Sustainable Materials Containing Biochar Particles: A Review

Abstract

:1. Introduction

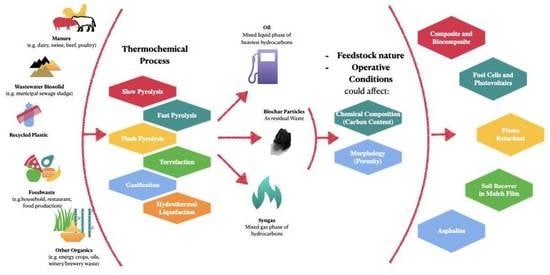

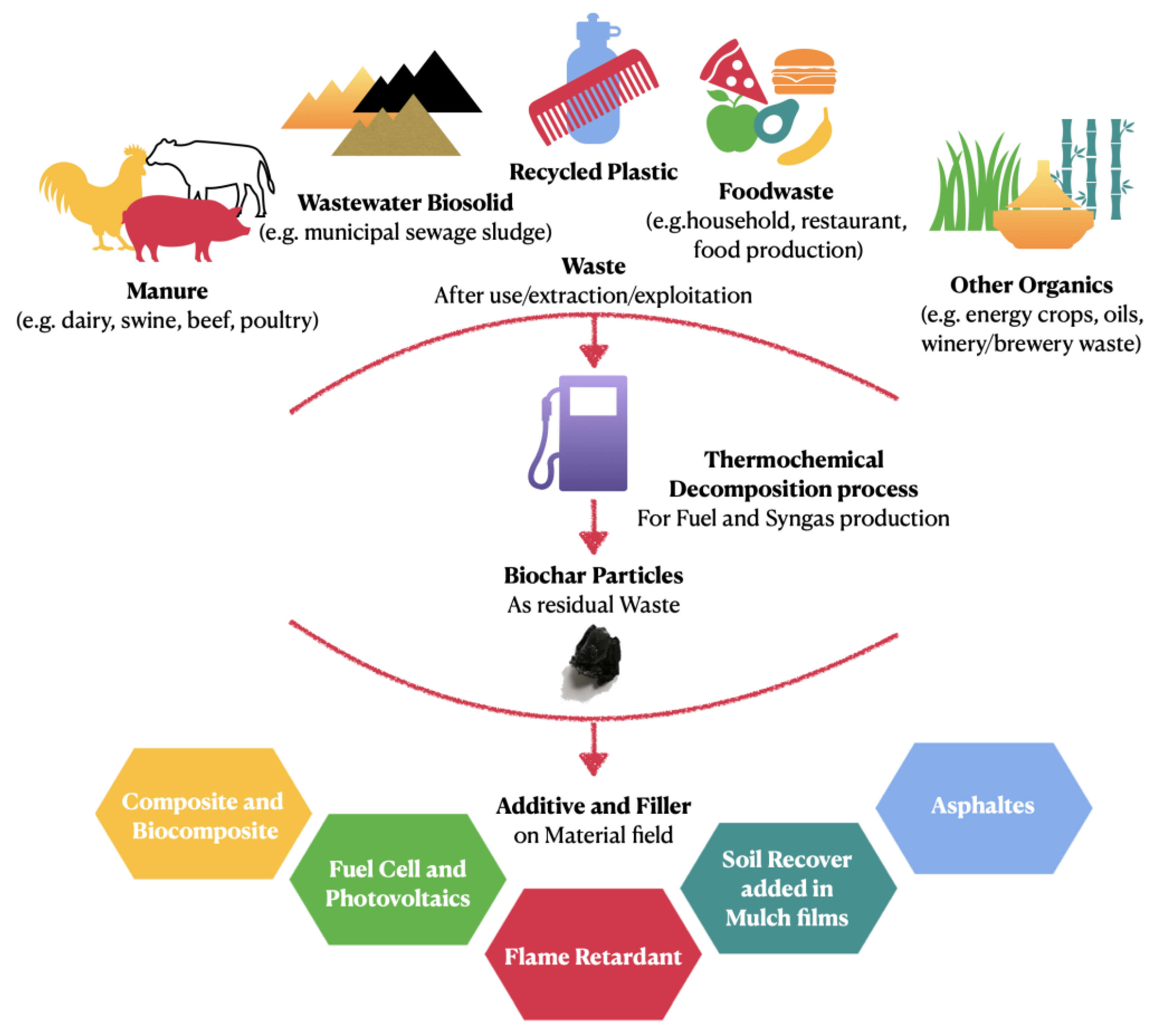

2. Biochar Particles: Production, Characteristics, and Properties

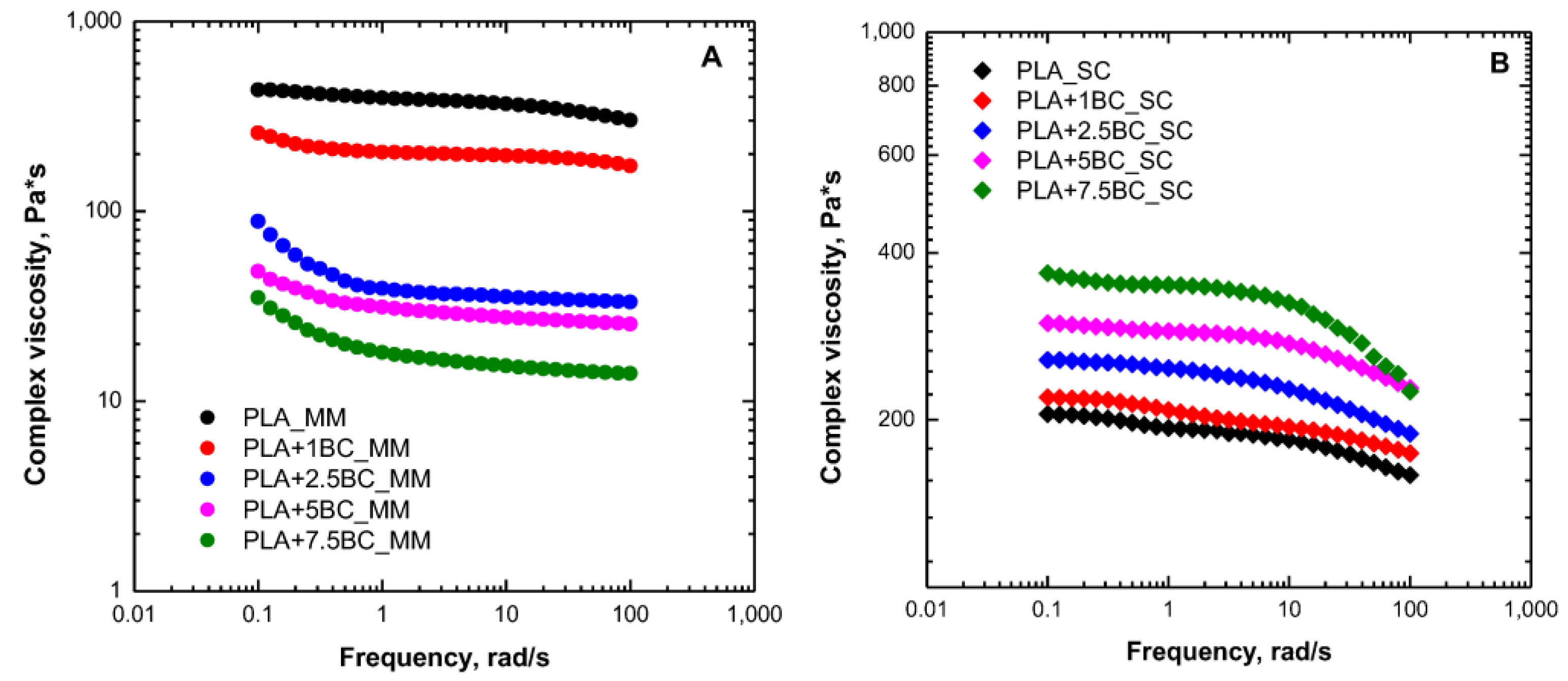

3. Polymer-Based Composites Containing BCp

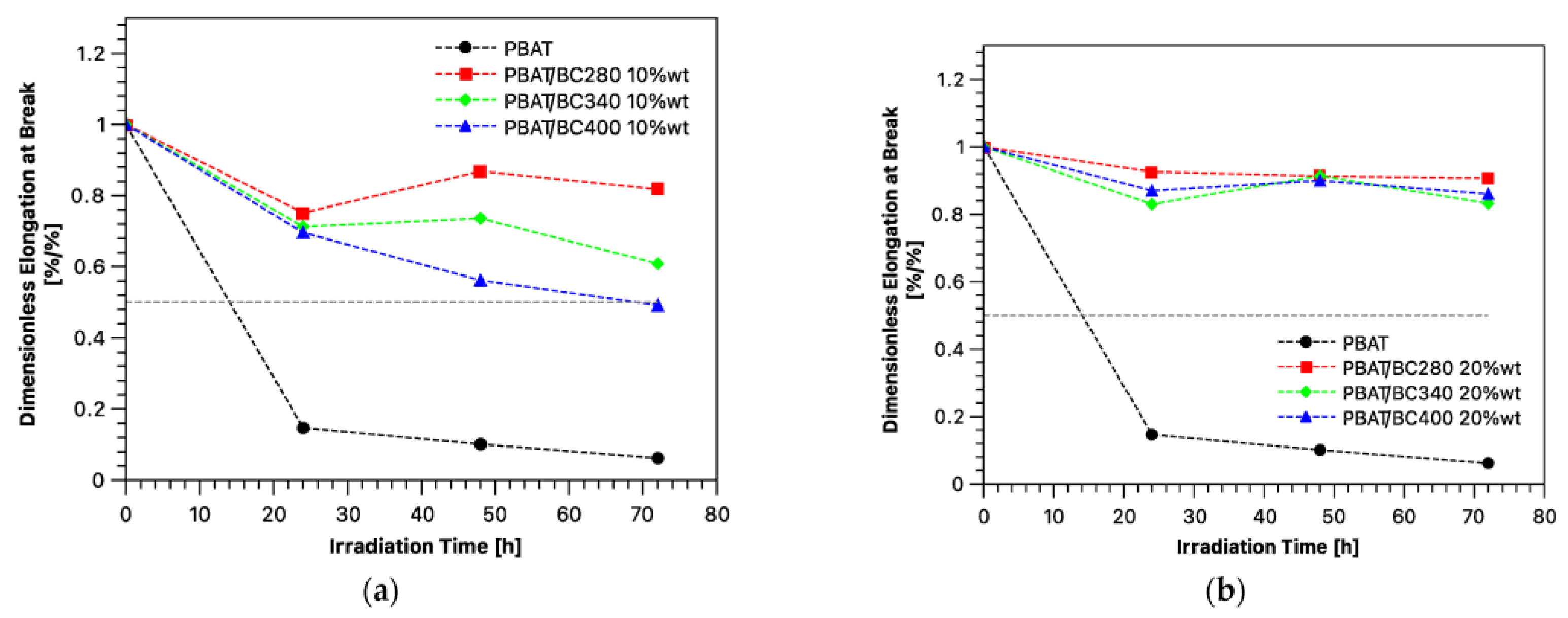

4. Bio-Polymer-Based Composites Containing BCp

5. Asphalts Composites Containing BCP

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ronzon, T.; M’Barek, R. Socioeconomic Indicators to Monitor the EU’s Bioeconomy in Transition. Sustain. Switz. 2018, 10, 1745. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef] [Green Version]

- Sizirici, B.; Fseha, Y.H.; Yildiz, I.; Delclos, T.; Khaleel, A. The Effect of Pyrolysis Temperature and Feedstock on Date Palm Waste Derived Biochar to Remove Single and Multi-Metals in Aqueous Solutions. Sustain. Environ. Res. 2021, 31, 9. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of Wood/Biomass for Bio-Oil: A Critical Review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Biocomposites with Size-Fractionated Biocarbon: Influence of the Microstructure on Macroscopic Properties. ACS Omega 2016, 1, 636–647. [Google Scholar] [CrossRef] [Green Version]

- Al Arni, S. Comparison of Slow and Fast Pyrolysis for Converting Biomass into Fuel. Renew. Energy 2018, 124, 197–201. [Google Scholar] [CrossRef]

- Maniscalco, M.; Infurna, G.; Caputo, G.; Botta, L.; Dintcheva, N.T. Slow Pyrolysis as a Method for Biochar Production from Carob Waste: Process Investigation and Products’ Characterization. Energies 2021, 14, 8457. [Google Scholar] [CrossRef]

- Volpe, M.; Panno, D.; Volpe, R.; Messineo, A. Upgrade of Citrus Waste as a Biofuel via Slow Pyrolysis. J. Anal. Appl. Pyrolysis 2015, 115, 66–76. [Google Scholar] [CrossRef]

- Vardon, D.R.; Moser, B.R.; Zheng, W.; Witkin, K.; Evangelista, R.L.; Strathmann, T.J.; Rajagopalan, K.; Sharma, B.K. Complete Utilization of Spent Coffee Grounds to Produce Biodiesel, Bio-Oil, and Biochar. ACS Sustain. Chem. Eng. 2013, 1, 1286–1294. [Google Scholar] [CrossRef]

- Palos, R.; Rodríguez, E.; Gutiérrez, A.; Bilbao, J.; Arandes, J.M. Cracking of Plastic Pyrolysis Oil over FCC Equilibrium Catalysts to Produce Fuels: Kinetic Modeling. Fuel 2022, 316, 123341. [Google Scholar] [CrossRef]

- Sarkar, J.K.; Wang, Q. Different Pyrolysis Process Conditions of South Asian Waste Coconut Shell and Characterization of Gas, Bio-Char, and Bio-Oil. Energies 2020, 13, 1970. [Google Scholar] [CrossRef]

- Antal, M.J.; Allen, S.G.; Dai, X.; Shimizu, B.; Tam, M.S.; Grønli, M. Attainment of the Theoretical Yield of Carbon from Biomass. Ind. Eng. Chem. Res. 2000, 39, 4024–4031. [Google Scholar] [CrossRef]

- Guizani, C.; Javier, F.; Sanz, E.; Salvador, S.; Guizani, C.; Escudero Sanz, F.J.; Salvador, S. Influence of Temperature and Particle Size on the Single and Mixed Atmosphere Gasification of Biomass Char with H2O and CO2 Influence of Temperature and Particle Size on the Single and Mixed Atmosphere Gasification of Biomass Char with H 2 O and CO 2. Fuel Process. Technol. 2015, 134, 175–188. [Google Scholar] [CrossRef] [Green Version]

- Barisano, D.; Canneto, G.; Nanna, F.; Villone, A.; Fanelli, E.; Freda, C.; Grieco, M.; Lotierz, A.; Cornacchia, G.; Braccio, G.; et al. Investigation of an Intensified Thermo-Chemical Experimental Set-Up for Hydrogen Production from Biomass: Gasification Process Integrated to a Portable Purification System—Part II. Energies 2022, 15, 4580. [Google Scholar] [CrossRef]

- Breault, R.W. Gasification Processes Old and New: A Basic Review of the Major Technologies. Energies 2010, 3, 216–240. [Google Scholar] [CrossRef] [Green Version]

- Grande, L.; Pedroarena, I.; Korili, S.A.; Gil, A. Hydrothermal Liquefaction of Biomass as One of the Most Promising Alternatives for the Synthesis of Advanced Liquid Biofuels: A Review. Materials 2021, 14, 5286. [Google Scholar] [CrossRef]

- Sepehri, A.; Sarrafzadeh, M.-H. Effect of Nitrifiers Community on Fouling Mitigation and Nitrification Efficiency in a Membrane Bioreactor. Chem. Eng. Process. -Process Intensif. 2018, 128, 10–18. [Google Scholar] [CrossRef]

- Rizwan, M.; Ali, S.; Qayyum, M.F.; Ibrahim, M.; Zia-ur-Rehman, M.; Abbas, T.; Ok, Y.S. Mechanisms of Biochar-Mediated Alleviation of Toxicity of Trace Elements in Plants: A Critical Review. Environ. Sci. Pollut. Res. 2016, 23, 2230–2248. [Google Scholar] [CrossRef]

- McKendry, P. Energy Production from Biomass (Part 1): Overview of Biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Ha, M.-A.; Apperley, D.C.; Evans, B.W.; Huxham, I.M.; Jardine, W.G.; Vietor, R.J.; Reis, D.; Vian, B.; Jarvis, M.C. Fine Structure in Cellulose Microfibrils: NMR Evidence from Onion and Quince. Plant J. 1998, 16, 183–190. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G.; Morgan, T.J. An Overview of the Organic and Inorganic Phase Composition of Biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-FIring of Coal and Biomass Fuel Blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Stamatelatou, K.; Antonopoulou, G.; Ntaikou, I.; Lyberatos, G. The Effect of Physical, Chemical, and Biological Pretreatments of Biomass on Its Anaerobic Digestibility and Biogas Production. In Biogas Production; Mudhoo, A., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 55–90. ISBN 978-1-118-40408-9. [Google Scholar]

- Ahmad, M.; Lee, S.S.; Dou, X.; Mohan, D.; Sung, J.-K.; Yang, J.E.; Ok, Y.S. Effects of Pyrolysis Temperature on Soybean Stover- and Peanut Shell-Derived Biochar Properties and TCE Adsorption in Water. Bioresour. Technol. 2012, 118, 536–544. [Google Scholar] [CrossRef]

- Chen, B.; Zhou, D.; Zhu, L. Transitional Adsorption and Partition of Nonpolar and Polar Aromatic Contaminants by Biochars of Pine Needles with Different Pyrolytic Temperatures. Environ. Sci. Technol. 2008, 42, 5137–5143. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Yang, X.; Spinosa, L. Development of Sludge-Based Adsorbents: Preparation, Characterization, Utilization and Its Feasibility Assessment. J. Environ. Manag. 2015, 151, 221–232. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.; Chen, M. Progress in the Preparation and Application of Modified Biochar for Improved Contaminant Removal from Water and Wastewater. Bioresour. Technol. 2016, 214, 836–851. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, G.; Wang, H. Current State of Sludge Production, Management, Treatment and Disposal in China. Water Res. 2015, 78, 60–73. [Google Scholar] [CrossRef]

- Vaughn, S.F.; Kenar, J.A.; Thompson, A.R.; Peterson, S.C. Comparison of Biochars Derived from Wood Pellets and Pelletized Wheat Straw as Replacements for Peat in Potting Substrates. Ind. Crops Prod. 2013, 51, 437–443. [Google Scholar] [CrossRef]

- Kołodyńska, D.; Wnętrzak, R.; Leahy, J.J.; Hayes, M.H.B.; Kwapiński, W.; Hubicki, Z. Kinetic and Adsorptive Characterization of Biochar in Metal Ions Removal. Chem. Eng. J. 2012, 197, 295–305. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.-M.; Dallmeyer, I.; Garcia-Perez, M. Influence of Feedstock Source and Pyrolysis Temperature on Biochar Bulk and Surface Properties. Biomass Bioenergy 2016, 84, 37–48. [Google Scholar] [CrossRef]

- Wang, S.; Gao, B.; Zimmerman, A.R.; Li, Y.; Ma, L.; Harris, W.G.; Migliaccio, K.W. Physicochemical and Sorptive Properties of Biochars Derived from Woody and Herbaceous Biomass. Chemosphere 2015, 134, 257–262. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, A.; Boussetta, A.; Yu, J.; Halouani, K.; Li, Y. Experimental Investigation of Direct Carbon Fuel Cell Fueled by Almond Shell Biochar: Part I. Physico-Chemical Characterization of the Biochar Fuel and Cell Performance Examination. Int. J. Hydrog. Energy 2013, 38, 16590–16604. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Ryu, C.; Gang, K.S.; Yang, W.; Park, Y.-K.; Jung, J.; Hyun, S. Comparison of Biochar Properties from Biomass Residues Produced by Slow Pyrolysis at 500 °C. Bioresour. Technol. 2013, 148, 196–201. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Liu, D.; Zhang, H.; Chen, Y.; Li, Q. Bamboo Pyrolysis Using TG–FTIR and a Lab-Scale Reactor: Analysis of Pyrolysis Behavior, Product Properties, and Carbon and Energy Yields. Fuel 2015, 148, 79–86. [Google Scholar] [CrossRef]

- Infurna, G.; Botta, L.; Maniscalco, M.; Morici, E.; Caputo, G.; Marullo, S.; D’Anna, F.; Dintcheva, N.Tz. Biochar Particles Obtained from Agricultural Carob Waste as a Suitable Filler for Sustainable Biocomposite Formulations. Polymers 2022, 14, 3075. [Google Scholar] [CrossRef]

- Liu, Z.; Han, G. Production of Solid Fuel Biochar from Waste Biomass by Low Temperature Pyrolysis. Fuel 2015, 158, 159–165. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Li, Z.; Feng, R.; Zhang, Y. Characterization of Corncob-Derived Biochar and Pyrolysis Kinetics in Comparison with Corn Stalk and Sawdust. Bioresour. Technol. 2014, 170, 76–82. [Google Scholar] [CrossRef]

- Jafri, N.; Wong, W.Y.; Doshi, V.; Yoon, L.W.; Cheah, K.H. A Review on Production and Characterization of Biochars for Application in Direct Carbon Fuel Cells. Process Saf. Environ. Prot. 2018, 118, 152–166. [Google Scholar] [CrossRef]

- Moralı, U.; Şensöz, S. Pyrolysis of Hornbeam Shell (Carpinus betulus L.) in a Fixed Bed Reactor: Characterization of Bio-Oil and Bio-Char. Fuel 2015, 150, 672–678. [Google Scholar] [CrossRef]

- Luo, L.; Xu, C.; Chen, Z.; Zhang, S. Properties of Biomass-Derived Biochars: Combined Effects of Operating Conditions and Biomass Types. Bioresour. Technol. 2015, 192, 83–89. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhong, Z.; Zhao, J.; Yang, M.; Li, W.; Zhang, H. Study on the Preparation of Activated Carbon for Direct Carbon Fuel Cell with Oak Sawdust. Can. J. Chem. Eng. 2012, 90, 762–768. [Google Scholar] [CrossRef]

- Hmid, A.; Mondelli, D.; Fiore, S.; Fanizzi, F.P.; Al Chami, Z.; Dumontet, S. Production and Characterization of Biochar from Three-Phase Olive Mill Waste through Slow Pyrolysis. Biomass Bioenergy 2014, 71, 330–339. [Google Scholar] [CrossRef]

- Uzun, B.B.; Apaydin-Varol, E.; Ateş, F.; Özbay, N.; Pütün, A.E. Synthetic Fuel Production from Tea Waste: Characterisation of Bio-Oil and Bio-Char. Fuel 2010, 89, 176–184. [Google Scholar] [CrossRef]

- Nanda, S.; Dalai, A.K.; Berruti, F.; Kozinski, J.A. Biochar as an Exceptional Bioresource for Energy, Agronomy, Carbon Sequestration, Activated Carbon and Specialty Materials. Waste Biomass Valorization 2016, 7, 201–235. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from Waste Derived Biochars: Mechanical, Thermal, Chemical, and Morphological Properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A Novel Approach in Organic Waste Utilization through Biochar Addition in Wood/Polypropylene Composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.T. Mechanical and Flammability Characterisations of Biochar/Polypropylene Biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Sarmah, A.K.; Bhattacharyya, D. Development of Waste Based Biochar/Wool Hybrid Biocomposites: Flammability Characteristics and Mechanical Properties. J. Clean. Prod. 2017, 144, 79–89. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Kalamkarov, A.L.; Sarmah, A.K.; Bhattacharyya, D. Biochar to the Rescue: Balancing the Fire Performance and Mechanical Properties of Polypropylene Composites. Polym. Degrad. Stab. 2017, 144, 485–496. [Google Scholar] [CrossRef]

- Das, O.; Hedenqvist, M.S. Wettability Properties of Biochar Added Wood/Polypropylene Composites. Acad. J. Polym. Sci. 2018, 1, 66–69. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kwon, J.H.; Han, T.H.; Durmus, A. Effect of Wood-Derived Charcoal Content on Properties of Wood Plastic Composites. Mater. Res. 2015, 18, 654–659. [Google Scholar] [CrossRef] [Green Version]

- Devallance, D.B.; Oporto, G.S.; Quigley, P. Investigation of Hardwood Biochar as a Replacement for Wood Flour in Wood-Polypropylene Composites. J. Elastomers Plast. 2016, 48, 510–522. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable Biocarbon from Pyrolyzed Perennial Grasses and Their Effects on Impact Modified Polypropylene Biocomposites. Compos. Part B Eng. 2017, 118, 116–124. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Khan, A.; Tagliaferro, A. Analysis of Biochar with Different Pyrolysis Temperatures Used as Filler in Epoxy Resin Composites. Biomass Bioenergy 2019, 122, 466–471. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a Cheap and Environmental Friendly Filler Able to Improve Polymer Mechanical Properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef] [Green Version]

- Ahmetli, G.; Kocaman, S.; Ozaytekin, I.; Bozkurt, P. Epoxy Composites Based on Inexpensive Char Filler Obtained from Plastic Waste and Natural Resources. Polym. Compos. 2013, 34, 500–509. [Google Scholar] [CrossRef]

- Özaytekin, İ.; Kar, Y. Synthesis and Properties of Composites of Oligoazomethine with Char. J. Appl. Polym. Sci. 2012, 123, 815–823. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, H.; Lu, W.; Zhang, D.; Ren, X.; Yu, W.; Wu, J.; Zhou, L.; Han, X.; Yi, W.; et al. Properties Evaluation of Biochar/High-Density Polyethylene Composites: Emphasizing the Porous Structure of Biochar by Activation. Sci. Total Environ. 2020, 737, 139770. [Google Scholar] [CrossRef]

- Li, S.; Li, X.; Deng, Q.; Li, D. Three Kinds of Charcoal Powder Reinforced Ultra-High Molecular Weight Polyethylene Composites with Excellent Mechanical and Electrical Properties. Mater. Des. 2015, 85, 54–59. [Google Scholar] [CrossRef]

- Li, S.; Huang, A.; Chen, Y.J.; Li, D.; Turng, L.S. Highly Filled Biochar/Ultra-High Molecular Weight Polyethylene/Linear Low Density Polyethylene Composites for High-Performance Electromagnetic Interference Shielding. Compos. Part B Eng. 2018, 153, 277–284. [Google Scholar] [CrossRef]

- Li, S.; Xu, Y.; Jing, X.; Yilmaz, G.; Li, D.; Turng, L.S. Effect of Carbonization Temperature on Mechanical Properties and Biocompatibility of Biochar/Ultra-High Molecular Weight Polyethylene Composites. Compos. Part B Eng. 2020, 196, 108120. [Google Scholar] [CrossRef]

- Arrigo, R.; Jagdale, P.; Bartoli, M.; Tagliaferro, A.; Malucelli, G. Structure-Property Relationships in Polyethylene-Based Composites Filled with Biochar Derived from Waste Coffee Grounds. Polymers 2019, 11, 1336. [Google Scholar] [CrossRef] [Green Version]

- Kane, S.; Van Roijen, E.; Ryan, C.; Miller, S. Reducing the Environmental Impacts of Plastics While Increasing Strength: Biochar Fillers in Biodegradable, Recycled, and Fossil-Fuel Derived Plastics. Compos. Part C Open Access 2022, 8, 100253. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Xu, H.; Lu, W.; Ren, X.; Cai, H.; Lei, H.; Huo, E.; Zhao, Y.; Qian, M.; et al. Biochar Filled High-Density Polyethylene Composites with Excellent Properties: Towards Maximizing the Utilization of Agricultural Wastes. Ind. Crops Prod. 2020, 146, 112185. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V. Three-Dimensional-Printed Sustainable Biochar-Recycled PET Composites. ACS Sustain. Chem. Eng. 2018, 6, 13940–13948. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.; Ugwu, C.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef] [Green Version]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Ho, M.; Lau, K.; Wang, H.; Hui, D. Improvement on the Properties of Polylactic Acid (PLA) Using Bamboo Charcoal Particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly(Lactic Acid) Biocomposites Reinforced with Ultrafine Bamboo-Char: Morphology, Mechanical, Thermal, and Water Absorption Properties. J. Appl. Polym. Sci. 2016, 133, 43425. [Google Scholar] [CrossRef]

- Kane, S.; Ryan, C. Biochar from Food Waste as a Sustainable Replacement for Carbon Black in Upcycled or Compostable Composites. Compos. Part C Open Access 2022, 8, 100274. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(Lactic Acid)-Biochar Biocomposites: Effect of Processing and Filler Content on Rheological, Thermal, and Mechanical Properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valentina, I.; Haroutioun, A.; Fabrice, L.; Vincent, V.; Roberto, P. Poly(Lactic Acid)-Based Nanobiocomposites with Modulated Degradation Rates. Materials 2018, 11, 1943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haeldermans, T.; Samyn, P.; Cardinaels, R.; Vandamme, D.; Vanreppelen, K.; Cuypers, A.; Schreurs, S. Bio-Based Poly(3-Hydroxybutyrate)/Thermoplastic Starch Composites as a Host Matrix for Biochar Fillers. J. Polym. Environ. 2021, 29, 2478–2491. [Google Scholar] [CrossRef]

- Pachekoski, W.M.; Dalmolin, C.; Agnelli, J.A.M. The Influence of the Industrial Processing on the Degradation of Poly(Hidroxybutyrate)—PHB. Mater. Res. 2012, 16, 237–332. [Google Scholar] [CrossRef] [Green Version]

- Luo, S.; Grubb, D.T.; Netravali, A.N. The Effect of Molecular Weight on the Lamellar Structure, Thermal and Mechanical Properties of Poly(Hydroxybutyrate-Co-Hydroxyvalerates). Polymer 2002, 43, 4159–4166. [Google Scholar] [CrossRef]

- Musioł, M.; Rydz, J.; Janeczek, H.; Kordyka, A.; Andrzejewski, J.; Sterzyński, T.; Jurczyk, S.; Cristea, M.; Musioł, K.; Kampik, M.; et al. (Bio)Degradable Biochar Composites—Studies on Degradation and Electrostatic Properties. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2022, 275, 115515. [Google Scholar] [CrossRef]

- Botta, L.; Teresi, R.; Titone, V.; Salvaggio, G.; La Mantia, F.P.; Lopresti, F. Use of Biochar as Filler for Biocomposite Blown Films: Structure-Processing-Properties Relationships. Polymers 2021, 13, 3953. [Google Scholar] [CrossRef]

- Terzioğlu, P.; Parın, F.N. Biochar Reinforced Polyvinyl Alcohol /Corn Starch Biocomposites. Süleyman Demirel Üniversitesi Fen Bilim. Enstitüsü Derg. 2020, 24, 35–42. [Google Scholar] [CrossRef]

- Abdullah, Z.W.; Dong, Y. Preparation and Characterisation of Poly(Vinyl) Alcohol (PVA)/Starch (ST)/Halloysite Nanotube (HNT) Nanocomposite Films as Renewable Materials. J. Mater. Sci. 2018, 53, 3455–3469. [Google Scholar] [CrossRef]

- Zuccarello, B.; Bartoli, M.; Bongiorno, F.; Militello, C.; Tagliaferro, A.; Pantano, A. New Concept in Bioderived Composites: Biochar as Toughening Agent for Improving Performances and Durability of Agave-Based Epoxy Biocomposites. Polymers 2021, 13, 198. [Google Scholar] [CrossRef] [PubMed]

- Picard, M.; Thakur, S.; Misra, M.; Mielewski, D.F.; Mohanty, A.K. Biocarbon from Peanut Hulls and Their Green Composites with Biobased Poly(Trimethylene Terephthalate) (PTT). Sci. Rep. 2020, 10, 3310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suriapparao, D.V.; Vinu, R. Effects of Biomass Particle Size on Slow Pyrolysis Kinetics and Fast Pyrolysis Product Distribution. Waste Biomass Valorization 2018, 9, 465–477. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Biomass Pyrolysis: A Review of the Process Development and Challenges from Initial Researches up to the Commercialisation Stage. J. Energy Chem. 2019, 39, 109–143. [Google Scholar] [CrossRef] [Green Version]

- Maljaee, H.; Madadi, R.; Paiva, H.; Tarelho, L.; Ferreira, V.M. Incorporation of Biochar in Cementitious Materials: A Roadmap of Biochar Selection. Constr. Build. Mater. 2021, 283, 122757. [Google Scholar] [CrossRef]

- Tan, K.; Qin, Y.; Wang, J. Evaluation of the Properties and Carbon Sequestration Potential of Biochar-Modified Pervious Concrete. Constr. Build. Mater. 2022, 314, 125648. [Google Scholar] [CrossRef]

- Speight, J.G. Asphalt Paving. In Asphalt Materials Science and Technology; Elsevier: Amsterdam, The Netherland, 2016; pp. 409–435. ISBN 978-0-12-800273-5. [Google Scholar]

- Walters, R.; Begum, S.A.; Fini, E.H.; Abu-Lebdeh, T.M. Investigating Bio-Char as Flow Modifier and Water Treatment Agent for Sustainable Pavement Design. Am. J. Eng. Appl. Sci. 2015, 8, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Walters, R.; Fini, E.; Abu-Lebdeh, T. Enhancing Asphalt Rheological Behavior and Aging SuSceptibility Using Biochar and Nano-Clay. Am. J. Eng. Appl. Sci. 2014, 7, 66–76. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Ye, P. Laboratory Evaluation of Asphalt Cement and Mixture Modified by Bio-Char Produced through Fast Pyrolysis. In Proceedings of the Pavement Materials, Structures, and Performance, American Society of Civil Engineers, Shanghai, China, 5 May 2014; pp. 140–149. [Google Scholar]

- Zhao, S.; Huang, B.; Ye, X.P.; Shu, X.; Jia, X. Utilizing Bio-Char as a Bio-Modifier for Asphalt Cement: A Sustainable Application of Bio-Fuel by-Product. Fuel 2014, 133, 52–62. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological Performance of Bio-Char Modified Asphalt with Different Particle Sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef]

| Thermochemical Process | Temperature Range [°C] | Heating Rate | Pressure | Residence Time | Primary Product |

|---|---|---|---|---|---|

| Slow Pyrolysis | 350–800 | Slow (<10 °C/min) | Atmospheric | Hours—Days | Char |

| Fast Pyrolysis | 400–600 | Very Fast (~1000 °C/s) | Vacuum-Atmospheric | Seconds | Oil |

| Flash Pyrolysis | 300–800 | Fast | Moderate (2–25 atm) | Minutes | Biocarbon/ Char |

| Torrefaction | 200–300 | Slow (<10 °C/min) | Atmospheric | Minutes—Hours | Friable Biomass |

| Gasification | 700–1800 | Moderate-Vary Fast | AtmosphericModerate | Seconds—Minutes | Syngas/ Producer gas |

| Hydrothermal Liquefaction | 250–450 | Moderate | Elevated 100–300 atm | Minutes—Hours | Bio-crude (oil) |

| Feedstock | Proximate Analysis | Elemental Analysis | |||||

|---|---|---|---|---|---|---|---|

| Volatile Matter [wt.%] | Fixed Carbon [wt.%] | Ash [wt.%] | C [wt.%] | H [wt.%] | N [wt.%] | O [wt.%] | |

| Alfalfa [33] (Medicago sativa) | 78.90 | 15.80 | 5.30 | 49.90 | 6.30 | 2.80 | 40.80 |

| Almond Shell [34] | 74.90 | 21.80 | 3.30 | 50.30 | 6.20 | 1.00 | 42.50 |

| Bagasse [35] | 71.00 | 13.70 | 2.10 | 51.71 | 5.32 | 0.33 | 42.64 |

| Bamboo [36] | 81.60 | 17.50 | 0.90 | 52.00 | 5.10 | 0.40 | 42.50 |

| Carob Waste [8,37] | 38.80 | 52.80 | 3.80 | 46.94 | 1.63 | 5.44 | - |

| Coconut Fiber [38] | 80.85 | 11.10 | 8.05 | 47.75 | 5.61 | 0.90 | 45.51 |

| Corncob [39] | 69.50 | 15.90 | 2.90 | 48.12 | 6.48 | - | 43.51 |

| Cornstalk [39] | 65.30 | 15.60 | 11.70 | 46.21 | 6.01 | - | 45.87 |

| Cocopeat [35] | 49.10 | 25.30 | 4.60 | 61.57 | 4.37 | 1.02 | 33.04 |

| Dead Eucalyptus leaves [40] | 77.60 | 16.90 | 0.80 | 52.90 | 8.10 | 0.30 | 47.90 |

| Hamlin citrus [33] | 77.90 | 17.80 | 9.40 | 50.70 | 6.60 | 1.60 | 42.90 |

| Hornbeam Shell [41] | 78.83 | 9.37 | 9.52 | 41.78 | 5.36 | 0.60 | 52.26 |

| Loblolly Pine [33] (Pinus taeda) | 77.60 | 14.50 | 2.30 | 55.50 | 5.60 | 0.40 | 45.90 |

| Maize straw [42] | - | - | 5.31 | 42.20 | 7.21 | 1.28 | 49.20 |

| Mesocarp Fiber [40] (Oil palm) | 72.80 | 18.90 | 8.30 | 51.50 | 6.60 | 1.50 | 40.10 |

| Oak sawdust [43] | 69.24 | 16.51 | 0.81 | 52.28 | 5.74 | 0.06 | 41.92 |

| Olive wood [44] | 79.60 | 17.20 | 3.20 | 49.00 | 5.40 | 0.70 | 44.90 |

| Paddy straw [35] | 56.40 | 15.40 | 20.90 | 48.75 | 5.98 | 1.99 | 43.28 |

| Pinewood [38] | 85.45 | 13.15 | 1.40 | 48.15 | 6.70 | 1.35 | 43.60 |

| Palm Kernel Shell [35] | 66.80 | 17.90 | 3.40 | 55.82 | 5.62 | 0.84 | 37.73 |

| Raw Pine sawdust [42] | 83.10 | 16.80 | 3.76 | 50.60 | 6.18 | 0.05 | 43.10 |

| Rice husk | 62.80 | 19.20 | 18.00 | 49.30 | 6.10 | 0.80 | 43.70 |

| Sawdust [39] | 70.40 | 18.50 | 1.20 | 48.37 | 4.98 | - | 46.27 |

| Tea waste [45] | 70.29 | 18.57 | 3.88 | 48.60 | 5.43 | 3.80 | 42.17 |

| Wood Stem [35] | 80.10 | 10.70 | 0.40 | 50.52 | 5.81 | 0.23 | 43.44 |

| Wood Bark [35] | 68.90 | 16.30 | 4.90 | 53.42 | 6.12 | 1.40 | 39.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Infurna, G.; Caruso, G.; Dintcheva, N.T. Sustainable Materials Containing Biochar Particles: A Review. Polymers 2023, 15, 343. https://doi.org/10.3390/polym15020343

Infurna G, Caruso G, Dintcheva NT. Sustainable Materials Containing Biochar Particles: A Review. Polymers. 2023; 15(2):343. https://doi.org/10.3390/polym15020343

Chicago/Turabian StyleInfurna, Giulia, Gabriele Caruso, and Nadka Tz. Dintcheva. 2023. "Sustainable Materials Containing Biochar Particles: A Review" Polymers 15, no. 2: 343. https://doi.org/10.3390/polym15020343

APA StyleInfurna, G., Caruso, G., & Dintcheva, N. T. (2023). Sustainable Materials Containing Biochar Particles: A Review. Polymers, 15(2), 343. https://doi.org/10.3390/polym15020343