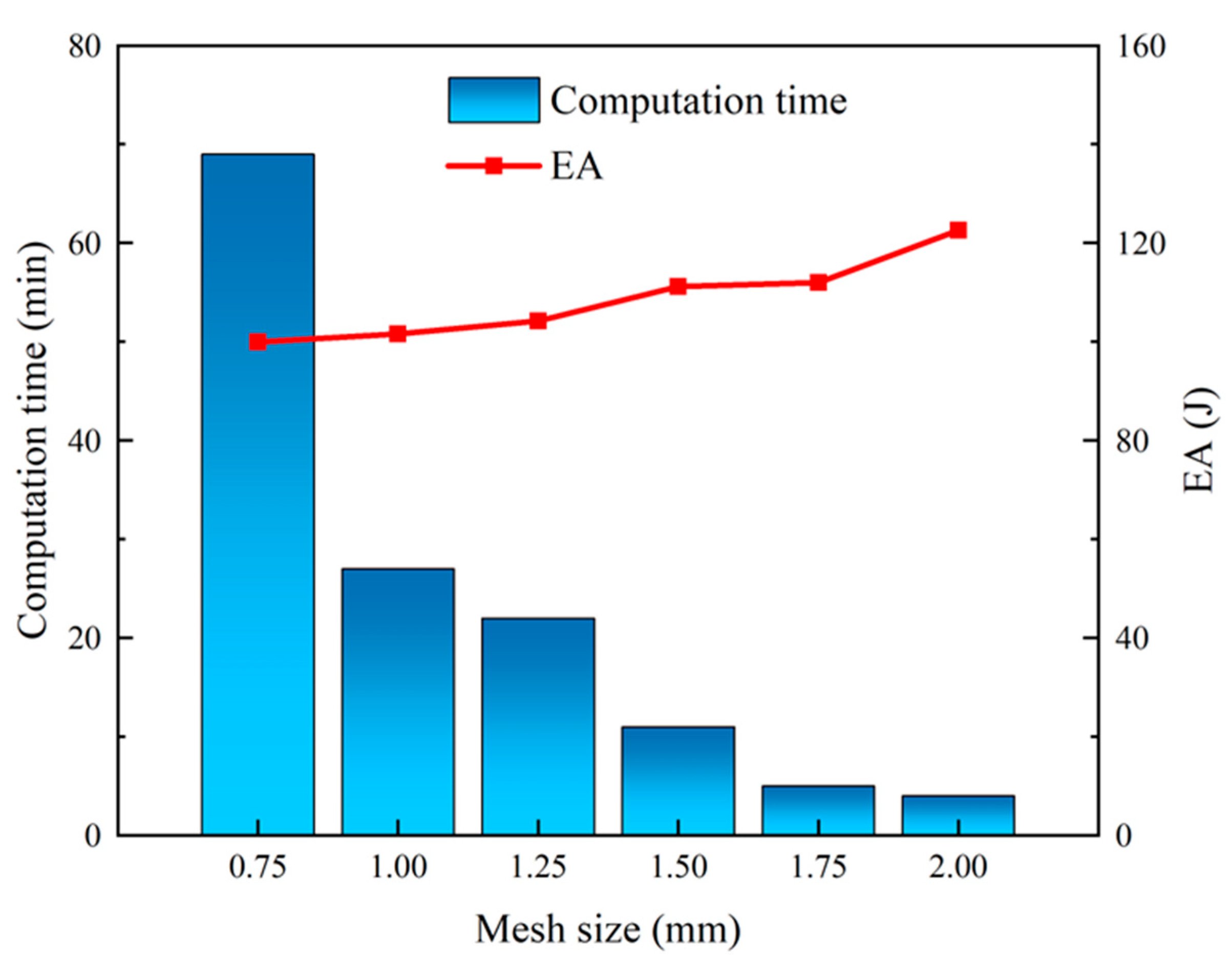

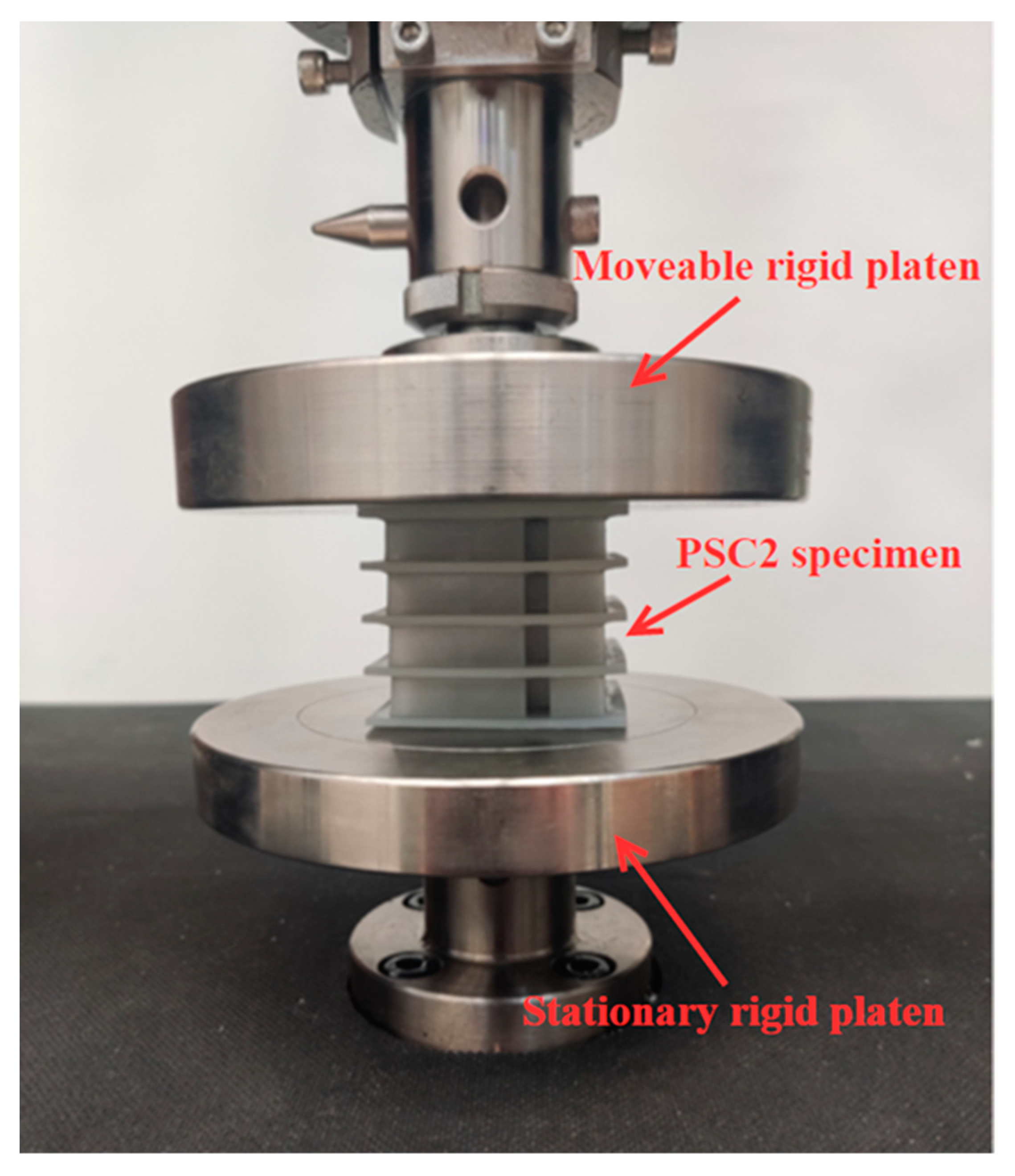

Section 3 describes the experimental setups used to study the material mechanical properties and quasi-static axial crushing of SSC structures, as well as crashworthiness indicators and the finite element (FE) model setup. In

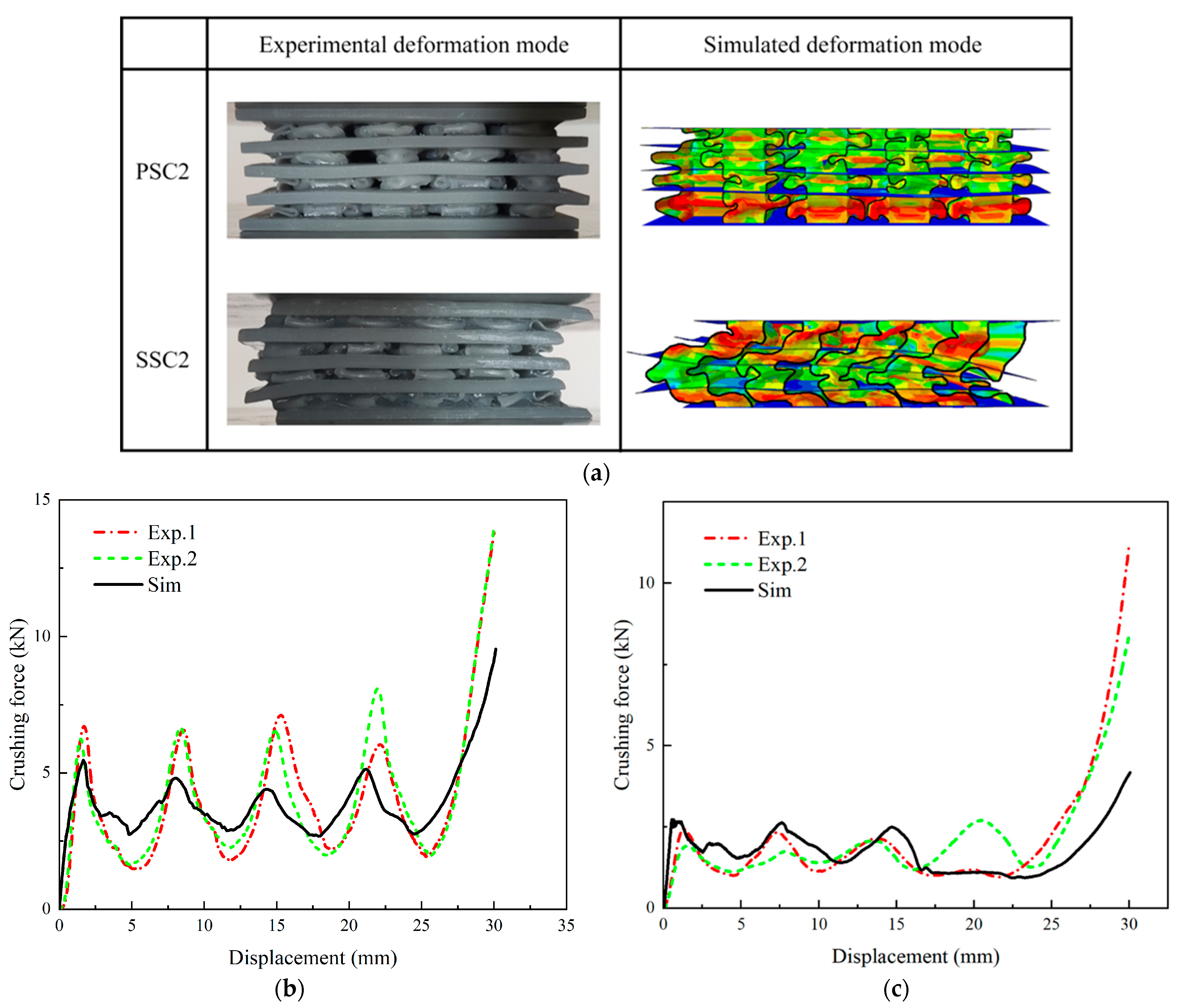

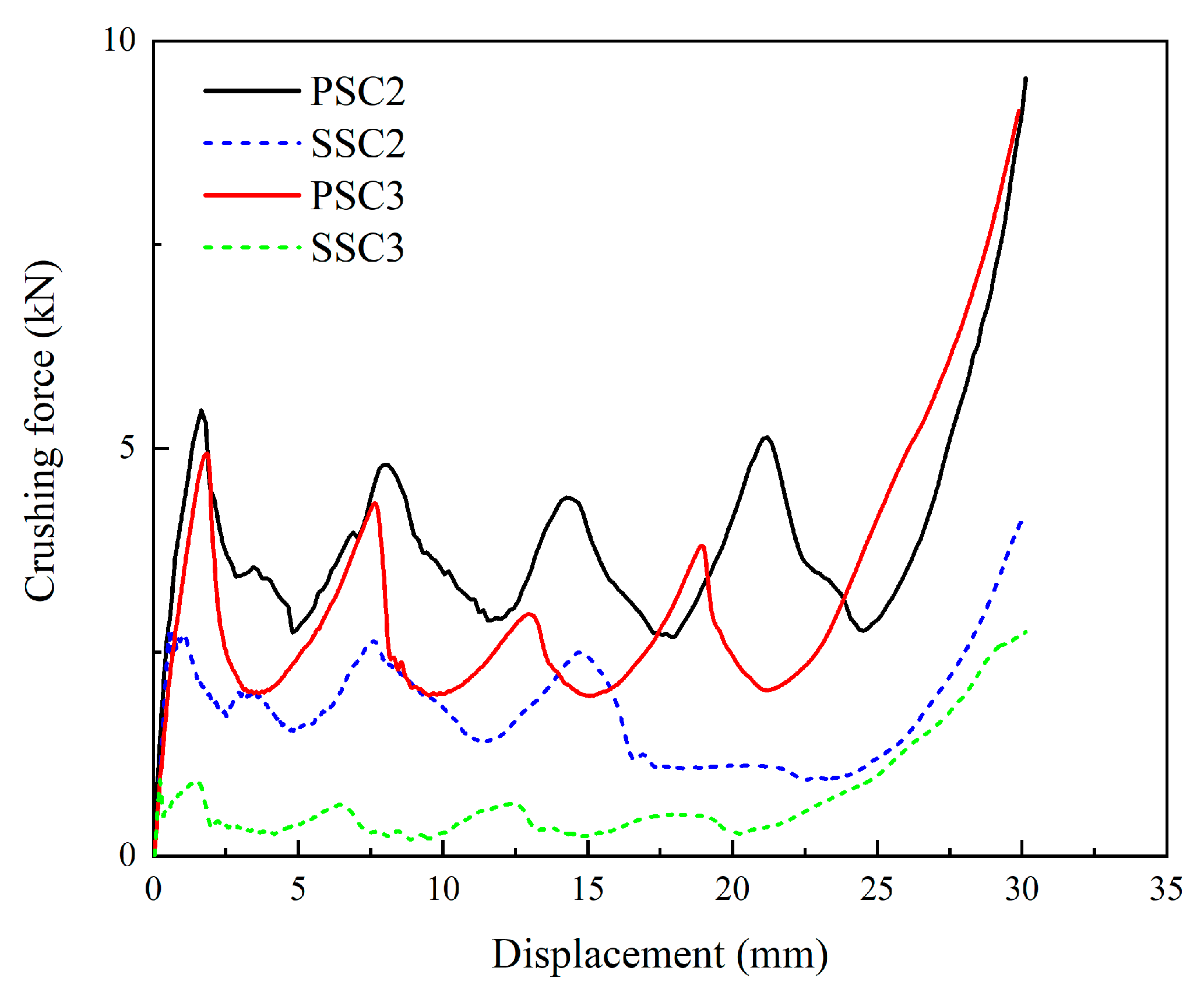

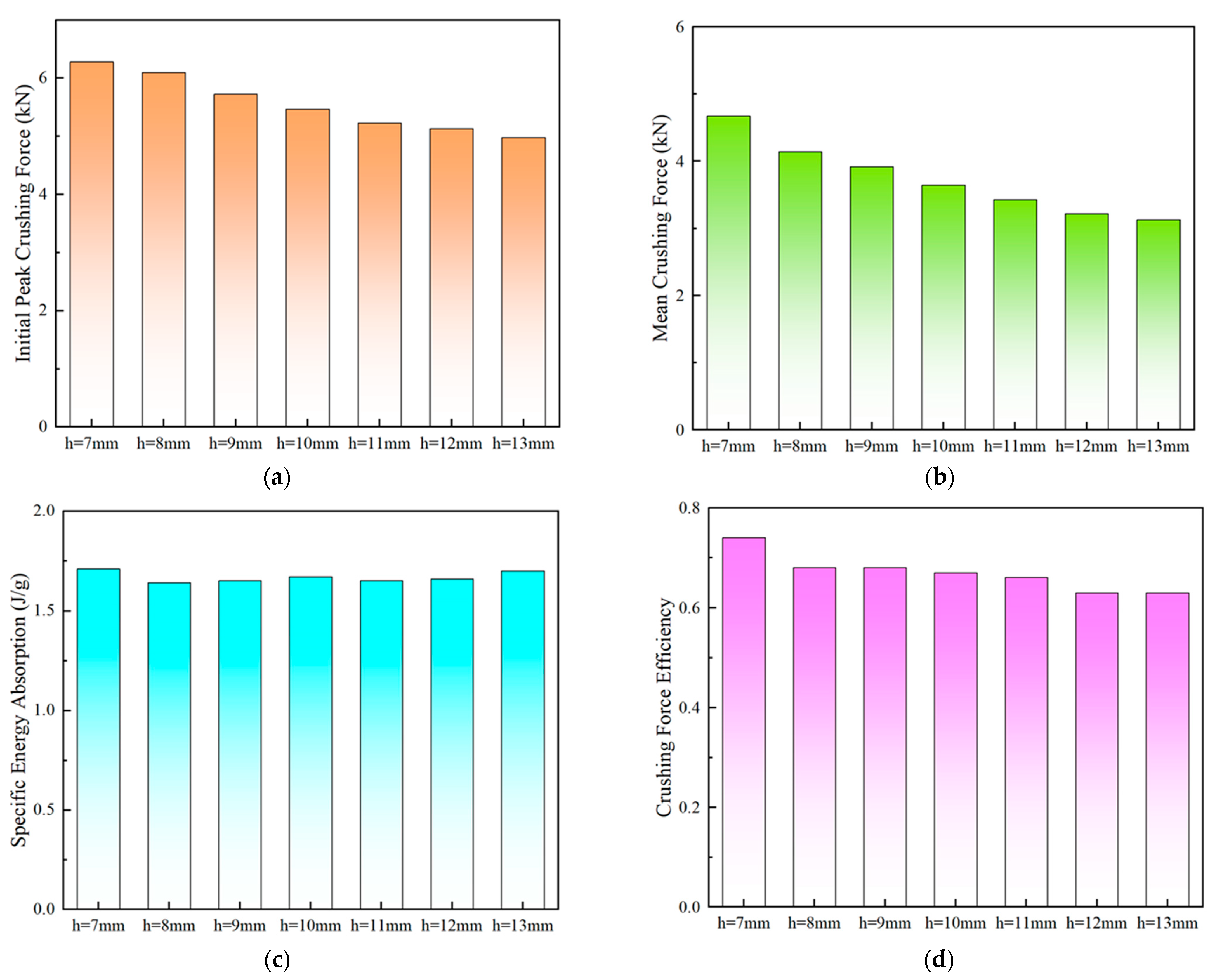

Section 4, the results of numerical simulations of the second-order SFC structures are verified with experimental results. In this section, we also present an analysis and comparison of the energy absorption characteristics of two different types of SFC sandwich structures. Furthermore, we delve into the influence of geometric parameters on energy absorption performance. Finally,

Section 5 explores the optimal configurations of PSC structures by establishing the response surface model. The conclusions are summarized in

Section 6.

6. Conclusions

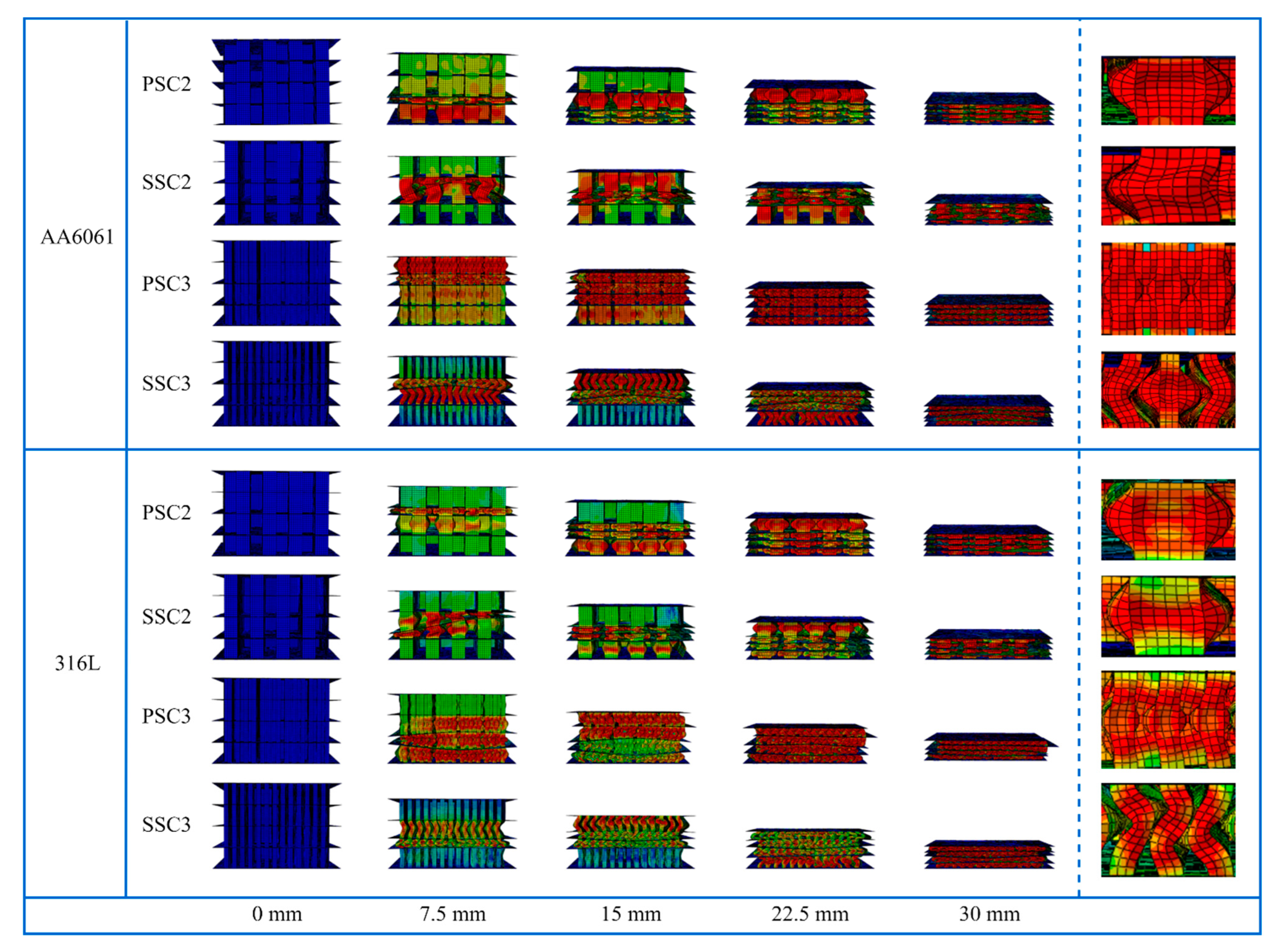

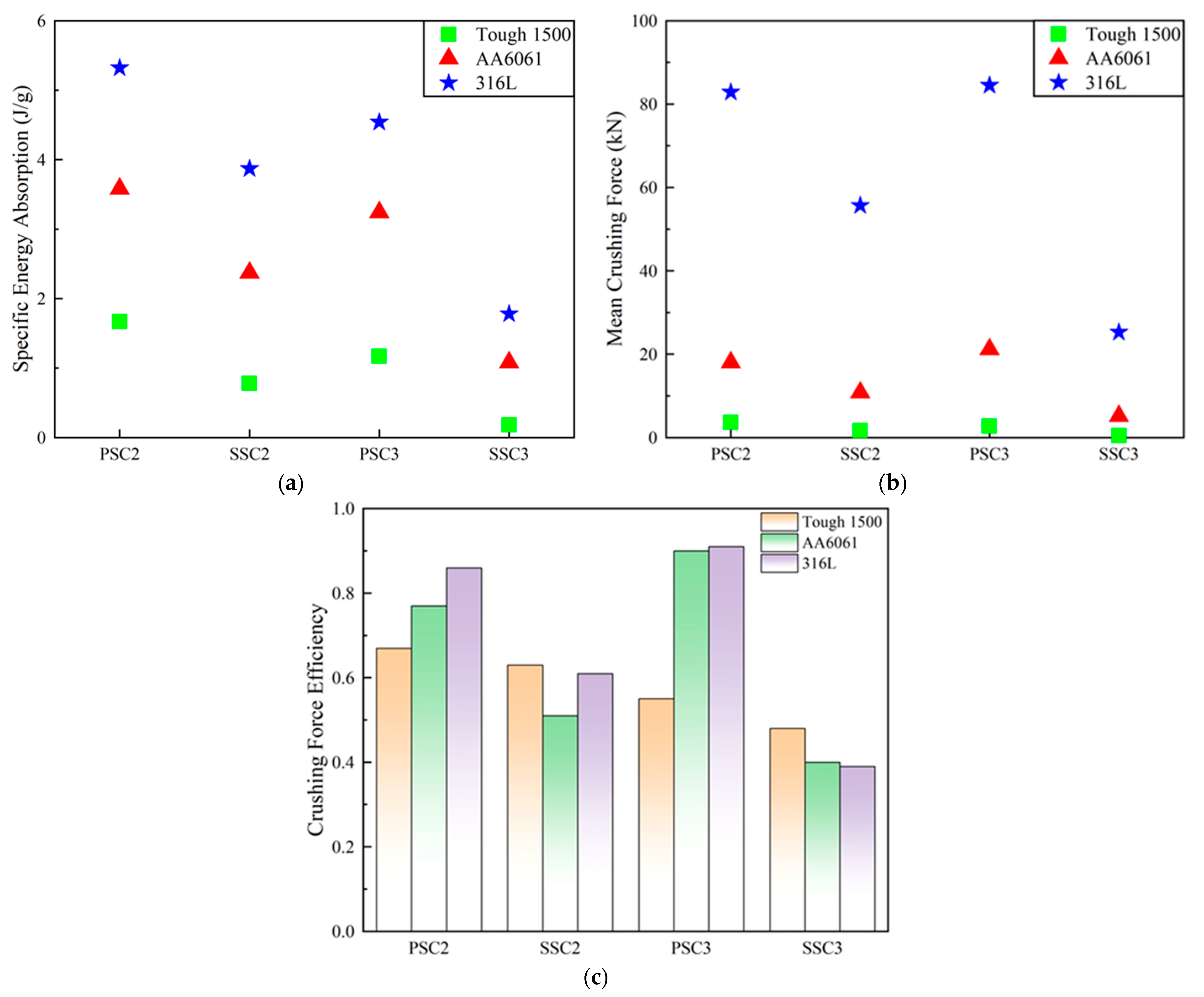

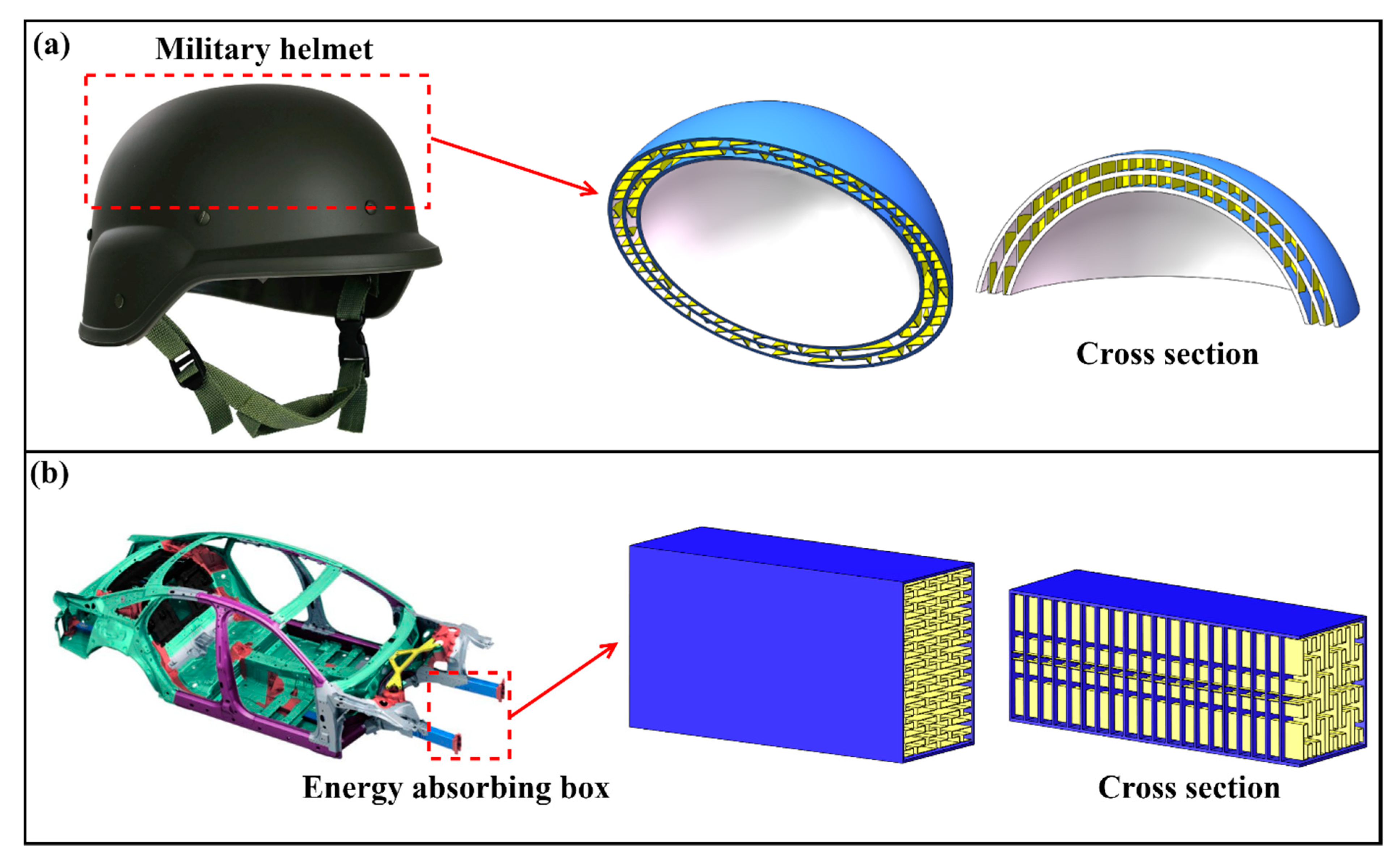

In this paper, novel multilayer thin-walled sandwich energy absorption structures are proposed based on the PSC to achieve ideal energy absorption. Polymer specimens were fabricated using 3D printing technology, and their compression behaviors and energy absorption properties were investigated through tests and FE simulations. The results indicated that PSC structures exhibited superior energy absorption performance compared to SSC structures with the same mass. Furthermore, the effects of layer height, septa thickness, and wall thickness on the crashworthiness of the PSC structure were studied through parametric analysis, which provided a reference for the selection of structural parameters in practical applications. Finally, the response surface method and the NSGA-II algorithm were used to further optimize the structure, and the effects of different materials on the mechanical properties of the structure were compared. The potential application of the PSC structure in the engineering field was also presented. In the future, with the further development of 3D printing technology, the difficulty and cost of preparing complex structures will also be reduced.

In summary, the novel multilayer thin-walled sandwich energy absorption structures proposed in this paper represent a novel approach to designing lightweight polymer structures with exceptional energy-absorbing properties, thereby offering significant potential for engineering applications.